Abstract

Pear fruit undergoes intense metabolic activities during postharvest storage due to its climacteric character, resulting in alteration in antioxidant properties of fruit. Thus, in the current study the influence of sodium alginate (SA; 1% and 2%) coating blended with pomegranate peel extract (PPE) or as pure coatings was investigated to assess their potential in the maintenance of antioxidant content in pear fruit cv ‘Punjab Beauty’ under low temperature storage. As compared to control, the SA + PPE coatings were effective in maintaining the higher total antioxidant activities (TAA), total phenolics content (TPC), ascorbic acid (AsA) and titratable acidity (TA) in stored pears. Further, the combined coatings suppressed internal browning (IB) throughout the 67 days of storage and lowered polyphenol oxidase (PPO) activity in fruits. The activity of PPO on the 45th day of storage was 35.42% lower in SA 2% + PPE coated fruit than in the control fruit. Thus, the coatings of SA + PPE emerged as a promising approach in maintaining antioxidant properties of pears during low temperature storage.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pears are recognized all over the world for their nutritional as well as commercial value. Consumption of the pears has been associated with the maintenance of health and prevention of various chronic and degenerative diseases in humans due to the presence of antioxidants (Oms-Oliu et al. 2008). However, climacteric behavior of fruit often causes the lowering of the phenolic compounds after harvest and leads to biochemical changes through the activation of several metabolic pathways leading to its depleted nutritive value. The low chill pears can be effectively grown in the subtropics of north western regions of India (Adhikary et al. 2021). The ripening of the fruit, coupled with oxidative stress, causes the elevation of reactive oxygen species (ROS) which are deleterious to the antioxidant content responsible for sustenance of fruit nutritional quality (Silva et al. 2010). The antioxidants (phenols & ascorbic acid) have a key role in detoxification of harmful free oxygen radicals and protect from the loss of nutritional value of the fruit (Hodges et al. 2004). These compounds are also directly linked to the enzymatic browning of the pear fruit during long term storage (Sinha et al. 2022). The reduced ascorbic acid content is related to the browning of the pear; in addition, the oxidation of the phenolics compounds due to activity of polyphenol oxidases (PPO) is responsible for production of the highly unstable quinones which are polymerized to brown pigments (Fawbush et al. 2009; Oms-Oliu et al. 2008). Thus, there is pre-requisite of some intervention for preservation of antioxidants in pear fruit for transportation to the distant markets with minimum loss of nutritive properties. Different storage regimes including cold storage, high CO2 atmosphere storage and postharvest chemical treatments (Khaliq et al. 2020) are required for the maintenance of postharvest quality of fruits. Recently, there is ample interest in inventing ecologically-friendly and cost-effective postharvest technologies in maintaining the antioxidants compounds in fruit during storage and handling.

Under regional conditions, the use of edible coating material could be a feasible strategy to preserve the fruit quality during the long-term storage in the absence of controlled atmosphere storage infrastructure. The edible coatings have been tested as an effective alternative postharvest treatment to avoid use of the synthetic preserving material for retarding browning and improving postharvest fruit quality (Sinha et al. 2021). Sodium alginate (SA) is gaining wide popularity among different types of the polysaccharide-based coating materials. SA is a natural polymer of D‑mannuronic acid and L‑guluronic acid obtained from the brown seaweed of the Phaeophyceae family (Nair et al. 2018a). It is biodegradable, non-toxic, cost-efficient, biocompatible and exhibits a unique colloidal property thus utilized as a potential coating material for the fruits (Li et al. 2019). It has been demonstrated that SA coatings exhibited as an efficient coating material in delaying the ripening process in stored guava (Nair et al. 2018a), ber (Rao et al. 2015), sweet cherry (Diaz-Mula et al. 2012), Fig (Reyes-Avalos et al. 2019), and in mango fruits (Yin et al. 2019). The effectiveness of SA can be enhanced by the addition of natural antioxidants or anti-microbial agents. SA blended with Ficus hirta fruit extract enhanced phenolic compounds, ascorbic acid (AsA) and titratable acidity (TA) in mandarins (Chen et al. 2016). The addition of the grapefruit seed extract in SA was effective in preserving antioxidant activities in table grapes preservation (Aloui et al. 2014). Sweet cherry fruits treated with SA + olive leaf extract registered higher antioxidant activity, total phenolics content (TPC), AsA and TA than that of control fruit (Zam 2019).

Pomegranate fruit (Punica granatum L.) has abundant nutritional benefits. Its peel is rich in bioactive compounds and utilized as an antimicrobial, bio-preservative and food disinfectant agent bearing excellent antioxidant qualities thus protect the cell from various forms of oxidative stresses (Tayel et al. 2009; Xi et al. 2017). The incorporation of pomegranate peel extract (PPE) in edible coating material has been shown as an effective matrix for the preserving bioactive compounds and it is also proven non-toxic even at higher doses (Nair et al. 2018b). Although some earlier studies demonstrated the effect of SA + PPE in retention of postharvest quality in guava fruit and capsicum (Nair et al. 14,15,a, b). However, the effect of PPE incorporated in SA on the antioxidant properties of pears during storage has not been explored. Till date no work has been documented regarding the influence of SA augmented with PPE coatings on retention of antioxidant properties of pear fruit during storage. Since bulk of the sub-tropical pears fruit produced in this region are transported to far-off markets of the country and hence it is imperative to retain nutritional quality of pear fruit over long-term storage. Thus the objective of this work was to investigate the efficiency of SA mixed with PPE on the maintenance of the antioxidant properties, phenolics content and reduction of browning in stored pears.

Materials and Methods

Raw Material and Pre-storage Treatments

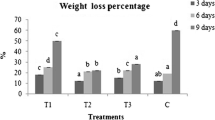

Pear fruits along with stalks were picked from theOrchard at the mature stage (soluble solid contents [SSC] 12.36 ± 0.12%, firmness 65.26 ± 2.87 N). Harvested fruit were transported to the laboratory for treatment applications. The fruits were sorted based on uniformity of appearance and free from of any mechanical injury. Afterwards, the sorted pears were disinfected with 100 ppm sodium hypochlorite solution and air dried in shade (Singh et al. 2021). The fruit were coated with SA 1%, SA 2%, SA 1% + PPE, SA 2% + PPE and PPE with the aid of fine bristle brush and the control fruit were dipped in distilled water. Afterwards, both the coated and uncoated fruit were packed in three-ply paper lined corrugated fibre board boxes with 5% perforation and kept at 0–1 °C with 90–95% RH for storage studies. Stored pear fruit were taken at 30, 45, 60 and 67 days for estimation of AsA, TPC, TAA, TA and PPO activity. At each sampling date, five fruits from each replicate were initially determined for IB and then the pulp of these fruits were further homogenized for the estimation of biochemical parameters viz AsA, TPC, TAA, TA and PPO activity.

Preparation of Coatings and Pomegranate Peel Extract

SA (1% and 2%) coatings were developed by diffusing 10 g and 20 g of SA, respectively, in distilled water at 70 °C with continuous stirring for a period of 1 h until the mixture became clear. After cooling, 0.5% of glycerol and CaCl2 solution (2%) were added as a plasticizer and firming agent, respectively, and final volume was adjusted to 1000 mL with distilled water (Nair et al. 2018a).

Pomegranate fruits (cv. ‘Bhagwa’) were procured from the farm of the institute and disinfected with sodium hypochlorite solution (100 ppm) and then rinsed with distilled water and the fruit peel were segregated and dried at 65 °C for constant weight in hot air oven. Afterwards, the dried peel was finely grounded and 100 g of sieved peel powder (40-mesh sieve) was left overnight in 1 L of ethanol (80%) at 25 °C. This solution was centrifuged at 10,000 × g for 20 min at 4 °C (Sigma 3–18K centrifuge, Germany) for the extraction of phenolic compounds, then filtered using Whatman No. 1 filter paper and the obtained filtrate was concentrated using rotary evaporator at 40 °C. The concentrated PPE extract was stored at 4 °C in amber coloured reagent bottle until further use (Nair et al. 2018a). From pomegranate peel concentrate, 2% of PPE solution was used for combined treatments or used as a pure coating solution. For combined coatings, 20 mL of PPE was incorporated to SA solution and the final volume of 1000 mL was adjusted with distilled water.

Determination of TPC

TPC was determined by homogenizing 1 g of fruit pulp tissue in 3 mL of 80% methanol and homogenate was centrifuged at 10,000 × g for 20 min at 4 °C. Subsequently, the methanolic extract (0.5 mL) was diluted to 10 mL by distilled water. From this 100 μL of aliquot of sample was taken and added to the test tube containing 1.5 mL of Folin–Ciocalteu’s reagent, 4 mL of 20% sodium carbonate solution and the volume was made to 10 mL using distilled water. The incubation of reaction mixture was done by keeping in dark conditions for 30 min and the absorbance was taken at 760 nm using spectrophotometer (Spectronic 20D+, Thermo Scientific, USA). TPC were expressed as milligram of gallic acid equivalent per kg of fresh weight (Singleton et al. 1999).

Measurement of AsA

The AsA content was determined using the 2,6-dichloroindophenol dye method and was expressed in mg of ascorbic acid per kg of sample (Ranganna 2007). For extraction, 10 g of pear fruit pulp was macerated with 70 mL of 3%HPO3 and was diluted to 100 mL using distilled water and filtered. From the filtered extract, 10 mL of aliquot was taken and titrated against 2,6-dichloroindophenol dye until the rose pink colour.

Determination of TA

The TA in fruit was determined by the titration method of Ranganna (2007) and expressed in terms of percentage of malic acid. For 2 mL of juice two drops of phenolphthalein indicator was added and titrated against the 0.1 N NaOH until the light pinkish colour appeared. The TA was calculated by the following equation:

Measurement of TAA

The antioxidant activity in pulp tissue was evaluated using the 2,2-diphenyl-1-picryl-hidrazil (DPPH) radical scavenging method. Extraction was performed by centrifuging a homogenized mixture of 3 g of fruit pulp with 30 mL of methanol at 10,000 × g for 15 min at 4 °C. The 100 μL supernatant was added to 3 mL of 0.1 mM DPPH methanol solution and incubation of the reaction mixture was performed for 20 min at 25 °C. The absorbance was recorded at 517 nm using spectrophotometer and calculated using the equation: DPPH radical scavenging (%) = [(Abs control − Abs sample) / Abs control] * 100 (Cao et al. 2012).

Extraction and Assay of PPO

PPO activity was assayed according to the method of Zauberman et al. (1991). Fruit pulp weighing 0.2 g was homogenized in 2 mL of 0.1 mM ice-cooled phosphate buffer (pH 6.8) for PPO enzyme extract and homogenized samples were centrifuged for 20 min at 10,000 × g. The centrifuged supernatants were utilized as PPO extracts. The activity of PPO was measured by adding 500 μL of enzyme extract in a cuvette with 1 mL of 0.1 mol L−1 phosphate buffer (pH 6.8), 0.5 mL of 0.1 mol L−1 catechol and the increasing in absorbance was recorded continuously at 410 nm at 1 min interval for a period of 3 min. PPO activity was expressed as units per min per gram of fresh weight (U min−1 gFW−1).

Internal Browning

CIE Lab colour space was used to determine the internal browning index of 10 pear fruits. Pear fruit pulp colour was estimated by giving an equatorial transverse cut to the fruit using the Colour Flex 450/00 spectrophotometer (Hunter Lab Colour Flex Hunter Associates Inc., Reston, VA, USA). IB was expressed in terms of colour index and measured by the following equation: Colour index = (1000 × a*) / (L* × b*) (Magwaza et al. 2014).

Statistical Analysis

The experiment was conducted using the completely randomized design (factorial) with four replicates. The findings were evaluated using two-way analysis (treatments × storage time) of variance (ANOVA) with p ≤ 0.05 level of significance in Statistical Analysis Software (SAS version 9.3 for Windows). The least significant difference test was used to compare the means among the treatments and the results were presented as a mean ± standard error. Further, correlation between different attributes was conducted using the Pearson correlation coefficient (p < 0.01).

Results and Discussion

Total Phenolics Content

Phenolics compounds are important secondary fruit metabolites and possess the antioxidant properties by trapping free radicals produced during oxidative stress. During the storage period, a decline in TPC was observed in all the fruits regardless of the coating treatment (Fig. 1a). However, this decline in the TPC was rapid in control fruit as compared to the treated fruit. The decline of TPC in untreated fruit might be related to the oxidation of phenols by PPO enzyme activity (Duan et al. 2011). On the 67th day of storage, the combined coatings (SA 2% + PPE and SA 1% + PPE) retained higher TPC (660.2 and 629 mg kg−1, respectively) in fruits than the sole application of SA 1 and 2% (580.2, and 606.7 mg kg−1, respectively) or PPE (585.0 mg kg−1). However, the pear coated with combined coatings registered a slower decline in TPC which might be due to the hypoxia and the activation of phenylalanine ammonia lyase (PAL) activity associated with the natural phenolic compounds present in PPE (Reyes-Avalos et al. 2019; Parsa et al. 2021). At the end of storage, TPC in SA 2% + PPE and SA 1% + PPE coated fruits was higher (17.89% and 13.82%, respectively) than the control which registered minimum TPC of 542.1 mg kg−1. Similar findings of restricted loss in TPC were observed in ‘Allahabad Safeda’ guava fruit coated with chitosan, SA and PPE (Nair et al. 2018a). The slower reduction of TPC in SA + PPE coated fruit may be attributed to the lower permeability of oxygen and lower activity of PPO enzyme (Wang and Gao 2013). In earlier studies strawberry fruit coated with the SA blended with carvacrol and methyl cinnamate exhibited restricted loss of TPC during storage (Peretto et al. 2017). Similarly in another study, ber fruit coated with SA enriched with antioxidants registered lower loss of TPC during storage (Rao et al. 2015).

Ascorbic Acid

Being an antioxidant, AsA possesses the detoxifying property of scavenging the free radicals of hydroxyl group, hydrogen peroxide and superoxide anion preventing the oxidative damage in fruit (Nair et al. 2018a). AsA content in both coated and uncoated pears decreased gradually throughout the low temperature storage period (Fig. 1b). However, the decline in AsA content was higher in control than the treated fruit that indicated the deteriorative action of ascorbic acid oxidase enzyme in oxidizing AsA to dehydroascrobic acid and phenol oxidase (Nazoori et al. 2020). On the 45th day of storage, the loss of AsA content in SA 1%, SA 2% and PPE treatments was 1.18, 1.05 and 1.13 times higher than the pears treated with SA 2% + PPE. At the end of 65 days of storage, the mixed coating of SA 2% + PPE and SA 1% + PPE exhibited significantly higher fruit AsA content of 58.3 and 55.5 mg kg−1, respectively, in comparison to sole SA 1 and 2% (53.0 and 45.7 mg kg−1) or PPE (49.0 mg kg−1). Similar results were obtained in ‘Nanfeng’ mandarins treated with composite SA and Ficus hirta coatings where maximum AsA was retained in coated fruit (Chen et al. 2016), whereas the untreated fruit recorded a faster rate of decline in AsA content with minimum AsA content of 42 mg kg−1. The reduced loss of AsA in SA + PPE coated fruit was related to the action of coating materials in lowering the permeability of O2 and CO2 and activities of the AsA oxidase enzyme (Zam 2019). Our results are in agreement with the findings of Nazoori et al. (2020) who reported that combined coatings of SA with AsA in ‘Gaviota’ strawberry registered higher AsA content during storage due to the lower oxygen permeability of coatings followed by reduction in the oxidative activity of vitamin C. Likewise sodium alginate + PPE coated ‘Allahabad safeda’ guava fruit (Nair et al. 2018a) and ‘California wonder’ capsicum (Nair et al. 2018b) retained higher AsA content as compared to control fruit (;).

Titratable Acidity

Regardless of treatment, the TA of fruit exhibited a decreasing trend with the progression of storage period (Table 1), probably because of utilization of organic acids as a substrate during ripening process and conversion into sugars (Adhikary et al. 2021). However, the highest TA was observed in fruit coated with SA + PPE as compared to pure coatings of SA or PPE and control. At the end of storage, the TA content in combined coatings (SA 2% + PPE and SA 1% + PPE) was 0.23% and 0.18%, respectively, which were 1.92 and 1.50 times higher than the control fruit. The preservation of TA content might be due to the protective layer formed on the fruit surface by SA + PPE coatings, which restricted the oxygen flux and prevented the oxidation of organic acids involved in the respiratory process (Nazoori et al. 2020). Hence, the control fruit recorded maximum loss in TA from zero to the 67th day (0.32 to 0.12%, respectively) of cold storage due to the maximum utilization of organic acids in metabolic process of the fruit (Parsa et al. 2021). Earlier studies by Zam (2019) also reported that the application of SA with olive leaf extract coatings in sweet cherry cv ‘Bigarreau Burlat’ slowed down the loss in TA with ripening and therefore recorded the maximum TA at the end of the storage. Similarly, higher TA was also recorded in the ‘Gola’ ber fruit coated with the SA with olive oil during storage as the metabolic activities were slowed down due to the coating application (Rao et al. 2015).

Total Antioxidant Activities

Antioxidant activities of fruit acts against several oxidation reactions initiated by the free radical and protect the tissue damage (Kumar et al. 2021). Our results displayed a consistent decrease in TAA during storage in all the treated and untreated fruit samples (Fig. 1c) which was probably due to the oxidation of the phenolics and AsA compounds (Sinha et al. 2021). However, the loss of antioxidant activity in control was higher than that of coated fruit. The reduction in TAA during 45 days of storage was 1.10 and 1.07 times lower in SA 2% + PPE and SA 1% + PPE coatings than SA 1%, SA 2% or PPE treatments. At 67 days, the maximum TAA of 54.34% was registered SA 2% + PPE coated pears, whereas uncoated fruit showed minimum TAA of 37.70%. The maximum retention of TAA was registered in SA + PPE coated fruit which might be attributed to the role of SA in modifying the internal atmosphere of fruit and lowering the oxidation (Nazoori et al. 2020), whereas PPE contain different levels of antioxidant capacity (Parsa et al. 2021). In an earlier study, ‘Gaviota’ strawberry fruit coated with SA + AsA retained higher TAA during storage (Nazoori et al. 2020). Similarly, ‘Bigarreau Burlat’ sweet cherry fruit coated with SA + olive leaf extract showed higher TAA activities than control fruit (Zam 2019).

Polyphenol Oxidase and Internal Browning

As the fruit ripening progressed, a constant increase in PPO activity was observed in all the coated as well as uncoated fruit (Fig. 1d). PPO activity in pure SA or PPE treated pears increased gradually over 45 days of storage period, thereafter a sharp increment in PPO activity was observed; however, this increment was strongly inhibited in fruit coated with SA + PPE (SA 2% + PPE and SA 1% + PPE), while a higher rate of increase in PPO activity was observed in control fruit from 0 to 67 days (11.35 to 28.85 U min−1 g FW−1) of cold storage condition. On the 67th day of storage the increase in PPO activity in control fruit was 30.95% higher as compared to SA 2% + PPE coatings, which registered lowest PPO activity of 19.92 U min−1 g FW−1. Also the rate of increase in PPO activity in composite coatings (SA 1% + PPE and SA 2% + PPE) were lower as compared to the sole coatings of SA 1 and 2% or PPE. One of the main causes of browning during postharvest storage of fruit is PPO mediated oxidation of phenols (Kaur et al. 2019). With the extension of storage time, pear fruit showed appearance of brown pulp coloration in all cold stored fruit samples (Table 1); however, the fruit coated with SA + PPE (SA 2% + PPE and SA 1% + PPE) and SA 2% showed no pulp browning throughout the 67 days of storage. While the SA 1% and PPE coatings were effective in delaying internal browning up to 2 months of storage, that of control fruit registered maximum IB index of 1.98 on the 60th day of storage and reached 4.67 IB at the end of storage.

The PPO enzyme catalyzes o‑hydroxylation of monophenols to o‑diphenols and also catalyzes the conversion of o‑diphenols to o‑quinones by oxidation reaction. The rapid polymerization of the o‑quinones produces polyphenols which causes internal browning (Nazoori et al. 2020). In damaged tissue the PPO and polyphenols react with each other (Li et al. 2019), while SA with PPE coating can prevent this interaction and thus the browning incidence. Hence, SA + PPE coatings effectively lowered PPO activity and pulp browning due to reduced oxygen exchange in the coated fruit. This reduces oxidation reactions by inhibiting the activity of the PPO enzyme which in turn suppresses IB in stored fruit. These results are in line with the findings of Li et al. (2019) in ‘Baihua’ peach fruit, where lower PPO activity and browning incidence was noted in the combined coatings of SA + rhubarb extract. Similarly, Nazoori et al. (2020) also reported lower PPO activity in ‘Gaviota’ strawberry coated with SA + AsA.

Correlation Analysis

Table 2 summarizes the Pearson’s correlation coefficient for the various assessed antioxidant attributes under low temperature storage. The TPC and AsA recorded strong positive correlation coefficient with TAA (R = 0.811, R = 0.784) in cold stored pear, whereas TPC was positively associated with the AsA (R = 0.937). The role of phenolics and ascorbic acid content to antioxidant activity is supported by the correlation studies that show a positive correlation coefficient. PPO had a significant negative correlation coefficient with TPC (R = −0.875) and positive correlation coefficient with IB (R = 0.593). The PPO and TPC additionally exhibited an inverse relationship while the PPO and IB had a positive correlation coefficient.

Conclusions

In the present study, the effects of SA + PPE coatings in the preservation of antioxidant properties of pear fruit during low temperature storage were studied. The results showed that the combined SA + PPE coatings were effective in retaining higher amount of TPC, TAA, AsA and TA content than the control fruit. Moreover, SA combined with PPE was more effective in retarding PPO activity and IB in stored pear fruit. Therefore, the combined coatings of SA augmented with PPE provides a safe, novel and cost-effective material to maintain the antioxidant property of fruit under low temperature condition for 67 days and can be commercialized to maintain the bioactive compounds in pears for fresh consumption. Future investigations involving the FT-IR and SEM analysis are required to gain further insights in understanding the surface textural properties of SA + PPE coated and uncoated pear fruit.

Abbreviations

- AsA:

-

Ascorbic acid

- DPPH:

-

2‑Diphenyl-1-picryl-hidrazil

- HPO3 :

-

Metaphosphoric acid

- IB:

-

Internal Browning

- PPE:

-

Pomegranate peel extract

- PPO:

-

Polyphenol oxidase

- SA:

-

Sodium alginate

- TA:

-

Titratable acidity

- TAA:

-

Total antioxidant activity

- TPC:

-

Total phenolics content

References

Adhikary T, Gill PPS, Jawandha SK, Bhardwaj RD, Anurag RK (2021) Efficacy of postharvest sodium nitroprusside application to extend storability by regulating physico-chemical quality of pear fruit. Food Chem 346:128934. https://doi.org/10.1016/j.foodchem.2020.128934

Aloui H, Khwaldia K, Sánchez-González L, Muneret L, Jeandel C, Hamdi M, Desobry S (2014) Alginate coatings containing grapefruit essential oil or grapefruit seed extract for grapes preservation. Int J Food Sci Technol 49:952–959. https://doi.org/10.1111/ijfs.12387

Cao X, Bi X, Huang W, Wu J, Hu X, Liao X (2012) Changes of quality of high hydrostatic pressure processed cloudy and clear strawberry juices during storage. Innov Food Sci Emerg Technol 16:181–190. https://doi.org/10.1016/j.ifset.2012.05.008

Chen C, Peng X, Zeng R, Chen M, Wan C, Chen J (2016) Ficus hirta fruits extract incorporated into an alginate—based edible coating for Nanfeng mandarin preservation. Sci Hotic 202:41–48. https://doi.org/10.1016/j.scienta.2015.12.046

Diaz-Mula HM, Serrano M, Valero D (2012) Alginate coatings preserve fruit quality and bioactive compounds during storage of sweet cherry fruit. Food Bioproc Tech 5:2990–2997

Duan J, Wu R, Strik BC, Zhao Y (2011) Effect of edible coatings on the quality of fresh blueberries (Duke and Elliott) under commercial storage conditions. Postharvest Biol Technol 59:71–79. https://doi.org/10.1016/j.postharvbio.2010.08.006

Fawbush F, Nock JF, Watkins CB (2009) Antioxidant contents and activity of 1 methylcyclopropene (1-MCP)-treated ‘Empire’ apples in air and controlled atmosphere storage. Postharvest Biol Technol 52:30–37

Hodges DM, Lester GE, Munro KD, Toivonen PMA (2004) Oxidative stress: importance for postharvest quality. Hort Sci 39:924–929

Kaur A, Gill PPS, Jawandha SK, Singh M (2019) Pre-storage exogenous application of boric acid extends storability and maintains quality of pear fruits. Sci Hotic 256:108616. https://doi.org/10.1016/j.scienta.2019.108616

Khaliq G, Saleh A, Bugti GA, Hakeem KR (2020) Guggul gum incorporated with basil essential oil improves quality and modulates cell wall-degrading enzymes of jamun fruit during storage. Sci Hotic 273:109608

Kumar N, Ojha A, Upadhyay A, Singh R, Kumar S (2021) Effect of active chitosan-pullulan composite edible coating enrich with pomegranate peel extract on the storage quality of green bell pepper. Lwt Food Sci Technol 138:110435. https://doi.org/10.1016/j.lwt.2020.110435

Li XY, Du XL, Liu Y, Tong LJ, Wang Q, Li JL (2019) Rhubarb extract incorporated into an alginate-based edible coating for peach preservation. Sci Hotic 257:108685

Magwaza LS, Landahl S, Cronje PJ, Nieuwoudt HH, Mouazen AM, Nicolaï BM, Terry LA, Opara UL (2014) The use of Vis/NIRS and chemometric analysis to predict fruit defects and postharvest behaviour of ‘Nules Clementine’ mandarin fruit. Food Chem 163:267–274. https://doi.org/10.1016/j.foodchem.2014.04.085

Nair MS, Saxena A, Kaur C (2018a) Effect of chitosan and alginate based coatings enriched with pomegranate peel extract to extend the postharvest quality of guava (Psidium guajava L.). Food Chem 240:245–252

Nair MS, Saxena A, Kaur C (2018b) Characterization and antifungal activity of pomegranate peel extract and its use in polysaccharide-based edible coatings to extend the shelf-life of capsicum (Capsicum annuum L.). Food Bioproc Tech 11:1317–1327

Nazoori F, Poraziz S, Mirdehghan SH, Esmailizadeh M, Zamani, Bahramabadi E (2020) Improving shelf life of strawberry through application of sodium alginate and ascorbic acid coatings. Int J Hortic Sci Technol 7:279–293

Oms-Oliu G, Soliva-Fortuny R, Martín-Belloso O (2008) Edible coatings with antibrowning agents to maintain sensory quality and antioxidant properties of fresh-cut pears. Postharvest Biol Technol 50:87–94

Parsa Z, Roozbehi S, Hosseinifarahi M, Radi M, Amiri S (2021) Integration of pomegranate peel extract (PPE) with calcium sulphate (CaSO4): A friendly treatment for extending shelf-life and maintaining postharvest quality of sweet cherry fruit. J Food Process Preserv 45:e15089. https://doi.org/10.1111/jfpp.15089

Peretto G, Du WX, Avena-Bustillos RJ, Berrios JDJ, Sambo P, McHugh TH (2017) Electrostatic and conventional spraying of alginate-based edible coating with natural antimicrobials for preserving fresh strawberry quality. Food Bioproc Tech 10:165–174

Ranganna S (2007) Handbook of analysis and quality control of fruit and vegetable products. Tata McGraw Hill, New Delhi https://doi.org/10.1016/S0076-6879(99)99017-1

Rao RTV, Baraiya NS, Vyas PB, Patel DM (2015) Composite coating of alginate-olive oil enriched with antioxidants enhances postharvest quality and shelf life of Ber fruit (Ziziphus mauritiana Lamk. Var. Gola). J Food Sci Technol 53:748–756. https://doi.org/10.1007/s13197-015-2045-3

Reyes-Avalos MC, Minjares-Fuentes R, Femenia A, Contreras-Esquivel JC, Quintero-Ramos A, Esparza-Rivera JR, Meza-Velázquez JA (2019) Application of an alginate–chitosan edible film on figs (Ficus carica): effect on bioactive compounds and antioxidant capacity. Food Bioproc Tech 12:499–511

Silva FJ, Gomes MH, Fidalgo F, Rodrigues JA, Almeida DP (2010) Antioxidant properties and fruit quality during long-term storage of “Rocha” pear: effects of maturity and storage conditions. J Food Qual 33:1–20

Singh V, Jawandha SK, Gill PPS (2021) Effect of exogenous putrescine treatment on internal browning and colour retention of pear fruit. J Food Meas Charact 15:905–913

Singleton VL, Orthofer R, Lamuela-Raventós RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol 299:152–178

Sinha A, Gill PPS, Jawandha SK, Kaur P, Grewal SK (2021) Chitosan-enriched salicylic acid coatings preserves antioxidant properties and alleviates internal browning of pear fruit under cold storage and supermarket conditions. Postharvest Biol Technol 182:111721. https://doi.org/10.1016/j.postharvbio.2021.111721

Sinha A, Gill PPS, Jawandha SK, Grewal SK (2022) Suppression of internal browning and maintenance of antioxidants in beeswax plus salicylic acid coated pear fruit during different storage conditions. Int J Food Sci Technol 57:3515–3522. https://doi.org/10.1111/ijfs.1567

Tayel AA, El-Baz AF, Salem MF, El-Hadary MH (2009) Potential applications of pomegranate peel extract forthe control of citrus green mould. J Plant Dis Prot 116:252–256. https://doi.org/10.1007/BF03356318

Wang SY, Gao H (2013) Effect of chitosan-based edible coating on antioxidants, antioxidant enzyme system, and postharvest fruit quality of strawberries (Fragaria x aranassa Duch.). LWT Food Sci Technol 52:71–79. https://doi.org/10.1016/j.lwt.2012.05.003

Xi J, He L, Yan LG (2017) Continuous extraction of phenolic compounds from pomegranate peel using high voltage electrical discharge. Food Chem 230:354–361. https://doi.org/10.1016/j.foodchem.2017.03.072

Yin C, Huang C, Wang J, Liu Y, Lu P, Huang L (2019) Effect of chitosan and alginate based coatings enriched with cinnamon essential oil microcapsules to improve the postharvest quality of mangoes. Materials 12:2039. https://doi.org/10.3390/ma12132039

Zam W (2019) Effect of alginate and chitosan edible coating enriched with olive leaves extract on the shelf life of sweet cherries (Prunus avium L. J Food Qual. https://doi.org/10.1155/2019/8192964

Zauberman G, Ronen R, Akerman M, Weksler A, Rot I, Fuchs Y (1991) Post-harvest retention of the red colour of litchi fruit pericarp. Sci Hortic 47:89–97. https://doi.org/10.1016/0304-4238(91)90030-3

Acknowledgements

The authors are thankful to Punjab Agricultural University, Ludhiana, India, for providing the necessary research facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

M. Megha, P. P. S. Gill, S. K. Jawandha, N. Kaur and A. Sinha declare that they have no competing interests.

Additional information

Data availability statement

Data will be made available on reasonable request.

Rights and permissions

Springer Nature oder sein Lizenzgeber (z.B. eine Gesellschaft oder ein*e andere*r Vertragspartner*in) hält die ausschließlichen Nutzungsrechte an diesem Artikel kraft eines Verlagsvertrags mit dem/den Autor*in(nen) oder anderen Rechteinhaber*in(nen); die Selbstarchivierung der akzeptierten Manuskriptversion dieses Artikels durch Autor*in(nen) unterliegt ausschließlich den Bedingungen dieses Verlagsvertrags und dem geltenden Recht.

About this article

Cite this article

Megha, M., Gill, P.P.S., Jawandha, S.K. et al. Effects of Sodium Alginate Plus Pomegranate Peel Extract Based Edible Coating on the Antioxidant Properties of Pear Fruit During Low Temperature Storage. Erwerbs-Obstbau 65, 1341–1348 (2023). https://doi.org/10.1007/s10341-023-00883-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-023-00883-y