Abstract

The enzyme 4-oxalocrotonate tautomerase (4-OT) encoded by the xylH gene is a part of the degradation pathway of aromatic compounds in Pseudomonas putida mt-2. 4-OT was described to catalyze Michael-type addition of acetaldehyde to β-nitrostyrene, and the whole cell system based on recombinantly expressed 4-OT has been developed previously. In this study biocatalytic process based on Escherichia coli whole cells expressing 4-OT was significantly improved using immobilization and ex situ product recovery strategies. Whole cell immobilization in alginate beads was applied in biocatalytic production of 4-nitro-3-phenyl-butanal from β-nitrostyrene and acetaldehyde. Immobilized biocatalyst showed wider pH activity range and could tolerate twofold higher initial concentrations of substrate in comparison to the free whole cell biocatalyst. Beads retained their initial activity over 10 consecutive biotransformations of the model reaction and remained suitable for the repetitive use with 85 % of the initial activity after two months of storage. Bioprocess was further improved by utilizing Amberlite XAD-2 hydrophobic resin for the product recovery. With this modification, the amount of organic solvent was reduced 40-fold in comparison to previously reported method making this biocatalytic process greener.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biocatalysis, as the application of enzymes and microbes in synthetic chemistry, has evolved as one of the efforts towards greener production processes [1, 2]. It is a practical and environmentally friendly alternative to traditional metallo- and organocatalysis in chemical synthesis. Biocatalysts are made from renewable sources, they are biodegradable, non-toxic and usually highly selective, which simplifies reaction and provides desired product in higher yields. Biocatalytic processes typically run at ambient temperature, atmospheric pressure and neutral pH, making them safer than chemical processes [3].

Enzymes used as biocatalysts, either free or in living cells, have limited stability and reusability. The most common methods used to prolong biocatalyst’s lifetime are using an organic or inorganic solid support [4–6]. Methods for immobilization range from adsorption and covalent bonding to encapsulation and entrapment, with the latest being the most common method for living or resting cells’ support [7, 8]. The potential advantages associated with the immobilization of biocatalyst are: higher stability with regard to temperature, pH, and catalyst poisoning, repetitive use of biocatalysts and easy separation from reaction media (easier downstream processing). Over the last three decades, there has been intensive research in the immobilization of cells and enzymes with the idea of improving the economics of biocatalysts application (e.g., higher reusability). Alginate is one of the most common materials used for whole cell biocatalyst immobilization due to its biocompatibility, hydrophilicity and low toxicity. Process of microbead gelation is very cost effective as it does not require complicated setup or expensive chemicals [9]. Also, due to the large pore sizes of polysaccharide network diffusional limitations for small molecules like enzymatic substrates are quite low and high activities of immobilized biocatalysts can be obtained, especially in the case of whole cell immobilization. Therefore, there are multiple recent studies of whole cell immobilization within alginate microbeads like recombinant E.coli cells harboring L-arabinose isomerase from Bacillus licheniformis [10], Gibberella intermedia CA3-1 cells with nitrilase activity [11] and Penicillium purpurogenum Li-3 for glycyrrhetic acid 3-O-mono-β-D-glucuronide synthesis [12].

The enzyme 4-oxalocrotonate tautomerase (4-OT, EC number 5.3.2.6) encoded by the xylH gene is a part of the degradation pathway of aromatic compounds in Pseudomonas putida mt-2 [13]. Due to its promiscuous activity, in addition of its natural way to convert 2-hydroxyhexa-2,4 dienedioate into 2-oxo-3-hexendioate, 4-OT was described to catalyze Michael-type addition of acetaldehyde to β-nitrostyrene [14], the isomerisation of cis-nitrostyrene to trans-nitrostyrene [15] as well as aldol condensation and dehydratation as free enzyme [14]. Nitroaromatic compounds, including β-nitrostyrene and derivatives are very interesting precursors in pharmaceutical and chemical industry [16, 17]. Whole cell system based on recombinantly expressed 4-OT has been developed in our laboratory and shown to be effective biocatalyst of asymmetric Michael addition of acetaldehyde and of different branched aldehydes to β-nitrostyrene [18, 19]. Although, excellent enantioselectivity and high yield of 4-nitro-3-phenyl-butanal was achieved, downstream processing (product recovery) was carried out using standard solvent extraction methodology which made this biocatalytic process in terms of the environmental impact less effective. Therefore, we have set in this study to improve the process by whole cell immobilization within alginate beads and improved product retrieval using hydrophobic Amberlite XAD-2 resin.

Materials and methods

Reagents

β-Nitrostyrene, acetaldehyde and all other chemicals were of analytical grade and purchased from Sigma–Aldrich (Munich, Germany). Ethyl acetate, ethanol and other solvents were of HPLC reagent grade and purchased from Fisher Scientific (Hampton, NH, USA). Sodium alginate was purchased from Sigma-Aldrich (Munich, Germany).

Ampicillin, isopropyl-β-D-1-thiogalactopyranoside (IPTG), other salts and reagents were purchased from Sigma-Aldrich (Munich, Germany). Glucose, tryptone, yeast extract, casamino acids and other media components were purchased either from Oxoid (Cambridge, UK) or Becton–Dickinson (Sparks, MD, USA). Amberlite® XAD-2 (650.4 µm) hydrophobic resin was purchased from Supelco (Bellefonte, Pennsylvania, USA). SYTO® 9 and propidium iodide (PI) dyes were purchased from Invitrogen (Carlsbad, California, USA).

Culture conditions for biocatalyst preparation

Recombinant E. coli BL21(DE3) strain expressing 4-oxalocrotonate tautomerase was previously constructed and maintained in our laboratory [18]. Whole cell biocatalyst was prepared as described previously using M9 minimal medium supplemented with casamino acids (0.5 %, w/v) and ampicillin (50 µg/ml) [20]. Once the culture had reached an optical density of 0.5 (600 nm; Spectrophotometer Ultrospec 3300pro, Amersham Biosciences), the cells were induced with 0.1 mM IPTG at 28 °C. After 12-h expression, the cells were harvested by centrifugation at 5000×g for 10 min in Eppendorf 5804R bench-top centrifuge. The wet cell pellets were resuspended to a concentration of cell dry weight (CDW) of 5 g/l (OD = 20) and 20 g/l (OD = 80), for free and immobilized biocatalyst, respectively, in 20 mM Tris–HCl buffer pH 7.4.

Biocatalyst immobilization

20 ml of cell suspension (CDW 20 g/l) was mixed with 20 ml of 4 % (w/v) alginate resuspended in Tris–HCl buffer (pH 7.4). Then, the mixture was added dropwise from syringe into 5 % (w/v) CaCl2 that was gently stirred. Two types of beads were made using 21 and 26 gauge needles. Resulting gel beads (diameter between 2 and 2.4 mm for big beads, and 1–1.4 for small beads) were hardened at room temperature for 30 min in 5 % (w/v) CaCl2 solution. Gel beads were stored in Tris–HCl buffer pH 7.4 supplemented with 5 mM CaCl2 at 4 °C.

To obtain capsules with liquid core, beads were coated with 2 % (w/v) chitosan for 30 min and the core was liquefied by immersing chitosan-coated beads in 55 mM sodium citrate for 15 min. Capsules with liquid core were then filtered, washed and stored in Tris–HCl buffer pH 7.4 at 4 °C.

4-Nitro-3-phenyl-butanal production and recycling of biocatalyst

Biotransformation using β-nitrostyrene and acetaldehyde was carried out in 50-ml Duran Schott glass bottles with screw-type plastic lids in 15 ml total reaction volume at 28 °C with shaking at 150 rpm. In the case of free cells, reaction contained 15 ml cell suspension (5 g/l of biocatalyst) while in the case of immobilized biocatalyst 7.5 g of beads/capsules in 20 mM Tris–HCl pH 7.4. In this way, comparable amounts of whole cells expressing 4-OT were used in each reaction. The β-nitrostyrene substrate was added in concentrations of 1 mM or 4 from 200 mM stock solution in ethanol and 10 or 40 mM acetaldehyde was added, respectively. Aliquots (100 µl) of cell suspension or buffer from immobilized biocatalyst were withdrawn from the reaction over time. Cell suspension samples were centrifuged at 13,000×g for 5 min. Samples were analyzed spectrophotometrically, following the depletion of β-nitrostyrene by reduction of absorbance at 320 nm (ε = 14.4 mM−1 cm−1) [14].

To determine the activity on different pH values, biotransformation with free cells and immobilized biocatalyst was carried out in Tris–HCl buffer adjusted to pH 7.4 and pH 9. In addition, reaction was carried out in glycine–HCl buffer adjusted to pH 4.

4-Nitro-3-phenyl-butanal retrieval and analysis

Biotransformation product extraction and purification was carried out as previously described when whole cells were used as a biocatalyst [18]. To recover the product from the reaction mixture containing immobilized biocatalyst, biocatalyst was removed by sieving and 0.2 g of Amberlite XAD-2 resin, particle size 650.4 µm, was added to remaining buffer and the mixture was shaken at 160 rpm for 1 h. Resin was separated by centrifugation, air dried and product was removed by adding minimal volume of ethyl acetate (1 ml). Ethyl acetate-containing product was evaporated under reduced pressure and remaining product was weighted and analyzed. Product identity and purity was confirmed by nuclear magnetic resonance (NMR) spectroscopy. 1H and 13C NMR spectra were obtained in deuterated chloroform with a Varian NMR system 200 MHz spectrometer. The enantiomeric excess was determined by HPLC (Agilent Technologies HP1100) using CHIRALPAK IA 250 column (Chiral Technologies Europe, Cedex, France).

In situ determination of immobilized cells survival

Cell survival within immobilized biocatalyst was assessed by fluorescent microscopy. Sliced capsules were stained with SYTO®9 and propidium iodide (PI) dyes (Invitrogen, Carlsbad, California, USA), staining live bacterial cells green and dead cells red, respectively. Mixture of SYTO® 9 (2.5 µM) and PI (2.5 µM) was added to the coverslips and samples were incubated at room temperature for 15 min in the dark. Coverslips were then placed on the microscope slide and cell viability was assessed using Olympus BX51 fluorescent microscope (Olympus, Tokyo, Japan) and Cytovision 3.1 software package (Applied Imaging Corporation, Santa Clara, USA).

Statistical analysis

The results were subjected to analysis of variance (ANOVA) and Tukey means tests, at 5 % significance level using Statistica 8.0/2008 (Stat Soft, Inc. Tulsa, OK, USA).

Results and discussion

We have previously designed and assessed biocatalyst based on the whole resting Escherichia coli BL21(DE3) cells expressing 4-oxalocrotonate tautomerase [18]. Whole cell biocatalyst showed increased tolerance to the initial substrate concentrations in comparison to the free enzyme [21]. Overall, using whole cell strategy bioprocess was improved 6 times in terms of reaction time with the retained enantioselectivity of more than 99 % ee. To further improve the process, recycling of the biocatalyst was attempted using repeated cycles of centrifugation and resuspension. However, using this strategy biocatalyst was quickly losing its activity, with product yield reducing to only 40 % after three cycles of reuse [18]. Reduction of the activity was due to inactivation of biocatalyst as well as product loss during recovery. Sequential addition of substrate without product removal improved the bioprocess, but the overall product yield was still at 56 % [18]. This was due to the product degradation upon prolonged exposure to aqueous medium or product loss during organic solvent extraction and purification. To address these problems, we have carried out immobilization of the whole cells expressing 4-OT in alginate, as well as ex situ product retrieval using Amberlite XAD-2 resin to avoid usage of excess organic solvent.

Immobilization of whole cell biocatalyst

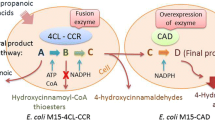

Whole cell biocatalyst was successfully immobilized with alginate making beads of approximately 2 and 1 mm in diameter by simply varying the needle gauge. To get immobilized biocatalyst in a form of liquid core capsules, smaller alginate beads (1 mm diameter) were coated in chitosan and core was liquefied with sodium citrate. Beads, capsules and free whole cell biocatalysts were applied in the model reaction of biotransformation of β-nitrostyrene and acetaldehyde into 4-nitro-3-phenyl-butanal, which was monitored by UV–Vis spectroscopy (λ max = 320 nm) (Fig. 1a). In all biotransformation experiments the same amount of either free or alginate-immobilized cells [5 g cell dry weight (CDW) per liter] was used. For the start, alginate-immobilized biocatalyst showed the activity on wider range of the pH in comparison to free whole cells being active at pH 4 (Fig. 1b). Lower pH had negative effect on biocatalyst activity and product yield. Reduction of temperature to 20 and 10 °C also had negative effect on biotransformation efficiency (results not shown). At the acidic pH, disruption of free cells was evident while immobilized biocatalyst retained 65.5 % of its activity at pH 4 (Fig. 1b), confirming that immobilization of the free cells provided protection to unfavorable environmental conditions such as low pH. Indeed, it was previously shown with purified 4-OT enzyme that when pH of the reaction buffer was lowered from pH 7–5.5, the increase in the 4-nitro-3-phenyl-butanal yield and the amount of generated side products was reduced [22]. Based on the experiments using buffers at different pH values, all subsequent experiments were performed in 20 mM Tris–HCl buffer at pH 7.4.

Biotransformation of β-nitrostyrene and acetaldehyde into 4-nitro-3-phenyl-butanal as model reaction for immobilized biocatalyst E. coli (4-OT) assessment (a). Activity of immobilized (black square) and free whole cell 4-OT biocatalyst (gray square) in glycine–Tris and Tris–HCl buffer at different pH values (b)

It was found that the best performing biocatalyst on 1 mM β-nitrostyrene was immobilized biocatalyst in a form of small beads (of 1 mm diameter) with reaction time of 20 min, overall product yield of 97.5 % and high enantioselectivity of >99 % ee (Table 1). This was 1.5-fold and 1.6-fold improvement in reaction time and product yield in comparison to free whole cell biocatalyst, respectively. Larger beads (of 2 mm diameter) had 3.8-fold lower specific activity in comparison to smaller beads, but retained high product yield and enantioselectivity. Lower activity was the result of increased diffusional limitations due to the increased diameter of alginate beads. These results were similar to the reported drop in relative activity of nitrilase from 100 to 65 % with the increased diameter of alginate beads from 1.8 mm to 3.8 mm [11]. The worst performing biocatalysts were capsules with liquid center that proved not to be stable under reaction conditions. Leaking of the liquid and immobilized cells occurred, which affected activity of the immobilized 4-OT and the product retrieval. It took 9 times longer (3 h in comparison to 20 min) for the capsules with liquid center to biotransform 1 mM β-nitrostyrene in comparison to small alginate beads (Table 1). Longer reaction time allowed racemisation of the product to occur, so lower ee of the product obtained with capsules was observed (Table 1).

Two initial β-nitrostyrene concentrations, 1 and 4 mM were used in reactions with immobilized and free 4-OT biocatalysts (Fig. 2a, b). Again, alginate beads of 1 mm diameter performed the best in terms of tolerating higher initial amount of the substrate. Capsules with liquid center, as well as free whole cells could not complete the biotransformation of 4 mM β-nitrostyrene even after 10-h incubation (Fig. 2b) which is in accordance with our previous results with free cells [18]. This result that alginate-immobilized biocatalysts showed increased tolerance to toxic substrate was in accordance with previously reported increased nitrilase activity of alginate-immobilized whole cell biocatalysts towards 3-cyanopyridine at concentration above 500 mM where free cells could not even transform the substrate completely [11]. Similarly, whole cells of Bacillus sp. CCZU11-1 were immobilized in calcium alginate which resulted in the increased tolerance towards higher concentrations of substrate, as well as the product [23].

Biotransformation with immobilized biocatalyst: biocatalyst recycling

Immobilized whole cell biocatalyst is advantageous as in this form they could easily be recycled and reused, thus avoiding the need for enzyme purification and significantly reducing the process cost [24]. Immobilization of the E. coli 4-OT biocatalyst resulted in much improved reusability than that of free cells during successive cycles of biotransformation of 1 mM β-nitrostyrene (Fig. 3a). Relative activity dropped to 92 % after 6 days of reuse of biocatalyst, which was stored in buffer at 4 °C between reactions. Furthermore, immobilized biocatalyst showed excellent storage properties being active even up to three months in storage (data not shown). After two months of reuse (24 cycles), the relative activity was over 85 % with product yield over 80 % and the beads did not rupture. It was evident that cells were still live after 60 days of storage and reusing from the live–dead bacterial staining of the immobilized biocatalyst (Fig. 3b).

Immobilized biocatalyst recycling applied on biotransformation of 1 mM β-nitrostyrene and 10 mM acetaldehyde. a Cycle 4 (day 1, black diamond); cycle 7 (day 2, gray diamond); cycle 10 (day 3, white diamond); cycle 12 (day 4, diamond); cycle 24 (day 60, black triangle). b Fluorescent microscopy of cross-cut section of single biocatalyst bead at day 1 and day 60 at ×40 magnification

Our results were slightly better in comparison to previously reported that the alginate-immobilized Acetobacter had retention of activity of 80 % after 90 days of storage and more than 50 % of activity after 25 cycles of reuse [25]. Also, immobilized Bacillus sp. CCZU11-1 [23] and Rhizopus oryzae [26] showed around 80 % of relative activity after 168 h and 12 cycles of biotransformation, respectively. Escherichia coli expressing recombinant monoamine oxidase immobilized with polyvinyl alcohol retained 91 % of activity after 15 months of storage, compared with first transformation with fresh biocatalyst [27].

Bioprocess improvement by ex situ product removal with Amberlite XAD-2 resin

Product removal strategy has been extensively used to improve biotechnological processes by reducing product decomposition and/or overcoming product inhibition [28, 29]. The successful examples mainly include the application of resins as product adsorbent to improve productivity and final product concentrations in whole cell biotransformation for the production of high value chemicals including some important aldehydes [30]. In addition, hydrophobic resin has been used for product recovery to lower the amount of the organic solvent used [31].

Previously, to recover 4-nitro-3-phenyl-butanal product from the biotransformation, the reaction mixture containing free cells was extracted with 200 ml of ethyl acetate [18] which raised the question of how green was the biocatalytic approach in comparison to organocatalysis. The attempt to recover product by XAD-2 resin from the biotransformation reactions containing free cells was not successful in terms of product recovery and biocatalyst recycling, because the mixture had to be filtered to separate cells from the resin, and after this step cells were rapidly losing their activity. Reaction buffer of immobilized beads was firstly sieved, and then XAD-2 resin was added which allowed easy product adsorption and removal using minimal volume of ethyl acetate (approximately 1–5 ml), thus reducing the amount of organic solvent by 40-fold. Subsequent purification by solvent evaporation gave a final yield of 97 % for the pure 4-nitro-3-phenyl-butanal (Supplementary File S1). Therefore, this solid-phase extraction system was shown to be applicable for the 4-OT model reaction and could further be applied in larger scale by constructing an external loop packed with resin to achieve continuous process. This approach was previously successfully used in biocatalytic production of the toxic catechols using bacterial monooxygenase biocatalyst whereby product adsorption by XAD-4 resulted in the stabilization of the product [32]. More recently, the system involving a cascade of processes using two packed-bed reactors with immobilized cells and two l-cysteine extractors with the cation-exchange resin Dowex 50 W to reduce product inhibition and unreacted substrate was described [33]. The range of commercially available matrices such as Dowex™, Relite™, or Lewatit™ provides a significant tool set for product recovery of small molecules from synthetic bioprocesses, especially the ones that are inhibitory to the microorganisms used in whole cell bioprocesses [32, 33].

Conclusions

The catalytic performance of E. coli 4-OT in the biotransformation of β-nitrostyrene and acetaldehyde was significantly improved by whole cell biocatalyst immobilization within alginate beads. Immobilized whole cell biocatalyst showed increased tolerance toward higher substrate concentrations compared to free cells. Also by repeated use in batch reactor after 24 cycles and 60 days of use immobilized whole cell biocatalyst lost less than 20 % of initial activity. Biocatalytic process was further improved by a hydrophobic-based ex situ product removal, resulting in substantial reduction of the organic solvent utilization. Based on these results it can be concluded that developed immobilized whole cell biocatalyst could be applied in green, more environmentally friendly biocatalytic process of asymmetric Michael addition of acetaldehyde and different branched aldehydes to β-nitrostyrene.

References

Bornscheuer UT, Huisman GW, Kazlauskas RJ, Lutz S, Moore JC, Robins K (2012) Engineering the third wave of biocatalysis. Nature 485:185–194

Drauz K, Gröger H, May O (2012) Enzyme catalysis in organic synthesis, Vol. 3, Wiley-VCH

Buchholz K, Kasche V, Bornscheuer UT (2012) Biocatalysts and Enzyme Technology second edition ed., Wiley-VCH

Bickerstaff G (2000) Immobilization of biocatalysts, 4 ed., Humana Press, New Jersey

Lalonde J, Margolin A (2002) Immobilization of enzymes, vol 1, 2nd edn. Wiley-VCH, Weinheim

Pedersen S, Christensen M (2000) Immobilized biocatalysts, 2nd edn. Academic Press, Amsterdam

End N, Schöning K-U (2004) Immobilized biocatalysts in industrial research and production, vol 242. Springer, Heidelberg

Meyer H-P, Birch JR (1999) Production with bacteria and mammalian cells—some experience. Chimia 53:562–565

Park JK, Chang HN (2000) Microencapsulation of microbial cells. Biotechnol Adv 18:303–319

Zhang Y-Z, Prabhu P, Lee J-K (2010) Alginate immobilization of recombinant Escherichia coli whole cells harboring L-arabinose isomerase for L-ribulose production. Bioprocess Biosyst Eng 33:741–748

Li H, Yang T, Gong J-S, Xiong L, Lu Z-M, Li H, Shi J-S, Xu Z-H (2015) Improving the catalytic potential and substrate tolerance of Gibberella intermedia nitrilase by whole-cell immobilization. Bioprocess Biosyst Eng 38:189–197

Kaleem I, Shen H, Lv B, Wei B, Rasool A, Li L (2014) Efficient biosynthesis of glycyrrhetic acid 3-O-mono-β-D-glucuronide (GAMG) in water-miscible ionic liquid by immobilized whole cells of Penicillium purpurogenum Li-3 in alginate gel. Chem Eng Sci 106:136–143

Harayama S, Rekik M, Ngai KL, Ornston LN (1989) Physically associated enzymes produce and metabolize 2-hydroxy-2,4-dienoate, a chemically unstable intermediate formed in catechol metabolism via meta cleavage in Pseudomonas putida. J Bacteriol 171:6251–6258

Zandvoort E, Geertsema EM, Quax WJ, Poelarends GJ (2012) Enhancement of the promiscuous aldolase and dehydration activities of 4-oxalocrotonate tautomerase by protein engineering. ChemBioChem 13:1274–1277

Zandvoort E, Geertsema EM, Baas BJ, Quax WJ, Poelarends GJ (2012) An unexpected promiscuous activity of 4-oxalocrotonate tautomerase: the cis-trans isomerisation of nitrostyrene. ChemBioChem 13:1869–1873

Milhazes N, Calheiros R, Marques MPM, Garrido J, Cordeiro MNDS, Rodrigues C, Quinteira S, Novais C, Peixe L, Borges F (2006) β-Nitrostyrene derivatives as potential antibacterial agents: a structure-property-activity relationship study. Bioorg Med Chem 14:4078–4088

Munoz DS, Hoyos P, Hernaiz MJ, Alcantara AR, Sanchez-Montero JM (2012) Industrial biotransformations in the synthesis of building blocks leading to enantiopure drugs. Biores Technol 115:196–207

Narancic T, Radivojevic J, Jovanovic P, Francuski D, Bigovic M, Maslak V, Savic V, Vasiljevic B, O’Connor KE, Nikodinovic-Runic J (2013) Highly efficient Michael-type addition of acetaldehyde to β-nitrostyrenes by whole resting cells of Escherichia coli expressing 4-oxalocrotonate tautomerase. Biores Technol 142:462–468

Radivojevic J, Minovska G, Senerovic L, O’Connor K, Jovanovic P, Savic V, Tokic-Vujosevic Z, Nikodinovic-Runic J, Maslak V (2014) Synthesis of γ-nitroaldehydes containing quaternary carbon in the a-position using a 4-oxalocrotonate tautomerase whole-cell biocatalyst. RSC Advances 4:60502–60510

Sambrook J, Russell WD (2001) Molecular cloning a laboratory manual, vol 3, 3rd edn. Cold Spring Harbour Laboratory Press, Cold Spring Harbour

Zandvoort E, Geertsema EM, Baas BJ, Quax WJ, Poelarends GJ (2012) Bridging between organocatalysis and biocatalysis: asymmetric addition of acetaldehyde to ss-nitrostyrenes catalyzed by a promiscuous proline-based tautomerase. Angew Chem Int Ed 51:1240–1243

Miao Y, Geertsema EM, Tepper PG, Zandvoort E, Poelarends GJ (2013) Promiscuous catalysis of asymmetric Michael-type additions of linear aldehydes to β-nitrostyrene by the proline-based enzyme 4- oxalocrotonate tautomerase. ChemBioChem 14:191–194

He Y-C, Liu F, Zhang D-P, Gao S, Li Z-Q, Tao Z-C, Ma C-L (2015) Biotransformation of 1,3-propanediol cyclic sulfate and its derivatives to diols by toluene-permeabilized cells of Bacillus sp. CCZU11-1. Appl Biochem Biotechnol. doi:10.1007/s12010-12014-11457-12012

Bornscheuer U, Buchholz K (2005) Highlights in biocatalysis—historical landmarks and current trends. Eng Life Sci 5:309–323

Chen XH, Wang XT, Lou WY, Li Y, Wu H, Zong MH, Smith TJ, Chen XD (2012) Immobilization of Acetobacter sp. CCTCC M209061 for efficient asymmetric reduction of ketones and biocatalyst recycling. Microb Cell Factories 11:119

Ban K, Hama S, Nishizuka K, Kaieda M, Matsumoto T, Kondo A, Noda H, Fukuda H (2002) Repeated use of whole-cell biocatalysts immobilized within biomass support particles for biodiesel fuel production. J Mol Cat B Enzymatic 17:157–165

Zajkoska P, Rosenberg M, Heath R, Malone KJ, Stloukal R, Turner NJ, Rebroš M (2015) Immobilised whole-cell recombinant monoamine oxidase biocatalysis. Applied Micro Biotechnol 99:1229–1236

Stark D, Von Stockar U (2003) In situ product removal (ISPR) in whole cell biotechnology during the last twenty years. Adv Biochem Eng Biotechnol 80:149–175

Woodley JM, Bisschops M, Straathof AJJ, Ottens M (2008) Future directions for in situ product removal (ISPR). J Chem Technol Biotechnol 83:121–123

Sardari RR, Dishisha T, Pyo SH, Hatti-Kaul R (2013) Biotransformation of glycerol to 3-hydroxypropionaldehyde: improved production by in situ complexation with bisulfite in a fed-batch mode and separation on anion exchanger. J Biotechnol 168:534–542

Whittall J, Sutton P (eds) (2010) Practical methods for biocatalysis and biotransformations. John Wiley & Sons Ltd, Chichester

Held M, Schmid A, Kohler HP, Suske W, Witholt B, Wubbolts MG (1999) An integrated process for the production of toxic catechols from toxic phenols based on a designer biocatalyst. Biotechnol Bioeng 62:641–648

Wang P, He J-Y, Yin J-F (2015) Enhanced biocatalytic production of l-cysteine by Pseudomonas sp. B-3 with in situ product removal using ion-exchange resin. Bioprocess Biosyst Eng 38:421–428

Acknowledgments

This work was supported by Ministry of Education and Science, Republic of Serbia Grant 173048 and 172049. Authors acknowledge COST Action CM1303.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Djokic, L., Spasic, J., Jeremic, S. et al. Immobilization of Escherichia coli cells expressing 4-oxalocrotonate tautomerase for improved biotransformation of β-nitrostyrene. Bioprocess Biosyst Eng 38, 2389–2395 (2015). https://doi.org/10.1007/s00449-015-1474-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-015-1474-8