Abstract

We report the synthesis of 1,3-dioleoyl-2-palmitoylglycerol (OPO) by a three-step method. Vinyl oleate was first synthesized by transvinylation between vinyl acetate and oleic acid. This was further reacted with glycerol at 35 °C for 8 h using 10 % (w/v) Novozym 435 to synthesize 1,3-diolein. The 1,3-diolein content in the crude reaction mixture was 90.8 % and was obtained at 82.3 % (w/w) yield with 98.6 % purity after purification. Finally, OPO was chemically synthesized by reacting purified 1,3-diolein with palmitic acid. 94.8 % OPO was produced in the crude reaction mixture and the regiopurity of OPO after purification was 98.7 % at 90.5 % yield based on positional distribution analysis. This is an innovative approach for the synthesis of 1,3-diolein in a solvent-free system as an alternative to previously presented studies that applied solvent system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The feeding of human milk is the best food for healthy infants until six months of life. Human milk contains 3–5 % total lipids, which provide 50–60 % of the dietary energy and approx. 98 % of the fat is in the form of triacylglycerols (TAG) with a unique fatty acid positional distribution (Esteban et al. 2011). The most common fatty acids in human milk fat are palmitic, oleic and linoleic acids. Palmitic acid content in human milk fat is about 20–25 % of total fatty acids, with 65–70 % of total palmitic acid at sn-2 position of TAGs (Jiménez et al. 2010). Dietary TAGs with palmitic acid at sn-2 position and oleic and linoleic acids at sn-1,3 positions represent two important benefits for infant nutrition. Firstly, dietary TAGs with saturated fatty acids at sn-2 position are better absorbed by forming micelles with bile acids (Lee et al. 2010). Thus, TAGs with palmtic acid at sn-2 position will provide more energy for the infant compared to those at sn-1,3 positions. According to the Food and Agricultural Organization, dietary fat should contribute to 40–60 % energy during the first 6 months of life, whereas adults only need 25–35 % energy from fat (Abrahamse et al. 2012). Secondly, TAGs with palmitic acid at the sn-2 position can reduce the loss of minerals. Thus, these types of TAGs will improve the absorption of minerals (Lee et al. 2010). The main component in the human milk fat is 1,3-dioleoyl-2-palmitoylglycerol (OPO). For this reason, there is now great interest in the synthesis of pure OPO.

Another important reason for the synthesis of pure OPO, as well as 1,2-dioleoyl-3-palmitoylglycerol (OOP), is their use in studies on the effect of palmitic acid positional distribution on fasting and post-prandial lipemia responses in animal and human experiments, as suggested by Hunter (2001). Recent studies are inconsistent probably because of the lack of purity of test fats used (Hunter 2001; Berry 2009). Minor changes in test fat structure induced by interesterification may not result in a significant difference in blood lipid parameters (Hunter 2001). Thus, some researchers found that the native and randomized fats experienced similar post-prandial metabolism processes in animals (Hodge et al. 1999), whereas other researchers concluded that there was a significant difference in post-prandial lipid metabolism when synthetically pure fats was used (Redgrave et al. 1988).

Generally, OPO can be synthesized by acidolysis and interesterification (Lee et al. 2010; Chen et al. 2004; Qin et al. 2011), but the purity of OPO synthesized by these methods is low (about 40 %). Enzymatic esterification has also been employed to synthesize OPO. Firstly, 2-monopalmitin was synthesized by the ethanolysis of tripalmitin with Novozym 435 lipase as catalyst and then esterified with oleic acid to obtain pure OPO (Pfeffer et al. 2007; Schmid et al. 1999, 1998). However, the main problem for the synthesis of OPO by this method is the acyl migration of 2-monopalmitin. The ratio of 1-monopalmitin and 2-monopalmitin at equilibrium state is 9:1 (Andrews et al. 2008). Thus, 2-monopaltin is unstable and will convert to 1-monopalmitin under the appropriate conditions. Fatty acid positional distribution analysis showed the regiopurity of OPO was no more than 90 % by this method (Schmid et al. 1999, 1998). An alternative approach for the synthesis of symmetrical TAGs has been reported using fatty acid vinyl esters as acyl donors (Andrews et al. 2008; Magnusson and Haraldsson 2010). However, commercial unsaturated fatty acid vinyl esters are hard to get. Thus, synthesis of vinyl oleate is necessary for the synthesis of OPO by this route.

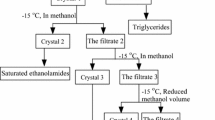

The present study describes a chemoenzymatic method for the synthesis of pure OPO as shown in Fig. 1. This is the first time to employ this route to synthesize OPO. In addition, this is also the first time to use solvent-free system to synthesize 1,3-DAG instead of solvent system used in previous studies.

Materials and methods

Materials

Diolein (85 % 1,3-diolein and 15 % 1,2-diolein) and 1-monoolein standards, palmitic acid (>99 %) and oleic acid (>99 %) were purchased from Sigma-Aldrich (Shanghai, China). Candida antarctica (Novozym 435) lipase B was provided by Novozymes (Beijing, China). This is a lipase immobilized on a macroscopic acrylate and has a declared activity of 10,000 PLU (propyl laurate unit)/g. All other reagents are of analytical grade and were purchased from Sinopharm Chemical Reagent Co. Ltd.

Chemical synthesis of vinyl oleate

Vinyl oleate was synthesized based on the previous methods (Lobell and Schneider 1994; Waldinger and Schneider 1996) and the synthetic route is presented in Fig. 1. Oleic acid (0.01 mol), vinyl acetate (0.45 mol), palladium acetate (12 mg) and KOH (1 mmol) were added into a 50 ml Erlenmeyer flask. The reaction mixture was stirred at room temperature for 30 h under N2. At the end of the reaction, the excess of vinyl acetate was removed under reduced pressure at 50 °C. The product obtained was purified by flash chromatography on silica gel with hexane/ethyl acetate (10:1, v/v). The yield was calculated based on the mass ratio of purified product to raw material before the purification.

Enzymatic synthesis of 1,3-diolein

Esterification was conducted with agitation at 35 °C for 8 h by reacting 2 mmol purified vinyl oleate with 1 mmol glycerol in a solvent-free system with 10 % (w/v) Novozym 435 as catalyst. At the end of the reaction, the crude reaction product was purified by flash chromatography on silica gel eluted with diethyl ether/hexane (1:1, v/v). Subsequently, the purified reaction product was qualified by TLC eluted with toluene/ethyl acetate/ether/acetic acid (80:10:10:0.2, v/v), derivatized and quantified by GC as described in the following section. All reactions were run in duplicated unless otherwise specified. The results were expressed as mean ± standard deviation.

Synthesis of OPO

Purified 1,3-diolein (0.5 mmol) was mixed with 0.55 mmol palmitic acid in 2 ml dichloromethane with 0.55 mmol N-ethyl-N′-(3-dimethylaminopropyl)-carbodiimide hydrochloride (EDCI) and 0.1 mmol 4-dimethylaminopyridine (DMAP) as catalysts. The solution was stirred at room temperature for 12 h. At the end of reaction, the solvent was removed under reduced pressure. The crude reaction mixture was purified by silica plug eluted with hexane/ethyl acetate (9:1, v/v).

Analysis of fatty acid composition at sn-2 position of OPO

Determination of fatty acid positional distribution at sn-2 position of OPO was based on the methods described by Shimada et al. (2003). OPO (150 mg) was mixed with 1 ml ethanol (dried using a 4 Å activated molecular sieve) and 0.6 ml hexane. Novozym 435 (80 mg) was used to start the reaction and the reaction was carried out with agitation at 35 °C for 4 h. The reaction was stopped by the separation of Novozym 435 lipase by filtration and 2-MAGs formed during sn-1,3 specific ethanolysis was separated by TLC eluted with hexane/diethyl ether/acetic acid (50:50:1, by vol.). The band corresponding to sn-2 MAGs was scraped off, derivatized with hexamethyldisilazane and trimethylchlorosilane, and then quantified by GC as described in the following section.

GC analysis of synthetic vinyl oleate

The synthetic product was quantified by GC equipped with a flame ionization detector using a 30 m × 0.25 mm × 0.25 μm fused-silica capillary column, PEG-20000. The carrier gas was 30 ml/min, and the split ratio was 10:1. The oven was programmed from 120 to 230 °C at 4 °C/min. The injector and detector were set to 260 °C.

Derivatization of synthetic 1,3-diolein and sn-2 MAGs for GC quantification

The GC analysis of partial acylglycerols was based on the previous methods (Pfeffer et al. 2007; Wang et al. 2012). The anhydrous reaction products were placed into a 2 ml glass vial for producing their ether derivatives for GC quantification. Pyridine (0.5 ml) was added followed by hexamethyldisilazane (0.15 ml) and trimethylchlorosilane (0.05 ml). The mixture was shaken for 15–30 s and allowed to stand for 20 min to allow the upper layer phase turn clear. The purity of partial acylglycerols was calculated according to the peak area ratio. A mixture standard of diolein (85 % 1,3-diolein and 15 % 1,2-diolein) was used as external standard and 1,3-diolein peak was identified according to the GC retention time.

The GC determination conditions of partial acylglycerols were the same with quantification of vinyl oleate except the followings: The oven temperature was programmed from 140 to 310 °C at a rate of 11 °C/min, and then held at 310 °C for 20 min. The injector and detector temperatures were set to 320 °C.

NMR analysis of synthetic OPO

1H NMR qualitative analysis of OPO was done with a Bruker NMR spectrometer (Avance III 400 MHz, Switzerland) with CDCl3 as solvent and tetramethyl silane (TMS) as the internal standard (chemical shift of 0 ppm).

Results and discussion

Chemical synthesis of vinyl oleate

In general, fatty acid vinyl esters as acyl donors have a higher reactivity compared to free fatty acids, fatty acid methyl esters and TAGs due to irreversibility of the reaction resulting from enolic leaving group tautomerizing to a non-nucleophilic acetaldehyde (Halldorsson et al. 2003). Many publications have succeeded in the synthesis of saturated 1,3-DAGs by the glycerolysis between saturated fatty acid vinyl esters and glycerol (Andrews et al. 2008; Magnusson and Haraldsson 2010). However, commercial vinyl oleate is not readily available. To synthesize OPO, we first synthesized vinyl oleate. Vinyl oleate was synthesized by the transvinylation between vinyl acetate and oleic acid with palladium acetate as catalyst. Vinyl oleate can be separated from oleic acid by GC and its content in the crude reaction mixture was (67.2 ± 4.3) % (area/area) after reaction. Pure vinyl oleate (>98 %) was obtained at (58.9 ± 2.2) % (w/w) yield after purification by flash chromatography on silica gel eluted with hexane/ethyl acetate (10:1, v/v). The results are similar to those of Waldinger and Schneider (1996). In the present study, we synthesized vinly oleate on a small scale. However, commercial saturated fatty acid vinyl esters are also synthesized by this route and the reaction is scalable (Port et al. 1952). Chemical synthesis of fatty acid vinyl ester was not environmentally benign, but our study showed that enzymatic method was ineffective for the transvinylation between vinyl acetate and acid.

Enzymatic synthesis of 1,3-diolein

When the reaction was conducted with agitation at 35 °C for 8 h by reacting 2 mmol vinyl oleate with 1 mmol glycerol with 10 % (w/v) Novozym 435 as catalyst, there were 90.8 ± 2.1 % 1,3-diolein and 2.2 ± 0.3 % 1,2-diolein produced. The crude reaction mixture was purified further by flash chromatography on silica gel eluted with diethyl ether/hexane (1:1, v/v). The final purity of 1,3-diolein after purification was 98.6 ± 0.5 % at 82.3 ± 1.2 % (w/w) yield. GC and TLC were used to quantify and qualify the reaction product, respectively. GC was an effective technology to separate 1-MAG (monoacylglycerol) from 2-MAG, and 1,3-DAG (diacylglycerol) from 1,2-DAG (Waldinger and Schneider 1996).

DAG has showed beneficial effects on the suppressing the accumulation of body fat and preventing the increase of body weight (Lo et al. 2008). Thus, the nutritional benefits of DAGs have attracted much attention for its synthesis, especially the synthesis of 1,3-diolein. Generally, 1,3-diolein can be synthesized either by the enzymatic esterification of free fatty acids with glycerol (Duan et al. 2010), MAGs with free fatty acids (Duan et al. 2013), or MAGs with fatty acid esters (Jin et al. 2011). However, the purity of 1,3-diolein in the reaction mixture was low (about 40 %). In addition, an efficient method for the synthesis of 1,3-DAGs by the irreversible esterification has been reported (Halldorsson et al. 2003). In order to synthesis pure 1,3-diolein by irreversible acylation between vinyl oleate and glycerol, vinyl oleate was synthesized first.

The selection of reaction system for the synthesis of 1,3-diolein is different from previous report. For the synthesis of saturated 1,3-DAGs, only solvent reaction system was used. Generally, saturated 1,3-DAGs have very high melting points (75 °C of melting point for 1,3-dipalmitin). If a solvent-free system is chosen, the reaction temperature should be above the melting point of saturated 1,3-DAGs in order to keep formed products liquid, whereas the reaction conducted at high temperature will result in the inactivation of lipase and acyl migration of 1,3-DAGs to 1,2-DAGs. Thus, solvent-system may be the only choice for the synthesis of saturated 1,3-DAGs. However, unsaturated 1,3-DAGs have a low melting point (25 °C for 1,3-diolein) (Small 1991), suggesting that a solvent-free system is feasible for the glycerolysis reaction between vinyl oleate and glycerol. This study, is the first use of a solvent-free system to synthesize 1,3-DAG. Another advantage for the irreversible reaction is the use of lower reaction temperature compared to reversible reactions between glycerol and free fatty acids or fatty acid esters. Reversible reaction conducted at a high reaction temperature may cause undesired acyl migration of DAGs.

Synthesis of OPO

OPO was synthesized by the esterification of 1,3-diolein and palmitic acid with EDCI and DMAP as catalysts. Generally, chemically-catalyzed esterification reaction between 1,3-diolein and palmitic acid was more effective compared to enzymatic reaction. At the end of reaction, there was (94.8 ± 3.1) % formed in the crude reaction mixture. After purification, the pure (>98 %) OPO was obtained at (90.5 ± 0.6) % (w/w) yield. Column chromatography was an effective method to remove the polar coupling agents, EDCI and DMAP (Rf < 0.05) (Andrews et al. 2008). EDCI and DMAP can also be removed by molecular distillation due to the much lower boiling point compared to TAGs. During the synthesis, 1,3-diolein may migrate to 1,2-diolein even though the low reaction temperature was employed. Thus, sn-2 fatty acid composition of OPO was determined based on previously reported method. Results showed (98.7 ± 1.6) % palmitic acid at sn-2 position of OPO. Acyl migration of 1,3-diolein to 1,2-diolein was minor at low temperature.

1H NMR spectroscopy of OPO shows the following: δ 0.88 (t, 9H, 3× –CH 3), 1.26–1.29 (m, 64H, 32× –CH 2–), 1.59–1.64 (m, 6H, 3× –OCOCH2CH 2CH2–), 2.0–2.02 (m, 8H, 2× –CH 2–CH=CH–CH 2–), 2.2–2.4 (t, 6H, 3× –OCOCH 2CH2CH2–), 4.10–4.22 (dd, 4H, 2× –OCH 2CHCH 2O–), 5.14–5.20 (m, 1H, –OCH2CHCH2O–), 5.42–5.45 (m, 4H, 2× –CH2–CH=CH–CH2–). Thus, we confirmed the OPO structure based on the information gave by 1H NMR.

Many publications have reported the synthesis of pure OPO or OPO-rich TAG. The main methods for the synthesis of pure OPO or OPO-rich TAG are acidolysis (Chen et al. 2004; Qin et al. 2011), interesterification (Lee et al. 2010) and enzymatic esterification (Pfeffer et al. 2007; Schmid et al. 1999, 1998). Generally, 30–45 % OPO was formed in the reaction mixture by enzymatic acidolysis and interesterification. Enzymatic esterification can also be used to synthesis OPO, However, 2-MAG is extreme unstable and the equilibrium ratio of 1-MAG and 2-MAG is 9:1. Thus, the esterification of 2-MAG with free fatty acid resulted in about 10 % undesired TAG isomer (Schmid et al. 1999; Muñío et al. 2009). An alternative method for the synthesis of OPO is the esterification of 1,3-diolein with palmitic acid. The synthesis of OPO using 1,3-diolein to react with palmitic acid may be more effective since 1,3-DAG is more stable compared to 2-MAG. However, few publication reports the synthesis of unsaturated 1,3-DAGs by the enzymatic esterification of fatty acid vinyl esters with glycerol.

In order to synthesize highly pure OPO, vinyl oleate was used for the synthesis of 1,3-diolein and further for the synthesis of OPO. This is the first report of the chemical synthesis of pure OPO by the esterification of 1,3-diolein with palmitic acid. In this study, the acyl migration of 1,3-diolein to 1,2-diolein was minor during the synthesis of 1,3-diolein and OPO due to the low reaction temperature.

Conclusions

An alternative method for the synthesis of OPO by synthesizing vinyl oleate and 1,3-diolein is reported. The main novelties are the establishment of irreversible acylation route for the synthesis of 1,3-diolein and OPO. Finally, the route for the synthesis of OPO is potentially scalable because the synthesis of vinyl oleate and synthesis of symmetrical TAG are scalable.

References

Abrahamse E, Minekus M, Aken GA, de Heijning B, Knol J, Bartke N, Oozeer R, Beek M, Ludwig T (2012) Development of the digestive system—experimental challenges and approaches of infant lipid digestion. Food Dig 3:63–77

Andrews PC, Fraser BH, Junk PC, Massi M, Perlmutter P, Thienthong N, Wijesundera C (2008) Large-scale synthesis of both symmetrical and unsymmetrical triacylglycerols containing docosahexaenoic acid. Tetrahedron 64:9197–9202

Berry SEE (2009) Triacylglycerol structure and interesterification of palmitic and stearic acid-rich fats: an overview and implications for cardiovascular disease. Nutr Res Rev 22:3–17

Chen ML, Vali SR, Lin JY, Ju YH (2004) Synthesis of the structured lipid 1,3-dioleoyl-2-palmitoylglycerol from palm oil. J Am Oil Chem Soc 81:525–532

Duan Z, Du W, Liu D (2010) Novozym 435-catalyzed 1,3-diacylglycerol preparation via esterification in n-butanol system. Process Biochem 45:1923–1927

Duan Z, Du W, Liu D (2013) Improved synthesis of 1,3-diolein by Novozym 435-mediated esterification of monoolein with oleic acid. J Mol Catal B Enzym 89:1–5

Esteban L, Jiménez MJ, Hita E, González PA, Martín L, Robles A (2011) Production of structured triacylglycerols rich in palmitic acid at sn-2 position and oleic acid at sn-1,3 positions as human milk fat substitutes by enzymatic acidolysis. Biochem Eng J 54:62–69

Halldorsson A, Magnusson CD, Haraldsson GG (2003) Chemoenzymatic synthesis of structured triacylglycerols by highly regioselective acylation. Tetrahedron 59:9101–9109

Hodge J, Li D, Redgrave TG, Sinclair AJ (1999) The metabolism of native and randomized butterfat chylomicrons in the rat is similar. Lipids 34:579–582

Hunter JE (2001) Studies on effects of dietary fatty acids as related to their position on triglycerides. Lipids 36:655–668

Jiménez MJ, Esteban L, Robles A, Hita E, González PA, Muñío MM, Molina E (2010) Production of triacylglycerols rich in palmitic acid at position 2 as intermediates for the synthesis of human milk fat substitutes by enzymatic acidolysis. Process Biochem 45:407–414

Jin J, Li D, Zhu X, Adhikari P, Lee KT, Lee JH (2011) Production of diacylglycerols from glycerol monooleate and ethyl oleate through free and immobilized lipase-catalyzed consecutive reactions. New Biotechnol 28:190–195

Lee JH, Son JM, Akoh CC, Kim MR, Lee KT (2010) Optimized synthesis of 1,3-dioleoyl-2-palmitoylglycerol-rich triacylglycerol via interesterification catalyzed by a lipase from Thermomyces lanuginosus. New Biotechnol 27:38–45

Lo SK, Tan CP, Long K, Yusoff MSA, Lai OM (2008) Diacylglycerol oil-properties, processes and products: a review. Food Bioprocess Technol 1:223–233

Lobell M, Schneider MP (1994) Synthesis of hydroxycarboxylic acid vinyl esters. Synthesis 1994:375–377

Magnusson CD, Haraldsson GG (2010) Chemoenzymatic synthesis of symmetrically structured triacylglycerols possessing short-chain fatty acids. Tetrahedron 66:2728–2731

Muñío MM, Robles A, Esteban L, González PA, Molina E (2009) Synthesis of structured lipids by two enzymatic steps: ethanolysis of fish oils and esterification of 2-monoacylglycerols. Process Biochem 44:723–730

Pfeffer J, Freund A, Bel-Rhlid R, Hansen CE, Reuss M, Schmid RD, Maurer SC (2007) Highly efficient enzymatic synthesis of 2-monoacylglycerides and structured lipids and their production on a technical scale. Lipids 42:947–953

Port WS, Jordan EF, Swern D (1952) Separation of vinyl esters of long chain fatty acids from the corresponding free fatty acids. US Patent 2,586,860

Qin XL, Wang YM, Wang YH, Huang HH, Yang B (2011) Preparation and characterization of 1,3-dioleoyl-2-palmitoylglycerol. J Agric Food Chem 59:5714–5719

Redgrave T, Kodali D, Small D (1988) The effect of triacyl-sn-glycerol structure on the metabolism of chylomicrons and triacylglycerol-rich emulsions in the rat. J Biol Chem 263:5118–5123

Robles A, Jiménez MJ, Esteban L, González PA, Martín L, Rodríguez A, Molina E (2011) Enzymatic production of human milk fat substitutes containing palmitic and docosahexaenoic acids at sn-2 position and oleic acid at sn-1,3 positions. LWT-Food Sci Technol 44:1986–1992

Schmid U, Bornscheuer U, Soumanou M, McNeill G, Schmid R (1998) Optimization of the reaction conditions in the lipase-catalyzed synthesis of structured triglycerides. J Am Oil Chem Soc 75:1527–1531

Schmid U, Bornscheuer U, Soumanou M, McNeill G, Schmid R (1999) Highly selective synthesis of 1,3-oleoyl-2-palmitoylglycerol by lipase catalysis. Biotechnol Bioeng 64:678–684

Shimada Y, Ogawa J, Watanabe Y, Nagao T, Kawashima A, Kobayashi T, Shimizu S (2003) Regiospecific analysis by ethanolysis of oil with immobilized Candida antarctica lipase. Lipids 38:1281–1286

Small DM (1991) The effects of glyceride structure on absorption and metabolism. Annu Rev Nutr 11:413–434

Waldinger C, Schneider M (1996) Enzymatic esterification of glycerol III. Enzymatic catalyzed synthesis of regioisomerically pure 1,3-sn-diacylglycerols and 1(3)-rac-monoacylglycerols derived from unsaturated fatty acids. J Am Oil Chem Soc 73:1513–1519

Wang X, Wang T, Wang X (2012) An improved method for synthesis of N-stearoyl and N-palmitoylethanolamine. J Am Oil Chem Soc 89:1305–1313

Acknowledgments

We acknowledge the Chinese Scholarship Council for providing the sponsorship to this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Zou, W., Sun, X. et al. Chemoenzymatic synthesis of 1,3-dioleoyl-2-palmitoylglycerol. Biotechnol Lett 37, 691–696 (2015). https://doi.org/10.1007/s10529-014-1714-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-014-1714-z