Abstract

Objective

To enhance rhamnolipids production in Pseudomonas aeruginosa, an optimization strategy based on selectively blocking the metabolic bypass that competed precursors with rhamnolipids biosynthesis pathway, containing exopolysaccharide (Psl and Pel) and polyhydroxyalkanoates (PHA) synthesis pathways.

Results

Blocking the synthesis of Psl and PHA by genes knockout, both mutants P. aeruginosa SG ∆pslAB and P. aeruginosa SG ∆phaC1DC2 can grow normally in fermentation medium and increase the production of rhamnolipids by 21% and 25.3%, respectively. While blocking the synthesis of Pel, the cell growth of the mutant strain P. aeruginosa SG ∆pelA was inhibited, thus its production yield of rhamnolipids was also decreased by 39.8%. In addition, simultaneously blocking the synthesis of Psl and PHA, a double mutant strain P. aeruginosa SG ∆pslAB ∆phaC1DC2 was constructed. Rhamnolipids production was significantly increased in strain SG ∆pslAB ∆phaC1DC2 by 69.7%.

Conclusion

Through selectively blocking metabolic bypasses, increasing the amount of glycosyl and fatty acid precursors can significantly enhance rhamnolipids production in P. aeruginosa.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rhamnolipids has a broad application prospect and great potential in the field of petroleum industry, environmental remediation, agriculture, food and medicine (Müller et al. 2012). However, the industrial applications of rhamnolipids are currently limited by the low production level and high costs of downstream separation and purification (Shah et al. 2016).

Currently, the studies about improving rhamnolipids production have been focused on the aspect of screening high-yield P. aeruginosa strains (Nordin et al. 2013), optimization of fermentation process (Neto et al. 2008; Ma et al. 2016), and regulation of genes related to rhamnolipid synthesis (Gutiérrez-Gómez et al. 2018; He et al. 2017). How to further increase the production of rhamnolipids? Regulating the competitive metabolic bypass of rhamnolipids synthesis pathways would be a breakthrough perspective.

Hydroxyalkanoyloxy-alkanoic acid (HAA) and dTDP-rhamnose are two required precursors in rhamnolipids synthesis. In P. aeruginosa, some metabolic pathways compete with the glycosyl precursors and lipid precursors, such as exopolysaccharide (EPS) and polyhydroxyalkanoates (PHA) synthesis pathways, as shown in Fig. 1 (Abdel-Mawgoud et al. 2011; Soberón-Chávez et al. 2005a). EPS mainly includes two polysaccharides, Pel and Psl. As shown in Fig. 1, the dTDP-d-glucose was used as glycosyl precursor for biosynthesis of Pel and Psl. Therefore, knocking out the key genes related to Pel and Psl synthesis to block their pathways will possibly supply more glycosyl precursors to rhamnolipids synthesis pathway. Fatty acids derivatives are used as lipid substrates in both PHA synthesis and rhamnolipids synthesis pathways (Soberón-Chávez et al. 2005b). Previous study showed that the rhlAB gene-deficient strain did not produce rhamnolipids, but PHA production was significantly improved (Choi et al. 2011). It suggested that the fatty acids precursors become more available for PHA synthesis when rhamnolipids synthesis is absent. Therefore, if the PHA synthesis pathway is blocked, more fatty acids precursors would flow into the synthesis of rhamnolipids.

In this study, using gene knockout technology, the competitive metabolic bypasses, EPS and PHA pathways, were blocked in P. aeruginosa SG. The effect of blocking the Pel, Psl and PHA pathways on the growth and rhamnolipids production was comparatively studied. Based on selectively blocking metabolic bypasses, enhancing rhamnolipids production in P. aeruginosa was discussed.

Methods

Bacterial strains, media and culture conditions

The rhamnolipids-producing strain P. aeruginosa SG (GenBank accession No. KJ995745) was isolated from the oil reservoir production fluid (Zhao et al. 2015b). LB medium was used to culture Escherichia coli DH5α and recombinant strains. During gene manipulation, 100 μg/mL of ampicillin and 50 μg/mL of kanamycin were used for recombinant E. coli strains, and 350 μg/mL of kanamycin was used for recombinant P. aeruginosa strains. The fermentation medium for rhamnolipids production contained (g/L): glycerol 60, NaNO3 4.87, K2HPO4·3H2O 5.49, KH2PO4 6.97, MgSO4·7H2O 0.8, CaCl2 0.13, KCl 1.0, NaCl 1.0. The inoculum of the fermentation medium is 3%. Fermentation was performed at 37 °C and 180 rpm for 10 days. The rhamnolipids concentration was determined by oil spreading technique (Zhao et al. 2016). The bacterial biomass of culture liquid was measured by spectrophotometric determination method at 600 nm.

All bacterial strains and plasmids used in this study are listed in Supplementary Table S1. The primer pairs for PCR amplified are listed in Supplementary Table S2.

The pel operon (pelABCDEFG) and the psl operon (pslABCDFEGHIJKLMNO) controls the synthesis of Pel polysaccharide and Psl polysaccharide, respectively (Byrd et al. 2009; Friedman and Kolter 2004). The lipid groups of both PHA and rhamnolipids are derived from the de novo synthesis of fatty acids and share β-hydroxy fatty acids as their precursors (Soberón-Chávez et al. 2005b). The genes phaC1 and phaC2 are two of key coding genes for polyhydroxyalkanoate synthases (Qi et al. 1997).

To generate the gene fragments pslAB, pelA and phaC1DC2, we use the genomic DNA from P. aeruginosa SG as the template and the primer pairs listed in Supplementary Table S2 for PCR process, respectively. The pslAB fragment is 2075 bp with a EcoRI and HindIII restriction site at the 5′- and 3′-end. The pelA fragment is 2142 bp with a EcoRI and HindIII restriction site at the 5′- and 3′-end. The phaC1DC2 fragment is 2482 bp with a SalI and a HindIII restriction site at the 5′- and 3′-end.

The pslAB, pelA and phaC1DC2 fragments were respectively cloned into pMD19T(simple) vector, which was confirmed to contain the objective gene by sequencing. The pslAB fragment contains two SmaI restriction sites at 1084 bp and 1509 bp. Plasmid pMD19-∆pslAB was purified and recovered to after pMD19T-pslAB was digested with SamI. The pelA fragment contains two SalI restriction sites at 1009 bp and 1903 bp. Plasmid pMD19T-∆pelA was got by digesting pMD19T-pelA with SalI. The phaC1DC2 fragment contains two Eco52I restriction sites at positions 637 bp and 896 bp and two BamHI restriction sites at positions 1455 bp and 2233 bp. Plasmid pMD19T- ∆phaC1DC2 was obtained by the digestion of pMD19T- phaC1DC2 with Eco52I and BamHI.

The ∆pslAB fragment was cloned into the EcoRI and HindIII sites of the mobilizable plasmid pK18mobSacB to construct recombinant plasmid pK18-∆pslAB. The ∆pelA fragment was cloned into the EcoRI and HindIII sites of plasmid pK18mobSacB to construct recombinant plasmid pK18-∆pelA. The ∆phaC1DC2 fragment was inserted into the plasmid pK18mobSacB after digesting with SalI and HindIII. The recombinant plasmids pK18-∆pslAB, pK18-∆pelA and pK18-∆phaC1DC2 were, respectively, transformed into E. coli S17-1 strain. Using conjugation (Schäfer et al. 1994), the plasmids pK18-∆pslAB, pK18-∆pelA and pK18-∆phaC1DC2 were, respectively, introduced into the wild-type P. aeruginosa SG. Transconjugants were selected on LB plates containing Ampicillin and kanamycin for the first recombination. The second crossover counter-selected event used one-third LB plates containing 20% sucrose and Ampicillin, which may result in restoration of the wild type condition. The single knockout mutants, P. aeruginosa SG ∆pslAB, P. aeruginosa SG ∆pelA and P. aeruginosa SG ∆phaC1DC2, were constructed. Plasmid pK18-∆pslAB was introduced into P. aeruginosa SG ∆phaC1DC2 to construct double knockout mutant P. aeruginosa SG ∆pslAB ∆phaC1DC2.

Results and discussion

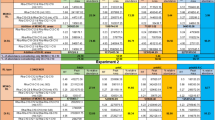

Three kinds of single mutant strains SG ∆pslAB, SG ∆pelA and SG ∆phaC1DC2 were cultured in fermentation medium to clarify the effects of these three metabolic pathways on P. aeruginosa SG growth and rhamnolipids synthesis. The results were shown in Fig. 2. Cell growth curves indicated that the growth trend of single mutant strain SG ∆pslAB and SG ∆phaC1DC2 was better than of the wild-type strain SG (Fig. 2a). The gene pelA deficient strain barely grew during the first 24 of fermentation, and its cell concentration was also lower than the wild-type strain SG during the subsequent fermentation time. These results indicated that pelA gene knockout had a negative effect on the growth of SG strain. The yield of rhamnolipids in pelA knockout strain was reduced to 7.198 g/L (3.432 g/L/OD600) (Fig. 2b), which may cause by the growth restriction of the strain. As shown in Fig. 2b, the rhamnolipid yields of strain SG ∆pslAB and SG ∆phaC1DC2 were 14.515 g/L (4.018 g/L/OD600) and 14.994 g/L (4.179 g/L/OD600), respectively. Strain SG ∆pslAB and SG ∆phaC1DC2 produced more rhamnolipids than strain SG 11.996 g/L (4.272 g/L/OD600) with increased values of 21% and 25.3%. In contrast, the rhamnolipids yield of SG ∆pelA is 39.8% lower than wild-type SG strain (Fig. 2b). At the same time, the correlations between the OD600 values and rhamnolipids yield of different strains were analyzed by SPSS Statistics software, including wild-type and knockout strains. The analysis results showed that the Pearson correlation coefficient was 0.985, and the P value was 0.112, which was not significant at the level of α = 0.05. Therefore, there is no correlation between OD600 values and rhamnolipids production of the tested strains. Therefore, the increase in rhamnolipids production is not a direct result of differential growth rates. Selectively blocking metabolic bypasses significantly enhanced rhamnolipids production in P. aeruginosa.

Effects of knocking out genes pslAB, pelA and phaC1DC2 on cell growth and rhamnolipids production of P. aeruginosa. Wild type strain P. aeruginosa SG was used as a control. Growth curve was determined by measuring OD600 value (a); curve of rhamnolipid concentration of the mutant strains SG ∆pslAB, SG ∆pelA, SG ∆phaC1DC2 and wild-type strain SG (b). The error bars indicate the standard deviation from the triplicate biological replicates

Although Psl polysaccharides is one of the components of P. aeruginosa biofilm, knocking out genes pslAB to block its synthesis does not affect the normal growth of strain SG under fermented conditions, but does increase the yield of rhamnolipids. Blocking the synthesis of Psl polysaccharides does allow more glycosyl precursors to flow to the synthesis of rhamnolipids, thereby increasing the yield of rhamnolipids. However, blocking of the synthesis of Pel polysaccharide significantly affect the normal growth of SG strain which may be related to its special role in biofilm of P. aeruginosa. The Pel Polysaccharide serves a structural role in the biofilm matrix of P.aeruginosa and protects the bacteria by enhancing the resistance to adverse environmental stress (Colvin et al. 2011). Results showed that Pel polysaccharide is more important than Psl polysaccharide in P. aeruginosa SG.

Knocking out genes phaC1DC2, the mutant strain SG ∆phaC1DC2 increased rhamnolipids production. Results indicated that removing the competition from lipid precursors in metabolic pathways can improve the synthesis of rhamnolipids. As an intracellular energy storage substance (Madison and Huisman 1999), the restriction of PHA synthesis does not affect the normal growth of SG strain. Previous studies showed that compared to the wild-type strains, rhamnolipids production was not enhanced in the PA14 ∆phaC1, PA14 ∆phaC2 and PAO1∆phaC1, PAO1∆phaC2 single mutants of P. aeruginosa PA14 and PAO1 (Choi et al. 2011). Just knocking out only one phaC gene can not completely block the synthesis of PHA. Therefore, we chose to knock out the three genes phaC1, phaD and phaC2 at the same time to ensure completely blocking the PHA synthesis.

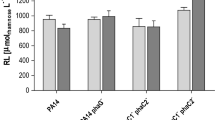

Blocking the synthesis of Psl polysaccharides and PHA have no inhibition effect on cell growth and can enhance the production of rhamnolipids. Therefore, genes pslAB and phaC1DC2 were knocked out to construct the double mutant strain SG ∆pslAB ∆phaC1DC2. The results of cell growth and rhamnolipids production were shown in Fig. 3. From the cell growth curve of the strains, the cell concentration and growth trend of the double mutant strain were better than that of the wild-type strain SG (Fig. 3a). Moreover, the rhamnolipids yield of the double mutant strain SG ∆pslAB ∆phaC1DC2 was dramatically increased to 21.496 g/L (5.98 g/L/OD600) (Fig. 3b). Simultaneously blocking the synthesis of Psl polysaccharides and PHA further significantly enhanced rhamnolipids production in P. aeruginosa. The rhamnolipids production was significantly increased (59%) in a mutant that completely impaired in PHA synthesis and over expressing rhlAB-R genes (Gutiérrez-Gómez et al. 2018). In previous studies on P. aeruginosa SG, it was found that the production of rhamnolipids improved 80% by increasing the copy number of rhlAB genes with modified promoter (Zhao et al. 2015a). Therefore, compared with other methods for increasing rhamnolipids production, the method of increasing rhamnolipid production by selectively blocking the secondary metabolic bypasses of rhamnolipids synthesis is effective and considerable.

Effects of simultaneously knocking out genes pslABand phaC1DC2 on cell growth and rhamnolipids production of P. aeruginosa. Wild type strain P. aeruginosa SG was used as a control. The cell growth curve was determined by measuring OD600 values (a); curve of rhamnolipid concentration of the double mutant strain SG ∆pslAB ∆phaC1DC2 and wild-type strain SG (b). The error bars indicate the standard deviation from the triplicate biological replicates

The metabolic engineering strategies of increase flux in precursor- providing pathway is feasible for improve rhamnolipids production in P. aeruginosa SG. Using the fermentation medium, the double mutant strain SG ∆pslAB ∆phaC1DC2 produced 21.496 g/L rhamnolipids, 69.7% higher than that of wild-type strain SG. We think the yield of rhamnolipids may be further enhanced after optimization of the medium composition and fermentation process. In further study, we will carry out the related study.

This study further clarified the competitive metabolic pathways and the key genes involved in the synthesis of rhamnolipids. From the aspect of selectively blocking metabolic bypass, we explored a metabolic pathway optimization strategy to increase rhamnolipids production of P. aeruginosa SG. Through selectively blocking metabolic bypasses, increasing the amount of glycosyl and fatty acid precursors can significantly enhance rhamnolipids production in P. aeruginosa. The results of this study provide data and ideas for enhancing rhamnolipids production by genetic modification and regulation.

References

Abdel-Mawgoud AM, Hausmann R, Lépine F, Müller MM, Déziel E (2011) Rhamnolipids: detection, analysis, biosynthesis, genetic regulation, and bioengineering of production. In: Soberón-Chávez G (ed) Biosurfactants: from genes to applications. Springer, Berlin, Heidelberg, pp 13–55

Byrd MS et al (2009) Genetic and biochemical analyses of the Psl exopolysaccharide reveal overlapping roles for polysaccharide synthesis enzymes in Psl and LPS production. Mol Microbiol 73:622–638

Choi MH, Xu J, Gutierrez M, Yoo T, Cho Y-H, Yoon SC (2011) Metabolic relationship between polyhydroxyalkanoic acid and rhamnolipid synthesis in Pseudomonas aeruginosa: comparative 13C NMR analysis of the products in wild-type and mutants. J Biotechnol 151:30–42

Colvin KM, Gordon VD, Murakami K, Borlee BR, Wozniak DJ, Wong GCL, Parsek MR (2011) The Pel polysaccharide can serve a structural and protective role in the biofilm matrix of Pseudomonas aeruginosa. PLoS Pathog 7(1):e1001264

Friedman L, Kolter R (2004) Genes involved in matrix formation in Pseudomonas aeruginosa PA14 biofilms. Mol Microbiol 51:675–690

Gutiérrez-Gómez U, Soto-Aceves MP, Servín-González L, Soberón-Chávez G (2018) Overproduction of rhamnolipids in Pseudomonas aeruginosa PA14 by redirection of the carbon flux from polyhydroxyalkanoate synthesis and overexpression of the rhlAB-R operon. Biotechnol Lett 40:1561–1566

He C, Dong W, Li J, Li Y, Huang C, Ma Y (2017) Characterization of rhamnolipid biosurfactants produced by recombinant Pseudomonas aeruginosa strain DAB with removal of crude oil. Biotechnol Lett 39:1381–1388

Ma KY, Sun MY, Dong W, He CQ, Chen FL, Ma YL (2016) Effects of nutrition optimization strategy on rhamnolipid production in a Pseudomonas aeruginosa strain DN1 for bioremediation of crude oil. Biocatal Agric Biotechnol 6:144–151

Madison LL, Huisman GW (1999) Metabolic engineering of poly(3-hydroxyalkanoates): from DNA to plastic. Microbiol Mol Biol Rev 63:21–53

Müller MM, Kügler JH, Henkel M, Gerlitzki M, Hörmann B, Pöhnlein M, Syldatk C, Hausmann R (2012) Rhamnolipids-next generation surfactants? J Biotechnol 162:366–380

Neto DC, Meira JA, de Araújo JM, Mitchell DA, Krieger N (2008) Optimization of the production of rhamnolipids by Pseudomonas aeruginosa UFPEDA 614 in solid-state culture. Appl Microbiol Biotechnol 81(3):441

Nordin N, Zakaria MR, Effendi Halmi M, Ariff A, Mohd Zawawi R, Wasoh H (2013) Isolation and screening of high efficiency bio-surfactant-producing bacteria Pseudomonas sp. J Biochem Microbiol Biotechnol 1:25–31

Qi Q, Rehm BHA, Steinbüchel A (1997) Synthesis of poly(3-hydroxyalkanoates) in Escherichia coli expressing the PHA synthase gene phaC2 from Pseudomonas aeruginosa: comparison of PhaC1 and PhaC2. FEMS Microbiol Lett 157:155–162

Schäfer A, Tauch A, Jäger W, Kalinowski J, Thierbach G, Pühler A (1994) Small mobilizable multi-purpose cloning vectors derived from the Escherichia coli plasmids pK18 and pK19: selection of defined deletions in the chromosome of Corynebacterium glutamicum. Gene 145:69–73

Shah MUH, Sivapragasam M, Moniruzzaman M, Yusup SB (2016) A comparison of recovery methods of rhamnolipids produced by Pseudomonas aeruginosa. Procedia Eng 148:494–500

Soberón-Chávez G, Lépine F, Déziel E (2005a) Production of rhamnolipids by Pseudomonas aeruginosa. Appl Microbiol Biotechnol 68:718–725

Soberón-Chávez G, Aguirre-Ramírez M, Sánchez R (2005b) The Pseudomonas aeruginosa RhlA enzyme is involved in rhamnolipid and polyhydroxyalkanoate production. J Ind Microbiol Biotechnol 32:675

Zhao F, Cui Q, Han S, Dong H, Zhang J, Ma F, Zhang Y (2015a) Enhanced rhamnolipid production of Pseudomonas aeruginosa SG by increasing copy number of rhlAB genes with modified promoter. RSC Adv 5:70546–70552

Zhao F, Zhang J, Shi R, Han S, Ma F, Zhang Y (2015b) Production of biosurfactant by a Pseudomonas aeruginosa isolate and its applicability to in situ microbial enhanced oil recovery under anoxic conditions. RSC Adv 5:36044–36050

Zhao F, Liang X, Ban Y, Han S, Zhang J, Zhang Y, Ma F (2016) Comparison of methods to quantify rhamnolipids and optimization of oil spreading method. Tenside Surfact Det 53(3):243–248

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (31700117), the China Postdoctoral Science Foundation (2017M621292) and the Science and Technology Service Network Initiative (KFJ-STS-ZDTP-064).

Supporting information

Supplementary Table S1—Shows all bacterial strains and plasmids in this study

Supplementary Table S2—Shows the primer pairs used to construct mutants SG ∆pslAB, SG ∆pelA and SG ∆phaC1DC2

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lei, L., Zhao, F., Han, S. et al. Enhanced rhamnolipids production in Pseudomonas aeruginosa SG by selectively blocking metabolic bypasses of glycosyl and fatty acid precursors. Biotechnol Lett 42, 997–1002 (2020). https://doi.org/10.1007/s10529-020-02838-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-020-02838-9