Abstract

Objective

To construct Pseudomonas aeruginosa PA14 derivatives that overproduce rhamnolipids (RL) by blocking the synthesis of the carbon-storage polymer polyhydroxyalkanoates (PHA) and by overexpressing the rhlAB-R operon that encodes for enzymes of RL synthesis and the RhlR transcriptional regulator.

Results

In contrast to previous results showing that overexpression of rhlAB-R genes in two P. aeruginosa strains (PAO1 and ATCC 9027) is sufficient to overproduce RL, we show that a PA14 derivative overexpressing the rhlAB-R operon did not increase the synthesis of these biosurfactants. In addition, PA14 mutants deficient in PHA production did not overproduce RL either. However, if the rhlAB-R genes were expressed in a mutant that is completely impaired in PHA synthesis, a significant increase in RL production was observed (59%). These results show that RL production in PA14 is limited both by the availability of fatty acid precursors and by the levels of the RhlA and RhlB enzymes that are involved in the synthesis of mono-RL.

Conclusions

The limitation of RL production by P. aeruginosa PA14 is multifactorial and diverse from the results obtained with other strains. Thus, the factors that limit RL production are particular to each P. aeruginosa strain, so strain-specific strategies should be developed to increase their production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The biosurfactants rhamnolipids (RL) produced by Pseudomonas aeruginosa have a high biotechnological potential and have been approved by the US Environmental Protection Agency for use in food products, cosmetics and pharmaceuticals. However, their industrial application is limited by the low level of their production (Banat et al. 2010) and also because P. aeruginosa is an opportunistic pathogen (Gellatly and Hancock 2013).

There have been different attempts to develop strains that overproduce RL, using modified P. aeruginosa strains (Grosso-Becerra et al. 2016) or heterologous hosts such as Pseudomonas putida KT2440 (Wittgens et al. 2011). The comparison of RL maximum yield and productivity between several strains of P. aeruginosa, including the type strain PAO1 and different heterologous hosts, showed that the best yield and productivity was obtained with PAO1 strain cultivated with sunflower oil as carbon source (Dobler et al. 2016).

In P. aeruginosa the production of RL is regulated at the level of transcription by a complex regulatory circuit called quorum-sensing (Williams and Cámara 2009). The rhlAB operon encodes the enzymes responsible for the synthesis of mono-RL (containing one molecule of rhamnose) whereas rhlC encodes the enzyme that synthesizes di-RL (RL with two rhamnose moieties) using mono-RL as substrate. Transcription of rhlAB and rhlC is activated by RhlR when coupled with the autoinducer butanoyl-homoserine lactone (Soberón-Chávez et al. 2005b). At 37 °C a positive RhlR-dependent regulatory loop is formed, leading to an increased expression of rhlAB and the formation of the rhlAB-R operon (Croda-García et al. 2011; Grosso-Becerra et al. 2014). It has been shown that the expression from a plasmid of the rhlAB-R operon increases RL production in P. aeruginosa strains PAO1 and ATCC 9027 (Grosso-Becerra et al. 2016).

The syntheses of RL and of polyhydroxyalkanoates (PHA) in P. aeruginosa are interconnected (Nitschke et al. 2011). It has been shown that RhlA, the first enzyme in the RL biosynthetic pathway, uses as substrates CoA-linked fatty acids derivatives (Abdel-Mawgoud et al. 2014) that are also intermediates of PHA synthesis. The synthesis of this polymer is catalyzed by the PhaC1 and PhaC2 synthases (Nitschke et al. 2011) using CoA-linked β-hydroxy fatty acids. When P. aeruginosa is cultured in media with either a sugar or glycerol as carbon source, the substrates of PhaC1 and PhaC2 synthases are provided by the PhaG transacylase, that converts ACP-β-hydroxy fatty acids to CoA-β-hydroxy fatty acids (Hoffmann et al. 2000). In addition, it has been reported that the intermediates synthetized by RhlA can be used as substrate for PHA synthesis (Soberón-Chávez et al. 2005a).

The engineered P. putida KT2440 strain used for RL production contains a plasmid for expression of the rhlAB operon from an inducible promoter and a mutation in phaC1 that reduces PHA synthesis; this strain produces similar levels of RL as the PAO1 wild type strain of P. aeruginosa (Wittgens et al. 2011).

The aim of this work is to construct P. aeruginosa PA14 derivatives with increased RL production. This strain is highly virulent (Lee et al. 2006) and produces high RL levels with a similar proportion of mono- and di-RL.

Methods

The concentration of RL was estimated by the orcinol method (Chandrasekaran and Bemiller 1980). PHA was determined by hypochlorite digestion (Berger et al. 1989) and spectophotometric quantification of fatty acids derivatives at 235 nm by a similar procedure to that reported for polyhydroxybutyrate (Slepecky and Law 1960). The conversion of absorbance at 235 nm to PHA weight (expressed as μg/mL) was experimentally determined using a standard curve obtained with a known dry weight of purified PHA resuspended in 1 mL of sulfuric acid as described in Supplementary Fig. S1. Each experiment was done in triplicate and the standard deviation is shown.

Strains were routinely cultured in PPGAS medium (Zhang and Miller 1992) at 37 °C. Samples to measure RL and PHA production were obtained at 16 h of growth; this time point corresponds to the early stationary phase of strain PA14 growth curve (Supplementary Fig. S2), and it has been reported that, at this PA14 growth stage, the RL and PHA maximum yields occur (Gutierrez et al. 2013).

Apramycin and gentamycin were used at a concentration of 100 μg/mL.

The proportion of mono- and di-RL was evaluated by analyzing the image (using the ImageJ software) obtained from a thin-layer chromatography done as previously described (Matsuyama et al. 1987).

The phaC2::MAR2xT7 strain obtained from the PA14 collection of mutants (Liberati et al. 2006) as a transposon insertion in phaC2 (ID 54085) is completely impaired in PHA production (Supplementary Fig. S3), so we hypothesized that it contained a mutated phaC1 gene besides the insertion in phaC2. The alignment of the nucleotide sequence of the phaC1 gene and also of the derived amino acid in the PA14 wild type strain (phaC1wt) and the phaC2::MAR2xT7 mutant (ID 54085) (phaC1m) showed that in the strain obtained from the PA14 mutant collection (ID 54085), the phaC1 gene has two nucleotide changes: a C to G transversion in nucleotide position 1276 and a G to A transition in nucleotide position 1651, that result in P426A and A551T substitutions in the PhaC1 amino acid sequence.

To further confirm that the phaC1 gene with two missense mutations (phaC1m) was not functional, we used the phaC1::MAR2xT7 mutant (ID 32531, Liberati et al. 2006) as recipient in complementation tests. We showed that the expression in trans from plasmid pUCP20 (West et al. 1994) of the phaC1m gene does not complement the PHA deficient phenotype of the phaC1::MAR2xT7 mutant, while the expression of phaC1wt fully complements PHA production (Supplementary Fig. S3). These results confirms that strain phaC2::MAR2xT7 (ID 54085) is a phaC1 phaC2 double mutant.

The aac(3)IV cassette which confers resistance to apramycin (Gust et al. 2003) was used to construct the phaG mutant. The PA14 derived ΔphaG::aac(3)IV mutant and the ΔphaG::aac(3)IV phaC1 phaC2::MAR2xT7 triple mutant used in this work were constructed as reported (Lesic and Rahme 2008). The oligonucleotides used to construct the ΔphaG::aac(3)IV mutant and the plasmids carrying the phaC1wt and phaC1m genes are shown in Supplementary Table S1.

Results and discussion

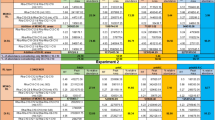

To increase RL production in PA14 we introduced plasmid pJGM4-rhlAB-R that has been shown to increase production of these biosurfactants in the P. aeruginosa strains PAO1 and ATCC 9027 (Grosso-Becerra et al. 2016) but, contrary to our prediction, the production of RL was not increased (Fig. 1). One explanation for this result is that in the PA14 background there is a limitation of the RhlA substrates, which are the CoA-linked fatty acid derivatives produced by RhlY and RhlZ (Abdel-Mawgoud et al. 2014) or of the RhlB substrate TDP-L-rhamnose (Soberón-Chávez et al. 2005b).

Evaluation of the effect of mutations in the PA14 genes encoding for the enzymes that participate in the PHA biosynthetic pathway and of the overexpression of the rhlAB-R operon in RL production. Overexpression of the rhlAB-R operon was achieved by introduction of plasmid pJG4-rhlAB-R in these PA14 derivatives. The only strain that showed significant RL overproduction was the ΔphaG::aac(3)IV phaC1 phaC2::MAR2xT7 triple mutant carrying pJG4-rhlAB-R

To increase the availability of the fatty acid precursor of RL we isolated the following PA14 mutants that are deficient in PHA production: a ΔphaG::aac(3)IV single mutant, a phaC1 phaC2::MAR2xT7 double mutant, and ΔphaG::aac(3)IV phaC1 phaC2::MAR2xT7 triple mutant.

The ΔphaG::aac(3)IV single mutant showed around a 30% decrease in PHA production, whereas the phaC1 phaC2::MAR2xT7 double mutant was completely impaired in PHA production (Supplementary Fig. S3). Contrary to our predictions, RL production was not increased in either of these mutants (Fig. 1).

These results suggest that the increase in the CoA-fatty acid RhlA substrates in the PHA-deficient mutants is not sufficient to increase the flux of the RL biosynthetic pathway that involves not only RhlA, but also RhlB and RhlC.

To determine whether PA14 RL production was limited both by the availability of the CoA-fatty acids precursors of RhlA and the activity of RhlA and RhlB enzymes, we introduced the pJGM4-rhlAB-R plasmid to the PA14 mutants deficient in PHA synthesis.

We found that the level of RL produced by PA14 derivatives is only increased in the ΔphaG::aac(3)IV phaC1 phaC2::MAR2xT7 triple mutant carrying plasmid pJGM4-rhlAB-R (Fig. 1). This increment in RL production represents a 59% higher level of total RL than the PA14 wild type strain. These results suggest that RL production by PA14 strain is limited not only by the availability of CoA-fatty acids precursors, but also by the RhlA and RhlB enzyme levels. It is also apparent that the factors that limit RL production might be particular for each P. aeruginosa isolate, and thus specific metabolic engineering strategies should be developed for each strain.

An unexpected finding was that the phaC1 phaC2::MAR2xT7 double mutant carrying pJGM4-rhlAB-R did not show an increase in RL production, even though it is completely impaired in PHA synthesis (Supplementary Fig. S3). This result suggests that the CoA linked (R)-β-hydroxy acids synthesized by PhaG cannot be used by RhlA as RL precursors.

The lack of correlation between null PHA production and increased synthesis of RL observed in this work, shows that the strategy for increasing RL production by partial blockage of the PHA biosynthetic pathway, such as the use of a phaC1 mutant in the P. putida KT2440 background (Wittgens et al. 2011) should be evaluated for each strain and not taken for granted.

We measured RL production as the equivalent of rhamnose concentration by the orcinol method after hydrolysis of RL. Thus, if the PA14 RL hyper-producing derivative ΔphaG::aac(3)IV phaC1 phaC2::MAR2xT7/pJG4-rhlAB-R presented a lower mono-RL/di-RL ratio, we could overestimate the increment of RL. To determine whether the proportion of mono-RL/di-RL ratio was significant altered in this PA14 derivative we performed a thin-layer chromatography of culture supernatants of this strain compared to PA14 and PAO1 strains (Fig. 2). Strain PAO1 produces a 1:3 ratio of mono-RL:di-RL (Müller et al. 2011), while PA14 has been reported to present a higher 1:2 ratio (Abdel-Mawgoud et al. 2014). It is apparent that the RL hyper-producing strain does not have a lower mono-RL:di-RL ratio, but a slightly higher one, suggesting that RhlC activity is somewhat limiting in this condition. This result shows that the 59% increment in RL production by PA14 ΔphaG::aac(3)IV phaC1− phaC2::MAR2xT7/pJG4-rhlAB-R was not an overestimation.

Production of mono-RL and di-RL observed by thin-layer chromatography (TLC). a Chromatogram of culture supernatants of P. aeruginosa strains [PA14 wild-type (wt), PAO1 wild-type (wt), and PA14 ΔphaG::aac(3)IV phaC1 phaC2::MAR2xT7/pJG4-rhlAB-R]; b TLC image analysis using the ImageJ software to determine the ratios of each RL type

The aim of this work was to show that it is feasible to increase RL production even in P. aeruginosa strains that have a high basal level of production of this biosurfactant. The PA14 strain produces around a 55% higher concentration of RL than PAO1 strain in our culture conditions (PAO1 produces 548 μmol of rhamnose in RL per litre of culture), and we were able to further increase their production by 59%. The effect on RL production of increasing the availability of the TDP-L-rhamnose substrate of RhlB and RhlC, and of the overexpression of RhlC remains to be determined.

References

Abdel-Mawgoud AM, Lépine F, Déziel E (2014) A stereospecific pathway diverts β-oxidation intermediates to the biosynthesis of rhamnolipids biosurfactants. Chem Biol 21:1–9

Banat I, Franzetti A, Bestetti G (2010) Microbial biosurfactants production, applications and future potential. Appl Microbiol Biotechnol 87:427–444

Berger E, Ramsay BA, Ramsay JA, Chavarie C (1989) PHB recovery by hypochlorite digestion of non-PHB biomass. Biotechnol Tech 3(4):227–232

Chandrasekaran EV, Bemiller JN (1980) Constituent analyses of glycosaminoglycans. Methods Carbohydr Chem 8:89–96

Croda-García G, Grosso-Becerra V, González A et al (2011) Transcriptional regulation of Pseudomonas aeruginosa rhlR: role of the Crp-ortholog Vfr (virulence factor regulator) and quorum-sensing regulators LasR and RhlR. Microbiology 157(9):2545–2555

Dobler L, Vilella LF, Almeida RC, Neves BC (2016) Rhamnolipids in perspective: gene regulation pathways, metabolic engineering, production and technological forecasting. New Biotechnol 33(1):123–133

Gellatly SL, Hancock REW (2013) Pseudomonas aeruginosa: new insights into pathogenesis and host defenses. Pathog Dis 67:159–173

Grosso-Becerra MV, Croda-García G, Merino E, Servín-González L et al (2014) Regulation of Pseudomonas aeruginosa virulence factors by two novel RNA thermometers. Proc Natl Acad Sci USA 111(43):15562–15567

Grosso-Becerra MV, González-Valdez A, Granados-Martínez MJ et al (2016) Pseudomonas aeruginosa ATCC 9027 is a non-virulent strain suitable for mono-rhamnolipids production. Appl Microbiol Biotech 100(23):9995–10004

Gust B, Challis GL, Fowler K et al (2003) PCR-targeted Streptomyces gene replacement identifies a protein domain needed for biosynthesis of the sesquiterpene soil odor geosmin. Proc Natl Acad Sci USA 100(4):1541–1546

Gutierrez M, Choi MH, Tian B et al (2013) Simultaneous inhibition of rhamnolipids and polyhydroxyalkanoic acid synthesis and biofilm formation by 2-bromoalkanoic acids: effect of inhibitor alkyl-chain length. PLoS ONE 8(9):e73986. https://doi.org/10.1371/journal.pone.0073986

Hoffmann N, Steinbüchel A, Rehm B (2000) The Pseudomonas aeruginosa phaG gene product is involved in the synthesis of polyhydroxyalkanoic acid consisting of medium-chain-length from non-related carbon sources. FEMS Microbiol Lett 184(2):253–259

Lee DG, Urbach JM, Wu G et al (2006) Genomic analysis reveals that Pseudomonas aeruginosa virulence is combinatorial. Genome Biol 7:R90

Lesic B, Rahme LG (2008) Use of the lambda Red recombinase system to rapidly generate mutants in Pseudomonas aeruginosa. BMC Biol Mol 9:20–28

Liberati NT, Urbach JM, Miyada S et al (2006) An ordered non-redundant library of Pseudomonas aeruginosa strain PA14 transposon insertion mutants. Proc Natl Acad Sci USA 103(8):2833–2838

Matsuyama T, Sogawa M, Yano I (1987) Direct colony thin-layer chromatography and rapid characterization of Serratia marscescens wetting agents. Appl Environ Microbiol 53:1186–1188

Müller MM, Hörmann B, Kugel M, Syldark C, Hausmann R (2011) Evaluation of rhamnolipid production capacity of Pseudomonas aeruginosa PAO1 in comparison to the rhamnolipids overproducing strains DSM2874. Appl Microbiol Biotechnol 89:585–592

Nitschke M, Costa SGVAO, Contiero J (2011) Rhamnolipids and PHAs: recent reports on Pseudomonas-derived molecules of increasing industrial interest. Process Biochem 46:621–630

Slepecky RA, Law JH (1960) A rapid spectophometric assay of alpha, beta-unsaturated acids and beta-hydroxy acids. Anal Chem 32:1697–1699

Soberón-Chávez G, Aguirre-Ramírez M, Sánchez R (2005a) The Pseudomonas aeruginosa RhlA enzyme is not only involved in rhamnolipid, but also in polyhydroxyalkanoate production. J Ind Microbiol Biotechnol 32:675–677

Soberón-Chávez G, Lépine F, Déziel E (2005b) Production of rhamnolipids by Pseudomonas aeruginosa. Appl Microbiol Biotechnol 68:718–725

West SEH, Schweizer HP, Dall C et al (1994) Construction of improved Escherichia-Pseudomonas shuttle vectors derived from pUC18/19 and sequence of the region required for their replication in Pseudomonas aeruginosa. Gene 148:81–86

Williams P, Cámara M (2009) Quorum sensing and environmental adaptation in Pseudomonas aeruginosa: a tale of regulatory networks and multifunctional signal molecules. Curr Opin Microbiol 12:182–191

Wittgens A, Tiso T, Arndt TT et al (2011) Growth independent rhamnolipid production from glucose using the non-pathogenic Pseudomonas putida KT2440. Microbial Cell Fact 10:80

Zhang Y, Miller RM (1992) Enhanced octadecane dispersion and biodegradation by a Pseudomonas rhamnolipid surfactant (biosurfactant). Appl Environ Microbiol 58:3276–3282

Acknowledgements

UGG and MPSA are doctoral student of Programa de Maestría y Doctorado en Ciencias Bioquímicas, Universidad Nacional Autónoma de México (UNAM), this study was performed in partial fulfillment of the requirements for UGG doctorate degree. UGG (CVU-422007) and MPSA (CVU-741217) received a fellowship from CONACYT. We acknowledge Abigail González-Valdez for technical assistance. This work was supported in part by grant IN200416 from Programa de Apoyo a Proyectos de Investigación e Innovación Tecnológica, (Dirección General de Asuntos del Personal Académico -UNAM) and grant 252269 from Consejo Nacional de Ciencia y Tecnología (CONACYT).

Supporting information

Supplementary Fig. 1—shows the standard curve use to determine PHA weight from absorbance at 235 nm.

Supplementary Fig. 2—presents the PA14 strain growth curve in PPGAS medium.

Supplementary Fig. 3—shows the PHA production of PA14 derivatives carrying mutations in genes involved in the synthesis of this fatty acid polymer, and the experiments showing that the phaC1 gene of the phaC2::MAR2xT7 mutant (ID 54085) is not functional since it is unable to complement the phaC1::MAR2xT7 mutant (ID 32531) for PHA synthesis.

Supplementary Table S1—shows the oligonucleotides used to construct the PA14 ΔphaG::aac(3)IV mutant and the pUCP20 derived plasmids expressing phaC1wt and phaC1m.

Supplementary Table S2—shows the results obtained from the analysis of the image of thin-layer chromatography presented in Fig. 2, using the ImageJ software.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gutiérrez-Gómez, U., Soto-Aceves, M.P., Servín-González, L. et al. Overproduction of rhamnolipids in Pseudomonas aeruginosa PA14 by redirection of the carbon flux from polyhydroxyalkanoate synthesis and overexpression of the rhlAB-R operon. Biotechnol Lett 40, 1561–1566 (2018). https://doi.org/10.1007/s10529-018-2610-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-018-2610-8