Abstract

Conventional techniques of soil stabilization involve using additives such as lime and cement. However, these methods take up a great deal of energy and cause considerable environmental pollution. Recently, bio-additives have been taken into account as sustainable development, cost-effective, and environmentally acceptable alternatives to chemical stabilizers in geo-environmental applications. In these techniques, bio-chemical activities, including bio-cementing, bio-clogging, bio-coating, and bio-encapsulation, are employed to stabilize soil particles. The present study aims to examine the impact of bio-stabilizers type and quantity on the geotechnical characteristics of soil for soil stabilization. For this purpose, the biochemical performance of various biological methods of soil stabilization (e.g., bio-microorganisms; bioenzymes; and biopolymers) is first presented. Then, the behaviors of bio-substances in all types of soils are investigated through a comprehensive review of previous research. Afterward, the biochemical behavior of bio-additives and their properties, mechanism, application, and interaction with soil particles are investigated on a microscopic and macroscopic scale. Next, the most effective factors in bio-stabilization are determined and evaluated. Finally, the essential recommendations for choosing the kinds and amount of bio-additives for soil stabilization are offered based on the soil type. The findings of this study indicate that the performance of bio-stabilizers is based on the percentage and type of bio-additives, soil type, and the quantity of electrostatic forces generated during cementation and hydrogel production. In addition, among various bio-additives, S. pasteurii and Bacillus sphaericus, TerraZyme, Xanthan gum, and Guar gum showed the best performance by increasing mechanical/shear strength by up to 300% and decreasing permeability, compressibility, and/or shrinkage properties. Furthermore, temperature, curing time, and soil pH were determined as crucial factors in establishing interlocking forces between soil particles and choosing the appropriate biomass.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Some soils may exhibit inadequate compressive, shear, and tensile resistance to the imposing stresses. Therefore, it is necessary to enhance the strength of such soils beneath building sites and sub-layers of transportation roads (Vincevica-Gaile et al., 2021). In addition, when buildings are constructed on problematic soils, the soil must possess adequate strength against loads and stresses. However, this soil strength might not exist on the construction site. Thus, it is essential to enhance the bearing capacity and mechanical properties of the soil (e.g., cohesion and friction). In this regard, soil stabilization is the most frequent method to improve the mechanical properties of soil (Huang et al., 2021).

Since ancient times, several methods have been used to stabilize soils for structural construction. The Romans and Chinese used various techniques for soil stabilization in their buildings and roadways, which date back more than 5,000 years (Aamir et al., 2019; Shalchian & Arabani, 2022). These improvement methods include i) incorporation of chemical additives such as lime, bitumen, fly ash, cement, and synthetic polymer that can alter the chemical properties of soils and ii) mechanical techniques such as compaction, ground anchorage, and nailing, blasting, vacuum consolidation, reinforcement that can modify the mechanical characteristics of soils (Jha & Sivapullaiah, 2020; Lakhanpal & Chopra, 2018). In addition to the mentioned procedures, a combination of chemical and mechanical methods (cement, polymers with preloading) has occasionally been used to enhance the soil's qualities (Onyejekwe & Ghataora, 2015). However, employing conventional methods for soil modification may involve significant drawbacks due to their adverse environmental impacts. Cement, for instance, which is among the most well-known stabilizers, is one of the key climate challenges since both the production of cement and the use of cement contribute to the acceleration of global warming by emitting a significant amount of carbon dioxide (CO2) into the atmosphere. In addition, using conventional stabilizers leads to the exhaustion of natural resources (Firoozi et al., 2017; Shalchian & Arabani, 2022). Therefore, problems concerning sustainable development and environmental concerns can be addressed by implementing soil stabilizing techniques using materials that are both affordable and environmentally compatible. In the past few years, biological soil stabilization approaches have emerged as a viable option among several strategies for soil improvement. In geo-environmental science, biological methods have been introduced as environmentally friendly techniques, and studies have shown promising results in this field (Chang et al., 2020; Choi et al., 2020; Rajoria & Kaur, 2014). These biological compounds have been introduced as an alternative to conventional soil treatment methods (Ramdas et al., 2021; Sharaky et al., 2018).

Biomaterials, such as microbial precipitation, bio-enzymes, and biopolymers, are eco-friendly materials following sustainable development requirements (Jang, 2020). Numerous bio-substances and bio-compounds in nature can stabilize and bind the soil particles together through biochemical processes according to the previous attempt of review articles (Baziar et al., 2021; DeJong et al. 2014b; Ghosh et al., 2021). However, one of the challenges in selecting the required biological substances is finding low-cost appropriate biological agents that cover a large area to stabilize existing soils. Microorganisms, bioenzymes, and biopolymers are the most suitable bio-additives for stabilizing and improving soil properties such as compressive strength, stiffness, erosion resistance, shear behavior, and hydraulic conductivity (Mallikarjun et al., 2022; Soldo et al., 2020; Umar et al., 2016). However, reviewing the literature shows that various effects, biochemical interactions, mechanisms, and limitations of these bio-based substances on the various type of soils (granular and cohesive) and their impacts on the mechanical properties of stabilized soil have not been completely comprehended (Jang, 2020; Ramdas et al., 2020). In addition, no thorough research has compared the behavior and effects of various bio-stabilizers on cohesive and granular soils. This shortcoming may stem from the fact that soil (either stabilized or unstabilized) exhibits a complex mechano-dynamic behavior influenced by numerous factors, including the soil's physical and chemical properties, bio-content, the amount of confining pressure, and environmental factors. Bio-stabilizers and their applications in soil stabilization are a multifaceted, interdisciplinary green technology that encourages interdisciplinary research and collaboration among environmental and geotechnical engineers, road and pavement engineers, green chemists, biotechnologists, and geo-microbiologists (Mekonnen et al., 2020; Rajoria & Kaur, 2014). Therefore, geo-environmental engineers are urged to investigate the mechanical characteristics and behavior of stabilized soil with bio-substances (Ramdas et al., 2021, 2022).

The present study aims to investigate the mechanism, interaction, and performance of soil stabilization in combination with biological materials to determine the type and percentage of compounds required to achieve optimal performance for the stabilization of different soils following sustainable and environmentally friendly geotechnics. To this end, the biochemical features and characteristics of bio-enzymes, bio-microbes, and biopolymers were analyzed, followed by examining the mechanisms, biochemical interactions, and impacts of these biological materials as soil stabilizers. Next, the influence of biological materials in soil stabilization was reviewed on a large/small scale based on biological soil stabilization, and the research gaps in their mechanisms were discussed. In addition, the benefits, limits, and potential future uses of each biocomposite for soil stabilization are discussed. Finally, the type and dosage of biological stabilizers recommended for various soils are outlined.

2 Material and method

2.1 Article selection criteria

The selection criteria for the papers to be reviewed are provided in Table 1. Methodological filters and considerations were given to English articles that primarily addressed the use of bio-materials for soil stabilization. Papers published in languages other than English were not included. This systematic review examined studies published between 1995 and 2023. The included publications were those that investigated the enhancement of soils' geotechnical qualities by incorporating the most abundant microorganisms, bio-enzymes, and bio-polymers and were published in peer-reviewed journals. This paper presents information obtained from previously published papers. The primary objective was to enlighten the readership about recent developments in geotechnical engineering about soil stabilization using more environmentally friendly and sustainable materials.

2.2 The results of research

The following databases, which included 320 documents, were searched: Google Scholar (175), Springer (95), and ScienceDirect (50), providing the most results for the studied topic. The papers underwent scientific peer assessment to ensure the reliability of the collected data. According to their data and/or references, 71 of the acquired articles were omitted because they did not meet the inclusion criteria, and 44 were excluded because they were duplicates. The ultimate revision yielded 141 eligible articles on the implementation of the most sustainable bio-based materials to improve soils' engineering characteristics, 9 of which were case studies and the remaining were experimental investigations. In addition, 66 essential publications were included to critically examine the global status of research on the usage of bio-compounds in geoengineering. At the beginning of the study, first-level keywords such as soil stabilization, bio-compounds in soil, and soil treatment were used; at the next level, more precise terms such as soil stabilization with a bio-microbe, soil stabilization with a bio-polymer, and soil stabilization with a bio-enzyme were applied. Sections 3 and 4 discuss the bio-based substances and their biochemical reactions. Sections 5, 6, and 7 provide a detailed review of research on soil stabilization utilizing microorganisms, bio-enzymes, and bio-polymers based on their type, number of applications, usage, and historical trend in the soil stabilization process. Then, the application of bio-materials at macro- and micro-scales and their cost are assessed.

3 Bio-based substances

Several substances derived from bio-sources (e.g., microorganisms, bio-enzymes, and biopolymers) have been examined as potential replacements for conventional chemical stabilizers in developing green and road geotechnical infrastructures. These substances have gained more attention regarding their high rate of bio-chemical activity, rapid growth, cheap curing, and non-toxicity in the soil matrix. Each biomaterial possesses unique chemical properties and induces distinct biochemical reactions in the soil matrix. Therefore, deeper comprehension of these bio-based materials and technologies is necessary for their increased use in soil stabilization (Choi et al., 2020; Ikeagwuani & Nwonu, 2019). As shown in Fig. 1, soil stabilization using biomaterials can be accomplished using microorganisms, bio-enzymes, and biopolymers. The use of microorganisms to achieve soil stabilization through bio-cementation through microbial precipitation (MICP), also known as “bio-grout”, is among the most prevalent methods. This method uses bacteria's metabolic activities to produce calcite precipitation (CaCO3). Accordingly, this biochemical interaction between microorganisms in the soil matrix causes soil particles to bind, resulting in higher soil compressive and shear strength (Cheng & Shahin, 2019). In other words, by adding microorganisms to the soil and their biochemical interactions with soil grains, the bio-cemented process binds the soil grains and strengthens the interlocking forces between soil particles (Kalkan, 2020; Robert & Chenu, 2021). In biological engineering, the so-called biocatalyst bio-enzymes can control how fast chemical reactions happen and how much energy is needed to switch from one product to another (Mekonnen et al., 2020). Bio-enzymes are protein molecules that catalyze chemical reactions in the soil to form cement bonds that stabilize soil structure and reduce water absorption tendency (Ganapathy et al., 2017). Biopolymer stabilization modifies the soil's properties by producing a “hydrogel” hydration. After dehydration, water molecules tend to escape from polymer chains, forming complexes of polymer chain attachments. In addition, during the drying process, hydrogels transform from “rubber gel” to “glass” (Muguda et al., 2017). Bio-enzymes are biomass materials derived from natural enzymes that work by interacting with clay particles to form a rock-like surface. Grains stick together and form a dense soil matrix (Joshi & Solanki, 2019; Kushwaha et al., 2018).

Bio-enzymes are proteins made up of a chain of amino acids that combine small parts to make a molecule and can improve the function of a molecule that already exists (Mekonnen et al., 2020; Rafique et al., 2016). Bio-enzymatic solutions increase water's hydration process by reducing water's surface tension. As a result, the thickness of absorbed water around the soil particles reduces, leading to the breakage of water molecules around the particles. Bio-enzymes use their chemical properties to absorb water and fill cavities, allowing clay grains to stick together and form a dense soil matrix (Joshi & Solanki, 2019; Kushwaha et al., 2018). On the other hand, based on the type of monomers making the polymers, biopolymers for soil stabilization can be categorized into polysaccharides, proteins, and nucleic acids. Based on their response to heat, biopolymers can also be classified as elastomers, thermoplastics, and thermosets. Generally, some biopolymers are water-sensitive, and wetter soils show poorer biopolymer-soil adhesion. As a result, when gel-type biopolymers are hydrated, they form hydrogels with significantly less tensile strength than compressive strength. Protein-based biopolymers are less prevalent than polysaccharides due to their higher cost and require greater water (Ibrahim et al., 2019; Kakkalameli et al., 2022; Krebsz et al., 2017). The engineering sciences have used at least eight types of biomaterial processes and mechanisms, each defined according to its operating mechanism. Figure 2 illustrates the procedure and effectiveness of biomaterial-based soil stabilization. In recent years, four prominent applications have been considered in geotechnical engineering: bio-clogging, bio-cementation, bio-coating, and bio-encapsulation (Lee et al., 2019). Bio-clogging or biological clogging in soil or porous matrix is a process to fill in the pores and voids in the soil/matrix to reduce the hydraulic conductivity of the soil or porous matrix significantly. Also, bio-cementation is the process of producing particle-binding compounds on-site through microbial activities to increase soil shear strength. The bio-encapsulation and bio-coating techniques involve enclosing and shielding soil microorganisms and particles to preserve their biochemical activities and decrease the water absorption tendency (Chu et al., 2014; Ivanov & Chu, 2008; Ivanov et al., 2019; Li et al., 2016).

Currently, liquid-type non-conventional stabilizers have surpassed conventional stabilizers used to improve pavement and soil beneath shallow foundations. These non-conventional additives were introduced as attractive and competitive materials since they can be incorporated in-situ into the soil matrix and rapidly sprayed or pressure-injected into the soil pores in the case of deep mixing. Although conventional stabilizers such as cement and lime are effective for enhancing poor soils with enough clay content, the enhancement rate in compressive and shear strength with the addition of cement is higher than that of lime after 1 and 2 weeks of curing, respectively. Cement requires a high quantity of additives (3–7%) to achieve better strength. In this respect, the optimum percentage found from previous research ranges from 3 to 8%. Therefore, excessive dosage of lime may result in acidic soil, which is undesirable. Combining appropriate bio-based stabilizers is an efficient method for decreasing the additive dosage of conventional stabilizers (Ramdas et al., 2021). In addition, compared to other conventional and other bio-stabilizers and bio-microorganisms, bio-enzymes, and bio-polymer, it requires less dosing, does not need specialist workers, boosts photosynthesis in plants, and creates only a small amount of disturbance (Ramdas et al., 2020).

The bio-chemical activities of each biomaterial for soil stabilization and improvement vary due to different biochemical compounds. In the following sections, the behavior of each bio-based substance is discussed separately according to its functions, availability, and historical applications.

4 Biochemical reaction of bio-based substances

4.1 Microorganisms

Precipitation of calcite uniformly within soils through biological activity is among the widely used methods to raise the pH that causes supersaturated environments defined as microbial-induced calcium carbonate precipitation (MICP). In recent years, MICP has been presented as a new branch of geotechnical engineering to improve soil mechanical and dynamic properties due to nontoxicity and low cost (Mujah et al., 2017). Conventional grouting methods for soil stabilization employ particulate (cement/lime), which can be costly and environmentally unfriendly (Qu et al., 2022). As an alternative to conventional soil improvement approaches, the MICP method should be considered for addressing geotechnical problems, including liquefaction and erosion, and boosting mechanical qualities like adhesion and friction (Kalkan, 2020). In this method, microorganisms are ubiquitous in the top and bottom soil layers and have been active for millions of years. There are often more than 109 cells per gram in the surface layers of soil, although the population density of microorganisms declines with depth (Schulz-Bohm et al., 2018). The number of microorganisms that can be exploited as biological agents is high, but their presence in the project site's soil may be negligible. In the MICP method, the microbial population is often boosted by injecting nutrients (bio-stimulation) or augmented by injecting additional microorganisms (bio-augmentation) (Cheng & Shahin, 2019; Taghavi, 2021). In either case, the objective is to increase the activity level and/or concentration of the microbial population to a level sufficient to initiate and sustain a bio-chemical reaction. The key contributions made toward the development of MICP approaches are outlined in the following section based on their historical order. Gollapudi et al. (1995) may have been the first to use MICP for geotechnical applications. They attempted to prevent the leaching of groundwater contaminants in extremely permeable channels by mixing a mixture of bacteria (Bacillus pasteurii) with sand (Gollapudi et al., 1995). The second attempt using bio-microorganisms to improve soil compressive and shear strength was made by (Rahman et al., 2020). To date, various microbes have been applied in soil matrix stabilization (Mohapatra & Pradhan, 2021). The simplest and most common process for generating microbial carbonate precipitation is using a urolytic bacteria with urease's enzymatic activity as a catalyst for biochemical reactions. In this process, the bacterium is cultivated in vitro and then injected into the soil (Mujah et al., 2017; Yi et al., 2021). This biological method employs urolytic bacteria abundant in soil and the natural environment. This method can produce controllable cementation at a much faster rate (less than 24 h) than chemical cementation in soil environments (Tang et al., 2020). The conceptual model of this process is illustrated in Fig. 3. Compared to other stabilizers, the MICP mechanism binds neighboring soil particles, thereby adhering and cementing them together in a chain of biochemical reactions (Chittoori et al., 2021). The series of general biochemical reactions entails the hydrolysis of urea by bacteria, the production of ammonia and carbon dioxide, and ultimately the biological deposition of calcium carbonate (CaCO3) that occur within the soil mass.

Due to the presence of hydroxide ions on their cell walls, bacterial cells have a negative charge and adhere to the surface of soil particles containing a relatively high nutrient concentration. However, calcium ion with calcium salt is absorbed by the bacterial cell wall's negative charge. Bacteria emit mineral carbonate and ammonium ions in reaction to adding urea to the environment (Jiang et al. 2022a). This response can lead to local super saturation in the presence of calcium ions, resulting in the formation of non-uniform carbonate deposition on the cell wall, which improves the soil's mechanical properties. In the presence of substrate and adequate microbial activity, cementation covers all cell surfaces. There are other microbial mechanisms for cementing soil masses that are presented in Table 2, including 1) Amino Acid Amino Acidification, 2) Denitrification, 3) Dissimilatory Sulfate Reduction, 4) Photosynthesis, 5) and Methane Oxidation. During amino acid metabolism, CO2 and ammonia are produced through microbial activity (Mujah et al., 2017).

These microorganisms are, therefore, frequently urease-positive bacteria. Aerobic bacteria are favored because their cellular respiration produces carbon dioxide, which increases when pH rises owing to ammonium formation (Naveed et al., 2020). According to the literature, most urease-positive bacteria used in geotechnical studies belong to the species shown in Fig. 1 (DeJong et al., 2010; Smit et al., 2022; Yu, 2021).

4.2 Bio-enzymes

Bio-enzymes are fermented enzymatic components derived from plant extracts. These enzymes are organic matter obtained as a concentrated liquid comprised of protein molecules (Mekonnen et al., 2020). Using bio-enzyme agents as soil stabilizing additives has been the subject of intense research regarding their high manufacturing capability, low cost, environmental safety (non-toxicity), and relatively wide applicability compared to conventional chemical stabilizers (e.g., Portland cement, hydrated lime, and bitumen), which are required in large amounts to stabilize soils. Research has demonstrated that biological enzymes and their derivatives are resistant to precipitation and can be used in any climate (Thomas & Rangaswamy, 2020). Because of the large specific surface area and cation exchange capacity that influence the soil matrix's expansion and shrinkage, mechanical stabilization methods cannot entirely remove the water layer that covers the particles (Kushwaha et al., 2022; Mekonnen et al., 2020). This propensity of soil masses to take in water is a consequence of hydrogen bonding (oxygen or hydroxyl molecules absorbing hydrogen from water), van der Waals gravity, and the bipolar gravity of the charged surface (Taha et al., 2013). Although these enzyme-based soil stabilizers offer numerous advantages over conventional chemical stabilizers, it is unclear how and under what circumstances these substances operate. Stabilizing methods with these substances suffer from restricted use, and their particular chemical makeup makes their long-term effectiveness difficult to predict. Bio-enzymes are biocatalysts that accelerate unaltered biochemical reactions. Consequently, it is essential to conduct a study to provide objective scientific evidence for applying novel enzymes as a product in soil stabilization. Applying enzyme stabilization for roads originates from using enzymes to substances used to treat the soil to improve agricultural applications in 1967. A procedure modification resulted in producing a material that is acceptable for stabilizing weak roadbeds. Enzymes, when added to soil, enhance the particles' wetting and adhesion capabilities. Bio-enzymes react with soil molecules to generate a cementing link that stabilizes the soil structure. At a larger application scale, the treated soil can form a dense, strong, hard, and water-repellent bond layer and structure that can be used as a soil stabilizer (Pooni et al., 2019). Bio-enzymes stimulate biochemical reactions in the soil to form a cementitious bond that stabilizes soil structure and decreases the soil's natural tendency to absorb water. Moreover, they increase soil density, thereby lowering water retention and erosion. Bio-enzymes can also be used in a wide range of soils regarding their better interaction of enzymatic components with ionic soils, as long as a small amount of clay particles are present in the soil mass (Khan & Taha, 2015). Bio-enzymes are commonly sold as a concentrated liquid that must be mixed with aqueous solutions on the construction site before being spread on the soil or injected into deeper soil layers to stabilize them (Mekonnen et al., 2020). Bio-enzymes are sensitive to temperature such that they operate optimally at low temperatures (35 °C) and degrade at higher temperatures. The basic mechanism of the bio-enzyme activity in clay structure considerably lowers the adsorbed water layer and the double water layer. According to the researchers, bio-enzyme soil stabilization can be performed in two distinct methods (Muguda & Nagaraj, 2019). The first stabilization approach employs cations as an ion exchange agent, a process similar to cation exchange that reduces the thickness of the double water layer in stabilized soil (Velasquez et al., 2006). In the second stabilization method, components of the enzyme material in the soil matrix are combined to initiate a series of reactions between the enzymes and large organic molecules present in the soil masses, leading to the formation of a reactive mediator. This process also involves the clay mineral bio-encapsulation. These organic molecules have large flat surfaces resembling clay particles and can coat the clay minerals to neutralize the negative charge and reduce the clay's water-absorption capacity (Scholen, 1995). Bio-enzymes can be absorbed into the pores between the layers of organic molecules, resulting in a decreased sensitivity to moisture and a reduction in soil particles swelling. As represented in Figs. 4 and 5, clay particles contain high concentrations of cations to compensate for the negative surface loads caused by a bond fracture and isothermal replacement. The hydroxyl (-) and hydrogen (+) ions are separated when a bioenzyme reduces the dipole moment of a water molecule. The hydroxyl ion is subsequently broken down into oxygen and hydrogen, and the hydrogen hydroxyl atom is converted into hydronium ions. Generally, it can absorb or repel positive or negative charges depending on the conditions. A sufficient amount of positively charged metal ions (e.g., sodium, potassium, aluminum, and magnesium) are present in the absorbed water layer to ensure uniformity of charge with respect to negative soil electrical ions.

Regarding the effect of bioenzyme components on the reduction of the electric charge of the water molecule, there is a sufficient negative charge to exert enough pressure on positively charged metal ions in the absorbed film or layer of water. Consequently, this process reduces the electrostatic potential of soil particles (Saini & Vaishnava, 2015; Shankar et al., 2012). When this reaction occurs, the metal ions are converted to free water, which is washed away or evaporated. Consequently, the thickness of the water layer surrounding the particles is diminished. In other words, the particles lose their ability to expand, and the soil's mass solidifies, resulting in soil stabilization and preparation for building and road construction. Adsorbed water surrounding soil particles has been identified as a key issue when discussing soft soils. Bio-enzyme can diminish or even eliminate the soil's adsorbed water layer and enhance the soil's cohesiveness and compaction characteristics. Bioenzyme soil stabilization creates a high-density, hard, water-resistant layer that provides an ideal soil surface for paving roads and controlling dust or erosion compared to other stabilizers (Mekonnen et al., 2020; Renjith et al., 2020).

4.3 Biopolymer

Since more than half a century ago, the polymer industry has been supported by fossil fuels. Nevertheless, the future shortage of petroleum resources (Sorrell et al., 2012) is an undeniable reality. Due to the enormous depletion of fossil fuel resources, sustainable development is now of paramount importance. Therefore, prominent scientific and political leaders have urged the fundamental change to “bio-based material”. The history of admixtures began in the 1920s with the introduction of the lignosulfonate biopolymer for ordinary Portland cement concrete plasticization. This biopolymer was the first functional polymer employed on a large scale in the building industry (Plank, 2004). Despite their many potential advantages over traditional chemical stabilizers, how and under what prerequisites these substances operate is still unknown. The applicability of these substances' stabilizing processes is limited, and their specific chemical composition makes it challenging to anticipate their long-term efficacy. In recent years, research on using bio-based polymers has increased dramatically, although these materials still represent a small portion of the polymer industry (Cywar et al., 2022). Biopolymers are a class of polymeric materials that are made by living organisms. Recently, these materials have gained attention in research and engineering fields because of their abundance, biocompatibility, and distinctive features.

Biopolymers are chain-like molecules made up of repetitive chemical blocks that can be dissolved in the environment and are produced from renewable sources (Christian, 2020). These materials are substances derived from natural sources like polysaccharides (e.g., cellulose), proteins like gelatin, casein, silk, and marine prokaryotes. Biopolymers can also be produced by synthesizing bio-derived monomers (e.g., polylactic acid) or microbial activity (Chang et al., 2020). Biopolymers of microbial origin that function as water-insoluble gels (Fig. 6) can be used to improve soil properties, enclose bioremediation areas, and reduce soil liquefaction (Latifi et al., 2017). Biopolymers’ non-toxicity, relative affordability, and biocompatibility have increased their application in engineering, medical devices, energy, and food packaging (Edebali, 2021; Mohiuddin et al., 2017). Engineers have recently considered biopolymers in civil engineering, particularly geotechnical engineering, because of their biocompatibility and environmentally friendly behavior. Owing to different biochemical processes, the mechanism and process of clay soil stabilization with sandy soils differ when using biopolymers. When a biopolymer solution is introduced to sandy soils, the biopolymer solution's suspended particles enter the pores between the sand particles and coat their surfaces (Chang et al., 2020). The presence of silica and silicate, which increase the hydrophilicity of sand grains, accelerates the process of biopolymer interaction with sand particles. When the surface of the sand particle comes into contact with biopolymers, the biopolymers cover the soil particles and form a strong shell and bridge, thereby initiating the stabilization process (Fatehi et al., 2021; Jang, 2020). In contrast, with time and water evaporation, biopolymers increase soil bond strength and bring soil particles closer together, decreasing pore spaces. Therefore, the fewer voids between soil particles, the greater the interaction of the biopolymers with each other and the soil particles (shorter bond chains), and the greater the strength of the soil masses to applied stresses. The sand particles form stronger bonds with increasing the amount or concentration of biopolymers (up to their optimal content) (Chen et al., 2019; Fatehi et al., 2021; Refaei et al., 2020). On the other hand, clayey soils show a different mechanism by adding biopolymers. Here, chemical bonds are formed by different electrostatic forces, hydrogen bonds, ionic bonds, or van der Waals bonds, which can change over time due to their ionic structures. It is noteworthy that kaolinite clay soils have negative and positive ions on their surfaces and montmorillonite soils typically have negative ions. As a result, they also interact with biopolymers due to the electrical charges of biopolymers, natural cations within the clay, and the amount of charge on soil particles. In general, the biopolymer covers the soil particles in clay soils (bio-capsulation and bio-coating) due to the bond between the layer that absorbs water and ions.

5 Effect of microorganisms on soil stabilization

5.1 Sporosarcina pasteurii (S. pasteurii) microorganism

Examining the impact of adding 1 mol of S. pasteurii microorganisms on the permeability and shear strength of a 5-m sand column in the Netherlands revealed that the samples' strength did not improve significantly at low concentrations of calcium carbonate (under). However, higher amounts of calcium carbonate resulted in a significant increase in strength compared to virgin sand, which had a strength of 570 kPa due to the injection mode of calcium carbonate with the maximum amount and at a distance of approximately 1 m. In this study, the minimum amount of calcium carbonate required to initiate microbial activity was determined to be 60 M. Besides, the permeability study revealed that the maximum amount of calcium carbonate 105 M reduces permeability by 90% (Whiffin et al., 2007). Applying S. pasteurii for soil bio-grouting in a large-scale study (100 m3) revealed that the values of soil stiffness increase with increasing compressive strength and shear wave. In this study, the estimated calcium carbonate values ranged from 12.6 to 27.3% of soil weight, with a peak compressive strength of 12.4 MPa. Additionally, the maximum modulus of Young of 8.5 GPa was observed (Van Paassen et al., 2010). The results of a study for stabilizing and reducing the potential erosion of sandy soil with S. pasteurii and considering three parameters, namely concentration, heat and humidity, and sampling preparation (wash or unwashed), demonstrated that a concentration of 1 × 107 cells/mL in 3 mol has the best performance for reducing soil erosion potential up to 70%. It was also proved that at humidity levels under 20%, soil erosion potential decreases as temperature rises. In addition, it was observed that when water and microorganisms are added to unwashed soil, crust-like layers cover the soil particles, which has a significant impact on the interaction between most particles and reduces erosion (Meyer et al., 2011). It was also found that by injecting S. Pasteurii into a sand column with a 61 cm height and a 2.54 cm diameter, the hydraulic conductivity decreased by approximately 60% in 36 days (Cunningham et al., 2011). The effects of wave, erosion and compressive strength were considered on fine-grained coastal sandy soils of North Carolina in America using a laboratory model and S. Pasteurii microorganisms. It was estimated that the amount of erosion due to the wave entering the stabilized soil is significantly reduced due to the cementation of materials and increased soil cohesion (Shanahan & Montoya, 2014). According to Zhao et al. (2014), the compressive strength due to the addition of S. Pasteurii is highly dependent on parameters such as urea/bacterial concentration, curing time, and sand type. This study determined that the compressive strength of stabilized and unstabilized soils is in the range of 1.76–2.04 MPa and 0.33–0.43 MPa, respectively, indicating a 5 times increase in soil compressive strength. Furthermore, in terms of improving soil engineering properties, it was noticed that the MICP process catalyzed by bacteria is much more effective than the urease-catalyzed process (Zhao et al., 2014). The impact of Pasteurii bacteria on the consolidation and shear strength of organic soil was assessed in a comprehensive study. Soil stabilization resulted in pH changes in the range of (8.3–9.3), which was a key parameter in CaCO3 precipitation. By conducting three stages of consolidation experiments, it was determined that the changes in porosity ratios for stabilized soils were reduced. It was also revealed that coefficient of volume compressibility (Mv) and coefficient of compressibility (CC) are greater for the virgin samples than those for the stabilized samples. This result suggest that the compressibility of the stabilized samples is reduced by filling the pores of organic soil with solid particles of calcite, which causes cementation between organic soil particles. Moreover, bio-filling between soil particles decreased permeability by 8% and increased cohesion strength and friction angle to 2.4 kPa and 8°, respectively (Canakci et al., 2015). Shear strength and stiffness of stabilized sand of Ottawa province in Canada by MICP were evaluated using triaxial tests under undrained and drained shear. The stress–strain behavior revealed that with increasing activity of Pasteurii, the strain hardening behavior changes to the softening behavior, and the corresponding transition from global to local failure occurs in the soil mass. Besides, this process increased the dilation of loose sand. Furthermore, it was found that the shear strength of sandy soil, the rate of stiffness reduction due to cement degradation before failure, and the softening behavior of samples after failure depended on the effective stress path and drainage conditions. The peak stress ratio increased from 1.3 for unstabilized sand to 1.9 for cemented sand (with a shear wave velocity of 1400 m/s). Moreover, the peak shear strength (qu) increased with increasing the cementation level (Montoya & DeJong, 2015). A laboratory model was used to simulate tidal cycles, erosion, and failure mechanisms of stabilized sandy coastal slopes with MICP. Tidal wave cycles were simulated with a gentle flow and applied to sandy soil mass to evaluate shoreline stability, resulting in significant separation of soil particle volume from the slope surface by tidal waves. However, stabilization of sandy soil with S. Pasteurii showed that using 0.7 M of CaCl2 and urea solution could dramatically enhance slope stability up to a steep slope of 53° and a slope angle prone to erosion up to 35° and can minimize slope erosion (Salifu et al., 2016). For low and high concentrations (0.1 to 1 mol) of S. Pasteurii mixture, wind tunnel tests at a speed of 45 km/h were performed to evaluate the erosion and weight loss of stabilized soil samples, and the results were compared with the weight loss of control samples. The findings revealed that the weight loss of stabilized samples relative to the weight loss of the virgin samples was 1.29% for low bacterial mix concentrations and 0.16% for high concentrations, indicating a significant improvement in erosion control in stabilized specimens. In addition, the penetration resistance of stabilized samples with high concentrations of the bacterial solution reached 56 kPa. SEM and x-ray analysis of the morphology of sedimentary CaCO3 crystals revealed that CaCO3 is mostly precipitated as Vaterite crystals that form point-to-point contacts between sand particles (Maleki et al., 2016). Studying the dynamic response and hysteresis loops using triaxial shear tests on stabilized soil with Pasteurii revealed that sand stabilization with this microorganism can improve soil engineering parameters such as liquefaction and seismicity resistance. In this study, the use of bacterial solution and nutrient salt proved to be effective for reducing the curing and precipitation time to 1–2 days (Han et al., 2016). Response and monotonic mechanical behavior of Ottawa sand in Canada stabilized by MICP method were investigated using four stabilization levels (unstabilized, slightly stabilized, medium stabilized, and highly stabilized) and three levels of effective confining pressure (100, 200, and 400 kPa). The results showed that stiffness, peak shear strength, and dilation increase with increasing calcite content at the effective confining pressure. In addition, the results demonstrated that the improvement of peak and residual friction angles and the initial elastic modulus before rupture (Ei) depend on the amount of cementation and the effective confining pressure (Feng & Montoya, 2016). In an experimental study, a combination of undrained compaction tests, calcite mass measurements, and SEM tests demonstrated that the strength of bio-cement sand strongly depends on the cement surface (or calcite content). Also, it was found that the effective friction angle and effective cohesion of bio-cement sand change linearly and exponentially, respectively, with increasing calcite content. Furthermore, the obtained results proved that S. Pasteurii has a significant effect on the stress path and failure behavior of stabilized sand (Cui et al., 2017). Using cyclic triaxial and shear wave tests with the addition of S. Pasteurii to sandy soil indicated that the mechanical behavior of sandy soil samples with a higher shear wave velocity is more resistant to liquefaction. In other words, stabilized specimens with greater shear wave velocities before inducing significant strains and increased pore pressures indicate an increase in failure cycles. Moreover, it was demonstrated that the behavior of stabilized sands under identical cyclic stress ratios differs. This result suggests that the behavior of stabilized soils is influenced not only by precipitation mass but also by the pattern of calcite sediment distribution within the mass (Feng & Montoya, 2017). A case study was conducted to evaluate the influence of soil stabilization with S. Pasteurii and its ability to reduce the sensitivity of lateral soils on a Brazilian road to soil saturation due to rainfall. The average vertical permeability coefficient decreased from 1.15 × 10–7 m/s for unstabilized to 1.92 × 10–8 m/s for stabilized samples, indicating an 83% reduction (Smith et al., 2017). The use of microbial carbonate precipitation to control surface and subsurface erosion in the laboratory via mixtures of sand and kaolin was assessed through a series of internal erosion tests. To this end, a rigid-walled column erosion-testing device was used that allowed for independent control of MICP stabilization. The results showed that soil stabilization with MICP improves erosion and volumetric shrinkage of sand and clay mixtures because of carbonate precipitation by direct adsorption /coating of fine particles and cohesion on the contact surface of coarse particles. It was also stated that the performance of MICP is more effective at preventing internal erosion in a mixture of sand and clay with a higher pore ratio due to the increased porosity and, consequently, the increased precipitation of calcium carbonate. Another issue that was proven in this study was that the difficulty in moving bacteria and injecting chemicals into the sand and clay mixtures washes away the calcium carbonate produced, which reduces the overall carbonate content and stabilization efficiency (Jiang et al., 2017). In another attempt, the results of the erosion control experiments demonstrated that stabilization with MICP could reduce cumulative erosion weight, erosion rate, and axial strain compared to virgin soil (Jiang & Soga, 2017). As an alternative to CaCl2 in the MICP process, researchers sought to develop a method for producing soluble calcium ions from two waste sources. For instance, the proposed limestone powder was obtained from aggregate mines, and acetic acid was obtained from rapid pyrolysis of lignocellulosic biomass. Based on the obtained results, the engineering properties of bio-cemented sand with mentioned compounds (e.g., permeability, compressive and tensile strength) depend on the calcium carbonate content. In this study, bio-clogging permeability decreased from 1 × 104 to 8.17–1.52 × 106 m/s (Choi et al., 2017). The results of soil column tests on 14 different soil types showed that a wide range of soil engineering properties is improved by MICP stabilization. After stabilization, the soil column samples had compressive strength in the range of 0.22–5.34 MPa, shear wave velocities from 151 to 1469 m /s, and a 3.5 times reduction in hydraulic conductivity. In addition, the relationships between soil improvement after stabilization, soil properties and calcite content showed that D10 particle size and fine particles might significantly affect the compressive strength and hydraulic conductivity of the soil, while the shear wave velocity was less sensitive to these cases (Gomez & DeJong, 2017). Another research investigated the effects of the oxygenation process and oxygen on the stabilization of MICP catalyzed by S. Pasteurii under three aeration conditions: aeration box conditions, limited air conditions, and open-air conditions. The results showed that dissolved oxygen in the limited air reactor decreased over time and was depleted in about 7 days. In addition, dissolved oxygen in the open air decreased by 50% after 7 days of stabilization due to the presence of surface air. The results also showed that the unconfined compressive strength (UCS) values of sand from Xiamen, China, and CaCO3 could be 100 times different, depending on oxygen supply conditions (Li et al., 2018b). The strength parameters of lateritic soil belonging to Anambra State (Nigeria) stabilized with Pasteurii were evaluated at various concentrations of 1.5 × 108, 6 × 108, 1.2 × 109, 1.8 × 109, and 2.4 × 109 ml, with a curing time of 12 h. Based on the obtained results, a suspension concentration of 1.2 × 109 ml is optimal for lateritic soil, as it can increase compressive strength up to 3 times (Osinubi et al., 2018). In a laboratory study, Sporosarcina ureae, an aureolytic microorganism, was compared with other aureolytic and non-aureolytic organisms of the genera Bacillus and Sporosarcina in terms of their ability to produce carbonate by urolytic MICP to strengthen and stabilize the soil. The results showed that the optimal pH for the growth of S. ureae is 9. Also, according to Fig. 7, the majority of microbial activity takes place under normal water conditions, which can increase soil shear strength from 15.77 to 135.80 kPa (Whitaker et al., 2018).

An experimental study was conducted to investigate the stabilization of loose sandy soils with S. Pasteurii. The results showed that solutions should be added gradually to the soil matrix to prevent the accumulation and flocculation of calcite precipitation on the surface of the sand (Sharaky et al., 2018). Characterizing plasticity and shrinkage of lateritic soil with the addition of S. Pasteurii revealed a general decrease in the values of Atterberg limits with increasing concentrations of S. Pasteurii. In this research, 75% of S. Pasteurii and 25% of cementitious reagent in suspension density of 2.40 × 109 with maximum calcite content of 6% presented the greatest increase in soil plasticity index (Osinubi et al., 2019). The possibility of culturing urolytic bacteria with low-cost reagents and increasing soil stabilization was assessed. To this end, standard laboratory media were replaced with growth media made from deionized water and tap water for the culture of S. Pasteurii. Surface penetration was applied to perform a bio-cementation mechanism on sand columns using different concentrations (0.25–1 mol). The soil was exposed to room temperature (26 ± 2 °C) for 3 weeks after 92 h of stabilization. Eventually, the results showed that the surface strength of the combined samples was in the range of 4,826–11,448 kPa (Omoregie et al., 2019). The effect of bacterial culture medium and the effect of time (curing) on wind erosion control in sandy soil were investigated in laboratory work. Sugar cane molasses (10%), Tryptic Soy Broth (as a bacterial culture medium of S. Pasteurii), urea solution (2%), and calcium chloride were used as experimental samples. Evaluation results revealed that the erodibility of the stabilized samples in the wind tunnel below the average speed of 16 m/s decreased from 52 to 0% (Nikseresht et al., 2019). In a laboratory study, the UCS and hydraulic permeability of soil from India were considered to examine the formation of mineral sediments between soil particles caused by the metabolic process of S. Pasteurii. The results revealed that calcite minerals can reduce the volume and diameter of pores between soil particles and create a dense microstructure in the soil mass by reducing the distance between soil particles. Moreover, it was observed that uniformity in microbial injection decreases hydraulic conductivity and increases UCS and sample stiffness (Vempada et al., 2020). Furthermore, it was found that S. Pasteurii can significantly improve stabilized sand's penetration and abrasion resistance by considering the effects of cement solution concentration and the number of stabilization cycles. It is noteworthy that this bacterium is an aureolytic bacterium for microbial solution preparation. According to this study, the formation of microorganism surface crusts on sandy soil walls becomes more apparent with increasing the number of treatments and dosage (Fig. 8) (Katebi et al., 2021). In another study, the stabilization of siliceous, silty, and calcareous sandy soils by bio-cementation with S. Pasteurii bacterial solutions was investigated at various levels of addition. The results demonstrated that the curing time of the solution has a significant effect on the physical and mechanical properties of sandy soils and the formation of calcite precipitation by bacterial activity, which leads to the cohesion and bond of soil particles. Moreover, it was proved that a high content of precipitated calcium carbonate increases shear and compressive strength by 4 to 7 times while reducing soil permeability (Mohamed 2021). The impact of urease activity and different bacterial concentration densities on cementation uniformity in coarse sands was studied. The result showed that the larger the space between soil particles, the longer it takes bacterial activity to improve mechanical parameters. Moreover, SEM analysis showed that slower rates of MICP reactions result in more efficient and uniform cementation (Konstantinou et al., 2021). A novel and simple method was presented based on the flocculation of S. Pasteurii bacterium to maximize bacterial retention in porous silica sand. The experiments were conducted in two columns of 300 mm and 1000 mm sand that were uniformly distributed. In this research, 10 mM Ca2 + and 20 mM urea were determined to be the optimal conditions for maximizing the highest urease retention rate of up to 85%. These conditions lead to more than 80% of the total urea conversion rate and 8–9% more calcium carbonate production. In addition, the range of soil strength in all stabilized columns is observed to be 40–50 × 103 kN/m2 (Yang et al., 2022).

A novel and simple method was presented based on the flocculation of S. Pasteurii bacterium to maximize bacterial retention in porous silica sand. The experiments were conducted in two columns of 300 mm and 1000 mm sand that were uniformly distributed. In this research, 10 mM Ca2 + and 20 mM urea were determined to be the optimal conditions for maximizing the highest urease retention rate of up to 85%. These conditions lead to more than 80% of the total urea conversion rate and 8–9% more calcium carbonate production. In addition, the range of soil strength in all stabilized columns is observed to be 40–50 × 103 kN/m2 (Yang et al., 2022). Two bacteria, Halomonas sp. and S. pasteurii, were used for the bio-cementation of sands in the east of Isfahan in Iran for a period of 42 days. After bio-cementation, the speed of ultrasonic waves and P waves reached approximately 390 m/s, indicating an increase in the angle of internal friction in soil samples containing bacteria due to crystal formation (Bagi & Rahimi, 2022). Mechanical properties of stabilized soils (cohesion, friction, stiffness, and permeability) by S. Pasteurii were evaluated in the sand column modeling of Shazhengjie Province (China). The authors reported that cohesion and friction improved because of the bio-cementation of bacteria interlocking forces and bonding forces, and permeability declined due to the bio-clogging (Yang et al., 2022). Applying S. Pasteurii in the silty sandy soils of the Caspian sea in Mazandaran Province (Iran) and conducting triaxial tests showed that the optimum dosage of bacteria strength improved from 700 to 1600 kPa (Karami et al., 2022).

5.2 Bacillus sphaericus microorganisms

Cheng et al. (2013) conducted a series of laboratory tests, including permeability, compressive strength, triaxial unsaturated consolidation, and durability, to determine the influence of Bacillus sphaericus microorganisms on sandy soil. The results showed that shear strength (cohesion and friction angle), stiffness, and shear modulus increase up to 150% with increasing calcium carbonate content in different degrees of saturation (20–100%). Moreover, the failure mechanism showed that in stabilized soil, tensile cracks appear first at the specimen's top and bottom, and then failure occurs. In Fig. 9, SEM analysis indicates that in a state of complete saturation, rhombic calcium carbonate crystals are formed in this process. The accumulated crystals are not only in the pores between the particles but also on the surface of the particles or suspended in empty spaces, resulting in inadequate cohesion between the soil particles. However, due to the homogeneous adsorbed solution on the surface of the sand particles caused by the surface tensile force, the effect of bio-coating on soil particles is readily apparent for stabilized sands at 20% saturation (Cheng et al., 2013). Applying a compressive strength test, the results of a laboratory investigation determined that the UCS of sand stabilized with Bacillus sphaericus increases; however, the extent of this improvement depended on the concentrations of calcium chloride and urease (0.1, 0.25, and 0.5 mol). The permeability test results also revealed that using a solution with a high concentration of calcium urea chloride leads to a rapid decrease in permeability during the early stages of precipitation formation, whereas using a solution with a low concentration leads to a gradual and more uniform decrease in permeability (Qabany & Soga, 2014).

Adding Bacillus sp to sandy soils reduced soil permeability from 104 m/s to 10–7 m/s when adding calcium carbonate (average 2.1 kg/m2). Furthermore, bending and compressive strength tests revealed that the shear strength, cohesion, and tensile strength have an increasing trend in flexural strength values ranging from 90 to 256 kPa, which are approximately 90 to 250 times higher than virgin soil. Compressive strength also increased up to 932 kPa (Chu et al., 2014). A new method for cementing sandy soils in marine environments on the Australian coast was developed by modifying the calcium carbonate formation technique. The proposed method involves washing urease-activated bacteria with high salinity tolerance. Next, a mixture of urea and seawater through porous sandy soil is used to release bacterial carbonate from the urease reaction and precipitate insoluble and semi-soluble carbonate calcium salts. According to the compressive strength results in this study, this parameter increased to 300 kPa, which is nearly twice as much as the MICP stabilization in which calcium and urea are highly concentrated. It was also found that the permeability of all stabilized samples was approximately 30% lower than that of control samples, indicating a reduced drainage ability (Cheng et al., 2014). The combined effect of fibers in the proportions of 0.4 and 0.8% and microorganisms of Bacillus sphaericus showed that using fibers results in more interlocking forces in the process of calcium carbonate precipitation in the soil matrix (Fig. 10). Fibers can also bridge between sand particles, pores, and the cementation of calcium carbonate. According to the findings, the unconfined compressive and tensile strengths of fiber-reinforced sand increased by 138 and 186%, respectively. Moreover, compared to virgin sand, the permeability decreased by 126%, and the brittleness by approximately 50% (Choi et al., 2016).

The effect of fundamental parameters (i.e., urease concentration, temperature, rainwater leaching, oil pollution, and ice-freeze cycle) was investigated on the activity of Bacillus sphaericus in sandy soil by conducting a UCS test. The results indicated that the formation of crystalline masses, which fill the spaces between the sand particles, plays a substantial role in enhancing compressive strength. In this research, the optimal stabilization of bio-sediment was achieved at 25 °C. It was also found that rainwater was detrimental to the biosynthesis process and that bacterial cohesion could be reduced using the two-phase injection method by rinsing with low ionic strength water (i.e., tap water, rainwater). The results also demonstrated that the conventional stabilization of MICP by the two-phase injection method is ineffective for stabilizing oil-contaminated soils. However, the method of pre-mixing biological microbes with soil can significantly increase the UCS values and stiffness of oil-contaminated soils. Moreover, the durability test of MICP-stabilized samples proved that this method has high durability against freezing and thawing. This property was attributed to the points of contact between the particles and the connection to each other due to the formation of sedimentary crystals (Cheng et al., 2017). Bacillus sphaericus was used to improve the strength and erosion resistance of low-plasticity clay (CL) soil in Fars Province (Iran) based on the controlling variables (i.e., curing time, bacterial cell density, precipitation agent concentration, and temperature). In this investigation, pinhole experiments were considered to examine the level of dispersion and erosion of soil samples. Here, the decrease in pH during microbial activity and the resulting reduction in the thickness of the double water layer, and the stabilization of exchangeable sodium ions, were considered the primary mechanisms for reducing the erosion potential of soil samples (Moravej et al., 2018). Direct shear creep experiments were carried out to examine the mechanical creep properties of siliceous sand of China and calcareous sand of China in which microbial solution was injected three, six, or nine times to form the MICP process. Compared to virgin sand, it was observed that the creep deformation of silica sand with MICP has a decreasing trend. In these experiments, the creep deformation of stabilized sand reduced by up to 88% by 9 times injection. SEM also revealed that calcium carbonate produced by microorganisms in soil pores and greater physical contact between sand particles are significant factors influencing the creep behavior of stabilized silica sand (Yuan et al., 2022). According to the results of an experimental study, the optimum cementation solution (0.5 M) can increase soil stability and penetration rate and reduce erosion (Namdar-Khojasteh et al., 2022).

5.3 Pararhodobacter sp microorganism

In a laboratory study, Pararhodobacter sp bacteria were examined, and the impacts of different parameters such as heat, curing, solution injection distance, Ca2+ concentration, sodium concentration in solution, and test period were investigated on UCS. After 28 days of curing, the compressive strength of samples was found to increase up to 10 MPa. The test conditions were a curing temperature of 30°C, distance injection of 1 day, and Ca2+ concentrations in a cementation solution of 0.3 mol (Danjo & Kawasaki, 2016). In addition, multiple regression analysis conducted for the expressed variables led to the following experimental formula:

The impact of bioremediation in contaminated coarse and fine-grained sand was evaluated using Pararhodobacter sp. The obtained results proved that bio-microorganism could improve the compressive strength of soil from 1.38 to 2.88 Mpa. It was also observed that the optimum bacterial concentration (109 cfu/mL) could play a significant role in reducing the contamination rate due to the absorption and treatment properties (Mwandira et al., 2017). In a laboratory study, the effect of the addition of Pararhodobacter sp and various factors were investigated on the engineering properties of stabilized soil. These properties included temperature and curing temperature, solution injection distance, Ca2+ concentration, bacterial population, re-injection of bacteria, and sand particle size. The obtained results revealed that after 14 days with a curing temperature of 30 °C, an injection interval of 1 day, and Ca2+ concentrations in the cement solution of 0.5 M, the compressive strength of the samples reached 10 MPa (Ggnn & Kawasaki, 2017). Multiple regression analysis also revealed that the conditions for estimating the compressive strength formula as a test period, D (days), and concentration of Ca2+ (Eq. 2):

The results of an experimental study proved that the incorporation of Pararhodobacter sp. in contaminated kiln slag (KS) can reduce permeability and boost compressive strength due to the bio-cementation process (Mwandira et al., 2019). In a large-scale study in Japan, the rate of bio-cementation and soil erosion of slope were investigated. The results indicated that due to the bio-cementation, the hydraulic conductivity of the slope decreased from 1.9 × 10–2 cm/s to 1.85 × 10–3 cm/s (by 90%). It was also found that Pararhodobacter sp could inhibit the excess infiltration of rainwater and improve surface runoff (Gowthaman et al., 2019). Conducting compressive tests on clay sand gathered from an engineering project in Hong’an City, China, proved that the addition of Pararhodobacter sp can increase UCS up to 198%. In addition, SEM evaluation showed that crystallization and mineralization of MICP can form a 3D network of structure and bridge the gaps (Hu et al., 2022).

5.4 Bacillus megaterium microorganism

In an experimental study, the effects and changes in the properties and behavior of silty soil (ML) were investigated by adding B. megaterium at a concentration of 108 × 38 cfu/ml. The results demonstrated that the shear strength and hydraulic conductivity of soil increased by 60% and decreased by 90%, respectively. In addition, the minimum amount of calcium required for modification and improvement of mechanical and physical soil parameters was 1 or 15 kg/m3 (Soon et al., 2014). The efficacy of MICP in enhancing shear strength and decreasing soil hydraulic conductivity was also examined. The variables tested in this study included soil types (tropical residual soils and sand) and soil density (85%, 90%, and 95% of the corresponding maximum density). This study demonstrated that microorganisms could effectively increase shear strength and decrease hydraulic conductivity for both soil types. However, soil mechanical parameters improved differently depending on soil density, soil type, and stabilization conditions, and shear strength improvement ratios for residual soil samples were significantly higher than for sand samples. However, due to particle–particle contact within the pore spaces of the soil mass, sand samples exhibited a greater reduction in hydraulic conductivity than residual soil samples (Soon et al., 2014). Another study investigated the combined effect of bio-cementation (BC) as an additive with fly ash (FA) to improve the geotechnical properties of expansive soils obtained from a slope along the Wuhan-Xian expressway in Hubei Province (China). To this end, a fixed 5% amount of Bacillus megaterium was blended with four concentrations of fly ash, 10%, 25%, and 50%, respectively. The results of compressive strength tests conducted on soil samples containing 25% FABC revealed that the compressive strength of expansive soil increases to approximately 50%. In addition, the analysis of SEM and XRD microstructures of expansive soil indicated that MICP is effective at enhancing soil strength parameters due to the decrease in liquid limit (LL) and plastic limit (PL) (Li et al., 2018a). The soil permeability of landfill located in Anambra state in Nigeria stabilized with B. megaterium indicated that the cementation and bio-filling of pores can significantly reduce the hydraulic conductivity and leachate up to 70% (Etim et al., 2022).

5.5 Bacillus pasteurii microorganism

Bacillus pasteurii microorganisms with initial values of 106 × 2 cells/mL were used to stabilize sandy soil. DeJong (2006) et al. determined that adding these microorganisms can increase soil's monotonic undrained bearing capacity and shear stiffness. For this purpose, they performed a series of laboratory tests, including Bender elements and Isotropically consolidated undrained triaxial compression. In addition, the response of values revealed that by adding microorganisms and due to the cementation, the soil's behavior could transform into a non-collapsible condition. Moreover, variations in the shear wave velocity demonstrated that this parameter initially decreases and then gradually reaches its maximum value. Also, as bio-microorganisms' activity reduces, this parameter tends to approach zero (DeJong et al., 2006). The dispersion potential of clay obtained from a mine in the eastern north of Iran was investigated by adding sodium hex metaphosphate and conducting shear strength, dual hydrometer, pinhole, and chemical tests. Also, biological stabilization methods with Bacillus sphaericus and Bacillus pasteurii were investigated to determine the influence of bacterial activities on soil improvement parameters. According to the obtained results and chemical properties, the role of carbonate produced in enhancing mechanical properties and erosion, soil chemical (Na ion exchange), and mechanical (cohesion and friction angle) properties was greater in B. pasteurii than in B. sphaericus (Abbaslou et al., 2020).

Microorganisms, particularly Sporosarcina pasteurii and Bacillus sphaericus, by producing bio-cementation using microbial-induced calcite precipitation, can significantly improve the mechanical properties of soils, including compressive strength, bearing capacity, and soil shear strength, up to 250%. In arid environments, bio-cementation can reduce soil hydraulic conductivity, settlement, shrinkage, seepage, and rainfall penetration. Bio-clogging and bio-cementation are two of the most important applications of bio-microorganisms. Through the biological activity, the bio-clogging process in coarse grain soil leads to the clogging of voids between soil spaces, which influences the pore spaces and permeability of the soil. The bio-cementation process results in the particle connecting, bonding, and interlocking of soil particles, thereby enhancing the soil's resistance. Microaerophilic bacteria that can thrive in the absence of oxygen are the most suitable for the bio-stabilization of soil. However, the effectiveness of bio-cementation and microorganisms in improving soil strength greatly relies on physical and environmental factors. In addition, research has shown that bio-cement may be treated in a wide range of environmental conditions, including severe pH, high temperatures, and void size. According to the findings, the optimal concertation of microbes depends on soil texture and physical and chemical parameters, and the optimal pH ranges 7–9.5. In addition, temperature plays a key influence in numerous bacterial activities, with the highest levels of activity occurring between 30 and 60°C. Furthermore, the size of bacteria is an important component with a significant effect on soil stabilization. The optimal size ranges between 0.5 m and 3 m and corresponds to reduced movement of microorganisms in the soil matrix.

6 Effect of bio-enzyme on soil stabilization

6.1 TerraZyme bio-enzyme

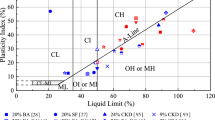

A comprehensive study was carried out on soil stabilization with TerraZyme and its effectiveness on base and subsoil soils. In this study, only short-term changes in soil properties were evaluated. The results showed no significant change in soil properties in the early days in cohesive soils, although the soil performance improved gradually (Lacuoture & Gonzalez, 1995). TerraZyme was used in a case study to improve a road in Malaysia that had severe problems during the monsoon season or after heavy rains. After two monsoon seasons of monitoring various parts of the road, it was noticed that the road was in excellent condition with no surface damage or erosion, despite being subjected to heavy rainfall. Hence, the road section did not need to be repaired, and it was suggested that this bio-stabilizer could improve road resistance parameters in various climates while causing minimal damage during hot and humid seasons (Zamri et al., 1999). Field studies and experiments in Brazil using TerraZyme as a biological enzyme stabilizer for road stabilization using Dynamic Cone Penetration test revealed that adding biological enzyme increased the strength of sandy soils, silty clay, sand silt, plastic and non-plastic clay, sandy loam, and clay mixed with clay of Brazilian roads (Brazetti & Murphy, 2000). A thorough investigation was conducted on TerraZyme's efficacy on lateritic and clay soils in the Kerala region (India). In this research, eight weeks were spent observing, recording, and comparing the reaction of enzyme-stabilized and control soil samples. The obtained results showed that the addition of TerraZyme increased the California Bearing Ratio (CBR) by 136 to 180 times compared to the initial value in all soil types studied (Isaac et al., 2003). In addition, stabilizing two types of high plasticity clay (CH) and CL soils with varying concentrations of TerraZyme (0.01–0.1%) demonstrated that using bio-enzymes can increase soil compressive strength due to bio-encapsulation of clay minerals. This improvement is attributed to the cation exchange of monovalent cations for covalent cations, the chemical decomposition of clay mineral structure, and reduction of double water thickness. Furthermore, the addition of bio-enzymes proved to decrease the interlayer adsorption of organic molecules, resulting in a decreased sensitivity to moisture (Tingle & Santoni, 2003). Shankar et al. (2012) investigated the effect of different doses of TerraZyme on the soil of Dacshina laterate (a region in India) with a liquid limit and plasticity index of 25 and 6%, respectively. Experiments on lateritic soils with varying amounts of sand revealed a modest improvement in the physical properties of lateritic soils. However, by increasing the bio-enzyme dose (200 ml/2m3 of soil), a 300% increase in CBR, 450% increase in compressive strength, and a 42% reduction in permeability were achieved after four weeks of curing. Additionally, it was noticed that bio-enzyme did not enhance soil cohesion (Ravi Shankar et al. 2009). The efficacy of bioenzyme in a case study of India's National Highway was investigated by conducting UCS and CBR experiments on three soils (sand, clay, and silt) at different enzyme doses, with liquid limit and soil plasticity index of 28 and 30, 46 and 6, and 5 and 6%, respectively. The results showed that after 4 weeks of curing, CBR increases by 157–673%, while UCS increases by 152–200% (Venkatasubramanian & Dhinakaran, 2011). According to a case study, using the TerraZyme bioenzyme as a stabilizer lowers the cost of road construction by 18 to 26% (Rajoria & Kaur, 2014). Changes in the compressive strength of expansive soils caused by the addition of Terrazyme (0.25 to 4 mol) were investigated. The results showed that the higher the amount of bioenzyme, the greater the increase in compressive strength, which increases to about 200% (Agarwal & Kaur, 2014). According to a laboratory study, the optimal dose of TerraZyme (2.5m3/200 ml) can increase soil-bearing capacity and decrease soil plasticity. According to this study, the bio-enzyme reacts with the adsorbed water layer of clay particles and reduces the water thickness of the double layer surrounding the soil particles. As a result, it lowers the voids between soil particles, thereby reducing soil permeability and soil swelling capacity (Saini & Vaishnava, 2015). Compaction parameters, Atterberg limits (liquid limit and plasticity limit), and soil strength of CL soil were investigated using 3 bio-enzymes, including DZ-1X, EarthZyme, and TerraZyme, in a laboratory comparison. Overall, it was found that the parameters did not change significantly due to a lack of changes, interaction, and chemical activity of bio-enzymes with soil (Khan & Taha, 2015). The addition of different doses of TerraZyme in combination with 500, 700, 900, and 1000 ml/m3 clay proved that increasing the bio-enzyme dose significantly increased the CBR value of soil samples. It was also mentioned that the curing time significantly impacts the bioenzymes' performance and efficiency (Panchal et al., 2017). Examining silty soil and silty sand with different bio-enzymes (e.g., TerraZyme, Road Ferment, and urease) at concentrations of 0.2–3 g/L and curing times of 7 and 21 days proved that all three bio-enzymes increased the erosion resistance of SC-SM soil up to 1,380%, whereas ML erosion resistance improved marginally (Shafii et al., 2019). The functional mechanism of TerraZyme in different doses on kaolinite soil was determined by measuring soil plasticity, enzyme-stabilized compressive strength, and curing age. The results revealed that by prolonging the curing time, the soil plasticity index decreases while the plastic and shrinkage limits increase. As a result, the plasticity and shrinkage indexes decrease, which means less propagation of cracks. In addition, evaluating the compressive strength properties revealed that the addition of bio-enzymes could increase soil strength by up to 30 times (Muguda & Nagaraj, 2019). Laboratory research revealed that the Terrazyme with the combination of 1% cement could have a significant effect on the strength parameters and soil plasticity characteristics. Table 3 reveals that the liquid limit of untreated soil is 91%, and it decreases to around 50.2 when 1% cement is added to clay soil. When a tiny percentage of 0.04 ml/kg of terrazyme was added to the soil–cement mixture, the liquid limit increased to 53%. Because of the hydrophilic properties of bioenzyme at low levels, there is a modest rise. After this phase, in the presence of 1% cement and 0.06 to 0.11 ml/kg of terrazyme, the liquid limit of the soil decreased to 48.7% compared to the liquid limit of the untreated soil. The same trend is observed for Plastic limit in 7 and 28 days. The plasticity index was 58% for clay soil, but after treatment, it decreased to 16.4%. The curing period has no noticeable impact on the consistency limits of soil–cement-terrazyme combinations. The decrease in plasticity index results in lower moisture absorption.

According to Table 4, increasing the TerraZyme dosage from 0.04 to 0.06 ml per kilogram (ml/kg) on the 1st day of curing improved the compressive strength of clay in the presence of 1% cement up to 233.9%. Then, by increasing the dosage of TerraZyme up to 0.11 ml/kg, the improvement percentage dropped to 192.15% on the 1st day. This is because the interaction between soil and bio-enzyme decreased, while the bio-bio-contact increased. The same trend was observed on different days of curing, from 7 to 28 days. Compressive strength improved after 28 days of curing for all dosages. An optimal dose of 0.06 ml/kg of TerraZyme reached 354.07% after 28 days of curing, which is approximately 354% greater than the strength of the untreated soil. Evidently, the highest level of biochemical reactions was attained with time (Thomas & Rangaswamy, 2021).

In another attempt, stabilizing residual soil of the north part of Sri Lanka with Terrazyme in various doses (0.5, 1, 2, and 3%) and compressive strength tests demonstrated that adding bioenzyme greatly improves the engineering properties of residual soil and adding 2% bioenzyme, compressive strength increased to 250% (Fazal et al., 2021). In a case study, various dosages of TerraZyme bio-enzyme (0.05 to 0.15 ml/kg) were employed to stabilize highway soil in Srinagar, India. After seven days of testing and soil sample collection, it was determined that adding 0.1 ml/kg to 1 m3 of soil increased its compressive strength and the California bearing ratio by 40% (Zargar et al., 2022). In another study, the integration of TerraZyme in clayey soil as a stabilizer showed that 0.08 ml/kg of the bio-enzyme could increase soil density and reduce settlement due to the bio-filling effect between soil particles (Kumar et al., 2022). The results of an experimental study demonstrated that the bio-enzyme-treated soil is stiffer than the untreated soil. Furthermore, 0.98 ml/kg of TerraZyme was the optimum treatment dosage, improved compressive strength up to 122.89%, and reduced the settlement of the stabilized soil (Kolhe & Dhatrak, 2022).

6.2 Renolith bio-enzyme