Abstract

The transient entanglement networks of cellulosic polysaccharides in concentrated solutions were characterized by the molecular weight between entanglements (M e) using dynamic viscoelasticity measurements. From the concentration dependence of M e, M e for the cellulosic polysaccharides in the molten state (M e,melt) was estimated as the material constant reflecting the chain characteristics. The values of M e,melt were compared among three cellulosic polysaccharides: cellulose, methylcellulose, and hydroxypropyl cellulose. Methylcellulose and hydroxypropyl cellulose were employed as cellulose derivatives having small and large side groups, respectively. It appeared that hydroxypropyl cellulose had significantly larger M e,melt compared with cellulose and methyl cellulose. However, the numbers of repeating glucose-ring units between entanglements were very close to each other among the three polysaccharides.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose is the most familiar polysaccharide as the result of long years of use in human history. In addition to cellulose in the natural form, many derivatives are known to be synthesized from cellulose by modifying the hydroxyl groups. The main aim of introducing the substituents is to change the physical properties of cellulose; for example, methylcellulose is water soluble in contrast to natural cellulose, because the methyl groups reduce the strength of hydrogen bonding between cellulose chains. Currently, cellulosic polysaccharides, meaning cellulose as well as its derivatives, are vital materials in several industries because of the various properties.

Cellulosic polysaccharides are also of interest in the field of chain characterization of polymers. The chain dimensions of cellulosic polysaccharides in various dilute solutions have been examined previously, and the effects of side groups (substituents) on the unperturbed chain parameters as well as on the hydrodynamic properties have been discussed based on the accumulated data (Brown et al. 1963; Brown and Henry 1964; Flory 1966; Kamide and Miyazaki 1978; Kamide and Saito 1987). Thus, chain characterization of cellulosic polysaccharides using dilute solutions has been successfully carried out. Studies on concentrated systems of cellulosic polysaccharides are also making good progress (Chen et al. 2009; Gericke et al. 2009; Haward et al. 2012; Kosan et al. 2008; Syang-Peng et al. 2009). A specific matter in concentrated polymer systems such as polymer melts and concentrated solutions is the entanglement coupling between polymer chains emerging from topological constraints of the interpenetrating polymer chains. It is recognized that entanglement coupling dominates the rheological behavior of concentrated polymer systems for long times (Doi and Edwards 1986; Ferry 1980). The entanglement coupling can be characterized by the molecular weight between entanglements (M e), which corresponds to an average mesh size of the transient entanglement network. The value of M e for a polymer melt (M e,melt) especially is a material constant; namely, M e,melt is a type of chain characteristics obtained only by examining the rheological behavior of concentrated polymer systems. Until now, however, M e,melt for the better part of cellulosic polysaccharides has been unknown, and effects of side groups on entanglement coupling for cellulosic polysaccharides have not even been considered.

In this article, M e,melt for three cellulosic polysaccharides, cellulose (C), methylcellulose (MC), and hydroxypropyl cellulose (HPC), has been estimated from the rheological data for their concentrated solutions. It should be noted that MC has small substituents of methyl groups, while HPC has larger ones of hydroxypropyl groups, characterized by the molecular weight of a repeating unit (M unit) below. Use of an ionic liquid as a solvent has made it possible to prepare solutions of these cellulosic polysaccharides at high concentrations where there is entanglement coupling. The values of M e,melt as well as the number of repeating glucose-ring units between entanglements (N unit) have been compared among the three polysaccharides.

Experimental

Materials

The cellulosic polysaccharides, C (Aldrich, USA), MC (Aldrich, USA), and HPC (Wako, Japan), were used without further purification. According to the manufacturers, the degrees of substitution per repeating unit were 1.7 and 3.8 for MC and HPC, respectively; therefore, the M unit for C, MC, and HPC was estimated to be 162, 186, and 383, respectively. The viscosities for 2 % aqueous solutions of MC and HPC at 20 °C were reported by the manufacturers to be 4000 cP and 1000–4000 cP, respectively, whereas that for C was unavailable. An ionic liquid, 1-butyl-3-methylimidazolium acetate (BmimAc; BASF, Germany), was used as received. As far as we tested, BmimAc was the only common solvent to prepare concentrated solutions of the three polysaccharides. Each polysaccharide sample was added to liquid BmimAc in a dry glass vessel, and then the mixture was stirred on a hot plate at about 80 °C for more than 6 h until complete dissolution. The concentration of the polysaccharides (c) ranged from 1.1 × 102 to 2.1 × 102 kg m−3 (ca. 10–20 wt%) for C, from 4.2 × 101 to 7.5 × 101 kg m−3 (ca. 4–7 wt%) for MC, from 5.2 × 101 to 2.6 × 102 kg m−3 (ca. 5–25 wt%) for HPC; the lowest c was slightly above the critical concentration for entanglement coupling, while the highest c was determined by the solubility. In the calculation of c, the densities of melts of the polysaccharides were commonly assumed to be 1.0 × 103 kg m−3 and that of BmimAc was quoted to be 1.055 × 103 kg m−3 (Horinaka et al. 2013).

Rheological measurements

The angular frequency (ω) dependence of the storage modulus (G′) and the loss modulus (G″) for the polysaccharide solutions was measured with an ARES rheometer (now TA Instruments, USA) under a nitrogen atmosphere. The geometry for the measured sample was a cone plate with a diameter of 25 mm and a cone angle of 0.1 rad. The value of ω ranged from 0.1 to 100 s−1, and the amplitude of the oscillatory strain (γ) was fixed at 0.1 so that the measurement could be performed in the linear viscoelasticity region. The above measurement was carried out at several temperatures (T) from 0 to 80 °C.

Results and discussion

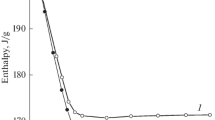

Figure 1 shows the ω dependence of G′ and G″ for the C solutions; the curves are shifted upwards by A to avoid overlapping for different cs. Each of the curves is the so-called master curve at the reference temperature (T r) of 80 °C obtained by means of a horizontal shift by a factor of a T for each T according to the frequency-temperature superposition principle. It appears that the time-temperature superposition principle holds well for the C solutions. At low ωa T , flow of the system can be seen for each c, although the terminal relation of G″ ∝ ω is observed only for the solution of c = 1.1 × 102 kg m−3. In the middle ωa T region, there is a plateau region in each G′ curve where G′ > G″, which becomes wider as c increases; this is the so-called rubbery plateau, indicating the existence of entanglements coupling in the C solutions. The reason that the plateau of G′ is slightly tilted is probably the polydispersity of the sample employed, although actual data on the polydispersity are not available. In Fig. 2, log a T is plotted against 1/T. All data points can be fitted by a single line regardless of c, as drawn in the figure, indicating that the T-dependence curve of a T can be represented by an Arrhenius-type equation. This trend implies that the solutions are homogeneous.

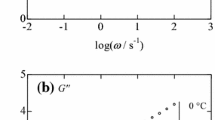

Figure 3 shows the master curves of the ω dependence of G′ and G″ at T r = 80 °C for the MC solutions obtained in the similar way to Fig. 1. Although the rubbery plateau region in each G′ curve is not obvious compared with that in Fig. 1, partly because of the low c, the rubbery plateau as well as the flow region is seen for each c in the G′ and G″ curves, which is typical of polymer solutions with entanglement coupling. The T-dependence curve of a T for the MC solutions is shown in Fig. 4. The values of a T at a given T are almost identical regardless of c, and all data points in the figure appear to fall on a single line.

The master curves of the ω dependence of G′ and G″ at T r = 80 °C for the HPC solutions are given in Fig. 5. The rubbery plateau region becomes wider as c increases, so that the flow region goes out of sight for the solution of c = 2.1 × 102 kg m−3. The Arrhenius-type plot of a T for the HPC solutions is shown in Fig. 6. As is the case of C and MC, the data points fall on a single line, namely, a T for these solutions shows almost the same T-dependence being independent of c. This result supports that the HPC solutions are homogeneous within the c range examined.

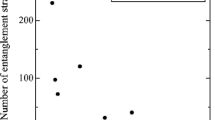

As demonstrated above, the rubbery plateau appears for all the solutions examined. From the analogy with the rubber elasticity, M e (in g mol−1) for a polymer in solution at the concentration of c can be given by

Here, \( G_{N}^{0} \) is the plateau modulus, which corresponds to the height of the plateau, and R is the gas constant (Doi and Edwards 1986; Ferry 1980). It should be noted that \( G_{N}^{0} \) is independent of the molecular weight of the polymer itself as long as the molecular weight is sufficiently greater than 2M e and the plateau appears (Ferry 1980; Onogi et al. 1970). As seen in the above figures, the actual plateaus obtained in this study were tilted to some extent, and therefore we defined \( G_{N}^{0} \) as the G′ value at ωa T where the loss tangent (tanδ = G″/G′) attained the minimum in the rubbery plateau region (Horinaka et al. 2011, 2013). For example, \( G_{N}^{0} \) for the HPC solution at c = 2.1 × 102 kg m−3 is determined to be 1.9 × 104 Pa in Fig. 5, which gives M e of 3.2 × 104 from Eq. 1 with T = T r. The values of M e for the C, MC, and HPC solutions obtained in this manner are double-logarithmically plotted against c in Fig. 7. For each polysaccharide, a straight line with a slope of −1 is drawn with the best fit method, because it has been reported that a relation of M e ∝ c −1 holds for many concentrated solutions of polymers (Doi and Edwards 1986; Masuda et al. 1972). It is seen that data points in the figure are fitted well by the line, indicating that the M e ∝ c −1 relation also holds for the C, MC, and HPC solutions examined in this study. Hence, M e,melt for the cellulosic polysaccharides can be estimated to be M e at c = 1.0 × 103 kg m−3 of the fitted line in Fig. 7 as we assume the density of the polysaccharides to be 1.0 × 103 kg m−3. The obtained values of M e,melt are 2.9 × 103, 2.5 × 103, and 6.2 × 103 for C, MC, and HPC, respectively. Here, it is noted that M e,melt for C estimated in the current study is consistent within the experimental error with that for C obtained in our previous study where another ionic liquid, 1-butyl-3-methylimidazolium chloride, was used as the solvent (Horinaka et al. 2011, 2012). The value of M e,melt for MC obtained in this study is slightly smaller than that for C. Considering the experimental error, this difference might be negligible. On the other hand, M e,melt for HPC is significantly larger. These results suggest that the effects of side groups on M e,melt are apparent but not monotonous against M unit. It was previously reported that there is an irregular tendency for the effect of the M unit on a chain stiffness parameter of cellulosic polysaccharides in dilute solutions, although direct comparison with our result is impossible (Brown and Henry 1964). It should be noted that aggregation behavior of the cellulosic polysaccharides does not account for the difference in M e,melt. It has been reported that side groups of cellulosic polysaccharides affect the solubility in conventional solvents, and extremely high substitution is necessary to obtain the molecularly dissolved solutions (Burchard 2003). For the ionic liquid solutions of cellulosic polysaccharides, it is recognized that dissolution on the molecular level is achieved by forming hydrogen bonds between the anions of the solvent and the hydroxyl protons of the solute, and therefore even cellulose can be molecularly dissolved in ionic liquids, as demonstrated by a light-scattering study (Chen et al. 2011; Swatloski et al. 2002). Our results in Figs. 1, 3, and 5 also indicate that there are no aggregates of the polysaccharides in all the solutions examined in this study; if the aggregates exist in the solution, another plateau (or at least shoulder), the so-called second plateau, should appear in the flow region before reaching the terminal behavior. Maeda et al. have explained the dynamic viscoelasticity data for an ionic liquid solution of cellulose over a wide range of frequency from the flow to the glassy zone successfully without taking the aggregated state of cellulose into consideration (Meda et al. 2013). Now, we consider N unit instead of M e,melt. Since cellulosic polysaccharides have a common backbone structure of repeating glucose-ring units, the contour length between entanglement coupling points can be compared using N unit. In other words, N unit represents the mesh size of the entanglement network in terms of length. The values of N unit calculated from M e,melt and M unit are 18, 13, and 16 for C, MC, and HPC, respectively. The values of N unit come closer to each other compared with M e,melt.

Conclusions

The effects of side groups on the entanglement network of cellulosic polysaccharide were examined in terms of the rheological properties M e,melt and N unit. Dynamic viscoelasticity measurements for the concentrated solutions of C, MC, and HPC in BmimAc provided M e,melt of 2.9 × 103, 2.5 × 103, and 6.2 × 103, respectively, indicating that there was a dependence of M e,melt on M unit, although the dependence appeared rather complicated. On the other hand, the effects of side groups were very small regarding N unit.

References

Brown W, Henry D (1964) Studies on cellulose derivatives part III. Unperturbed dimensions of hydroxyethyl cellulose and other derivatives in aqueous solvents. Makromol Chem 75:179–188

Brown W, Henry D, Ohman J (1963) Studies on cellulose derivatives part II. The influence of solvent and temperature on the configuration and hydrodynamic behavior of hydroxyethyl cellulose in dilute solution. Makromol Chem 64:49–67

Burchard W (2003) Solubility and solution structure of cellulose derivatives. Cellulose 10:213–225

Chen X, Zhang Y, Cheng L, Wang H (2009) Rheology of concentrated cellulose solutions in 1-butyl-3-methylimidazolium chloride. J Polym Environ 17:273–279

Chen X, Zhang Y, Ke F, Zhou J, Wang H, Liang D (2011) Solubility of neutral and charged polymers in ionic liquids studies by laser light scattering. Polymer 52:481–488

Doi M, Edwards SF (1986) The theory of polymer dynamics. Clarendon, Oxford

Ferry JD (1980) Viscoelastic properties of polymers. Wiley, New York

Flory PJ (1966) Treatment of the effect of excluded volume and deduction of unperturbed dimensions of polymer chains. Configurational parameters for cellulose derivatives. Makromol Chem 98:128–135

Gericke M et al (2009) Rheological properties of cellulose/ionic liquid solutions: from dilute to concentrated states. Biomacromolecules 10:1188–1194

Haward SJ et al (2012) Shear and extensional rheology of cellulose/ionic liquid solutions. Biomacromolecules 13:1688–1699

Horinaka J, Yasuda R, Takigawa T (2011) Entanglement properties of cellulose and amylose in an ionic liquid. J Polym Sci B Polym Phys 49:961–965

Horinaka J, Okuda A, Yasuda R, Takigawa T (2012) Molecular weight between entanglements for linear D-glucans. Colloid Polym Sci 290:1793–1797

Horinaka J, Urabayashi Y, Takigawa T, Ohmae M (2013) Entanglement network of chitin and chitosan in ionic liquid solutions. J Appl Polym Sci 130:2439–2443

Kamide K, Miyazaki Y (1978) The partially free draining effect and unperturbed chain dimensions of cellulose, amylose, and their derivatives. Polym J 10:409–431

Kamide K, Saito M (1987) Cellulose and cellulose derivatives: recent advances in physical chemistry. Adv Polym Sci 83:1–56

Kosan B, Michels C, Meister F (2008) Dissolution and forming of cellulose with ionic liquids. Cellulose 15:59–66

Masuda T, Toda N, Aoto Y, Onogi S (1972) Viscoelastic properties of concentrated solutions of poly(methyl methacrylate) in diethyl phthalate. Polym J 3:315–321

Meda A, Inoue T, Sato T (2013) Dynamic segment size of the cellulose chain in an ionic liquid. Macromolecules 46:7118–7124

Onogi S, Masuda T, Kitagawa K (1970) Rheological properties of anionic polystyrenes. I. Dynamic viscoelasticity of narrow-distribution polystyrenes. Macromolecules 3:109–116

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellose with ionic liquids. J Am Chem Soc 124:4974–4975

Syang-Peng R et al (2009) Sol/gel transition and liquid crystal transition of HPC in ionic liquid. Cellulose 16:9–17

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Horinaka, Ji., Urabayashi, Y. & Takigawa, T. Effects of side groups on the entanglement network of cellulosic polysaccharides. Cellulose 22, 2305–2310 (2015). https://doi.org/10.1007/s10570-015-0670-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0670-7