Abstract

Encapsulation of various materials on textiles is an interesting task because of the controlled release and higher stability. Here, a robust cotton fabric was prepared through novel simultaneous treatment and nano-encapsulation of Chamomile extract using Tragacanth gum (TG) as the wall material and an environmentally friendly binder with hydrogel properties. The nano-encapsulated and treated cotton (NE&TC) fabric was characterized by FESEM, FT-IR and UV-Vis spectrophotometry, which indicated the successful encapsulation of the plant extract within the TG and material and linkage on the cotton fabric. The peaks at 1736 and 1777 cm−1 related to the TG and Chamomile extract in the FT-IR spectrum and a strong peak around 270–400 nm in the UV-Vis spectrum of the NE&TC fabric confirmed the nano-encapsulation and treatment. The prepared NE&TC fabric indicated a relatively good washing and rubbing durability with reasonable release behavior. The DSC pattern of the NE&TC fabric showed a peak at 162 °C confirming the presence of Chamomile extract in the nanocapsules. This article proposes a novel method for the application of TG as a natural polymer on cotton fabric for obtaining multifunction purposes including in-situ synthesis of encapsulated Chamomile extract, stabilization of nanocapsules and introduction of hydrogel properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

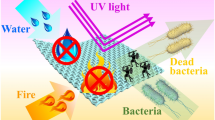

Various materials have been loaded on different textile substrates to achieve diverse properties such as aroma, flame retardant, antibacterial, insect proofing, ultraviolet protection, thermal storage and mosquito repellent (Chen et al. 2011a; El-Shishtawy et al. 2011; Ghayempour and Mortazavi 2015a; Kang et al. 2013; Kumar et al. 2014; Liu et al. 2014; Manna et al. 2015; Shen et al. 2014; Solomon et al. 2012). Encapsulation is a packaging method of materials to protect them from different environmental conditions such as evaporation, oxidation, heat, acid or alkali conditions, moisture and interaction with other compounds. In addition, the controlled release property is the most important advantage of the encapsulation technique (Ghayempour and Mortazavi 2014; Yu et al. 2010). Diverse chemical and physical methods have been reported for encapsulation of different materials based on the properties of the prepared capsules such as the type of core and wall materials, required size, permeability, release rate and economic issues. Electrospray, extrusion, emulsion, complex coacervation, interfacial polymerization, in-situ polymerization and microemulsion are the important encapsulation techniques (Dastjerdi and Montazer 2010; Ghayempour and Mortazavi 2013, 2015b; Ghosh 2006; Kristensen et al. 2010; Murillo-Cremaes et al. 2010; Zhang et al. 2011). Microemulsion is a method including of mixing the aqueous and oil materials in the presence of a selected surfactant. This leads to a lower surface tension creating a microemulsion with low energy consumption (Ghayempour et al. 2015).

An important factor in the finishing of textile substrates with the encapsulated products is the stabilizing method. Encapsulated materials have been applied on textile substrates by various techniques such as printing, padding, immersion, coating, UV and microwave irradiations. In some techniques, the capsules were stabilized on the fabric through thermal processing at high temperature, which led to breakage of the capsule wall and escape of the contents. In most cases, a binder is necessary for fixing the capsules on the textile substrates. Most of the binders are synthetic chemicals with side effects on the capsule stability, fabric structure and also human body. The type of binder and the application and stabilizing method can be influenced the various properties of the treated fabric, such as the handle, thickness, mass, stiffness and washing durability (Ghayempour and Mortazavi 2015a; Li et al. 2005; Mondal 2008; Rodrigues et al. 2009; Sánchez et al. 2010).

Application of the encapsulated materials on the textile substrates is usually carried out in several separate steps including encapsulation, centrifuging, drying and finally fixing with a binder, which is time-consuming and costly with unexpected side effects. The present work introduces a single-step process through simultaneous nano-encapsulation of plant extracts and stabilization on the cotton fabric. We have already introduced TG as a wall material for fragrant nanocapsules and stabilizing agent for nanoparticles (Ghayempour et al. 2015, 2016). TG also has excellent properties such as emulsification, viscosity, stability, biocompatibility and biodegradability. The hydrophilic structure of TG leads to hydrogel properties by holding large amounts of water in the three-dimensional network. Hydrogels have been utilized in various fields including hygienic products, agriculture, food additives, pharmaceuticals, drug delivery systems and many others (Ahmed 2015). According to these advantages, TG could be considered as a suitable natural polysaccharide for our purposes in this research. Therefore, encapsulation of Chamomile extract and treatment on the cotton fabric were simultaneously carried out through the combination of the microemulsion as the encapsulation method and immersion as the treatment method using an ultrasonic homogenizer. The prepared NE&TC fabric was characterized by field emission scanning electron microscopy (FESEM), Fourier transform infrared (FT-IR) spectroscopy, UV-Vis spectrophotometry and differential scanning calorimetry (DSC). Finally, the physical properties of the prepared NE&TC fabric were evaluated and thoroughly discussed.

Experimental

Materials

Chamomile flowers and TG were prepared from the Fars region, Iran. Ethanol as the solvent for extraction, Triton X-100 as the surfactant and aluminum chloride as the cross-linking agent were purchased from Merck Co., Germany. Deionized water was used to prepare the various solutions. A bleached 100 % cotton fabric with 140 g−2, 20 Nm yarn count, 22 yarn cm−1 warp and 25 yarn cm−1 weft was used as the textile material.

Extraction of Chamomile

Chamomile flower (0.25 g) was added to a mixture of 30 ml distilled water and 10 ml ethanol in a glass beaker and sonicated with a 400 W and 24 kHz Hielscher ultrasonic homogenizer (UP400S, Germany) equipped with a titanium sonotrode with diameter of 3 mm. The extraction was carried out in an amplitude of 50 % and cycle of 0.5 for 5 min. The sample was then filtered by a centrifuge device (RST 24&16, Iran) for 10 min, and the supernatant was used as the Chamomile extract.

Simultaneous nano-encapsulation and treatment

Triton X-100 (0.2 ml) was added to a 3 ml mixture of Chamomile extract and commercial almond oil with the ratio of 1:3 and sonicated for 5 min. The prepared microemulsion was transferred to 100 ml solution containing TG 1 % and Triton X-100 and then sonicated to obtain a steady white microemulsion. The cotton fabric was immersed into the prepared microemulsion for 5 min, and then nano-encapsulation was carried out by adding aluminum chloride 2 %. The prepared NE&TC fabric was finally washed with deionized water to remove the excess TG from the cotton fabric surface. Further, a cotton fabric sample was treated with a mixture of TG, Chamomile extract and almond oil without aluminum chloride through an immersion method named as a blank for comparison with the NE&TC fabric.

Characterization of NE&TC fabric

Morphology and elemental analysis of NE&TC fabric were investigated by an FESEM device coupled with EDX (VEGA2-TESCAN scanning electron microscopy, Czech Republic). FT-IR spectra of the samples were obtained using a FT-IR spectrophotometer (Thermo Nicolet, model: Nexus 670, USA). A DSC system (20/10 TA Instruments, USA) was used to investigate the thermal behavior of NE&TC fabric by heating to 250 °C with an increasing rate of 10°C min−1 under N2 steady flow. UV-Vis spectra of the samples were studied by a UV-Vis spectrophotometer (UV-Vis array spectrophotometer, Iran) to study the washing and rubbing stability and release behavior of the samples. The washing test was carried out for 45 min at 30 °C according to the ISO 105-C10 standard test method, and the rubbing test was carried out by a crockmeter/rubbing fastness tester (SDL Atlas, M238AA, USA) according to the ISO 105-X12 standard test method. To investigate the release behavior of chamomile extract from NE&TC fabric, the sample was cut into 5 × 5-cm pieces and stirred with 5 ml phosphate buffer for 2, 4, 8, 12, 18 and 24 h to remove the fabricated nanocapsules from the fabric surface and studied by a UV-Vis spectrophotometer. The antimicrobial activity of NE&TC fabric was measured using the colony counter method according to the AATCC Test 100 Standard Method. Escherchia coli (E. coli, ATCC 25923) as the gram-negative bacteria, Staphylococcus aureus (S. aureus, ATCC 25922) as the gram-positive bacteria and Candida albicans (C. albicans, ATCC 3153) as the fungus were the microbes used in this assay. A colony of microbes was inoculated on a nutrient agar plate and cultivated at 37 °C for 24 h. They were inoculated into 20 ml broth and cultivated at 37 °C for 24 h. The number of living microbes was calculated using the optical density at 580 nm. The microbe number was adjusted to 1–2 × 106 CFU ml−1 using nutrient broth; 1 ml broth was added to 20 ml nutrient culture medium and cultivated at 37 °C for 2 h with shaking. The number of living microbes was adjusted to 1 ± 0.3 × 105 CFU ml−1. Samples were cut into pieces with 48 ± 0.1 mm in diameter and sterilized in an autoclave at 121 °C for 15 min. 0.2 ml of the prepared inoculator was applied to the samples. They were cultivated at 37 °C for 18 h. The percentage of microbe reduction (R) was calculated using Eq. (1).

where A and B are the number of microbes on the raw cotton fabric (control) and NE&TC fabric, respectively.

The properties of NE&TC fabric including water retention and water absorbency were also evaluated by ASTM D2402-07 and AATCC 79-2014 standard test methods. Further, the mass, stiffness and thickness of the samples were measured according to the SIST EN 12127:1999, ASTM D-1388-64 and SIST EN ISO 5084:1999 standard methods, respectively.

Results and discussion

Simultaneous nano-encapsulation and fabrication were carried out to apply the plant extracts on the cotton fabric. This work is a novel approach in textile finishing because of performing one-single-step processing. Figure 1 indicates the suggested mechanism for simultaneous nano-encapsulation and treatment of Chamomile extract on the cotton fabric through the microemulsion method. This technique is based on mixing the aqueous and oil compounds in the presence of a selected surfactant (Dong et al. 2016; Gupta 2011). The nano-encapsulation of the aqueous Chamomile extract into a water-soluble polymer was proposed through trapping of the extract in an oil-based material using a surfactant, and then the prepared microemulsion was used as the core material. Therefore, Triton X-100 was added to an emulsion containing Chamomile extract and almond oil. Triton X-100 creates micelles with a hydrophilic center and hydrophobic external surface. The Chamomile extract traps in the center of the micelles, and almond oil surrounds the formed micelles. Introducing TG to the mixture leads to the formation of a new layer of micelles with a hydrophobic center and hydrophilic surface. Therefore, TG covers the Chamomile extract and almond oil as double-layer micelles. The prepared microemulsion was transferred on the cotton fabric, and both encapsulation and fabrication occurred in the presence of aluminum chloride. The encapsulation was carried out through cross-linking between the aluminum ions and carboxylic groups of TG. Further, cotton is a cellulosic-based polymer containing d-glucopyranose units linked with 1,4-glycosidic bonds cross-linked via intermolecular hydrogen bonds. The interactions between aluminum ions and hydroxyl groups of cellulose and also the intermolecular hydrogen bindings between TG and cellulose lead to stabilization of the nano-encapsulated Chamomile extract on the cotton fabric.

Characterization of NE&TC fabric

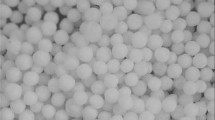

The FESEM images of NE&TC fabric are indicated in Fig. 2a, b, confirming the nanocapsules containing Chamomile extract were successfully formed and treated on the cotton fabric surface. This proves the prepared nanocapsules have a spherical shape with an average size of 55–70 nm. However, the blank fabric treated without aluminum chloride indicated the formation of a film layer of TG on the cotton fabric without nano-encapsulation (Fig. 2c, d). Also, the peak of the aluminum element was observed in the EDX pattern of the NE&TC fabric (Fig. 2e). This confirmed the encapsulation of Chamomile extract trapped in the double-layer micelles through aluminum ions.

The nano-encapsulation and fabrication were also confirmed by FT-IR spectra of the NE&TC fabric, TG, Chamomile extract, raw cotton fabric and blank sample (Fig. 3a). The peaks appearing at 3420, 1629 and 1743 cm−1 in TG related to the stretching vibrations of hydroxyl, carboxylate and carbonyl groups, respectively. The FT-IR spectrum of Chamomile extract originated from its components including terpenoids such as α-bisabolol, chamazulene and sesquiterpenes; coumarins such as umbelliferone; flavonoids such as luteolin, apigenin and quercetin; spiroethers; tannins; anthemic acid and polysaccharides (McKay and Blumberg 2006). A broad peak at 3390 cm−1 related to the hydroxyl groups, a peak at 2923 cm−1 corresponding to C–H, a peak at 1775 cm−1 attributed to cyclic ester carbonyl of umbelliferone and a peak at 1732 cm−1 related to the carbonyl groups of luteolin and quercetin appeared in the FT-IR spectrum of the chamomile extract. The most important peaks in the FT-IR spectrum of raw cotton fabric can be described as the stretching vibrations of –OH at 3347 cm−1, aliphatic C–H at 2900 cm−1 and C–O–C at 1058 cm−1 (Chen et al. 2011b). In the FT-IR spectrum of NE&TC fabric, a higher intensity of the hydroxyl peak at 3346 cm−1, bifurcation of the C-H peak at 2900 and 2920 cm−1, appearance of a peak related to cyclic ester carbonyl at 1777 cm−1 and a peak at 1736 cm−1 obtained from contraction of 1743 (TG) and 1732 cm−1 (Chamomile extract) confirmed the presence of TG and Chamomile extract on the prepared NE&TC fabric. Encapsulation of Chamomile extract into TG was confirmed with a peak at 1111 cm−1 related to the Al–O–C bond because of the cross-linking of aluminum ions with the oxygen atoms of carboxyl groups in the TG structure. The FT-IR spectrum of the blank sample is almost similar to that of NE&TC fabric without the peak related to the Al–O–C bond. The lower intensity of the peak corresponding to cyclic ester carbonyl at 1775 cm−1 in the FT-IR spectrum of the blank sample indicated the lower content of Chamomile extract on the blank sample compared with the NE&TC fabric. Figure 3b indicates the UV-Vis spectra of pure Chamomile extract and the remaining solutions of the NE&TC fabric and blank sample. The UV-Vis spectrum of Chamomile extract showed strong absorbance within 270 and 400 nm. The same absorbance also appeared in the UV-Vis spectrum of NE&TC fabric confirming the presence of Chamomile extract on the cotton fabric. Also, Chamomile extract was successfully loaded on the cotton fabric in the blank sample; however, its content was lower than on the NE&TC fabric.

Washing stability

One of the important properties of the finished fabrics is the washing stability. The washing stability of the NE&TC fabric was investigated by FESEM, FT-IR and UV-Vis analysis. FESEM images of the NE&TC fabric after washing are presented in Fig. 4a, indicating a relatively good washing stability as some nanocapsules still remained on the fabric surface after washing. The EDX pattern of the NE&TC fabric after the washing test is shown in Fig. 4b. As seen, the intensity of the signals related to oxygen, carbon and aluminum decreased in comparison with the unwashed NE&TC fabric (Fig. 2e). Figure 4c represents the FT-IR spectrum of the NE&TC fabric after washing and indicates the peaks related to the carbonyl and cyclic ester carbonyl groups of TG and Chamomile extract at 1736 and 1777 cm−1. Also, a peak related to the Al–O–C bond appeared at 1113 cm−1. This evidence confirmed the presence of nanocapsules containing Chamomile extract on the NE&TC fabric after washing. Figure 4d shows the UV-Vis spectra of the remaining solutions of NE&TC fabric before and after washing. The lower absorbance peak appearing within 270 and 400 nm in the spectrum of the washed NE&TC fabric compared with the unwashed one proved the Chamomile extract remained on the NE&TC fabric after washing.

Rubbing stability

FESEM, FT-IR and UV-Vis were used to investigate the rubbing stability of NE&TC fabric. Figure 5a shows the FESEM images of NE&TC fabric after the rubbing test, indicating a few nanocapsules still remaining on the NE&TC fabric after rubbing. Elemental analysis of the rubbed NE&TC fabric indicated a weak signal related to aluminum. This confirms plenty of nanocapsules remained on the NE&TC fabric after the rubbing test. The FT-IR spectra of the NE&TC fabric before and after rubbing (Fig. 5c) confirmed the same result as for FESEM images. The weakened peaks at 1738 and 1775 cm−1 related to the TG and Chamomile extract and the peak at 1112 cm−1 related to the Al–O–C bond in the spectrum of rubbed NE&TC fabric indicated nanocapsules containing Chamomile extract on the fabric. A lower absorbance in the UV-Vis spectrum of the rubbed NE&TC fabric compared with NE&TC fabric is in accord with the FESEM image observations and FT-IR spectrum (Fig. 5d). The Chamomile extract on the rubbed NE&TC fabric led to an absorbance peak with the value of 0.6 in the range of 270–400 nm.

Thermal analysis

The thermal behavior of TG, raw cotton and NE&TC fabrics are displayed in Fig. 6. The DSC plot of TG indicated a very broad exothermic peak at 89 °C with the onset temperature of 36 °C and the end temperature of 210 °C. Also, the raw cotton fabric indicated a broad exothermic peak at 79 °C with the onset temperature of 29 °C and end temperature of 175 °C. These peaks with latent heat of 301 J g−1 for TG and 114 J g−1 for the raw cotton fabric were related to the dehydration of TG and cotton fabric due to the hydrophilic nature of their functional groups. The DSC plot of NE&TC fabric indicated two peaks merged and formed one single peak at 78 °C with the onset of 36 °C and the end temperature of 128 °C with latent heat of 73 J g−1. The second peak at 162 °C could be attributed to the evaporation of Chamomile extract and almond oil from the nanocapsules. In this work, Chamomile extract was encapsulated in TG in the presence of almond oil. Chamomile extract was trapped in the inner microemulsion and encapsulated into TG with almond oil. The temperature at 143 °C possibly led to the breakage of the linkages between aluminum ions and TG and destroyed the nanocapsule wall; therefore, Chamomile extract and almond oil leaked out of the nanocapsules. The leakage and evaporation of Chamomile extract and almond oil from the nanocapsules occurred within 143–200 °C with latent heat of 15 J g−1.

Chamomile extract release from NE&TC fabric

The release of Chamomile extract from NE&TC and blank fabric samples was studied by UV-Vis spectra at different times along with stirring. Figure 7a shows a slow increase in the absorbance peak of NE&TC fabric along with prolonged stirring. TG was used as the wall material for nano-encapsulation and also as a binder to produce a stable nanocapsule containing Chamomile extract on the cotton fabric. Chamomile extract was gradually released from the nanocapsules from the cotton fabric; however, the absorbance at 310 nm increased from 0.35 to 1.29 after 24 h. This indicated a good stability and controlled release of the plant extracts from NE&TC fabric. However, the blank sample showed a very poor release behavior as the UV-Vis absorbance at 310 nm sharply increased to 0.69 after just 2 h and to 0.92 after 4 h. In addition, prolonged stirring had a very low impact on the absorbance intensity (Fig. 7b). Therefore, there was no control on the release behavior of the blank sample as nearly the entire Chamomile extracts were released from the fabric during the first hour of stirring.

Antimicrobial assay

Antimicrobial activity of NE&TC fabric was measured according to the AATCC Test 100 Standard Method. NE&TC fabric indicated relatively good antimicrobial activity with microbe reduction of 80 ± 0.1 % against E. coli, 90 ± 0.1 % against S. aureus and 92 ± 0.1 % against C. albicans. Antimicrobial activity of NE&TC fabric was related to Chamomile extract encapsulated and stabilized on the cotton fibers. Chamomile has been used in traditional medicine as an analgesic, antispasmodic and antiinflammatory and for the treatment of skin diseases such as eczema and acne. Also, it has good antimicrobial activity due to compounds such as α-bisabolol, chamazulen, umbelliferone, apigenin, quercetin, β-farensene, luteolin and matricin. For instance, interactions of α-bisabolol and apigenin existing in Chamomile extract lead to the antimicrobial activities (Roby et al. 2013).

Other fabric properties

Cotton fabric has a high water retention ability because of the cellulosic structure. Also, TG is a natural polysaccharide that can swell in water and forms a stiff gel because of having a water-swellable fraction called bassorin (Montazer and Kahali 2016). NE&TC fabric indicated 13.5 % more water retention than the raw cotton fabric, as expected. Also, the required time for water absorption into the raw cotton fabric was 8.22 s, which decreased to 0 s for NE&TC fabric because of the hydrogel properties of TG on the treated fabric. The weight of NE&TC fabric increased 3.6 % compared with the raw cotton fabric relating to TG on the fabric in the form of nanocapsules and a film layer. The thickness of the samples was not significantly changed, increasing from 0.45 mm for raw fabric to 0.46 mm for NE&TC fabric. The results indicated the stiffness of NE&TC fabric (187.66 N m−1) was similar to that of the raw fabric (182.97 N m−1). These results confirmed the low impacts of the treatment on various properties of the fabric.

Conclusions

Plant extracts and essential oils have usually been encapsulated into polymeric capsules and applied on textile substrates for various purposes such as antimicrobial, fragrant, and mosquito repellent properties. In this research, Chamomile extract was successfully nano-encapsulated and stabilized on cotton fabric through single-step processing. Natural and nontoxic TG was used as the wall material for nano-encapsulation, and the encapsulated Chamomile extract in TG was loaded on the cotton fabric through the interaction of aluminum ions with hydroxyl groups of cellulose and intermolecular hydrogen bonding between TG and cellulose. The FESEM images, FT-IR and UV-Vis spectra of the prepared NE&TC fabric indicated successful encapsulation and treatment of Chamomile extract on the cotton fabric. The prepared NE&TC fabric also showed good washing and rubbing stability. The thermal behavior of NE&TC fabric indicated a peak at 162 °C with latent heat of 15 J g−1 related to the evaporation of Chamomile extract and almond oil from nanocapsules. The lower trend of the absorbance intensity of UV-Vis spectra for 24 h indicated the good release behavior of the treated fabric. Further, high water retention and low water absorption times of NE&TC fabric confirmed the hydrogel properties of the fabric. Overall, the multifunctional properties includ controlled release behavior and hydrogel properties without significant changes in weight, stiffness and thickness obtained on the cotton fabric by using a natural, friendly polymer, namely TG, and encapsulating a plant extract through in-situ synthesis of nanocapsules and fixing on the fabric surface by the formation of a film layer. This was also stabilized by the formation of various linkages between aluminum chloride and cellulose and/or TG.

References

AATCC Test Method 79-2014, Absorbency of textiles. American Association of Textile Chemists and Colorists, Research Triangle Park, NC, USA

Ahmed EM (2015) Hydrogel: preparation, characterization, and applications: a review. J Adv Res 6:105–121. doi:10.1016/j.jare.2013.07.006

ASTM D-1388-64 (1975) Method A: standard test method for stiffness of fabrics. ASTM, New York

ASTM D2402–07 (2012) Standard test method for water retention of textile fibers (centrifuge procedure). ASTM International, West Conshohocken

Chen S, Chen S, Jiang S, Xiong M, Luo J, Tang J, Ge Z (2011a) Environmentally friendly antibacterial cotton textiles finished with siloxane sulfopropylbetaine. ACS Appl Mater Interfaces 3:1154–1162. doi:10.1021/am101275d

Chen X, Yu J, Zhang Z, Lu C (2011b) Study on structure and thermal stability properties of cellulose fibers from rice straw. Carbohydr Polym 85:245–250. doi:10.1016/j.carbpol.2011.02.022

Dastjerdi R, Montazer M (2010) A review on the application of inorganic nano-structured materials in the modification of textiles: focus on anti-microbial properties. Colloids Surf B 79:5–18. doi:10.1016/j.colsurfb.2010.03.029

Dong X, Zhu Q, Dai Y, He J, Pan H, Chen J, Zheng Z-P (2016) Encapsulation artocarpanone and ascorbic acid in O/W microemulsions: preparation, characterization, and antibrowning effects in apple juice. Food Chem 192:1033–1040

El-Shishtawy RM, Asiri AM, Abdelwahed NAM, Al-Otaibi MM (2011) In situ production of silver nanoparticle on cotton fabric and its antimicrobial evaluation. Cellulose 18:75–82

Ghayempour S, Mortazavi SM (2013) Fabrication of micro–nanocapsules by a new electrospraying method using coaxial jets and examination of effective parameters on their production. J Electrostat 71:717–727. doi:10.1016/j.elstat.2013.04.001

Ghayempour S, Mortazavi SM (2014) Antibacterial activity of peppermint fragrance micro–nanocapsules prepared with a new electrospraying method. J Essent Oil Res 26:492–498. doi:10.1080/10412905.2014.949882

Ghayempour S, Mortazavi SM (2015a) Microwave curing for applying polymeric nanocapsules containing essential oils on cotton fabric to produce antimicrobial and fragrant textiles. Cellulose 22:4065–4075. doi:10.1007/s10570-015-0765-1

Ghayempour S, Mortazavi SM (2015b) Preparation and investigation of sodium alginate nanocapsules by different microemulsification devices. J Appl Polym Sci. doi:10.1002/app.41904

Ghayempour S, Montazer M, Mahmoudi Rad M (2015) Tragacanth gum as a natural polymeric wall for producing antimicrobial nanocapsules loaded with plant extract. Int J Biol Macromol 81:514–520. doi:10.1016/j.ijbiomac.2015.08.041

Ghayempour S, Montazer M, Mahmoudi Rad M (2016) Tragacanth gum biopolymer as reducing and stabilizing agent in biosonosynthesis of urchin-like ZnO nanorod arrays: a low cytotoxic photocatalyst with antibacterial and antifungal properties. Carbohydr Polym 136:232–241. doi:10.1016/j.carbpol.2015.09.001

Ghosh SK (2006) Functional coatings and microencapsulation: a general perspective. In: Functional coatings. Wiley-VCH Verlag GmbH & Co. KGaA, pp 1–28. doi:10.1002/3527608478.ch1

Gupta S (2011) Biocompatible microemulsion systems for drug encapsulation and delivery. Curr Sci 101:174–188

International Standard, ISO 105-C10 (2006) Textiles-tests for colour fastness: colour fastness to washing with soap or soap and soda. International Organization for Standardization (ISO), Switzerland

International Standard, ISO 105-X12 (2001) Textiles-tests for colour fastness: colour fastness to rubbing. International Organization for Standardization (ISO), Switzerland

Kang Z-Z, Zhang B, Jiao Y-C, Xu Y-H, He Q-Z, Liang J (2013) High-efficacy antimicrobial cellulose grafted by a novel quaternarized N-halamine. Cellulose 20:885–893

Kristensen JB, Meyer RL, Poulsen CH, Kragh KM, Besenbacher F, Laursen BS (2010) Biomimetic silica encapsulation of enzymes for replacement of biocides in antifouling coatings. Green Chem 12:387–394. doi:10.1039/B913772F

Kumar A, Kulkarni P, Samui AB (2014) Polyethylene glycol grafted cotton as phase change polymer. Cellulose 21:685–696. doi:10.1007/s10570-013-0120-3

Li S, Boyter H, Qian L (2005) UV curing for encapsulated aroma finish on cotton. The Journal of The Textile Institute 96:407–411. doi:10.1533/joti.2005.0116

Li Z et al (2015) Sonochemical synthesis of hydrophilic drug loaded multifunctional bovine serum albumin nanocapsules. ACS Applied Materials & Interfaces 7:19390–19397. doi:10.1021/acsami.5b05558

Liu Y, Liu Y, Ren X, Huang TS (2014) Antimicrobial cotton containing N-halamine and quaternary ammonium groups by grafting copolymerization. Appl Surf Sci 296:231–236. doi:10.1016/j.apsusc.2014.01.106

Manna J, Goswami S, Shilpa N, Sahu N, Rana RK (2015) Biomimetic method to assemble nanostructured Ag@ZnO on cotton fabrics: application as self-cleaning flexible materials with visible-light photocatalysis and antibacterial activities. ACS Appl Mater Interfaces 7:8076–8082. doi:10.1021/acsami.5b00633

McKay DL, Blumberg JB (2006) A review of the bioactivity and potential health benefits of peppermint tea (Mentha piperita L.). Phytother Res 20:619–633. doi:10.1002/ptr.1936

Mondal S (2008) Phase change materials for smart textiles—an overview. Appl Therm Eng 28:1536–1550

Montazer M, Kahali P (2016) A novel polyvinyl alcohol–tragacanth/nano silver hydrogel on polyester fabric through in situ synthesis method. J Ind Text 45:1635–1651

Murillo-Cremaes N, Lopez-Periago AM, Saurina J, Roig A, Domingo C (2010) A clean and effective supercritical carbon dioxide method for the host-guest synthesis and encapsulation of photoactive molecules in nanoporous matrices. Green Chem 12:2196–2204. doi:10.1039/C004762G

Roby MHH, Sarhan MA, Selim KA-H, Khalel KI (2013) Antioxidant and antimicrobial activities of essential oil and extracts of fennel (Foeniculum vulgare L.) and chamomile (Matricaria chamomilla L.). Ind Crops Prod 44:437–445. doi:10.1016/j.indcrop.2012.10.012

Rodrigues SN, Martins IM, Fernandes IP, Gomes PB, Mata VG, Barreiro MF, Rodrigues AE (2009) Scentfashion®: microencapsulated perfumes for textile application. Chem Eng J 149:463–472

Sánchez P, Sánchez-Fernandez MV, Romero A, Rodríguez JF, Sánchez-Silva L (2010) Development of thermo-regulating textiles using paraffin wax microcapsules. Thermochim Acta 498:16–21

Shen Y, Zhen L, Huang D, Xue J (2014) Improving anti-UV performances of cotton fabrics via graft modification using a reactive UV-absorber. Cellulose 21:3745–3754. doi:10.1007/s10570-014-0367-3

SIST-EN 12127 (1999) Determination of mass per unit area using small samples. CEN, Brussels

SIST-EN ISO 5084:1999 (1996) Determination of thickness of textiles and textile products. CEN, Brussels

Solomon B, Sahle FF, Gebre-Mariam T, Asres K, Neubert RHH (2012) Microencapsulation of citronella oil for mosquito-repellent application: formulation and in vitro permeation studies. Eur J Pharm Biopharm 80:61–66

Yu W, Lin J, Liu X, Xie H, Zhao W, Ma X (2010) Quantitative characterization of membrane formation process of alginate–chitosan microcapsules by GPC. J Membr Sci 346:296–301

Zhang L et al (2011) Bioinspired preparation of polydopamine microcapsule for multienzyme system construction. Green Chem 13:300–306. doi:10.1039/C0GC00432D

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghayempour, S., Montazer, M. A robust friendly nano-encapsulated plant extract in hydrogel Tragacanth gum on cotton fabric through one single step in-situ synthesis and fabrication. Cellulose 23, 2561–2572 (2016). https://doi.org/10.1007/s10570-016-0958-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0958-2