Abstract

A novel amidase gene (bami) was cloned from Brevibacterium epidermidis ZJB-07021 by combination of degenerate PCR and high-efficiency thermal asymmetric interlaced PCR (hiTAIL-PCR). The deduced amino acid sequence showed low identity (≤55 %) with other reported amidases. The bami gene was overexpressed in Escherichia coli, and the resultant inclusion bodies were refolded and purified to homogeneity with a recovery of 22.6 %. Bami exhibited a broad substrate spectrum towards aliphatic, aromatic and heterocyclic amides, and showed the highest acyl transfer activity towards butyramide with specific activity of 1331.0 ± 24.0 U mg−1. Kinetic analysis demonstrated that purified Bami exhibited high catalytic efficiency (414.9 mM−1 s−1) for acyl transfer of butyramide, with turnover number (K cat) of 3569.0 s−1. Key parameters including pH, substrate/co-substrate concentration, reaction temperature and catalyst loading were investigated and the Bami showed maximum acyl transfer activity at 50 °C, pH 7.5. Enzymatic catalysis of 200 mM butyramide with 15 μg mL−1 purified Bami was completed in 15 min with a BHA yield of 88.1 % under optimized conditions. The results demonstrated the great potential of Bami for the production of a variety of hydroxamic acids.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Amidases (EC 3.5.1.4) are a class of enzymes catalyzing the hydrolysis of a variety of amides to their corresponding acids and ammonia. Based on their specific amino acid homology, amidases were classified into two families: the amidase signature (AS) family and the nitrilase superfamily [10, 14]. The amidase signature family is characterized by the presence of the GGSSGG motif in a conserved stretch of approximately 130 amino acids [10, 28]. They are widespread in both eukaryotic and prokaryotic organisms. Due to excellent regio-, chemo- and enantioselective properties, AS amidases are increasingly recognized as attractive tools for the preparation of optically active compounds [12, 24, 30, 43]. Although some AS amidases have been cloned and overexpressed in E. coli [11, 23, 39, 41], high-level expression of amidases often leads to formation of insoluble inclusion bodies (IBs) in the cytoplasm [18, 25, 37]. In many cases, optimization of culture conditions, such as temperature, pH and autoinduction media could not eliminate the formation of IBs, and the amidase expression efficiency was unsatisfactory [32, 35, 42]. Therefore, it is necessary to establish an efficient refolding protocol to obtain bioactive amidases.

Besides their amide hydrolysis ability, most amidases were reported to exhibit acyl transfer activity and received great attention for synthesis of pharmaceutically important hydroxamic acids in the recent years [2, 5, 31]. The fatty hydroxamic acids have been studied as inhibitors of cyclooxygenase and 5-lipooxygenase with a potent anti-inflammatory activity, and thus, were recommended for the treatment of ureaplasma and anemia [17, 20]. Butyrylhydroxamic acid (BHA) is an efficient histone deacetylase inhibitor of erythropoiesis and shows great potential for β-chain hemoglobinopathies therapeutics [9]. Moreover, BHA has been proved to be capable to enhance memory in rodent behavioral models and could be further used as a potent memory enhancer and mood stabilizer [13]. Generally, BHA was prepared through chemical route by N-acylation of O-substituted hydroxylamine with butyric acid chloride as substrate [3]. However, it was very difficult to prevent further acylation during the reaction and the yield of BHA was unsatisfactory in most cases.

In our previous study, an amidase-producing strain Brevibacterium epidermidis ZJB-07021 was isolated and characterized [22]. Characterization of the purified amidase from B. epidermidis ZJB-07021 suggested that the enzyme exhibited both hydrolysis and acyl transfer activity, and showed the highest hydrolysis activity of 391.5 ± 2.0 U mg−1 towards butyramide [34]. In this paper, the gene encoding B. epidermidis amidase (bami) was cloned and expressed in E. coli. The refolding, purification and application of Bami in biosynthesis of BHA was investigated.

Materials and methods

Chemicals, strains and plasmids

Brevibacterium epidermidis ZJB-07021 was isolated in our laboratory and deposited at the China Center for Type Culture Collection (CCTCC) under the accession number of CCTCC M207076. E. coli BL21 (DE3) (Novagen, Germany) was used as the host for recombinant protein expression. Plasmid pGEM-T (Promega, USA) and pET-28b(+) (Novagen, Germany) were used as vectors for the cloning and expression, respectively. LA Taq DNA polymerase was purchased from Takara (Dalian, China). Restriction enzymes and T4 DNA ligase were supplied by Thermo scientific Co., Ltd (Shanghai, China). Primer synthesis and DNA sequencing were conducted by Sunny Biological Co., Ltd. (Shanghai China). The DNA gel extraction, plasmid miniprep and PCR cleanup kits were purchased from Axygen (Hangzhou, China). All chemicals used were of analytical grade and commercially available.

Cloning of bami gene from B. epidermidis ZJB-07021

The strategy used for cloning the complete bami gene was illustrated in Fig. 1. A pair of degenerate primers (5′-CGCBDTCCGTCCTCRGCCAATGGCGTC-3′ and 5′-GTCYGTGACCTGCTGYAAGNCGTGAC-3′) were used to clone the partial fragment of bami from the genomic DNA of B. epidermidis ZJB-07021. Degenerate primers were designed according to the partial amino acid sequence of purified Bami identified by MALDI-TOF/TOF–MS (RLPSSANGVTGLKPTWGRV), and the conserved fragment was obtained by alignment and comparative analysis of several amidase sequences from Brevibacterium sp. (VLAAGHAFQQVTD). The PCR products were cloned into pGEM-T and sequenced. To amplify the flanking fragments of the bami, high-efficiency thermal asymmetric interlaced PCR (hiTAIL-PCR) was applied according to Liu et al. [26]. The primers used in hiTAIL-PCR were listed in Table 1. The PCR products were purified and cloned into pGEM-T and sequenced.

Cloning strategy for full-length bami gene. The specific primers bami-50, 51, 52 and bami-30, 31, 32 were designed according to the known 783-bp partial bami gene. The primers LAD and AC1 were designed according to Liu et al. [26], which were universally applicable for various organisms

The full-length bami was amplified by PCR using the specific primers bami-F (5′-CATGCCATGGGCATGCAGGGAGGCATGATGACCACAC-3′) and bami-R (5′-CGGGATCCTCAGAGCCCGGCCGGGTGGCTGGT-3′), which contained artificial NcoI and BamHI restriction enzyme sites (underlined). The amplified fragment with the expected size was purified and double-digested with NcoI and BamHI, and then inserted into NcoI-BamHI-digested pET-28b(+). The resultant recombinant plasmid pET28b-bami was transformed into E. coli BL21 (DE3) competent cells, and spread onto solid Luria–Bertani (LB) medium supplemented with 50 μg mL−1 kanamycin. The positive clones were confirmed by DNA sequencing.

Expression of recombinant amidase and isolation of IBs

The positive colonies were grown at 37 °C in Luria–Bertani (LB) medium containing 50 μg mL−1 kanamycin. When the optical density at 600 nm reached 0.6, isopropyl-β-D-thiogalactopyranoside (IPTG) (final concentration of 0.1 mM) was added and the cells were grown at 28 °C for another 8 h. The resultant cells (1 L) were harvested by centrifugation at 9000×g, 4 °C for 10 min. The cell pellet was resuspended in Tris–HCl buffer (100 mM, pH 7.5), and disrupted by ultrasonication (200 W, pulse 1 s, pause 1 s) for 20 min at 4 °C. Sonicated cells were centrifuged at 14,000×g, 4 °C for 10 min and the pellet containing recombinant amidase as IBs was separated. To remove contaminating membrane proteins, pellets were further washed twice at 4 °C with wash buffer composed of 100 mM Tris–HCl, pH 7.5, 2 M urea, 50 mM NaCl and 2 % (v/v) Triton X-100. The washed IBs were harvested by centrifugation at 9000×g, 4 °C for 10 min, and used for solubilization and refolding.

Solubilization and refolding of amidase from IBs

The washed IBs were solubilized in 5 mL Tris–HCl buffer (100 mM, pH 7.5) containing 8 M urea, 50 mM NaCl, 5 mM dithiothreitol (DTT) and kept for 4 h at room temperature. Solubilized amidase was centrifuged at 14,000×g, 4 °C for 20 min and the supernatant was filtered through 0.22 μm filter (Millipore, USA). Refolding was performed by step-wise dialysis against refolding buffer (100 mM Tris–HCl, pH 7.5, 50 mM NaCl, 1 mM DTT) containing 6, 4, 2 and 0.5 M urea, respectively. Refolding proceeded for approximately 36 h at 4 °C (without stirring). Refolded sample was centrifuged at 14,000×g, 4 °C for 20 min, and the supernatant was pooled and used for purification.

Purification of refolded recombinant amidase

Refolded recombinant amidase was applied to a DEAE anion ion-exchange column (1.5 × 20 cm, Bio-Rad laboratories, USA) previously equilibrated with Tris–HCl buffer (100 mM, pH 7.5). After washing, elution was carried out using a linear gradient of NaCl (0–1.0 M) in Tris–HCl buffer (100 mM, pH 7.5) at a flow rate of 1 mL min−1. The active fractions were eluted at a conductivity of 50–58 mS cm−1, dialyzed against Tris–HCl buffer (100 mM, pH 7.5) at 4 °C for 24 h, and analyzed by 12 % SDS polyacrylamide gel electrophoresis (SDS-PAGE). Protein concentration was determined by Bradford method using bovine serum albumin (BSA) as the standard [7].

Acyl transfer reaction and amidase activity assay

Acyl transfer activity of Bami was determined according to the method developed by Brammar and Clarke [8]. The standard reaction mixture (l mL) comprised 690 μL Tris–HCl buffer (100 mM, pH 7.5), 100 μL butyramide solution [1.0 M in Tris–HCl buffer (100 mM, pH 7.5)], 200 μL hydroxylamide hydrochloride solution (5.0 M, pH was adjusted to 7.5 with 10 M NaOH) and 10 μL diluted refolded Bami. The reaction was carried out at 50 °C, unless otherwise stated. Aliquots (1 mL) of reaction mixture was stopped at regular intervals and mixed with 2 mL of acidic FeCl3 solution (356 mM FeCl3 in 0.65 M HCl). The formation of BHA/Fe(III) complex was determined spectrophotometrically at 500 nm. One unit of acyl transfer activity was defined as the amount of enzyme that catalyzed the production of 1 μmol BHA per min.

Analytical methods

The molar extinction coefficient (ɛ M) of BHA/Fe(III) complex was determined spectrophotometrically at 500 nm. To form a BHA/Fe(III) complex, 2 mL of FeCl3 solution was added into 1 mL aqueous BHA solution with concentrations from 0.5 to 2.0 mM. The ɛ M of BHA/Fe(III) was determined from the slope of a calibration curve. The concentration of BHA, butyramide and butyric acid in the reaction mixture was determined by Agilent 6890 N GC system equipped with a capillary column AT-FFAP (0.25 mm ID × 30 m, 0.33 μm film thickness) and a FID detector with N2 as carrier gas. The flow rate of carrier gas was 1.0 mL min−1, and the temperatures of the oven, injector and detector were set at 170, 250 and 250 °C, respectively. The retention times of BHA, butyric acid and butyramide were 2.4, 3.0, and 5.2 min, respectively.

Effects of pH and temperature on Bami activity

To investigate the pH dependency of acyl transfer reaction, Bami activity was determined at various pHs (4.0–10.0) with Citric acid–Sodium citrate buffer (4.0–6.0), Na2HPO4–NaH2PO4 buffer (6.0–7.5), Tris–HCl buffer (7.0–8.5) and Glycine–NaOH buffer (8.5–10.0). The optimal reaction temperature was determined under the standard conditions at various temperatures (20–60 °C).

Substrate specificity of Bami and bi-substrate kinetic analysis

To examine substrate specificity of the acyl transfer activity of recombinant Bami, various aliphatic, aromatic and heterocyclic amides were tested as substrates (final concentration 10 mM).

For kinetic analysis, enzyme assays were carried out under the standard assay conditions. The concentration of butyramide was varied from 2 to 10 mM at different hydroxylamine hydrochloride concentrations ranging from 40 to 200 mM. The kinetic parameters were calculated from the initial-velocity double-reciprocal plot.

Bioprocess development for the production of BHA

To work out the optimal combination of the substrate and co-substrate, the reactions were carried out with butyramide concentrations from 50 to 500 mM and hydroxylamine hydrochloride concentrations ranging from 100 to 1000 mM. To obtain high yield of BHA, time course of the bioprocess at different temperatures (30, 40, and 50 °C) was investigated. Samples were withdrawn at regular intervals to monitor the progress of the reaction. The influence of Bami loading on the formation of BHA was also examined. Varied amounts of purified Bami (5, 10, 15 μg mL−1) were used to study optimum enzyme concentration for high conversion.

Nucleotide sequence accession number

The nucleotide sequence of the gene encoding Bami from B. epidermidis ZJB-07021 was available from GenBank under Accession Number KT807799.

Results

Cloning of bami gene from B. epidermidis ZJB-07021

A 783-bp fragment was amplified from B. epidermidis ZJB-07021 genomic DNA by PCR with the degenerate primers, designed on the basis of the amidase amino acid sequences obtained from MALDI-TOF/TOF–MS and conserved fragment of Brevibacterium sp. amidases. Amplification of unknown flanking regions of the bami gene by hiTAIL-PCR, a 3225-bp amplicon was obtained by assembling partial and flanking fragments. Nucleotide sequence analysis showed that the full-length bami gene consisted of an open reading frame (ORF) of 1410 bp, coding for a protein of 469 amino acids with a calculated isoelectric point of pH 4.98 and molecular mass of 49,574 Da. Based on the deduced amino acid sequence analysis, Bami was classified into the AS family of amidase. In the region located seven nucleotides upstream of the start codon atg, a putative ribosome-binding site (GGAG) was detected. Moreover, the sequence of 19 amino acids obtained by MALDI-TOF/TOF–MS was also involved in the deduced amino acid sequence.

Expression, refolding and purification of Bami

As shown in Fig. 2a, recombinant Bami was not observed in soluble fractions (lane 2) but only in the insoluble IBs (lane 3). Although efforts towards soluble expression were made through optimization of expression conditions (e.g., expression plasmid, induction temperature, IPTG concentration and induction time) (data not shown), most of recombinant Bami still accumulated as IBs. Therefore, insoluble aggregate of the IBs was renatured and applied to a DEAE anion ion-exchange column. As illustrated in Fig. 2b, a single band corresponding to the molecular mass of about 50 kDa was obtained, which was in accordance with the predicted molecular mass of Bami. Approximately, 56.6 mg of purified active Bami was recovered from 1 L culture broth. The overall yield of purified refolded Bami from the IBs was about 22.6 % (Table 2).

SDS-PAGE analysis of expression and purification of recombinant Bami from E. coli IBs. Samples were analyzed on 12 % SDS polyacrylamide gel. Lane M, low molecular weight marker proteins in a and b. a SDS-PAGE analysis of recombinant Bami. Lane 1 the cell lysate of uninduced recombinant strain; Lane 2 soluble extract of induced recombinant strain; Lane 3 insoluble fraction of induced recombinant strain. b SDS-PAGE analysis of the refolding and purification of IBs. Lane 1 the precipitate of IBs; Lane 2 the refolded Bami; Lane 3 eluted fraction of Bami from DEAE chromatography

Effects of pH and temperature on acyl transfer activity

To quantify BHA formed in the acyl transfer activity, the molar extinction coefficient (ɛ M) of BHA/Fe(III) complex of 10.16 × 102 L mol−1 cm−1 was calculated from the slope of calibration curve.

The effect of pH on Bami-mediated acyl transfer reaction was tested at various pHs (4.0–10.0). Figure 3a revealed that Bami showed maximum activity at pH 7.5 in 100 mM Tris–HCl buffer. The effect of temperature on acyl transfer activity was studied from 20 to 60 °C. As presented in Fig. 3b, the highest acyl transfer activity of 1370.7 ± 55.5 U mg−1 was observed at 50 °C and the enzymatic activity was then rapidly dropped with further increase of temperature. In comparison, Bami showed highest hydrolysis activity at 40 °C.

Effects of pH and temperature on amidase. a Optimal pH for acyl transfer activity. The enzyme activity was determined in different buffer systems at various pH values by the standard assay method. b Optimal temperature for hydrolysis and acyl transfer activity. The enzyme activity was determined at different temperatures by the standard assay method. All activities were measured in three separate experiments and expressed as means ± standard deviations

Substrate specificity and kinetic parameters

The substrate spectrum of acyl transfer activity of Bami was investigated. As summarized in Table 3, Bami showed acyl transfer activity towards a broad spectrum of aliphatic, aromatic and heterocyclic amides. For linear aliphatic monoamides, the increase in carbon chain length led to a considerable increase of Bami acyl transfer activity. The highest activity was observed with butyramide as substrate and the specific activity decreased progressively towards propionamide, acetamide and formamide. Although Bami exhibited moderate activity towards nicotinamide and isonicotinamide, surprisingly no activity was observed for 2-, 5-, and 6-chloride-substituted nicotinamides.

The kinetic parameters of Bami were determined from the initial-velocity double-reciprocal plots. As shown in Fig. 4, the acyl transfer reaction was catalyzed by the Ping-Pong Bi–Bi mechanism [16]. V max, Km amide and \(Km_{{{\text{NH}}_{ 2} {\text{OH}}}}\) values were calculated as 4322.7 μM min−1 mg−1, 8.6 mM and 128.5 mM, respectively. Its turnover number (K cat) and catalytic efficiency (K cat/Km amide, K cat/\(Km_{{{\text{NH}}_{ 2} {\text{OH}}}}\)) were 3569.0 s−1, 414.9 mM−1 s−1 and 27.9 mM−1 s−1, respectively. The Bami exhibited 15.6 times higher K cat value for butyramide and hydroxylamine than the amidase from Rhodococcus sp. R312 (229 s−1) [16].

Reciprocal plots obtained from a series of concentration of hydroxylamine and butyramide. a 1/v versus 1/[Butyramide] at different hydroxylamine concentrations. Symbols: 40 mM (filled square); 50 mM (open square); 66.6 mM (filled circle); 100 mM (open circle); 200 mM (filled triangle). b 1/v-axis intercept replot

Bioprocess development for the production of BHA

As Bami showed different Km values for butyramide and hydroxylamine, the effect of substrate/co-substrate ratio on the reaction was studied. The highest activity of 1706.5 ± 42.7 U mg−1 was detected with the reaction mixture composed of 200 mM butyramide and 500 mM hydroxylamine hydrochloride (Fig. 5). Therefore, a substrate/co-substrate ratio of 2:5 was adopted for the following study.

Optimization of the combination of substrates. The concentration of butyramide was varied from 50 to 500 mM. Concentration of hydroxylamine hydrochloride: 100 mM (filled square); 250 mM (open square); 500 mM (filled circle); 750 mM (open circle); 1000 mM (filled triangle). The enzyme activity was determined in pH 7.5 Tris–HCl buffer at 50 °C. All activities were measured in three separate experiments and expressed as means ± standard deviations

Temperature is one of the most important factors controlling biochemical reactions. As shown in Fig. 6, the concentration of BHA reached 169.7 mM with the highest conversion of 84.9 % at 50 °C, while it decreased significantly when the reaction was performed at 30 and 40 °C. In addition, the by-product butyric acid was remarkably accumulated under lower reaction temperatures compared to the biotransformation performed at 50 °C. Therefore, the temperature of 50 °C was adopted as the operating temperature in the study.

The concentration of butyrylhydroxamic acid formed at different temperatures. Reaction conditions: 100 mM pH 7.5 Tris–HCl buffer, butyramide (200 mM), hydroxylamine (500 mM), 10 μg mL−1 purified Bami. Butyrylhydroxamic acid at 30 °C (filled square), 40 °C (filled circle), 50 °C (filled triangle), butyric acid at 30 °C (open square), 40 °C (open circle), 50 °C (open triangle). All activities were measured in three separate experiments and expressed as means ± standard deviations

The influence of Bami loading on the production of BHA was also examined. As shown in Fig. 7, the yield of BHA was improved apparently with the increase of Bami concentration from 5 to 10 μg mL−1 in the reaction mixture. However, at 15 μg mL−1 concentration, maximum yield 87.5 % was obtained in 15 min, which was slightly higher than that of 84.9 % achieved at 10 μg mL−1 in 20 min. This indicated that the additional biocatalyst could not improve the conversion drastically. To obtain higher yield of BHA, 15 μg mL−1 purified Bami was selected as the optimal amount of catalyst in this study.

The concentration of butyrylhydroxamic acid formed with different biocatalyst loadings. Reaction conditions: 100 mM pH 7.5 Tris–HCl buffer, butyramide (200 mM), hydroxylamine (500 mM), 50 °C. Butyrylhydroxamic acid formed with 5 μg mL−1 (filled square), 10 μg mL−1 (filled circle), 15 μg mL−1 (filled triangle) Bami, butyric acid formed with 5 μg mL−1 (open square), 10 μg mL−1 (open circle), 15 μg mL−1 (open triangle) Bami. All activities were measured in three separate experiments and expressed as means ± standard deviations

To further evaluate the potential of the bioprocess for practical use, a 100 mL reaction was carried out in a 200 mL stirred-tank reactor. Under the condition of substrate/co-substrate ratio 2:5, pH 7.5 (100 mM Tris–HCl buffer), temperature 50 °C and purified refolded Bami loading 15 μg mL−1, a BHA yield of 88.1 % was achieved from 200 mM butyramide within 15 min.

Discussion

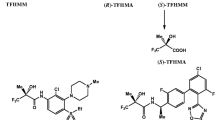

In this study, a novel amidase gene was cloned from B. epidermidis ZJB-07021 which was previously isolated in our laboratory. Taking advantage of amino acid sequence of the peptide fragment identified by MALDI-TOF/TOF–MS and the conserved sequence of Brevibacterium sp. amidases, a 783-bp fragment was amplified by PCR, and the sequenced fragment was further utilized with the hiTAIL-PCR strategy to amplify the complete bami gene. A homology search of NCBI database revealed that Bami exhibited a low sequence identity with other reported amidases. The most related proteins were D-amino acid amidase from D. acidovorans (GenBank Accession No: BAE87102) [21], D-amidase from V. paradoxus (GenBank Accession No: CAE06273) [25] and R-amidase from C. acidovorans KPO-2771-4 (GenBank Accession No: E12107) [19], which shared 52–55 % of identity with Bami. Interestingly, all of them exhibited R-stereospecificity. As shown in Fig. 8, the alignment of the four R-amidases revealed that they formed a sub-family which shared G(A, V) SSSG (residues 156–161), a slight deviation from the characteristic motif of the AS family (GGSSGG) found in other enzymes. In addition, the R-amidases shared some other conserved regions, including LHGVPXAXKDL (residues 77–87), GXDTGGSIR (residues 176–184) and KPTWGRVSRHG (residues 196–206). The putative catalytic triad of K85-S158-S182 was also involved in the conserved regions.

Multiple alignment of the amino acid sequences of Bami and other R-stereospecificity amidases. Abbreviations: Bami, R-stereoselective amidase from B. epidermidis ZJB-07021 (GenBank Accession No: KT807799); Dami, D-amino-acid amidase from D. acidovorans (GenBank Accession No: BAE87102); Vami, D-amidase from V. paradoxus (GenBank Accession No: CAE06273); Cami, R-enantioselective amidase from C. acidovorans KPO-2771-4 (GenBank Accession No: E12107). The putative catalytic triad K-S-S was annotated with filled circles. The framed region represented the corresponding sequences obtained from MALDI-TOF/TOF–MS

Most of the recombinant Bami was overexpressed as insoluble IBs, which were devoid of biological activity, and therefore, solubilization and mild refolding to recover the desired enzyme was necessary. The IBs showed unique characteristics of high expression of protein, resistance to protease attack and simple purification procedure of the denatured protein [29]. However, one of the key issues for making full use of the IBs was to develop a refolding procedure with an ideal yield. In the current work, the IBs of Bami were firstly purified by detergent washing and then solubilized with 8 M urea solution. Combined with an efficient refolding method and one-step purification, 22.6 % of IBs was refolded into bioactive amidase. The yield of Bami (56.6 mg purified Bami from 1 L culture) was much higher than the final yield of Sulfolobus tokodaii strain 7 amidase (6.3 mg from 1 L culture) processed with another folding procedure [38].

The optimal pH of the recombinant Bami was similar to most of the reported amidases [1, 4, 33], which showed the maximum acyl transfer activity around neutral pH. It has been proved that both amidase-catalyzed hydrolysis and acyl transfer reactions shared the same mechanism [27]. However, the reaction temperature had different effects on Bami-catalyzed hydrolysis and activity. The Bami showed the maximum acyl transfer activity at 50 °C, whereas its hydrolysis activity was hardly detected at the same temperature. Hydroxylamine is a better acyl acceptor than water, and the acyl transfer reaction with hydroxylamine proceeds faster than the hydrolysis of the same substrate [14]. Hydrolysis activity might be more dependent on the stable conformation of the active pocket of amidase using water as acceptor, and was prone to be inactive at high temperature. This characteristic of Bami was employed to reduce the formation of by-product butyric acid, resulting in a higher yield of BHA. Several bioprocesses for the synthesis of hydroxamic acid were summarized in Table 4. Interestingly, high yields (>90 %) of hydroxamic acids were usually obtained at high temperatures (>45 °C), which verified the conclusion that hydrolysis activity of amidase was more sensitive to high temperature compared with acyl transfer activity. It was reported that linear molecules were preferred substrate for acyl transfer reaction while bulky side-chain-containing amides exhibited close Kcathydrolysis and Kcatacyl transfer values [16]. In this paper, it was also observed that butyramide (linear molecule) was hydrolyzed more slowly compared to its acyl transfer reaction under the same conditions (<40 °C). In addition, the substrate specificity study indicated that Bami had potential applications for the production of various high-value hydroxamic acids.

The biosynthesis of BHA from butyramide was studied using the purified recombinant Bami. To our knowledge, molar ratio of substrate and co-substrate was a crucial parameter for higher yield in enzymatic synthesis of hydroxamic acid. A 2:5 molar ratio of butyramide to hydroxylamine was selected so that acyl group of amide was transferred more efficiently to hydroxylamine, leading to the formation of corresponding hydroxamic acid [15]. It was also observed that the increased concentration of butyramide and hydroxylamine resulted in substrate inhibition, which was similar to amidase from Alcaligenes sp. MTCC 10674 [5] and Bacillus smithii strain IITR6b2 [2]. There were several undesirable reactions accompanying the biosynthesis of hydroxamic acids from amides, and by-products would be irreversibly produced by the initial amides hydrolysis and final hydroxamic acids hydrolysis [16]. In this study, both of the undesirable hydrolysis reactions were evidently observed at 30 and 40 °C (Fig. 6). However, the by-product formation by Bami was significantly relieved at 50 °C as compared to lower temperatures, and the by-product concentration did not increase as the reaction proceeded. It was probably caused by the inactivation of amidase hydrolysis activity ahead of acyl transfer activity with increase of temperature.

In this paper, the sequence of the R-amidase gene from B. epidermidis ZJB-07021 has been elucidated by the hiTAIL-PCR approach. After assembling partial and flanking fragments, the complete gene was cloned from genomic DNA and transferred into E. coli. The strategies for heterologous expression, refolding and purification of the Bami were established successfully. An efficient biocatalytic process for the synthesis of BHA by the Bami was also developed with high conversion in a short period of reaction time. Increase of temperature was observed to prevent the undesired hydrolysis reactions while had no effect on the acyl transfer activity. These unique characteristics, together with the broad substrate spectrum, make Bami a potential catalyst for the production of BHA and other valuable hydroxamic acids.

References

Agarwal S, Choudhury B (2014) Presence of multiple acyltransferases with diverse substrate specificity in Bacillus smithii strain IITR6b2 and characterization of unique acyltransferase with nicotinamide. J Mol Catal B Enzym 107:64–72. doi:10.1016/j.molcatb.2014.05.017

Agarwal S, Gupta M, Choudhury B (2013) Bioprocess development for nicotinic acid hydroxamate synthesis by acyltransferase activity of Bacillus smithii strain IITR6b2. J Ind Microbiol Biotechnol 40:937–946. doi:10.1007/s10295-013-1299-x

Ando W, Tsumaki H (1983) A facile preparation of aliphatic hydroxamic acid from N,N,O-tris (trimethylsilyl) hydroxylamine and acid chloride. Synthetic Commun 13:1053–1056. doi:10.1080/00397918308082726

Bhatia RK, Bhatia SK, Kumar V, Bhalla TC (2015) Bi-substrate kinetic analysis of acyl transfer activity of purified amidase from Pseudomonas putida BR-1. Catal Lett 145:1033–1040. doi:10.1007/s10562-014-1467-2

Bhatia RK, Bhatia SK, Mehta PK, Bhalla TC (2013) Bench scale production of benzohydroxamic acid using acyl transfer activity of amidase from Alcaligenes sp. MTCC 10674. J Ind Microbiol Biotechnol 40:21–27. doi:10.1007/s10295-012-1206-x

Bhatia RK, Bhatia SK, Mehta PK, Bhalla TC (2014) Biotransformation of nicotinamide to nicotinyl hydroxamic acid at bench scale by amidase acyl transfer activity of Pseudomonas putida BR-1. J Mol Catal B Enzym 108:89–95. doi:10.1016/j.molcatb.2014.07.001

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. doi:10.1016/0003-2697(76)90527-3

Brammar WJ, Clarke PH (1964) Induction and repression of Pseudomonas aeruginosa amidase. J Gen Microbiol 37:307–319. doi:10.1099/00221287-37-3-307

Cao H, Jung M, Stamatoyannopoulos G (2005) Hydroxamide derivatives of short-chain fatty acid have erythropoietic activity and induce γ gene expression in vivo. Exp Hematol 33:1443–1449. doi:10.1016/j.exphem.2005.08.007

Chebrou H, Bigey F, Arnaud A, Galzy P (1996) Study of the amidase signature group. BBA-Protein Struct Mol Enzymol 1298:285–293. doi:10.1016/S0167-4838(96)00145-8

Cheong TK, Oriel PJ (2000) Cloning of a wide-spectrum amidase from Bacillus stearothermophilus BR388 in Escherichia coli and marked enhancement of amidase expression using directed evolution. Enzyme Microb Technol 26:152–158. doi:10.1016/S0141-0229(99)00150-7

Egorova K, Trauthwein H, Verseck S, Antranikian G (2004) Purification and properties of an enantioselective and thermoactive amidase from the thermophilic actinomycete Pseudonocardia thermophila. Appl Microbiol Biotechnol 65:38–45. doi:10.1007/s00253-004-1607-5

Fass DM, Shah R, Ghosh B, Hennig K, Norton S, Zhao WN, Reis SA, Klein PS, Mazitschek R, Maglathlin RL, Lewis TA, Haggarty SJ (2010) Short-Chain HDAC inhibitors differentially affect vertebrate development and neuronal chromatin. ACS Med Chem Lett 2:39–42. doi:10.1021/ml1001954

Fournand D, Arnaud A (2001) Aliphatic and enantioselective amidases: from hydrolysis to acyl transfer activity. J Appl Microbiol 91:381–393. doi:10.1046/j.1365-2672.2001.01378.x

Fournand D, Arnaud A, Galzy P (1998) Study of the acyl transfer activity of a recombinant amidase overproduced in an Escherichia coli strain. Application for short-chain hydroxamic acid and acid hydrazide synthesis. J Mol Catal B Enzym 4:77–90. doi:10.1016/S1381-1177(97)00024-6

Fournand D, Bigey F, Arnaud A (1998) Acyl transfer activity of an amidase from Rhodococcus sp. strain R312: formation of a wide range of hydroxamic acids. Appl Environ Microbiol 64:2844–2852

Gao WY, Mitsuya H, Driscoll JS, Johns DG (1995) Enhancement by hydroxyurea of the anti-human immunodeficiency virus type 1 potency of 2-β-fluoro-2′,3′-dideoxyadenosine in peripheral blood mononuclear cells. Biochem Pharmacol 50:274–276. doi:10.1016/0006-2952(95)00106-A

Guo FM, Wu JP, Yang LR, Xu G (2015) Soluble and functional expression of a recombinant enantioselective amidase from Klebsiella oxytoca KCTC 1686 in Escherichia coli and its biochemical characterisation. Process Biochem 50:1264–1271. doi:10.1016/j.procbio.2015.05.005

Hayashi T, Yamamoto K, Matsuo A, Otsubo K, Muramatsu S, Matsuda A, Komatsu KI (1997) Characterization and cloning of an enantioselective amidase from Comamonas acidovorans KPO-2771-4. J Ferment Bioeng 83:139–145. doi:10.1016/S0922-338X(97)83572-6

Holmes LB (1996) Hydroxamic acid: a potential human teratogen that could be recommended to treat ureaplasma. Teratology 53:227–229. doi:10.1002/(SICI)1096-9926(199604)53:4<227::AID-TERA4>3.0.CO;2-#

Hongpattarakere T, Komeda H, Asano Y (2005) Purification, characterization, gene cloning and nucleotide sequencing of D-stereospecific amino acid amidase from soil bacterium: Delftia acidovorans. J Ind Microbiol Biotechnol 32:567–576. doi:10.1007/s10295-005-0246-x

Jin SJ, Zheng RC, Zheng YG, Shen YC (2008) R-enantioselective hydrolysis of 2,2-dimethylcyclopropanecarboxamide by amidase from a newly isolated strain Brevibacterium epidermidis ZJB-07021. J Appl Microbiol 105:1150–1157. doi:10.1111/j.1365-2672.2008.03841.x

Komeda H, Asano Y (2000) Gene cloning, nucleotide sequencing, and purification and characterization of the D-stereospecific amino-acid amidase from Ochrobactrum anthropi SV3. Eur J Biochem 267:2028–2035. doi:10.1046/j.1432-1327.2000.01208.x

Krieg L, Ansorge-Schumacher MB, Kula MR (2002) Screening for amidases: isolation and characterization of a novel D-amidase from Variovorax paradoxus. Adv Synth Catal 344:965–973. doi:10.1002/1615-4169(200210)344:9<965:AID-ADSC965>3.0.CO;2-Z

Krieg L, Slusarczyk H, Verseck S, Kula MR (2005) Identification and characterization of a novel D-amidase gene from Variovorax paradoxus and its expression in Escherichia coli. Appl Microbiol Biotechnol 66:542–550. doi:10.1007/s00253-004-1716-1

Liu YG, Chen YL (2007) High-efficiency thermal asymmetric interlaced PCR for amplification of unknown flanking sequences. Biotechniques 43:649–656. doi:10.2144/000112601

Maestracci M, Thiery A, Arnaud A, Galzy P (1986) A study of the mechanism of the reactions catalyzed by the amidase Brevibacterium sp. R312. Agric Biol Chem 50:2237–2241. doi:10.1080/00021369.1986.10867736

Mayaux JF, Cerebelaud E, Soubrier F, Faucher D, Petre D (1990) Purification, cloning, and primary structure of an enantiomer-selective amidase from Brevibacterium sp. strain R312: structural evidence for genetic coupling with nitrile hydratase. J Bacteriol 172:6764–6773

Nahálka J, Mislovičová D, Kavcová H (2009) Targeting lectin activity into inclusion bodies for the characterisation of glycoproteins. Mol BioSyst 5:819–821. doi:10.1039/B900526A

Nojiri M, Taoka N, Yasohara Y (2014) Characterization of an enantioselective amidase from Cupriavidus sp. KNK-J915 (FERM BP-10739) useful for enzymatic resolution of racemic 3-piperidinecarboxamide. J Mol Catal B Enzym 109:136–142. doi:10.1016/j.molcatb.2014.08.016

Pandey D, Singh R, Chand D (2011) An improved bioprocess for synthesis of acetohydroxamic acid using DTT (dithiothreitol) treated resting cells of Bacillus sp. APB-6. Bioresour Technol 102:6579–6586. doi:10.1016/j.biortech.2011.03.071

Park HJ, Uhm KN, Kim HK (2008) R-stereoselective amidase from Rhodococcus erythropolis No. 7 acting on 4-chloro-3-hydroxybutyramide. J Microbiol Biotechnol 18:552–559

Ravi Kant B, Shashi Kant B, Praveen Kumar M, Tek Chand B (2013) Production and characterization of acyl transfer activity of amidase from Alcaligenes sp. MTCC 10674 for synthesis of hydroxamic acids. J Microb Biochem Technol 5:001–005. doi:10.4172/1948-5948.1000090

Ruan LT, Zheng RC, Zheng YG, Shen YC (2016) Purification and characterization of R-stereospecific amidase from Brevibacterium epidermidis ZJB-07021. Int J Biol Macromol 86:893–900. doi:10.1016/j.ijbiomac.2016.02.020

Sahdev S, Khattar SK, Saini KS (2008) Production of active eukaryotic proteins through bacterial expression systems: a review of the existing biotechnology strategies. Mol Cell Biochem 307:249–264. doi:10.1007/s11010-007-9603-6

Sharma M, Sharma NN, Bhalla TC (2012) Biotransformation of acetamide to acetohydroxamic acid at bench scale using acyl transferase activity of amidase of Geobacillus pallidus BTP-5x MTCC 9225. Indian J Microbiol 52:76–82. doi:10.1007/s12088-011-0211-5

Shen W, Chen H, Jia K, Ni J, Yan X, Li S (2012) Cloning and characterization of a novel amidase from Paracoccus sp. M-1, showing aryl acylamidase and acyl transferase activities. Appl Microbiol Biotechnol 94:1007–1018. doi:10.1007/s00253-011-3704-6

Suzuki Y, Ohta H (2006) Identification of a thermostable and enantioselective amidase from the thermoacidophilic archaeon Sulfolobus tokodaii strain 7. Protein Expr Purif 45:368–373. doi:10.1016/j.pep.2005.06.017

Trott S, Bürger S, Calaminus C, Stolz A (2002) Cloning and heterologous expression of an enantioselective amidase from Rhodococcus erythropolis strain MP50. Appl Environ Microbiol 68:3279–3286. doi:10.1128/aem.68.7.3279-3286.2002

Vejvoda V, Martínková L, Veselá AB, Kaplan O, Lutz-Wahl S, Fischer L, Uhnáková B (2011) Biotransformation of nitriles to hydroxamic acids via a nitrile hydratase-amidase cascade reaction. J Mol Catal B Enzym 71:51–55. doi:10.1016/j.molcatb.2011.03.008

Wu ZM, Zheng RC, Zheng YG (2016) Exploitation and characterization of three versatile amidase super family members from Delftia tsuruhatensis ZJB-05174. Enzym Microb Technol 86:93–102. doi:10.1016/j.enzmictec.2016.02.002

Xue Z, Chao Y, Wang D, Wang M, Qian S (2011) Overexpression of a recombinant amidase in a complex auto-inducing culture: purification, biochemical characterization, and regio-and stereoselectivity. J Ind Microbiol Biotechnol 38:1931–1938. doi:10.1007/s10295-011-0979-7

Zheng RC, Wang YS, Liu ZQ, Xing LY, Zheng YG, Shen YC (2007) Isolation and characterization of Delftia tsuruhatensis ZJB-05174, capable of R-enantioselective degradation of 2,2-dimethylcyclopropanecarboxamide. Res Microbiol 158:258–264. doi:10.1016/j.resmic.2006.12.007

Acknowledgments

This work was supported by the National Nature Science Foundation of China (No. 21202150), National Science Foundation of Zhejiang (Y4080334, LY13B060004) and National High Technology Research and Development Program of China (No. 2012AA022201B).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ruan, LT., Zheng, RC. & Zheng, YG. A novel amidase from Brevibacterium epidermidis ZJB-07021: gene cloning, refolding and application in butyrylhydroxamic acid synthesis. J Ind Microbiol Biotechnol 43, 1071–1083 (2016). https://doi.org/10.1007/s10295-016-1786-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-016-1786-y