Abstract

The complex problems in the real world, an increase in competition among producers, the advancements in equipment and manufacturing products, the high cost of factory equipment and, etc., have led to the production structure change from a centralized structure to a decentralized one. In recent years, distributed systems have become increasingly important. So in order to adapt to market competition and to respond quickly to changing market demand, there is a need to study this problem. An important aspect of planning in a distributed environment is decentralized production. In such cases, it becomes more important to consider the problem of distributed scheduling. In this regard, this paper provides a systematic literature review on the multi-factory scheduling problems in the past eleven years and report the research gaps. To this end, first, the related research was classified based on the shop environments. Then, after reviewing the existing papers and summarizing them, future researches and emerging research fields of the multi-factory scheduling problem are reported. This review indicates that future research should focus on open shop production environments. The results also show only 4% of the papers focus on the virtual alliance. Therefore, researchers need to consider the virtual alliance in the production network and investigate the participation and competition between the partners in such network. Studying the topic of Industry 4.0 in multi-factory scheduling and subsequently investigating the related topics such as information sharing and real-time data are also the new trends in this field. Considering the complex series–parallel structures in the multi-factory production and defining objective functions related to environmental issues such as reducing pollutants and noise are other suggestions for future studies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, dispersing and distribution of production activities have attracted the attention of competing organizations in global markets (Naderi and Ruiz 2014). In this environment, to increase competitiveness and respond to market changes, the factories have changed their production systems from a single factory to a multi-factory. The multi-factory production system is one of the production systems that has received much attention from researchers and industries in the same period. Leung et al. (2003) have raised a practical example of multi-factory production problems. They studied a multi-national clothing manufacturer in Hong Kong. The manufacturing company produces a number of products and distributes them in North America and Europe. The company's factories are located in different countries, including China, the Philippines, Thailand, and other Southeast Asian countries. Therefore, efficient scheduling is essential for factories to stay in a competitive environment to respond to market changes. At the beginning of the current century, this problem has been considered simultaneously in both the industry and the academic environment. For the following reasons, traditional manufacturing systems are unable to respond to these markets (Gao 2011).

-

The response time to random changes in the market is not satisfactory.

-

Inadequate and inaccurate information due to the geographical magnitude of the distribution of customers has caused decision-makers to make decisions based on intuition or very little information.

-

The organizational structure of traditional systems is predetermined and inflexible. Therefore, they are not flexible against new markets and their changes.

Therefore, in order to overcome these drawbacks, several factories cooperate with each other. Although the scheduling of such a multi-factory production network is much more complicated than single factory scheduling problems, due to its wide range of applications in industry, in the past few years, research on the distributed environments in multi-factory production networks has been one of the most attractive topics (Chung et al. 2009).

There are two types of distribution networks in a multi-factory environment: (i) all factories belong to an organization and they work together to maximize the profits of that single organization, and (ii) a number of independent factories establish a multi-agent production network with the virtual alliance. This network is called a production network with the virtual alliance or multi-agent production network. In this case, the purpose of creating such a virtual alliance is to achieve greater benefits for each member of the network compared to individual production. In both above cases, if distributed activities are properly managed and organized, the virtual production network can reduce production costs and increase flexibility and efficiency (Shi and Gregory 2003). It is clear that distributed scheduling problems are much more complicated than classical scheduling; because two decisions have to be made: allocating jobs to appropriate factories and determining the jobs’ scheduling considering one or more objective functions. Since there are many significant applications of the multi-factory production system in real-world problems, e.g., energy-producing industries (Westfield 1955), auto manufacturers (Gnoni et al. 2003), food and chemical processing industries (Timpe and Kallrath 2000) steel companies (Sambasivan and Yahya 2005) and drug manufacturing (Beheshtinia et al. 2018), this problem has attracted the attention of many researchers.

This study reviews the papers related to the distributed production network scheduling that have been done in recent years. In fact, as a continuation of Behnamian and Fatemi Ghomi (2016), it is the second comprehensive review on the problem of multi-factory production network scheduling. In that review, they surveyed the multi-factory scheduling researches was from 1989 to 2011. In this paper, first, the literature is classified based on the nature of the shop configuration into five aspects, i.e., single machine, parallel machines, flowshop, job shop, and open shop. Then based on this classification, the related papers are review and finally, after summarizing and analyzing them, several future research trends are introduced.

The remains of the paper are organized as follows: Sect. 2 presents the research methodology and classification of the multi-factory production system. Section 3 reviews the multi-factory scheduling papers according to the presented classification. The literature review is analyzed in Sect. 4. Finally, Sect. 5 discusses the conclusions and the emerging research fields in a multi-factory scheduling problem.

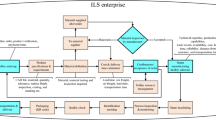

2 Research methodology and classification

In this section, the research methodology and the classification of multi-factory scheduling problem are presented. There are two general research methodologies for writing a review paper, (i) systematic structure (Snyder 2019), (ii) concept-centric structure, introduced by Webster and Watson (2002). In the concept-centric structure, the subject is expressed in a conceptual framework. In this structure, a matrix is compiled as papers are read. As the reading goes on, the key concepts are grouped logically, and the literature is synthesized by discussing the identified concepts. Then, analyses are performed using classified concepts. But, in the systematic structure, the review was done systematically by identifying, evaluating, collecting, and analyzing data from past researches (Liberati 2009). This structure was first used in medical research, but in recent years, it has also been widely used in other scientific fields of research. In fact, this type of review is carried on using resource search, predefined inclusion and exclusion criteria, evaluation, extraction, and generation of data (Snyder 2019). Based on the above explanations and considering systematic classifications of shop environments in scheduling problems, the systematic structure seems more suitable for the present review. So, in this paper, a systematic review structure is used, and its purpose is to summarize and analyze the results and, identify research gaps in the past research on distributed scheduling.

Although no limitation on the production environment was applied, based on the (Baker and Trietsch 2013), references were categorized based on the shop environments, including single machine, parallel machines, flowshop, and job shop. In this regard, at first, the literature was searched mainly on major databases such as SpringerLink, Science Direct, IEEE Xplore, Scopus, and other web sources up to 2021. All the mentioned databases were searched for references with “multi-factory”, “multi-agent”, and “distributed scheduling” in their titles and keywords. Then, some of the searched papers were removed due to their irrelevant content or publication time. Since this paper is a continuation of Behnamian and Fatemi Ghomi (2016), the papers published before 2011 were excluded from search results. Finally, the results are analyzed and based on their summaries, the research gaps and new trends are provided.

3 Literature review

In recent years, the production scheduling problem has been studied by many researchers, that in most of them, the non-distributed scheduling problems as classic planning have been studied. The first research on the multi-factory distributed scheduling problem was done out by Williams (1981) in 1981. In this research, joint scheduling in production and distribution problem in complex networks with the objective of minimizing production and distribution costs has been investigated.

Many studies have so far been conducted in the field of distributed scheduling problems. In the following, the papers associated with each of the produced environments have been investigated according to the presented category.

3.1 Single machine

The simplest scheduling problem is the single machine scheduling problem. There is only one machine or source in this production system. In practice, scheduling problems in more complex environments are decomposed into single machine sub-problems (Pinedo 2012). In this regard, Macarthur et al. (2011) proposed a decentralized task distribution algorithm (DTDA). They analyzed the scheduling of unrelated parallel machines and the multi-agent task allocation. Ruifeng and Subramaniam (2011) divided the multi-stage system into a number of subsystems and solved each of them by a discrete Markov process. They proposed an approximate model to minimize operational costs for the multi-plant production system. They assumed that the amount of inventory in each buffer was controlled by the system (S, Q).

Sun et al. (2015) studied the integrated problem of production and distribution of multi-factories and multi-products with considering marine constraints. They developed a mixed-integer planning model with the objectives of minimizing production cost, warehouses cost, transportation cost, and penalty cost. To solve this problem, they introduced a heuristic algorithm called due-date based cut-off rule (DBC). Also, they proposed a genetic algorithm (GA) that is guided by a fuzzy controller. Karimi and Davoudpour (2017a) studied the integrated problem of scheduling and transportation in a supply chain with a series structure. The objective of the problem is to minimize the sum of inventory and transportation costs. They assumed that inventory maintenance cost is dependent on the production stage and transportation and delivery of jobs among factories are allowed. They proposed a mixed-integer programming (MIP) model as well as a time-indexed formulation. Also, they proposed a relaxation model and an approximate algorithm for this problem. In another paper, they studied the multi-factory production system problem in the series environment considering the various delivery deadlines (Karimi and Davoudpour 2017b). They proposed a knowledge-based imperialistic competitive algorithm to determine the number of batches, assign jobs to batches, and scheduling the batches production and delivery in each factory.

Marandi and Fatemi Ghomi (2019a) developed a MIP model for the integrated multi-factory production and distribution scheduling, applying the vehicle routing approach to minimize the total tardiness and transportation costs. To solve this problem, they proposed an improved imperialist competitive algorithm (IICA). In another paper (Marandi and Fatemi Ghomi 2019b), they studied the multi-factory scheduling problem with batch delivery. They developed a MIP model to minimize the sum of transportation cost, maintenance cost, and delay cost. Furthermore, due to the complexity of the problem, they proposed a learning-oriented simulated annealing algorithm and a hybrid cloud theory-based learning-oriented simulated annealing (HCLSA) algorithm. Gharaei and Jolai (2019) proposed a mathematical model for the integrated scheduling and distribution problem in a multi-factory environment considering batch delivery and routing decisions between customers. They proposed the multi-agent approach to solve the problem. Due to the complexity of the problem, they presented a multi-objective ant colony optimization (ACO) algorithm. They also used a simulated annealing algorithm to improve the quality of the solutions of the proposed algorithm.

These papers are summarized in Table 1.

3.2 Parallel machines

In this environment, two sub-problems should be solved, i.e., (i) assigning the job to the factory, and (ii) scheduling the job in each factory. In this regard, Terrazas-Moreno and Grossmann (2011) studied a distributed production network, which consists of several factories with parallel structures. They developed a MIP model to minimize operational costs. To solve the problem, they used two decomposition methods. In the first one, a bi-level decomposition was extended to multi-site multi-market networks and, in the second method, they applied a combination of the multi-level decomposition method with the Lagrangian relaxation method. Behnamian and Fatemi Ghomi (2013) studied the multi-factory production scheduling problem with considering communications policies. They assumed that the factories had been located geographically in different places. In this problem, they assumed machines in the factories have different speeds. To minimize the makespan, they proposed a MIP model and the longest processing time-based heuristic algorithm and GA. Furthermore, they proposed a lower bound for this problem. For this problem, Behnamian (2014) proposed mixed-integer linear programming and solved it with the improved ϵ-constraint method. To solve the problem, the author proposed a decomposition method based on hybrid variable neighborhood search (VNS) and tabu search (TS) algorithms to minimize the cost of job processing and maximize production profit. In this paper, it is assumed that the factories are independent. In another research, Behnamian (2017a) studied distributed scheduling problem with parallel factories. In this paper, it is assumed that jobs can be transferred from the factory with more workload to the factory with less workload. For the first time, the author proposed a matheuristic algorithm based on the electromagnetism-like algorithm and benders decomposition algorithm to minimize the production costs. Behnamian (2016) proposed a graph coloring-based algorithm to scheduling a parallel job in the multi-factory scheduling problem with parallel structure. In this problem, jobs can be transferred between factories to balance the workloads in the production network. In the proposed approach, first, jobs are decomposed into several sets of the job through semidefinite programming and rounding algorithm and, then, for scheduling the set of jobs generated in the first stage, a particle swarm optimization (PSO) algorithm was proposed. Behnamian (2017b) proposed a MIP model for the problem of distributed production network with heterogeneous parallel factories distributed in different geographical places. In this research, the author proposed a new method called anarchic particle swarm optimization (APSO) to minimize the makespan. In this research, the proposed algorithm is inspired by the anarchic behavior of a society. Lei et al. (2020a) studied distributed scheduling problem in the heterogeneous production network. They assumed that the manufacturing system has unrelated parallel machines. To minimize the makespan, they proposed a mathematical model and an imperialist competitive algorithm (ICA) with memory.

Liu and Lei (2020) studied distributed unrelated parallel machines scheduling problem considering preventive maintenance constraints. They proposed an artificial bee colony with a division (DABC) algorithm for the problem. In the proposed algorithm, the swarm is divided into one employed bee colony and three onlooker bee colonies. Behnamian and Fatemi Ghomi (2020) addressed the multi-factory scheduling problem with heterogeneous factories. In this problem, the factories available to process the jobs have different speeds in which each factory has identical parallel machines. To minimize the sum of the earliness and tardiness (E/T) and total completion time, they proposed a mixed-integer linear program model and a heuristic algorithm. Pan et al. (2020) proposed a knowledge-based two-population optimization algorithm for the distributed parallel machines scheduling with the objectives of minimizing the total energy consumption and total tardiness. They used two methods based on problem-specific knowledge and a random heuristic for the initial solutions. Lei et al. (2020b) proposed an improved artificial bee colony for the multi-objective distributed production network with the unrelated parallel machines. To perform the search process in the stages of the employed bee and onlooker bee in the proposed algorithm, they applied different combinations of searches of global and neighborhood. For the first time, Wachtel and Elalouf (2020) proposed a fully polynomial approximation scheme (FPTAS) approximation method for job assignment in a multi-factory environment. The proposed method is very general and is used for various objective functions.

These papers are summarized in Table 2.

3.3 Flow shop

The flowshop scheduling problem is one of the most well-known scheduling problems. This problem has been attracted many researchers in recent decades. This production system has many applications, such as semiconductor industries, electronics, aircraft engine production, and petrochemicals.

Gao and Chen (2011) addressed the distributed permutation flowshop scheduling problem with the objective of minimizing the maximum completion time. In this problem, the considered multi-factory production system has a parallel structure. Due to the complexity of the problem, they proposed a hybrid algorithm based on the GA and three local search algorithms. Naderi and Ruiz (2014) presented a scatter search (SS) algorithm to minimize the makespan. Wang et al. (2016) studied this problem considering the machine breakdown. In order to minimize the makespan, they proposed a fuzzy logic-based hybrid estimation of distribution algorithm. Also, to preserve population diversity, they proposed a fuzzy logic-based adaptive evolution strategy. Deng et al. (2016) proposed an improved harmony search algorithm for the distributed two machines flowshop scheduling problem. They developed a two-step decoding method for solution representation. The distributed no-wait flowshop scheduling problem for the first time was investigated by Lin and Ying (2016). In order to minimize the makespan, they proposed a MIP model and iterated cocktail greedy (ICG) algorithm. Deng and Wang (2017) proposed a competitive memetic algorithm (CMA) to solve the distributed permutation flowshop scheduling problem with the objective of minimizing the makespan and total tardiness. Cai et al. (2018) studied this problem with transportation and eligibility constraints. They proposed a mathematical model with the objectives of minimizing the makespan, maximum lateness, transportation costs, and setup costs. They developed several heuristic algorithms for solving the single-objective problem and a GA for solving the multi-objective problem. Zhang and Xing (2018) addressed the distributed two-stage assembly flowshop scheduling problem. In this paper, to minimize the total completion time, they proposed a memetic algorithm (MA) based on the social spider optimization (SSO) algorithm. Also, Lei and Li (2020c) proposed a cooperated teaching–learning-based optimization (CTLBO) to solve this problem. Huang et al. (2021) presented an improved iterative greedy algorithm based on the groupthink (gIGA) for distributed assembly permutation flowshop scheduling problem with the objective of minimizing the total flow time. Song and Lin (2021) developed a genetic programming hyper-heuristic (GP-HH) algorithm for the distributed assembly permutation flow shop scheduling problem with sequence dependent setup time. To minimize the maximum completion time of this problem, Zhang et al. (2021) developed a matrix-cube-based estimation of distribution algorithm (MCEDA).

Ruiz et al. (2019) proposed two improved iterated greedy algorithms to solve the distributed permutation flowshop scheduling problem. Pan et al. (2019a) studied this problem with the total flowtime objective function. To solve the problem, they proposed three heuristic algorithms and four metaheuristic algorithms (discrete artificial bee colony (DABC), scatter search (SS), iterated greedy (IG), and iterated local search (ILS)). Lin and Zhang (2016) studied the distributed assembly permutation flowshop scheduling problem. They proposed a hybrid biogeography-based optimization (HBBO) algorithm to minimize the makespan. Furthermore, to improve the hybrid algorithm, they proposed a local search algorithm. Pan et al. (2019b), in another research, developed a MIP model with the objective of minimizing the makespan for this problem. Due to the complexity of the problem, they proposed three heuristic algorithms, two VNS algorithms, and an iterative greedy algorithm. Hatami et al. (2013) developed a MIP model for this problem with the objective of minimizing the makespan. Due to the Np-hardness of this problem, the authors suggested three heuristic algorithms and a variable neighborhood descent (VND) algorithm. In another paper, Hatami et al. (2014) proposed two simple algorithms. Wang and Wang (2016) proposed an estimation of the distribution-based memetic algorithm to solve this problem. Gonzalez-Neira et al. (2017) studied this problem with random processing and assembly times. They proposed a hybrid algorithm based on simulation methods to solve this problem. To solve this problem, Zhang and Yin (2020) proposed a GA in which a greedy mating pool and an effective crossover strategy based on the local search were used. Zhang et al. (2020) proposed a MIP model and a MA to solve the distributed flexible assembly permutation flowshop scheduling problem to minimize the makespan. Li et al. (2021a) studied the distributed assembly flow shop scheduling with fuzzy processing time. To minimize the fuzzy makespan, they developed an imperialist competitive algorithm with empire cooperation (ECICA). Rifai et al. (2016) studied a multi-objective adaptive large neighborhood search (MOALNS) algorithm for the distributed permutation flowshop scheduling problem. They developed a MIP model with the objectives of minimizing the makespan, total costs, and average tardiness. Zhang et al. (2018a) studied the distributed flowshop scheduling problem considering the flexible assembly operation and setup time. They developed a mathematical model with the objective of minimizing the makespan. This problem consists of four decisions: assigning jobs to factories, determining the sequence of jobs in each factory, determining an assembly machine for each product, and determining the sequence of products on each assembly machine. To solve the problem, they proposed a heuristic algorithm and a hybrid metaheuristic algorithm entitled the HPSO and HVNS algorithms.

Fu et al. (2019a) studied the stochastic flowshop scheduling problem in a distributed manufacturing system. To minimize the objective functions, total tardiness, and energy consumption, they proposed a multi-objective mathematical model. Furthermore, due to the complexity of the problem, the authors proposed a brain storm optimization (BSO) algorithm. In another paper, Fu et al. (2019b) studied this problem considering the makespan and total energy consumption objective functions. They proposed a multi-objective mathematical model with the chance constraint. Bargaoui et al. (2017) studied the distributed permutation flowshop scheduling problem in the multi-factory environment. To solve this problem by considering the multi-agent systems, they proposed an evolutionary algorithm based on the chemical reaction optimization (CRO) algorithm. Zhang et al. (2018b) proposed a discrete differential evolution algorithm (DDE) for this problem with blocking. They used four heuristic algorithms to generate the initial population. Fernandez-Viagas et al. (2018), to minimize the total flowtime, proposed eighteen heuristic algorithms and an evolutionary algorithm (EA). Wang et al. (2019) investigated the multi-objective problem by considering the sequence-dependent setup time (SDST). To minimize the makespan and total energy consumption, they proposed a multi-objective MIP model and a multi-objective whale swarm algorithm (MOWSA). Shao et al. (2019) studied the multi-objective distributed no-wait flowshop scheduling problem with SDST. They developed a MIP model with the objectives of minimizing the makespan and the total weight tardiness for it. To solve the problem, they also proposed a Pareto-based estimation of distribution algorithm (PEDA) and a heuristic algorithm for generating the initial population. Chen et al. (2019) developed a MIP model for the distributed heterogeneous flowshop scheduling. To minimize the makespan, they proposed a probability model-based memetic algorithm (PMMA). Meng et al. (2019) studied the distributed scheduling problem in the permutation flowshop production environment with the customers’ order constraint. In this problem, they assumed a set of customer orders needs to be manufactured in a number of factories and each order composed of some defined jobs should be processed in the same factory. In order to minimize the makespan, they developed a mathematical model and proposed three heuristic and three metaheuristic algorithms. Chen et al. (2019b) studied the energy-efficient distributed no-idle permutation flow shop scheduling problem to minimize makespan and total energy consumption. To solve this problem, they proposed a collaborative optimization algorithm (COA).

Zhao et al. (2020) proposed an ensemble discrete differential evolution (EDE) algorithm and a MIP model for distributed blocking flowshop scheduling problem (DBFSP). Also, for this problem, Shao et al. (2020a) proposed a hybrid enhanced discrete fruit fly optimization algorithm (HEDFOA) in the blocking flowshop environment. To initialize the common central location of all fruit fly swarms, they proposed an efficient heuristic. Shao et al. (2021a) studied the distributed permutation flow shop scheduling problem considering the mixed blocking. To minimize the makespan, they proposed an improved NEH heuristic and efficient iterated greedy (EIG) algorithm. In another research, Shao et al. (2020b) assumed the processing times to be fuzzy. To solve this problem with the objective minimize the fuzzy makespan, they proposed two new heuristic algorithms based on the problem-specific knowledge and the NEH heuristic and two iterated greedy (IG) algorithms to minimize the fuzzy makespan. Chen et al. (2021) considered a distributed flowshop scheduling problem with blocking. They proposed six heuristic algorithms and an iterated greedy (IG) algorithm to minimizing the makespan. Wang et al. (2020) proposed a multi-objective MIP model to minimize makespan and energy consumption. They developed a new problem-dependent local search algorithm to improve the exploitation capability of the multi-objective whale swarm algorithm. Hamzadayi (2020) developed a new mathematical model and hybrid Benders decomposition algorithms for solving the distributed permutation flowshop scheduling problem (DPFSP). For the first time, Jing et al. (2020) considered due windows in the distributed permutation flowshop scheduling problem. To minimize the total weighted E/T, they presented an iterated greedy (IG) algorithm. Also, they proposed an adapted NEH heuristic to generate an initial solution. In another paper, they (Jing et al. 2021) modeled a robust distributed permutation flowshop problem. They assumed processing times to be uncertain. To solve, the authors presented a new iterated greedy algorithm (IGA) and a new iterated local search algorithm (ILS) to minimize the makespan. They used an NEH heuristic algorithm to initialize the proposed algorithms. Khare and Agrawal (2020) modeled a distributed permutation flowshop scheduling problem with the objective of minimizing total tardiness. To solve the problem, they proposed two heuristic algorithms, hybrid discrete Harris hawks optimization and an enhanced variant of iterated greedy algorithm. To more easily solve the distributed permutation flowshop scheduling problem, Yang et al. (2020) used a helper objective to turn the single-objective problem into a multi-objective problem. They presented an improved swarm intelligence optimization algorithm to solve both objective functions (original and helper goal). Liu (2020) considered the distributed flowshop group scheduling problem with the objectives of minimizing total flowtime. The author proposed twenty heuristic algorithms, including eight simple heuristics, eight hybrid heuristics, and four NEH-based heuristics to solve this problem. Ali (2020) proposed a mathematical model and a construction heuristic and tabu search algorithm to solve the permutation flowshop scheduling problem to minimize makespan. The author considered assumptions of no-wait and heterogeneous in the problem. Mao et al. (2021) proposed an effective multi-start IGA for the distributed permutation flow shop scheduling problem considering preventive maintenance operation. They used a heuristic algorithm to improve initialization. Also, to prevent falling into the local optima, they presented a destruction phase and a construction phase. For the first time, Rifai et al. (2021) considered sequence-dependent setup time in distributed reentrant permutation flow shop problem. They proposed a multi-objective adaptive large neighborhood search (MOALNS) to solve this problem. Baysal et al. (2021) proposed an artificial bee colony algorithm to solve the distributed fuzzy permutation flow shop scheduling problem. The authors assumed the due dates of the jobs and processing time of the jobs to be trapezoidal fuzzy numbers and triangular fuzzy numbers, respectively. Meng and Pan (2021) considered the lot-streaming and carryover SDST in the distributed permutation flowshop scheduling problem. Factories of the problem are heterogeneous. They proposed an enhanced artificial bee colony algorithm (NEABC) to minimize the makespan. Ali et al. (2021) formulated distributed permutation flowshop scheduling problem. To minimize the total completion time, they proposed the TS algorithm. Li et al. (2021b) considered the mixed no-idle constraints in the distributed flow shop scheduling problem. In this research, they proposed a MIP model and an adaptive iterated greedy (AIG) algorithm to minimize total flow time. They used a restart strategy to prevent falling into the local optima. Li et al. (2021c) considered the heterogeneous factories in the distributed no-wait flowshop scheduling problem. Factories have a different number of machines, machine technology, raw material supply, and transportation conditions. They presented the discrete artificial bee colony algorithm (DABC) to minimize the makespan. In the proposed algorithm, they used the variable neighborhood descent (VND) algorithm to increase the search of the algorithm in the solution space. Isguder and Hamzaday (2021) proposed two new mathematical models by inspiration from the models of the multiple-traveling salesman problem (mTSP). They developed six different Benders decomposition algorithms and a hybrid Benders decomposition algorithm.

For the first time, Ying and Lin (2018) studied the distributed hybrid flowshop scheduling problem with multiprocessor tasks. To solve the problem, they proposed a MIP model and a self-tuning iterated greedy algorithm (sIGA) to minimize the makespan. In the proposed algorithm, the adaptive cocktail decode method was used. Li et al. (2020) proposed a machine position-based mathematical model and a discrete artificial bee colony algorithm (DABC) for the distributed hybrid flowshop scheduling problem with SDST. They proposed two heuristic algorithms and a random strategy for generating the initial solution. To minimize the makespan and the maximum of the total agreement index, Cai et al. (2020) proposed a collaborative variable search (CVS) for solving the fuzzy distributed two-stage hybrid flowshop scheduling problem with SDST. In another paper (Cai et al. 2020a), they proposed a dynamic shuffled frog-leaping algorithm (DSFLA) to minimize makespan in the distributed hybrid flowshop scheduling problem. Also, they developed a lower bound for this problem. Cai et al. (2020b) studied the bi-objective distributed scheduling in the hybrid flowshop. They proposed a shuffled frog-leaping algorithm with memeplex quality (MQSFLA) to minimize total tardiness and makespan. Wang and Li (2020) studied a fuzzy distributed hybrid flow shop problem. To minimize the makespan and the fuzzy total energy consumption and maximize the total agreement index, they proposed the shuffled frog leaping algorithm with the collaboration of multiple search strategies (SFLA-CMSS). Lei and Wang (2020) studied the distributed scheduling problem in a two-stage hybrid flowshop environment to minimize makespan and the number of tardy jobs. In this problem, setup time is assumed sequence-dependent. To solve this problem, they proposed a shuffled frog-leaping algorithm with memeplex grouping. Shao et al. (2020c) developed a mathematical model for distributed hybrid flow shop scheduling problem. To minimize the makespan, they proposed two algorithms called DNEH with smallest-medium rule algorithm and the multi-neighborhood iterated greedy algorithm. Cai and Lei (2021) modeled a distributed hybrid flow shop scheduling with fuzzy processing time. The considered objective functions for this problem were (i) minimize the makespan, (ii) minimize the fuzzy total energy consumption, and (iii) maximize the total agreement index. Also, to solve this problem, they proposed a cooperated shuffled frog-leaping algorithm (CSFLA). Wang and Wang (2020) studied the distributed hybrid flow shop scheduling problem to minimize the makespan. The authors assumed factories to be heterogeneous. To solve the problem, they proposed a bi-population memetic algorithm. Shao et al. (2021b) considered a distributed hybrid flow shop scheduling. To minimize the makespan, total weighted E/T and total workload, they proposed a multi-objective evolutionary algorithm. Their proposed algorithm was based on multiple neighborhood local searches. Wu and Xia (2021) developed two models for the distributed flow shop scheduling problem and reentrant scheduling problem in the manufacturing of seamless steel tubes. To solve these problems, they used the fruit fly optimization method and simulated annealing algorithm, respectively.

The reviewed papers are summarized in Table 3.

3.4 Job shop

The job shop scheduling problem is one of the most important topics in production management and is one of the most complex topics in combinatorial optimization. In this environment, each job consists of several operations and it has its own production route.

The distributed job shop scheduling problem is investigated for the first time by Jia et al. (2002). The aim of this problem is to determine the most appropriate factory problem for each job (assignment), determine the most appropriate machine problem for each job (routing), and determine the operation sequences on each machine (sequence). In this paper, a web-based system is proposed for production scheduling to facilitate the collaboration between distribution plants in different geographic regions. In another research, Jia et al. (2003) proposed a modified GA with a two-step encoding method. To evaluate the performance of the proposed algorithm, they compared the GA results with the algorithm proposed by Muth et al. (1963). Chan et al. (2005) studied the problem of Jia et al. (2003) and, to solve it, they proposed a GA with dominant genes. Furthermore, Jia et al. (2007) proposed an integrated genetic algorithm-Gantt chart. Moon and Seo (2005) proposed a mathematical model and an evolutionary algorithm for solving this problem considering precedence constraints, flexible sequences, and alternative machines. The objective of this problem is to minimize the makespan. Liu et al. (2006) addressed the scheduling problems in a hybrid distributed manufacturing execution system. To solve this problem in the dynamic state, they proposed an approach based on a GA, multi-agent method, multi-closed loop control, and user cooperation structure. Moon et al. considered the multi-factory scheduling problem in a job shop environment. To minimize the makespan, they used topology sorting to generate a set of operations sequences and developed an evolutionary search approach to find feasible solutions. Wang et al. (2006) studied the distributed scheduling problem in a dynamic job shop production environment to minimize the production costs considering job deadlines. The authors developed a GA that was improved by iterative algorithms.

Naderi and Azab (2014) proposed two MIP models for distributed job shop scheduling problems. They solved small-size instances by CPLEX and solve medium and large-size instances by three heuristic algorithms and three greedy heuristics. In another paper, Naderi and Azab (2015) proposed a MIP model with the objective of minimizing the makespan. To solve the problem, they developed a greedy algorithm and simulated annealing algorithm, which improves by a local search. Chaouch et al. (2017) proposed three algorithms, namely modified ant colony optimization (MACO), ant system (AS), and ant colony system (ACS) for distributed job shop scheduling problem. The results of this paper showed that the MACO algorithm has better performance than the other two algorithms. Xia et al. (2019) developed a multi-objective model to minimize the makespan and total energy consumption. To solve this problem, they proposed a multi-objective artificial bee colony algorithm (MOABC). Lohmer et al. (2020) developed a mathematical model with the objective of the due date for this problem. Also, they proposed an adapted greedy heuristics and a GA to solve a large problem. Şahman (2021) proposed a hybrid algorithm based on the discrete spotted hyena optimizer (DSHO) and a greedy heuristic approach to solve the distributed job shop scheduling problem with the objective of minimizing the makespan. Jiang et al. (2020) studied this problem to minimize makespan and energy consumption. They proposed an effective modified multi-objective evolutionary algorithm with decomposition method (MMOEA/D) to solve the problem.

The flexible job shop scheduling problem is more complicated than the job shop problem. This problem in a distributed environment has attracted the attention of a number of researchers. For the first time, this problem was studied by Chan et al. (2006). They developed a MIP model with the objective of minimizing the makespan. Also, because of the complexity of the studied problem, they proposed a method based on the GA. In the proposed approach, the idea of dominant genes was used to identify and save the best chromosomes in the next generation. Liu et al. (2014) proposed a mathematical model and a GA for the distributed flexible job-shop scheduling problems to minimize the makespan. They used the real data of a Taiwanese fastener manufacturer to validate the proposed algorithm. To solve the distributed scheduling problem in the flexible job shop environment, Wu et al. (2017) proposed a GA. In the proposed algorithm, they used a new representation method for solution encoding. Chang and Liu (2017) proposed a hybrid GA for distributed flexible job shop scheduling problem with the objective of minimizing the makespan. To solve this problem, Li et al. (2018) proposed a hybrid Pareto-based tabu search algorithm (HPTSA). To minimize the makespan, maximum workload, total job volume, and the sum of the E/T, they proposed a hybrid Pareto-based tabu search algorithm (HPTSA). Marzouki et al. (2018) proposed a CRO algorithm to solve the distributed flexible job shop scheduling problem. Lu et al. (2018) studied the flexible job shop problem in a distributed environment. Due to the complexity of the problem, they proposed a genetic-based algorithm. To a similar problem, Wu and Liu (2018) presented a mathematical model and an improved differential evolution simulated annealing algorithm (IDESAA) to minimize the makespan. Ziaee (2014) proposed a heuristic algorithm based on a constructive procedure to solve the distributed flexible job shop problem. Wu et al. (2019) developed a multi-objective mixed-integer linear programming model for the distributed assembly flexible job shop problem. To minimize the E/T and total production cost, they proposed a simulated annealing algorithm improved by crossover and mutation operators. Luo et al. (2020) studied the distributed flexible job shop scheduling problem. They assumed the operations of a job could not be transferred between different factories. To solve the problem, they proposed an efficient memetic algorithm (EMA). Mahmoodjanloo et al. (2020) studied the distributed flexible job shop scheduling problem in the dynamic environment. They developed two mathematical models for the static and the dynamic states with the objective of minimizing the total cost. They used a physical cyber system to obtain real-time data. To minimize the makespan, Meng et al. (2020a) developed four different MIP models in the distributed flexible job shop scheduling problem. In another paper, Meng et al. (2020b) developed a novel MIP model with the objective of minimizing energy consumption. Also, to solve large-size instances, they proposed a hybrid algorithm based on the shuffled frog-leaping algorithm. Du et al. (2021) considered the crane transportation in the distributed flexible job shop scheduling problem. The authors developed a MIP model to minimize makespan and total energy consumption. To solve the problem, based on the estimation of distribution algorithm and variable neighborhood search, they proposed a hybrid algorithm. Xu et al. (2021) formulated a mathematical model for distributed flexible job shop scheduling problem with the objectives of minimizing makespan, costs, quality, and carbon emission. They presented a fuzzy analytical hierarchy process and a hybrid genetic algorithm and tabu search to solve this multi-objective problem. The papers of this section are summarized in Table 4.

4 Research survey results

The purpose of this section is to analyze the reviewed papers in terms of their shop scheduling environment, having single or multiple objective functions, solution methods used, and their type of production network ownership in order to identify existing research gaps and provide suggestions for researchers.

In this paper, a total of 110 papers from the past eleven years have been reviewed. The distribution of sources of these papers is presented graphically in Fig. 1. As shown in Fig. 2, due to the practical nature of the problem, the multi-factory production scheduling problems have gained considerable attention in the last decade and the number of researches in this field is quite increasing.

Figure 3 classifies the reviewed papers according to their objective functions. As is clear from this analysis, among 110 papers, 75% (83 papers) have addressed single objective problems and just 25% of them (27 papers) have been dedicated to multi-objective problems. Furthermore, Fig. 4 reveals that 74% of the single objective multi-factory production scheduling problem papers consider minimizing the makespan as a widely used objective function in the multi-factory production scheduling problems. As shown in Fig. 5, most of the published papers (62%) considered flowshop production environment and few papers addressed other production environments (i.e., parallel machines, job shop, and single machine). Furthermore, no research has been done on multi-factor scheduling in open shop environments. The results of Fig. 6 indicate that in 96% of the published papers, the factories are managed by a central unit, while only 4% of the papers consider the production network as a virtual alliance. In this condition, factories are working together to create a virtual production network. In fact, production networks with the virtual alliances provide a highly permeable and flexible structure, with very simple relationships and very low input and output constraints. In this production network, the factories can achieve more benefits than independent production.

According to studies on the published papers, a few numbers of resources have focused on communications between factories. Communications between factories improve interoperability between subsystems in a distributed model. This problem can be done by smartening the production system. Also, the number of studies that have considered the possibility of jobs transferring between factories in the distributed scheduling model has been very small. Obviously, not considering this issue will cause the multi-factory problem to become scheduling of several independent factories, and this leads to reduce the inherent attractiveness of the distributed scheduling problem and its complexity. Almost all of the research uses parallel factory structures, while series structure, as well as hybrid series–parallel modes in the form of integrated scheduling in the supply chain management, can improve system performance.

The solving techniques in this problem are also classified into five major categories (i.e., approximate algorithm, exact method, metaheuristic algorithm, heuristic algorithm, and hybrid algorithm). The number of studies in each technique is shown in Table 5.

As it is clear in this section, the largest portion of the proposed algorithms is related to metaheuristic, heuristic, and hybrid algorithms, which due to the complex nature of these problems, achieving these results has not been far from the mind. In this regard, the metaheuristic algorithms have been used 85 times in papers, while the approximate algorithms and exact methods have been used only three times.

5 Conclusions and emerging research fields

Due to the importance of the multi-factory production scheduling problem in the real world and industry, this research provided a review of this scheduling problem. After classification of publications based on shop environments, the multi-factory production scheduling in the single machine, parallel machines, flow shop, and job shop were reviewed between 2011 and 2021. Based on the analysis of reviewed papers, the emerging research fields are as follows:

The study in parallel machines, job shop and single machine production environments are appropriate topics for future research. In this regard, considering the open shop environment is especially recommended. Considering the virtual alliance production network in the different production environments is recommended. On this subject, integrating Industry 4.0 in manufacturing systems provides the advantages of real-time tracking and monitoring of the entities (Huang et al. 2019). In Industry 4.0, manufacturing systems are updated at a smart level, and the integration of new technologies of information and communication is done using tools such as radio-frequency identification (RFID), big data, IoT, etc. Since in this generation of industry decisions are made faster, it is suggested that the most important features of Industry 4.0, such as participation, information sharing, flexibility, real-time data, and being online, be used in the multi-factory scheduling problems. Another common fault that occurs accidentally in smart factories is the failure of machines. In order to increase the system tolerance against failures, using the concept of reliability in the Industry 4.0 environment is suggested. It is also suggested that communication between factories be considered in the multi-factory scheduling problem in order to make it smarter, more practical, and more logical. In most researches, it is assumed that buffers between every two subsequent factories in a series structure have infinite capacity.

In recent years with the advent of just-in-time (JIT) systems, scheduling problems with JIT-related objective functions have become more operational. Therefore, the study of distributed JIT scheduling is suggested. Random events in the real world include the arrival of new jobs, failure of machines, changes to the due date, new orders, cancellation of orders, and delays in operations. Therefore, considering these events in multi-factory scheduling is suggested as future research. The study of multi-objective multi-factory production scheduling is another interesting topic for researchers. It is suggested that researchers consider environmental-related objective functions as well as the social responsibility of factories. For example, defining objective functions related to environmental issues such as reducing pollutants, efficient use of energy in scheduling, and reducing noise in the production process, are our other suggestions for future studies. Specifically, the study of distributed energy-efficient scheduling is suggested to those interested in this field.

As shown in the results, most papers have been using metaheuristic and heuristic algorithms. In the future, applying less frequent methods such as matheuristics, decomposition-based methods, and approximate algorithms are suggested. In particular, the use of decomposition methods is highly recommended due to the structure that exists in multi-factory scheduling problems. To use these methods, by decomposing the problem into assigning the jobs to the appropriate factory and scheduling the assigned jobs in the factory, researchers can use methods such as Benders decomposition, branch, and cut and, etc. In most papers, it is assumed that machines are constantly available. Therefore, it is suggested that constraints of the unavailability of machines be studied. Furthermore, integrating other supply chain decisions with the multi-factory scheduling problem is a new topic in the field. As an example, simultaneous consideration of the distribution problem with the multi-factory scheduling problem and integration of the classical vehicle routing problems in the production network scheduling is very attractive.

Due to the conflicting interests of members in virtual alliances, it inadvertently creates issues such as simultaneous cooperation and competition between the partners in the production network. Addressing such issues and using game theory topics is another future suggestion for this field. One important feature in multi-factory scheduling is the possibility of jobs transferring between factories. Considering the transportation time of jobs among factories is another suggestion. Obviously, in the real world, the number of vehicles is not unlimited, nor are they exactly the same. Adding hypotheses of vehicle heterogeneity in the movement of jobs as well as constraints on the number of transport fleets could be used in future research. Considering the real conditions in the problem, such as dynamic scheduling and scheduling in conditions of uncertainty such as fuzzy scheduling and stochastic/robust scheduling is our suggestion in this review. Our latest and perhaps less relevant suggestion for researchers is to use the concepts of multi-agent scheduling in scheduling other systems. For example, in health systems, and especially in operating room scheduling, considering hospitals as agents can be a great application of distributed scheduling. In such cases, the objective function can be the participation of several independent hospitals in a hospital network with a virtual alliance to reduce casualties in emergency patients.

References

Ali A (2020) Optimization of the distributed permutation flowshop scheduling problem,” parallel flowshop, distributed permutation flowshop, tabu search, total completion time, makespan, no-wait heterogenous DPFSP

Ali A, Gajpal Y, Elmekkawy TY (2021) Distributed permutation flowshop scheduling problem with total completion time objective. Opsearch 58(2):425–447

Baker KR, Trietsch D (2013) Principles of sequencing and scheduling. John Wiley & Sons, New York

Bargaoui H, Driss OB, Ghédira K (2017) Towards a distributed implementation of chemical reaction optimization for the multi-factory permutation flowshop scheduling problem. Proc Comput Sci 112:1531–1541

Beheshtinia MA, Ghasemi A, Farokhnia M (2018) Supply chain scheduling and routing in multi-site manufacturing system (case study: a drug manufacturing company). J Model Manag 13(1):27–49

Behnamian J (2014) Decomposition based hybrid VNS–TS algorithm for distributed parallel factories scheduling with virtual corporation. Comput Oper Res 52:181–191

Behnamian J (2016) Graph colouring-based algorithm to parallel jobs scheduling on parallel factories. Int J Comput Integr Manuf 29(6):622–635

Behnamian J (2017a) Matheuristic for decentralized factories scheduling problem. Appl Math Modell 47:668–684

Behnamian J (2017b) Heterogeneous networked cooperative scheduling with anarchic particle swarm optimization. IEEE Trans Eng Manage 64(2):166–178

Behnamian J, Fatemi Ghomi SMT (2013) The heterogeneous multi-factory production network scheduling with adaptive communication policy and parallel machine. Inf Sci 219:181–196

Behnamian J, Fatemi Ghomi SMT (2016) A survey of multi-factory scheduling. J Intell Manuf 27(1):231–249

Behnamian J, Ghomi SF (2020) Multi-objective multi-factory scheduling. RAIRO Oper Res 55:S1447–S1467

Cai J, Lei D (2020) Fuzzy distributed two-stage hybrid flow shop scheduling problem with setup time: collaborative variable search. J Intell Fuzzy Syst 38:1–11

Cai S, Yang K, Liu K (2018) Multi-objective optimization of the distributed permutation flow shop scheduling problem with transportation and eligibility constraints. J Oper Res Soc China 6(3):391–416

Cai J, Zhou R, Lei D (2020a) Dynamic shuffled frog-leaping algorithm for distributed hybrid flow shop scheduling with multiprocessor tasks. Eng Appl Artif Intell 90:103540

Cai J, Lei D, Li M (2020b) A shuffled frog-leaping algorithm with memeplex quality for bi-objective distributed scheduling in hybrid flow shop. Int J Prod Res 1–18:2020

Cai J, Lei D (2021) A cooperated shuffled frog-leaping algorithm for distributed energy-efficient hybrid flow shop scheduling with fuzzy processing time. Complex Intell Syst

Chan FTS, Chung SH, Chan PLY (2005) An adaptive genetic algorithm with dominated genes for distributed scheduling problems. Expert Syst Appl 29(2):364–371

Chan FTS, Chung SH, Chan PLY (2006) Application of genetic algorithms with dominant genes in a distributed scheduling problem in flexible manufacturing systems. Int J Prod Res 44(3):523–543

Chang HC, Liu T-K (2017) Optimisation of distributed manufacturing flexible job shop scheduling by using hybrid genetic algorithms. J Intell Manuf 28(8):1973–1986

Chaouch I, Driss OB, Ghedira K (2017) A modified ant colony optimization algorithm for the distributed job shop scheduling problem. Proc Comput Sci 112:296–305

Chen J, Wang L, Peng Z (2019b) A collaborative optimization algorithm for energy-efficient multi-objective distributed no-idle flow-shop scheduling. Swarm Evolut Comput 50:100557

Chen S, Pan Q-K, Gao L (2021) Production scheduling for blocking flowshop in distributed environment using effective heuristics and iterated greedy algorithm. Robot Comput Integr Manuf 71:102155

Chen J, Wang L, He X, Huang D (2019) A probability model-based memetic algorithm for distributed heterogeneous flow-shop scheduling. In: 2019 IEEE congress on evolutionary computation (CEC), pp 411–418

Chung SH, Lau HCW, Ho GTS, Ip WH (2009) Optimization of system reliability in multi-factory production networks by maintenance approach. Expert Syst Appl 36(6):10188–10196

Deng J, Wang L (2017) A competitive memetic algorithm for multi-objective distributed permutation flow shop scheduling problem. Swarm Evol Comput 32:121–131

Deng J, Wang L, Shen J, Zheng X (2016) An improved harmony search algorithm for the distributed two machine flow-shop scheduling problem. Harmony search algorithm. Springer, Berlin, pp 97–108

Du Y, Li J, Luo C, Meng L (2021) A hybrid estimation of distribution algorithm for distributed flexible job shop scheduling with crane transportations. Swarm Evolut Comput 62:100861

Emin Baysal M, Sarucan A, Büyüközkan K, Engin O (2021) Distributed fuzzy permutation flow shop scheduling problem: a bee colony algorithm. Intelligent and fuzzy techniques: smart and innovative solutions. Springer, Cham, pp 1440–1446

Fernandez-Viagas V, Perez-Gonzalez P, Framinan JM (2018) The distributed permutation flow shop to minimise the total flowtime. Comput Ind Eng 118:464–477

Fu Y, Wang H, Huang M (2019a) Integrated scheduling for a distributed manufacturing system: a stochastic multi-objective model. Enterp Inf Syst 13(4):557–573

Fu Y, Tian G, Fathollahi-Fard AM, Ahmadi A, Zhang C (2019b) Stochastic multi-objective modelling and optimization of an energy-conscious distributed permutation flow shop scheduling problem with the total tardiness constraint. J Clean Prod 226:515–525

Gao J (2011) A hybrid genetic algorithm for the distributed permutation flowshop scheduling problem. Int J Comput Intell Syst 497–508:2012

Gao J, Chen R (2011) A hybrid genetic algorithm for the distributed permutation flowshop scheduling problem. Int J Comput Intell Syst 4(4):497–508

Gharaei A, Jolai F (2019) A Pareto approach for the multi-factory supply chain scheduling and distribution problem. Oper Res

Gnoni MG, Iavagnilio R, Mossa G, Mummolo G, Di Leva A (2003) Production planning of a multi-site manufacturing system by hybrid modelling: a case study from the automotive industry. Int J Prod Econ 85(2):251–262

Gonzalez-Neira EM, Ferone D, Hatami S, Juan AA (2017) A biased-randomized simheuristic for the distributed assembly permutation flowshop problem with stochastic processing times. Simul Model Pract Theory 79:23–36

Hamzadayı A (2020) An effective benders decomposition algorithm for solving the distributed permutation flowshop scheduling problem. Comput Oper Res 123:105006

Hatami S, Ruiz R, Andrés-Romano C (2013) The distributed assembly permutation flowshop scheduling problem. Int J Prod Res 51(17):5292–5308

Hatami S, Ruiz R, Andrés Romano C (2014) Two Simple constructive algorithms for the distributed assembly permutation flowshop scheduling problem. Managing complexity. Springer, Cham, pp 139–145

Huang Z, Kim J, Sadri A, Dowey S, Dargusch MS (2019) Industry 4.0: development of a multi-agent system for dynamic value stream mapping in SMEs. J Manuf Syst 52:1–12

Huang Y-Y, Pan Q-K, Huang J-P, Suganthan P, Gao L (2021) An improved iterated greedy algorithm for the distributed assembly permutation flowshop scheduling problem. Comput Ind Eng 152:107021

İşgüder H, Hamzadayi A (2021) A hybrid benders decomposition algorithm and new models for the distributed permutation flowshop scheduling problem. Avrupa Bilim ve Teknoloji Dergisi, No. 23, Article No. 23

Jia HZ, Fuh JYH, Nee AYC, Zhang YF (2002) Web-based multi-functional scheduling system for a distributed manufacturing environment. Concurr Eng 10(1):27–39

Jia HZ, Nee AYC, Fuh JYH, Zhang YF (2003) A modified genetic algorithm for distributed scheduling problems. J Intell Manuf 14(3):351–362

Jia HZ, Fuh JYH, Nee AYC, Zhang YF (2007) Integration of genetic algorithm and Gantt chart for job shop scheduling in distributed manufacturing systems. Comput Ind Eng 53(2):313–320

Jiang E, Wang L, Peng Z (2020) Solving energy-efficient distributed job shop scheduling via multi-objective evolutionary algorithm with decomposition. Swarm Evolut Comput 58:100745

Jing X-L, Pan Q-K, Gao L, Wang Y-L (2020) An effective Iterated Greedy algorithm for the distributed permutation flowshop scheduling with due windows. Appl Soft Comput 96:106629

Jing X-L, Pan Q-K, Gao L (2021) Local search-based metaheuristics for the robust distributed permutation flowshop problem. Appl Soft Comput 105:107247

Karimi N, Davoudpour H (2017a) Integrated production and delivery scheduling for multi-factory supply chain with stage-dependent inventory holding cost. Comput Appl Math 36(4):1529–1544

Karimi N, Davoudpour H (2017b) A knowledge-based approach for multi-factory production systems. Comput Oper Res 77:72–85

Khare A, Agrawal S (2020) Effective heuristics and metaheuristics to minimise total tardiness for the distributed permutation flowshop scheduling problem. Int J Prod Res 1–17:2020

Lei D, Liu M (2020) An artificial bee colony with division for distributed unrelated parallel machine scheduling with preventive maintenance. Comput Ind Eng 141:106320

Lei D, Wang T (2020) Solving distributed two-stage hybrid flowshop scheduling using a shuffled frog-leaping algorithm with memeplex grouping. Eng Optim 52(9):1461–1474

Lei D, Yuan Y, Cai J, Bai D (2020a) An imperialist competitive algorithm with memory for distributed unrelated parallel machines scheduling. Int J Prod Res 58(2):597–614

Lei D, Yuan Y, Cai J (2020b) An improved artificial bee colony for multi-objective distributed unrelated parallel machine scheduling. Int J Prod Res 59:1–13

Lei D, Su B, Li M (2020c) Cooperated teaching-learning-based optimisation for distributed two-stage assembly flow shop scheduling. Int J Prod Res 1–14:2020

Leung SC, Wu Y, Lai KK (2003) Multi-site aggregate production planning with multiple objectives: a goal programming approach. Prod Plan Control 14(5):425–436

Li J-Q, Duan P, Cao J, Lin X-P, Han Y-Y (2018) A hybrid pareto-based Tabu search for the distributed flexible job shop scheduling problem with E/T criteria. IEEE Access 6:58883–58897

Li Y et al (2020) A discrete artificial bee colony algorithm for distributed hybrid flowshop scheduling problem with sequence-dependent setup times. Int J Prod Res 1–20:2020

Li M, Su B, Lei D (2021a) A novel imperialist competitive algorithm for fuzzy distributed assembly flow shop scheduling. J Intell Fuzzy Syst 40(3):4545–4561

Li Y-Z, Pan Q-K, Li J-Q, Gao L, Tasgetiren MF (2021b) An Adaptive Iterated Greedy algorithm for distributed mixed no-idle permutation flowshop scheduling problems. Swarm Evolut Comput 63:100874

Li H, Li X, Gao L (2021c) A discrete artificial bee colony algorithm for the distributed heterogeneous no-wait flowshop scheduling problem. Appl Soft Comput 100:106946

Liberati A et al (2009) The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate healthcare interventions: explanation and elaboration. BMJ 339:b2700

Lin S-W, Ying K-C (2016) Minimizing makespan for solving the distributed no-wait flowshop scheduling problem. Comput Ind Eng 99:202–209

Lin J, Zhang S (2016) An effective hybrid biogeography-based optimization algorithm for the distributed assembly permutation flow-shop scheduling problem. Comput Ind Eng 97:128–136

Liu T-K, Chen Y-P, Chou J-H (2014) Solving distributed and flexible job-shop scheduling problems for a real-world fastener manufacturer. IEEE Access 2:1598–1606

Liu Y (2020) Effective heuristics to minimize total flowtime for distributed flowshop group scheduling problems. In: 2020 5th international conference on mechanical, control and computer engineering (ICMCCE), pp 708–711

Liu X, Hongguang B, Yue M, Qiunan M (2006) A new approach for planning and scheduling problems in hybrid distributed manufacturing execution system. In: 2006 6th world congress on intelligent control and automation. vol 2, pp 7357–7361

Lohmer J, Spengler D, Lasch R (2020) Multi-factory job shop scheduling with due date objective. In: 2020 IEEE international conference on industrial engineering and engineering management (IEEM), pp 79–84

Lu P-H, Wu M-C, Tan H, Peng Y-H, Chen C-F (2018) A genetic algorithm embedded with a concise chromosome representation for distributed and flexible job-shop scheduling problems. J Intell Manuf 29(1):19–34

Luo Q, Deng Q, Gong G, Zhang L, Han W, Li K (2020) An efficient memetic algorithm for distributed flexible job shop scheduling problem with transfers. Exp Syst Appl 160:113721

Macarthur K, Vinyals M, Farinelli A, Ramchurn S, Jennings N (2011) Decentralised parallel machine scheduling for multi-agent task allocation. In: Fourth international workshop on optimisation in multi-agent systems, Taipei, Taiwan

Mahmoodjanloo M, Tavakkoli-Moghaddam R, Baboli A, Bozorgi-Amiri A (2020) Dynamic distributed job-shop scheduling problem consisting of reconfigurable machine tools”, in advances in production management systems. Towards smart and digital manufacturing. Springer, Cham, pp 460–468

Mao J, Pan Q, Miao Z, Gao L (2021) An effective multi-start iterated greedy algorithm to minimize makespan for the distributed permutation flowshop scheduling problem with preventive maintenance. Exp Syst Appl 169:114495

Marandi F, Fatemi Ghomi SMT (2019a) Integrated multi-factory production and distribution scheduling applying vehicle routing approach. Int J Prod Res 57(3):722–748

Marandi F, Fatemi Ghomi SMT (2019b) Network configuration multi-factory scheduling with batch delivery: a learning-oriented simulated annealing approach. Comput Ind Eng 132:293–310

Marzouki B, Driss OB, Ghédira K (2018) Solving Distributed and flexible job shop scheduling problem using a chemical reaction optimization metaheuristic. Proc Comput Sci 126:1424–1433

Meng T, Pan Q-K (2021) A distributed heterogeneous permutation flowshop scheduling problem with lot-streaming and carryover sequence-dependent setup time. Swarm Evolut Comput 60:100804

Meng T, Pan Q-K, Wang L (2019) A distributed permutation flowshop scheduling problem with the customer order constraint. Knowl Based Syst 184:104894

Meng L, Zhang C, Ren Y, Zhang B, Lv C (2020a) Mixed-integer linear programming and constraint programming formulations for solving distributed flexible job shop scheduling problem. Comput Ind Eng 142:106347

Meng L, Ren Y, Zhang B, Li J-Q, Sang H, Zhang C (2020b) MILP modeling and optimization of energy- efficient distributed flexible job shop scheduling problem. IEEE Access 8:191191–191203

Moon C, Seo Y (2005) Evolutionary algorithm for advanced process planning and scheduling in a multi-plant. Comput Ind Eng 48(2):311–325

Muth JF, Thompson GL, Winters PR (1963) Industrial scheduling. Prentice-Hall, Englewood Cliffs

Naderi B, Azab A (2014) Modeling and heuristics for scheduling of distributed job shops. Expert Syst Appl 41(17):7754–7763

Naderi B, Azab A (2015) An improved model and novel simulated annealing for distributed job shop problems. Int J Adv Manuf Technol 81(1):693–703

Naderi B, Ruiz R (2014) A scatter search algorithm for the distributed permutation flowshop scheduling problem. Eur J Oper Res 239(2):323–334

Pan Q-K, Gao L, Wang L, Liang J, Li X-Y (2019a) Effective heuristics and metaheuristics to minimize total flowtime for the distributed permutation flowshop problem. Expert Syst Appl 124:309–324

Pan Q-K, Gao L, Xin-Yu L, Jose FM (2019b) Effective constructive heuristics and meta-heuristics for the distributed assembly permutation flowshop scheduling problem. Appl Soft Comput 81:105492

Pan Z, Lei D, Wang L (2020) A knowledge-based two-population optimization algorithm for distributed energy-efficient parallel machines scheduling. IEEE Trans Cybern 1–13:2020

Pinedo ML (2012) Scheduling: theory, algorithms and systems, 4th edn. Springer, New York

Rifai AP, Nguyen H-T, Dawal SZM (2016) Multi-objective adaptive large neighborhood search for distributed reentrant permutation flow shop scheduling. Appl Soft Comput 40:42–57

Rifai AP, Mara STW, Sudiarso A (2021) Multi-objective distributed reentrant permutation flow shop scheduling with sequence-dependent setup time. Exp Syst Appl 183:115339

Ruifeng C, Subramaniam V (2011) Performance evaluation for tandem multi-factory supply chains: an approximate solution. Int J Prod Res 49(11):3285–3305

Ruiz R, Pan Q-K, Naderi B (2019) Iterated Greedy methods for the distributed permutation flowshop scheduling problem. Omega 83:213–222

Şahman MA (2021) A discrete spotted hyena optimizer for solving distributed job shop scheduling problems. Appl Soft Comput 106:107349

Sambasivan M, Yahya S (2005) A Lagrangian-based heuristic for multi-plant, multi-item, multi-period capacitated lot-sizing problems with inter-plant transfers. Comput Oper Res 32(3):537–555

Shao W, Pi D, Shao Z (2019) A pareto-based estimation of distribution algorithm for solving multiobjective distributed no-wait flow-shop scheduling problem with sequence-dependent setup time. IEEE Trans Autom Sci Eng 16(3):1344–1360

Shao Z, Pi D, Shao W (2020a) Hybrid enhanced discrete fruit fly optimization algorithm for scheduling blocking flow-shop in distributed environment. Exp Syst Appl 145:113147

Shao Z, Shao W, Pi D (2020b) Effective heuristics and metaheuristics for the distributed fuzzy blocking flow-shop scheduling problem. Swarm Evolut Comput 59:100747

Shao W, Shao Z, Pi D (2020c) Modeling and multi-neighborhood iterated greedy algorithm for distributed hybrid flow shop scheduling problem. Knowl Based Syst 194:105527

Shao Z, Shao W, Pi D (2021a) Effective constructive heuristic and iterated greedy algorithm for distributed mixed blocking permutation flow-shop scheduling problem. Knowl Based Syst 221:106959

Shao W, Shao Z, Pi D (2021b) Multi-objective evolutionary algorithm based on multiple neighborhoods local search for multi-objective distributed hybrid flow shop scheduling problem. Exp Syst Appl 2021:115453

Shi Y, Gregory M (2003) From original equipment manufacturers to total solution providers: emergence of a global manufacturing virtual network in the electronics industry. Int J Serv Technol Manage 4:331–346

Snyder H (2019) Literature review as a research methodology: an overview and guidelines. J Bus Res 104:333–339

Song H-B, Lin J (2021) A genetic programming hyper-heuristic for the distributed assembly permutation flow-shop scheduling problem with sequence dependent setup times. Swarm Evolut Comput 60:100807

Sun XT, Chung SH, Chan FTS (2015) Integrated scheduling of a multi-product multi-factory manufacturing system with maritime transport limits. Transp Res Part E Logist Transp Rev 79:110–127

Terrazas-Moreno S, Grossmann IE (2011) A multiscale decomposition method for the optimal planning and scheduling of multi-site continuous multiproduct plants. Chem Eng Sci 66(19):4307–4318

Timpe CH, Kallrath J (2000) Optimal planning in large multi-site production networks. Eur J Oper Res 126(2):422–435

Wachtel G, Elalouf A (2020) Efficient approximation scheme for job assignment in a multi-factory environment. J Ind Prod Eng 37(7):313–320

Wang L, Li D (2020) Fuzzy distributed hybrid flow shop scheduling problem with heterogeneous factory and unrelated parallel machine: a shuffled frog leaping algorithm with collaboration of multiple search strategies. IEEE Access 8:214209–214223

Wang S-Y, Wang L (2016) An estimation of distribution algorithm-based memetic algorithm for the distributed assembly permutation flow-shop scheduling problem. IEEE Trans Systems Man Cybern Syst 46(1):139–149

Wang J, Wang L (2020) A bi-population cooperative memetic algorithm for distributed hybrid flow-shop scheduling. IEEE Trans Emerg Top Comput Intell 1–15:2020

Wang K, Huang Y, Qin H (2016) A fuzzy logic-based hybrid estimation of distribution algorithm for distributed permutation flowshop scheduling problems under machine breakdown. J Oper Res Soc 67(1):68–82

Wang G, Li X, Gao L, Li P (2019) A multi-objective whale swarm algorithm for energy-efficient distributed permutation flow shop scheduling problem with sequence dependent setup times. IFAC-PapersOnLine 52:235–240

Wang G, Gao L, Li X, Li P, Tasgetiren MF (2020) Energy-efficient distributed permutation flow shop scheduling problem using a multi-objective whale swarm algorithm. Swarm Evolut Comput 57:100716

Wang Y, Yan L, Zhu H, Yin C (2006) A genetic algorithm for solving dynamic scheduling problems in distributed manufacturing systems. In: 2006 6th world congress on intelligent control and automation. vol 2, pp 7343–7347

Webster J, Watson RT (2002) Analyzing the past to prepare for the future: writing a literature review. MIS Q 26(2):13–23

Westfield FM (1955) Marginal analysis, multi-plant firms and business practice: an example. Q J Econ 69(2):253–268

Williams J (1981) Heuristic techniques for simultaneous scheduling of production and distribution in multi-echelon structures: theory and empirical comparisons. Manage Sci 27:336–352

Wu X, Xie Z (2021) Heterogeneous distributed flow shop scheduling and reentrant hybrid flow shop scheduling in seamless steel tube manufacturing, in bio-inspired computing: theories and applications. Springer, Singapore, pp 78–89

Wu M-C, Lin C-S, Lin C-H, Chen C-F (2017) Effects of different chromosome representations in developing genetic algorithms to solve DFJS scheduling problems. Comput Oper Res 80:101–112

Wu X, Liu X, Zhao N (2019) An improved differential evolution algorithm for solving a distributed assembly flexible job shop scheduling problem. Memetic Comput 11(4):335–355

Wu X, Liu X (2018) An improved differential evolution algorithm for solving a distributed flexible job shop scheduling problem. In: 2018 IEEE 14th international conference on automation science and engineering (CASE), pp 968–973

Xie J, Gao L, Pan Q, Tasgetiren MF (2019) An effective multi-objective artificial bee colony algorithm for energy efficient distributed job shop scheduling. Proc Manuf 39:1194–1203

Xu W, Hu Y, Luo W, Wang L, Wu R (2021) A multi-objective scheduling method for distributed and flexible job shop based on hybrid genetic algorithm and tabu search considering operation outsourcing and carbon emission. Comput Ind Eng 157:107318

Yang X, Wang R, Zhang T (2020) Single-objective distributed permutation flowshop scheduling optimization via multi-objectivization by a helper objective. In: 2020 6th international conference on big data and information analytics (BigDIA), pp 23–27

Ying K-C, Lin S-W (2018) Minimizing makespan for the distributed hybrid flowshop scheduling problem with multiprocessor tasks. Exp Syst Appl Int J 92:132–141

Zhang G, Xing K (2018) Memetic social spider optimization algorithm for scheduling two-stage assembly flowshop in a distributed environment. Comput Ind Eng 125:423–433

Zhang X, Yin M (2020) An enhanced genetic algorithm for the distributed assembly permutation flowshop scheduling problem. Int J Bio Inspired Comput 15:113

Zhang G, Xing K, Cao F (2018a) Scheduling distributed flowshops with flexible assembly and set-up time to minimise makespan. Int J Prod Res 56(9):3226–3244

Zhang G, Xing K, Cao F (2018b) Discrete differential evolution algorithm for distributed blocking flowshop scheduling with makespan criterion. Eng Appl Artif Intell 76:96–107

Zhang G, Xing K, Zhang G, He Z (2020) Memetic algorithm with meta-lamarckian learning and simplex search for distributed flexible assembly permutation flowshop scheduling problem. IEEE Access 8:96115–96128

Zhang Z-Q, Qian B, Hu R, Jin H-P, Wang L (2021) A matrix-cube-based estimation of distribution algorithm for the distributed assembly permutation flow-shop scheduling problem. Swarm Evolut Comput 60:100785

Zhao F, Zhao L, Wang L, Song H (2020) An ensemble discrete differential evolution for the distributed blocking flowshop scheduling with minimizing makespan criterion. Exp Syst Appl 160:100557

Ziaee M (2014) A heuristic algorithm for the distributed and flexible job-shop scheduling problem. J Supercomput 67(1):69–83

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bagheri Rad, N., Behnamian, J. Recent trends in distributed production network scheduling problem. Artif Intell Rev 55, 2945–2995 (2022). https://doi.org/10.1007/s10462-021-10081-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10462-021-10081-5