Abstract

In this study, Rhodococcus pyridinivorans cells containing hyperactive acyltransferase was immobilized on various macromolecules based-polymeric matrices and used to improve acetohydroxamic acid production. The calcium-alginate-based matrix retained the maximum residual activity up to 97.8% as compared to free cells (576 U/mg of dry cell weight). After immobilization, cells exhibited a significant improvement in their tolerance towards pH, temperature, and metal ions as potent enzyme inhibitors. Immobilized cells showed 25.5-fold higher thermal stability at 60 °C to control (free cells). Compared to free cells, immobilized cells exhibited a high bioconversion of acetamide and hydroxylamine-HCl to acetohydroxamic acid up to 96% molar conversion. Repeated bench-scale production at 3-L culture, immobilized cells showed 9.5-fold higher residual conversion as compared to control (100%), after five cycles of reuses. The product characterization achieved high purity (97%) of acetohydroxamic acid. This finding showed high feasibility to achieve efficient conversion that can be scaled up to the industrial level for biotechnological application.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Amidases (amidohydrolases) are amide bond-cleaving enzymes that exist both in the prokaryotic and eukaryotic systems. These are widely used as a potential biocatalyst in the catalysis of amides to ammonia and acids [1]. These enzymes are classified as aliphatic and signature amidases and shared evolutionary relationship with the nitrilase superfamily due presence of cysteine residue and highly conserved motif (GGSSGG) in their catalytic site [2, 3]. Signature amidases exhibit diverse substrate specificity for aliphatic, aromatic, α-substituted amides and have inherent regio-, stereo-, and enantio-selectivity. Besides the amide hydrolysis reaction, the acyl transfer activity of the amidases has been extensively investigated for both the aliphatic and signature amidases via the Ping-Pong Bi-Bi mechanism [4, 5]. In this mechanism, amides transfer acyl groups to hydroxylamine in presence of enzymes to form an acyl-enzyme complex and consequently, resulting in the formation of the corresponding hydroxamic acid and ammonia [6]. The synthesis of hydroxamic acids using acyltransferase from amidases has been demonstrated by Alcaligenes [7], Bacillus [8], Escherichia [9], and Rhodococcus [10]. Hydroxamic acids are synthesized via acyltransferase primarily includes aceto-, butyro-, and benzo-hydroxamic acids, and nicotinic acid, butrylhydroxamic acid using corresponding amides [3, 7, 11]. These compounds are widely used for potential applications as anti-microbial agents, tumors-inhibitor, and inhibitors to metalloproteases, cyclooxygenase, and 5-lipooxygenase [12, 13]. Acetohydroxamic acid and α-amino hydroxamate are used as anti-human immunodeficiency virus agents, in the treatment of anemia, and plasma infection along with urease inhibitors in animals and plants [4]. Due to the high chelating potential of hydroxamic acids, these are potentially used in wastewater treatments and nuclear technology [12]. Hydroxamic acids are synthesized through both chemical and biological methods. Biotransformation is mostly preferred over the standard chemical conversion process as they include mild reaction conditions, substrate, and product specificity, the formation of a product with high purity, potential for conducting stereo- and regio-selective transformations that are troublesome to attain through typical chemical strategies [14,15,16]. In the previous studies, free cells are widely employed in the acyltransferase-mediated conversion of amides to hydroxamic acids that can be limited by the instability of free cells [17]. Immobilization is a useful approach to overcome such limitations, including stability, and reusability. The immobilization methods such as adsorption, covalent binding, cross-linking, and entrapment have been widely reported to improve biotransformation [18, 19]. Among these methods, the cells immobilization through entrapment within polymeric matrices such as agar, alginate, and polyvinyl alcohol can be easily prepared and used over covalent or cross-linking methods that require additional chemical modifications of support before their use [17, 20, 21]. Alginate is a well-demonstrated low-cost matrix with high biocompatibility, and the structure involves a glycosidic bond between β-d-mannuronic acid and α-l-guluronic acid that is easily complexed with calcium to achieve desired strength and flexibility [22,23,24]. Previously, various materials were reported for whole-cell immobilization and hydroxamic acids production, includes alginate [17, 25, 26], agar [25, 26], reverse micelles [27], polyacrylamide [25, 26], hydrogel [26], carrageenan [26], and polyvinyl alcohol-alginate [25].

In the present study, efforts have been made to immobilize the whole cells of Rhodococcus pyridinivorans on different matrices. The biomacromolecules-based matrix, which showed high catalytic efficiency was selected for further optimization. The immobilized cells revealed better properties than free cells and previously reported data. The results highlighted that an efficient process was established for biotransformation of acetamide and hydroxylamine HCl to acetohydroxamic acid in a high-volume capacity of 3-L. A higher molar conversion rate was achieved with improved acyltransferase activity by using free cells and immobilized cells, providing an approach for the industrial production of acetohydroxamic acid on a commercial scale.

2 Materials and Methods

2.1 Chemicals

Acetohydroxamate 98%, amides, and nitriles were purchased from Thermo Fisher Scientific (Mumbai, India). Media components were obtained from Hi-Media (India). HPLC solvents were used of HPLC grade (Merck, Germany). All other reagents or chemicals used were of high purity or analytical grade from the commercial sources.

2.2 Screening, Identification, and Culture Conditions for Acyltransferase Production

The soil samples were collected from Shimla, Himachal Pradesh, India, and the enrichment of nitrile degrading microorganisms was performed through supplementation of acetamide (1%, w/v) in 50 mL sterile saline for incubation of 72 h at 30° C and 150 rmp. Previously, a total of 48 isolated bacterial cultures on nutrient agar plates were screened for intracellular amidase activity [4]. The high amidase activity showing five bacterial cultures were used in this study and screened for acyltransferase activity. Further, the hyperactive bacterium (RL-3e) was used for 16S RNA sequencing (Xcelris Genomics, Ahmedabad, India). Molecular analysis of 16S rRNA gene (~ 1.5 kb) was evaluated through PCR of genomic DNA using forward primer: 5′-AGTCGAACGATGAAGCCCAG-3′ and reverse primer: 3′- AACTGAGACCGGCTTTAAGG-5′ [17]. The strain was identified through BLAST analysis of the partial sequences of the 16S rRNA gene and deposited in NCBI Gen-Bank (Accession number KU837232). The phylogenetic analysis was carried out by Phylogeny.fr software [28]. The identified strain as R. pyridinivorans KU837232 was grown on nutrient agar (1%, glucose). Two-steps procedure was used for acyltransferase production: i) pre-culture – R. pyridinivorans was cultured in modified nutrient broth (pH 7.5) containing peptone (5 g/L), beef extract (3 g/L), yeast extract (1 g/L) and glucose (10 g/L) for incubation of 24 h at 30° C and agitation rate of 150 rpm (ORBITEK® Laboratory, SCIGENICS, India) [29], and ii) production media (pH 7.0)—pre-culture inoculum (8%, v/v) was transferred to fresh production media containing components (w/v): acetamide [3.0% (stock concentration of 2 M)], yeast extract (1.5%), NaCl (0.5%), and glucose (0.2%). The flasks were incubated at 30° C for 18 h at 150 rpm. The fully-grown cells were harvested by centrifugation (LBHCR- 105, LABOCON, India) at 10,000 rpm for 10 min) and resuspended in phosphate buffer (pH 7.0). The biomass dry cell weight (dcw) was measured after drying samples at 80° C for incubation of 24 h [30].

2.3 Acyltransferase Assay

The acyltransferase activity of free or immobilized cells was measured spectrophotometrically (UV/VIS Spectrophotometer, Labindia Instruments, Mumbai India) by Brammar and Clarke method using acetamide and hydroxylamine-HCl in phosphate buffer [4].

2.4 Whole-Cells Immobilization

The cells immobilization was performed through entrapment within various polymers (w/v): agar (2%), alginates (2%), carrageenan (4%), polyacrylamide (19%), and polyvinyl alcohol (PVA, 10%) using cells loading of 5 mg-dcw/mL [30, 31]. After encapsulation, loosely bounded cells were washed, and immobilized beads were stored in phosphate buffer (0.2 M, pH 7.5). The residual acyltransferase activity of immobilized whole cells was measured as a similar assay to free cells (100%). The matrix showing high residual activity was selected for further studies. The concentration of alginate (1–3%, w/v) was optimized for effective immobilization. The leaching was measured by the ratio of OD600 of washed to initial cells loaded after one cycle of reuse × 100.

2.5 Optimization of Process Parameters

The acyltransferase activity of free or immobilized cells was assayed (reaction volume of 2 mL) at different pH buffers (7.0–10.5). Further, the influence of buffer molarity (25–400 mM), incubation temperature (25–75° C), thermostability, metal ions, and enzyme inhibitors (1 mM) on the catalytic activity was evaluated. The variation of substrates combination of acetamide (100–400 mM) and hydroxylamine-HCl (200–600 mM) was monitored to achieve high catalytic conversion followed by different temperatures (45–60° C) for incubation up to 1 h.

2.6 Bench-Scale Biotransformation and Downstream Processing

Initially, the effect of DTT (1–20 mM) was evaluated on the biotransformation by free or immobilized cells in the reaction mixture of 50 mL. The free cell reaction was performed in 0.2 M glycine–NaOH (pH 9.0) buffer containing acetamide (300 mM), hydroxylamine-HCl (500 mM), and inoculum (0.468 g-cdw/L) at 45°°C with an agitation rate of 200 rpm for 30 min. Whereas, immobilized cell’s reaction was evaluated using similar substrates concentration, inoculum, and incubation period in 0.15 M glycine–NaOH (pH 8.0) buffer at 55° C and agitation rate of 150 rpm. Further, the batch reaction was scaled up to a working volume of 3-L in 14-L of the fermenter (Scigenics India Pvt. Ltd.). To recover the product, a mixture containing free cells was separated through centrifugation at 4000 g for 15 min and beads through filtration. After cell recovery, the resulting reaction mixture was subjected to lyophilization, and purification of the product was carried through the solvent extraction process [4, 12]. The reusability of free and alginate beads immobilized cells was assessed incubation of 30 min for up to 5 cycles [31].

2.7 Instrumental Analysis

The concentration of acetohydroxamic acid and residual acetamide was analyzed using HPLC (Waters, Bangaluru, India) equipped with column (Merck, Purospher® STAR, reverse phase-encapped, 5 µm, 4.6 mm × 250 mm, Germany) and photodiode array detector [4]. Fourier-transform infrared (FTIR) spectroscopy analysis was performed using Nicolet iS10 FTIR Spectrometer (Thermo Fisher Scientific, USA) at the wavenumber region of 4000–500/cm. Gas chromatography-mass spectroscopy (GC–MS) measurement was accomplished by GC–MS TSQ 8000, Thermo Fisher Scientific, USA) equipped with the TRACE 1300 GC along with an auto-sampler to confirm acetohydroxamic acid in the purified sample [32].

3 Results and Discussion

3.1 Screening and Identification of the Isolate

Previously isolated bacterial cultures (RL-3a-3e) showing intracellular amidases activity were screened for acyltransferase activity (Table S1). The high activity showing isolate (RL-3e) was selected for further studies. The obtained 16S rRNA gene sequence of the efficient amidase-producing bacterium was aligned with reference sequences obtained from the BLAST search program and a phylogenetic tree was constructed (Fig. S1). The bacterium showed a strong relationship with other Rhodococcus sp. for the 16S rRNA gene sequences, and 98% sequence similarity with R. pyridinivorans NS1 KP3341251strain was observed, and the sequence was submitted in NCBI Gene Bank (KU837232).

3.2 Immobilization of Whole-Cells in Various Polymeric Macromolecules Matrices

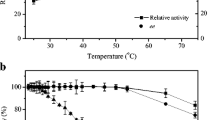

The catalytic activity of encapsulated cells within polymeric macromolecules matrices was assayed in a glycine–NaOH buffer (0.2 M pH 8.5) and compared with free cells (Fig. 1a). Among these matrices, calcium-alginate showed high residual activity of 97.8% (562 U/mg-dcw) as compared to free cells (576 U/mg-dcw). In contrast, a remarkable decreased residual activity was recorded in PVA (82%), agar (66%), carrageenan (60%), and polyacrylamide (56%). These significant variations in the residual activity of immobilized cells might be associated with cells differential responses towards matrix, and polymer rigidity, or their biocompatibility [17, 33].The alginate immobilized R. pyridinivorans showed much higher residual acyltransferase activity as compared to a maximum of 75% of residual activity retained by Bacillus megaterium after immobilization [17].The rigidity of the matrix plays a significant influence on the diffusion of substrate and product during catalysis and operational stability of beads [23]. The variation of alginate concentration led to the significant impact of the biocatalytic activity that might be associated with the rigidity of the polymer structure during the formation of the beads (Fig. 1b). The optimum concentration of 2% alginate was noted for the efficient catalytic activity of 97.8% as compared to free cells. The image of prepared alginate beads is presented in Fig S2. A gradual decreased residual activity to 67.9% at a higher alginate concentration up to 3.0% might be correlated with elevated rigidity that caused mass transfer limitation or alteration of physiological properties of immobilized cells [22, 33]. In contrast, beads with lower alginate concentrations to 2% exhibited minor inhibition of residual activity that might be disadvantageous to achieve better operational stability due to their higher fragile nature [34]. The high cell leaching of 18.6% at lower alginate (1%, w/v) was noted that might be correlated with the higher structural instability of alginate as compared to low leaching of 0.7% at high alginate (3%, w/v) (Fig. 1b). However, the alginate optimum concentration (2%, w/v) founded as desirable to achieve efficient immobilization.

3.3 Characterization of Immobilized cells

The optimal acyltransferase activity was observed in the alkaline region for free and immobilized cells (Fig. 2a). Free cells exhibited maximum activity of 645 U/mg-dcw at pH 9, whereas immobilized cells showed a pH shift of 0.5 with an activity of 744 U/mg-dcw (pH 9.5). Previous studies reported the optimal activity of amidases at neutral pH [35], while Bacillus amidases exhibited at alkaline pH 8.0–9.0 [17, 19]. A shift in optimum pH might be associated with physiological changes due to binding matrix and inadequate diffusion [21]. At pH 8.5–10.5, the immobilized cells retained over 78% of their initial activity, while the free cells lost ~ 60% of residual activity at pH 10.5 (Fig. 2a). In terms of buffer molarity, the optimum acyltransferase activity of 796 U/mg-dcw for immobilized cells was recorded at 150 mM of glycine–NaOH (pH 9.5) buffer, while free cells showed optimum value at higher buffer molarity of 200 mM (Fig. 2b). Immobilized cells were founded more stable to retain high residual activity active of 66% at 400 mM as compared to free with lower residual activity of 30%. A considerable decrease in residual activity might be due to the similar charged groups of enzyme and buffer interact electrostatically [7]. Previously, the lower maximum acyltransferase activity of 104 U/mg-dcw (at pH 7.5) and 110 U/mg-dcw (at 110 mM, phosphate buffer) was reported from amidase of Pseudomonas putida BR-1[12].

The effect of temperature on acyltransferase activity of the immobilized cells and free cells was investigated over a range of 25 to 75° C (Fig. 2c). The optimum temperature of 60 and 65° C was noted for free (645 U/mg-dcw) and immobilized cells (884 U/mg-dcw). P. putida BR-1 exhibited low acyltransferase activity of 138 U/mg-dcw at the optimum temperature of 50° C [12]. A shift in temperature optimum for immobilized cells attributed to less susceptibility towards heat than free cells that might be associated with enhanced thermal tolerance and adaptability through changes of physicochemical properties after immobilization [19, 21]. Previously, a lower optimum temperature of 55° C reported for acyltransferase activity of free and alginate immobilized Bacillus sp. [17].

The thermostability profile of free and immobilized cells was compared at different temperatures of 45–65° C for incubation of 10 h (Fig. 3). Both free and immobilized cells residual activity decreased with increasing temperature from 45 to 65° C. The stability of immobilized cells improved 1.6-, 3.4-, 7.9-, and 25.5-folds at 45, 50, 55, and 60° C than those of free cells. At a high temperature (65° C), the immobilized cells retained 55% of the residual activity at 4 h (Fig. 3a). In contrast, free cells lost more than 90% of residual activity under similar conditions (Fig. 3b). Previously, the purified amidases of Bacillus sp. APB-6 showed lower half-life of 1.5 h at 55° C [36]. The better stability of cells after immobilization is associated with a protective microenvironment within the matrix [17]. The decrease in the stability of immobilized cells at higher temperatures might be correlated with biocatalyst deactivation or structural distortion of the matrix that can be associated with cell leaching [21]. Overall, immobilized cells exhibited broad pH, buffer, and temperature stability as compared to free cells.

3.4 Effect of Metal Ions and Inhibitors

The activity of free and immobilized cells was highly influenced by the presence of metal ions and enzyme inhibitors (Table 1). Immobilized cells showed better stability in presence of metal ions and inhibitors than those of free cells. In presence of DTT, free and immobilized cells exhibited 10 and 19% higher residual activity as corresponding to control (1051 U/mg-dcw). The observed results suggested that sulphydryl groups are essential for enzyme activity like other aliphatic amidases belonging to the nitrilase superfamily that stabilized in presence of DTT [3]. Metal ions HgCl2, PbNO3, AgNO3, and CuSO4 strongly inhibited the acyltransferase activity that might be associated with blocking of free sulphydryl groups of a cysteine residue in enzyme active site [36]. On the other hand, metal ions such as cobalt chloride, ferric chloride, zinc sulphate, sodium azide substantially inhibited the activity of up to 55% for free cells. In contrast, immobilized cells retained up to 2.2-fold higher residual activity (97.6%). Thiol groups covalently bind to the porous matrix and form strong complexes that might help preserve better catalytic activity to immobilized cells over free cells [4, 32].

3.5 Conversion of Acetamide and Hydroxylamine

Initially, the effect of substrates acetamide and hydroxylamine-HCl concentration were evaluated to achieve efficient conversion by free and immobilized cells (Fig. 4). The concentrations of both acetamide and hydroxylamine-HCl exhibited a variable to influence the conversion by free (Fig. 4a), and immobilized cells (Fig. 4b). The optimum conversion was recorded at 300 and 500 mM of acetamide and hydroxylamine-HCl, respectively. In contrast, acyltransferase from Bacillus sp. APB-6 exhibited optimum activity at acetamide (300 mM), and hydroxylamine-HCl (800 mM) [4, 36]. A higher concentration of hydroxylamine-HCl suggested that a strong-nucleophile is required to achieve a fast reaction rate, and specified products [12]. After immobilization, cells showed better substrate tolerance to achieve higher conversion. Previously studies also support better conversion to other products by acyltransferase [12, 14, 35].

Free and immobilized cells exhibited different optimum temperatures; however, the rate of denaturation and product inhibition might be affected by their stability and conversion rate. The conversion of free and immobilized cells was compared (Fig. 5). Immobilized cells showed a slightly higher conversion of 90% at 55° C for incubation of 30 min to free cells with the maximum conversion of 89% at 45° C. This effect might be due to a protective shield provided by the alginate matrix to entrapped cells from adverse physical conditions and toxicity of substrate [14]. Amidases have a stronger affinity towards hydroxamic acid (act as substrate), therefore complete conversion of acetamide to hydroxamic acid is difficult to achieve [4, 14]. The complex structure of the substrate might also affect the rate of conversion by amidases [1, 5, 35]

3.6 Bench-Scale Biotransformation and Reusability

Initially, the influence of DTT concentration was evaluated to enhance the conversion via improving acyltransferase activity at the working volume of 50 mL. At 1 mM of DTT, no significant changes were observed on conversion as compared to control (Fig. 6a). Further, increasing the DTT concentration to 10 mM resulted in high conversion of 96.2% as compared to free cells at 94.2%. DTT acts as a disulfide reductant that is considered as essential for stabilizing sulphydryl groups to maintain high acyltransferase activity [3, 4]. Previously, a similar optimum concentration (10 mM) of DTT was reported for acetohydroxamic acid production by Bacillus sp. APB-6 [4]. This finding suggested that the immobilized acyltransferase activity of amidase is hyperactive and readily converts acetamide to acetohydroxamic acid or other aliphatic and aromatic amides as compared to reported literature presented in Table 2.

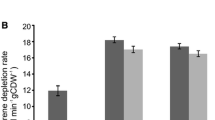

To achieve a high product amount, the conversion was scaled up to 3 L in presence of 10 mM of DTT, and the product was estimated at different intervals (Fig. 6b). The production of acetohydroxamic acid was observed quite consistent on process scaling from 50 mL to 3-L. The amount of 279 mM (93%) acetohydroxamic acid was obtained by free cells, while immobilized cells recorded higher production of 288 mM (96%) at 3-L culture. Previously, biotransformation under batch mode has reported up to 1-L of culture (Table 2). A 3-L cultures freeze-drying, the amount of 174 and 180 g of acetohydroxamic acid powder recovered for free and immobilized cells, respectively. The solvent extracted samples HPLC analysis showed high purity of acetohydroxamic acid of 96% for free cells and 97% for immobilized cells (Fig. S3). In FTIR spectra of purified acetohydroxamic acid, the peaks at 3455, 2582, 1722, and 1415 cm−1 attributed to the stretching vibrations of N–H, C-H, OH, CO, and N–OH groups, respectively (Fig. S4). Whereas peaks at 2857 and 3115 cm−1 confirmed the stretching vibrations of an alkyl group. Further, the GC–MS spectrum showed a mass/charge ratio (m/z = 76.1) with 100% relative abundance of parenting molecular ion along with other associated peaks due to possible fragments (Fig. S5). The peaks at m/z of 43.0, 45.0, 58.1, and 60.1 revealed H≡OH22+, H2C = C–OH22+, HO-NH2+≡CH, and HO–HN = C = O fragments ions confirmed the acetohydroxamic acid. From a commercial point of view, reusability is an important parameter [33, 34]. The reusability of free and immobilized cells was compared under repeated batch mode at a 3-L (Fig. 6c). After five cycles, free cells significantly declined residual conversion to 10.0%. In contrast, immobilized cells retained a high conversion of 93.4% under similar conditions. Previously, few studies reported acetohydroxamic acid biotransformation by immobilized cells with very small working volumes of 1–2 mL [17, 27]. Therefore, this study proved a significant outcome towards the sustainable feasibility of bioprocess at large capacity by immobilized cells.

4 Conclusion

In this study, alginate immobilized cells of R. pyridinivorans emerged as a good source of bioconversion as compared to free cells in terms of improved enzyme activity, stable catalytic efficiency, thermostability, and formation of acetohydroxamic acid under optimum physicochemical conditions. The pH and thermal stability of alginate entrapped cells were improved after immobilization. The immobilized cells showed 25.5 higher thermal stability in comparison to the free cells. The stable repeated batches with 96% conversion were obtained successfully at the bench scale for the first time. The product analysis confirmed the recovery at high purity of 97%. Overall, this process has great potential in the production of acetohydroxamic acids and can be employed in industrial and biotechnological processes on a commercial scale.

References

Kim J-S, Patel SKS, Tiwari MK, Lai C, Kumar A, Kim YS, Kalia VC, Lee J-K (2020) Int J Mol Sci 21:7859

Chhiba-Gonindjee VP, van der Westhuyzen CW, Bode ML, Brady D (2019) Appl Microbiol Biotechnol 103:4679–4692

Ruan LT, Zheng RC, Zheng YG (2016) J Ind Microbial Biotechnol 43:1071–1083

Pandey D, Singh R, Chand D (2011) Bioresour Technol 102:6579–6586

Singh RV, Sharma H, Gupta P, Kumar A, Babu V (2019) Indian J Biochem Biophys 56:373–377

Fournand D, Bigey F, Arnaud A (1998) App Env Microbiol 64:2844–2852

Bhatia RK, Bhatia SK, Mehta PK, Bhalla TC (2013) J Ind Microbiol Biotechnol 40:21–27

Prabha R, Nigam V (2020) Biocatal Biotransform 38:445–456

Pai O, Banoth L, Ghosh S, Chisti Y, Banergee UC (2014) Process Biochem 49:655–659

Ismailsab M, Monisha TR, Pooja V, Santoshkumar M, Anand SN, Timmanagouda BK (2017) Biocatal Biotransform 35:74–85

Sharma M, Sharma NN, Bhalla TC (2012) Indian J Microbiol 52:76–82

Bhatia RK, Bhatia SK, Mehta PK, Bhalla TC (2014) J Mol Catal B Enzym 108:89–95

Mohammad AA (2019) Curr Org Chem 23:978–993

Agarwal S, Gupta M, Choudhury B (2013) J Ind Microbiol Biotechnol 40:937–946

Ansu K, Poonam S, Attri CS, Seth A (2016) Res J Chem Environ 20:35–47

Dong A, Brown C, Bai S, Dong J (2018) Int J Biol Macromol 112:591–597

Sogani M, Mathur N, Bhatnagar P, Sharma P (2012) Int J Environ Sci Technol 9:119–127

Lin CP, Wu ZM, Tang XL, Hao CL, Zheng RC, Zheng YG (2019) Bioresour Technol 274:371–378

Maksimova YG, Gorbunovaa AN, Zorinac AS, Maksimov AU, Ovechkinaa GV, Demakova V (2015) Appl Biochem Microbiol 51:64–69

Lin C, Xu K, Zheng R, Zheng Y (2019) Chem Commun 55:5697–5700

Mortazavi S, Aghaei H (2020) Int J Biol Macromol 64:1–12

Anisha GS, Prema P (2008) Bioresour Technol 99:3325–3330

Lassouane F, Aït-Amar H, Amrani S, Rodriguez-Couto S (2019) Bioresour Technol 271:360–367

Mohamad NR, Marzuki NHC, Buang NA, Huyop F, Wahab RA (2015) Biotechnol Biotechnol Equip 29:205–220

Sogani M, Mathur N, Sharma P, Bhatnagar P (2012) J Environ Res Dev 6:695–701

Kumari P, Duni C (2017) J Innov Pharma Biol Sci 4:121–127

Bernardo M, Pachecoa R, Serralheirob MLM, Karmalia A (2013) J Mol Catal B Enzym 93:28–33

Dereeper A, Guignon V, Blanc G, Audic S, Buffet S, Chevenet F, Dufayard JF, Guindon S, Lefort V, Lescot M, Claverie JM, Gascuel O (2008) Nucleic Acids Res 1:465–469

Bhalla TC, Miura A, Wakamoto A, Ohba Y, Furuhashi K (1992) Appl Microbiol Biotechnol 37:184–190

Patel SKS, Shanmugam R, Kalia VC, Lee JK (2020) Bioresour Technol 304:e123022

Patel SKS, Kumar V, Mardina P, Li J, Lestari R, Kalia VC, Lee J-K (2018) Bioresour Technol 263:25–32

Bedade DK, Singhal RS (2018) Bioresour Technol 261:122–132

Wahab RA, Elias N, Abdullah F, Ghoshal SK (2020) React Funct Polym 152:e104613

Singh R, Pandey D, Devi N, Chand D (2018) Bioproc Biosyst Eng 8:225–1232

Singh RV, Sharma H, Ganjoo A, Kumar A, Babu V (2020) J Appl Microbiol 129:1589–1597

Pandey D, Patel SKS, Singh R, Kumar P, Thakur V, Chand D (2019) Indian J Microbiol 59:500–507

Acknowledgements

The authors are highly grateful to the Department of Biotechnology, Himachal Pradesh University, Shimla, India, for providing the laboratory and chemical facilities during the study. Computational Facility of Bioinformatics Centre, Himachal Pradesh University Shimla is also duly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Devi, N., Patel, S.K.S., Kumar, P. et al. Bioprocess Scale-up for Acetohydroxamic Acid Production by Hyperactive Acyltransferase of Immobilized Rhodococcus Pyridinivorans. Catal Lett 152, 944–953 (2022). https://doi.org/10.1007/s10562-021-03696-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-021-03696-4