Abstract

Microbial contamination and mold growth are common causes of strawberry deterioration during storage. The growing need for extending shelf-life while enhancing the overall quality of perishable fruits has generated increasing interest in the development of novel preservation technologies. This study used electrostatic spraying (ES) technology as an innovative and efficient technique for the application of edible alginate coating enriched with carvacrol and methyl cinnamate (natural antimicrobials) on fresh strawberries. The efficiency of the electrostatic technology was compared to non-electrostatic (conventional) spray (NES) technology in terms of transfer efficiency and coating evenness. Furthermore, physicochemical and textural parameters (such as weight loss, visible decay, firmness, surface color, total soluble phenolic content, and antioxidant capacity) of ES and NES coated fruits were studied and compared to uncoated controls. ES technology demonstrated higher transfer efficiency and evenness than NES, which led to a significant reduction of visible decay over uncoated controls. The delay in microbial spoilage by ES (11 days) was greater than by NES (10 days) and uncoated strawberries (7 days). ES coating significantly inhibited strawberry decay with only 5.6 % of infected fruits, compared to 16.6 and 8.3 % for control and NES fruits after 13 days of storage, respectively. At the end of 13 days of storage, ES coating demonstrated superior performance on strawberry firmness, color retention, and weight loss reduction. Additionally, no differences were observed between uncoated and coated fruits with regard to their antioxidant and total soluble phenolics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Edible coatings have been widely applied on fresh fruits to provide protection against physical and mechanical damage, as well as retard spoilage and reduce loss of quality by creating a semi-permeable barrier to gases, water vapor, and volatile compounds (Andrade et al. 2012). As an alternative approach to common methods, such as modified atmosphere packaging or low storage temperature, edible coatings are also environmentally friendly and they can serve as carriers of food additives that enhance safety, nutritional, and sensory attributes of fruit (Tapia et al. 2008). However, the development of new type of coatings that match properties and requirements of specific perishable targets must be combined with practical application technologies to provide efficient coating performance, and improve quality of coated food product. Electrostatic spraying is an evolving technique that is relatively simple and quick, and it can be used to improve the distribution and application of coatings on fresh products. Recently, there has been an increased interest in utilizing electrostatic spraying technology for the application of powder and liquid coatings in the food industry, to extend shelf-life and increase quality of minimally processed foods (Khan et al. 2012b).

In electrostatic coating, an intense electrical field is applied to the coating material while it is forced out away from the electrode. The electrically charged coating material is attracted to the nearest grounded target as a result of electrostatic attraction, allowing the charged particles to disperse over the whole surface. Therefore, electrostatic spray applications exhibit a higher transfer efficiency and coating evenness compared to spraying methods that apply uncharged droplets (Khan et al. 2013a). This method might improve the overall quality of the coated target (Bailey 1998), as well as reduce processing cost (Khan et al. 2013b).

The versatility of electrostatic technology for different type of coating materials allowed the food industries, especially those involving powder coating for seasoning and flavors, to use this technology to overcome problems related to uneven coating, excessive use of expensive additives, and release of dust to the surrounding environment while at the same time decrease additional cleaning needs and health hazards for the line operators (Ratanatriwong et al. 2009). Different food products such as French fries, cheese, bread, and potato chips have been successfully coated using electrostatically charged powders (Ratanatriwong et al. 2003; Amefia et al. 2006, Khan et al. 2012a). However, whereas the electrostatic coating of powders on different food systems has advanced, the technology for electrostatic coating of liquids is still limited due to several factors. These factors are mainly related to the characteristics of liquids such as droplet size and resistivity (inverse of conductivity), which might affect the coating process. Electrostatic liquid coating was first utilized in the paint industry, and in agriculture as a novel technology for the application of pesticides on different crops, such as cabbage (Perez et al. 1995) and blueberry plants (Scherm et al. 2007), resulting in a better leaf coverage and less damage than conventional spray methods. Moreover, as sanitizers, fine liquid antimicrobial coatings have been electrostatically sprayed on different type of food products (Russell 2003 Ganesh et al. 2010; Ganesh et al. 2012). Chocolate (Gorty and Barringer 2011; Luo et al. 2012) and lipid-based materials (Bocanegra et al. 2005; Marthina and Barringer 2012) have been successfully electrosprayed and their barrier and anti-browning properties on apple slices and candy tablets were also investigated (Khan et al. 2013b).

Considering the increasing demand for fresh and ready-to-eat fruits, characterized as living tissues with a short shelf-life, electrostatic liquid coating could be also considered as an adequate and innovative postharvest technique for improving the shelf-life and overall quality of fruits. To the best of our knowledge, no prior research has been reported on the application of electrostatic antimicrobial coatings for its potential to prolong the shelf-life of fresh fruits. The incorporation of natural antimicrobial compounds in the coatings can inhibit microbial growth, which is considered the major cause of fruit’s deterioration. Additionally, the application of alginate-based antimicrobial coatings has the potential to extend strawberries’ shelf-life by reducing their respiration rate due to the selective permeability of this polymer to O2 and CO2 (Rojas-Graü et al. 2007).

Peretto et al. (2014a) optimized the use of alginate coatings containing carvacrol and methyl cinnamate on a previous study. They selected alginate, carvacrol, and methyl cinnamate based on their proved functionality, antimicrobial, and antifungal properties (Lambert et al. 2001), respectively. The incorporation of methyl cinnamate, which is also one of the major volatile components of strawberry aroma produced and released during fruit maturation, was needed to overcome undesirable sensory issue arising from the utilization of carvacrol. Indeed, this compound is the major component of oregano and thyme essential oils (EOs).

Therefore, in this study, emphasis was given to electrostatic application of alginate coating enriched with carvacrol and methyl cinnamate (natural antimicrobials) for preserving quality and increasing shelf-life of fresh strawberries. The performance of electrostatic and non-electrostatic spraying technology was evaluated in terms of transfer efficiency and coating evenness. Furthermore, physicochemical and textural parameters of electrostatic and non-electrostatic spray coated fruits were studied and compared to uncoated controls.

Materials and Methods

Preparation of Alginate Coating Solutions

Food-grade sodium alginate (Keltone® LV, ISP, San Diego, CA, USA) was used as a primary ingredient in edible coatings formulation. Coating solution was prepared by dissolving sodium alginate powder (2 %, w/v) in distilled water while heating on a stirring hot plate for 15 min at 70 °C until the mixture became clear. Then, 1.5 % (w/v) glycerol (Starwest Botanicals Inc., Rancho Cordova, CA, USA) was added to the solution and stirred for 5 min to provide good flexibility to the coating. Antimicrobial coating was obtained by adding 0.98 % (w/w) carvacrol and 1.45 % (w/w) methyl cinnamate (Sigma-Aldrich, St. Louis, MO, USA) active compounds into the alginate solution and homogenizing the mixture with a Polytron 3000 (Kinematica, Luzern, Switzerland) for 10 min at 4000 rpm. Considering the insolubility of methyl cinnamate in water, it was previously dissolved in ethanol (40 %, w/w) at 40 °C under stirring at 220 rpm for 5 min. Concentration of the active compounds used was based on optimization of carvacrol and methyl cinnamate concentration results, obtained on a previous study (Peretto et al. 2014a). Antimicrobial solutions were prepared fresh on the day of treatment and kept at 40 °C in a closed container until spray application.

Resistivity of coating was determined using a Ransburg Multifunction Electrostatic Meter (ITW Ransburg, Toledo, OH, USA) to ensure the value of the coating was suitable for electrostatic application (lower than 0.1 MΩ).

Strawberry Preparation and Storage Conditions

Fresh strawberries (Fragaria x ananassa) were harvested by California giant (Watsonville, CA, USA) and sent by overnight shipping to a local wholesale distributor (Fuji Melon, Oakland, CA, USA). Strawberries were picked up from the distributor earlier in the morning, and kept at 2 °C until treatments. Berry samples selected for uniform size, color, weight, and absence of physical and pathological defects were randomized and placed on a metallic rack, coated and later transferred to polystyrene weighing dishes for storage at 7.5 °C (±0.5 °C), 90 % RH for 13 days, as average of common commercial storage conditions. Uncoated fruits (controls) were stored at the same conditions as the sprayed samples. All treatments (electrostatic and non-electrostatic sprayed fruits) and controls were tested immediately after spraying (day 0), and at 4, 8, and 13 days of storage. Strawberries were distributed into groups of 36 fruits for each treatment, with three replicates for treatment. Each replicate consisted of 12 fruits arranged in three trays (four fruits per tray).

Spraying of Alginate Coating

A cordless 85 kV vector solo waterborne electrostatic gun applicator (ITW Ransburg, Toledo, OH, USA) was used to coat targets, at 85 kV for electrostatic spray (ES) coating and, 0 kV for non-electrostatic spray (NES) coating. Three different valves on the applicator controlled the amount of fluid, air pressure, and pattern size. The equipment consisted of an isolated fluid system, an air line, and an applicator nozzle (Fig. 1).

The air supply line was set at 100 psig and coating material was supplied at 70 g/min through the fluid line. NES coating was performed using the same equipment with the same settings except the voltage was zero. Alginate coating was applied at ambient temperature on the whole surface of four strawberries at a time placed on top of a metallic rack (16 cm high), previously disinfected with ethanol. In this way, the fruits were grounded for allowing the charged droplets to be attracted towards them. The strawberries were positioned in a square shape with a 2 cm space between them and the applicator was set up in a vertical position at 60 cm away from the targets. The operating parameters and valve settings were tested and adjusted based on previous tests in order to obtain a short-round-spray pattern for uniform surface coverage.

The weight of strawberries before and after coating was recorded and used to calculate the transfer efficiency as TE (%) = [(W f −W i )/W s ] × 100, where W f and W i are the weight of targets after and before coating, respectively, and W s is the weight of the material sprayed toward the targets during the spraying period (6 s).

Coating evenness was indirectly evaluated by comparing the color parameter b* of water sensitive paper (Q. Instruments, Jena, Germany) applied on the back side of the fruits, not directly exposed to the spray. The water sensitive papers were applied only on the back of the fruits based on the results of our preliminary tests in which papers applied on top and sides of the fruits having the same b* value, after ES and NES, were considered as being completely covered by the coating solution. One water sensitive paper disk (6 mm in diameter) was attached to each fruit and the color parameter b* of each disk was determined after spraying, using a CM508D Konica Minolta spectrophotometer (Konica–Minolta Inc., Ramsey, NJ, USA) under a standard white reflector plate. The water sensitive paper changed color from yellow to blue, when in contact with aqueous drops. Therefore, the blueness (−b*) to yellowness (+b*) value was used to determine the coating efficiency of the ES and NES applications on coated targets. Three color readings were recorded for each paper disk using a CM-A195 target mask 3 mm in diameter.

Physicochemical Analysis

Visual Decay and Weight Loss of Strawberries

Strawberries were inspected daily and considered spoiled when a visible lesion, characterized as brown spots and softening of the infected area, was observed. The results were expressed as percentage of spoiled fruits based on the total number of fruits. The same fruits for each treatment were weighed daily throughout the storage time. Weight loss was expressed as percentage loss based on initial weight.

Color and Firmness of Strawberries

L*, a*, and b* colorimetric values were obtained using a CM508D spectrophotometer (Konica—Minolta Inc., Ramsey, NJ, USA). Eighteen strawberries, for each treatment, were selected for color assessment and five measurements were made on the surface of each fruit by changing the position of the target mask over the fruit.

Strawberry firmness was determined using a TA-XT2 texture analyzer (Stable Micro System Ltd., UK) on the same 18 fruits used for color determination. The force required for a 2 mm probe to penetrate 7 mm into strawberry flesh at a rate of 2 mm/s was measured. Berries were cut into two pieces alongside and texture was measured on areas free of seeds one time at both sides at the highest elevation closer to the stem end. Six fruits for each replicate (18 fruits per treatment) were used for the measurement at day 0, 4, 8, and 13.

Antioxidant Capacity (AC) and Total Soluble Phenolics (TSP) of Strawberries

An adaptation of the DPPH method (Brand-Williams et al. 1995) was used to estimate the AC of strawberries. Five grams of homogenized strawberry tissue, obtained from six fruits (six for each replicate, 18 fruits per treatment), were extracted with 20 mL of methanol, collected in polytetrafluoroethylene (PTFE) tubes, and stored for 48 h at 4 °C. Homogenates were then centrifuged in a SORVALL RC 5C Plus with a SA–600 rotor (Kendro Laboratory Products, Newtown, CT, USA) at 29,000 g for 15 min at 4 °C. Sample aliquots of 50 μL were taken from the clear supernatant (equivalent methanol volume as control) and reacted with 2950 μL of DPPH reagent (obtained by dissolving 0.047 g/L in methanol) in a covered shaker at room temperature, until steady state conditions were reached (no significant decrease in absorbance was experienced as compared with the control, 20–22 h). The spectrophotometer was blanked with methanol, the solutions were placed in 4.5 mL disposable cuvettes, and the absorbance at 515 nm was recorded using a UV–1700 spectrophotometer (Shimadzu Scientific Instruments, Inc., Columbia, MD, USA). The AC was calculated by measuring the decrease in absorbance of samples as compared with the methanol samples and quantifying as μg Trolox equivalent from a standard curve developed with Trolox (0–750 μg/mL) and expressed as mg Trolox per g fresh weight.

The same methanol extract used to determine AC was also used for TSP analysis. The assay was conducted according to Swain and Hillis (1959) method with some modifications. A 150 μL aliquot of methanol extract was taken from the clear supernatant, diluted with 2400 μL of nanopure water, followed by 150 μL of 0.25N Folin–Ciocalteu’s reagent, and incubated for 3 min at room temperature. The reaction was stopped by adding 300 μL of 1 N sodium carbonate and the mixture was incubated for 25 min. A standard curve was developed with different concentration of gallic acid, ranging from 0 to 0.375 mg/mL. Results obtained from the readings of absorbance at 765 nm were expressed as mg of gallic acid per 100 g fresh weight.

Statistical Analysis

Data were statistically processed by ANOVA using the CoStat 6.4 (CoHort software, USA) program. Means were separated by HSD Tukey test at the significance level of p ≤ 0.05. Triplicate samples were used for all measurements.

Results and Discussion

Transfer Efficiency and Coating Evenness

Alginate-based coating (2.03 g) was sprayed onto four strawberries at a time. On average, the weight difference before and after coating for all ES fruits was 1.18 g whereas only 0.51 g weight gain was measured for NES coated fruits. The use of electrostatic spraying technology for the application of antimicrobial alginate coating led to a significant improvement on transfer efficiency compare to NES coating technology (Fig. 2a). Transfer efficiency could be considered a measurement of process efficiency, as it determines the amount of material reaching the targets compared to the portion of the material lost in the surrounding environment. Even though some coating material was also delivered into the surrounding area, during ES treatment, the transfer efficiency value of ES coated fruits reached approximately 60 %. The positive effect of ES treatment, on increasing coating deposition on target surface, has been studied and reported in many works where food product were coated with seasonings (Amefia et al. 2006). Law (2001) reported that electrostatic spray of liquids, used either as potential sanitizers or pesticides, increased transfer efficiency and provided an overall better coverage of the crops’ surface, leading to identical appearance of all product sides. The indicated effective coverage was due to the self-dispersion of the charged particles across the whole target surface.

a Transfer efficiency (TE %) and b coating evenness of electrostatic spray (ES) and non-electrostatic spray (NES) coating. Data shown are the means of triplicate samples and the bars indicate their corresponding standard deviation. a–b different letters indicate significant differences among treatments (p ≤ 0.05)

Strawberries coated using the ES technology had a more uniform coating compared to those fruits coated using the conventional NES technology (Fig. 2b). The significant lower b* value, an indicator of blue chromacity, indicated that the back sides of ES coated fruits were reached by the coating droplets to a greater extent than those fruits coated using the NES treatment (32.5 vs 50.1). The electrical field applied to the liquid coating, induced electrostatic forces with sufficient intensity to overcome surface tension forces that atomized the liquid surface into a spray of charged particles. Due to their charges, the droplets repelled each other and created a cloud of charged droplets that was attracted to the coating target creating a uniform film of liquid coating. Therefore, ES spray can increase droplets depositions on targets and overcome common problems of uneven distribution and poor surface coverage obtained with conventional NES treatment (Amefia et al. 2006).

Visual Decay and Weight Loss of Strawberries

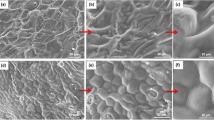

In order to determine the effectiveness of electrostatic antimicrobial coating for improving quality of fresh strawberries, visual decay and weight loss, as primary determinants of quality, were monitored daily throughout the storage period and compared to uncoated (control) and NES coated fruits. Fungal decay (Fig. 3) occurred rapidly on the uncoated (control) fruits, with 2.7 % of strawberries showing sign of infection after 7 days of storage and 8.3 % after three additional days of storage (day 10). NES coated fruits started to show first signs of mold growth at day 10. However, the ES treatment provided superior postharvest disease control as the fruits coated under this treatment did not develop any fungal decay until 11 days of storage, exhibiting 66 % less spoilage than the control. The 1 day of spoilage delay recorded for ES coated strawberries over those NES coated strawberries may have important economic implications, as the fruits can last longer in the fresh market. Moreover, the decay for the ES coated fruits was significantly (p ≤ 0.05) reduced compared to the control fruits for the remaining storage period and beyond 13 days of storage. The ES coating treatment significantly inhibited strawberry decay with only 5.6 % of spoiled fruits, compared to 16.6 and 8.3 % for control and NES fruits after 13 days of storage, respectively. The visual appearance of uncoated (control), NES and ES coated strawberries at the end of 13 days of storage is shown in Fig. 4. The application of ES coating treatment led to more inhibition of mold growth, by forming an even coating on the surface of the strawberries that allowed the antimicrobial properties of carvacrol and methyl cinnamate to perform more effectively, than those observed under NES coating treatment. Especially, methyl cinnamate has been proven to have antifungal activity against phytopathogenic fungi under in vitro conditions (Vaughn et al. 1993; Rahmani et al. 2010) and in practical application on shelf-life extension of strawberry, when methyl cinnamate is released as vapor from edible film (Peretto et al. 2014b). Strawberries are potential sources for foodborne pathogen and fungal infections, as they are not washed before packaging. Thus, utilization of antimicrobial coating to prevent these infections has gained importance over other treatments. Similar positive outcomes were obtained in sanitation application using liquid electrostatic spraying technology in the food industry. Ganesh et al. (2010) demonstrated that electrostatically sprayed food-grade acids were more effective in reducing Salmonella typhymurium on spinach compared to conventional spray system, due to the more even distribution of the liquid antimicrobial solution on the whole sample surface. Similarly, Law and Cooper (2001) reported that air-assisted antimicrobial electrostatic spray provided better control of fungal infection on banana over conventional hydraulic sprays.

Visual decay of strawberries expressed as percentage of infected fruits during storage at 7.5 °C for not coated (control), electrostatic spray (ES), and non-electrostatic spray (NES) coated fruits. Data shown are the means of three replicates of 36 fruits for each replicate and bars indicate standard deviation. a–b different letters indicate significant differences among treatments (p ≤ 0.05)

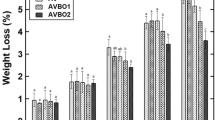

The weight loss of strawberries was also evaluated and it increased with storage time in all coated and uncoated fruits as expected (data not shown). Even though no significant differences were detected among treatments, uncoated fruits (controls) showed higher weight loss tendency than all NES and ES coated fruits throughout the storage time. Moreover, NES coated fruits showed higher weight loss than ES coated fruits. It was previously reported in another study that the application of alginate-based edible coatings minimize the weight loss of fresh fruits and prolong the shelf-life without causing undesirable anaerobic respiration (Rojas-Graü et al. 2007). This phenomenon was explained by the barrier to water vapor provided by the coating that are enhanced when ES coating is applied as having a higher transfer efficiency compared to conventional spray coatings.

Color and Firmness of Strawberries

The marketability of fresh strawberries is strongly influenced by sensory and visual appearance such as color of the skin. Table 1 shows that uncoated fruits exhibited significant color changes during postharvest storage, especially considering the brightness (L*), which significantly (p ≤ 0.05) decreased after 4 days of storage, probably because of the high gas exchange and respiration rate. The absence of coating as barrier to gases might have caused a higher metabolic rate, which led to a faster degradation of the fruits that developed dark tissues and brown spots, and affected their brightness.

Application of thin layer of antimicrobial coating can extend shelf-life of food products as well as improve their qualitative attribute by creating a modified atmosphere.

Moreover, significant differences in L* value were determined among treatments, showing brighter color for those fruits coated with alginate. This desirable color improvement was possibly due to the reflection of the light generated by the presence of the shiny oil droplets of carvacrol in the coating solution. Similarly, Vargas et al. (2006) reported an increase of luminosity of strawberries coated with chitosan-oleic acid compared to uncoated fruits.

Positive a* value, a measure of redness, was significantly higher in control strawberries compared to ES coated berries after 4 days of storage. This fact might be explained by the phytotoxic activity of the EOs in the coating solution, as being directly in contact with the fruits led to a possible higher discoloration of fruit’s skin (Amiri et al. 2008). However, this discoloration was not significant when compared to NES strawberries. Moreover, whereas no significant changes were detected on the redness of ES coated fruits throughout the storage period, on NES coated fruits it significantly decreased. This outcome might indicate that electrostatic technology maintained the color of strawberries even after 13 days of storage, due to the coating evenness generated over the fruit’s surface.

Major changes in strawberry color may be seen by the assessment of b* values. A positive b* value is a measure of yellowness, and a negative value of blueness. Among treatments, b* value was lower for uncoated (control) strawberries in comparison with coated fruits. The decrease in b* value was especially noted at day 4, when b* value of uncoated fruits was significantly (p ≤ 0.05) lower than those of treated fruits, but did not show significant difference from day 0. In addition, during 13 days of storage, no significant differences were observed between those fruits coated under the ES and NES treatments. Nevertheless, ES coated strawberries showed a better retention of b* value during the storage time compared to those coated under NES treatment. These results could be due to the more uniform and efficient alginate coating achieved with the ES treatment.

Texture loss is one of the most important and visible changes that occurs during fruit maturation as a consequence of metabolic changes and water loss that can seriously compromise storage life of fresh fruits. The application of antimicrobial alginate coating on strawberries using ES technology showed significant (p ≤ 0.05) higher fruit firmness and mechanical properties in comparison with uncoated (control) fruits and fruits coated with the NES technology (Fig. 5). Texture data indicated that although the maximum force (as measure of firmness) required to penetrate the flesh of the fruits did not greatly vary within the different treatments, during the storage period, the uncoated fruits showed higher firmness loss (7 %) after 13 days of storage, whereas, the firmness loss for coated fruits was less marked, especially when ES was used (5.9 %). Significant differences (p ≤ 0.05) between firmness of ES and NES coated strawberries were observed during storage, except on day 4. The mechanical properties of strawberries seemed to be better preserved when coated by ES, especially during the second part of the storage period (day 8 and 13), where significant differences were determined. Texture changes in strawberry fruit are related to the degradation of cell wall components mainly due to the action of extracellular pectolytic enzymes produced by Botrytis cinerea (Aguilar and Huitrón 1993). As reported in our previous study (Peretto et al. 2014b), the antimicrobial activity of carvacrol and methyl cinnamate could have indirectly decreased the amount of pectolytic enzymes, by inhibiting microbial growth. Furthermore, the effective gas barrier properties exerted by the alginate coating could have reduced the metabolic activity of strawberries and helped to maintain a better fruit firmness. Many polysaccharide-based coatings have been developed for the preservation of strawberry quality, including the prevention of water loss and texture changes during postharvest storage. For instance, starch-based coating was proved to improve overall sensory conditions, due to firmness retention and turgency (García et al. 1998).

Firmness of not coated (control), electrostatic spray (ES), and non-electrostatic spray (NES) coated strawberries during storage at 7.5 °C. Data shown are the means of three replicates of 36 fruits for each replicate and bars indicate standard deviation. a–b different letters indicate significant differences among treatments (p ≤ 0.05)

Antioxidant Capacity and Total Soluble Phenols (TSP) of Strawberries

Strawberries are rich source of phytochemicals with antioxidant properties that have been associated to health-protecting benefits. However, unsuitable storage conditions may deplete the amount of antioxidant in strawberries. For this reason, we decided to measure DPPH (antioxidant capacity) and TSP of strawberries in this study. TSP are the major antioxidants in fruit tissues and they are produced as secondary metabolites in response to different type of stress to protect cellular constituents. The application of coating enriched with antimicrobials could be considered a stress. The antioxidants increase or decrease during storage might depend on the severity of stress, time, and storage conditions. In our previous study (Peretto et al. 2014b), both TSP and DPPH increased during storage time. Wang and Gao (2013) demonstrated that strawberries treated with chitosan maintained high levels of phenolics and antioxidants. In the present study, the antioxidant capacity of strawberries did not change greatly throughout the 13 days of storage period. Significant differences in antioxidant capacity (AC) among fruits were detected only after 4 days of storage where uncoated fruits showed the lowest AC value (Table 2). The level of antioxidants in fresh strawberries can be influenced by the application of edible coatings as a consequence of passive modified atmosphere that control gas exchange (Falguera et al. 2001). Some studies suggested that application of edible coatings, as a tool to improve postharvest storage of fresh products, could induce a stress condition to treated fruits and trigger high synthesis of phenolic compounds, which contribute to the antioxidant power (Oms-Oliu et al. 2008). Results of the present study showed that the use of ES technology did not increase the antioxidant capacity and total soluble phenols of strawberries, although higher values were maintained when the fruits were coated with the alginate antimicrobial coating.

Conclusions

Electrostatic spray technology for the application of liquid coating showed higher functionality in terms of transfer efficiency and evenness than a conventional non-electrostatic spray method. The antimicrobial and barrier properties of alginate-based coating enriched with carvacrol and methyl cinnamate were enhanced by the application of electrostatic spray technology, which improved the distribution and uniformity of the coating over the target surface. These improved coating applications led to significant increase in several quality properties of electrostatic coated strawberries during storage and extended their shelf-life, especially when compared to uncoated fruits. Therefore, considering these outcomes, electrostatic spray can be adopted for potential liquid coating application to improve the shelf-life of perishable fruits and, at the same time, minimize the waste of coating materials.

References

Aguilar, G., & Huitrón, C. (1993). Conidial and mycelial-bound exo-pectinase of Aspergillus sp. FEMS Microbiology Letters, 108, 127–132.

Amefia, A. E., Abu-Ali, J. M., & Barringer, S. A. (2006). Improved functionality of food additives with electrostatic coating. Innovative Food Science and Emerging Technology, 7, 176–181.

Amiri, A., Dugas, R., Pichot, A. L., & Bompeix, G. (2008). In vitro and in vitro activity of eugenol oil (Eugenia caryophylata) against four important postharvest apple pathogens. International Journal of Food Microbiology, 126, 13–19.

Andrade, R. D., Skurtys, O., & Osorio, F. A. (2012). Atomizing spray systems for application of edible coatings. Comprehensive Reviews in Food Science and Food Safety, 11, 323–337.

Bailey, A. G. (1998). The science and technology of electrostatic powder spraying, transport and coating. Journal of Electrostatics, 45, 85–120.

Bocanegra, R., Gaonkar, A. G., Barrero, A., Loscertales, I. G., Pechack, D., & Marquez, M. (2005). Production of cocoa butter microcapsules using an electrospray process. Journal of Food Science, 70(8).

Brand-Williams, W., Cuvelier, M. E., & Berset, C. (1995). Use of a free radical method to evaluate antioxidant activity. Lebensmittel Wissenschaft Technolgie, 28, 25–28.

Falguera, V., Quintero, J. P., Jiménez, A., Muñoz, J. A., & Ibarz, A. (2001). Edible films and coatings: structures, active functions and trends in their use. Trends in Food Science and Technology, 22, 292–303.

Ganesh, V., Hettiarachchy, N. S., Ravichandran, M., Johnson, M. G., Griffis, C. L., Martin, E. M., Meullenet, J. F., & Ricke, S. C. (2010). Electrostatic sprays of food-grade acids and plant extracts are more effective than conventional sprays in decontaminating Salmonella Typhimurium on spinach. Journal of Food Science, 75(9), M574–M579.

Ganesh, V., Hettiarachchy, N. S., Griffis, C. L., Martin, & Ricke, S. C. (2012). Electrostatic spraying of food-grade organic and inorganic acids and plant extracts to decontaminate Escherichia coli O157:H7 on spinach and iceberg lettuce. Journal of Food Science, 77(7), M391–M396.

García, M. A., Martino, M. N., & Zaritzky, N. E. (1998). Starch-based coatings: effect on refrigerated strawberry (Fragaria x ananassa) quality. Journal of the Science of Food and Agriculture, 76, 411–420.

Gorty, A. V., & Barringer, S. A. (2011). Electrohydrodynamic spraying of chocolate. Journal of Food Processing and Preservation, 35(4), 542–549.

Khan, M. K. I., Schutyser, M. A. I., Schroën, K., & Boom, R. (2012a). Electrostatic powder coating of foods—state of the art and opportunities. Journal of Food Engineering, 111, –5.

Khan, M. K. I., Schutyser, M. A. I., Schroën, K., & Boom, R. (2012b). The potential of electrospraying for hydrophobic film coating on foods. Journal of Food Engineering, 108(3), 410–416.

Khan, M. K. I., Mujawar, L. H., Schutyser, M. A. I., Schroën, K., & Boom, R. (2013a). Deposition of thin lipid films prepared by electrospraying. Food Bioprocess Technology, 6, 3047–3055.

Khan, M. K. I., Cakmak, H., Tavman, S., Schutyser, M., & Schroën, K. (2013b). Anti-browning and barrier properties of edible coatings prepared with electrospraying. Innovative Food Sci Emerg Technol

Lambert, R. J. W., Skandamis, P. N., Coote, P. J., & Nychas, G. J. E. (2001). A study of the minimum inhibitory concentration and mode of action of oregano essential oil, thymol and carvacrol. Journal of Applied Microbiology, 91, 453–462.

Law, S. E. (2001). Agricultural electrostatic spray application: a review of significant research and development during the 20th century. Journal of Electrostatic, 51, 25–42.

Law, S. E., & Cooper, S. C. (2001). Air-assisted electrostatic sprays for postharvest control of fruit and vegetable spoilage microorganisms. IEE Transaction on Industry Application, 37, 1597–1602.

Luo, C. J., Loh, S., Stride, E., & Edirisinghe, M. (2012). Electrospraying and electrospinning of chocolate suspensions. Food and Bioprocess Technology, 5(6), 2285–2300.

Marthina, K., & Barringer, S. A. (2012). Confectionery coating with an electrohydrodynamic (EHD) system. Journal of Food Science, 77(1), E26–E31.

Oms-Oliu, G., Soliva-Fortuny, R., & Martin-Belloso, O. (2008). Using polysaccharide-based coatings to enhance quality and antioxidant properties of fresh-cut melon. LWT- Food Science and Technology, 41, 1862–1870.

Peretto, G., Du, W.-X., Avena-Bustillos, R. J., Berrios, J., Sambo, P., & McHugh, T. H. (2014a). Optimization of antimicrobial and physical properties of alginate coating containing carvacrol and methyl cinnamate using response surface methodology. Journal of Agriculture and Food Science, 62, 984–990.

Peretto, G., Du, W.-X., Avena-Bustillos, R. J., Sarreal, B. L., Hua, S. S. T., Sambo, P., & McHugh, T. H. (2014b). Increasing strawberry shelf-life with carvacrol and methyl cinnamate antimicrobial vapors released from edible films. Postharvest Biology and Technology, 89, 11–18.

Perez, C. J., Shelton, A. M., & Dereksen, R. C. (1995). Effect of application technology and bacillus thuringiensis subspecies on management of B. thuringiensis subsp. kurstaki-resistant diamondback moth. Journal of Economic Entomology, 88, 1113–1119.

Rahmani, N. A. M. A., Shaari, K., Ali, A. M., & Cheng-Lian, G. E. (2010). Antimicrobial activity of Cinnamomum impressicostatum and C. pubescens and bioassay-guided isolation of bioactive (E)-methyl cinnamate. Journal of Biological Science, 10, 101–106.

Ratanatriwong, P., Barringer, S. A., & Delwiche, J. (2003). Sensory preference, coating evenness, dustiness, and transfer efficiency of electrostatically coated potato chips. Journal of Food Science: Sensory and Nutritive Qualities of Food, 68(4), 1542–1547.

Ratanatriwong, P., Suwansri, S., Barringer, S. A., & Tanasukarn, P. (2009). Effect of electrostatic coating on consumer acceptance and process efficiency of seasoned coated snacks. Asian Journal of Food and Agro-Industry, 2(1), 51–64.

Rojas-Graü, M. A., Tapia, M. S., Rodríguez, F. J., Carmona, A. J., & Martin-Belloso, O. (2007). Alginate and gellan-based edible coatings as carriers of antibrowning agents applied on fresh-cut Fuji apples. Food Hydrocolloids, 21, 118–127.

Russell, S. M. (2003). The effect of electrolyzed oxidative water applied using electrostatic spraying on pathogenic and indicator bacteria on the surface of eggs. Poultry Science, 82, 158–162.

Scherm, H., Savelle, A. T., & Law, S. E. (2007). Effect of electrostatic spray parameters on the viability of two bacterial biocontrol agents and their deposition on blueberry flower stigmas. Biocontrol Science and Technology, 17, 285–293.

Swain, T., & Hillis, W. E. (1959). The phenolic constituents of Prunus domestica. Journal of the Science and Food Agriculture, 10, 63–68.

Tapia, M. S., Rojas-Graü, M. A., Carmona, A., Rodríguez, F. J., Soliva-Fortuny, R., & Martin-Belloso, O. (2008). Use of alginate- and gellan-based coatings for improving barrier, texture and nutritional properties of fresh-cut papaya. Food Hydrocolloids, 22, 1493–1503.

Vargas, M., Albors, A., Chiralt, A., & González-Martínez, C. (2006). Quality of cold-stored strawberries as affected by chitosan–oleic acid edible coatings. Postharvest Biology and Technology, 41, 164–171.

Vaughn, S. F., Spencer, G. F., & Shasha, B. S. (1993). Volatile compounds from raspberry and strawberry fruit inhibit postharvest decay of fungi. Journal of Food Science, 58, 793–796.

Wang, S. Y., & Gao, H. (2013). Effect of chitosan-based edible coating on antioxidants, antioxidant enzyme system, and postharvest fruit quality of strawberries (Fragaria x aranassa Duch.). Food Science and Technology, 52, 71–79.

Acknowledgments

This work was supported by the Department of Agronomy, Food, Natural Resources, Animals and Environment (DAFNAE) of the University of Padova (Italy). The authors declare no competing financial interest. We are grateful for the assistance provided by the Western Regional Research Center, Agricultural Research Service, the US Department of Agriculture, and Global Application Technologies from Toledo, OH, USA.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peretto, G., Du, WX., Avena-Bustillos, R.J. et al. Electrostatic and Conventional Spraying of Alginate-Based Edible Coating with Natural Antimicrobials for Preserving Fresh Strawberry Quality. Food Bioprocess Technol 10, 165–174 (2017). https://doi.org/10.1007/s11947-016-1808-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-016-1808-9