Abstract

The present study reports the application of feather hydrolysates (FHs) obtained from the hydrolysis of chicken feathers by Bacillus safensis LAU 13 (KJ461434) and Aquamicrobium defluvii FH 20 (OM281847.1) as organic nitrogen fertilizer for the cultivation of Corchorus olitorius, Celosia argentea and Amaranthus caudatus. Foliar treatment of the vegetables with FHs (100%, v/v) remarkably improved their growth and yield performances. The FHs induced over 1.5-fold improvement in root length, shoot height, shoot fresh weight, dry weight, leaf number, leaf area and chlorophyll contents of the vegetables compared to water after 6 weeks of cultivation. In most cases, FHs at optimal levels displayed better growth promotion than NPK fertilizer. FHs elevated the nitrogen content (25.53–29.79%), organic carbon (33.77–38.96%), and microbial load (102–104 cfu/g) of soil after 6 weeks. Vegetables fertilized with FHs showed improvements in crude protein, crude fibre, ash, phenols, flavonoids, and proanthocyanidin contents to controls. Also, about 1.1-fold improvement in hydrogen peroxide and DPPH radicals scavenging activities was obtained. Significant lipid peroxidation inhibition against ferrous ion (Fe2+) damage in precision-cut liver slices with higher catalase activities was recorded. Thus, the bacterial FHs significantly enhanced the growth, nutritional and antioxidant properties of the vegetables as well as soil nutrient and biological activities. Hence, the application of the bacterial FHs can be substituted for synthetic fertilizer to promote sustainable agricultural food production in an ecologically benign manner.

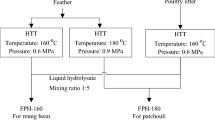

Graphical abstract

Bacterial feather hydrolysates improved growth, nutritional and nutraceutical qualities of vegetables as eco-friendly biofertilizers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The steady rise in the global population indicates that it would reach 9.7 billion people by 2050 (UN, 2022). This will require very huge staple and healthy foods for the survival of the people. Presently, agricultural sector is facing the challenge of how to increase food production to sustain the steadily rising world population in a cost-effective and environmentally benign manner (Rouphael and Colla 2020). Application of synthetic fertilizers for crop production had been a common practice, whereas the practice detrimentally affects the quality of soil and the environment. However, the application of slow-release nitrogenous organic fertilizers has proven to be a safer and better substitute to boost agricultural productivity (Chatzistathis et al. 2021) for the actualization of Sustainable Development Goal 2 (SDG 2; zero hunger) of the United Nations. Organic fertilizers stimulate physiological processes in plants and can enhance crop yield and quality and induce tolerance or recovery from abiotic stress (du Jardin 2015).

Several organic wastes have been investigated and utilized in the production of biodegradable bioplastics (Sharma et al. 2018) and as fertilizers, sources of renewable energy and for soil amendment (Chia et al. 2020). Biotechnological valorization of nitrogenous organic wastes like poultry feathers via microbial transformation (Adelere and Lateef 2016a) to yield valuable products such as animal feed supplements and organic fertilizers for sustainable agricultural practice has been explored (Sobucki et al. 2019). The process promotes bio- and circular economy (Mahjoub and Domscheit 2020) in the utilization of agricultural wastes such as corncob among others (Elegbede et al. 2021). In our laboratory, a series of agrowastes have been used to produce high-end products that include enzymes such as fructosyltransferase using kolanut pod and plantain peel (Lateef et al. 2012), keratinase using chicken feather (Lateef et al. 2015a) and xylanase using corncob (Elegbede and Lateef 2018, 2019), citric acid (Adeoye and Lateef 2021, 2022), feather-based adsorbents (Azeez et al. 2020) and nanomaterials (Adelere and Lateef 2016b) within the framework of circular economy to convert wastes to wealth.

Globally, about 8.5 million tons of chicken feather wastes are generated annually from agro-industrial processing (Da Silva 2018), which constitutes a threat to the environment due to their recalcitrant keratin content (Lateef et al. 2010), but which can be degraded by some microorganisms that include fungi (Kumari and Kumar 2020) and bacteria (Lateef et al. 2015b). Keratins are insoluble, fibrous and structural proteins that are found in the epidermis and its appendages like feathers, hair, wool, nail, hoof, and horns (Hassan et al. 2020). They are resistant to degradation by common proteolytic enzymes like trypsin and pepsin due to their structural stabilization by tightly packed peptide chains and the presence of several cross-linkages by disulphide bonds, hydrogen bonding and hydrophobic interactions (Adelere and Lateef 2019).

The conventional methods for keratinous waste treatment, such as burning, landfilling, steam pressure cooking and chemical hydrolysis consume enormous energy, are non-eco-friendly and also impair their biotechnological values (Gupta and Ramnani 2006). However, microbial fermentation is an effective way to valorize feathers in a biotechnological manner to produce multi-applicable keratinolytic enzymes and feather hydrolysates (FHs) (Reddy et al. 2021). Studies on the biotechnological valorization of keratinous wastes have led to the isolation of several species of vast keratinolytic bacteria (Lateef et al. 2015c), fungi (Kumar and Yadav 2020) and actinomycetes from soil and keratinous wastes with production of potent keratinases (Zhang et al. 2016). Feather hydrolysates are rich in free amino acids, ammonia, peptides, and some biologically important products that can stimulate soil microbial activity which will in turn facilitate the assimilation of nutrients by plants for better growth by releasing essential and non-essential amino acids (Bokveld et al. 2021), thereby resulting to the production of superior biofertilizer (Bhari et al. 2021). They can also be utilized as slow-release nitrogen (N) organic fertilizers to boost agricultural food production (Kaur et al. 2021). The application of FH can also improve water holding capacity, C/N ratio and mineral contents of soil (Bhari et al. 2021).

Vegetables are edible parts of certain plants like leaves, stems and roots that are usually consumed raw, mildly processed, or taken as an addition to other food items (Ganesh et al. 2022) due to abundance of proteins and minerals (Omale and Emmanuel, 2011). They are rich in dietary fibre (Sarker et al. 2022a), numerous vitamins (Sarker et al. 2022b), minerals (Sarker et al. 2022c), proteins (Sarker et al. 2020) and trace elements (Sarker et al. 2022d). They can help to safeguard against all forms of malnutrition and reduce the risks of non-communicable diseases (Afshin et al. 2019). They contain phytochemicals like carotenoids (Sarker et al. 2022e), phenols (Sarker and Oba 2020), antioxidants (Sarker et al. 2020) and flavonoids (Sarker and Oba 2020) that can act to scavenge free radicals to reduce the incidence of diseases such as cancer, cardiac defect, stroke, hypertension, birth defects, cataracts and diabetes (Ramya and Patel 2019). Regular consumption of fruits and vegetables can reduce the death rate and daily consumption of 400 g of fruits, and vegetables had been recommended by WHO to enjoy their health and nutritional benefits (Frank et al. 2019).

Despite the huge benefits associated with the intake of fruits and vegetables, their global consumption level is still below the WHO recommendation due to a gap in production. Hence, awareness was raised about the importance of fruits and vegetables to promote good health and well-being towards achieving the SDGs of the UN (FAO 2020). It has been estimated that by 2050, between 800 million and 1.9 billion people in sub-Saharan Africa will not have access to 400 g of fruits and vegetables per day as recommended by WHO (Mason-D'Croz et al. 2019). Part of the strategies for making fruits and vegetables available for human consumption is to increase their production at a low cost and in an environmentally sustainable manner. Thus, keratinous wastes can be valorized to produce organic fertilizer as one of the strategies to boost the growth of nutritious vegetables.

This study reports the application of feather hydrolysates obtained after the hydrolysis of chicken feathers by Bacillus safensis LAU 13 and Aquamicrobium defluvii FH 20 as organic nitrogen fertilizer for the cultivation of some important vegetables in Nigeria, namely Corchorus olitorius (Jute mallow), Celosia argentea (Cockscomb) and Amaranthus caudatus (Pendant amaranth). We recently showed that FHs positively influenced germination, vigour index and vegetative growth of the three vegetables in soilless and pot experiments (Adelere and Lateef 2022). In the present study, we compared the effects of feather hydrolysates on growth, nutritional, antioxidant and some nutraceutical/functional attributes of the grown vegetables in relation to cultivations using water and NPK fertilizer. Until now, there is no study on the evaluation of feather hydrolysates on the growth of Corchorus olitorius, Celosia argentea and Amaranthus caudatus under field conditions.

Materials and methods

Isolation of keratinolytic bacteria

The keratinolytic Bacillus safensis LAU 13 as previously reported (Lateef et al. 2015b) was collected from the culture collection of the Laboratory of Industrial Microbiology and Nanobiotechnology, LAUTECH, Ogbomoso. In addition, another potent keratinolytic bacterium was isolated from the feather dump. A soil sample of 1 g was dispersed in 9 ml of sterile distilled water, and an aliquot of 0.5 ml was inoculated into keratin-based medium for the selective growth of bacterial isolates using the pour plate method as recently reported (Adelere and Lateef 2022). The plates were incubated at 37 °C for up to 3 days. Thereafter, distinct colonies observed through morphological features were sub-cultured on yeast extract agar plates to obtain pure cultures. The pure cultures were stored on yeast extract agar for further use.

Characterization of the new keratinolytic isolate

Among the isolates that were obtained, isolate FH 20 with high keratinolytic activity was preliminarily characterized by morphological and biochemical methods (Brenner et al. 2004). Following the molecular characterization of the isolate as reported (Adelere and Lateef 2022), it was identified as a strain of Aquamicrobium defluvii with accession number (OM281847.1). It was the first species in the genus of Aquamicrobium with keratinolytic activity (Adelere and Lateef 2022).

Determination of keratinolytic activities and bioconversion of chicken feather wastes into feather hydrolysates

Each of the keratinolytic bacterial strains was used for the inoculum development by inoculating into a medium consisting of 1% keratin powder, 0.2% yeast extract, pH 7.5 and incubated at 37 °C at 100 rpm for 24 h. Feather degradation was carried out by inoculating 1 ml of inoculum into 19 ml of fermentation medium (keratin-based medium without agar and nystatin) in 100-ml flasks (Lateef et al. 2015b). The cultures were incubated at 37 °C at 100 rpm for up to 7 days. Samples were withdrawn at 24-h interval and centrifuged, and the crude keratinase obtained was used to determine the keratinolytic activity (Adelere and Lateef 2022).

In separate flasks that were cultured for 7 days, the content of each flask was collected and centrifuged at 5000 rpm for 20 min and the supernatant was heated at 60 °C for 30 min to kill the bacterial culture. The heated supernatant served as feather hydrolysate which was used without further purification to grow the plants.

Determination of nitrogen and amino acid composition of feather hydrolysates

The amino acid composition of the feather hydrolysates was determined using high-performance thin-layer chromatography (HPTLC) analysis (Gurav et al. 2020). The nitrogen composition of the feather hydrolysate was determined using a TOC-L total organic carbon analyser equipped with a TNM-L unit (Sobucki et al. 2019).

Effect of feather hydrolysates as biofertilizer for vegetable growth under field conditions

This study was conducted following a modified method by Tamreihao et al. (2017). The three leafy vegetables Corchorus olitorius var. corete potagere, Celosia argentea var. cristata and Amaranthus caudatus var. hemera were cultivated in the Botanical Gardens, Department of Pure and Applied Biology, LAUTECH, Ogbomoso (8.1650° N, 4.2763° E) between June and September 2021 on sandy loamy soil. The experiment was a randomized complete block design with four replications. The field was divided into plots (1 m2) separated by a space of 50 cm. The treatment blocks were then spaced 70 cm apart. Six treatments were considered, namely 25, 50, 75, 100% feather hydrolysates, negative control (water only) and positive control (NPK fertilizer).

Seeds were planted in each plot using a broadcasting method and immediately after planting, plots were wet with 1 L of feather hydrolysate, while an equal volume of well water was used to treat both positive and negative control plots. In addition, for the positive control experiment, 15 g of NPK fertilizer was used to treat each corresponding plot a week before planting using the broadcasting method. Two weeks after germination, the same amount of booster dose of feather hydrolysates was applied using the foliar spray technique, while NPK fertilizer was applied using the localized mode of application appropriately. The plants were thinned after two weeks of germination to maintain 12 plants per plot. The vegetables were grown for six weeks before harvesting. After 6 weeks, 8 plants from each plot were uprooted randomly and parameters such as shoot height, shoot fresh weight and shoot dry weight were estimated. The leaf area was determined using the Montgomery equation (Eq. 1) according to He et al. (2020) as follows:

Determination of chlorophyll contents and proximate compositions of the vegetables

The proximate composition of dry leaves was determined following the AOAC method as detailed by Sarker et al. (2022d). The chlorophyll content was determined as described by Sarker et al. (2022d) with little modifications. The fresh leaf of each vegetable plant (30 mg) was submerged in a test tube containing 7 ml of 80% acetone and incubated in the dark for 72 h. Thereafter, absorbance readings at 645 and 663 nm were taken and the total chlorophyll content was determined using Eq. 2:

C is the total chlorophyll contents in mg/g fresh weight of leaf, A645 and A663 are the absorbance readings of the extract at 645 and 663 nm, Y is the volume of extract, and n is the fresh weight of leaf.

Determination of ammonium nitrogen, total organic carbon and microbial properties of soil

The ammonium nitrogen of the composite soil sample collected from the cultivated site was determined using standard laboratory procedures outlined by Mylavapus and Kennelley (2002), while the total organic carbon was determined following the methods of McLeod (1973). Microbial loads of the composite soil sample before and after treatments were also enumerated as earlier described (Adelere and Lateef 2022). The soil sample was serially diluted in sterile water, and inoculated into nutrient agar (NA) and potato dextrose agar (PDA) plates. The plates were incubated for 24 h at 37 °C (NA) and 48 h at 30 ± 2 °C (PDA) for the enumeration of bacterial and fungal loads, respectively.

Antioxidant activities of the vegetables

DPPH radical scavenging assay was carried out as described by Azeez et al. (2019) by reacting 1 mL of graded concentrations of methanolic extract of each plant (4 mg/mL) with 4 ml methanolic solution of 0.1 mM DPPH. The mixture was shaken and left in a dark box to stand for 30 min at room temperature (30 ± 2 °C). One mL of absolute methanol mixed with 4.0 mL of 0.1 mM methanolic DPPH was also prepared and used as a control. The absorbance of the resulting solution was measured at 517 nm using a UV–Vis spectrophotometer. The percentage of DPPH radical scavenging activity (%DRSA) was calculated according to Eq. 3:

where A0 is the absorbance of the control and A1 is the absorbance of the extractives/standard.

The ability of the extracts to scavenge hydrogen peroxide was determined according to the method documented by Gülçin et al. (2005). Exactly 4 mL of each extract (50–800 µg/mL) was added to hydrogen peroxide solution (0.6 ml, 40 mM) and reacted for 10 min. Distilled water was used as blank, the H2O2 solution was used as the control, and the absorbance readings were taken at 230 nm. The percentage of hydrogen peroxide scavenged by the extracts and a standard compound was calculated following Eq. 4:

The lipid peroxidation inhibition assay (LPI) was determined according to the methods described by Liu and Ng (2000). Excised rat liver was homogenized in phosphate buffer (10%, w/v) and then centrifuged to obtain homogenate. Liver homogenate of 0.5 mL was added to 0.1 mL of the vegetable extract (10 µg/mL), and the mixture was then added with FeSO4 (50 μL, 10 mM). The reaction mixture was incubated at 37 °C for 20 min. Thereafter, TCA (1 mL, 28%) and 1.5 mL of TBA (1%) were added and heated at 100 °C for 15 min. After cooling, the absorbance was taken at 532 nm. The control consisted of the same compositions without the vegetable extract. Percentage inhibition of lipid peroxidation (% LPI) was calculated using Eq. 5:

where Acontrol is the absorbance of the control and Asample is the absorbance of the tested sample.

Catalase activity assay was carried out following the method described by Cohen et al. (1970) with modifications by dispensing 0.8 mL hydrogen peroxide (30 mM) into an Eppendorf tube containing phosphate buffer (1.0 mL). Thereafter, vegetable extract (75 μL) and liver homogenate (125 μL) were added. Tube contents were then mixed thoroughly by inversion. The reaction was stopped after 3 min with 1 mL of 6 M H2SO4. Potassium permanganate (3 mL, 0.01 M) was then added and an absorbance reading at 480 nm within 30–60 s was taken. The catalase activity was determined as stated in Eq. 6.

V is the total volume of the reaction mixture; M is the molar extinction coefficient which is 40.0; W is the weight of tissue; and v is the volume of sample used.

Phytochemical analysis of the vegetables

Total phenol content was estimated as described by McDonald et al. (2001). Briefly, 1 mL of each of the sample solutions was added to 0.2 mL of Folin–Ciocalteu reagent and 2 mL of distilled water. Thereafter, 1 mL of 15% Na2CO3 was mixed with the solution. The solution was incubated at 40 °C for 30 min, and the absorbance was read at 760 nm. Total phenol content was expressed as mg/g of gallic acid as extrapolated from the standard curve of gallic acid.

Total flavonoid content was determined according to the procedure of Zhishen et al. (1999) with little modifications involving the use of catechin as a standard. The vegetable extract (0.1 mL, 0.1 mg/mL) was added to 0.3 mL distilled water followed by 5% NaNO2 (0.03 mL). After 5 min of reaction under 25 °C, AlCl3 (0.03 mL, 10%) was added. After another 5 min, the reaction mixture was added with 0.2 mL of 1 mM NaOH. Finally, the reaction mixture was diluted to 1 mL with water and the absorbance was measured at 510 nm. The results were expressed as mg/g of catechin as extrapolated using the standard curve of catechin.

Determination of proanthocyanidin was carried out as described by Sun et al. (1998). The vegetable extract (0.5 mL, 0.1 mg/mL) was mixed with 3 mL of 4% vanillin-methanol solution and 1.5 mL hydrochloric acid. The mixture was allowed to stand for 15 min; thereafter, absorbance was taken at 500 nm. The total content of proanthocyanidin was expressed as mg/g of catechin based on extrapolation of the standard curve obtained for catechin.

Statistical analysis

Data were analysed using SPSS statistical package version 20. The values were expressed as means ± SD, and the significance difference was determined by ANOVA (p < 0.05) and Duncan’s multiple range test.

Results and discussion

Feather degradation by keratinolytic bacteria

The previously isolated keratinolytic Bacillus safensis LAU 13 (KJ461434) (Lateef et al. (2015b) and the newly isolated Aquamicrobium defluvii FH 20 (OM281847.1) from the chicken feather dump site exhibited remarkable keratin-degrading ability as the feather substrate was almost completely degraded during the period of fermentation (4–5 days). The new isolate was a gram-negative, short rod, motile, aerobic and non-spore-forming bacterium. It was catalase and oxidase positive, but coagulase negative. Using the molecular technique, it was identified as Aquamicrobium defluvii strain FH 20 with accession number OM281847.1. Its homology is 97.60% similar to the sequence of Aquamicrobium defluvii TLA-7 (KU163265.1) that was isolated from a landfill stabilization pond in Greece (Ntougias 2016).

Isolation of a wide variety of keratinolytic bacterial species from natural habitats including soils (Lateef et al. 2010), birds’ nests (Saarela et al. 2017), hot spring and keratin wastes have been reported by various authors (Akhter et al. 2020). During the fermentation of chicken feather by the isolates, B. safensis LAU 13 produced the maximum keratinolytic activity (KA) of 56.7 U/ml, while 45.2 U/ml was recorded as KA for Aquamicrobium defluvii FH 20. Authors have reported similar activities. For instance, Lateef et al. (2015b) previously reported KA of 50.4 U/ml for B. safensis LAU 13. Similarly, Alahyaribeik et al. (2020) reported maximum KA of 50.41 and 35.41 U/ml after 48 h of fermentation by strains of B. licheniformis and B. pumilus, respectively, using feathers as substrate, while Biswas et al. (2021) reported the isolation of Bacillus cereus PKID1 that produced highest KA of 80 ± 0.28 U/ml on feather wastes.

The ammonium nitrogen content of FH obtained from the feather waste degradation by Bacillus safensis LAU 13 and Aquamicrobium defluvii FH 20 was 13.16 and 12.60%, respectively, which are within the range of values reported by previous authors. Gurav et al. (2020) reported the presence of 8.03% nitrogen content in the FH resulting from feather degradation by Chryseobacterium sp. RBT, whereas Sobucki et al. (2019) reported a nitrogen content of 15.36% for feather hydrolysate of Bacillus sp. CL18. A nitrogen content of 12% was reported for the feather protein hydrolysate of Chryseobacterium sediminis RCM-SSR-7 (Kshetri et al. 2019).

Amino acid profiles of feather hydrolysates

The essential and non-essential amino acid constituents of the FHs are shown in Table 1. The FH obtained after feather hydrolysis by B. safensis LAU 13 is richer in glycine (3.86 mg/mL), alanine (3.45 mg/mL) and leucine (2.52 mg/mL) than cysteine, tryptophan and methionine that are smaller in quantities. Similarly, the FH obtained through Aquamicrobium defluvii FH 20 feather degradation has some similarities in amino acids contents as it contained leucine (4.20 mg/mL) and glycine (3.80 mg/mL) in larger quantities than phenylalanine, cysteine, lysine, tyrosine and tryptophan that are present in small amounts. The amino acid profiles of the FHs as obtained herein correspond with the amino acids composition of the valorized chicken feather (Hendrick et al. 2021). The slight variation in proportion might be attributed to the difference in the keratin-degrading ability of the two bacterial strains. The richness of feather hydrolysates has positioned them for agricultural application as biofertilizer (Adelere and Lateef 2019) among a series of applications of microbial degradation of keratins (de Menezes et al. 2021), which enhances soil fertility, promotes the growth of beneficial soil microbiota and stimulate plant growth (Tamreihao et al. 2019).

Effects of feather hydrolysates as biofertilizer on grown vegetables

The application of feather hydrolysates on Corchorus olitorius, Amaranthus caudatus and Celosia argentea led to improved growth and better performances of the vegetables (Fig. 1) after 6 weeks of cultivation. C. olitorius plant treated with 100% FH of Bacillus safensis showed statistically significant higher shoot height (SH), root length (RL), shoot fresh weight (SFW), shoot dry weight (SDW), leaf number (LN), leaf area (LA), and chlorophyll contents (CC) compared to other treatments. However, in Amaranthus caudatus and Celosia argentea, the NPK fertilizer treatment was found to be the best in the same parameters measured. The Bacillus safensis FH and NPK fertilizer activities on the three vegetables were almost similar but they had significantly higher effects than the water treatment (Table 2). The Bacillus safensis FH (100%) boosted the C. olitorius shoot height (68.67 cm), shoot fresh weight (65.05 g) and shoot dry weight (14.33 g) corresponding to 2.64, 5.14 and 4.71-fold improvement over the water-treated plants. It also increased the leaf number, leaf area and chlorophyll content relative to water treatment by 2.15, 2.19 and 2.99-fold, respectively (Table 2). The chlorophyll increment of 1.45-fold was obtained for C. olitorius treated with 100% FH of B. safensis in comparison with NPK treatment. The NPK fertilizer performed optimally in Amaranthus caudatus and Celosia argentea as it boosted the shoot height, shoot fresh weight, shoot dry weight, leaf number and leaf area average by 1.5-fold in comparison with their respective controls.

Similar growth-promoting activities were obtained on the vegetable plants treated with feather hydrolysate of Aquamicrobium defluvii FH 20 (Fig. 1). For the three vegetables, the FH (100%) had higher significant effects in all the evaluated parameters than their respective positive (NPK fertilizer) and negative (water) controls. In C. olitorius, the highest shoot height (70.10 cm), shoot fresh weight (66.91 g), leaf number (19.45) and leaf area (19.35 cm2) corresponding to 2.57, 5.14, 1.95 and 2.17-fold enhancement over the water-treated plants were obtained upon treatment with the FH (Table 3). Furthermore, the FH of A. defluvii enhanced the shoot height, root length, shoot fresh and dry weight, leaf number and leaf area of Amaranthus caudatus and Celosia argentea plants averagely by twofold compared to water-treated plants. FH treatments also performed better than NPK fertilizer treatments in Amaranthus caudatus and Celosia argentea (Table 3). The chlorophyll contents of the vegetables treated with 75 and 100% FH of A. defluvii had higher values than the control plants. In C. olitorius treated with 75 and 100% FH, the chlorophyll was significantly increased by 3.48–4.13 folds compared to the control. At 100% FH application, the chlorophyll contents of the three vegetables were higher than NPK-treated plants, though the differences were not significant.

Generally, FHs of B. safensis and A. defluvii at 100% concentration significantly enhanced the growth characteristics and yield performances of the vegetables than the control and NPK-treated plants. It was only in Amaranthus caudatus and Celosia argentea that the NPK application slightly performed better than Bacillus safensis FH. Also, it was observed that the plant growth-promoting activities of the FHs are dose-dependent as the plant growth characteristics increased with the concentrations of FHs to reach the maximum at the application of 100% FHs.

The potent growth-promoting activities displayed by the FHs on the vegetables could be attributed to their richness in nitrogen, and amino acids or possibly the presence of some plant growth-promoting molecules. There exist several reports on the positive effects of feather hydrolysates on the growth and yield performance of plants. For instance, Jain et al. (2016) reported a significant increase in the growth of wheat upon treatment with feather hydrolysate against the untreated plant. Recently, Gurav et al. (2020) utilized FH obtained from biodegraded poultry feather wastes by Chryseobacterium sp. RBT to enhance the plant height, fruit weight, and leaf chlorophyll content of brinjal and chilli plants by over onefold improvement. An increase in chlorophyll content of the leaf may significantly enhance the photosynthetic process which in turn will promote plant growth. Keratin hydrolysates have been reported to be capable of increasing the growth and biomass productivity of several horticultural crops (Colla et al. 2015) and suitable for agro-industrial applications (Bhari et al. 2021). Aside chicken feathers (Raguraj et al. 2022), FHs as plant growth enhancers are derived from degradation of cattle hooves (Abirami et al. 2020) and human hair (Choudhary et al. 2022).

Protein hydrolysates stimulate nutrient uptake in the plant via an increase in soil microbial activity and soil enzymatic activities, improved micronutrient mobility and solubility and increased root length (Colla et al. 2015). In addition, protein hydrolysates mostly contain precursor molecules for the biosynthesis of important growth-promoting phytohormones (Tamreihao et al. 2019). Also, it had been proposed that feather hydrolysates can enhance the membrane permeability of plant cells to stimulate the uptake of nutrients from the soil (Paul et al. 2013). Thus, the FHs of B. safensis and A. defluvii obtained herein have also demonstrated very remarkable plant growth-promoting ability on the three vegetables which adds to the existing reports on the potential application of feather hydrolysates as organic fertilizers.

More so, the FHs performed averagely better than the conventional NPK fertilizer on the vegetables; hence, the FHs stand a better chance as substitutes to chemical fertilizer for sustainable agricultural food production. This report represents the first reference on the comparative evaluation of the effects of NPK fertilizer and microbial FHs on the cultivation of Corchorus olitorius, Amaranthus caudatus and Celosia argentea.

Effect of feather hydrolysates on nutritional qualities of the vegetables

The proximate compositions of Corchorus olitorius, Amaranthus caudatus and Celosia argentea leaves were improved upon treatments with B. safensis LAU 13 FH (Table 4) when compared with control. The highest values were obtained for crude protein (15.76%), carbohydrate (21.18%), lipid (4.78%) and ash content (13.12%) in the C. olitorius plant treated with FH (100%) over other treatments except for the NPK- and water-treated plants that showed higher crude fibre (8.20%) and moisture content (12.01%), respectively. In Amaranthus caudatus and Celosia argentea, the NPK fertilizer and FH (100%) application improved majorly all the parameters measured over the water-treated plants. The FH treatment resulted in over onefold improvement in crude protein and ash content of both vegetables over their respective controls. Comparatively, NPK fertilizer and FH at higher concentrations equally improved the proximate compositions of Amaranthus caudatus and Celosia argentea with negligible differences.

Similarly, A. defluvii FH demonstrated positive effects on the proximate properties of the three vegetables (Table 5). The effects of FH increased with the concentration as the best results were produced at the highest concentration. The crude protein in the 100% FH-treated C. olitorius, C. argentea, and A. caudatus was 16.31, 16.63 and 16.73% corresponding to 1.17, 1.08 and 1.06-fold improvement compared to their control plants. In addition, the treatment with FH (100%) produced over onefold enhancement of the carbohydrate, crude fibre and ash contents of the three vegetables over their respective controls. The efficacy of FH depreciated as the concentration decreased such that a concentration of 50% below had almost the same effects as the untreated plants. The NPK fertilizer application produced favourable effects on the vegetables as it produced a similar enhancement of the proximate compositions with the feather hydrolysate of A. defluvii.

The applications of B. safensis and A. defluvii FHs improved the nutritional properties of the three vegetables in comparison with the untreated control. The FHs produced a very similar effect with the NPK fertilizer application in the three vegetables. The rise in protein content of the FH-fertilized vegetable plants could be attributed to the richness of the FHs in nitrogen and amino acids which the plants might utilize as a building block for protein synthesis. Recently Gurav et al. (2020) successfully utilized 20% FH obtained through the bioconversion of chicken feather wastes by Chryseobacterium sp. RBT to elevate the protein content of brinjal and chilli fruits by more than 1.2-fold. The application of FH as fertilizer had been reported to enhance the protein content of bananas (Gurav and Jadhav 2013). Similarly, Tamreihao et al. (2019) reported that FHs were capable of improving the nutritional qualities of plants such as protein, amino acids and mineral compositions. The FHs as reported herein do not only promote plant growth and yield performance but remarkably improve the nutritional quality of the vegetables. Thus, the FHs stand a good chance to improve the agronomic and nutritional quality of vegetables in a sustainable agricultural practice.

Antioxidant activities of vegetables grown with feather hydrolysates

The vegetables grown with FHs of B. safensis and A. defluvii exhibited antioxidant activities in a dose-dependent manner. The leaf extract (1 mg/mL) of Corchorus olitorius, Celosia argentea and Amaranthus caudatus grown with 25–100% FH of B. safensis exhibited 29.11–46.39% scavenging activities on DPPH, while the water- and NPK-treated vegetables and ascorbic acid (100 µg/mL) showed 23.12–41.42%, 30.73–42.76% and 46.12% activities, respectively (Table 6). The maximum radical scavenging activities corresponding to 1.96, 1.12 and 1.16-fold enhancement over control (water) were produced by Corchorus olitorius, Celosia argentea and Amaranthus caudatus leaf extracts obtained from 100% FH, respectively. In Corchorus olitorius, Celosia argentea and Amaranthus caudatus treated with 100% FH of B. safensis, higher significant DPPH-scavenging activities were produced by the leaf extracts compared with NPK treatment. The highest hydrogen peroxide radical scavenging activities of 67.65, 75.99 and 60.21% were demonstrated by 100% FH-treated Corchorus olitorius, Celosia argentea and Amaranthus caudatus, respectively, representing 1.35, 1.25 and 1.27-fold improvement compared to the water-treated vegetables. Higher significant peroxide scavenging activities were obtained in the extracts of Corchorus olitorius and Amaranthus caudatus treated with 100% FH of B. safensis compared with NPK treatment. In Celosia argentea, the values were also higher but not statistically significant compared with NPK treatment.

Similar results were obtained on the antioxidant activities of the vegetables cultivated with A. defluvii FH. The FH improved the DPPH-scavenging activities of the three vegetables with optimal activities recorded at 100% FH treatment compared to other treatments. Maximum scavenging activities of 44.21, 43.21 and 39.42% were obtained with Corchorus olitorius, Amaranthus caudatus and Celosia argentea extract (Table 7) equivalent to 1.07, 1.05 and 1.08-fold enhancement over the control (water). The values were significantly higher for Corchorus olitorius and Celosia argentea in comparison with NPK treatment, while Amaranthus caudatus also recorded a higher DPPH-scavenging value but not statistically different from that of NPK. The 100% FH-treated vegetables produced maximum values of 64.43, 76.47 and 61.76% hydrogen peroxide scavenging activities that were significantly better than all other treatments. Generally, the antioxidant activities of the vegetables cultivated with B. safensis and A. defluvii FHs were dose-dependent as the best activities were produced by FHs of 75–100% concentrations. At optimal level, the FHs performed remarkably better than both water and NPK fertilizer in the three vegetables and compete favourably with ascorbic acid (100 µg/ml) that was used as standard.

Living cells are often exposed to free radicals emanating from food metabolism or other factors like exposure to radiation, germs, allergens and other environmental pollutants (Hekimi et al. 2011). Thus, the consumption of healthy foods such as fruits and vegetables with high antioxidant properties is gaining attention. Recently, Gurav et al. (2020) reported that brinjal and chilli fruits cultivated with bacterial feather hydrolysate demonstrated potent DPPH radical scavenging activity of 34.89 and 27.56% compared to values of 28.97 and 23.58% obtained for control plants, respectively. Hydrogen peroxide is toxic to cells because it produces hydroxyl radicals in the cells (Halliwell 1991). Thus, its removal is very important for antioxidant defence in cells or food systems. In this study, the feather hydrolysates have demonstrated immense capabilities to boost the scavenging activities of the three vegetables on both DPPH and H2O2, attesting to their improved functionalities. Thus, consumption of these vegetables will increase their benefits on the health status of the consumers.

Hepatoprotective effect of vegetables grown with the feather hydrolysates

The vegetables induced lipid peroxidation (LPO) inhibition against ferrous ion (Fe2+) damage in the precision-cut liver slices (PCLS). Significant higher LPO inhibitions of 76.24, 76.06 and 77.85% were obtained for Corchorus olitorius, Celosia argentea and Amaranthus caudatus grown with 100% FH of B. safensis, respectively (Table 6). These values corresponded to 1.07, 1.03 and 1.11-fold improvement over their respective water-treated plants (control). The activity of FH is dose-dependent as better LPO inhibition was obtained with the highest dose. The 100% FH treatments on the three vegetables compete favourably with ascorbic acid (100 µg/mL) in LPO inhibition with higher performances, though not statistically significant.

Similarly, A. defluvii FH at the concentration of 100% produced Corchorus olitorius, Celosia argentea and Amaranthus caudatus whose extracts demonstrated significantly higher LPO inhibition better than other FH concentrations and their controls (Table 7). The FH at the concentration of 75–100% induced over 1.0-fold improvement in the LPO inhibitory activity of the three vegetables. Generally, Corchorus olitorius, Celosia argentea and Amaranthus caudatus fertilized with 100% FHs of B. safensis and A. defluvii exhibited LPO inhibitory activities by more than 1.02-fold over NPK fertilized plants. It was observed that the three vegetables treated with the bacterial FHs at the optimal dose exerted LPO inhibition averagely better than ascorbic acid used as standard.

Lipid peroxidation is a process that occurs when free radicals oxidize biomolecules such as lipids, proteins and nucleic acids to induce damage to the biological system (Badmus et al. 2011), thereby causing cancer, cardiovascular and neurodegenerative disease among others. Phytochemical constituents of plants have been reported as scavengers of free radicals and inhibitors of lipid peroxidation (Beutner et al. 2001). High lipid peroxidation inhibitions as demonstrated by FHs-treated vegetables in this study could be ascribed to their richness in antioxidant molecules such as phenolic and flavonoid compounds. Hence, the ability of vegetables fertilized by bacterial FHs to attenuate liver cell damage by ferrous ions suggests their promising application as organic fertilizers to boost the nutraceutical properties of vegetables.

Catalase activities of the vegetables treated with Bacillus safensis FH were remarkably enhanced. Plants treated with 50–100% FH of B. safensis showed higher catalase activities than the water-treated control plants in a dose-dependent manner (Table 6). Corchorus olitorius, Celosia argentea and Amaranthus caudatus cultivated with 100% FH produced optimum significantly different activities of 334.25, 325.14 and 297.33 unit/mg protein, respectively, which represented 1.08, 1.11 and 1.07-fold improvement over water-treated plants. All vegetables grown with 100% FH produced significantly higher catalase activities than NPK-treated plants and the ascorbic acid used as standard except in A. caudatus where a lower value was obtained.

Also, A. defluvii FH produced positive catalase effects in all the vegetables. Plants treated with 75–100% FH exhibited higher catalase activities compared to those treated with water (Table 7). Activities of all vegetables fertilized with 100% FH were significantly better than control plants by more than 1.03-fold. They also displayed significantly higher catalase activities than the positive control (NPK fertilizer) and the ascorbic acid except for A. caudatus whose activity was found below that of ascorbic acid.

Peroxide is a by-product that is continuously generated in the body through metabolic reactions, whose accumulation is toxic to cells and tissues. However, the body often gets rid of it via the secretion of catalase in the mammalian liver. Catalase is an antioxidant enzyme involved in the elimination of oxidants through the reduction of hydrogen peroxide to water and oxygen to prevent tissues from being attacked by hydroxyl radicals (Dasuri et al. 2013). Hence, the consumption of diets that are rich in catalase concentration can be encouraged to attenuate hydroxyl radical activity. The ability of vegetables fertilized by bacterial FHs to display potent catalase activities in the liver homogenate as obtained in this study could be attributed to their high phenolic and flavonoid contents. Thus, consumption of the vegetables will improve antioxidant activity in the body, particularly in detoxifying hydrogen peroxide and preventing of generation of noxious hydroxyl radicals.

Phytochemical compositions of vegetables grown with the feather hydrolysates

Phytochemical constituents of Corchorus olitorius, Celosia argentea and Amaranthus caudatus cultivated with B. safensis FH are shown in Table 8. The total phenolic, flavonoids and total proanthocyanidin contents found in the three vegetables cultivated with the FH ranged from 265.26–372.15 mg/g gallic acid, 57.13–79.21 mg/g catechin and 87.45–152.14 mg/g catechin, respectively. It was observed that the amount of phytochemical constituents increased with the concentration of FH. In C. olitorius, cultivated with 100% FH, the highest total phenols (362.07 mg/g GA), flavonoids (68.14 mg/g CE) and total proanthocyanidin (134.78 mg/g CE) representing 1.30, 1.17 and 1.23-fold improvement over water-treated vegetables were obtained, respectively. More so, the FH at optimal level increased the total phenols, flavonoids and total proanthocyanidin in C. argentea and A. caudatus by more than 1.1-fold compared to control (water). Also, the application of FH at 100% significantly improved the phytochemical constituents of the three vegetables compared to the positive control (NPK fertilizer). The improvements were 3.61–18.01% for flavonoids, 7.17–15.91% for total phenols and 8.52–21.47% for total proanthocyanidin.

Similarly, the application of FH of A. defluvii elevated the phenolic, flavonoids, and total proanthocyanidin contents in the three vegetables. The FH at the concentration of 100% demonstrated potent activity as their vegetables in most cases contained significantly higher amounts of the phytochemicals than other treatments. The highest total phenolics (360.45 mg/g GAE), flavonoids (66.44 mg/g CE) and total proanthocyanidin (125.17 mg/g CE) contents were obtained in C. olitorius grown with 100% FH (Table 9) corresponding to 1.07, 1.08 and 1.04-fold enhancement over the control plants, respectively. C. argentea treated with 100% FH was richer in total phenolics (310.83 mg/g GAE), flavonoids (65.42 mg/g CE) and total proanthocyanidin (124.88 mg/g CE) contents than other treatments. Results were similar in A. caudatus with maximum total phenolics (366.61 mg/g GAE), flavonoids (69.74 mg/g CE) and total proanthocyanidin (139.77 mg/g CE) contents in the 100% FH treatment. Comparatively, the FH of A. defluvii at 100% considerably enhanced the phytochemical constituents of the vegetables more than the NPK- and water-treated plants. At 100% FH, there were improvements of 12.52–16.79%, 6.51–30.75% and 3.04–14.65% for flavonoids, total phenolics and total proanthocyanidin, respectively, when compared with NPK treatment. Antioxidant compounds such as phenolics, flavonoids and proanthocyanidin that are present in leafy vegetables play vital roles in offering protection against the actions of free radicals (Khanam et al. 2012; Sarker et al. 2020).

Authors have reported phytochemical constituents similar to what was obtained in this study. For instance, Zahin et al. (2016) reported 261.4 mg/g GA as the highest phenolic content in Psidium guajava leaf. Similarly, Aryal et al. (2019) estimated 292.65 mg/g GA as the highest phenolic content in Alternanthera sessilis and 39.38 mg/g CE as the peak flavonoid contents found in Portulaca oleracea leaf extract. It is observed that there exists a significant correlation between the antioxidant activities and the phytochemical constituents of the FHs cultivated Corchorus olitorius, Celosia argentea and Amaranthus caudatus. Thus, this study demonstrates that these vegetables are potential sources of natural antioxidants and growing them using FHs as demonstrated herein is a sustainable way of improving their antioxidant capabilities.

Effect of feather hydrolysates on the nutrients and microbiota in the cultivated field

The total organic carbon and ammonium nitrogen contents of the cultivated field before treatment were estimated as 2.31 and 0.47%, respectively. Treatment with FHs of B. safensis LAU 13 and A. defluvii FH 20 enhanced the total organic carbon and nitrogen contents of the soil. FH of B. safensis elevated the total organic carbon and nitrogen contents to 3.21 and 0.61%, while that of A. defluvii improved to 3.09 and 0.59%, respectively. However, NPK fertilizer application increased the initial value of the total organic carbon and nitrogen content of the soil to 2.51 and 0.67%, respectively. Thus, treatment with the bacterial FHs displayed a better effect at increasing the organic carbon of the soil (33.77–38.96%) which may be attributed to the presence of organic products like amino acids, peptides, soluble proteins and enzymes in the hydrolysates. In addition, studies have described FHs obtained through microbial degradation of feather wastes as excellent soil amendment products (Jain et al. 2016) that improved soil fertility owing to their richness in organic carbon and nitrogenous products (Nurdiawati et al. 2019).

Applications of FH and NPK fertilizer considerably improved the microbial quality of the cultivated field. For instance, B. safensis FH used to cultivate Corchorus olitorius, Celosia argentea and Amaranthus caudatus increased the bacterial and fungal loads in the range of 3.98 × 102–5.07 × 105 cfu/g and 1.18 × 102–2.54 × 104 cfu/g, respectively. The FH of Aquamicrobium defluvii used for cultivation of the three vegetables increased the bacterial and fungal loads in the range of 3.83 × 102–1.08 × 105 cfu/g and 1.46 × 102–4.31 × 104 cfu/g, respectively (Table 10). The increase in microbial loads was also recorded for soils treated with NPK fertilizer, but the values are comparatively lower than those obtained for FHs-treated soils. Generally, the FHs treatment increased microbial populations in the range of 101–103 for bacteria and 101–102 for fungi when compared with the final microbial loads obtained for the control (water).

The improved microbial loads of the FHs-treated soils could be attributed to a high amount of organic matter and nitrogenous products in the FHs which stimulates soil microbial activities. For instance, de Menezes et al. (2021) affirmed that keratin hydrolysates being rich in peptides, amino acids and other important products stimulated soil microbial activity which will in turn facilitate the assimilation of nutrients by plants for better growth. More so, the application of feather hydrolysate has been reported to boost microbial activities in barren soil (Jain et al. 2016). The FH could serve as a source of nutrients to stimulate microbial growth in the amended soil (Bhari et al. 2021). Studies have shown that the application of feather hydrolysates as biofertilizers can enhance the activities of plant growth-promoting bacteria in the soil (Bhange et al. 2016) by acting as biostimulants (Kaur et al. 2021). Hence, it is evident that soil treatment with the FHs of B. safensis and A. defluvii resulted in an improved soil ecosystem and microbial community.

Conclusion

In this study, both Aquamicrobium defluvii FH 20 and Bacillus safensis LAU 13 significantly hydrolyzed chicken feathers to produce robust feather hydrolysates that were rich in nitrogen, amino acids and keratinase. Application of 100% FHs mostly enhanced the growth, yield performance and proximate composition of Corchorus olitorius, Celosia argentea and Amaranthus caudatus compared to the control plants. The FHs treatment also improved nitrogen content, organic carbon and microbial activities in the soil. Furthermore, the application of FHs boosted the antioxidant activities of the vegetables to scavenge DPPH and H2O2, and inhibited lipid peroxidation with higher levels of total phenols, flavonoids and total proanthocyanidin compared to control plants. Hence, the FHs can be deployed as organic nitrogen fertilizer to substitute synthetic NPK fertilizer for improved and sustainable production of vegetables. We demonstrate for the first time, the influence of bacterial feather hydrolysates on the growth, nutritional, phytochemical, antioxidant and hepatoprotective activities of Corchorus olitorius, Celosia argentea and Amaranthus caudatus grown on the field. The study is significant in the successful deployment of bacteria for valorization of chicken feathers to produce eco-friendly biofertilizers that can enhance food production in their applications.

Data availability

Data available on reasonable request.

References

Abirami S, Ragavi R, Antony VS (2020) Utilization of keratinolytic Lichtheimia corymbifera AS1 for degradation of cattle hoove—a slaughter house waste to use in plant growth. Biointerface Res Appl Chem 10:6417–6426

Adelere IA, Lateef A (2019) Degradation of keratin biomass by different microorganisms. In: Sharma, S., and Kumar, A. (eds) Keratin as a Protein Biopolymer. Springer Series on Polymer and Composite Materials. https://doi.org/10.1007/978-3-030-02901-2_5. Springer International Publishing AG, Cham, Switzerland. ISBN 978–3–030–02900–5.Pp. 123–162.

Adelere IA, Lateef A (2016a) Keratinases: emerging trends in production and applications as novel multifunctional biocatalysts. Kuwait J Sci 43(3):118–127

Adelere IA, Lateef A (2016b) A novel approach to the green synthesis of metallic nanoparticles: the use of agro-wastes, enzymes and pigments. Nanotechnol Rev 5(6):567–587. https://doi.org/10.1515/ntrev-2016-0024

Adelere IA, Lateef A (2022) Valorization of feather by Bacillus safensis and Aquamicrobium defluvii for growth promotion in leafy vegetables. Waste Biomass Valoriz. https://doi.org/10.1007/s12649-022-01904-9

Adeoye AO, Lateef A (2021) Biotechnological valorization of cashew apple juice for the production of citric acid by a local strain of Aspergillus niger LCFS 5. J Genetic Eng Biotechnol 19:137. https://doi.org/10.1186/s43141-021-00232-0

Adeoye AO, Lateef A (2022) Improving the yield of citric acid through valorization of cashew apple juice by Aspergillus niger: mutation, nanoparticles supplementation and Taguchi technique. Waste Biomass Valoriz 13:2195–2206. https://doi.org/10.1007/s12649-021-01646-0

Afshin A, Sur PJ, Fay KA, Cornaby L, Ferrara G, Salama JS, Mullany EC, Abate KH, Abbafati C, Abebe Z, Murray CJ (2019) Health effects of dietary risks in 195 countries, 1990–2017: a systematic analysis for the global burden of disease study 2017. The Lancet 393(10184):1958–1972. https://doi.org/10.1016/S0140-6736(19)30041-8

Akhter M, Wal Marzan L, Akter Y, Shimizu K (2020) Microbial bioremediation of feather waste for keratinase production: an outstanding solution for leather dehairing in tanneries. Microbiol Insights. https://doi.org/10.1177/1178636120913280

Alahyaribeik S, Sharifi SD, Tabandeh F, Honarbakhsh S, Ghazanfari S (2020) Bioconversion of chicken feather wastes by keratinolytic bacteria. Process Saf Environ Prot 135:171–178. https://doi.org/10.1016/j.psep.2020.01.014

Aryal S, Baniya MK, Danekhu K, Kunwar P, Gurung R, Koirala N (2019) Total phenolic content, flavonoid content and antioxidant potential of wild vegetables from Western Nepal. Plants 8(4):96. https://doi.org/10.3390/plants8040096

Azeez L, Adejumo AL, Lateef A, Adebisi SA, Adetoro RO, Adewuyi S, Tijani KO, Olaoye S (2019) Zero-valent silver nanoparticles attenuate Cd and Pb toxicities on Moringa oleifera via immobilization and induction of phytochemicals. Plant Physiol Biochem 139:283–292. https://doi.org/10.1016/j.plaphy.2019.03.030

Azeez L, Lateef A, Adejumo AL, Adeleke JT, Adetoro RO, Mustapha Z (2020) Adsorption behaviour of Rhodamine B on hen feather and corn starch functionalized with green synthesized silver nanoparticles (AgNPs) mediated with cocoa pods extracts. Chem Afr 3:237–250. https://doi.org/10.1007/s42250-019-00113-7

Badmus JA, Adedosu TO, Fatoki JO, Adegbite VA, Adaramoye OA, Odunola OA (2011) Lipid peroxidation inhibition and antiradical activities of some leaf fractions of Mangifera indica. Acta Pol Pharm 68(1):23–29

Beutner S, Bloedorn B, Frixel S, Hernández Blanco I, Hoffmann T, Martin HD, Mayer B, Noack P, Ruck C, Schmidt M, Walsh R (2001) Quantitative assessment of antioxidant properties of natural colorants and phytochemicals: carotenoids, flavonoids, phenols and indigoids. The role of β-carotene in antioxidant functions. J Sci Food Agric 81(6):559–568

Bhange K, Chaturvedi V, Bhatt R (2016) Ameliorating effects of chicken feathers in plant growth promotion activity by a keratinolytic strain of Bacillus subtilis PF1. Bioresour Bioproc 3:13. https://doi.org/10.1186/s40643-016-0091-y

Bhari R, Kaur M, Singh RS (2021) Chicken feather waste hydrolysate as a superior biofertilizer in agroindustry. Curr Microbiol 78:2212–2230. https://doi.org/10.1007/s00284-021-02491-z

Biswas I, Mitra D, Senapati A, Mitra D, Chattaraj S, Ali M, Das Mohapatra PK (2021) Valorization of vermicompost with bacterial fermented chicken feather hydrolysate for the yield improvement of tomato plant: A novel organic combination. Int J Recycl Organ Waste Agric 10(1):29–42

Bokveld A, Nnolim NE, Digban TO, Okoh AI, Nwodo UU (2021) Chryseobacterium aquifrigidense keratinase liberated essential and nonessential amino acids from chicken feather degradation. Environ Technol. https://doi.org/10.1080/09593330.2021.1969597

Brenner DJ, Krieg NR, Staley JT (2004) Bergey’s manual of systematic bacteriology. 2nd ed, Part B New York, NY: Springer p 323–358

Chatzistathis T, Fanourakis D, Aliniaeifard S, Kotsiras A, Delis C, Tsaniklidis G (2021) Leaf age-dependent effects of boron toxicity in two Cucumis melo varieties. Agronomy 11(4):759. https://doi.org/10.3390/agronomy11040759

Chia WY, Chew KW, Le CF, Lam SS, Chee CSC, Ooi MSL, Show PL (2020) Sustainable utilization of biowaste compost for renewable energy and soil amendments. Environ Poll 267:115662. https://doi.org/10.1016/j.envpol.2020.115662

Choudhary BL, Raha P, Kundu A, Rani M (2022) Replacement of synthetic nitrogenous fertilizer by human hair hydrolysates in cultivation of mung bean (Vigna radiata L.). Waste Biomass Valoriz. https://doi.org/10.1007/s12649-022-01737-6

Cohen G, Dembiec D, Marcus J (1970) Measurement of catalase activity in tissue extracts. Anal Biochem 34(1):30–38. https://doi.org/10.1016/0003-2697(70)90083-7

Colla G, Nardi S, Cardarelli M, Ertani A, Lucini L, Canaguier R, Rouphael Y (2015) Protein hydrolysates as biostimulants in horticulture. Sci Hortic 196:28–38. https://doi.org/10.1016/j.scienta.2015.08.037

Da Silva RR (2018) Keratinases as an alternative method designed to solve keratin disposal on the environment: its relevance on agricultural and environmental chemistry. J Agric Food Chem 66:7219–7221. https://doi.org/10.1021/acs.jafc.8b03152

Dasuri K, Zhang L, Keller JN (2013) Oxidative stress, neurodegeneration, and the balance of protein degradation and protein synthesis. Free Radical Biol Med 62:170–185. https://doi.org/10.1016/j.freeradbiomed.2012.09.016

de Menezes CLA, Santos RDC, Santos MV, Boscolo M, da Silva R, Gomes E, da Silva RR (2021) Industrial sustainability of microbial keratinases: production and potential applications. World J Microbiol Biotechnol 37(5):86. https://doi.org/10.1007/s11274-021-03052-z

du Jardin P (2015) Plant biostimulants: definition, concept, main categories and regulation. Sci Hortic 196:3–14. https://doi.org/10.1016/j.scienta.2015.09.021

Elegbede JA, Lateef A (2018) Valorization of corn-cob by fungal isolates for production of xylanase in submerged and solid state fermentation media and potential biotechnological applications. Waste Biomass Valoriz 9(8):1273–1287. https://doi.org/10.1007/s12649-017-9932-y

Elegbede JA, Lateef A (2019) Optimization of the production of xylanases in corncob-based media by Aspergillus niger and Trichoderma longibrachiatum using Taguchi approach. Acta Biologica Szegediensis 63(1):51–58

Elegbede JA, Ajayi VA, Lateef A (2021) Microbial valorization of corncob: novel route for biotechnological products for sustainable bioeconomy. Environ Technol Inno 24:102073

FAO (2020) Fruit and vegetables–your dietary essentials. Int Year Fruits Veg. https://doi.org/10.4060/cb2395en

Frank SM, Webster J, McKenzie B, Geldsetzer P, Manne-Goehler J, Andall-Brereton G, Houehanou C, Houinato D, Gurung MS, Bicaba BW, Jaacks LM (2019) Consumption of fruits and vegetables among individuals 15 years and older in 28 low-and middle-income countries. J Nutr 149(7):1252–1259. https://doi.org/10.1093/jn/nxz040

Ganesh KS, Sridhar A, Vishali S (2022) Utilization of fruit and vegetable waste to produce value-added products: conventional utilization and emerging opportunities-a review. Chemosphere 287:132221

Gülçin I, Alici HA, Cesur M (2005) Determination of in vitro antioxidant and radical scavenging activities of propofol. Chem Pharm Bull 53(3):281–285. https://doi.org/10.1248/cpb.53.281

Gupta R, Ramnani P (2006) Microbial keratinases and their prospective applications: an overview. Appl Microbiol Biotechnol 70(1):21–33. https://doi.org/10.1007/s00253-005-0239-8

Gurav RG, Jadhav JP (2013) A novel source of biofertilizer from feather biomass for banana cultivation. Environ Sci Pollut Res 20(7):4532–4539. https://doi.org/10.1007/s11356-012-1405-z

Gurav R, Nalavade V, Aware C, Vyavahare G, Bhatia SK, Yang YH, Bapat V, Jadhav J (2020) Microbial degradation of poultry feather biomass in a constructed bioreactor and application of hydrolysate as bioenhancer to vegetable crops. Environ Sci Pollut Res 27(2):2027–2035. https://doi.org/10.1007/s11356-019-06536-6

Halliwell B (1991) Reactive oxygen species in living systems: source, biochemistry, and role in human disease. Am J Med 91(3):S14–S22. https://doi.org/10.1016/0002-9343(91)90279-7

Hassan MA, Abol-Fotouh D, Omer AM, Tamer TM, Abbas E (2020) Comprehensive insights into microbial keratinases and their implication in various biotechnological and industrial sectors: a review. Int J Biol Macromol 154:567–583. https://doi.org/10.1016/j.ijbiomac.2020.03.116

He J, Reddy GV, Liu M, Shi P (2020) A general formula for calculating surface area of the similarly shaped leaves: evidence from six Magnoliaceae species. Global Ecol Conserv 23:e01129

Hekimi S, Lapointe J, Wen Y (2011) Taking a “good” look at free radicals in the aging process. Trends Cell Biol 21(10):569–576. https://doi.org/10.1016/j.tcb.2011.06.008

Hendrick Q, Nnolim NE, Nwodo UU (2021) Chryseobacterium cucumeris FHN1 keratinolytic enzyme valorized chicken feathers to amino acids with polar, anionic and non-polar imino side chain characteristics. Biocatal Agric Biotechnol 35:102109

Jain R, Jain A, Rawat N, Nair M, Gumashta R (2016) Feather hydrolysate from Streptomyces sampsonii GS 1322: a potential low cost soil amendment. J Biosci Bioeng 121(6):672–677. https://doi.org/10.1016/j.jbiosc.2015.11.003

James O, Emmanuel UC (2011) Comparative studies on the protein and mineral composition of some selected Nigerian vegetables. Afr J Food Sci 5(1):22–25. https://doi.org/10.5897/AJFS.9000055

Kaur M, Bhari R, Singh RS (2021) Chicken feather waste-derived protein hydrolysate as a potential biostimulant for cultivation of mung beans. Biologia 76(6):1807–1815. https://doi.org/10.1007/s11756-021-00724-x

Khanam UKS, Oba S, Yanase E, Murakami Y (2012) Phenolic acids, flavonoids and total antioxidant capacity of selected leafy vegetables. J Funct Foods 4(4):979–987. https://doi.org/10.1016/j.jff.2012.07.006

Kshetri P, Roy SS, Sharma SK, Singh TS, Ansari MA, Prakash N, Ngachan SV (2019) Transforming chicken feather waste into feather protein hydrolysate using a newly isolated multifaceted keratinolytic bacterium Chryseobacterium sediminis RCM-SSR-7. Waste Biomass Valoriz 10(1):1–11. https://doi.org/10.1007/s12649-017-0037-4

Kumar J, Yadav R (2020) Keratinolysis of chicken feather and human hair by nondermatophytic keratinophilic fungi isolated from soil. J Appl Nat Sci 12(4):568–574

Kumari M, Kumar J (2020) Chicken feather waste degradation by Alternaria tenuissima and its application on plant growth. J Appl Nat Sci 12(3):411–414

Lateef A, Oloke JK, Gueguim-Kana EB, Sobowale BO, Ajao SO, Bello BY (2010) Keratinolytic activities of a new feather-degrading isolate of Bacillus cereus LAU 08 isolated from Nigerian soil. Int Bioremed Biodegrad 64(2):162–165. https://doi.org/10.1016/j.ibiod.2009.12.007

Lateef A, Oloke JK, Gueguim-Kana EB, Raimi OR (2012) Production of fructosyltransferase by a local isolate of Aspergillus niger in both submerged and solid substrate media. Acta Aliment 41(1):100–117. https://doi.org/10.1556/AAlim.41.2012.1.12

Lateef A, Adelere IA, Gueguim-Kana EB (2015a) Bacillus safensis LAU 13: a new source of keratinase and its multi-functional biocatalytic applications. Biotechnol Biotechnol Equip 29(1):54–63. https://doi.org/10.1080/13102818.2014.986360

Lateef A, Adelere IA, Gueguim-Kana EB (2015b) The biology and potential biotechnological applications of Bacillus safensis. Biologia 70(4):411–419. https://doi.org/10.1515/biolog-2015-0062

Lateef A, Adelere IA, Gueguim-Kana EB, Asafa TB, Beukes LS (2015c) Green synthesis of silver nanoparticles using keratinase obtained from a strain of Bacillus safensis LAU 13. Int Nano Lett 5(1):29–35. https://doi.org/10.1007/s40089-014-0133-4

Liu F, Ng TB (2000) Antioxidative and free radical scavenging activities of selected medicinal herbs. Life Sci 66(8):725–735. https://doi.org/10.1016/S0024-3205(99)00643-8

Mahjoub B, Domscheit E (2020) Chances and challenges of an organic waste-based bioeconomy. Curr Opin Green Sustain Chem 25:100388. https://doi.org/10.1016/j.cogsc.2020.100388

Mason-D’Croz D, Bogard JR, Sulser TB, Cenacchi N, Dunston S, Herrero M, Wiebe K (2019) Gaps between fruit and vegetable production, demand, and recommended consumption at global and national levels: an integrated modelling study. Lancet Planet Health 3(7):e318–e329. https://doi.org/10.1016/S2542-5196(19)30095-6

McDonald S, Prenzler PD, Antolovich M, Robards K (2001) Phenolic content and antioxidant activity of olive extracts. Food Chem 73(1):73–84. https://doi.org/10.1016/S0308-8146(00)00288-0

McLeod S (1973) Studies on wet oxidation procedures for the determination of organic carbon in soils. Notes on Soil Techniques pp 73–79

Mylavarapu RS, Kennelley ED (2002) UF/IFAS extension soil testing laboratory (ESTL) analytical procedures and training manual. University of Florida, Circular, EDIS, p 1248

Ntougias S (2016) Phylogenetic identification and enzyme activities of indigenous bacteria from a landfill stabilization pond. Environ Proc 3(2):341–352. https://doi.org/10.1007/s40710-016-0150-6

Nurdiawati A, Suherman C, Maxiselly Y, Akbar MA, Purwoko BA, Prawisudha P, Yoshikawa K (2019) Liquid feather protein hydrolysate as a potential fertilizer to increase growth and yield of patchouli (Pogostemon cablin Benth) and mung bean (Vigna radiata). Int J Recycl Organ Waste Agric 8(3):221–232. https://doi.org/10.1007/s40093-019-0245-y

Paul T, Halder SK, Das A, Bera S, Maity C, Mandal A, Das PS, Mohapatra PKD, Pati BR, Mondal KC (2013) Exploitation of chicken feather waste as a plant growth promoting agent using keratinase producing novel isolate Paenibacillus woosongensis TKB2. Biocatal Agric Biotechnol 2(1):50–57. https://doi.org/10.1016/j.bcab.2012.10.001

Raguraj S, Kasim S, Md Jaafar N, Nazli MH (2022) Growth of tea nursery plants as influenced by different rates of protein hydrolysate derived from chicken feathers. Agronomy 12(2):299. https://doi.org/10.3390/agronomy12020299

Ramya V, Patel P (2019) Health benefits of vegetables. Int J Chem Stud 7(2):82–87

Reddy CC, Khilji IA, Gupta A, Bhuyar P, Mahmood S, AL-Japairai KAS, Chua GK (2021) Valorization of keratin waste biomass and its potential applications. J Water Proc Eng 40:101707. https://doi.org/10.1016/j.jwpe.2020.101707

Rouphael Y, Colla G (2020) Biostimulants in agriculture. Front Plant Sci 11:40. https://doi.org/10.3389/fpls.2020.00040

Saarela M, Berlin M, Nygren H, Lahtinen P, Honkapää K, Lantto R, Maukonen J (2017) Characterization of feather-degrading bacterial populations from birds’ nests–Potential strains for biomass production for animal feed. Int Biodeterior Biodegradation 123:262–268. https://doi.org/10.1016/j.ibiod.2017.07.006

Sarker U, Oba S (2020) Phenolic profiles and antioxidant activities in selected drought-tolerant leafy vegetable amaranth. Sci Rep 10:18287

Sarker U, Hossain M, Oba S (2020) Nutritional and antioxidant components and antioxidant capacity in green morph Amaranthus leafy vegetable. Sci Rep 10:1336. https://doi.org/10.1038/s41598-020-57687-3

Sarker U, Azam M, Talukder M, Alam Z (2022a) Genetic variation in mineral profiles, yield contributing agronomic traits, and foliage yield of stem amaranth. Genetika 54(1):91–108

Sarker U, Iqbal MA, Hossain MN, Oba S, Ercisli S, Muresan CC, Marc RA (2022b) Colorant pigments, nutrients, bioactive components, and antiradical potential of danta leaves (Amaranthus lividus). Antioxidants 11(6):1206

Sarker U, Oba S, Alsanie WF, Gaber A (2022c) Characterization of phytochemicals, nutrients, and antiradical potential in Slim Amaranth. Antioxidants 11(6):1089

Sarker U, Oba S, Ercisli S, Assouguem A, Alotaibi A, Ullah R (2022d) Bioactive phytochemicals and quenching activity of radicals in selected drought-resistant Amaranthus tricolor vegetable Amaranth. Antioxidants 11(3):578

Sarker U, Rabbani M, Oba S, Eldehna WM, Al-Rashood ST, Mostafa NM, Eldahshan OA (2022e) Phytonutrients, colorant pigments, phytochemicals, and antioxidant potential of orphan leafy Amaranthus species. Molecules 27(9):2899

Sharma S, Gupta A, Kumar A, Kee CG, Kamyab H, Saufi SM (2018) An efficient conversion of waste feather keratin into ecofriendly bioplastic film. Clean Technol Environ Policy 20(10):2157–2167. https://doi.org/10.1007/s10098-018-1498-2

Sobucki L, Ramos RF, Gubiani E, Brunetto G, Kaiser DR, Daroit DJ (2019) Feather hydrolysate as a promising nitrogen-rich fertilizer for greenhouse lettuce cultivation. Int J Recycl Organ Waste Agric 8(1):493–499. https://doi.org/10.1007/s40093-019-0281-7

Sun B, Ricardo-da-Silva JM, Spranger I (1998) Critical factors of vanillin assay for catechins and proanthocyanidins. J Agric Food Chem 46(10):4267–4274. https://doi.org/10.1021/jf980366j

Tamreihao K, Devi LJ, Khunjamayum R, Mukherjee S, Ashem RS, Ningthoujam DS (2017) Biofertilizing potential of feather hydrolysate produced by indigenous keratinolytic Amycolatopsis sp. MBRL 40 for rice cultivation under field conditions. Biocatal Agric Biotechnol 10:317–320. https://doi.org/10.1016/j.bcab.2017.04.010

Tamreihao K, Mukherjee S, Khunjamayum R, Devi LJ, Asem RS, Ningthoujam DS (2019) Feather degradation by keratinolytic bacteria and biofertilizing potential for sustainable agricultural production. J Basic Microbiol 59(1):4–13. https://doi.org/10.1002/jobm.201800434

United Nations (2022). Population. https://www.un.org/en/global-issues/population Accessed on 13 May 2022

Zahin M, Ahmad I, Shireen I, Husain FM, Aqil F (2016) Broad spectrum antioxidant properties of 20 Indian medicinal plants. J Herbs Spices Med Plants 22(2):118–129. https://doi.org/10.1080/10496475.2015.1057888

Zhang RX, Gong JS, Dou WF, Zhang DD, Zhang YX, Li H, Lu ZM, Shi JS, Xu ZH (2016) Production and characterization of surfactant-stable fungal keratinase from Gibberella intermedia CA3-1 with application potential in detergent industry. Chem Pap 70:1460–1470. https://doi.org/10.1515/chempap-2016-0086

Zhishen J, Mengcheng T, Jianming W (1999) The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem 64(4):555–559. https://doi.org/10.1016/S0308-8146(98)00102-2

Acknowledgements

AL appreciates the authority of Ladoke Akintola University of Technology, Ogbomoso, Nigeria, for provision of some facilities used in this study. AIA is grateful to Tertiary Education Trust Fund (TETFund) for PhD sponsorship, and the authority of Federal University of Technology, Minna, Nigeria, for the study leave granted to undertake this study. Farm Help Agrostores, Moniya, Ibadan, Oyo State, is deeply appreciated for the gift of vegetable seeds.

Funding

The study received partial funding through PhD sponsorship of Isiaka Adedayo Adelere by the Tertiary Education Trust Fund (TETFund) through the Federal University of Technology, Minna, Nigeria.

Author information

Authors and Affiliations

Contributions

AL contributed to the study conception and design. Material preparation, data collection and analysis were performed by IAA under supervision by AL. The first draft of the manuscript was written by IAA, and both authors commented on previous versions of the manuscript. Both authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

Authors (Isiaka Adedayo Adelere and Agbaje Lateef) declare that they have no financial or competing interests.

Ethical approval

Human subject was not used in the study. Rat was procured from the institution’s animal house which was maintained according to the recommendations in the Guide for the Care and Use of Laboratory Animals by the National Institutes of Health (Bethesda, Maryland, USA).

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Adelere, I.A., Lateef, A. Application of bacterial feather hydrolysates as biofertilizers in growing leafy vegetables: yield, nutritional, phytochemical, antioxidant and hepatoprotective profiles. Clean Techn Environ Policy 25, 2951–2969 (2023). https://doi.org/10.1007/s10098-023-02540-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-023-02540-0