Abstract

Soil stabilization using additives is considered as one of the sustainable alternative techniques to deal with acute material shortages. Critically reviewing the contemporary works on soil stabilization would help practitioners and researchers to comprehend the merits and demerits of each stabilization method, influential parameters, and associated constraints. Furthermore, the critical analysis might aid the authorities to develop standard protocols about the use of various additives for soil stabilization, which would persuade the industry personnel to adopt sustainable practices. This paper presents a methodical review of the present soil stabilization methods under five key areas namely, underlying chemistry, the influential factors, performance indicators, economic and environmental aspects, and industrial perspectives. Findings of the review indicate that cement-based stabilizers perform well irrespective of soil type and curing conditions, on the contrary, lime-based stabilizers require appropriate temperature and pH for strength development. The degree of stabilization depends mainly on soil type, compaction level, and curing type and condition. Most of the soils treated with different additives exhibited a reduction in plasticity index, and maximum dry density against stabilizer dosage irrespective of soil type. The typical values of unconfined compressive strength and California bearing ratio of inorganic and organic soils except for peat, treated with a 5% dosage of all common types of stabilizers, fall in between 700 and 1,500 kPa and 30–60%, respectively. Cement and cementitious blends exhibited better cost-to-strength, energy-to-strength, and CO2 emission-to-strength ratios for soils with low plasticity whereas lime-blended stabilizers seemed effective for high-plastic soils.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Present road construction projects often suffer from material shortage due to an inadequate supply of quality materials (Dawson et al. 1995; Huang et al. 2007). Historically, road construction materials are being extracted from natural mineral deposits (Terashi and Juran 2000; Huang et al. 2007). Heightened environmental laws have prevented exploitation of natural mineral deposits, which in turn has led to inadequate material production (Mohajerani et al. 2020; Nunes et al. 1996). Alternatively, quality materials are being transported from other regions. Transport charges, however, contribute to the escalation in material cost (Asgari et al. 2015; Pongsivasathit et al. 2019; Prusinski and Bhattacharja 1999; Terashi and Juran 2000). Besides, exploiting natural minerals and transporting materials are considered extremely impactful to the environment and unsustainable (Balaguera et al. 2018; Dawson et al. 1995; Rocha et al. 2021). Construction projects have been thereby shifting from conventional practices to cost-effective and innovative strategies. Soil stabilization is one such technique, widely deployed in road construction projects, which treats in-situ soil to enhance its inherent properties to make it suitable for construction.

Stabilization improves the engineering properties of soil including dry density, swelling potential, plasticity, Unconfined Compressive Strength (UCS), California Bearing Ratio (CBR), Modulus of Resilience (MR), and permeability (Halsted et al. 2008; Teerawattanasuk and Voottipruex 2019) of weak in-situ soils either by mechanical means or by chemical means by adding and blending foreign agents or by both (Afrin 2017; Firoozi et al. 2017; Zumrawi 2015). In mechanical stabilization, granular materials are blended and consolidated to remove excessive amounts of air and/or water, and thus form a well-graded and compacted soil stratum (Hicks 2002). When inherited properties of soil are extensively incompatible with construction, mechanical stabilization alone may not be sufficient to achieve the required standard properties for construction (Afrin 2017). In such circumstances, foreign additives are traditionally added to in-situ soil to improve soil properties (Degirmenci et al. 2007; Firoozi et al. 2017; Halsted et al. 2008; Petry and Little 2002). These additives chemically react with soil constituents to enhance the engineering properties of in-situ soil.

Table 1 summarizes the stabilization methods that deployed alternative additives to enhance engineering properties of various geotechnical elements. Commonly, mechanical stabilization accompanied by chemical stabilization was found to be effective in improving weak soils (Gomes Correia et al. 2016; Ikeagwuani and Nwonu 2019). Particularly, the problematic soils require a chemical stabilizer to enhance strength and reduce swell-shrink behavior. On the other hand, chemical stabilization could potentially harm the workmen during construction and may cause a detrimental impact on the environment (Phummiphan et al. 2016). From economic and ecological perspectives, recent studies have shown that deploying industrial by-products and agro-wastes as additives is beneficial. Detailed advantages and disadvantages of the use of mechanical and chemical stabilization methods are presented in Table 2. To select the best stabilization method, engineering knowledge, and experience are vital since there are no stringent standards that govern the application of various stabilization techniques. Nelson et al. (2015) list the following as decisive factors based on which engineers may choose the appropriate stabilization method; the expansive nature of soil, the chemical composition of the soil, the reactivity of soil, design of active zone, the presence of undesirable chemical substances, heterogeneity of soil profile and hydraulic conductivity and soil fracturing.

1.1 Mechanical Stabilization

Soils with poor grading or containing fine particles with high plasticity may be improved by mechanical stabilization (Hicks 2002). During mechanical stabilization, other granular materials with better gradation are blended with in-situ soil to alter their particle size distribution. The mix is compacted and densified by applying compaction energy using rollers, rammers and vibrators (Afrin 2017). With the addition of granular particles, internal friction is improved in soil, which contributes to the increase in shear strength (Hicks 2002). Mechanical stabilization may result in a change in the plasticity properties of the mix (Hicks 2002). Ultimately, the stability of mechanically stabilized soil greatly depends on the inherent properties of the blended soils (Afrin 2017).

1.2 Chemical Stabilization

Traditionally, weak in-situ soils are blended with chemically active compounds including cement, lime, Fly Ash (FA), and rice husk ash (RHA) (Arulrajah et al. 2018; Basha et al. 2005; Degirmenci et al. 2007; Firoozi et al. 2017; Halsted et al. 2008; Petry and Little 2002; Yaghoubi et al. 2019) to improve mechanical and durability characteristics. Besides, non-traditional stabilizers including phosphogypsum, cement kiln, eggshell powder (ESP), Silica Fume (SF), Blast Furnace Slag Cement (BFSC) and Metakaolin (MK) have been deployed in the recent past to treat weak soils (Bellum et al. 2020; Dave et al. 2020; Degirmenci et al. 2007; Eisa et al. 2021; Miller and Azad 2000; Oluwatuyi et al. 2018). FA, SF and BFSC are industrial by-products used alone or together with cement/lime to stabilize soils (Arulrajah et al. 2018; Ebrahim Asghari-Kaljahi and Mansouri 2020). MK is the calcined form of clay. Agro-wastes include Bagasse Ash (BA), Olive Fly Ash (OFA), Parawood Ash (PAW), ESP and RHA. Table 3 summarizes the oxide compositions of stabilizers determined using X-ray fluorescence (XRF). SiO2 and CaO constitute significant components of most stabilizers Cement and lime blended stabilizers have been commonly used in soil stabilization (Pongsivasathit et al. 2019; Prusinski and Bhattacharja 1999), which are often deployed to treat soils with a high fraction of clay. The primary factors that determine the degree of chemical reactions are chemical composition, morphology, and fineness of the additives (Singh et al. 2015). The rich SiO2 and Al2O3 content and the desired Si/Al ratio in FA and MK make them popular in geopolymer applications (Duxson et al. 2007; Van Jaarsveld et al. 1997). RHA and SF contain a significant amount of SiO2 that enables them to be used as silica suppliers in geopolymerization. FA and bottom ash are found to be effective pozzolans in instituting cementitious reactions. The rich Ca content in BFSC, ESP, phosphogypsum and cement kiln is found to contribute to the formation of the C–A–S–H phase and hence strength enhancement (Temuujin et al. 2009; Yip et al. 2005). The FA, BFSC and RHA were discovered to exhibit a great degree of reactivity due to their smaller sizes (Ke et al. 2015; Provis and Van Deventer 2009). The amorphous or semi-crystalline that exist in MK, SF, BFSC and FA could be another reason for higher reactivity as they can dissolve easily in alkaline conditions (Bassani et al. 2019). Another critical factor in chemical stabilization is particle shape. MK particles are of platy shape that leads to rheological issues and hence increase water demand (Li et al. 2010). The spherical shape of FA particles improves the workability of the mix and provides strong and durable binding (Duxson et al. 2007; Jitsangiam et al. 2021).

According to Unified Soil Classification System (USCS), soils containing more than 50% particles passing through the No. 200 sieve (finer than 75 μm) are classified as silt–clay materials ("ASTM D2487, Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System)," 2017). The presence of extensive amounts of clay with high plasticity brings about an increase in activity (ratio between plasticity index and clay fraction in soil). During moisture changes, highly active clays exhibit extensive swell and shrink behavior. This is due to the electrostatic charges carried by clay particles that attract water molecules to form adsorbed and double-layer of water around them. The surrounding water causes substantial expansion and contraction in the soil during moisture level changes. The Ca2+ present in cement or lime-based stabilizers retard the formation of double-layer and hence contribute to controlling excessive volume changes in soil (Halsted et al. 2008; Prusinski and Bhattacharja 1999). A thorough understanding of the underlying chemistry behind all these processes is beneficial for designing soil stabilization.

Reviewing the existing literature, the authors found that chemical and mechanical combined stabilization has been widely explored in the published literature. However, no methodical state-of-the-art review is available on soil stabilization for road construction that covers underlying chemistry, parameters influencing the stabilization process, improvements in engineering properties and economic and environmental benefits.

1.3 Review Method

The literature reviewed in this paper was selected by employing keyword combinations including, soil stabilization, pavement, soil stabilizers and engineering properties in Web of Science and Scopus platform journals from 1986 to 2023. A total of 155 publications that covered the intended scope of the review were screened out, which comprised of 154 soil-stabilizer combinations. Figure 1 depicts the statistics of the reviewed literature. Figure 1a–c show the details of the treated soils, additives, and the classification of additives. More than 75% of the soil stabilization studies were conducted on fine-grained soils with low to high plasticity. Fat clay (CH) had been explored extensively followed by Lean clay (CL). From the perspectives of stabilizers, studies that deployed cement blended stabilization dominated with 35% followed by that of hydrated lime blended with 22%.

1.4 Review Objective and Scope

From the identified literature, this comprehensive review intends to cover details of underlying chemical reactions that occur during soil stabilization with different types of stabilizers, the factors influencing stabilization, variation in performance indicators with stabilizer dosage, and economic and environmental comparison between different types of stabilizers. It is envisioned that this review would provide practitioners and researchers with a comprehensive understanding of the stabilization process of different types of soils with various types of stabilizers. Further, the presented information would assist authorities to make decisions regarding soil stabilization.

The review gives more focus on the soil stabilization process practiced in tropical weathered countries. The associated parameters and conditions that are imperative for soil stabilization in tropical conditions are therefore appraised.

1.5 Organization of the Paper

The presentation of a methodical review on soil stabilization in this paper is organized as follows. Section 2 elaborates on the details of chemical reactions that occur during the application of traditional soil stabilizers. In addition, a brief review of non-traditional soil stabilizers and their stabilization potential are also discussed. Section 3 discusses the influential parameters that affect the degree of soil stabilization and their impact on the soil stabilization process. Section 4 presents performance parameters used to measure the degree of stabilization and their variations with the quantity of stabilizers. Section 5 details the economic and environmental comparisons between various stabilizers used in soil stabilization. In Sect. 6, industrial perspectives on the use of additives have been explored. Sections 7 and 8 summarize the key findings from published literature and the way forward, respectively.

2 Soil stabilizers and Stabilization Mechanism

This section describes the underlying mechanisms and chemical reactions behind soil stabilization with cement, lime, FA, and RHA. Furthermore, a brief review of the evolution of non-traditional stabilizers in soil stabilization is presented.

2.1 Cement in Soil Stabilization

Conventionally, ordinary Portland cement (OPC), which adheres to British Standard–12, is used in soil stabilization ("BS 12: Specification for Portland cement," 1996). OPC reportedly contains the following chemical compounds required for stabilization; tricalcium silicate (C3S), dicalcium silicate (C2S), tricalcium aluminate (C3A), and tetracalcium aluminoferrite (C4AF), where C, A, F, and S simply denote CaO, Al2O3, Fe2O3, and SiO2, respectively (Barnes and Bensted 2001; Dunuweera and Rajapakse 2018; Thiery et al. 2007). These components react with water and soil at various phases during stabilization to alter the properties of in-situ soil.

2.1.1 Chemistry and Mechanism of Cement Stabilization

Four distinct chemical processes occur in the following order when OPC is added to in-situ soil containing clay, namely; cation exchange, particle restructuring, cementitious hydration, and pozzolanic reaction (Halsted et al. 2008; Prusinski and Bhattacharja 1999). All these chemical processes assist in gradual changes in properties of in-situ soil.

2.1.1.1 Cation Exchange and Reduction in Plasticity

In clay, two types of crystalline patterns are formed; one is a silica sheet formed by silicon-oxygen tetrahedron units, and the second is a gibbsite (alumina)/brucite (magnesia) sheet produced by octahedral units (Das 2008). By repeatedly stacking silica/alumina/magnesia sheets, various clay minerals are formed (Das 2008; Halsted et al. 2008). Due to the inherent atomic configuration, clay minerals carry negative charges on their surfaces and positive charges at edges. To neutralize charges, they attract water via two mechanisms; one is directly attracting water molecules by forming hydrogen bonds and the second is attracting cations which in turn attract water molecules (Das 2008; Halsted et al. 2008). The electrically attracted water surrounds clay particles and forms a double layer, which holds responsible for the plasticity property of clay. Cations vary in terms of their affinity for attraction, which contributes to the change in the thickness of the double layer (Das 2008). OPC is an excellent calcium-based additive; when blended with clay, Ca2+ is of lower affinity for attraction and tends to replace Na+ or K+, which are of a higher affinity for attraction (Halsted et al. 2008; Prusinski and Bhattacharja 1999). This exchange of cations leads to a reduction in the thickness of the double e layer, and hence loss of plasticity (Halsted et al. 2008; Prusinski and Bhattacharja 1999). Figure 2 illustrates the change in double-layer thickness when Ca2+ replace monovalent Na+. However, adsorbed water remains unaffected due to cation exchange (Das 2008).

2.1.1.2 Particle Restructuring and Shear Strength Improvement

Clay particles generally form a parallel structural orientation; each particle carries negative charges at surfaces and positive charges at edges (Das 2008). When cement is added, cations in cement induce a random edge-to-surface attraction of clay particles that activates the flocculation of clay particles (Halsted et al. 2008; Prusinski and Bhattacharja 1999). With the deposition of cement particles, flocculated clay particles then form weak bonds at the edge surface that result in agglomeration (Halsted et al. 2008; Prusinski and Bhattacharja 1999). Flocculation followed by agglomeration institutes the formation of granular particles from clay particles (Firoozi et al. 2017). Produced granular particles with improved texture assist to increase internal friction, and hence shear strength.

2.1.1.3 Cementitious Hydration and Soil Particle Binding

The typical mineralogical composition of OPC is as follows; 55–65% of C3S, 15–25% of C2S, 8–14% of, C3A, and 8–12% of C4AF (Aïtcin 2016; Barnes and Bensted 2001; Dunuweera and Rajapakse 2018; Zumrawi 2015). Less than 5% gypsum (calsulfatephate dehydrate, \({\text{C}}{\overline{\text{S}}}{\text{H}}_{{2}}\), where \({\overline{\text{S}}}\) denotes SO3) is also added to OPC to retard the early hardening of cement due to the active reaction of C3A (Aïtcin 2016). Each constituent in OPC reacts with water at different degrees and at different times. The chemical reaction between the constituents of OPC and water is called hydration, which is accountable for the setting and hardening of cement paste. The C3S phase in OPC first reacts with water and contributes to initial setting and early strength development followed by C2S (Barnes and Bensted 2001). These hydration reactions of C3S and C2S under ambient conditions form C–S–H (C3S2H3) and are given in Eqs. (1) and (2) as follows (Hoover and Ulm 2015; Prusinski and Bhattacharja 1999).

Tricalcium silicate (C3S) hydration

Dicalcium silicate (C2S) hydration

where H refers to H2O. The release of hydrated lime (HL) from both reactions maintains a pH level of about 12.5 in mortar and concrete systems (Bell 1996; Prusinski and Bhattacharja 1999). The solubility of silica and alumina increases significantly with an increase in pH greater than 12 ("ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993). At higher pH levels greater than 12, due to the higher solubility of silica and alumina, pozzolanic reactions of cement will be accelerated. If in-situ soil is of high plasticity, a significant fraction of Ca2+ is exhausted during cation exchange to reduce plasticity, thereby formation of hydrated lime will decrease that in turn will reduce pH levels and hence retard pozzolanic reactions. For such highly plastic soils, cement alone may not be sufficient for stabilization. Additional Ca2+ required for cation exchange is supplied by adding a fraction of lime to the soil at the start of stabilization, which helps to compensate for the loss in pH value of the soil ("ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993).

C3A, among all the components present in OPC, is highly reactive (Barnes and Bensted 2001). The hydration reaction of C3A in the absence of sulphate ions institutes rapid hardening of motor/concrete, a phenomenon referred to as ‘flash-set’, so concrete loses its slump swiftly (Aïtcin 2016; Barnes and Bensted 2001). In the presence of sulphate ions, the hydration of C3A is more retarded and it slowly forms ettringite (\({\text{C}}_{{6}} {\text{A}}{\overline{\text{S}}}_{{3}} {\text{H}}_{{{32}}}\)) that temporarily blocks its early hydration and hardening (Aïtcin 2016; Firoozi et al. 2017). Sulphate ions in OPC are supplied by gypsum. Equations (3–5) describe the two types of hydration reactions of C3A with and without sulphur (Aïtcin 2016; Firoozi et al. 2017).

Tricalcium aluminate (C3A) hydration in the absence of sulphate

Tricalcium aluminate (C3A) hydration in the presence of sulphate

Once gypsum in OPC is fully consumed, sulphate content in the solution drops below a critical value. Further hydration transforms ettringite into monosulphoaluminate (\({\text{C}}_{{4}} {\text{A}}{\overline{\text{S}}}{\text{H}}_{{{12}}}\)) as follows

The hydration of the ferrite phase in OPC is like that of C3A. When sulphate the level drops, meta-stable iron substituted AFm phases form. When the temperature rises, meta-stable AFm phases decompose into C3AH6–C3FH6. The corresponding chemical reactions are given in Eqs. (8–10) (Aïtcin 2016; Firoozi et al. 2017).

Provided that sufficient water is available, complete hydration will occur to form C–S–H and C–A–H, which will bind soil particles together. This process will turn flocculated particles into large soil grains, and hence the gradation of soil will improve (Halsted et al. 2008; Prusinski and Bhattacharja 1999). The availability of water depends on the water-to-cement ratio adopted for stabilization (Barnes and Bensted 2001; Ribeiro et al. 2016).

2.1.1.4 Pozzolanic Reaction

As described earlier, cementitious hydration forms HL, which elevates pH levels. S and A present in clay are thoroughly soluble at high pH levels. When pH increases S and A dissolve easily from clay lattice. Released S and A enter reaction with HL to initiate secondary soil stabilization. These reactions are referred to as secondary cementitious reactions or pozzolanic reactions; typically take place at a slower rate for an extended period. The pozzolanic reactions are governed by Eqs. (11) and (12).

The timeline of the soil stabilization process with cement (OPC) additive is shown in Fig. 3. It is a series of overlapping chemical reactions between clay minerals and OPC constituents. An uninterrupted supply of required constituents and conditions are to be guaranteed to achieve the targeted soil properties. As OPC contains S, soil stabilization with cement is independent of the constituents of the soil (Asgari et al. 2015).

2.1.2 Selection of Cement Stabilizer Dosage

The quantity of cement (OPC) to be blended with soil should be sufficient to the supply required chemical components to support the reactions described in Eqs. (1–12). As pointed out earlier, the clay mineral composition, especially the ones with monovalent cations (Ex. Montmorillonite) consumes a large amount of cement for initial cation exchange. The remaining portion of cement will involve in the cementitious hydration reaction and will contribute to strength development. It is therefore recommended that the minimum cement dosage used for stabilization should be more than the quantity absorbed during initial ion exchange reactions ("ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993). Table 4 details soil types along with plasticity, and respective cement dosages, and resulted in UCS of stabilized soils reported in numerous studies. The general trend shows that when plasticity increases, the optimum amount of cement required for soil stabilization increases. Cement stabilization improves UCS of non-plastic, coarse-grained soils and soils with low plasticity to be in the range of 3,000–4,800 kPa for cement dosage less than 10%. Highly plastic soils and peat showed moderate to low improvement in the UCS compared to non-plastic or low plastic soils when cement dosage was increased.

2.2 Lime in Soil Stabilization

Lime supplied in the following forms is effective for soil stabilization; hydrated lime (HL), slurry lime (SL), and quicklime (QL) (Hicks 2002). Hydrated lime is in fine powder form whereas slurry lime is a semi-liquid mixture (Hicks 2002). Quicklime is produced by the calcination of limestone at elevated temperatures (Kumar et al. 2007). Quicklime reacts with water to create hydrated lime and release a substantial amount of heat during the reaction (Firoozi et al. 2017). Hydrated lime absorbs CO2 and becomes CaCO3. The reactions of the limestone cycle are given in Eqs. (13–15).

Soil stabilization using lime undergoes almost similar reaction phases to what cement stabilization does except for hydration reactions. Ca2+ present in lime gradually replaces monovalent cations in clay, which modifies diffused hydrous double-layer around clay particles (Bell 1996). The reduction in double-layer escalates attraction between clay particles and thus attracts clay particles form flocs. On the other hand, available HL provides highly alkaline conditions in which S and A are highly soluble. Released S and A from clay minerals enter a pozzolanic reaction with HL to form C–S–H and C–A–H, as described in Eqs. (11 and 12).

It should be noted that, during lime stabilization, due to the absence of cement clinker components including C3S, C2S, C3A, and C4A, primary cementitious hydration reactions that were prominent in cement stabilization would not occur. Instead, a secondary cementitious reaction such as the pozzolanic reaction would take place. Pozzolanic reactions take place at slower rates over a long period; therefore, the rate of strength gain in lime-stabilized soils is lesser than that in cement stabilization (Bell 1996; Hicks 2002; Sariosseiri and Muhunthan 2009). For the occurrence of these reactions, there should be ample supply of required lime, clay minerals, and other pozzolanic material, and higher alkaline levels (Kassim and Chern 2018). Low temperature, low soil pH, and organic matter present in soil are believed to impede the progress of pozzolanic reactions (Hicks 2002).

As described earlier, a fraction of added lime is first adsorbed by clay minerals until the affinity of the soil for lime is satisfied (Bell 1996). This amount of lime exhausted in the initial cation exchange might be determined by the Initial Consumption of Lime (ICL) test stipulated in BS 1924–1 ("BS 1924–1: Hydraulically bound and stabilized materials for civil engineering purposes. Sampling, sample preparation and tests of materials before treatment," 2018). Rogers et al. (1997) have also prosed a method to determine ICL which was later deployed by researchers (Consoli et al. 2014). The remaining lime component enters a pozzolanic reaction to develop strength characteristics in stabilized soil. The amount of lime to be added to the soil for stabilization therefore should exceed the minimum levels that are expected to be exhausted in cation exchange (Al-Mukhtar et al. 2010; "ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993).

Respective lime dosages deployed for different soil types and the resulting UCS reported in numerous studies are detailed in Table 5. Hydrated lime and quicklime were used alternatively depending on the application. The soils with high plasticity showed significant improvement in UCS when stabilized with lime. Also, a study reported that an extremely alkaline environment might retard the lime stabilization process, which could be controlled by adding some acids (Mishra et al. 2019).

2.3 Non-traditional Soil Stabilization

2.3.1 Fly Ash in Soil Stabilization

FA is an industrial by-product created by the combustion of coal, chiefly used as a reinforcing material in bricks, concrete, and pavements (Bhattacharjee and Kandpal 2002; Fly Ash Facts for Highway Engineers 2003; Ramaji 2012; Sutcu et al. 2019). Out of four classes of FA products, classes C and F gained attention to be used in the soil stabilization process. SiO2 + Al2O3 + Fe2O3 content by weight in classes C and F is more than 70% and between 50 and 70%, respectively ("ASTM C618, Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete," 2019). While class C can be used as a stand-alone cementitious material due to its rich CaO content, class F needs the addition of other cementing agents such as cement and lime (Fly Ash Facts for Highway Engineers 2003).

The chemical reactions that occur during soil stabilization using FA resemble the reactions that occur during soil stabilization using cement/lime. Initially, the monovalent cations are replaced with Ca2+ to reduce plasticity (Christopher et al. 2000). Cementitious and pozzolanic reactions during soil stabilization with FA can be represented by Eqs. (14), (11), and (12) occur in the given order (Arman and Munfakh 1972; Tastan et al. 2011). Pozzolanic reactions in FA are slow, and happen over a long period (Ahmaruzzaman 2010). Class C FA produces more C–S–H and C–A–H than class F due to its higher CaO content (> 20% by weight) (Sridharan et al. 1997). A combination of lime and FA is commonly used in soil stabilization, which exhibits similar performance to cement-stabilized soil ("ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993). Deploying FA in road construction is reported to reduce construction costs by 10–20% (Ahmaruzzaman 2010).

2.3.2 RHA in Stabilization

RHA is produced by burning rice husk at elevated temperatures of more than 600 °C (Singh and Singh 2021). RHA has high pozzolanic content due to its rich silica concentration (Moayedi et al. 2019). Compared to traditional additives, RHA has a significantly low reaction time, which attracted researchers to study about deploying RHA for soil stabilization (Moayedi et al. 2019). RHA is often applied along with cement or lime as it does not have cementitious components. A study by Rahgozar et al. examined the usage of RHA and OPC to treat clayey sand (Rahgozar et al. 2018). The stabilized soil sample with 6% RHA and 8% OPC, cured for 28-days yielded UCS and CBR almost 25 and 18 times more than those of the values for untreated soil, respectively. A similar study by Basha et al. (2005) found that 15–20% RHA and 6–8% OPC were the optimum amounts to reduce the plasticity of residual soil to improve strength characteristics. A study reported that treating lateritic soil with high doses of RHA yielded considerable improvements compared to lime and cement (Rahman 1986).

2.3.3 SF in Stabilization

Silica fume is an industrial by-product in the manufacturing of silicon and silicon alloy (Lewis 2018; Türköz et al. 2021). Annually, 2.5 million tons of SF is produced worldwide (Lewis 2018). A study by Ahmad et al. claimed that peat treated with SF produced slightly better UCS than the ones treated with OPC (Ahmad et al. 2021a, b). Researchers found that adding SF to expansive clays improved strength characteristics while reducing the plasticity index (Phanikumar and Ramanjaneya Raju 2020; Singh et al. 2020). In geopolymer application, SF is deployed to supply silica as it contains a substantial amount of silica. Due to the amorphous structure, SF easily dissolves in an alkaline medium that promotes chemical reactions (Bassani et al. 2019). SF particles are spherical and with comparatively higher surface area, which improves the workability of the mix and provides more contact surface for chemical reactions (Türköz et al. 2021).

2.3.4 Coal Bottom Ash in Stabilization

As a result of the combustion of pulverized coal in thermal power plants, coal bottom ash (CBA) is generated as a residue (Hashemi et al. 2019). Approximately 8.5 million tons of CBA are annually generated across the globe (Hashemi et al. 2018; Ranjbar and Kuenzel 2017). The presence of silica and alumina in CBA improved strength characteristics such as UCS, and CBR, and reduced the shrink and swell potential of expansive black cotton soil (Navagire et al. 2022). Deploying coal bottom ash partially to replace OPC is a cost-effective and environmentally friendly option. However, the application of CBA possesses certain limitations as the resultant properties of stabilized soil vary, and the processing is complicated. Also, the existence of toxic heavy metals such as Ni, Cd, Zn, and Pb might cause harm to human beings and the environment, unless it is rightly handled (Hashemi et al. 2019; Zhou et al. 2022).

2.3.5 Geopolymer Technology

Production of cement, lime, FA, and RHA is considered energy-intensive, which emits harmful substances like CO2 into the environment (Durastanti and Moretti 2020; Imbabi et al. 2012; Ivanov et al. 2015; Mayooran et al. 2017; Moretti et al. 2019; J. Zhang et al. 2014a, b). To mitigate detrimental impacts on environment, sustainable practices such as replacing conventional additives with non-traditional ones have gained considerable attention in pavement construction (Consoli et al. 2020). Tingle and Santoni (2003) evaluated the usage of twelve non-traditional additives including acid, enzymes, lignosulfonate, petroleum emulsion, polymers, and a tree resin in clay soil stabilization. Soils stabilized with Lignosulfonate and polymers produced better UCS, but others exhibited trivial strength improvements. Importantly, most of the stabilized samples with said additives showed inferior performance against moisture increment.

A study reported that additive is the prime contributor to stabilization cost (Rocha et al. 2021). Accordingly, in the recent past, employing waste material for soil stabilization has been recognized as an environmentally friendly and economically advantageous strategy (Anupam et al. 2013; Imtiaz and Lovell 1992; Zhang 2013). ESP and fibers are some of the potential cost-effective replacements (Consoli et al. 2020; Rahgozar et al. 2018; Saldanha et al. 2021; Sharma et al. 2015).

ESP contains a substantial amount of calcium carbonate (CaCO3), which could be exploited to establish cementitious bonds during soil stabilization (Amaral et al. 2013; Lechtanski 2000). Consoli et al. (2020) explored the usage of quicklime and hydrated lime derived from eggshell residues for soil stabilization. The authors claimed that the mechanical properties of stabilized soil improved with the accumulation of eggshells. A similar study by Saldanha et al. (2021) revealed that eggshell limes have adequate physical–chemical–mineralogical characteristics required for soil stabilization. The study also found that deploying eggshell limes significantly reduced environmental impacts. Oluwatuyi et al. (2018) investigated using ESP and OPC to stabilize lateritic soil for highway construction. The results of the study revealed that CBR and UCS values of ESP and OPC stabilized soil were better than the soils stabilized with OPC or ESP alone. A similar study by Maduabuchi and Obikara (2018) investigated the potential of OPC and ESP mix for lateritic soil stabilization. Accumulation of ESP in this mix was found to reduce plasticity and Maximum Dry Density (MDD), whereas Optimum Moisture Content (OMC) and CBR increased.

Geopolymer technology and bio-cementation are two noteworthy strategies to be mentioned as long as state-of-the-art soil stabilization techniques are concerned (Chung et al. 2021; Consoli et al. 2020; Gowthaman et al. 2021; Maduabuchi and Obikara 2018; Naveed et al. 2020; Oluwatuyi et al. 2018). In the geopolymer technique, aluminosilicate precursors are activated using alkali activators to form an inorganic binder that agglomerates soil grains (Davidovits 1991b). The chemical reactions that occur during geopolymer formation are given in Eqs. (16) and (17) (Davidovits 1991a; Khale and Chaudhary 2007; Reddy et al. 2016; Singh 2018). Firstly, aluminosilicate precursors release Al3+ at highly alkaline conditions that subsequently form \({\text{AlO}}_{{4}}^{ - }\) tetrahedra, which attracts group I cations to balance charges (Duxson et al. 2007; Khale and Chaudhary 2007). These react with SiO2 tetrahedra and give an amorphous three-dimensional polymeric chain (Davidovits 1991b; Duxson et al. 2007; Khale and Chaudhary 2007). Equation (16) explains the formation of the intermediate form of geopolymer precursor from the synthesization of silica and alumina in the presence of NaOH solution. Equation (17) describes the formation of a geopolymer chain consisting of Polysialate (-Si–O-Al-O-) bonds.

Geopolymer technology uses RHA/FA, MK, and ESP as precursor materials and NaOH (caustic soda)/Na2SiO3 as an alkali activator (Davidovits and Sawyer 1985; Poorveekan et al. 2021). In addition, the available CaO in ESP and SiO2 in RHA contribute to the formation of C–S–H under the presence of NaOH, and hence institute strength development in stabilized soil (Amaral et al. 2013; Moayedi et al. 2019). Some studies have deployed Na2SiO3 and NaOH together as activators (Mashri et al. 2020; Shekhawat et al. 2019). Phummiphan et al. (2016) examined the stabilization potential of marginal lateritic soil using high calcium FA-based geopolymer with alternative ratios of Na2SiO3 and NaOH as alkali activators. The study revealed that at a Na2SiO3: NaOH ratio of 50:50, the maximum 90-day UCS was obtained. A similar study reported that 3–5% OPC and 4–8% FA-based geopolymer improved the mechanical characteristics of marginal lateritic soil (Teerawattanasuk and Voottipruex 2019). Tan et al. (2021a, b) treated CH-type soil with fly ash as a precursor and KOH as an alkaline activator, and further reinforced it with coir fiber. The authors concluded that the stabilized specimens exhibited improved strength parameters and failure strain. A similar study was conducted on the same soil with coir fiber coated with linseed oil and turpentine oil (Tan et al. 2021a, b). Treated fibers were found to improve compressive strength and post-peak stress behavior. Further, the microstructural analysis revealed the formation of A–S–H and C–S–H gel, which improved the interaction between the coir fiber surface and the geopolymer matrix. The application potential of soil stabilization with geopolymer technology, however, remains unevaluated for road construction.

2.3.6 Bio-cementation

Bio-cementation process harnesses bacteria containing active urease enzymes (Gowthaman et al. 2021; Jia He et al. 2020; Naveed et al. 2020). Soil is subjected to cultivated bacteria, a solution of urea, and calcium chloride. Bacterial action decomposes urea into carbonate and ammonium ions as given in Eq. (18) (Gowthaman et al. 2021). Supplied Ca2+ and produced carbonate ions form CaCO3 mineral within the soil framework as shown in Eq. (19) (Gowthaman et al. 2021). The bacteria cells attached to the aggregate surfaces provide nucleation to the formed CaCO3 mineral and institute crystal growth between adjacent soil particles, which results in the cementation of particles (Mujah et al. 2017).

2.3.7 Nanomaterial in Soil Stabilization

By adding nanoparticles as a foreign substance, the soil structure at the atomic level can be manipulated (Ghasabkolaei et al. 2017). Due to the high specific surface area, the nanoparticles actively engage in reactions with clay minerals, ions and organic matter (Ghasabkolaei et al. 2017; Zhang 2007). These reactions have a profound influence on the physical and chemical characteristics of treated soil (Kacha and Shah 2021; Zhang 2007). Researchers have explored the use of a variety of nanomaterial additives to stabilize weak soils including nano-silica, nano-alumina, carbon nanotube and nanofiber, and colloidal silica (Alipour et al. 2022; Alsharef et al. 2016; Gallagher and Mitchell 2002; Zhang 2007). Alipour et al. (2022) conducted studies on deploying nano-alumina and nano-silica to treat problematic soil. The authors concluded that nano-alumina reduced swelling potential in stabilized samples more than nano-silica did. From the strength perspective, nano-silica stabilized samples outperformed nano-alumina treated samples. A study incorporated carbon nanotube and nanofiber into clayey sand (Alsharef et al. 2016). A clear decrease in hydraulic conductivity was observed when the composition of carbon nanotube and nanofiber increased as they filled the pores between the soil particles. A marginal change in the plasticity index was observed. A similar reduction in hydraulic conductivity was reported by Persoff et al. when colloidal silica was used to treat sand (Persoff et al. 1999). Incorporating colloidal silica in loose sand was found to mitigate the risk of liquefaction (Gallagher and Mitchell 2002). By adding nanoparticles as a foreign substance, the soil structure at the atomic level can be manipulated. The existence of nanomaterials might alter the physical and chemical characteristics of treated soil due to significantly high specific surface area (Kacha and Shah 2021). Alipour et al. (2022) conducted studies on deploying nano-alumina and nano-silica to treat problematic soil in Iran. The authors concluded that nano-alumina contributed better to reducing swell potential. Meanwhile, the presence of nano-silica improved strength.

3 Parameters Influencing Soil Stabilization

The success of soil stabilization depends on parameters including soil type, the amount of organic matter present in the soil, sulphates and sulphide composition of the soil, state of compaction, moisture content, the temperature during stabilization, and curing (Maclean and Lewis 1963; Sherwood 1993). Appropriate control of these factors would contribute to steer strength development in stabilized soils, and to achieve desired levels of physical and mechanical characteristics (Afrin 2017; Sherwood 1993).

3.1 Soil Type

Soil is characterized by its particle size distribution and plasticity properties into granular soils/coarse-grained soils and cohesive soils/fine-grained soils ("ASTM D2487, Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System)," 2017; Das 2007; "M145‐91, Classification of soils and soil‐aggregate mixtures for highway construction purposes," 2012). Generally, granular soils require a relatively large amount of additives at the initial stages of stabilization to fill considerably large voids present between soil particles (Maclean and Lewis 1963). Strength development with the accumulation of additives is guaranteed if the additive dosage exceeds the minimum dosage requirement for filling the voids. For fine-grained soils, strength development starts immediately as additives start cementing particles together from the beginning itself (Maclean and Lewis 1963). As per the ORN31 standard, stabilizing soils with a uniformity coefficient below 5 is economically disadvantageous and the maintenance of such soil stabilization is highly expensive ("ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993).

The plasticity index is the widely accepted measure of soil expansion characteristics or swelling potential (Halsted et al. 2008). Fine soils with a plasticity index of less than 10, generally respond well to cement stabilization, whereas lime stabilization is effective if the plasticity index is greater than 10 (Hicks 2002; "ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993). For clays with extremely high swelling potential, a small fraction of lime is first added to eliminate dramatic volume changes (Croft 1967; Stocker 1972, 1974). Thereafter, cement is added to improve the mechanical characteristics of soil (Prusinski and Bhattacharja 1999).

Concisely, the particle size and plasticity index of the soil dictate the choice of appropriate additive type/s and the amount of additive to be added to stabilize the soil concerned. Lime is particularly effective in reducing plasticity rapidly in high-plastic soils, whereas cement can perform well in all types of soils.

3.2 Presence of Organic Matter

The top layers of soil often constitute decomposed organic matter up to a depth of 1.5 m (Maclean and Lewis 1963; Sherwood 1993). The presence of organic matter in in-situ soil may react with a fraction of Ca2+ to form insoluble compounds, which limits the amount of available Ca2+ for pozzolanic reactions (Tastan et al. 2011). The organic matter in soil absorbs significantly large amounts of water, which can potentially reduce the available water for cementitious hydration reactions (Hampton and Edil 1998). Thus, the presence of organic matter prevents stabilizers from developing desired strength characteristics (Zumrawi 2015). Oliveira et al. (2012) found that an increase in organic matter caused an increment in compressibility characteristics. The influence of organic content in soil on its mechanical properties including UCS and MR was found to have a hyperbolic relationship (Tastan et al. 2011).

Maclean and Lewis (1963) proposed conducting diagnostic tests to detect the presence of organic matter in the soil. This test was performed by measuring the pH value of in-situ soil one hour after adding 10% OPC and water. A measured pH value less than 12.1 indicated that organic matter present in soil was capable of preventing cement hardening (Maclean and Lewis 1963), which interpreted that cement stabilization for that particular soil type was ineffective. Ahmad et al. (2021a, b) recommended using OPC and filler materials to fill the voids in peat using cementitious products. They also emphasized the need of deciding the stabilizer dosage in treating organic soil by considering the indexed properties and the presence of humus. Chen and Wang (2006) added extra admixture to overcome the issues of organic matter in cement-stabilized soft soil.

Organic soils contain less amount of clay particles and a substantial portion of humus. Soft organic soils of different types (Pt, OL, and OL-OH) were stabilized using six different types of FA-class C and F, and OPC—type I (Tastan et al. 2011). Pt-type soil attained lower UCS and MR values than the other two. The authors concluded that CaO content and CaO/SiO2 ratio in FA affected the increase in UCS and MR. Ahmad et al. (2021a, b) used a combination of SF and OPC to treat peat soil. UCS and CBR of the stabilized specimens improved with the stabilizer dosage and time. Strength characteristics improved with the increase in SF content in the mix. This was due to the development of compact and dense structure of peat. Morphological analysis conducted on the stabilized specimens revealed that the formation of C–S–H and C–A–H led to a dense peat matrix (Ahmad et al. 2023). Also, the strength development rate in SF stabilized specimens was more rapid than that of OPC. Stabilization of peat soil is challenging and consumes a lot of money, and requires additional stabilizer dosage to initiate the process (Ahmad et al. 2021a, b). From the environmental perspective, partially replacing OPC with lime, fly ash, kaolin, etc. is considered beneficial.

The amount of organic matter present in the soil is the key to fixing the stabilizer dosage. Grassland soils, high plasticity index soils, poorly drained soils, and lowland soils are susceptible to containing substantial amount of organic matter. Such soils need additional stabilizers or extra admixture to treat organic matter present in the soil.

3.3 Sulphates and Sulphides

Sulphate ions react with calcium-based additives to form ettringite (\({\text{C}}_{{6}} {\text{A}}{\overline{\text{S}}}_{{3}} {\text{H}}_{{{32}}}\)) and with additional hydration, ettringite is transformed into monosulphoaluminate (\({\text{3C}}_{{4}} {\text{A}}{\overline{\text{S}}}{\text{H}}_{{{12}}}\)) as given in Eqs. (5) and (6) (Afrin 2017; Aïtcin 2016; Firoozi et al. 2017). Produced compounds occupy larger volumes than the reactants. This expansive nature breaks the bonds in stabilized soil (Maclean and Lewis 1963). Sulphate content in the soil can be determined according to British Standard 1377–3 ("BS 1377–3—Methods of test for Soils for civil engineering purposes—Part 3: Chemical and electro-chemical tests," 1990).

Sulphides present in industrial by-products might be oxidized in the presence of water to form sulphuric acid (\({\overline{\text{S}}\text{H}}\)). Cementitious hydration reactions form HL and C–S–H, which further reacts with \({\overline{\text{S}}\text{H}}\) to form gypsum (\({\text{C}}{\overline{\text{S}}}{\text{H}}_{{2}}\)) as shown in Eqs. (20) and (21).

Formed gypsum enters a similar reaction with cementitious products to form ettringite and monosulphoaluminate as shown in Eqs. (5) and (6).

If the pH of a system is high, ettringite can precipitate when an adequate amount of sulphate, calcium, and alumina ions are available along with water (Diaz Caselles et al. 2020).The addition of lime or cement can release HL in the system, which can potentially increase the pH of the system (Celik and Nalbantoglu 2013; Diaz Caselles et al. 2020). On the other hand, soils with significant amount of alumina and calcium ions are susceptible to the formation of ettringite and monosulphoaluminate. Therefore, the choice of additive requires considering the chemical composition of the soil and its contribution to the pH of the system to eliminate sulphate attack.

3.4 State of Compaction

Stabilized soil is compacted until it reaches MDD under OMC. For a particular soil sample, MDD and OMC can be determined according to the modified Proctor compaction test stipulated in British Standard 1377–4 ("BS 1377–4, Methods of test for—Soils for civil engineering purposes—Part 4, Compaction-related tests," 1990). For each additive content, 5–6 stabilized soil samples are to be cast with alternative moisture contents, and their corresponding dry densities are measured. By plotting dry densities against moisture contents, MDD and OMC can be determined by choosing the highest density and respective moisture content, respectively, for a designated additive content ("BS 1377–4, Methods of test for—Soils for civil engineering purposes—Part 4, Compaction-related tests," 1990). During cement stabilization, hardening reactions described in Eqs. (1) and (2) start occurring immediately when water is added to the soil cum cement mix. The hardened soil–cement mix might require additional compaction energy to obtain the required MDD, also compaction may break the bonds formed during hardening that resulting in a loss of strength. To prevent compaction from being hindered by hardening, the cement-stabilized soil samples should be immediately compacted (Afrin 2017; "ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993).

For cement-stabilized soils, generally, MDD decreases with the increase in cement content, however, OMC increases (Basha et al. 2005; Pongsivasathit et al. 2019). A similar tendency in MDD and OMC was also reported in lime-stabilized soils (Asgari et al. 2015; Rahman 1986). On the contrary, in soil stabilized with cement and FA-based mix, with increasing FA content, MDD decreased initially and then increased (Degirmenci et al. 2007; Zumrawi 2015). Basha et al. (2005) reported that MDD decreased with increasing additive content including cement, RHA, a mixture of 4% cement blended with RHA, and a mixture of 8% cement blended with RHA. OMC, however, increased in all cases. These variations in MDD could be attributed to the change in grain size distribution, specific gravity of soils and type of stabilizing agent (Nalbantoğlu 2004; Rahman 1986, 1987). Stabilized soils form large grains through the agglomeration process that consequently occupy larger spaces, which in turn increase voids between soil grains. An increase in the volume of voids contributes to a decrease in MDD. When the stabilizer is of high specific gravity, some soils have shown a decrease in MDD due to the agglomeration of grains initially. Continuous accumulation of stabilizer will start filing the voids, which would reduce the volume of voids and consequently increase MDD. Decreased levels of MDD obtained in stabilized soils imply that lower levels of compaction are required to achieve designated MDD which eventually saves money spent on compaction (Muntohar and Hantoro 2000).

Figure 4 illustrates a comparison of MDD and OMC variations between various soil types stabilized with different stabilizing agents. MDD of most of the stabilized soils range between 1.2 and 1.8 Mg/m3, and OMC values fall between 15 and 45%. With the increase in stabilizer dosage, all stabilizers except cement kiln and fly ash showed decreasing and increasing trends in MDD and OMC, respectively.

MDD and OMC variation in various soils stabilized with different stabilizer/s. GW, SM, SP, SC, OH, CH, CL, ML, and MH are standard USCS notations used to represent soil types. OPC ordinary Portland cement, RHA Rice husk ash, LME Lime, FLA C Fly ash, class C, FLA F Fly ash, class F, CKN Cement kiln dist, PHP Phosphogypsum and ESP Eggshell powder (Basha et al. 2005; Degirmenci et al. 2007; Maduabuchi and Obikara 2018; Mishra et al. 2019; Muntohar and Hantoro 2000; Nath et al. 2017; Oluwatuyi et al. 2018; Pongsivasathit et al. 2019; Rahman 1986; Rimal et al. 2019; Zumrawi 2015)

The MDD reduces with the increase in additive dosage for all typical stabilizers. Reduction in MDD could impact the strength characteristics of the stabilized mix. The stabilizer dosage is therefore carefully manipulated to satisfy the standard requirements of each application. Backfills of retaining walls are benefited from the reduction in MDD as the lateral pressure exerted by the soil on the structures decreases.

3.5 Curing

Curing in stabilized soils is performed by maintaining the required moisture levels and temperature to support cementitious reactions throughout the curing age (Mitchell and Hooper 1961). For cement-based stabilizers, cementitious hydration takes place immediately to bind soil particles together, followed by pozzolanic reactions (Aïtcin 2016). For the other stabilizers including, lime, RHA, FA, and ESP, pozzolanic reactions slowly start occurring and continue for a long period (Bell 1996; Prusinski and Bhattacharja 1999). ORN 31 standard recommends UCS tests to be done on samples sealed and moist-cured at 25 °C for 7 days and soaked for 7 days, whereas CBR tests to be carried out on samples sealed and moist-cured at 25 °C for 21 days and soaked for 7 days ("ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993).

3.5.1 Moisture Content

A sufficient amount of moisture is required during the soil stabilization process to support compaction and cementitious reactions (Afrin 2017). Compaction and stabilization are governed by OMC and water-to-cement ratio, respectively (Zumrawi 2015). Both parameters are expressed in terms of the dry weight of the soil (Zumrawi 2015).

Granular soils may be stabilized with OMC obtained from the Proctor compaction test (Maclean and Lewis 1963). The mechanical characteristics of cement-stabilized soil greatly depend on the water-to-cement ratio (Miura et al. 2001). Literature report a hyperbolic relationship between UCS and water-to-cement ratio (Chian et al. 2016; Cong et al. 2014; Miura et al. 2001) for various types of soils. However, a study by Ribeiro et al. (2016) revealed that maximum UCS resulted when the optimum water-to-cement ratio was in the range of 1.0–1.5 for cement-stabilized silty-sand. Large UCS was attained for higher cement dosage irrespective of the water-to-cement ratio. Moreover, the authors claimed that UCS developed faster due to the formation of dispersive bonds between sand grains when larger water-to-cement ratios were adopted. However, the speed of curing did not guarantee maximum strength (Ribeiro et al. 2016).

For cement stabilization of cohesive soils, the recommended moisture content is 2% below the plastic limit to yield high states of compaction and to obtain low water absorption in hardened soil–cement (Maclean and Lewis 1963). Asgari et al. (2015) found that the initial water-to-stabilizer ratio significantly affected the mechanical properties of stabilized CL-type soil. For cement and lime-treated soils, three different initial water-to-stabilizer ratios were used; 2% less than OMC (dry side), OMC, and 2% more than OMC (wet side). Soils stabilized with dry side water yielded higher UCS than wet side. Lime stabilization with hydrated lime or quicklime consumes water amounts to 20–30% of their self-weight (Hebib and Farrell 2003; Sherwood 1993). Soils with great water affinity such as clay and peat absorb plentiful water leaving insufficient water available for hydration reactions (Hebib and Farrell 2003; Hicks 2002).

Appropriate moisture content is vital in attaining high strength characteristics. The amount of water to be added is dictated by parameters of compaction and stabilization. The OMC required for compaction needs to be manipulated by accommodating the moisture requirements pertaining to soil plasticity and additive consumption.

3.5.2 Temperature

In the presence of elevated curing temperatures, higher degrees of hydration reaction take place, which expedite the release of HL required for pozzolanic reactions. The temperature rise and availability of ample amount of HL accelerate the pozzolanic reaction, which promotes strength development in stabilized soils at both early and mature ages (Afrin 2017; Rao and Shivananda 2005; Zhang et al. 2014a, b). George et al. (1992) claimed that lime-stabilized soil at 50 °C resulted in more strength gain than that treated at lower temperatures. A similar influence of temperature on UCS of clay soil stabilized with lime has been reported by Bell (1996). Al-Mukhtar et al. (2010) found that increasing the curing temperature from 20 to 50 °C multiplied the rate of pozzolanic reaction by six. Zhang et al. (2014a, b) claimed that higher curing temperatures not only yielded higher short-term UCS but also ultimate UCS in cement-treated clay. In the published literature, the mechanical characteristics of stabilized soils were evaluated at temperatures ranging between 20 and 50 °C, considering typical air temperature variations in different countries.

To capitalize on the positive impact provided by elevated temperatures, studies have recommended to carryout stabilization of soil with cement and pozzolanic additives such as Lime, FA, and RHA during warmer conditions for better results (Sherwood 1993). Also, the practical implications pertaining to elevated temperatures are another concern. On the other hand, carbonation might increase with the temperature rise, which needs to be dealt with appropriately.

3.5.3 Curing Age

According to the reviewed literature, typical curing ages set to monitor the change in properties of stabilized soil are 3, 7, 14, 28, 56, and 91 days (Asgari et al. 2015; Ho et al. 2017; Latifi et al. 2017; Oluwatuyi et al. 2018; Phummiphan et al. 2016; Prusinski and Bhattacharja 1999; Rahman 1987; Rimal et al. 2019). Rarely researchers have tested the properties of stabilized soils at 1 day or 180, 224, 300, and 365 days (Kalantari and Prasad 2014; Lemaire et al. 2013; Rimal et al. 2019; Zhang et al. 2014a, b). Figure 5 illustrates the UCS development over the curing age. In all the soil-stabilizer combinations, rapid strength development is visible for up to 28 days, the rate of strength gain decreases afterward and eventually, it attains an asymptotic relation with curing age. A study compared the effect of curing age in cement and lime-stabilized soils, and found that the most significant changes occurred after 1 h curing period, and subsequent changes were marginal (Christensen 1969). In the initial stages of curing, cementitious hydration reactions are prominent in cement-based additives that contribute to rapid strength development. Pozzolanic reactions occur after cementitious hydration reaction at slower rates, which contribute to slower strength gain. In soil stabilization using stabilizers such as lime, RHA, FA, and ESP, strength development is caused by pozzolanic reactions only that provide a slower strength gain. Eventually, at the exhaust of required inputs for pozzolanic reactions, strength gain becomes zero. Horpibulsuk et al. (2010) found that, with the increase in curing age, hydration reactions increased to form cementitious products. They filled pores between granular particles and reduced total pore volume. Reduction in pores consequently contributed to an increase in strength.

Variation in unconfined compressive strengths for different soil types and stabilizers with curing age. SM, OH, CH, CL, and MH are standard USCS notations used to represent soil types. OPC ordinary Portland cement, LME Lime, FLA C Fly ash, class C, ESP Eggshell powder, SH-85 calcium-based powder additive

For all types of additives, the strength development in stabilized soil has been significant up to 28 days from the treatment. Appropriate curing conditions are to be ensured during this period to guarantee that the stabilized soil attains the maximum possible strength.

3.5.4 Curing Types

Kalantari and Prasad (2014) explored the effect of types of curing including air curing, moist curing, and moist curing with a surcharge load of 10 kPa on cement-stabilized peat samples. The authors measured the UCS of cured samples under the above conditions after curing periods of 28, 90, and 180 days, and found that moist curing with surcharge load resulted in the highest percent increase in UCS. Similarly, a study by Ho et al. (2017) compared sealed (for 91 days) and drying (sealed for 7 days and air-cured from 7th to 91st day) curing conditions for cement-stabilized sand and concluded that drying curing conditions produced the highest UCS. Different types of curing mediums including distilled water and seawater have been used by researchers (Chian et al. 2016; Xiao et al. 2014). Emarah and Seleem (2018) found that adding seawater to lime stabilization of highly expansive clay yielded a significant reduction in swelling potential and an improvement in compression potential. Table 6 provides details of curing methods used for different soil types stabilized with various stabilizing agents. Figure 6 illustrates the variation of UCS against curing age for different curing types.

Variation in unconfined compressive strengths for different curing types and soils with curing age. Pt and SP are standard USCS notations used to represent soil types; OPC ordinary Portland cement, LP Liquid polymer, A Air curing, M Moist curing, MS Moist curing with surcharge, S Sealed curing, AM Air curing and moist curing, and AH Air curing and heating at 100 °C (Ho et al. 2017; Kalantari and Prasad 2014; Rezaeimalek et al. 2017)

3.6 Carbonation

In lime stabilization, HL or C could react with atmospheric CO2 to form CaCO3, which is an insoluble content. Equations (13) and (15) govern chemical reactions of the formation of CaCO3. Similarly, in cement stabilization, cementitious hydration products including C–S–H and C–A–H formed at initial stages, are susceptible to carbonation, and their chemical reactions are shown in Eqs. (22) and (23) (Gourley and Greening 1999).

Other stabilizing agents including FA-class C, ESP, phosphogypsum, and cement kiln dust, which have rich C content also could potentially react with atmospheric CO2 to form CaCO3.

This early formation of CaCO3 retards pozzolanic reaction and strength gain, which could potentially lead to premature failure of pavements. To prevent carbonation from occurring at the pre-stabilization stage, it is important to minimize the exposure of stabilizing agents to air during manufacturing and storing processes. At post-stabilization, direct exposure of stabilized soil with air is to be curtailed by sealing it with polythene or a layer of water.

The carbonation effect can be quantified in stabilized soil by measuring the pH of stabilized soil. The presence of HL and OPC will have a pH > 12.4, C–S–H and C–A–H will have a pH ranging from 11.0 to 12.6 and CaCO3 will have pH = 8.3 (Gourley and Greening 1999). Indicators including phenolphthalein, phenol red, and dilute hydrochloric acid have been prescribed to detect the presence of C, HL, C–S–H, and C–A–H (Gourley and Greening 1999; Netterberg 1984).

Carbonation affects the durability of the stabilized soil and hence promotes progressive strength reduction, which can lead to structural failure. Calcium-rich additives are more susceptible to a higher degree of carbonation if exposed to air after stabilization. Typical additives such as OPC and lime contain significant amounts of calcium, and so do non-traditional stabilizers including FA-class C, ESP, and phosphogypsum. This emphasizes the need for proper curtailment of stabilized soil with air.

4 Engineering Properties of Stabilized Soil

The performance of soil stabilization has been historically evaluated through physical attributes including Atterberg limits and density (Amaral et al. 2013; Miller and Azad 2000; Muntohar and Hantoro 2000; Nath et al. 2017; Zumrawi 2015); mechanical parameters such as UCS, CBR, MR, indirect tensile strength, and Young’s modulus (Miller and Azad 2000; Mishra et al. 2019; Muntohar and Hantoro 2000; Oluwatuyi et al. 2018; Pongsivasathit et al. 2019; Praticò and Puppala 2012); swelling characteristics namely swelling potential and swell pressure (Nalbantoğlu 2004; Zumrawi 2015), and durability aspects including resistance to loss in strength (Oluwatuyi et al. 2018). Limiting criterion of these properties are stipulated in different standards for various pavement applications (Hicks 2002; "ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993; "SCA/5—Standard Specifications for Construction and Maintenance of roads and bridges," 2009; "Standard Specifications for Transportation materials and Methods of Sampling and Testing," 2015). Table 7 details the tests conducted to assess the performance of stabilized soil in numerous studies and the respective standards. Fundamentally, strength-related tests such as UCS, CBR, third point loading test, dynamic flexural loading, and resilient modulus are conducted on stabilized soil samples compacted at MDD or to match minimum field requirements. Atterberg limits and pH tests are conducted to monitor the change in plasticity and carbonation, respectively. Recently, advanced tests such as X-ray diffraction (XRD) analysis and Scanning Electron Microscope (SEM) are being conducted to examine mineralogical and morphological characteristics.

4.1 Physical Attributes

After adding stabilizing agent, soil particles undergo cation exchange and particle restructuring through which soil plasticity and density change. The changes in plasticity and density can be measured by conducting Atterberg limits and Proctor compaction tests, respectively. Density properties have already been discussed in Sect. 3.4. The Atterberg limits test is conducted according to ASTM D4318 ("ASTM D4318, Standard test methods for Liquid Limit, Plastic Limit, and Plasticity Index of soils," 2005) standard to determine the consistency limits of stabilized soil. By estimating Liquid Limit (LL) and Plastic Limit (PL), Plasticity Index (PI) can be estimated by finding the difference between LL and PL.

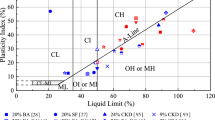

Figure 7 shows Atterberg limits obtained for various soil types stabilized with different stabilizing agents. Variation of LL with stabilizer dosage remains unchanged or decreases for all types of soils except OH, on the contrary PI decreased with the increase in stabilizer dosage in all soil types. As briefly noted earlier, when the stabilizing agent is added to soil, cations present that are of high affinity to water are replaced with low-affinity ones in the stabilizer. The exchange of ions retards the ability of soil particles to attract and retain water around, which turns soils less plastic. The degree of change in plasticity greatly depends on the type and amount of cations present in soil and stabilizing agents (Bell 1996; Miller and Azad 2000). An organic component present in the OH soil type consumes a large amount of water, which might have contributed to the slight rise in LL. Cement-based stabilizing agents are effective for soils with a PI less than 10, whereas lime stabilization is effective for soils with a PI above 10 (Hicks 2002; "ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993).

Variation of Liquid limit (LL) and plasticity index (PI) of different soil types with various stabilizer dosages. SC, ML, MH, CL, CH, and OH are standard USCS notations used to represent soil types; RHA Rice husk ash, LME Lime, OPC ordinary portland cement, FLA C Fly ash, class C, FLA F Fly ash, class F, CKN cement kiln dist, PHP phosphogypsum and ESP Eggshell powder (Degirmenci et al. 2007; Maduabuchi and Obikara 2018; Miller and Azad 2000; Muntohar and Hantoro 2000; Nath et al. 2017; Rahman 1986; Zumrawi 2015)

4.2 Mechanical Parameters

The structural stability of stabilized soils is assessed by determining their mechanical parameters. Historically, UCS (Amaral et al. 2013; Asgari et al. 2015; Bell 1996; Consoli et al. 2020; Degirmenci et al. 2007; Latifi et al. 2017), MR (Bhuvaneshwari et al. 2019; Ikechukwu et al. 2021; Pongsivasathit et al. 2019; Solanki et al. 2010; Tastan et al. 2011) and CBR (Basha et al. 2005; Oluwatuyi et al. 2018; Pongsivasathit et al. 2019; Zumrawi 2015) have been predominantly used in the studies to assess improvement in mechanical parameters. In addition to these three, a few studies have used indirect tensile strength (Praticò and Puppala 2012), third point loading (Pongsivasathit et al. 2019), and Young’s modulus (Cong et al. 2014; Sariosseiri and Muhunthan 2009) for evaluation.

Figure 8a shows the variation of UCS with stabilizer dosage for diverse types of soil. Cement-stabilized SC soil produced exceptionally well UCS as the readily available coarse grain in sand contributed to strength gain. For cement-based stabilizers (OPC, cement kiln), improvement in UCS with stabilizer dosage was drastic for all soil types. For 5–15% stabilizer dosage, the UCS of most of the stabilized soil lay between 700 and 1500 kPa. When cement-blended stabilizers were added to the soil, cementitious hydration occurred immediately, which could be attributed to the initial rapid strength gain. The rate of strength gain declined thereafter. On the contrary, lime stabilization showed a steep increase in UCS up to 4% dosage and then began to decline for subsequent accumulation in lime dosage. This phenomenon could be associated with the reduction in dry density of lime-stabilized soils (Bell 1996). Stabilization of organic soil with high plasticity, with FA (class C/F) up to 20% dosage achieved strengths less than 80 kPa. OPC and RHA mix stabilization showed a moderate improvement in UCS and reached a maximum UCS of 1,190 kPa at a dosage of 30%. Both RHA and FA entered a pozzolanic reaction with soil components at a slower rate, which improved the UCS of stabilized soil at a steady rate. The presence of organic matter in OH-type soil maintained a lower pH value, which heavily retarded pozzolanic reaction and strength gain in FA-stabilized soil. UCS requirements stipulated in ORN 31 for stabilized road base (CB1), stabilized road base (CB2), and stabilized sub-base (CS) are 3,000–6,000, 1,500–3,000, and 750–1,500 kPa, respectively ("ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993). SC and CL type soils stabilized with OPC at 5–10% dosage satisfied the minimum requirements for stabilized road base (CB1). For stabilized sub-base, CL, CH, ML, and MH-type soils treated with the combination of OPC, RHA, SH85, CKN, and LMN at a dosage of 5–10% might be suitable. However, another CL-type soil required more than 20% dosage of the combination of OPC and RHA to satisfy the minimum requirements for stabilized sub-base. This might be attributed to the chemical composition of the soil that exhausted a substantial portion of additives in cation exchange. Organic soil treated with fly ash was unsuitable to be used for road pavements.

Variation of mechanical properties with various stabilizer dosages. SC, SM, OH, CH, CL, ML, MH, and OH are standard USCS notations used to represent soil types; RHA Rice Husk Ash, LME Lime, FLA C Fly ash, class C, FLA F Fly ash, class F, CKN Cement Kiln dist and ESP Eggshell powder (Asgari et al. 2015; Basha et al. 2005; Bhuvaneshwari et al. 2019; Ikechukwu et al. 2021; Latifi et al. 2017; Muntohar and Hantoro 2000; Nalbantoğlu 2004; Nath et al. 2017; Oluwatuyi et al. 2018; Onyelowe et al. 2021; Praticò and Puppala 2012; Rahman1986; Rimal et al. 2019; Jaritngam et al. 2014; Soltani et al. 2017; Tastan et al. 2011; Zumrawi 2015)

Figure 8b shows the CBR variation with stabilizer dosage for diverse types of soils. CBR variation with stabilizer dosage resembles the trend observed in UCS variation. Coarse-grained soils stabilized with RHA, Lime, OPC, ESP, and OPC showed rapid improvements at the initial stage and gradually attained a saturated state. Lime stabilization, as explained earlier, increased and then declined due to the associated changes in dry density. Highly plastic soils stabilized with lime or RHA did not show notable improvement in CBR values. A minimum CBR value recommended for subgrade and sub-base applications is 15% and 30%, respectively ("ORN31, A guide to the structural design of bitumen surfaced roads in tropical and sub-tropical countries," 1993). MH-type soil stabilized with RHA or lime could not satisfy the minimum requirements for the stabilized pavement. Mostly, sandy soils stabilized with OPC, lime, and ESP at a dosage of less than 5% satisfied the minimum requirements for sub-base and subgrade. Surprisingly, a CH-type soil too showed drastic improvement in CBR. Sandy clay treated with an RHA dosage of more than 10% satisfied the minimum requirements for sub-base and subgrade.

The state-of-the-art world practices follow the mechanistic-empirical design of pavements, which assesses the performance of a pavement under repeated loading ("AASHTO Guide for Design of Pavement Structures," 1993). MR is one of the vital input parameters for the mechanistic-empirical design of pavements, which measures elastic characteristics of subgrade incorporating nonlinear characteristics (Fabiana et al. 2011; Qubain et al. 2000; Saberian et al. 2018). Figure 8c shows the change in MR with stabilizer dosage. Lime-stabilized soils showed a steep increase in MR even with small lime dosages. FA-based stabilizers showed a steady improvement in MR with higher stabilizer dosages. However, the final MR obtained at 30% stabilizer dosage was much less than that of lime (< 10%) stabilized soils. Due to higher CaO content, higher MR was observed in soil stabilized with FA–C compared to that of FA-F.

Young’s modulus variation with stabilizer dosage is illustrated in Fig. 8d. Young’s modulus of soil stabilized with lime-based stabilizer increased with stabilizer dosage up to 5–10% and thereafter showed a descending trend whereas cement-based stabilizer exhibited continuous improvement.

4.3 Swelling Potential and Swell Pressure

Figure 9 displays the variation in swelling potential with stabilizer dosage for fine-grained soils. In general, swelling potential reduced with an increase in stabilizer dosage for all types of stabilizers. Lime-based stabilizers showed a rapid reduction in swell potential during the initial stages of stabilization, compared to other stabilizers. This could be attributed to the abundantly available Ca2+ in lime-based stabilizers, which replaced cations that in turn reduce the affinity of clay particles toward water. This lowered the water-attracting capacity of clay particles. Thereafter, pozzolanic reactions occurred to form flocs in the treated soil, which eventually reduced both plasticity and swelling potential. Cement–based stabilizers immediately started hydration reactions, which gradually formed granular particles. The formation of granular particles brought down plasticity and swelling potential. Agglomeration of particles is the major factor in controlling the swell potential of clayey soils.

Variation of swelling potential with various stabilizer dosages. CH, CL, and MH are standard USCS notations used to represent soil types; OPC ordinary Portland cement, RHA Rice Husk Ash, LME Lime, FLA C Fly ash, class C, FLA F Fly ash, class F, QARHA Quicklime activated RHA, HARHA Hydrated lime activated RHA and CARHA calcite activated RHA (Muntohar and Hantoro 2000; Nalbantoğlu 2004; Onyelowe et al. 2021; Soltani et al. 2017)

High swell potential corresponds to high swell pressure, which is exhibited by soil upon inundation. Excessive swell-shrink behavior exerts fatigue load on the structural elements and eventually leads to structural failure. Calcium-rich additives are observed to be effective in reducing the swell potential of high-plasticity soils. Also incorporating lime or RHA-based additives and other additives might work well in reducing swell potential. The determination of additive dosage should take account into the amount of additive exhausted in the initial cation exchange.

4.4 Durability Aspects