Abstract

Objectives

To investigate the lipase-catalyzed synthesis of high purity sn-1/3 and sn-2 monoacylglycerols (1/3-MAG and 2-MAG) of different fatty acids (FAs).

Results

The 1/3-MAGs of three FAs (16:0, 17:0, 16:1) were synthesized using lipase-catalyzed esterification of glycerol with FAs. The 2-MAGs were obtained from the ethanolysis of synthetic triacylglycerols using sn-1,3 regiospecific lipase. The effects of lipase types, substrate ratio, temperature, reaction time and lipase load on the MAG conversion were studied. Under the optimal conditions, high purities (96.74%, 95.44%, 92.96%) with acceptable isolated yields (51.00%, 54.28%, 46.00%) were obtained for 1/3-16:0-MAG, 1/3-17:0-MAG, and 1/3-16:1-MAG, respectively. For 2-16:0-MAG, 2-17:0-MAG, and 2-16:1-MAG, the purities were 92.64, 95.04, and 96.48%, with isolated yields of 50.64, 52.16, and 26.12%, respectively. The molecular structures of the synthetic compounds were confirmed by 1H NMR, and MS and the melting points were characterized by DSC.

Conclusions

High purity MAG isomers can be synthesized via lipase-catalyzed reactions to be building blocks for production of functional lipids, the melting points of which are largely governed by the hydrophobic interactions among the alkanyl chains.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Monoacylglycerols (MAGs) are an important amphiphilic emulsifier with both hydrophilic and hydrophobic groups that are widely used in the food, pharmaceutical and cosmetic industries (Damstrup et al. 2005; Zeng et al. 2010). In addition, MAGs are a building block for synthesis of unsymmetrical and symmetrical triacylglycerols (TAGs), which can be used to study the relationships between structure and function (Irimescu et al. 2002; Pfeffer et al. 2007). MAGs can be divided into sn-1/3 monoacylglycerols (1/3-MAGs) and sn-2 monoacylglycerols (2-MAGs). MAGs are mainly prepared by the glycerolysis of edible oil in industry, but the glycerolysis step makes it difficult to obtain high purity MAG isomer.

The physicochemical and nutritional properties of MAG are related not only to their fatty acid (FAs) composition but also to their acylation position distribution on the glycerol backbone. The palmitic acid attached to the specific position sn-1/3 but not sn-2 on the glycerol backbone is difficult for infants to digest (Kennedy et al. 1999). MAGs rich in DHA (22:6 n-3), and EPA (20:5 n-3) at the sn-2 position can prevent coronary heart disease (Calder and Yaqoob. 2012) and cancer growth (Murphy et al. 2012). 2-18:1-MAG has been reported to display strong antioxidant, anti-atherosclerotic, and protein glycation inhibitory activities (Cho et al. 2010). Certain 1/3-MAGs have also been studied for their unique applications, although there is less relevant literature. 1/3-MAG microemulsions of capric (10:0), undecanoic (11:0), lauric (12:0) and myristic (14:0) acids have antibacterial activity against the growth of Gram-positive and Gram-negative bacteria (Dole et al. 2010; Petra et al. 2014). For these reasons, studies of the synthesis of high purity MAG isomers are of great significance.

In this study, 1/3-MAG was produced by direct esterification, and 2-MAG was produced by a two-step synthesis. This study aimed to provide an effective synthesis of 1/3-MAG and 2-MAG with different FAs.

Materials and methods

Materials

Dipalmitin (> 99%, a mixture of 70% 1,3-dipalmitin and 30% 1,2-dipalmitin), tripalmitin (> 99%), palmitic acid (> 98%), palmitoleic acid (> 98%), and glycerol (> 99%) were obtained from Sigma-Aldrich Chemical Co., Ltd. Lipozyme 435 (Candida Antarctica lipase B, immobilized on acrylic resin), Lipozyme RMIM (Rhizomucor miehei, immobilized on macroporous anion exchange resins), Lipozyme TLIM (Thermomyces lanuginosus, immobilized on silica granulation) and NS40086 (Rhizomucor miehei, immobilized on macroporous acrylic resin) were kindly donated by Novozymes. Heptadecanoic acid (> 98%) and t-BuOH (> 98%) were purchased from Aladdin Co., Ltd. Monopalmitin (> 95%), ethyl palmitate (> 95%) were bought from Tokyo Chemical Industry Co., Ltd. HPLC-grade n-hexane and iso-propyl alcohol were obtained from J&K Scientific Co., Ltd. Analytical grade reagents were purchased from Sinopharm Chemical Reagent Co., Ltd.

HPLC analysis

The conversion of the reaction was quantified by HPLC analysis according to our previous method (Zhang et al. 2018) using a Thermo HPLC system (Waters Corp, Milford, MA) equipped with a Sepax HP-Silica column (4.6 mm × 250 mm × 5 μm, Sigma-Aldrich Corp, Tokyo, Japan) and a refractive index detector (HPLC-RID). The mobile phase consisted of n-hexane/iso-propyl alcohol/formic acid (15:1:0.003, v/v/v), and a flow rate of 0.5 mL/min. Each peak was confirmed by the corresponding standard. The contents of individual component were calculated on the basis of the peak area.

All reactions and determinations were done in duplicate and data are presented as the means ± standard deviations. Statistical analysis was performed using one-way ANOVA with Tukey’s test. The statistical significance was evaluated at p < 0.05.

The conversion of each compound was calculated by:

The content/ratio of each compound for condition screening (in figures) was calculated by:

Synthesis of 1/3-MAG

The reaction mixture included 2 mmol of FAs, 16–32 mmol of glycerol, 300 mg of 4 Å molecular sieves and 5 mL of t-BuOH. To better monitor the progress of the reaction, 20 μL samples were taken from the reaction mixture at regular intervals and analyzed by thin-layer chromatography (TLC silica gel 60, 5 × 10 cm2, Rushan, China). The TLC plates were developed using a modified two-step method according to the previously reported method (Wei et al., 2015a). The product was diluted with 50 μL methanol/CHCl3 (1:3, v/v) and then it was spread twice on the plates, first run with a mixture of CHCl3/methanol/acetic acid (98.5:1.5:1, v/v/v) to 4.2 cm. After the plate was completely dried, it was then run again with a mixture of hexane/ether/acetic acid (70:30:1, v/v/v) to 8 cm. The plates were then dried and sprayed with 1% of 2,7-dichlorofluorescein in ethanol as a chromogenic agent. Under these conditions, MAG, 1,2-DAG, 1,3-DAG, FFA and TAG had a Rf of 0.138, 0.4, 0.45, 0.65 and 0.95 cm, respectively. Finally, the 1/3-MAG content was quantified by HPLC-RID.

After the reaction was completed, we filtered off the lipase and molecular sieves and then removed the t-BuOH by rotatory evaporation under vacuum. The reaction mixture containing compound 16:0/17:0 was dissolved in 30 mL of DCM, we washed out the unreacted FAs with saturated Na2CO3 solution three times, and then we completely removed the excessive glycerol with a saturated NaCl solution three times. The traces of water in the mixture after purification were removed by anhydrous sodium sulfate, and the solvent of the organic phase was removed by rotatory evaporation under vacuum again. 1/3-16:1-MAG reaction mixture purification was similar to the reaction monitoring method by using TLC plates. The obtained purity synthetic compounds were identified by 1H NMR and MS analysis, which has been described clearly in the “Methods” section.

Synthesis of TAG

Lipase type, reactant molar ratio, reaction temperature and time were investigated. The optimal conditions were based on the maximum ratio of TAG to total esters. The purification of 16:0-TAG and 17:0-TAG was carried out according to the previously described method (Wei et al. 2015b). After removal of the molecular sieves and lipase, the mixture was dissolved in a water bath at 80 °C and then transferred to a separating funnel to purify it by liquid–liquid extraction. 1.5 times of the equivalent of 0.5 M potassium hydroxide-hydroalcoholic solution (30% ethanol, by vol.) was added to wash out unreacted palmitic acid, then collected the hexane phase. The pure product was obtained after evaporating away the solvent.

The product separation of 16:1-TAG synthesis was conducted by TLC due to the small amount of reactants. For TLC analysis, 20 cm plates were employed (TLC silica gel 60, 20 × 10 cm2, Rushan, China) with hexane/ether/acetic acid (80:20:1, v/v/v) as the developing solvent. Under these conditions, TAG can be separated well from other by-products.

Synthesis of 2-MAG

The alcoholysis reaction of TAG and ethanol was carried out to produce 2-MAG. Lipase type, reaction time, reactant weight ratio and lipase load on 2-MAG contents were investigated. The ethanolysis product contained MAG, DAG, ethyl ester (EE) and TAG. After removing the solvent, two purification methods were undertaken according to the amount of MAG. The ethanolysis product of 16:0/17:0 was dissolved in 85% (by vol.) ethanol–water solution and washed several times with hexane. After collecting the ethanol–water phase with MAG, the water and ethanol were removed by rotary evaporation to obtain a purer MAG. Subsequently, excess water was further removed by freeze-drying. The purification of 2-16:1-MAG was similar to 1/3-16:1-MAG. The obtained pure synthetic compound was identified by 1H NMR and MS analysis, which has been described clearly in the “Methods” section.

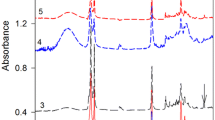

1H NMR, LC–MS, and DSC

Identification of the synthesized MAG was carried out by 1H NMR spectroscopy analysis (Nicolet, USA) at 400 MHz, with CDCl3 as the solvent and TMS as the internal standard (chemical shift of 0 ppm). Mass spectrometry (MS) analysis was done by using a mass spectrometer with a hybrid quadrupole time-of-flight analyzer (Waters, USA). The melting point of the synthetic compounds was measured by differential scanning calorimetry (DSC) as previously described (Wei et al. 2015a).

Identification of sn-1/3 monopalmitoylglycerol (1/3-16:0-MAG)

Yield 51.00%, white solid; melting point 66.97 °C; 1H NMR (400 MHz, CDCl3, 25 °C, TMS): 1H NMR: δ = 4.25–4.10 (m, 2H, –CH2–O–C=O), 3.93 (ddd, 1H, J = 10.3, 5.9, 4.3 Hz, –CH–OH), 3.74–3.55 (m, 2H, –CH2–OH), 2.35 (t, 2H, J = 7.6 Hz, –CH2–), 2.09 (bs, 2H, 2 × –OH), 1.63 (p, 2H, J = 7.4 Hz, –CH2–), 1.25 (s, 24H, –CH2–), 0.84-0.91(m, 3H, –CH3); MS, m/z calcd for C19H38O4: 330.51; found: 353.29 (M + Na+).

Identification of sn-1/3 monoheptadecanoin (1/3-17:0-MAG)

Yield 54.28%, white solid; melting point 58.77 °C; 1H NMR (400 MHz, CDCl3, 25 °C, TMS): 1H NMR: δ = 4.20 (qd, 2H, J = 11.7, 5.4 Hz, –CH2–O–C=O), 3.95 (ddd, 1H, J = 10.3, 5.9, 4.3 Hz, –CH–OH), 3.74-3.59 (m, 2H, –CH2–OH), 2.37 (t, 2H, J = 7.6 Hz, –CH2–), 2.07 (bs, 2H, 2 × –OH), 1.64 (p, 2H, J = 7.3 Hz, –CH2–), 1.27 (s, 26H, –CH2–), 0.92–0.87 (m, 3H, –CH3); MS, m/z calcd for C20H40O4: 344.52; found: 367.31 (M + Na+).

Identification of sn-1/3 monopalmitolein (1/3-16:1-MAG)

Yield 46.00%, white liquid; melting point 19.21 °C; 1H NMR (400 MHz, CDCl3, 25 °C, TMS): δ = 5.40–5.30 (m, 2H, –CH=CH–), 4.18 (qd, 2H, J = 11.7, 5.4 Hz, –CH2–O–C=O), 3.96–3.82 (m, 1H, –H–OH), 3.75-3.57 (m, 2H, –CH2–OH), 2.35 (t, 2H, J = 7.6 Hz, –CH2–), 2.01 (q, 4H, J = 6.7, 6.2 Hz, 2 × –CH=CH–H), 1.82 (bs, 2H, 2 × –OH), 1.67–1.58 (m, 2H, –CH2–), 1.37-1.22 (m, 16H, –CH2–), 0.91–0.85 (m, 3H, –CH3); MS, m/z calcd for C19H36O4: 328.50; found: 351.28 (M + Na+).

Identification of sn-2 monopalmitoylglycerol (2-16:0-MAG)

Yield 50.64%, white solid; melting point 55.44 °C; 1H NMR (400 MHz, CDCl3, 25 °C, TMS): δ = 4.97 (p, 1H, J = 4.7 Hz, –CH–), 3.88 (d, 4H, J = 4.7 Hz, 2 × –CH2–OH), 2.42 (t, 2H, J = 7.6 Hz, –CH2–), 2.15 (bs, 2H, 2 × –OH), 1.75–1.61 (m, 2H, –CH2–), 1.30 (s, 24H, –CH2–), 0.92 (t, 3H, J = 6.7 Hz, –CH3); MS, m/z calcd for C19H38O4: 330.51; found: 353.30 (M + Na+).

Identification of sn-2 monoheptadecanoin (2-17:0-MAG)

Yield 52.16%, white solid; melting point 58.23 °C; 1H NMR (400 MHz, CDCl3, 25 °C, TMS): δ = 4.93 (p, 1H, J = 4.7 Hz, –CH–), 3.83 (d, 4H, J = 4.7 Hz, 2 × –CH2–OH), 2.37 (t, 2H, J = 7.6 Hz, –CH2–), 2.15 (bs, 2H, 2 × –OH), 1.64 (p, 2H, J = 7.3 Hz, –CH2–), 1.25 (s, 26H, –CH2–), 0.88 (t, J = 6.8 Hz, 3H, –CH3); MS, m/z calcd for C20H40O4: 344.52; found: 367.30 (M + Na+).

Identification of sn-2 monopalmitolein (2-16:1-MAG)

Yield 26.12%, white liquid; melting point 13.53 °C; 1H NMR (400 MHz, CDCl3, 25 °C, TMS): δ = 5.40–5.29 (m, 2H, –CH=CH–), 4.92 (p, 1H, J = 4.7 Hz, –CH–), 3.88-3.43 (m, 4H, 2 × –CH2–OH), 2.41–2.19 (m, 2H, –CH2–), 2.01 (q, 4H, J = 6.4 Hz, 2 × –CH=CH–H), 1.82 (bs, 2H, 2 × –OH), 1.64 (t, 2H, J = 7.1 Hz, –CH2–), 1.47–1.04 (m, 16H, –CH2–), 0.93–0.80 (m, 3H, –CH3); MS, m/z calcd for C19H36O4: 328.5; found: 351.29 (M + Na+).

Results and discussion

Optimization of the synthesis of sn-1/3 monopalmitoylglycerol (1/3-16:0-MAG)

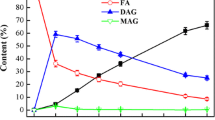

The fatty acid 16:0 was chosen as a representative for the parameter study. t-BuOH was chosen as the reaction solvent due to its weak polarity and because it does not influence the lipase activity or affect the solubility of glycerol or long-chain fatty acids. The effects of the molar ratio and reaction time are shown in Fig. 1. From 1-5 h of reaction, the content of 1/3-16:0-MAG had a higher value at a molar ratio of 1:16 (palmitic acid:glycerol) compared with other molar ratios. Therefore, 1:16 of substrate molar ratio was selected as the optimal value for the following selected reaction times. The content of 1/3-MAG increased from 22.24 to 92.50% with the reaction process from 0.5 to 2 h and then decreased slightly to a constant value. At the same time, the 2-16:0-MAG content was also relatively low at 2 h (Fig. 1b). Therefore, the following reaction was conducted with 1:16 (palmitic acid:glycerol) for 2 h to investigate other optimal factors.

Optimization of enzymatic synthesis of sn-1/3 monopalmitoylglycerol. Content of 1/3-16:0-MAG (filled circle) and 2-16:0-MAG (open circle) are shown in the figures. Reaction conditionsa different molar ratio, 4% Lipozyme 435 (w/w, relative to total reactants) and at 40 °C for different times; b molar ratio (palmitic acid:glycerol) 1:16, 4% Lipozyme 435 (w/w, relative to total reactants) and at 40 °C for different times, c molar ratio (palmitic acid:glycerol) 1:16 and at 40 °C for 2 h; d molar ratio (palmitic acid:glycerol) 1:16, 4% Lipozyme 435 (w/w, relative to total reactants) at different temperatures for 2 h

The quantity of lipase has a great influence on the reaction rate. 1/3-16:0-MAG content tended to increase and then decrease as the lipase load increased. Meanwhile, the content of 2-16:0-MAG kept increasing (Fig. 1c). The reaction rate was accelerated with more DAG and TAG generated after adding lipase. In the reaction system, the excessive glycerol and DAG/TAG continued to produce MAG including the by-products 2-16:0-MAG. Considering that 2-16:0-MAG is difficult to separate from 1/3-16:0-MAG, 4% lipase was chosen for further reactions.

The effect of the reaction temperature was determined as shown in Fig. 1d. The contents of 1/3-16:0-MAG and 2-16:0-MAG were both lower at 30 °C and 70 °C than their contents at other temperatures. This phenomenon was attributable to the effect of temperature on enzyme activity. The maximum value of 1/3-16:0-MAG was observed at 40 °C with a relatively lower 2-16:0-MAG content. Thus, 40 °C was chosen as the optimal value for the reaction temperature.

Under the optimal conditions of a molar ratio of 1:16 (palmitic acid:glycerol), 4% Lipozyme 435 (w/w, relative to total reactants), and 40 °C for 2 h, approximately 92.5% of 1/3-16:0-MAG was obtained in the crude reaction mixture.

Synthesis of different fatty acyls sn-1/3 monoacylglycerols (1/3-MAG)

The optimal conditions for the synthesis of 1/3-16:0-MAG determined by a single parameter study were further applied to the esterification of the other two FAs, and the individual reactions were slightly adjusted. Following the optimized conditions, the 1/3-MAG of the different FAs were synthesized. The results are shown in Table 1. The content of 1/3-MAG in the reaction mixture after purification was greater than 95% except for the content of 1/3-16:1-MAG at 92.96%.

The conversion of 16:1 was slightly lower, which may be explained by the lower enzyme activity at relatively lower reaction temperature. The melting points of 16:0, 17:0 and 16:1 are 61.12 °C, 57.03 °C and − 0.088 °C (detected by DSC), respectively. The molecular packing of 16:1 was loose because of a double bond, and it resulted in a lower melting point than 16:0 and 17:0. Therefore, 35 °C, which is slightly lower than 40 °C, was selected for the reaction. However, the melting points of 16:0 and 17:0 are close, and under the same reaction conditions, the conversion was almost the same.

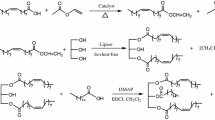

Optimization of synthesis of tripalmitin (16:0-TAG)

The synthesis of 16:0-TAG was described in a previous step to provide raw materials for 2-16:0-MAG, and it was conducted by enzymatic esterification of palmitic acid and glycerol. The selection of the optimal factor is based on the ratio of tripalmitin to total palmitic acid esters greater than 95% due to the easier removal of FFA compared with DAG from the TAG.

Five commercial lipases were examined to select the most suitable lipase for the synthesis of the 16:0-TAG (Fig. 2a). When lipase G is found as a free enzyme, its catalytic effect is much lower than that of the immobilized enzyme. The catalytic effects of Lipozyme 435 and NS40086 were not significant, and the ratios of tripalmitin to total esters were 91.44% and 90.32%, respectively. Lipozyme 435 was chosen as a catalyst for further experiments due to its stability at high temperatures.

Optimization of enzymatic synthesis of 16:0-TAG. Reaction conditionsa molar ratio (glycerol: palmitic acid) 1:8, 10% lipase (w/w, relative to total reactants) and at 60 °C for 12 h; b 10% Lipozyme 435 (w/w, relative to total reactants) and at 70 °C for 12 h; c molar ratio (glycerol:palmitic acid) 1:6, 10% Lipozyme 435 (w/w, relative to total reactants) and at different temperatures for 12 h; d molar ratio (glycerol:palmitic acid) 1:6, 10% Lipozyme 435 (w/w, relative to total reactants) and at 70 °C for different times

The substrate molar ratio from 1:3 to 1:8 (glycerol: palmitic acid) was investigated. As shown in Fig. 2b, the ratio of TAG to total esters kept growing to a stable value within the entire substrate molar ratio range. The maximum value was observed at 1:8. However, the ratio of 16:0-TAG to total esters was 95.58% at a molar ratio of 1:4, which met the requirement of more than 95%. Thus, 1:4 of substrate molar ratio was selected as the optimal value in the following synthesis.

The reaction temperature has a significant impact on the reaction rate and enzyme activity. The ratio of 16:0-TAG to total esters tends to increase rapidly and then slowly (Fig. 2c). Even though the ratio of 16:0-TAG to total esters showed no significant difference at 65 °C and 70 °C, the value was 91.57% at 65 °C, which is lower than 95%. Therefore, 70 °C was chosen for the next reaction studies.

The ratio of tripalmitin to total ester increased gradually when the reaction time was extended. The maximum value was observed at 6 h. Thus, the optimal reaction conditions for tripalmitin were: substrate molar ratio (glycerol: palmitic acid) 1:4, 10% Lipozyme 435 (w/w, relative to total reactants) at 70 °C for 6 h. Under the optimal reaction conditions, the ratio of tripalmitin to total esters was 96.02%. The results of triacylglycerols esterification are summarized in Table 2. A molar ratio of 1:3.5 was used to synthesize 16:1-TAG due to 16:1 being precious. The conversion of the three synthetic TAGs were both higher than 95%.

Optimization of synthesis of sn-2 monopalmitoylglycerol (2-16:0-MAG)

The optimization of 2-16:0-MAG synthesis was conducted with lipase-catalysis ethanolysis of 16:0-TAG. Acyl migration between 2-MAG and 1/3-MAG is an important point in the synthesis of 2-MAG. Temperature is the thermodynamic parameter that influences the equilibrium of acyl migration. Due to the high melting point of 16:0-TAG, the minimum temperature at which reactions was 55 °C. Thus, the ethanolysis reaction was conducted at 55 °C.

Three immobilized lipases, namely, Lipozyme 435, Lipozyme RMIM and Lipozyme TLIM were investigated (Fig. 3a). Lipozyme 435 provided the highest 2-16:0-MAG content of 18.90%, while Lipozyme RMIM showed the lowest catalytic activity with 2.85% of 2-16:0-MAG content in the ethanolysis reaction. The high catalytic activity of Lipozyme 435 was attributed to the polarity of ethanol, which makes it change into a 1,3-regiospecific lipase (Wang et al. 2014). Meanwhile, the ethanol molecule takes away the essential water molecule at the active site of Lipozyme RMIM and TLIM, causing a loss of catalytic activity (Piyatheerawong et al. 2004).

Optimization of reaction conditions for the synthesis of 2-16:0-MAG. Reaction conditionsa 0.5 g tripalmitin, 2 g anhydrous ethanol, 10% lipase (w/w, relative to total reactants) and at 55 °C for 2 h; b 0.5 g tripalmitin, 2 g anhydrous ethanol, 10% Lipozyme 435 (w/w, relative to total reactants) and at 55 °C for different times; c 0.5 g tripalmitin, 10% Lipozyme 435 (w/w, relative to total reactants) and at 55 °C for 1 h; d 0.5 g tripalmitin, 2 g anhydrous ethanol and at 55 °C for 1 h

As shown in Fig. 3b, TAG was rapidly converted into 2-MAG and 1,2-DAG within 0.5 h of the reaction. After 1 h, most of the TAG and DAG were converted into 2-16:0-MAG and the maximized 2-16:0-MAG content value was observed at 1 h. With an extension of the reaction time, the 2-16:0-MAG content constantly decreased, while the content of EE kept increasing. The cause of this phenomenon is acyl migration. 2-16:0-MAG was converted to 1/3-16:0-MAG by the acyl migration, then further converted into EE and glycerol, which increased the content of EE and decreased the conversion of 2-16:0-MAG. Therefore, 1 h was the optimal value of the reaction time.

In the ethanolysis reaction, the alcohol solvent acted as both a reactant and the reaction media. And the alcohol would give decreasing acyl migration rate because of its strong polarity (Li et al. 2010). A little anhydrous ethanol will lead to a large amount of by-products such as TAG and DAG. Conversely, an excess amount of ethanol will decrease the enzyme activity. As the substrate weight ratio (tripalmitin, anhydrous ethanol) ranged from 1:2 to 1:4, the content of 2-16:0-MAG increased from 24.14% to 29.39% (Fig. 3c). When the ethanol quantity continued to increase, the content of 2-16:0-MAG had no significant difference among weight ratios from 1:4 to 1:4.5. Thus, a weight ratio of 1:4 was used for further experiments.

Figure 3d shows the content of 2-16:0-MAG increased from 24.27 to 29.29% with the lipase added from 4 to 8%, and then slightly decreased when the lipase load increased from 10 to 12%. Considering the enzyme cost and 2-MAG content, 8% of the lipase load was chosen. Under the optimal conditions, 0.5 g tripalmitin, 2 g anhydrous ethanol, 8% Lipozyme 435 (w/w, relative to total reactants) and at 55 °C for 1 h, the 2-MAG content was approximately 29.29% in the total reaction mixture.

Synthesis of different fatty acyls sn-2 monoacylglycerol (2-MAG)

The results of 2-MAG synthesis are shown in Table 3. The content of 2-MAG in the purification mixture of all samples was higher than 90%. The conversion of 2-16:0-MAG was highest at 86.29%, and the conversion of 2-17:0-MAG and 2-16:1-MAG was approximately 70%. At the end of the ethanolysis reaction of 2-17:0-MAG and 2-16:1-MAG, more TAG and 1,2-MAG were present. This means the optimal reaction condition of 2-16:0-MAG was not the optimal reaction condition of the other two FAs, although it was applicable as well for them. The lowest two-step yield of 2-16:1-MAG was also observed as shown in Table 3. 16:1 is an unsaturated fatty acid with one double bond. The angle formed by the double bond resulted in the difficulty of the lipase-catalyzed hydrolysis reaction. Therefore the conversion of 2-16:1-MAG was lower compared to the conversions of other 2-MAGs (Table 3). High purity of 2-16:1-MAG was obtained with the sacrificed of the isolated yield.

Thermal properties of the MAGs

Thermal properties, Tonset, Tm ΔH, and ΔT1/2 of the synthetic MAGs are shown in Table 4. For the 1/3-MAGs, the melting points (Tm) increased in the order of 16:1-MAG < 17:0-MAG < 16:0-MAG. While the 2-MAGs have the Tm in the order of 16:1-MAG < 16:0-MAG < 17:0-MAG. The temperature at which the thermal effect starts (Tonset) had the same increasing order as the melting points. The melting points of 1/3-16:0-MAG and 1/3-16:1-MAG were significantly higher than the corresponding 2-MAG isomers (6–11 °C higher). However, the melting point of 1/3-17:0-MAG and 2-17:0-MAG showed no significant difference (0.5 °C higher). The ΔT1/2 which is the width of the phase transition at the half peak height of the synthetic MAGs are also present in Table 4. 16:1-MAGs that are having a double bond in the alkanyl chain showed larger ΔT1/2 values which indicating a broader gel-to-liquid crystalline transition. The changes of transition enthalpy (ΔH) of the MAGs are generally negatively correlated with the melting points. The ΔT1/2 and ΔH of the 1/3-16:0-MAG were significantly different from the other MAGs. The reasons are the geometry of the headgroup of the 1/3-16:0-MAG which enable stronger intra- and inter-molecular hydrogen bonding, and the probably higher hydrophobic interactions among the even alkanyl chains. These results indicating the differences of the phase transition of the MAG isomers, its influence on the lipid digestion and metabolism, and the building of lipid matrix based on MAGs need further investigation.

Conclusion

A group of 1/3- and 2-MAGs were synthesized by a facile and scalable approach and were structurally identified by 1H NMR and MS. The high purity MAGs of three different FAs (16:0, 17:0 and 16:1) were obtained from moderate to high conversion, with excellent purity of the desired monoacylglycerols. Under the optimal conditions for the molar ratio 1:16 (FA: glycerol) (4% Lipozyme 435, 40 °C for 2 h) the purity of 1/3-MAG of the three FAs (16:0, 17:0 and 16:1) were 96.74%, 95.44% and 92.96%, with yields of 51.00%, 54.28% and 46.00%, respectively. Under the optimal conditions (0.5 g TAG, 2 g anhydrous ethanol, 8% Lipozyme 435 and at 55 °C for 1 h) the purity of 2-MAG of three FAs (16:0, 17:0 and 16:1) were 92.64%, 95.04% and 96.48%, with yields of 50.64%, 52.16% and 26.12%, respectively. The synthetic compounds displayed variable melting points that were influenced both by the FA composition and distribution. The optimal conditions obtained in this study could be further applied to the synthesis of different fatty acyl monoacylglycerols, which could be used to study the association between position distributions of FAs in dietary lipids and health status.

References

Calder PC, Yaqoob P (2012) Marine omega-3 fatty acids and coronary heart disease. Curr Opin Cardiol 27:412–419

Cho KH, Hong JH, Lee KT (2010) Monoacylglycerol (MAG)-oleic acid has stronger antioxidant, anti-atherosclerotic, and protein glycation inhibitory activities than MAG-palmitic acid. J Med Food 13:99–107

Damstrup ML, Jensen T, Sparsø FV, Kiil SZ, Jensen AD, Xu X (2005) Solvent optimization for efficient enzymatic monoacylglycerol production based on a glycerolysis reaction. J Am Oil Chem Soc 82:559–564

Dole M, Jani R, Svobodová H (2010) Antimicrobial properties of 1-monoacylglycerols prepared from undecanoic (C11:0) and undecenoic (C11:1) acid. Eur J Lipid Sci Tech 112:1106–1114

Irimescu R, Iwasaki Y, Hou CT (2002) Study of TAG ethanolysis to 2-MAG by immobilized Candida antarctica lipase and synthesis of symmetrically structured TAG. J Am Oil Chem Soc 68:879–883

Kennedy K, Fewtrell MS, Morley R, Abbott R, Quinlan PT, Wells JC, Bindels JG, Lucas A (1999) Double-blind, randomized trial of a synthetic triacylglycerol in formula-fed term infants: effects on stool biochemistry, stool characteristics, and bone mineralization. Am J Clin Nutr 70:920–927

Li W, Du W, Li Q, Li RW, Li DH (2010) Dependence on the properties of organic solvent: study on acyl migration kinetics of partial glycerides. Bioresour Technol 101:5737–5742

Murphy RA, Mourtzakis M, Mazurak VC (2012) n-3 polyunsaturated fatty acids: the potential role for supplementation in cancer. Curr Opin Clin Nutr Metab Care 15:246–251

Petra Š, Věra K, Iva H, Petr H, Zdeňka K, Leona B (2014) Formulation, antibacterial activity, and cytotoxicity of 1-monoacylglycerol microemulsions. Eur J Lipid Sci Tech 116:448–457

Pfeffer J, Freund A, Bel-Rhlid R, Hansen CM, Schmid R, Maurer S (2007) Highly efficient enzymatic synthesis of 2-monoacylglycerides and structured lipids and their production on a technical scale. Lipids 42:947–953

Piyatheerawong W, Iwasaki Y, Xu X, Yamane T (2004) Dependency of water concentration on ethanolysis of trioleoylglycerol by lipases. J Mol Catal B-Enzym 28:19–24

Wang X, Li M, Wang T, Jin Q, Wang X (2014) An improved method for the synthesis of 2-arachidonoylglycerol. Process Biochem 49:1415–1421

Wei W, Feng F, Perez B, Dong M, Guo Z (2015a) Biocatalytic synthesis of ultra-long-chain fatty acid sugar alcohol monoesters. Green Chem 17:3475–3489

Wei W, Feng Y, Zhang X, Cao X, Feng F (2015b) Synthesis of structured lipid 1,3-dioleoyl-2-palmitoylglycerol in both solvent and solvent-free system. LWT Food Sci Technol 60:1187–1194

Zeng FU, Yang B, Wang YU, Wang WF, Ning ZI, Li L (2010) Enzymatic Production of Monoacylglycerols with Camellia Oil by the Glycerolysis Reaction. J Am Oil Chem Soc 87:531–537

Zhang Y, Wang X, Xie D, Zou S, Jin Q, Wang X (2018) Synthesis and concentration of 2-monoacylglycerols rich in polyunsaturated fatty acids. Food Chem 250:60–66

Acknowledgements

This work was financially supported by a National Natural Science Foundation of China Grant (31701558), Young Elite Scientists Sponsorship Program by CAST (2017QNRC001) and the National First-class Discipline Program of Food Science and Technology (JUFSTR20180202).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, X., Cheng, Y., Jin, Q. et al. Biocatalytic synthesis and characterization of sn-1/3 and sn-2 monoacylglycerols. Biotechnol Lett 41, 789–799 (2019). https://doi.org/10.1007/s10529-019-02684-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-019-02684-4