Abstract

In recent years, biosurfactants have attracted attention because of their low toxicity, high biodegradability, and good ecological acceptability. However, their production in submerged liquid culture is hampered by the severe foaming that occurs. Solid-state cultivation can avoid this problem. In the current work, we optimized the production of a rhamnolipid biosurfactant by Pseudomonas aeruginosa UFPEDA 614, grown on a solid medium impregnated with a solution containing glycerol. During the study, we increased the production of the biosurfactant over tenfold, with levels reaching 172 g of rhamnolipid per kilogram of dry initial substrate after 12 days. On the basis of the volume of impregnating solution added to the solid support, this yield is of the order of 46 g/L, which is comparable with the best results that have been obtained to date in submerged liquid cultivation. Our results suggest that there is a great potential for using solid-state cultivation for the production of rhamnolipids.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Surfactants have important applications in the oil industry due to their ability to reduce the surface tension at oil–water interfaces. They can be used not only to enhance oil recovery from mature oil reservoirs but also in the management of oil spills. Surfactants manufactured by the chemical industry are being used for these applications, but they pose environmental problems because of their toxicity and resistance to degradation (Mulligan 2005). There is currently interest in replacing these chemical surfactants with surfactants of biological origin. These “biosurfactants” are usually less toxic and more easily biodegradable (Karanth et al. 1999; Makkar and Cameotra 2002; Nitschke et al. 2005a, 2005b; Costa et al. 2006).

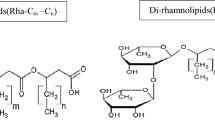

Biosurfactants produced by bacteria, fungi, and yeasts include glycolipids, lipoaminoacids, lipopeptides, lipoproteins, lipopolysaccharides, phospholipids, monoglycerides, and diglycerides. Among these, the rhamnolipids produced by strains of Pseudomonas have received much attention due to their remarkable tensioactive and emulsifying properties (Maier and Soberón-Chavez 2000; Mulligan 2005). Rhamnolipids are well suited for applications in bioremediation of oil pollutants since they have high emulsification activity and minor antibiotic effects. Furthermore, they are less strongly retained on negatively charged soil particles than are non-ionic or cationic chemical surfactants (Mulligan 2005; Bordas et al. 2005).

In a previous work, we produced rhamnolipids by submerged liquid culture (SLC) of Pseudomonas aeruginosa UFPEDA 614 in Erlenmeyer flasks (Monteiro et al. 2007). However, when we attempted to transfer the process to bioreactors, we faced a problem that has already been reported: SLC in bioreactors involves forced aeration and agitation, and large quantities of foam are produced when the biosurfactant starts to be secreted into the medium (Veenanadig et al. 2000; Lee and Kim 2004; Yeh et al. 2006). This foaming reduces the productivity of the process and increases the risks of contamination. Although the foam can be combated by the addition of anti-foaming agents or by mechanical means, these strategies are not highly effective and they increase the costs of bioreactor operation or downstream processing.

We then turned to solid-state cultivation (SSC), which had not previously been tried for the production of rhamnolipids. SSC has the potential to avoid foaming problems even when biosurfactants are produced in forcefully aerated bioreactors. We obtained a rhamnolipid preparation with excellent surfactant properties, with emulsification indices (E) of over 90% with kerosene, gasoline, and diesel after 24 h (Meira 2007). Since the rhamnolipid yields obtained in SSC by Meira (2007) were quite low, the aim of the current work was to optimize the production of rhamnolipids by P. aeruginosa in this system.

Materials and methods

Microorganism and cultivation

P. aeruginosa UFPEDA 614, originally isolated from a petrochemical plant located in Canto do Amaro, Rio Grande do Norte, Brazil, was provided by the Department of Antibiotics at the University of Pernambuco, Recife, Brazil. Stock cultures were stored in Luria–Bertani (LB) broth with 40% (w/v) glycerol at −18 °C. Each seed culture was prepared by inoculating 1 mL of stock culture into 50 mL of LB broth, within a 250-mL conical flask. This was incubated at 30 °C and 200 rpm in an orbital shaker until the optical density at 600 nm reached 0.6 to 0.8, indicating that it was in mid-exponential phase. The broth was then used as inoculum for SSC or SLC.

Production of rhamnolipids by SSC

In the “standard cultivation”, each 250-mL Erlenmeyer flask contained 10 g of dry sugarcane bagasse (kindly donated by Usina de Álcool Melhoramentos, Jussara, Paraná, Brazil), which had been dried at room temperature. The flask was then autoclaved at 121 °C for 15 min. Fifty milliliters of impregnating solution was inoculated with 2 mL of seed culture, and this was mixed into the bagasse. Inoculation levels quoted represent the volume of seed culture as a percentage of the volume of the impregnating solution, so this inoculation level will be referred to as 4%. The impregnating solution itself contained, per liter, 3.0 g KH2PO4, 7.0 g K2HPO4, 0.2 g MgSO4.7H2O, and 1 g (NH4)2SO4 and glycerol (Meira 2007). The amount of glycerol is quoted as percent (v/v; volume of glycerol per total volume of impregnating solution). The inoculated flasks were incubated at 30 °C.

In the experiments that involved partial or total replacement of sugarcane bagasse with sunflower seed meal, the fraction of ground whole sunflower seeds that was used was either that retained between 10- and 20-mesh sieves (openings of 1.7 and 0.85 mm, respectively) or that which passed through the 10-mesh sieve. In all cases, the total initial mass of dry solids was maintained at 10 g.

Production of rhamnolipids by submerged liquid cultivation

One milliliter of mid-exponential phase seed culture was inoculated into a 250-mL Erlenmeyer flask containing 50 mL sterile impregnating solution with 3% (v/v) glycerol. Flasks were incubated at 30 °C at 200 rpm on an orbital shaker for 12 days.

Extraction of rhamnolipids

Each flask received 100 mL of distilled water and was agitated for 1 h at 200 rpm at 30 °C on an orbital shaker. The suspension was filtered through cheesecloth, the excess liquid being squeezed out manually. This procedure was done three times. The extract was centrifuged for 10 min at 12,500×g, and the supernatant was extracted at least three times with chloroform–methanol (3:1, v/v), with 15 mL of this solvent mixture being used for each extraction. The organic phase was concentrated at reduced pressure at 40 °C, giving rise to a crude extract containing the rhamnolipids.

Quantification of rhamnolipids

Rhamnolipids were quantified by measuring the amount of rhamnose, using the phenol-sulfuric acid method (Dubois et al. 1956) with rhamnose as the standard. A control was done with a sample prepared from uncultured medium in order to check for interference from medium components. Since the rhamnose moiety represents only part of the rhamnolipid molecule, it is necessary to multiply the mass of rhamnose by a correction factor. This factor has been calculated as ranging between 3.0 (Itoh et al. 1971) and 3.4 (Benincasa et al. 2002). Note that the number is not exact since the rhamnolipid biosurfactant is not composed of a single molecule but rather of family of congeners that have different molecular masses (Monteiro et al. 2007). In the current work, we use an average value of 3.2.

Factorial experiment

Rhamnolipid production by SSC was optimized using a 22 complete factorial design with four axial points and four central points. The regression analyses, statistical significances, and response surfaces were obtained using Statistica version 6.0.

Results

Initial studies

In the study undertaken by Meira (2007) of rhamnolipid production in SSC, rhamnolipid levels were still increasing at the time of their last sample, at 288 h. Therefore, our first experiment was a kinetic study with a longer culture time. We used the best substrate identified by Meira (2007), namely sugarcane bagasse, with an impregnating solution containing 3% (v/v) glycerol. We express rhamnolipid levels in two different ways. Firstly, we use the traditional basis, in which product concentrations in SSC systems are expressed as the mass of product per kilogram of initial dry solids (hereafter, this will be written as “g/kg-IDS”). Secondly, in order to allow a direct comparison with results obtained in SLC, we express the product concentration per liter of impregnating solution added to the sugarcane bagasse (hereafter, this will be written as “g/L-IS”).

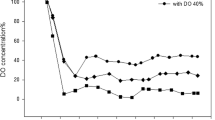

The rhamnolipid level initially increased linearly, reaching 3.78 g/L-IS (equivalent to approximately 19 g/kg-IDS) at 216 h (Fig. 1). The level then increased slowly, reaching a plateau at values of around 4.5 g/L-IS (23 g/kg-IDS) over the period of 400 to 700 h.

We then studied the effect of various changes to the culture medium. All the changes reported in Table 1 are relative to the standard cultivation, which used the same conditions as the experiment shown in Fig. 1. The comparison was done on the basis of the rhamnolipid level at 288 h. The standard cultivation was repeated several times. Rhamnolipid levels were quite reproducible, at around 4.0 g/L-IS (STD, Table 1).

Removal of the buffer or the salts from the impregnating solution decreased rhamnolipid production (GS and GB, Table 1). Replacement of the reagent grade glycerol with crude glycerol obtained from biodiesel production also led to lower levels (CG, Table 1). The effect of the residual sugars within the sugarcane bagasse was tested using bagasse that had been previously washed (WB, Table 1). However, washing gave a significantly lower rhamnolipid yield.

The best results for rhamnolipid production that have been reported for SLC were obtained with the addition of either oils or residues rich in oils to the culture medium (Lang and Wullbrandt 1999; Nitschke et al. 2005b; Costa et al. 2006; Benincasa et al. 2002; Benincasa and Accorsini 2008). Therefore we tested soy, corn, and sunflower oils as replacements for glycerol in the formulation of the medium (YO, CO, and FO, Table 1). However, in all three cases, the rhamnolipid production was lower than that obtained in the standard culture. This may be due to physical considerations, since the substrates in which the oils were added had a different appearance in that a layer of oil was visible on the surface of the substrate particles. This layer would have interfered with gas transfer within the substrate bed.

Based on the consideration that the deceleration of rhamnolipid production in Fig. 1 might be due to exhaustion of glycerol, two strategies were tried. Firstly, 6% (v/v) glycerol was added at the start of the cultivation (G6, Table 1). However, this gave a rhamnolipid level of 4.06 g/L-IS, which is not significantly different from that obtained in the standard cultivation. Secondly, a cultivation was initiated as a standard cultivation, but after 144 h an additional aliquot of glycerol (identical to the one added at the beginning) was added (G3G3, Table 1). However, this caused a large reduction in rhamnolipid production, producing only 0.48 g/L-IS. This may be due to the fact that the substrate agglomerated while the second glycerol aliquot was being mixed in.

In another attempt to improve production, the bacterium was allowed to grow in the impregnating solution on a shaker at 30 °C and 200 rpm for 24 h before the impregnating solution was mixed in with the bagasse (PF, Table 1). This strategy was successful, with the rhamnolipid level at 288 h being increased to 7.04 g/L-IS.

Rhamnolipid production was also significantly improved by substituting 50% of the sugarcane bagasse with sunflower seed meal (the fraction between 10 and 20 mesh), with 6.18 g/L-IS being reached (BSG3, Table 1). This result prompted us to increase the amount of glycerol. A yield of 17.92 g/L-IS was obtained in a cultivation in which an impregnating solution that contained 6% (v/v) glycerol was added to the 50:50 mixture of bagasse and sunflower seed meal at the start of the cultivation (BSG6, Table 1). This value is over four times higher than that obtained with the original standard cultivation. It is also higher than the value of 12.18 g/L obtained in SLC (Table 1), in a comparison based on the volume of liquid used in the two processes. The good results obtained with the addition of sunflower seed meal may be due to the fact that oils are good inductors of rhamnolipid production, as shown by studies in SLC (Trummler et al. 2003; Nitschke et al. 2005b; Costa et al. 2006; Benincasa et al. 2002, Benincasa and Accorsini 2008). Note that addition of sunflower oil in the form of a meal avoided the problem that occurred when sunflower oil itself was added (i.e., coating of the substrate by an oil film). Another possible reason for the better production is that the combination of substrates produced a substrate bed with better properties, given that the mixture of sunflower seed meal and bagasse produced fewer agglomerates than did the substrate based on bagasse only.

Optimization of the positive factors identified in the initial study

We studied the three positive factors identified in the initial study, namely the pre-culture of the inoculum in the impregnating solution, the use of sunflower seed meal, and the addition of more glycerol.

Sunflower seed meal was used as the sole solid substrate and in combination with sugarcane bagasse. Sunflower seed meal alone gave rhamnolipid values of 11.10 g/L-IS (Table 2). This value is higher than had been obtained for the standard cultivation in the initial studies; however, it is lower than the other values in Table 2. The best results of around 39 g/L-IS were obtained with a 50:50 mixture of bagasse and sunflower seed meal, using an impregnating solution with 10% (v/v) glycerol. These results are approximately double the best results reported in Table 1.

In these studies, the strategy of pre-culturing the inoculum in the impregnating solution gave a slightly higher rhamnolipid level in the cases in which the lower glycerol concentrations (3% and 6% v/v) were used. However, in the case of supplementation with 10% (v/v) glycerol, this strategy led to a marginally lower yield. Since rhamnolipid levels were highest in this 10% (v/v) glycerol treatment, the strategy of pre-culturing the inoculum in the impregnating solution was not used in the remaining studies.

Production profile under optimized conditions

Given that large changes had been made in the culture conditions and that significant changes in rhamnolipid production had been obtained, we repeated the kinetic profile, using a 50:50 mixture of sugarcane bagasse and sunflower seed meal, supplemented with impregnating solution containing 10% (v/v) glycerol. As was the case in Fig. 1, the maximum productivity occurred at around 200 h (Fig. 2). However, the rhamnolipid level at this time was over tenfold higher for the optimized process (46.86 g/L-IS) than for the original process (3.78 g/L-IS). Note that, in this experiment, the entire fraction of sunflower seed meal that passed through the 10-mesh sieve was used, whereas previously we had been using the fraction retained between the 10- and 20-mesh sieves. This change increased biosurfactant production, in comparison with the result of around 40 g/L-IS given in the last entry in Table 2. Possibly, the fines that result from the grinding contain nutrients or inducers that are especially conducive to biosurfactant production.

Kinetics of the production of rhamnolipids by Pseudomonas aeruginosa UFPEDA 614 in solid-state cultivation using optimized culture conditions (a 50:50 mixture, by mass, of sugarcane bagasse and sunflower seed meal with an impregnating solution containing 10% v/v glycerol). Values plotted are the means of triplicate flasks ± the standard error of the mean

Response surface optimization

The results in Table 2 indicated that the amount of sunflower seed meal used and the amount of glycerol added were the two most important factors affecting rhamnolipid production. We therefore undertook a 22 complete factorial design with four axial points and four central points, centered on the best conditions from Table 2 (bagasse + sunflower, 10% (v/v) glycerol). The independent variables were the glycerol concentration in the impregnating solution (% v/v) and the relative amounts of sugarcane bagasse and sunflower seed meal (percent contributions by mass). Table 3 shows the original and coded values of these variables while Table 4 shows the design, the experimental result obtained (Y, rhamnolipid level at 288 h, g/L-IS) and the value predicted by the fitted equation (Ŷ). This fitted equation is given by:

where X 1 represents the coded value of the glycerol concentration in the impregnating solution and X 2 represents the coded value of the percentage contributions of sugarcane bagasse and sunflower seed meal.

The value of the determination coefficient (R 2) for rhamnolipid production was 0.97, indicating that 97% of the total variation in rhamnolipid production is attributed to the independent variables, and only 3% could not be explained by the model. In other words, the equation fit well to the experimental data. The analysis of variance showed that the linear, quadratic and interaction terms were significant (p < 0.05), except for the linear term of the glycerol concentration. The fact that the interaction term was significant is not surprising, since the previous experiments had shown that an increase in glycerol had its strongest effect when sunflower seed meal was also added to the system.

The model itself is significant, with a very low p value and an F value eight times greater than the tabulated value (Table 5). It is therefore possible to construct a response surface (Fig. 3). This response surface shows that the center point, at which we had arrived by one-by-one variations, is in fact very close to the optimum.

Response surface for the production of rhamnolipids by Pseudomonas aeruginosa UFPEDA 614 in solid-state cultivation. The independent variables are the glycerol concentration in the impregnating solution and the relative amounts of sugarcane bagasse to sunflower seed meal (for this graph, the original values were used rather than the coded ones). The response variable is the rhamnolipid level at 288 h, expressed in terms of the volume of impregnating solution used (i.e., as g/L-IS)

Discussion

We report, for the first time in the journal literature, the production of rhamnolipids in SSC. In the present studies, we have increased the productivity of this system over tenfold.

Previous studies of biosurfactant production in SSC have been done with lipopeptides produced by strains of Bacillus. Ohno et al. (1992, 1993, 1995a, 1995b, 1996), in an attempt to produce compounds active against phytopathogens, used strains of Bacillus to produce various lipopeptides that have both antibiotic and biosurfactant properties. They obtained levels of iturin A up to 1.65 g/kg-moist solids (Ohno et al. 1996). Based on their initial moisture content of almost 80% (w/w, wet basis), this would correspond to a yield of approximately 8 g/kg-dry solids. In the case of surfactin production, they achieved levels of almost 3 g/kg-dry solids (Ohno et al. 1995a, 1995b). In a later study, Veenadig et al. (2000) studied the production of surfactants by Bacillus subtilis cultivated on wheat bran. However, they did not identify the particular biosurfactant produced nor did they quantify biosurfactant production directly. Rather, they analyzed the results of their cultivations on the basis of the emulsifying activity and the reduction in surface tension when samples of cultured solid substrate were added to water. Since these are only qualitative methods without a linear dependence on the real biosurfactant concentration, it is difficult to make any meaningful evaluation of their results. More recently, Das and Mukherjee (2007) produced lipopeptide biosurfactants using two thermophilic strains of B. subtilis grown on a substrate derived from waste potato peels. Their best yield was 92 g/kg-dry solids. Our best yield was 172 g/kg-IDS. Of course, since lipopeptide and rhamnolipid biosurfactants are chemically different, it is not possible to draw any further conclusions from this comparison.

Our work suggests that SSC has the potential to be a viable alternative to SLC for the production of rhamnolipids. On the basis of the volume of impregnating solution added to the solid support, our best yield is of the order of 46 g/L. This value compares well with values that have been obtained in SLC: 16 g/L (Benincasa et al. 2002), 22.7 g/L (Lee et al. 2004), 32 g/L (Matsufuji et al. 1997), 45 g/L (Trummler et al. 2003), and 46 g/L (Linhardt et al. 1989). These values for SLC were obtained at small scale, and it is difficult to obtain similar values for SLC at larger scales in bioreactors due to the foaming problem. In the case of SSC, our results suggest that production will be best when the bed remains static throughout the cultivation, which limits the bioreactor choice to trays or packed beds (Mitchell et al. 2000). Based on the fact that Veenadig et al. (2000) did not report any foaming problems in their packed-bed SSC bioreactor, we can infer that the forced aeration in a larger scale packed-bed will not provoke foaming, avoiding the need for foam-combating systems. In any case, the success of our flask system suggests that production in tray bioreactors is feasible. Although such bioreactors are labor-intensive, they have been used extensively in industry, especially in Asian countries (Durand 2002).

In conclusion, since our value of 46 g/L compares well with the best results that have been obtained in SLC (on the basis of the volume of liquid added to the system), there seems to be good potential for using SSC for the production of rhamnolipids, especially given the fact that SSC technology avoids the problem of foaming that complicates scale-up of SLC processes for biosurfactant production. Further attention to the use of SSC for rhamnolipid production is therefore warranted, not only for improving yields even further in laboratory-scale studies but also for scaling-up to pilot scale.

References

Benincasa M, Accorsini FR (2008) Pseudomonas aeruginosa LBI production as an integrated process using the wastes from sunflower-oil refining as a substrate. Bioresour Technol 99:3843–3849

Benincasa M, Contiero J, Manresa MA, Moraes IO (2002) Rhamnolipid production by Pseudomonas aeruginosa LBI growing on soapstock as the sole carbon source. J Food Eng 54:283–288

Bordas F, Lafrance P, Villemur R (2005) Conditions for effective removal of pyrene from an artificially contaminated soil using Pseudomonas aeruginosa 57SJ rhamnolipids. Environ Pollut 138:69–76

Costa SGVAO, Nitschke M, Haddad R, Eberlin M, Contiero J (2006) Production of Pseudomonas aeruginosa LBI rhamnolipids following growth on Brazilian native oils. Process Biochem 41:483–488

Das K, Mukherjee AK (2007) Comparison of lipopeptide biosurfactants production by Bacillus subtilis strains in submerged and solid state fermentation systems using a cheap carbon source: Some industrial applications of biosurfactants. Process Biochem 42:1191–1199

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Durand A (2002) Bioreactor designs for solid state fermentation. Biochem Eng J 13:113–125

Itoh S, Honda H, Tomota F, Suzuki T (1971) Rhamnolipids produced by Pseudomonas aeruginosa grown on n-paraffin. J Antibiot 24:855–859

Karanth NGK, Deo PG, Veenanadig NK (1999) Microbial production of biosurfactants and their importance. Curr Sci 77:116–126

Lang S, Wullbrandt D (1999) Rhamnose lipids—biosynthesis, microbial production and application potential. Appl Microbiol Biotechnol 51:22–32

Lee KM, Hwang SH, Ha SD, Jang JH, Lim DJ, Kong JY (2004) Rhamnolipid production in batch and fed-batch fermentation using Pseudomonas aeruginosa BYK-2 KCTC 18012P. Biotechnol Bioprocess Eng 9:267–273

Lee BS, Kim EK (2004) Lipopeptide production from Bacillus sp. GB16 using a novel oxygenation method. Enzyme Microb Technol 35:639–647

Linhardt RJ, Bakhit R, Daniels L, Mayerl F, Pickenhagen W (1989) Microbially produced rhamnolipid as a source of rhamnose. Biotechnol Bioeng 33:365–368

Maier RM, Soberón-Chávez G (2000) Pseudomonas aeruginosa rhamnolipids: biosynthesis and potential applications. Appl Microbiol Biotechnol 54:625–633

Makkar RS, Cameotra SS (2002) An update on the use of unconventional substrates for biosurfactant production and their new applications. Appl Microbiol Biotechnol 58:428–434

Matsufuji M, Nakata K, Yoshimoto A (1997) High production of rhamnolipids by Pseudomonas aeruginosa growing on ethanol. Biotechnol Lett 19:1213–1215

Meira JA (2007) Produção de biosurfactantes por fermentação no estado sólido e desenvolvimento de aplicações para tratamento de solos contaminados por hidrocarbonetos. Masters dissertation, Universidade Federal do Paraná

Mitchell DA, Berovic M, Krieger N (2000) Biochemical engineering aspects of solid state bioprocessing. Adv Biochem Eng/Biotechnol 68:61–138

Monteiro SA, Sassaki GL, de Souza LM, Meira JA, Araújo JM, Mitchell DA, Ramos LP, Krieger N (2007) Molecular and structural characterization of the biosurfactant produced by Pseudomonas aeruginosa DAUPE 614. Chem Phys Lipids 147:1–13

Mulligan CN (2005) Environmental application for biosurfactants. Environ Pollut 133:183–198

Nitschke M, Costa SGVAO, Contiero J (2005a) Rhamnolipid surfactants: an update on the general aspects of these remarkable biomolecules. Biotechnol Prog 21:1593–1600

Nitschke M, Costa SGVAO, Haddad R, Gonçalves LAG, Eberlin M, Contiero J (2005b) Oil waste as unconventional substrate for rhamnolipid biosurfactant production by Pseudomonas aeruginosa LBI. Biotechnol Prog 21:1562–1566

Ohno A, Ano T, Shoda M (1992) Production of antifungal antibiotic, iturin in a solid state fermentation by Bacillus subtilis NB22 using wheat bran as a substrate. Biotechnol Lett 14:817–822

Ohno A, Ano T, Shoda M (1993) Production of the antifungal peptide antibiotic, iturin by Bacillus subtilis NB22 in solid state fermentation. J Ferment Bioeng 75:23–27

Ohno A, Ano T, Shoda M (1995a) Production of a lipopeptide antibiotic, surfactin, by recombinant Bacillus subtilis in solid state fermentation. Biotechnol Bioeng 47:209–214

Ohno A, Ano T, Shoda M (1995b) Effect of temperature on production of lipopeptide antibiotics, iturin A and surfactin by a dual producer, Bacillus subtilis RB14, in solid-stage fermentation. J Ferment Bioeng 80:517–519

Ohno A, Ano T, Shoda M (1996) Use of soybean curd residue, okara, for the solid state substrate in the production of a lipopeptide antibiotic, iturin A, by Bacillus subtilis NB22. Process Biochem 31:801–806

Trummler K, Effenberger F, Syldatk C (2003) An integrated microbial/enzymatic process for production of rhamnolipids and L-(+)-rhamnose from rapeseed oil with Pseudomonas sp. DSM 2874. Eur J Lipid Sci Technol 105:563–571

Veenanadig NK, Gowthaman MK, Karanth NGK (2000) Scale up studies for the production of biosurfactant in packed column bioreactor. Bioprocess Eng 22:95–99

Yeh MS, Wei TH, Chang JS (2006) Bioreactor design for enhanced carrier-assisted surfactin production with Bacillus subtilis. Process Biochem 41:1799–1805

Acknowledgment

The work was supported financially by Corn Products Brasil and CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico, Brazil), a Brazilian government agency for the advancement of science and technology. Research scholarships were granted to David Mitchell and Nadia Krieger by CNPq and to Doumit Camilios Neto by CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior, Brazil).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Camilios Neto, D., Meira, J.A., de Araújo, J.M. et al. Optimization of the production of rhamnolipids by Pseudomonas aeruginosa UFPEDA 614 in solid-state culture. Appl Microbiol Biotechnol 81, 441–448 (2008). https://doi.org/10.1007/s00253-008-1663-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-008-1663-3