Abstract

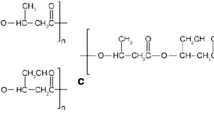

Low density polythene (LDPE) is the most widely used packaging material primarily because of its excellent mechanical properties, barrier properties against water, light weight, low cost and high energy effectiveness. However, due to its ubiquitous nature, and resistance to biodegradability, the disposal strategies are crucial and need attention. Recently, microorganisms have become the focus of interest for environmental friendly disposal of plastic and polymer-based waste. This manuscript aims to investigate the extent of biodegradability of LDPE by four different strains of Pseudomonas bacteria—Pseudomonas aeruginosa PAO1 (ATCC 15729), Pseudomonas aeruginosa (ATCC 15692), Pseudomonas putida (KT2440 ATCC 47054) and Pseudomonas syringae (DC3000 ATCC 10862). Degradation of LDPE was determined by weight loss of the sample, morphological changes, mechanical and spectroscopic variations. The eluted compounds after degradation were analysed by gas chromatography coupled with mass spectroscopy. Our results show that Pseudomonas spp. can degrade LDPE films.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Low density polythene (LDPE) has been widely used due to its versatile nature and effectiveness. Each year, an estimated 500 billion to 1 trillion plastic bags are consumed worldwide [8]. After their use, these packaging materials are dumped in landfills leading to pollution since they are non-biodegradable under natural environmental conditions [1]. The recalcitrant nature of LDPE to biological attack was believed to be contributed by the hydrophobic carbon backbone and high molecular weight of the polymer. Thus, over the years, the rapid biodegradation of plastic has been a subject of interest in the waste management problem.

One of the major strategies to facilitate disintegration and subsequent degradation is by direct degradation of LDPE by microorganisms using only the polymer as sole carbon source [8]. Several previous studies have reported on biodegradation of polythene by bacterial [2, 11] and fungal species [2,4, 13] It has been reported that Pseudomonas spp. degrade polythene bags made of LDPE in natural as well as artificial environment. However, the effect of natural environment was shown to be more pronounced than in vitro conditions due to the presence of bacterial and fungal consortium in the former [2]. Norman et al. [7] and Tadros et al. [12] have previously reported on the biodegradability potential of Pseudomonas aeruginosa, Pseudomonas fluorescens and fungi Penicillium simplicissimum on synthetic plastics. Concurrently, it has also been postulated that the biodegradation of any synthetic material initiates with the colonization of microorganism on the surface of the material [8]. Also, the evidence of increased bacterial adhesion on LDPE surface coupled with certain additives such as starch and pro-oxidants by Scanning electron microscopy has been previously reported [2, 8]. Though, it is known that some Pseudomonas strains can degrade polythene, a comparative analysis on the degradation potency of polythene by Pseudomonas spp. in vitro remains to be investigated. This study reports on the degradation of polythene by four different strains of Pseudomonas spp. Biodegradation is characterized by a loss in weight of the samples, change in tensile strength (TS), variation in physical and chemical properties, carbon dioxide production, change in molecular weight distribution and bacterial counts, changes in infra red (IR) spectrum of the sample after biotic exposure [2, 8]. Also, the rate of biodegradation has been reported to be affected by irradiation with UV light and chemicals [8], by surface area [1], by antioxidant [3], by additives and also by the molecular weight of the plastic [5]. This investigation enlightens on the use of bacteria for biodegradation purposes.

Materials and Methods

Microorganisms

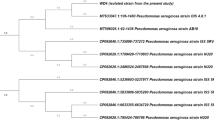

The microorganisms selected for this investigation are—Pseudomonas aeruginosa PAO1(ATCC 15729), Pseudomonas aeruginosa (ATCC 15692), Pseudomonas putida (KT2440 ATCC 47054) and Pseudomonas syringae (DC 3000 ATCC 10862). Bacterial cultures were stored in Isosensitest broth at 4°C and were plated in Isosensitest agar for further investigation.

Nutrient Basal Media Contents

The basal mineral media used for testing the biodegradability of LDPE consisted of the following elements (prepared in distilled water): 12.5 g l−1 K2HPO4; 3.8 g l−1 KH2PO4; 1.0 g l−1 (NH4)2SO4; 0.1 g l−1 MgSO4·7H2O and 5 ml trace element solution which contained each of the following elements (prepared in distilled water): 0.232 g l−1 H3BO3; 0.174 g l−1 ZnSO4·7H2O; 0.116 g l−1 FeSO4(NH4)2SO4·6H2O; 0.096 g l−1 CoSO4·7H2O; 0.022 g l−1 (NH4)6Mo7O24·4H2O; 8.0 mg l−1 CuSO4·5H2O; 8.0 mg l−1 MnSO4·4H2O.

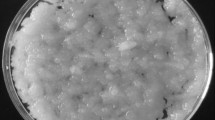

Polyethylene Film Preparation and Culture Condition

LDPE films (commercially used NTUC plastic bags) were cut into (5 cm × 1 cm) strips and then washed with 70% ethanol for 30 min, washed with distilled water, and subsequently dried in incubator at 60°C and subsequently exposed to the bacterial culture medium. The inoculation and incubation was carried out in complete aseptic condition. In each falcon tube, 30 ml of the basal mineral medium and 600 μl of the bacterial stock solution (24 h old) were mixed together and 90 mg (about 10 strips) of LDPE films were added [2, 12]. The initial concentration of bacterial inoculum was maintained at 0.5 McFarland Standard. The tubes were incubated on a rotary shaker (120 rpm) at 37°C, and the lid was slightly open for aeration. The tests were performed in triplicate for each strain of bacteria. The films were removed at 40, 80 and 120 days after incubation and checked for weight changes, mechanical properties changes and morphological (surface) changes. A set of control experiments were performed in the test tubes containing only the LDPE films in basal nutrient medium devoid of bacterial inoculum.

Planktonic and Biofilm Cell Growth Kinetics Study

An aliquot from each of the four groups of incubated tubes was taken at regular intervals for the first 40 days of incubation for quantification of bacterial cells by serial dilution technique followed by plating in Isosensitest agar plates for viable colony count. The control tubes were also tested regularly for contamination.

The biofilm cells were quantified using the conventional method. Here, the biofilm layer formed on the plastic surface was removed by immersing the plastic films in 2 ml of 0.9% NaCl for 2 h and it was vortexed for 5–10 min. An aliquot from this suspension was taken, serially diluted and plated on Isosensitest agar plates for colony counting. The colony forming units for biofilm cells were calculated using the formula given below [6];

Biodegradability Tests

Weight Loss Measurements

The plastic films after exposure to all four bacterial suspensions were taken and washed thoroughly with 2% SDS for 4 h. The strips were then dried at 60°C over night and the percentage weight loss was determined using the following formula:

TS Testing

The films (5 cm × 1 cm) were tested in materials testing machine (Model INSTRON 5566) with a crosshead speed of 10 mm/min. The testing conditions were maintained at a room temperature of 35–37°C with a relative humidity of 65%. The negative control maintained at similar incubation conditions was also tested and compared with the positive control. Three LDPE strips were tested for each group and the average was reported as the final result.

Spectroscopic Analysis

The changes in the polymer bonds due to biodegradation were determined using FTIR-ATR spectrophotometer. The plastic films exposed to all the four strains of bacteria were analyzed at regular intervals in Magna-IR 560 Spectrophotometer (Nicolet) and FTIR spectra of the films were obtained by OMINIC. E.S·P.5.0 software. Carbonyl index (CI) was used to measure the degree of biodegradation as its value depends on the degraded carbonyl bond. CI is obtained by the formula:

Surface Morphology

The changes in surface morphology of the LDPE films before and after biotic exposure were investigated using Scanning Electron Microscope (SEM) (JEOL JSM-5600LV). The plastic strips were taken out after 40, 80 and 120 days of incubation and fixed with 5% gluteraldehyde (0.1 M PBS, pH 7.4) for 3 h. The LDPE strips were completely rinsed with 0.1 M PBS followed by post fixation with 2% gluteraldehyde–3% formaldehyde solution (v/v) in 0.1 M PBS. The films were again rinsed thoroughly in 0.1 M PBS before subsequent dehydration in 70, 90 and 100% acetone (0.1 M PBS). The films were dried overnight and sputter coated with gold before imaging. For analyzing the surface changes on the plastic films incubated with bacteria, the biofilm layer formed on the surface was washed off with 2% SDS (and quantified) before SEM observation (as reported above).

Gas Chromatography Coupled with Mass Spectroscopy (GC–MS) Analysis

The degraded products can be identified by GC–MS analysis of the samples. The plastic films weighing 0.5 g was cut into pieces and mixed with 10 ml chloroform. The mixture was ultrasonicated for 2 h at a temperature of 55°C. The extract was evaporated at room temperature and it was mixed with 2 ml of chloroform before filtering using 0.2 μm PTFE syringe filter. This filtered sample was analyzed in GC coupled with MS using helium as carrier gas. The GC was equipped with HP 5MS or DB 5MS (30 m × 0.25 mm ID, film thickness 0.25 μ) of medium polarity. The oven temperature was programmed for 40°C for 3 min to 280°C at 10°C/min, and then held at 4 min at 280°C. The samples exposed to Pseudomonas aeruginosa PAO1 were analyzed in GC–MS and was compared with the negative control since samples incubated with Pseudomonas aeruginosa PAO1 show maximum degradation as estimated by the above techniques.

Results

Planktonic and Biofilm Cell Growth Kinetics

Biofilm formation was initiated from the 40th day of incubation. It was observed that the initial period of growth of both planktonic and biofilm cells were rapid. This was because the bacterial strains are capable of using polythene films as carbon source. Biofilm growth was found to be steadily increasing on 80th and 120th days compared with the 40th day. However, the rate of growth decreased compared to the initial period. On the other hand, the serial dilutions and colony counting methods showed that bacterial proliferation became more or less constant after 15 days and very small increase in the bacterial counts was observed. The biofilm cells as well as the planktonic cells show similar growth curve (Figs. 1, 2). This can be attributed to the acclimatization of bacterium in the basal medium with the degraded carbon source from the plastics.

Weight Loss Measurements

After 120 days of incubation period, the percentage of weight reduction was 20% in Pseudomonas aeruginosa (PAO1) (B1), 11% in Pseudomonas aeruginosa (ATCC) strain (B2), 9% in Pseudomonas putida (B3), and 11.3% in Pseudomonas syringae (B4) strain. The weight reduction for the negative control was 0.3%. The weight loss of the polythene films can be attributed to the breakdown of carbon backbone due to enzymatic degradation by these bacteria. The percentage change in the weight of polythene from 40 days to 120 days of exposure to Pseudomonas spp. is shown in Fig. 3. We observed that maximum loss in weight was seen for polythene incubated with Pseudomonas aeruginosa PAO1.

Mechanical Properties

The initial TS and extension at break (EAB) for LDPE films were 0.0032 + 0.0003 MPa and 134 mm + 3%, respectively. After 120 days of incubation with Pseudomonas aeruginosa PAO1 (B1), the TS was found to decrease to −0.00078 ± 0.00011 MPa and the EAB was found to be 79 mm ± 3%. In case of incubation with Pseudomonas aeruginosa ATCC (B2), TS reduced to 0.00026 ± 0.0002 MPa and EAB decreased to 92 mm ± 3%. When exposed to Pseudomonas putida (B3), TS and EAB change to 0.00057 ± 0.0002 MPa and 112 mm ± 2% respectively, and on incubation with Pseudomonas syringae (B4), TS and EAB reduced to 0.0012 ± 0.0004 MPa and 110 mm ± 3% respectively. The changes in TS of the polythene films after biotic exposure are shown in Fig. 4. Thus, we observe that maximum decrease in TS is observed for polythene incubated with Pseudomonas aeruginosa PAO1.

Spectroscopic Variations

Structural changes in biologically treated LDPE films were analyzed using FTIR. A significant reduction in CI was observed from 40 to 120 days of incubation of the samples. After the incubation period the CI value of the LDPE films were found to be reduced by 80% when exposed to Pseudomonas aeruginosa PAO1 (B1), by 16% in the case of Pseudomonas aeruginosa ATCC (B2), by 28% when exposed to Pseudomonas putida (B3) and decreased by around 78% in the case of Pseudomonas syringae (B4). A significant reduction in carbonyl peak (1740 cm−1) was found with respect to the internal band absorbance (1460 cm−1). The reduction in CI with respect to negative control with the increase in incubation period is shown in Fig. 5. Thus, we observe that maximum decrease in CI is observed for polythene incubated with Pseudomonas aeruginosa PAO1.

Morphological Changes

The changes in surface morphology of the LDPE films were investigated by SEM after 40, 80 and 120 days of biotic exposure (after removal of biofilm). The surface changes on the polythene films were analyzed after washing with 2% SDS. It was observed that signs of surface deformation appeared after 80 days of incubation. The micro cracks on the surface can be seen after 80–120 days of incubation, although the biofilm started to form within 40 days. Scanning electron micrographs of biofilm formation are shown in Fig. 6 and the presence of surface deformation after biofilm removal is shown in Fig. 7.

Scanning electron micrographs revealing the absence of biofilm in the negative control (a–c) and the presence of biofilm formed by Pseudomonas aeruginosa PAO1 (B1) (d– f). Pseudomonas aeruginosa ATCC (B2) (g–i). Pseudomonas putida (B3) (j–l) and Pseudomonas syringae (B4) (m–o) after 40, 80 and 120 days of incubation respectively

Scanning electron micrographs revealing the surface changes (after washing the biofilm layer with 2% SDS) after incubation with Pseudomonas aeruginosa PAO1 (B1) (a–c). Pseudomonas aeruginosa ATCC (B2) (d–f). Pseudomonas putida (B3) (g–i) and Pseudomonas syringae (B4) (j– l) after 40, 80 and 120 days of incubation respectively

GC–MS Analysis

A wide variety of both volatile and semi volatile compounds were eluted by gas chromatography. GC–MS was performed for samples incubated with Pseudomonas aeruginosa PAO1. The degradation products after exposure to Pseudomonas aeruginosa PAO1 include long chain fatty acids, esters, hydrocarbons, oxygenated chemical compounds predominantly containing aldehydes, ketones, esters and ether groups, unsaturated fatty acids and certain unknown compounds. Most of the chemical compounds were eluted and detected in initial stage of the experiments (i.e. minutes). The chemicals included alkanes (such as Octadecane, Tetracosane, Pentacosane and Hexacosane), fatty acids (such as Hexadecanoic acid and Octanoic acid), ester group of alcohol and other unknown compounds. Compounds of low molecular weight such as benzene, trichloroethylene were eluted first whereas compounds having high molecular weight such as palmitic acids and other unsaturated fatty acids were eluted later. The dissociation rate of Pseudomonas aeruginosa PAO1 was found to be higher than the negative control (Fig. 8).

Discussion

Degradation of LDPE by microorganism had been known for several years. Previous reports have studied on the degradation capacity of bacterial and fungal consortium under natural conditions [2] though very few have reported in vitro activity of the microorganisms under controlled conditions. The present investigation was performed to provide a comparative analysis on biodegradation of LDPE films by different species of Pseudomonas. The present study reports on the biodegradability of LDPE by Pseudomonas aeruginosa PAO1, Pseudomonas aeruginosa ATCC, Pseudomonas putida and Pseudomonas syringae. The LDPE films were found to develop biofilm on the surface within 40 days of incubation in all the four strains of Pseudomonas spp, however the biofilm development was rapid in the case of Pseudomonas aeruginosa PAO1 (B1). Biofilm reduces the hydrophobicity of the polymer and hence it improves the degradation rate [3]. Moreover the hydrophobicity of the bacteria would be facilitated in the absence of carbon source which in turn leads to increase in attachment properties of the bacteria [10]. Extended period of incubation of the polythene film for up to 120 days results in reduction in the weight of the plastic sample in all the four strains of bacteria. In the present study, the count of the biofilm cells increased steadily during the first 40 days of incubation. All the four bacterial strains adhered to the polythene films and biofilm cells quantified were found to be of the same order for all the bacterial strains. It was also found that the growth of planktonic cells follow the same pattern as that of the biofilm cells. It was further noticed that the biofilm cells and planktonic cells show very slow changes in growth over a period of time. These results are consistent with earlier observations of Tolker-Nielsen et al. [9] who reported that Pseudomonas spp. have slow rate of microcolony formation when compared to other microorganisms. The biofilm formation presumably induced partial biodegradation. Spectrophotometric variations of LDPE films and the value of CI which determines the extent of degradation decreases with increase in incubation time and is maximum for Pseudomonas aeruginosa PAO1. The decrease in CI was complemented by decrease in weight and TS. These results suggest on the polythene degradation potential of Pseudomonas species.

Analysis of chemical composition of LDPE films by GC-MS revealed the presence of alkanes, aromatic hydrocarbon, chlorocarbon, saturated fatty acids as well as unsaturated fatty acid and other unknown compounds. The degradation of LDPE by microbes was facilitated by the formation of biofilm on the surface which enables them to breakdown the high molecular weight polymer into smaller fragments through enzymatic processes. The mechanism of degradation has been postulated to be under the presence of a series of enzymatic solubilization, however the exact mechanism has not been fully understood.

These findings support the previous work on biodegradation of LDPE under natural environmental conditions although in vitro studies have not been fully investigated using individual bacterial strains. They also provide novel ways of implementing plant pathogen for degradation purpose over a long run. Thus the information procured acts as an evidence for degradation capability of human and plant pathogens on LDPE which can be further enhanced in an industrial scale for degrading the recalcitrant materials.

Abbreviations

- LDPE:

-

Low density polythene

- GC–MS:

-

Gas chromatography coupled with mass spectroscopy

- TS:

-

Tensile strength

- EAB:

-

Extension at break

- CI:

-

Carbonyl index

References

Burd D (2008) Plastic Not Fantastic. In, Canada. http://wwsef.uwaterloo.ca/archives/2008/08BurdReport.pdf. Accessed 20 April 2008

Kathiresan K (2003) Polythene and plastic-degrading microbes in an Indian mangrove soil. Rev Biol Trop 51(3–4):629–633

Kiatkamjornwong S, Thakeow P, Sonsuk M (2001) Chemical modification of cassava starch for degradable polyethylene sheets. Polym Degrad Stab 73(2):363–375

Kim M (2003) Evaluation of degradability of hydroxypropylated potato starch/polyethylene blend films. Carbohydr Polym 54(2):173–181

Koutny M, Amato P, Muchova M, Ruzicka J, Delort AM (2009) Soil bacterial strains able to grow on the surface of oxidized polyethylene film containing prooxidant additives. Int Biodeterior Biodegrad 63(3):354–357

Mahdavi M, Jalali M, Kasra KR (2008) Biofilm formation by Salmonella enteritidis on food contact surfaces. J Biol Sci 8(2):502–505

Norman RS, Frontera-Suau R, Morris PJ (2002) Variability in Pseudomonas aeruginosa lipopolysaccharide expression during crude oil degradation. Appl Environ Microbiol 68(10):5096–5103

Roy PK, Surekha P, Tulsi E, Deshmukh C, Rajagopal C (2008) Degradation of abiotically aged LDPE films containing pro-oxidant by bacterial consortium. Polym Degrad Stab 93:1917–1922

Tolker-Nielsen T, Brinch UC, Ragas PC, Andersen JB, Jacobsen CS, Molin S (2000) Development and dynamics of Pseudomonas sp. biofilms. J Bacteriol 182(22):6482–6489

Sanin SL, Sanin FD, Bryers JD (2003) Effect of starvation on the adhesive properties of xenobiotic degrading bacteria. Process Biochem 38(6):909–914

Sivan A, Szanto M, Pavlov V (2006) Biofilm development of the polyethylene-degrading bacterium Rhodococcus ruber. Appl Microb Biotechnol 72(2):346–352

Tadros RM, Noureddini H, Timm DC (1999) Biodegradation of thermoplastic and thermosetting polyesters from Z-protected glutamic acid. J Appl Polym Sci 74(14):3513–3521

Upreti MC, Srivastava RC (2003) A potential Aspergillus species for biodegradation of polymeric materials. Curr Sci 84(11):1399–1402

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kyaw, B.M., Champakalakshmi, R., Sakharkar, M.K. et al. Biodegradation of Low Density Polythene (LDPE) by Pseudomonas Species. Indian J Microbiol 52, 411–419 (2012). https://doi.org/10.1007/s12088-012-0250-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12088-012-0250-6