Abstract

Plastic accumulation has become a serious environmental threat. Mitigation of plastic is important to save the ecosystem of our planet. With current research being focused on microbial degradation of plastics, microbes with the potential to degrade polyethylene were isolated in this study. In vitro studies were performed to define the correlation between the degrading capability of the isolates and laccase, a common oxidase enzyme. Instrumental analyses were used to evaluate morphological and chemical modifications in polyethylene, which demonstrated a steady onset of the degradation process in case of both isolates, Pseudomonas aeruginosa O1-P and Bacillus cereus O2-B. To understand the efficiency of laccase in degrading other common polymers, in silico approach was employed, for which 3D structures of laccase in both the isolates were constructed via homology modeling and molecular docking was performed, revealing that the enzyme laccase can be exploited to degrade a wide range of polymers.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

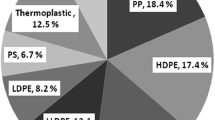

The functioning of our current world relies significantly on plastics. Over the last 50–60 years, other conventional materials have been supplanted by plastics due to their durability. The diversity found in the composition of hydrocarbons has led to the formation of over 20 different types of plastics including, polyethylene (PE), polyurethane (PU), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), polyethylene terephthalate (PET), exhibiting highly versatile properties such as high durability, light-weight and low cost (Sivan 2011). It is the inimitability and the versatility of plastics that have paved the way for their technological and societal benefits in the current “Plastic age” (Thompson et al. 2009).

Globally, plastics are mass-produced in quantities ranging from 350 to 400 million tonnes per year due to their extensive use (Danso et al. 2019). Excessive production and low recycling rates are the main reasons why they have now become a serious threat to the environment (Jaiswal et al. 2020). The extreme resistance of plastics due to their hydrophobic nature is an issue that requires immediate attention. Over a period of time, discarded plastics get broken down into smaller particles ranging around 5 mm due to weathering, UV radiation and the action of waves and winds. These smaller broken-down plastic particles termed as ‘Microplastics’ impose a serious hazardous impact on the entire ecosystem and are categorized as major pollutants on both land and water (Fotopoulou and Karapanagioti 2017; Mohanan et al. 2020). Given these circumstances, it has now become more important than ever to speed up the degrading process of plastics. Extensive studies employing microbes and their enzymes could direct us towards a promising solution.

Current research is centered on determining the ability of bacteria, both individually and in consortia, to break down the long hydrocarbon chain. Various isolates from diversified sources such as contaminated soil and water bodies have been identified to have this degradation ability (Sivan 2011; Gan and Zhang 2019). According to the plastics microbial bio-degradation database (PMBD) around 954 bacterial and fungal isolates have been studied across the globe for their degradation efficiency (Gan and Zhang 2019). Achromobacter sp. (Das et al. 2012), Acinetobacter sp. (Cregut et al. 2013), Alcaligenes sp., Arthrobacter sp., Comamonas acidovorans(Priya et al. 2022), Corynebacterium sp. (Ali et al. 2021), Lysinibacillus sp. (Mukherjee et al. 2016), Microbacterium sp., Micrococcus sp. (Ali et al. 2021), Stenotrophomonas sp. (Dey et al. 2020), Paenibacillus sp. (Bardají et al. 2019) are some of the bacterial species that have been reported to exhibit degradational activity. Among fungal strains, Fusarium sp., Penicillium sp. (Restrepo-Flórez et al. 2014), Rhizopus sp. (Kumar Sen and Raut 2015), Trametes versicolor (Yang et al. 2014), Trichoderma sp. (Sowmya et al. 2014) were noted to have received attention owing to their degradational ability. However, Acinetobacter sp., Aspergillus niger, Bacillus sp., Pseudomonas sp., Rhodococcus ruber, and Trametes versicolor, are the ones that have been extensively studied.

The secretion of extracellular enzymes and the formation of biofilms, resulting in the structural change of the hydrocarbon chain, have been identified as the primary strategies used by microbes exhibiting degradational activity. It has also been revealed that this degradation process is aided by the involvement of more than one enzyme (Das et al. 2012; Montazer et al. 2020). In recent studies, shreds of evidence have proved that initial oxidation of the hydrocarbon chain is a main requisite for microbes to carry out degradation, which is facilitated by the secretion of these enzymes (Montazer et al. 2020; Restrepo-Flórez et al. 2014).

Hence, in this study, laccase, a highly desired enzyme with multiple industrial applications was chosen to be explored, in order to understand its potential in bio-degradation. Laccase was preferred due to their frequent mentions in the recent metagenomic studies as one of the enzymes being primarily involved in polymer degradation (Purohit et al. 2020). An attempt was made in this study to investigate the relationship between the oxidative enzyme laccase and bio-degradation of polymers. To understand the role of the laccase in in-situ degradation, laccase secreted by the normal flora of the soil such as Bacillus cereus and Pseudomonas aeruginosa were analyzed. With respect to plastic to be treated, polyethylene was preferred for the study owing to its massive production and minimal recycling rates. With almost 47 million tonnes of polyethylene produced every year globally, low density polyethylene (LDPE) accounts to around 55 percent of the total polyethylene produced. Among which only 5% of them undergo recycling, thus, making LDPE the right candidate for the study (https://www.thebusinessresearchcompany.com/report/low-density-polyethylene-global-market-report). In this study, in vitro studies were carried out, where the growth pattern of the microbes along with their degradation potential and the level of secretion of the target enzyme were examined by culturing the isolates in presence of LDPE. In addition, an in silico analysis was also conducted by performing molecular docking for the target enzyme with common polymers to determine the polymer against which the enzyme's degradation potential can be further exploited.

Materials and methods

Screening and isolation

The soil sample was collected from multiple sites in the Municipal garbage dump yard located in Tambaram, a suburb in Chennai, India (12°56′03.8” N, 80°06′03.0” E). The collected soil sample was transferred to the lab in a sterile container which was then used as the source for isolation of bacteria with the potential to degrade plastics. The screening procedure was carried out by weighing 1 g of the collected soil sample and adding it to the 9 mL of Brain Heart Infusion (BHI) broth. This was incubated overnight at 37 °C, 120 rpm to enrich the growth of microbes present. 10 mL of the overnight enriched culture was then used as inoculum in the 90 mL of Mineral salt media, which composed of 0.5 g/L K2HPO4; 0.04 g/L KH2PO4; 0.1 g/L NaCl; 0.002 g/L CaCl2∙2H2O; 0.2 g/L (NH4)2SO4; 0.02 g/L MgSO4∙7H2O; 0.001 g/L FeSO4 with pH adjusted to 7.8 (Bardají et al. 2019). The only carbon source provided in the medium was 1% of low-density polyethylene (LDPE) sheets with dimensions 1 × 1 cm procured from Apollo Plastics, Chennai, India. This experimental set-up was then incubated at 37 °C; 120 rpm for 30 days. During the incubation period, the cultures were then plated onto BHI agar in intervals (7th, 15th and 30th day).

Bacterial identification

The individual colonies observed on the agar plates were the ones that were able to thrive with LDPE as their sole source of carbon. Identification procedures were performed for the isolates that consistently survived until the 30th day of incubation. Individual colonies were streaked on HiCrome Bacillus agar for preliminary identification (Alippi 2019). For identification by MALDI-TOF/MS, pure colonies were submitted, which were processed using Bruker UltrafleXtreme MALDI-TOF/MS. The dried droplet method was used for spotting the sample, where a single colony from the freshly streaked plate was evenly spread onto the MALDI-TOF MS target plate followed by layering the spotted dried culture with 1 µL of the matrix, α- Cyano-4-hydroxycinnamic acid (HCCA) (Avanzi et al. 2017). For confirmation, the isolates were also subjected to 16S rDNA sequencing, which involved amplifying the gene under standard conditions using the universal primers 27F (5'-AGAGTTTGATCCTGGCTCAG-3') and 1492R (5'- TACCTTGTTACGACTT-3') and submitting it in for sequencing. Similarity searches of the nucleotide sequences were performed with BLASTn, a tool provided by the NCBI database to identify highly homologous sequences. Phylogenetic relationship was established between the identified isolates and isolates of the same genera that had been previously reported for their degradational ability. This was accomplished by utilizing MEGA11 (Tamura et al. 2021), where the 16S sequence of each isolates were initially aligned using ClustalW, a package of MEGA11, and then a phylogenetic tree was generated using the Neighbor-Joining statistical approach with 1000 bootstrap replications. The 16S sequences of the obtained isolates were deposited into the GenBank database and assigned an entry number.

Growth kinetics in presence of LDPE

Overnight cultures of the isolates were inoculated in Mineral salt media in an 1:10 ratio and were incubated at 37 °C overnight at 120 rpm in a shaker incubator. The mineral salt media was supplemented with 1% LDPE. Control cultures were maintained where the media was devoid of LDPE. OD measurements at 620 nm were recorded every 24 h using a Thermo Scientific Genesys UV-Visible Spectrophotometer for the isolates grown in the presence and absence of LDPE. This was performed for a period of 2 weeks (Auta et al. 2017).

Qualitative assay for laccase enzyme production

The laccase secretion was assessed by using ABTS [2, 2- azino-bis (3-ethylbenzthiazoline-6-sulfonic acid)] as substrate, which was procured from Sisco Research Laboratories Pvt Ltd, India (Kang et al. 2019). The cell-free supernatant was used as the enzyme source for this experiment, as extracellular enzymes play a key role in reducing the hydrophobicity of the polymers. The isolates were cultured in mineral salt media in the ratio of 1:10 in the presence and absence of LDPE. The samples were collected on the 7th day of their incubation so that the comparison of laccase secretion level remains unskewed by the difference in their growth rate. This time point was chosen as the growth of the isolates grown in the presence and absence of LDPE were on par with each other. The collected samples were centrifuged at 6000 rpm for 10 min. The cell-free supernatant obtained was further used for the assay as the enzyme source (Suzuki et al. 2003). The acquired enzyme source was added to the reaction mixture, which constituted 100 mM of Sodium Acetate Buffer at pH 5, 0.1 M ABTS making up to a total volume of 200 µL. The presence of laccase in the system was assessed visually and was further confirmed by measuring the intensity of green color formation by recording their absorbance at 420 nm (Kang et al. 2019).

Scanning electron microscopy (SEM)

Morphological changes in the surface topography of the microbially treated and untreated LDPE sheets were examined under a Hi-Resolution SEM (Thermo Scientific Apreo S). In order to remove the bacteria that adhered to the sheets, the LDPE sheets to be observed were washed with 70% ethanol and air-dried. This was followed by sputter coating the target with aluminium. Untreated LDPE sheets that served as control were also observed (Saeed et al. 2022; Jeon and Kim 2013; Chatterjee et al. 2010).

Fourier transform infrared spectroscopy (FT-IR)

FT-IR was used to analyze the modifications in the chemical structure of the polymer. Using the IR-Tracer 100 from Shimadzu with Attenuated Total Reflectance (ATR) as the recommended mode of operation, the spectrum was captured between 4000 and 400 cm−1. The untreated and the microbially treated LDPE sheets were submitted for analysis (Bardají et al. 2019).

X-Ray diffraction (XRD)

To compare the level of crystallinity between the treated and untreated samples, an X-ray Diffractometer, Bruker was employed. X-ray diffraction patterns were obtained at a wide-angle operation mode with an angular interval of 2θ from 10° to 100° with an increment of 0.02° per scan. The current and voltage of the X-ray source were set at 40 mA and 40 kV with λ at 1.5418 Å. All the samples were analyzed at room temperature and under standard operating procedures (Mukherjee and Kundu 2014; Esmaeili et al. 2013). The obtained XRD spectra was plotted using OriginPRO 2022b and was further extrapolated to determine the percentage of crystallinity. The percentage of crystallinity of each sample was calculated by the following equation.

where A1, A2 and A3 represents the integrated area of characteristic peak of polyethylene 19, 21 and 23.7 at 2θ. (Maroof et al. 2020).

GC-MS analysis

To understand the intermediates formed during the degradation process, the LDPE sheets were incubated for two weeks with the respective isolates at ambient temperature with continuous shaking. The treated LDPE sheets were subjected to GC-MS analysis with xylene as solvent using Shimadzu, QP2010 Plus. Untreated commercial LDPE sheet was used as a control. The GC-MS was performed with the following parameters: The column flow was set to 1 mL/min and helium was employed as the carrier gas. The oven temperature was maintained at 35 °C, which was then raised to 160 and 300 °C with a holding time of 3 and 5 min respectively. The temperature were raised at the rate of 15 and 5 °C/min. The injection temperature was set at 300 °C while the pressure was maintained at 47.6 kPa (Shahnawaz et al. 2016; Sumathi et al. 2016). The degradation products were identified based on their mass spectra and retention times and by comparing the key relevant peaks with the NIST 14s and the Wiley 8 database.

Modeling and validation of protein structure

Homology modelling was performed to generate 3D models for the enzyme laccase from Bacillus cereus and Pseudomonas aeruginosa, due to their unavailability. Sequences retrieved from Uniprot ID A0A855BJL6 and A0A8D9JAG0 were used as target sequences for the enzyme from Bacillus cereus and Pseudomonas aeruginosa respectively. The target sequences were subjected to BLASTp (Basic Local Alignment Search Tool) in the PDB database. Based on the results obtained, the 3D structures with PDB IDs 6t0y, 1t8h, 6dZd, 1z9t and 7fbg were opted as templates. 19 Homology models were generated for each organism using Modeller 9.14, Swiss-Prot and iTasser. The generated models were validated by examining ERRAT (Colovos and Yeates 1993), Verify3D (Bowie et al. 1991), ProSA (Wiederstein and Sippl 2007) and Ramachandran plot (Lüthy et al. 1992). These analyses provide us with the data regarding the interaction among the non-bonded atoms, compliance of the amino acid sequence of the protein with the generated 3D model and other stereo chemical qualities of the generated protein model (Pontius et al. 1996).

Polymers used in the study

For the study, the most widely used polymers, including polyethylene (PE), polyethylene terephthalate (PET), polypropylene (PP), polystyrene (PS), polyurethane (PU), and polyvinyl chloride (PVC) were chosen. The 3D structures of the above-mentioned polymers were acquired from PubChem and Chemtube3D (https://pubchem.ncbi.nlm.nih.gov/) and (https://www.chemtube3d.com/).

Molecular docking

Molecular docking was performed using Autodock 4.2 to predict the binding affinity that the laccase of the chosen bacterial sources possesses for the target polymers. The DoGSiteScorer-Binding site discovery tool (Volkamer et al. 2012) was used to estimate the binding pocket of the receptor. Prior to docking, the receptor molecules were prepared by performing removal of water molecules, addition of polar hydrogen and Gasteiger charges (Morris et al. 1998). Every ligand was subjected to 10 Lamarckian Genetic Algorithms with a maximum number of energy evaluations set to 2,500,000. The docking score was calculated in terms of binding energy for each polymer with the laccase of both the organisms. The generated docked conformations were visualized using open source molecular visualization softwares such as PyMOL and BIOVIA Discovery Studio Client 2020.

Results

Isolation and identification of bacterial isolates

Individually streaked onto HiCrome Bacillus Agar for preliminary identification were the cultures that were able to survive in the mineral salt media until the 30th day of incubation. The isolates O1-P and O2-B were able to persist, which on streaking onto HiCrome Bacillus agar differential media, exhibited distinctive morphological characteristics (Fig. 1A). HiCrome Bacillus Agar was chosen over other options in this investigation, because it was anticipated that when using soil as the sample source, the likelihood of isolating a Bacillus sp is high. As mentioned by (Alippi 2019) Bacillus cereus produces bright blue colonies on HiCrome Bacillus agar owing to the presence of the enzyme beta-glucosidase in them, which breaks down the chromogenic mixture in the media and produce blue colonies and hence, O2-B was tentatively identified to be Bacillus cereus (Fig. 1). These isolates were subjected to identification using MALDI-TOF/MS, which identifies bacterial culture based on their protein profiles. MALDI-TOF/MS identified the obtained isolates to be Pseudomonas aeruginosa and Bacillus cereus respectively, with a log score value that ranged around 2 (Supplementary Figs. 1, 2). This was further confirmed by sequencing their 16S gene. The isolate O1-P exhibited 97.44% similarity to Pseudomonas aeruginosa DSM 50071, whereas the isolate O2-B showed 97.97% similarity to Bacillus cereus ATCC 14579. The acquired 16S rDNA sequences for the isolates O1-P and O2-B were deposited in GenBank under the accession numbers ON798416 and ON799262 respectively. To add upon, the species obtained in this study have already been reported to be capable of degradation in earlier investigations. Thus, these isolates may certainly be used to understand the role of enzyme laccase in degradation (Bhatia et al. 2014) (Auta et al. 2017). Figure 1C, D depicts the phylogenetic relationship established between microbes of the same genus that have been earlier reported for their degradation potential.

Isolated cultures O1-P and O2-B streaked onto A HiCrome Bacillus agar and B Brain heart infusion agar for growth and preliminary identification based on colony morphology. On identifying the isolates by sequencing the 16S rRNA gene, phylogenetic relationship was established between polymer degrading species of the same genera C Pseudomonas sp. and D Bacillus sp. by employing Neighbor-joining statistical method, with bootstrap iterations set at 1000 which is denoted as percentages in all branches. The nucleotide substitution is set at 0.01 per nucleotide position. The isolate obtained in the study is mentioned with a marker and all the isolates considered are provided with their GenBank accession number in brackets

Growth kinetics in presence of LDPE

The sustainability of the isolates in the presence and absence of LDPE sheets was assessed by monitoring their growth in minimal media individually. During the initial phase of growth, the isolates were able to survive by utilizing the residual media carried over during inoculation. Around day 7 of incubation, the samples that were not provided with LDPE sheets started to slow down, while the isolates that were provided with LDPE sheets as external carbon source continued to grow progressively in their log phase. Figure 2 depicts the growth profile of the isolates. Both the isolates that were cultured in the absence of LDPE sheets entered stationary phase early, with their maximum absorbance not exceeding 0.4. This reduction in growth rate could be attributed to the depletion of residual media and the lack of external carbon source (LDPE sheets). While, the prolonged log phase exhibited by isolates supplemented with LDPE sheets emphasizes the ability of the obtained isolates to utilize LDPE as their carbon source. In particular, the isolate Pseudomonas aeruginosa O1-P (Fig. 2A) cultivated in the presence of LDPE remained in the log phase even after the 10th day of incubation with their maximum absorbance ranging around 0.8, clearly exhibiting a superior growth pattern than Bacillus cereus O2-B (Fig. 2B).

Growth kinetics for the isolated cultures was monitored for a period of 14 days by culturing the microbes in Mineral salt media with only LDPE as carbon supplement. For comparison, control cultures were maintained without any form of additional carbon source. A Pseudomonas aeruginosa O1-P, B Bacillus cereus O2-B, C Co-culture (Both the isolates)

Qualitative assay for laccase enzyme production

The secretion of laccase by the obtained isolates as a response to LDPE treatment was evaluated by performing an assay that employs ABTS as substrate. The cell-free supernatant of the cultures that were grown with and without LDPE was used as the enzyme source for this assay. The variation in the intensity of the green color observed on performing the assay indicates the level of laccase. As observed in Fig. 3A, a significant rise in intensity was observed in samples that were grown in presence of LDPE, while the cultures grown devoid of LDPE did not record an induced production of laccase. In specific, the laccase level was notably higher in Pseudomonas aeruginosa O1-P as compared to Bacillus cereus O2-B. The co-culture set-up that had both the isolates working in synergy also showed increased production of laccase which may be mostly attributable to the isolate Pseudomonas aeruginosa O1-P. The intensity of the color formation observed visually was also validated by measuring their absorbance at 420 nm as shown in Fig. 3B.

The secretion of the enzyme laccase by the isolates was observed both with and without LDPE (shown in the image as LDPE + and LDPE−). Substrate called ABTS was used to carry out the experiment. A The development of an intense green colour denotes laccase formation. B The intensity of the colour development was measured at 420 nm. The analyses were performed in duplicates (n = 3 replicates). The mean data were used for preparation of the Fig. The bar graph was created using Origin 2022b software. (Color figure online)

SEM analysis

The LDPE sheets that were subjected to microbial treatment were examined for surface-level degenerative characteristics, which revealed the formation of fissures, holes, and grooves (Fig. 4A, B), suggesting the possibility of the commencement of disruption in the intact LDPE sheets. In contrast, the control LDPE sheets that had not undergone microbial treatment were observed to have majorly smooth and homogeneous surface. (Fig. 4C).

FT-IR

To look for modification in the chemical structure undergone by the LDPE sheets after microbial treatment, the FT-IR spectra of pure untreated LDPE sheet were compared against the spectra of the LDPE sheets that were treated with P. aeruginosa O1-P and B. cereus O2-B. Characteristic peaks for LDPE were noticed at 2850.83 and 2914.49 cm−1 both indicating C–H stretching mode, 720.43 cm−1 representing CH2 rocking vibration and 1469.78 cm-1 representing C=C stretching vibration (Sowmya et al. 2014). The band noticed at 1054–1200 cm−1 in the untreated LDPE was not detected in the other microbially treated samples indicating a structural modification in the treated LDPE sheets. Most importantly, the broad peak at 3200–3500 cm−1 was noticed only in the case of Pseudomonas aeruginosa O1-P treated and the co-culture set up, demonstrating the dominance of P. aeruginosa O1-P over B. cereus O2-B in the degradation process (Fig. 5).

FT-IR spectra were obtained between 400 and 4000 cm−1 for the LDPE sheets that had been subjected to microbial treatment for 30 days. LDPE sheets that had not been treated served as the control. The samples were treated with microorganisms individually and in combination (Bacillus cereus O2-B + Pseudomonas aeruginosa O1-P) denoted as co-culture in the Fig. The graph was created using OriginPro 2022b software

X-ray diffraction

The level of crystallinity of the LDPE sheets was assessed by comparing the XRD spectra of the untreated control sheet with that of the microbially treated LDPE sheets. This would reveal the structural changes undergone by the polymer as a result of microbial treatment. Maroof et al. 2020, in their study have shown that the peaks at 19°, 21° and 23.7° which are all reflections from the 001, 110 and 200 planes respectively are all the characteristic peaks of pure polyethylene. The intensity of the peaks is associated with the crystallinity of the LDPE sheets (Mukherjee and Kundu 2014). These specific peaks were monitored in this XRD analysis, which revealed a dip in their intensity in the case of microbially treated LDPE sheets, thereby indicating the initiation of transition from a crystalline to an amorphous structure. To understand this transition, % crystallinity was calculated by considering the reference and characteristic peaks of polyethylene (Table 1). The LDPE sheets treated with P. aeruginosa O1-P has undergone about 8.9% decrease in crystallinity, whereas B.cereus O2-B has undergone about 7.3% decrease. In the co-culture set-up, the authors were able to observe 10% decrease in crystallinity (Fig. 6).

XRD spectra obtained at angles 10–40° for the LDPE sheets that were microbially treated. LDPE sheets that had not been treated served as the control. The samples were treated with microorganisms individually and in combination (Bacillus cereus O2-B + Pseudomonas aeruginosa O1-P) denoted as co-culture in the Fig. The graph was created using OriginPro 2022b software

GC-MS analysis

GC-MS can provide valuable information about the metabolic pathways utilized by the microorganism. The by-products formed due to the degradation activity are revealed by the GC-MS analysis. The spectra obtained from the LDPE sheets treated with the isolates of this study shows the presence of intermediates such as aldehydes, ketones and esters. The compounds identified from the chromatogram of the control samples were compared with the microbially treated samples (Table 2; Supplementary Fig. 3). The GC-MS spectra reported the presence of silane, which is used in the cross-linking of polyethylene whose effect on the degrading process is not well understood. The compounds such as oxalic acid, and 1-hexadecanol with RT of 10.02 and 14.01 were noticed in the sample treated with B. cereus O2-B, whereas, in the sample treated with P. aeruginosa O1-P, 1,2 naphthalene diol and dioctyadecyl diester were observed with RT of 13.24 and 18.77 respectively. Both the isolates reported the presence of aldehyde groups with RT of 7.72 indicating their degradation activity on the plastic sheets. The peaks denoting the presence of solvent are not tabulated in Table 2. The compounds reported in the GC-MS analysis fall into the category of alcohols, aldehydes and esters which are all identified to be intermediates in the alkane-degrading pathways (Ru et al. 2020).

3D Model generation and validation

With more than 70 PDB structures available for various fungal laccases, very few 3D structures were available for bacterial laccases and thus homology modeling was performed by choosing the closely related structures as templates. The sequence data for the laccase of B. cereus and P. aeruginosa were obtained from Uniprot with ID A0A855BJL6 and A0A8D9JAG0 respectively. To identify the homologous relationship of the target sequences, BLASTP was performed against the PDB database. The structures with a sequence identity of more than 30% were opted as templates for both the sequences to perform homology modelling. The generated homology models were examined and validated (Supplementary Tables 1, 2) by analyzing their ramachandran plot (Fig. 8A, C), ProSA (Fig. 8B, D), ERRAT and Verify 3D. The root mean square (RMSD) value which was calculated by superimposing the generated models with their respective template structures was crucially considered to single out the most preferable model (Fig. 7C, D).

The generated 3D models for the enzyme laccase for the isolated cultures by Swiss-Model. A Bacillus cereus O2-B [Model No. 19]. B Pseudomonas aeruginosa O1-P [Model No.19]. Superimposed imposed model of the built 3D model with the template structure (PDB ID-7fbg). C Bacillus cereus O2-B. D Pseudomonas aeruginosa O1-P

For Bacillus cereus, the homology model number 19 (Supplementary Table 1) that had an overall quality factor of 89.28% generated by ERRAT was chosen to be further used in the study. The selected model also had a better RMSD value of 0.053 Å and around 89.7% of their amino acid residues were placed in the favorable region as per the Ramachandran plot (Fig. 8A). The Verify3D score was recorded to be 91.39%, which also falls above the cut-off score to qualify as a good model. To add upon, the structural validation was performed by ProSA, which evaluated the z-score of the generated protein model to be −8.3. As depicted by ProSA plot (Fig. 8B), the z-score of the generated model is estimated to be within the range of other native proteins of similar size, that were determined by other experimental methods such as X-Ray and NMR. Henceforth, taking into account all the data obtained from various validation methods, the model number 19 was considered to be a better model to be further pursued in the study.

Similarly, in the case of Pseudomonas aeruginosa, it was homology model number 19 (Supplementary Table 2) that exhibited better configurations than the others as validated by the methods mentioned above. The selected homology model showed an overall quality factor of 89 and 96.73% being the score generated by Verify3D validation. On validating the model with the ramachandran plot (Fig. 8C), 87.60% of amino acid residues were found to be present in the favourable region, but had only 0.6% amino acid residues in the disallowed region, while the rest 10.7 and 1.1% of the amino acid residues fall under allowed and generously allowed regions respectively. The RMSD value was determined to be 0.638 Å favouring the selection of this model. Furthermore, the z-score obtained from ProSA validation was −5.74, which also falls into the range of other similar native proteins that were experimentally determined (as represented in plot Fig. 8D). Considering the data of all the validation methods, homology model number 19 was selected (Supplementary Table 2). The final 3D structures generated for the enzyme laccase of both organisms were visually represented in Pymol, an open-source molecular visualization software (Fig. 7A, B).

Molecular docking

The polymers were docked with the validated 3D models generated for the enzyme laccase of Bacillus cereus and Pseudomonas aeruginosa. The interaction of the amino acids with the target polymers are depicted in Figs. 9, 10. The data obtained from the molecular docking study revealed that the residues located around the Cu site were actively involved in contributing to the catalytic domain of the protein. It is the His47, His80, Cys121, Cys125, His142, His 250, Arg251 involved in interaction in B. cereus, whereas it is His36, Val 68, Cys72, His89, Ala120, Ile125, His219, Arg220 in case of P. aeruginosa. On closer inspection, it is evident that the aliphatic hydrocarbons mostly interact via hydrophobic and van der waals interactions, while the aromatic hydrocarbons have been noticed to form H-bond with the enzyme laccase. The predicted binding score and interaction of the laccases with other common polymers are tabulated in Tables 3, 4.

Discussion

Employing microbes for the bio-degradation of plastics is currently being extensively investigated. It is a well-known fact that soil microbes contribute to the degradation of plastics, but, in their native state, it takes around hundreds of years to achieve the same. Pursuing clear knowledge of the mechanism employed by these microbes would aid the researchers in engineering them to develop a real-life solution. Hence, in this study, soil microbes from contaminated environments that have developed the ability to thrive on LDPE as their sole carbon source were isolated and identified via MALDI-TOF and 16s rDNA sequencing. The screened LDPE degrading isolates were identified to be Pseudomonas aeruginosa O1-P and Bacillus cereus O2-B.

The identified isolates were monitored for their growth pattern under the influence of LDPE to understand their sustainability with LDPE as their carbon source. As the overnight culture was added as inoculum in the minimal media, the isolates were able to utilize the carbon source from the carried-over media. This was performed to stabilize the growth of the isolates during the initial lag phase to avoid a complete lack of carbon source. Interestingly, around day 7, as the residual carbon source in the media gradually depleted, the isolates began thriving on LDPE sheets for their carbon source and recorded a steady and prolonged log phase. While the isolates that were not supplemented with LDPE sheets recorded slow growth and entered the stationary phase early. This pattern was uniform to both of the obtained isolates emphasizing their potential to sustain with LDPE as their carbon source. This pattern of growth kinetics observed in this study is in correspondence with the earlier investigation where the growth pattern of the isolate Pseudomonas citronellolis EMBS027 was assessed in presence of LDPE and glucose. The isolate demonstrated a steady growth with their maximum absorbance reaching up to 0.2 at 600 nm when provided with glucose and 0.15 when supplemented with LDPE, at a similar time point, which are almost on par with each other. This clearly shows their ability to utilize and sustain with LDPE (Bhatia et al. 2014). This finding supports the claim made in this study, that the isolates obtained in this investigation can maintain their growth cycle by sustaining with LDPE as their sole carbon source.

The understanding of the growth profile of the obtained isolates helped in channelizing the study towards understanding if the oxidative enzyme laccase has any role in the degradation process. With recent studies revealing laccase as one of the predominant enzymes in polyethylene degradation, the presence of laccase was assessed in the obtained isolates (Santo et al. 2013; Sumathi et al. 2016; Ndahebwa Muhonja et al. 2018). A laccase assay was employed using ABTS as the substrate providing insights into the relationship between the obtained soil isolates' production of laccase and the breakdown process of LDPE. In the current study, the production of laccase was observed to be induced in cultures that were grown in presence of LDPE as their sole carbon source in comparison to the cultures that were not supplemented with LDPE. This increase in laccase production observed under the influence of a polymer (LDPE) was also noted by (Sumathi et al. 2016), where, they illustrated how the production of laccase by the bacteria Cochliobacillus sp. plays an important role in the breakdown of low molecular weight PVC. With a clear induction in laccase production noticed in presence of LDPE, it could be implied that the isolates are striving to survive in the nutrient-deficit environment by triggering the production of laccase, which would facilitate the bacteria to oxidize more hydrocarbons, thereby increasing the susceptibility of the hydrocarbon to fragmentation.

On establishing the association between the production of laccase by the isolates and their sustainability with LDPE degradation, the LDPE sheets that were microbially treated were subjected to instrumental examinations to analyze the structural, morphological and chemical modifications that may have occurred during the treatment. In recent studies, SEM, FTIR, and XRD have been the most often employed techniques to assess deterioration (Kunlere et al. 2019; Bardají et al. 2019). Changes in the surface topography of the LDPE sheets were observed using SEM in the treated and untreated LDPE sheets which indicates the disturbances in the intactness of the treated LDPE sheet (Fig. 4). Morphologically, the introduction of grooves and fissures in the treated sheets adds evidence to the occurrence of degradation. FT-IR was performed to obtain insights into chemical modifications that the polymer would have undergone. The broad peak recorded between 3200 and 3500 cm−1 indicates the presence of a –OH group. Since the hydrocarbon chain of the polymer does not possess any –OH group in its native state (as observed in control) (Fig. 5) the newly formed –OH group in the microbially treated LDPE sheets could be the resultant by-products from the oxidation activity of the enzymes (Kumar Sen and Raut 2015; Arregui et al. 2019). (Fig. 5). Importantly, as this peak observed around 3200–3500 cm−1 represents the O–H group, it could also indicate the presence of H–O–H. But due to the absence of a scissor peak at 1630 cm−1, this broad peak would be associated with the compound class of alcohols (Smith 2017). As mentioned earlier, it is through the secretion of enzymes that the microbes contribute to plastic degradation. In specific, it is the oxidative enzymes such as laccase that play a major role in initial degradation. They function by oxidizing the terminal or sub-terminal regions of the hydrocarbon chain, resulting in the formation of alcohols, which are identified by FTIR spectra and confirmed by GC-MS analyses in this study. Also, given that laccase works by oxidation and that Pseudomonas aeruginosa O1-P had recorded an increased production of laccase, this OH peak observed may be attributed to laccase's activity. The subsequent oxidations by these enzymes would result in the formation of –CHO and –COOH groups in the hydrocarbon chain, making them more susceptible to fragmentation. The increase in the secretion of laccase under the influence of LDPE (as observed in the ABTS assay) (Fig. 3) helps us to understand and correlate the occurrence of the –OH peak (Fig. 5) with the enzyme’s role in degradation (Dey et al. 2020; Mohanan et al. 2020). On the other hand, no peak was observed at the 3200–3550 cm−1 region in the case of B. cereus O2-B, which also corresponds to the very weak colour development observed when assayed for the presence of laccase. Additionally, the band observed around 1054–1200 cm−1 was noticed in the untreated sample and disappeared after treatment. This band is associated with siloxane (Si–O–Si), a common additive used in the commercial manufacturing of LDPE for improving the lubricity of polyethylene. The disappearance of this band and other chemical modifications observed in the structural backbone of the hydrocarbon indicates the signs of degradation (Launer and Arkles 2013). To add upon this, variations in the intensity of the peaks in the XRD diffractogram (Fig. 6) were also analyzed, which demonstrates the decrease in the amount of crystalline nature of the LDPE sheets in the case of microbially treated samples. The calculated % crystallinity aided in determining the structural modification undergone by the treated LDPE sheets. The 8–10% reduction noticed in the crystallinity of the LDPE sheets, indicates their gradual transition to amorphousness (Maroof et al. 2020).

On confirming the degradation of LDPE by assessing their morphological, chemical and structural modifications, the intermediates formed during the process of degradation were also assessed. In an investigation by Kyaw et al. 2012, the intermediates produced as a result of Pseudomonas sp. acting on LDPE were examined by performing GC-MS analysis. The finding shows about 18 different compounds, including the 1,2-benzene dicarboxylic acid and heptadecyl ester that are also reported in the current study. A study by Sangale et al. 2019, also reported the presence of similar intermediates suggesting the degrading mechanism employed by the microbes hardly differs. The alkanes [CH2–CH2–CH2]n that are subjected to treatment by microbes would result in alcohols [CH2–CH2–CH2–OH]n with the action of oxidative enzymes. The oxidative enzymes would add oxygen molecules in the terminal or sub-terminal ends of the alkane chain (Amobonye et al. 2021). The presence of 1-hexadecanol in the microbially treated samples and their absence in untreated samples serve as evidence for the first step of the degradation process. Hexadecane (C16H34) being a straight-chain alkane, the presence of 1-hexadecanol (C16H34O) shows the occurrence of terminal oxidation, thereby serving as a confirmation for the action of oxidative enzymes. Further action of the microbes by enzymes such as dehydrogenases and esterases are reported to play an important role in the formation of carboxylic acids, ketones, and ester groups during the polymer breakdown (Mahalakshmi and Siddiq 2012; Pramila and Vijaya Ramesh 2015). The presence of compounds such as oxalic acids even more substantiates the action of degradation. Additionally, esters are also noted in the GC-MS reports, which are formed as by-products during the process of sub-terminal oxidation. In the present study, the presence of major classes of intermediates substantiates the onset and progression of the polymer breakdown. The compounds identified in this study can help in further elucidating the metabolic pathways in plastic degradation by microorganisms.

With the data obtained from instrumental analyses like SEM, FT-IR, XRD and GC-MS, evidence for the progressive commencement of degradation have been provided in this study. This clearly explains that the observed induced secretion of laccase is the response mechanism adapted by the bacteria to survive in a carbon-depleted medium. The secreted enzymes oxidize the hydrocarbon chain causing structural modification leading to degradation. As a clear relationship has been established between laccase and LDPE degradation, the study was further extended in silico to analyze the efficiency of this enzyme against other commonly used polymers such as PET, PP, PS, PU and PVC.

Molecular docking studies were employed to reveal the polymer with which our target enzyme can bind with better affinity, implying the possibility of a higher rate of degradation (Tables 3, 4). With existing data on laccase, it was understood that the region around the T1 copper site of the enzyme formed the catalytic region of the enzyme making it favourable for the binding of ligands. As the laccase of Trametes versicolor has been extensively studied, it was understood that the residues His 66, His 111, Phe 162, Leu 164, Phe 332 and Pro 391 involved in ligand interaction, while Asp 206 in the same region contributed to the ligand stabilization along with His 458 (Arregui et al. 2019). In specific, it is histidine that is predominantly engaged in the interaction, by playing an important role in ligand stabilization as a proton donor and acceptor. Thus, with the major interactive sites of laccase from earlier studies as reference (Arregui et al. 2019; Scheiner et al. 2002), the interactions noticed in this study were analysed. As mentioned earlier, in laccase of B.cereus, His47, His80, Cys121, Cys125, His142, His 250 and Arg251 were found to be predominantly involved in interactions with all ligands, while in P. aeruginosa, it was His36, Val 68, Cys72, His89, Ala120, Ile125, His219, Arg220. Among the predicted interacting residues, it is histidine that is frequently observed contributing to ligand stabilization Arregui et al. 2019. Moreover, with laccase being a multi-copper oxidase, the amino acid residues present around the Cu site were found to actively contribute to the catalytic activity of the enzyme (Figs. 9, 10). Additionally, it was observed that the laccase was able to interact with aromatic hydrocarbons with better affinity by readily forming hydrogen bonds, whereas, the interaction with the aliphatic hydrocarbons lacked hydrogen bonds. The stability of the ligands lacking hydrogen bonds could be attributed to the numerous hydrophobic interactions noticed (Yadalam et al. 2021). With the aid of the other hydrophobic and van der waals interactions observed, the oxidative enzymes would be able to act on the hydrocarbon chain, thereby subsequently reducing the hydrophobicity of the polymer and favouring the access of polymers to the enzymes. Further, in order to determine the polymer towards which the enzyme would be highly efficient, the predicted binding score and various docked poses obtained were analysed. The laccase of P. aeruginosa generated a binding score of −4.58 kcal/mol against polyurethane followed by −4.08 kcal/mol for polystyrene (Table 4). Similarly, the laccase of B. cereus also recorded a binding score of −5.57 kcal/mol against polyurethane (Table 3). The obtained binding scores are in range with the binding score exhibited by PETase against PET in a recent study (Duru et al. 2021). This enzyme PETase has been experimentally demonstrated and supported with multiple data for its exclusive mechanism against PET (Tanasupawat et al. 2016; Joo et al. 2018; Duru et al. 2021). In short, this study suggests that the laccase of Pseudomonas aeruginosa and Bacillus cereus can function with higher efficiency, initiating the oxidation of polymer, leading to a domino of reactions, that would eventually result in the breakdown of the hydrocarbon structures (Hubbard and Kamran Haider 2010).

Conclusion

The findings of this study provides insights into the degradation mechanism employed by microbes involving laccase. We identified isolates Pseudomonas aeruginosa O1-P and Bacillus cereus O2-B that were able to thrive with LDPE as their only carbon source. Further, FT-IR data revealed that the LDPE sheets treated with Pseudomonas aeruginosa had undergone oxidation which can directly be correlated with the induced production of laccase. Despite the minimal induction in the laccase production in Bacillus cereus, LDPE sheets treated with Bacillus cereus also exhibited progressive onset of degradation as monitored by SEM, FT-IR, XRD and GC-MS profiling. This puts forward the statement that the degradation process is not caused by a single enzyme. With an established link between laccase and bio-degradation, laccase’s effectiveness against other common polymers was examined in silico. The enzyme also demonstrated better affinity for polymers other than PE in molecular docking studies, demonstrating its efficiency in breaking down multiple polymers, making them a potential candidate to be further explored for degradation studies. Exploiting these enzymes by delving into proteomics and understanding their metabolic pathways is the key to the development of scale-able technologies to address this global concern.

Data availability

The datasets presented in this study can be found in online repositories. The names of the repository/repositories and accession number(s) can be found in the article.

Change history

12 September 2024

A Correction to this paper has been published: https://doi.org/10.1007/s10532-024-10094-1

References

Ali SS et al (2021) Degradation of conventional plastic wastes in the environment: a review on current status of knowledge and future perspectives of disposal. Sci Total Environ 771:144719

Alippi AM (2019) Data associated with the characterization and presumptive identification of Bacillus and related species isolated from honey samples by using HiCrome Bacillus agar. Data Brief 25:104206

Amobonye A, Bhagwat P, Singh S, Pillai S (2021) Plastic biodegradation: frontline microbes and their enzymes. Sci Total Environ 759:143536

Arregui L et al (2019) Laccases: structure, function, and potential application in water bioremediation. Microb Cell Fact 18:200

Auta HS, Emenike CU, Fauziah SH (2017) Screening of Bacillus strains isolated from mangrove ecosystems in Peninsular Malaysia for microplastic degradation. Environ Pollut 231:1552–1559

Avanzi IR et al (2017) Rapid bacteria identification from environmental mining samples using MALDI-TOF MS analysis. Environ Sci Pollut Res Int 24:3717–3726

Bardají DKR, Furlan JPR, Stehling EG (2019) Isolation of a polyethylene degrading Paenibacillus sp. from a landfill in Brazil. Arch Microbiol 201:699–704

Bhatia M, Girdhar A, Tiwari A, Nayarisseri A (2014) Implications of a novel Pseudomonas species on low density polyethylene biodegradation: an in vitro to in silico approach. Springerplus 3:497

Bowie JU, Lüthy R, Eisenberg D (1991) A method to identify protein sequences that fold into a known three-dimensional structure. Science 253:164–170

Chatterjee S, Roy B, Roy D, Banerjee R (2010) Enzyme-mediated biodegradation of heat treated commercial polyethylene by Staphylococcal species. Polym Degrad Stab 95:195–200

Colovos C, Yeates TO (1993) Verification of protein structures: patterns of nonbonded atomic interactions. Protein Sci 2:1511–1519

Cregut M, Bedas M, Durand M-J, Thouand G (2013) New insights into polyurethane biodegradation and realistic prospects for the development of a sustainable waste recycling process. Biotechnol Adv 31:1634–1647

Danso D, Chow J, Streit WR (2019) Plastics: environmental and biotechnological perspectives on microbial degradation. Appl Environ Microbiol. https://doi.org/10.1128/AEM.01095-19

Das G, Bordoloi NK, Rai SK, Mukherjee AK, Karak N (2012) Biodegradable and biocompatible epoxidized vegetable oil modified thermostable poly(vinyl chloride): thermal and performance characteristics post biodegradation with Pseudomonas aeruginosa and Achromobacter sp. J Hazard Mater 209–210:434–442

Dey AS, Bose H, Mohapatra B, Sar P (2020) Biodegradation of unpretreated low-density polyethylene (LDPE) by Stenotrophomonas sp. and Achromobacter sp, isolated from waste dumpsite and drilling fluid. Front Microbiol 11:603210

Duru CE, Duru IA, Enyoh CE (2021) In silico binding affinity analysis of microplastic compounds on PET hydrolase enzyme target of Ideonella sakaiensis. Bull Natl Res Cent 45:1–8

Esmaeili A, Pourbabaee AA, Alikhani HA, Shabani F, Esmaeili E (2013) Biodegradation of low-density polyethylene (LDPE) by mixed culture of Lysinibacillus xylanilyticus and Aspergillus niger in soil. PLoS ONE 8:e71720

Fotopoulou KN, Karapanagioti HK (2017) Degradation of various plastics in the environment. The handbook of environmental chemistry. Springer, New York, pp 71–92

Gan Z, Zhang H (2019) PMBD: a comprehensive plastics microbial biodegradation database. Database. https://doi.org/10.1093/database/baz119

Hubbard RE, Kamran Haider M (2010) Hydrogen bonds in proteins: role and strength. eLS. https://doi.org/10.1002/9780470015902.a0003011.pub2

Jaiswal S, Sharma B, Shukla P (2020) Integrated approaches in microbial degradation of plastics. Environ Technol Innov 17:100567

Jeon HJ, Kim MN (2013) Isolation of a thermophilic bacterium capable of low-molecular-weight polyethylene degradation. Biodegradation 24:89–98

Joo S et al (2018) Structural insight into molecular mechanism of poly(ethylene terephthalate) degradation. Nat Commun 9:382

Kang BR, Kim SB, Song HA, Lee TK (2019) Accelerating the biodegradation of high-density polyethylene (HDPE) Using Bjerkandera adusta TBB-03 and Lignocellulose substrates. Microorganisms 7:304

Kumar Sen S, Raut S (2015) Microbial degradation of low density polyethylene (LDPE): a review. J Environ Chem Eng 3:462–473

Kunlere IO, Fagade OE, Nwadike BI (2019) Biodegradation of low density polyethylene (LDPE) by certain indigenous bacteria and fungi. Int J Environ Stud 76:428–440

Kyaw BM, Champakalakshmi R, Sakharkar MK, Lim CS, Sakharkar KR (2012) Biodegradation of low density polythene (LDPE) by Pseudomonas species. Indian J Microbiol 52:411–419

Launer PJ, Arkles B (2013) Infrared analysis of organosilicon compounds: spectra-structure correlations. In silicon compounds: silanes and silicones 3rd edition 223–226

Lüthy R, Bowie JU, Eisenberg D (1992) Assessment of protein models with three-dimensional profiles. Nature 356:83–85

Mahalakshmi V, Siddiq A (2012) Analysis of polyethylene degrading potentials of microorganisms isolated from compost soil. Int J Pharm Biol Arch 3:1190–1196

Maroof L et al (2020) Identification and characterization of low density polyethylene-degrading bacteria isolated from soils of waste disposal sites. Environ Eng Res. https://doi.org/10.4491/eer.2020.167

Mohanan N, Montazer Z, Sharma PK, Levin DB (2020) Microbial and enzymatic degradation of synthetic plastics. Front Microbiol 11:580709

Montazer Z, Habibi Najafi MB, Levin DB (2020) Challenges with verifying microbial degradation of polyethylene. Polymers 12:123

Morris GM et al (1998) Automated docking using a Lamarckian genetic algorithm and an empirical binding free energy function. J Comput Chem 19:1639–1662

Mukherjee S, Kundu PP (2014) Alkaline fungal degradation of oxidized polyethylene in black liquor: studies on the effect of lignin peroxidases and manganese peroxidases. J Appl Polym Sci. https://doi.org/10.1002/app.40738

Mukherjee S, Chowdhuri UR, Kundu PP (2016) Bio-degradation of polyethylene waste by simultaneous use of two bacteria: Bacillus licheniformis for production of bio-surfactant and Lysinibacillus fusiformis for bio-degradation. RSC Adv 6:2982–2992

Ndahebwa Muhonja C, Magoma G, Imbuga M, Makonde HM (2018) Molecular characterization of low-density polyethene (LDPE) degrading bacteria and fungi from Dandora Dumpsite, Nairobi, Kenya. Int J Microbiol 2018:4167845

Pontius J, Richelle J, Wodak SJ (1996) Deviations from standard atomic volumes as a quality measure for protein crystal structures. J Mol Biol 264:121–136

Pramila R, Vijaya Ramesh K (2015) Potential biodegradation of low density polyethylene (LDPE) by Acinetobacter baumannii. J Bacteriol Res. https://doi.org/10.5897/JBR201.0152

Priya A, Dutta K, Daverey A (2022) A comprehensive biotechnological and molecular insight into plastic degradation by microbial community. J Chem Technol Biotechnol 97:381–390

Purohit J, Chattopadhyay A, Teli B (2020) Metagenomic exploration of plastic degrading microbes for biotechnological application. Curr Genom 21:253–270

Restrepo-Flórez J-M, Bassi A, Thompson MR (2014) Microbial degradation and deterioration of polyethylene—a review. Int Biodeterior Biodegradation 88:83–90

Ru J, Huo Y, Yang Y (2020) Microbial degradation and valorization of plastic wastes. Front Microbiol 11:442

Saeed S, Iqbal A, Deeba F (2022) Biodegradation study of polyethylene and PVC using naturally occurring plastic degrading microbes. Arch Microbiol 204:497

Sangale MK, Shahnawaz M, Ade AB (2019) Gas chromatography-mass spectra analysis and deleterious potential of fungal based polythene-degradation products. Sci Rep 9:1599

Santo M, Weitsman R, Sivan A (2013) The role of the copper-binding enzyme—laccase—in the biodegradation of polyethylene by the actinomycete Rhodococcus ruber. Int Biodeterior Biodegradation 84:204–210

Scheiner S, Kar T, Pattanayak J (2002) Comparison of various types of hydrogen bonds involving aromatic amino acids. J Am Chem Soc 124:13257–13264

Shahnawaz M, Sangale MK, Ade AB (2016) Bacteria-based polythene degradation products: GC-MS analysis and toxicity testing. Environ Sci Pollut Res Int 23:10733–10741

Sivan A (2011) New perspectives in plastic biodegradation. Curr Opin Biotechnol 22:422–426

Smith, BC (2017) Alcohols—the rest of the story. Spectroscopy Online https://www.spectroscopyonline.com/view/alcohols-rest-story-alf3

Sowmya HV, Ramalingappa K, M. & Thippeswamy, B. (2014) Degradation of polyethylene by Trichoderma harzianum—SEM, FTIR, and NMR analyses. Environ Monit Assess 186:6577–6586

Sumathi T, Viswanath B, Sri Lakshmi A, SaiGopal DVR (2016) Production of Laccase by Cochliobolus sp. isolated from plastic dumped soils and their ability to degrade low molecular weight PVC. Biochem Res Int 2016:9519527

Suzuki T et al (2003) A thermostable laccase from Streptomyces lavendulae REN-7: purification, characterization, nucleotide sequence, and expression. Biosci Biotechnol Biochem 67:2167–2175

Tamura K, Stecher G, Kumar S (2021) MEGA11: molecular evolutionary genetics analysis version 11. Mol Biol Evol 38:3022–3027

Tanasupawat S, Takehana T, Yoshida S, Hiraga K, Oda K (2016) Ideonella sakaiensis sp nov., isolated from a microbial consortium that degrades poly(ethylene terephthalate). Int J Syst Evol Microbiol 66:2813–2818

Thompson RC, Swan SH, Moore CJ, vom Saal FS (2009) Our plastic age. Philos Trans R Soc Lond B 364:1973–1976

Volkamer A, Kuhn D, Grombacher T, Rippmann F, Rarey M (2012) Combining global and local measures for structure-based druggability predictions. J Chem Inf Model 52:360–372

Wiederstein M, Sippl MJ (2007) ProSA-web: interactive web service for the recognition of errors in three-dimensional structures of proteins. Nucleic Acids Res 35:W407–W410

Yadalam PK et al (2021) Antiviral essential oil components against SARS-CoV-2 in pre-procedural mouth rinses for dental settings during COVID-19: a computational study. Front Chem 9:642026

Yang J, Yang Y, Wu W-M, Zhao J, Jiang L (2014) Evidence of polyethylene biodegradation by bacterial strains from the guts of plastic-eating waxworms. Environ Sci Technol 48:13776–13784

Acknowledgements

We acknowledge the Nanotechnology Research Centre (NRC) and SRM Central Instrumentation Facility (SCIF), SRMIST for providing the research facilities.

Funding

No funding was received for this study.

Author information

Authors and Affiliations

Contributions

SF, RN and TM contributed to the conception, design of the experiments. SF contributed to data acquisition and drafted the manuscript. SF, RN, TM contributed to data analysis and have critically revised the manuscript. All authors gave final approval and agreed to be accountable for all aspects of the work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original Online version of this article was revised: to correct co-author to Shafana Farveen Mohamed

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shafana Farveen, M., Madhavan, T. & Narayanan, R. Association of Laccase from Bacillus cereus O2-B and Pseudomonas aeruginosa O1-P with the bio-degradation of polymers: an in vitro to in silico approach. Biodegradation 34, 383–403 (2023). https://doi.org/10.1007/s10532-023-10028-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10532-023-10028-3