Abstract

Consuming hygienic and secure food has become challenging for everyone. The preservation of excess food without negatively affecting its nutritional values, shelf life, freshness, or effectiveness would undoubtedly strengthen the food industry. Nanotechnology is a new and intriguing technology that is currently being implemented in the food industry. Metal-based nanomaterials have considerable potential for use in packaging and food processing. These materials have many advanced physical and chemical characteristics. Since these materials are increasingly being used in food applications, there are certain negative health consequences related to their toxicity when swallowed through food. In this article, we have addressed the introduction and applications of metal/metal oxide nanoparticles (MNPs), food processing and food packaging, applications of MNPs-based materials in food processing and food packaging, health hazards, and future perspectives.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The design, development, and use of systems, structures, and technologies through nanoscale atom and molecular manipulation is known as nanotechnology. In general, nanomaterials are known for their particle sizes of less than 100 nm (Agriopoulou et al., 2020; Sim et al., 2021). It is feasible to develop nanomaterials that are considerably distinct from their bulk materials in terms of their mechanical, optical, magnetic, and catalytic properties. The properties of nanomaterials may be changed, when necessary, by carefully regulating the processes of synthesis, size, shape, and functionalization (Baig et al., 2021; Jeevanandam et al., 2018). Nanoparticles (NPs) are generally divided into ceramic, carbon-based, metal/metal oxide-based nanoparticles (MNPs), lipid-based, and polymeric NPs. This general classification is based on their basic physicochemical features (Kumar et al., 2021). Inorganic NPs have been attracted for their advanced features, such as a large surface area, stability, electronic, optical, magnetic, catalytic, and others (Jiang et al., 2017; Tiwari et al., 2022; Valcárcel and López-Lorente, 2014). MNPs have widespread applications in different fields, including information technology, catalysis, electronics, pharmaceuticals, environmental remediation, sensors, and biological and food sciences (Dos Santos et al., 2020; Joshi et al., 2021). MNPs and their composite-based materials have also played a remarkable role in food preservation, protection, and shelf-life enhancement. The incorporation of MNPs in the development of materials with antibacterial characteristics may extend the shelf life of food as well as the qualities of food (Dos Santos et al., 2020). In the food industry, MNPs are used to assist with food preservation, protection, and shelf-life extension. The use of MNPs has made it possible to improve the characteristics of food packaging, such as mechanical strength, permeability, and antibacterial activity. MNPs are employed in food processing, packaging, storage, and laboratory quality control (Couto and Almeida, 2022). Foods are organic materials derived from either plants or animals. Foods become perishable as a result of physical, chemical, or microbiological processes. Food spoilage can affect the colour, nutritional content, texture, and palatability of the food (Alamu and Mooya, 2017). In the food value chain, processing and value addition are essential phases. Food processing cannot be entirely avoided because of the need to feed a growing human population. The demand for processed food is anticipated to rise more as worldwide populations grow (MacDonald and Reitmeier, 2017). Effective packing reduces waste and ensures that the food will be of the desired quality during its entire shelf life. Even though packaging is important for preserving food, it sometimes, and in today’s times, often becomes a source of waste (Gupta and Dudeja, 2017; Robertson, 2005). NPs have been used in food processing to enhance nutritive value, flow characteristics, colour, flavour, and stability, as well as to improve shelf life (Bereka, 2015). The performance of MNPs is generally influenced by their particle size, morphology, surface area, concentration, surrounding medium, and metal ion release. Some health hazards may result from reduced size and increased surface area, the migration of MNPs into food from packaging, and consumer exposure to MNPs (Ashfaq et al., 2022). In order to fulfil customer needs and their commercial adoption to minimise nano-enabled food, the application of nanotechnology needs a uniform regulatory framework and labelling of foods. The usage of MNPs in the food industry has come under scrutiny due to toxicity concerns, which have prompted a number of inquiries concerning prospective adoption (Kumar et al., 2021). As a result, several circumstances must be taken into account while developing and using packing materials (Dash et al., 2022). In this article, we have discussed the introduction of NPs, MNPs, role of MNPs and their nanocomposites in food technology, food processing, food packaging, the health hazards of MNPs, and future perspectives.

NPs and MNPs

NPs show improved physical, chemical, and biological properties due to their larger surface area, improved mechanical strength, functionality, and chemical stability. The shape, size, and structure of the NPs are distinct. They may vary in size from 1 to 100 nm and can have morphologies like cylindrical, spherical, tubular, hollow core, conical, flat, etc. The NPs may be crystalline or amorphous, and they may contain one or more loose or agglomerated crystals. (Ealias and Saravanakumar, 2017; Joudeh and Linke, 2022). There are three possible dimensions of a nanoparticle: zero, one, and two. These materials are attracting the attention of a number of researchers across an array of fields as a result of their extraordinary properties (Khan et al., 2019). Numerous MNPs belong within the scope of inorganic-based nanomaterials. Organic and inorganic NPs can be found in nanoscale objects. The common organic NPs include micelles, ferritin, fullerenes, quantum dots, liposomes, dendrimers, etc. (Khan et al., 2022). Some common inorganic NPs are gold (Au), silver (Ag), copper (Cu), cupric oxide (CuO), zinc oxide (ZnO), cerium oxide (CeO2), titania (TiO2), calcium oxide (CaO), manganese oxide (MnO2), magnesium oxide (MgO), iron oxides etc. (Majhi and Yadav, 2021; Negrescu et al., 2022). Some of the applications of these inorganic NPs are depicted in Fig. 1 (Ahmed et al., 2022; Nikolova and Chavali, 2020; Naseem and Durrani, 2021).

Food processing and food packaging

Food processing is any systematic modification that takes place to a food before it is made available for consumption. Food can be dried or frozen to preserve nutrients and freshness. It might also be more difficult to create a frozen meal with the ideal ratio of ingredients and nutrients (Mihretie et al., 2019). The process of processing food affects all phases of food production, including food making, ingredients, and final products. It extends past the stage where the formulation is premixed into the final product. The various requirements of food producers globally are additionally fulfilled by the adaptability of food processing technologies and solutions (Knorr and Watzke, 2019). The food processing sector has recently become an internationally recognised instance of industrial growth. The past several years has witnessed an enormous rise in production from agriculture, which has resulted in significant revenue and employment (Khan and Singh, 2022). Processed foods, typically regarded as unhealthy, lead to increased food security in terms of nutrition and food (Li et al., 2019). The present-day food sector focuses on food packaging. Good packaging minimises waste and ensures that the food will maintain its intended quality for the duration of its shelf life (Robertson, 2014). Food packaging may pose concerns related to food safety, whereas becoming an essential component of the food business and helping in safe storage. Irradiated packaging materials can introduce harmful non-food substances into the food. The relevant government approves each of these food packaging materials separately and runs them through stringent inspection processes (Gupta and Dudeja, 2017). Packaging materials’ potential for carrying out all of the functions needed by the package depends on both their chemical and physical properties. The most important aspects to take into account in this instance are the transport, mechanical, optical, and chemical characteristics (Berk, 2013).

Role of MNPs in food processing

The need for NPs has been recognised in a number of food science and food microbiology fields, which has resulted in the development of novel applications in the field. These fields are food processing, food safety, food packaging, production of functional foods, distribution of food, food preservation, and the extension of the shelf life of food (Biswas et al., 2022; Singh et al., 2017). MNPs and their nanocomposites show remarkable antimicrobial activities that extend the shelf life of food and food-related products (Dos Santos et al., 2020). In food processing, metal-based nanostructures were mainly utilised as antimicrobials, antioxidants, and nutraceuticals, as well as in nanofiltration (wastewater treatment before release into the environment) (Fig. 2) (Kumar et al., 2021; 2022).

Antimicrobials and antioxidants

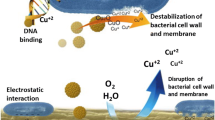

The interaction between MNPs and the cell wall contributes to their antibacterial activity (Fig. 3). This interaction leads to cell destruction, the formation of reactive oxygen species (ROS), the destruction of the cell membrane, DNA and protein damage, etc. (Couto and Almeida, 2022). Gram-positive bacteria are enveloped in a layer of peptidoglycan that creates an intricate network. Gram-positive bacteria often have negatively charged teichoic acids on their cell walls and surfaces. Gram-negative bacteria have an outer membrane made up of phospholipids as well as partially phosphorylated lipopolysaccharides, in addition to a thin layer of peptidoglycan. These lipopolysaccharides help to raise the negative surface charge of the cell envelope. Positively charged MNPs form strong bonds with membranes, leading cell walls to be damaged and, as a result, increasing the permeability of the cells. MNPs are capable of producing ROS, which induce oxidative stress inside the cell. Biomolecules and metal ions typically have a non-specific interaction (Sánchez-López et al., 2020). Particle size, shape, agglomeration, content, and crystallinity are some of the factors that influence the antifungal activities of MNPs. The surface area-to-volume ratio is more favourable for small NPs, which may enhance their antifungal efficiency. The manufacturing by-products can alter the surface chemistry of the NPs, which in turn affects their antifungal activity (Cruz-Luna et al., 2021).

Coupling the antioxidant functional components or captivating the functional bioactivates on the surface of the MNPs represents the best approach for integrating the surface activities of the nanoscaled particles with the antioxidant effects of integrated functional moieties. The antioxidant activities of MNPs are presented in Fig. 4. MNPs may have the ability to function as antioxidants because of their high surface-to-volume ratio (Ge et al., 2022). Antioxidants have a major impact on all biosystems’ efficacy. As biological systems come into contact with molecular oxygen, free radicals are formed (Dobrucka, 2018; Valgimigli et al., 2018). The overproduction of ROS leads to damage to DNA, lipids, carbohydrates, and proteins. Further, ROS also causes oxidative stress. MNPs behave as antioxidants by transferring both hydrogen and a single electron. Total oxyradical scavenging in hydrogen transfer involves the use of a hydrogen atom, whereas single-electron transfer is the reduction of oxidative compounds through an electron donation. Within the cells, free radicals are produced via the process of oxidation (Bhardwaj et al., 2020).

Zorraqun-Pena et al. (2020) reported that Ag NPs have a lot of promise for application in food processing and packaging since they are the nanomaterial with the most potent antibacterial activity. They concluded that Ag NPs have a great potential to destroy different pathogenic bacteria. Espitia et al. (2016) reported the potential use of ZnO NPs as antimicrobial agents in food processing. ZnO is now used as a food additive and is designated by the US Food and Drug Administration as generally recognised as safe. He et al. (2016) reported that MgO NPs have considerable potential as antibacterial agents in food processing due to their structure, surface properties, and stability. The antibacterial activity of MgO NPs is due to their interaction with bacterial cells, which results in oxidative stress and the destruction of the cell membrane. Pop and others (2020) studied the antibacterial behaviour of CeO2 NPs for different Gram-positive and Gram-negative bacteria. The antibacterial activity of CeO2 NPs was conducted against Salmonella typhimurium, Listeria monocytogenes, Escherichia coli, Staphylococcus aureus, and Bacillus cereus. The CeO2 NPs demonstrated efficient antibacterial activity against all five pathogens. The effects of TiO2 NPs on the amount, bioaccessibility, and antioxidant activity of polyphenols in apple juice were examined by Li et al. (2022). The results demonstrated that introducing TiO2 NPs substantially lowered the levels of total polyphenol and the major individual polyphenols in the apple juice as a result of the development of polyphenol-TiO2 NPs charge transfer complex aggregation. The incorporation of TiO2 NPs further reduced apple polyphenols’ bioaccessibility and antioxidant capabilities in a dose-dependent manner. Ajmal et al. (2019) reported the excellent antioxidant and antibacterial activity of biologically synthesised TiO2 NPs. They investigated dose- and size-dependent antioxidant and antibacterial activities. Bhakya et al. (2016) studied the antioxidant activity of Helicteres isora root extract-based AgNPs. Ag NPs had strong antioxidant activity when compared to conventional antioxidants such as butylated hydroxytoluene (BHT) and ascorbic acid. The generation of potential antioxidant AgNPs for commercial use may be effectively accomplished using Helicteres isora root extract. The biocidal characteristics of Ag NPs and the antioxidant and antiaging characteristics of flavonoids in apple extract may be combined to effectively develop a hydrogel, according to a study by Nagaich et al. (2016).

Nutraceuticals

Nutraceuticals, also known as nutritional supplements, are found in food or dietary components that provide health advantages. such as the ability to treat and prevent disease. Nutraceuticals are available in different forms, such as capsules, tablets, powders, tinctures, single ingredients, and combination formulations (Torabally and Rahmanpoor, 2019). “Nutraceuticals” are bioactive substances that are believed to be found in natural products. Prebiotics, probiotics, dietary fibre, polyunsaturated fatty acids, antioxidants, and other varieties of herbal or natural components can all be categorised as foods that are used as nutraceuticals (AlAli et al., 2021; Kumar et al., 2021; Singh et al., 2020). The main functions of nutraceuticals are presented in Fig. 5 (AlAli et al., 2021; Anand and Bharadvaja, 2022; Helal et al., 2019). The delivery of nutraceuticals and bioactive ingredients in functional foods for improving human health has shown significant potential for development through the application of nanotechnology. It might improve the dissolution of micronutrients and bioactive ingredients, improve their bioavailability, and maintain their stability throughout processing, storage, and administration (Chen et al., 2006).

Shamprasad et al. (2022) investigated the effects of Crotalaria juncea extract and Kaempferitrin (KF)-based Ag NPs and Cu NPs on the methicillin-resistant S. aureus planktonic mode of growth. Both NPs have identical destruction kinetics to prevent the infection from spreading and have an impact on the hydrophobicity and permeability of the membrane. When administered KF/AgNPs, the liver’s morphology appeared virtually identical to that of a healthy liver and did not exhibit any significant cytological changes. Afzelin and quercetrin from Crotolaria tetragona were used by Lotha et al. (2018) to synthesise Ag NPs. Against Pseudomonas aeruginosa and Salmonella typhi, AgNPs showed significant bacteriostatic and bactericidal activity. Based on time-kill assays, green-synthesised AgNPs had a bactericidal effect on Salmonella typhi that was equivalent to that of chemically synthesised AgNPs. Fluorescent imaging and SEM imaging demonstrated the antibiofilm capability of AgNPs, which were extremely efficient at sub-MIC concentrations in generating 50% biofilm inhibition against the food-borne pathogen Salmonella typhi. Uresti-Porras et al. (2021) studied the role of ZnO NPs in the interaction with the nutritional composition of bell pepper plants. ZnO NPs have improved the contents of N, P, Mn, Mg, Fe, ascorbic acid, and antioxidant activity. Lydia et al.‘s investigation (2020) revealed that yoghurt was added to Au NPs to improve their nutritional content. The Au NPs were synthesised using Punica granatum L. seed oil. The use of this functional yoghurt in food, nutraceuticals, and medicines might be crucial. In the study by Guo et al. (2015), the Ca alginate NPs loaded with collagen peptide can be exploited as a novel Ca supplement in the food sectors.

Nanofiltration

Nanofiltration (NF) is an energy-efficient membrane separation technology that can successfully reject multivalent ions and organic molecules (Zhang et al., 2022). NF membranes are the membrane technology that is most widely used, and they may be used in the food industry as they are reliable, affordable, and have standardised operations (Yadav et al., 2022). For the fractionation, concentration, and purification of various products and by-products, NF has developed into a technologically and economically appealing operation in the food processing sector (Cassano et al., 2019; Mohammad et al., 2019). The major applications of NF in different food sectors are presented in Table 1.

Wastewater discharged during food processing and other food-related operations may include a variety of organic and inorganic pollutants. This polluted wastewater is cleaned up using MNPs-based nanomaterials before it is released into the environment. One of the emerging techniques for the removal of organic and inorganic contaminants in surface water is nanofiltration (NF) (Didi, 2021; Shon et al., 2013). NF has been considered a potential separation method for producing potable water in recent decades (Guo et al., 2022). MNPs-based materials have been successfully used to remove organic and inorganic pollutants and microbes from wastewater (Naseem and Durrani, 2021). The following metal-based nanocomposites (Table 2) can be used in the treatment of wastewater released after food processing and containing different organic and inorganic contaminants:

Applications of MNPs in food packaging

Food degradation causes a significant risk, rendering it inappropriate for customers to purchase. Packaging is essential for handling food properly and preserving its quality. Protection, convenience, containment, and communicating with consumers are the four primary purposes of traditional food packaging (Ashfaq et al., 2022). Nanomaterials have received a lot of attention in the last decade due to their outstanding features that make them unique in applications for food packaging as they improve thermal, mechanical, and gas barrier capabilities (Chaudhary et al., 2020). In food packaging, nanomaterials can be used for improved as well as active packaging. The main functions of packaging are to increase shelf life and nutrient contents (Chadha et al., 2022). MNPs-based nanomaterials have many improved properties and great potential for food packaging (Nikolic et al., 2021). The main advantages of MNPs-based nanomaterials in food packaging are presented in Fig. 6 (Adeyeye and Ashaolu, 2021; Coman, 2019; Kumar et al., 2021).

Common MNPs-based nanomaterials used in food packaging

MNPs are a good candidate for food packaging due to their improved physicochemical properties, including a large surface area and antibacterial properties (Adeyemi et al., 2023). MNPs have the capacity to destroy microorganisms through different mechanisms and to prevent the growth of biofilms (Couto and Almeida, 2022). Potential health risks may arise due to the migration of very small-sized MNPs into food from packaging and consumer exposure to nanoparticles (Ashfaq et al., 2022). The development of regulatory frameworks and strategies for assessing specific biosafety risks remains a difficult task that requires in-depth study (Couto and Almeida, 2022). Some of important MNPs used in food packaging are described below:

TiO2

Titanium dioxide nanoparticles (TiO2 NPs) are manufactured in large quantities throughout the world due to their use in a large number of applications. TiO2 NPs differ in their physicochemical properties from their fine particle counterparts (Shi et al., 2013). The four common and popular TiO2 polymorphs are anatase (tetragonal), rutile (tetragonal), brookite (orthorhombic), and TiO2 (B) (monoclinic) (Gupta and Tripathi, 2011). TiO2-NPs are commonly used in sensors, antimicrobial agents, photocatalysis, food additives, and cosmetics (Sagadevan et al., 2022). TiO2 has photocatalytic capabilities that make it capable of destroying microorganisms whenever exposed to light. The inactivation of microorganisms is facilitated by hydroxyl radicals and ROS that develop on the illuminated TiO2 surface. TiO2 NPs may be used to coat food packaging materials, producing effective antimicrobial coatings that can maintain food quality, improve shelf life, and ensure food safety (Othman et al., 2014).

Othman et al. (2014) reported the food packaging properties of TiO2 coated low density polyethylene (LDPE) film. The antimicrobial activity of TiO2/LDPE has been investigated against Escherichia coli under different conditions. The developed film has the potential to be used to package food, extending its shelf life while maintaining its quality and safety. Hosseinzadeh and others (2020) studied the TiO2/chitosan-based film for effective packaging of meat. The meat’s physicochemical, microbiological, and other characteristics were evaluated after a 10-day packing. The synthesised material was found to be effective for the storage of the meat. Tang et al. (2018) reported functional Au-TiO2 nanocomposites in antibacterial sodium alginate film for food packaging. When exposed to light, the antibacterial properties of the Au-TiO2/sodium alginate composite film have been improved by around 60% and 50% against Staphylococcus aureus and Escherichia coli, respectively. The composite film has excellent potential for use in the food packaging industry due to its degradable and antibacterial characteristics. The food packaging properties of PVA/cellulose nanocrystals (CNC)/TiO2 have been investigated by Van Nguyen and Lee (2022). PVA/CNC/TiO2 films significantly avoided weight loss and deterioration in packaging experiments with fresh garlic, demonstrating the promising potential of PVA/CNC/TiO2 nanocomposites for food-packing applications. Youssef et al. (2023) studied the food packaging ability of TiO2/low-density polyethylene (P-LDPE). On the basis of antimicrobial behaviour, mechanical properties, and permeability measurements, the synthesised nanocomposite has excellent potential for food packaging. Bodaghi and Hagh (2019) have used a clay/TiO2-nanocomposite coating and found its feasibility to lower the risk of infections and contamination while also enhancing the maintenance of pear fruit quality. Zandi et al. (2020) reported the food packaging capabilities of TiO2/ZnO/LDPE nanocomposite for packaging of fresh apple and grape fruits. The LDPE nanocomposite-based material with nanoparticles of TiO2 and ZnO might extend the shelf life of apples and grapes during production and distribution. Chitosan/TiO2 nanocomposite was developed by Kustiningsih et al. (2019) for packaging and its capacity to render Staphylococcus aureus inactive. After a 24-hour incubation period, there were no Staphylococcus aureus bacteria in the chitosan-TiO2 nanocomposite.

ZnO

Zinc oxide (ZnO) is a white-coloured and very common transition metal oxide. ZnO is frequently used in the cement, glass, batteries, ceramics, paint, lubricants, plastics, pigments, and food industries. ZnO NPs have potential applications in wastewater treatment, electronics, solar cells, textiles, cosmetics, and food packaging (Gudkov et al., 2021; Pushpalatha et al., 2022; Song et al., 2023). The application of ZnO/cellulose/PVA/polyphenol-based nanocomposite in food packaging has been investigated by Song et al. (2023). Gram-negative Escherichia coli and Gram-positive Staphylococcus aureus were used to determine the antibacterial activity, and their respective inhibition zones were 4.4 and 6.3 mm. The suggested nanocomposite might be a potential material for the packaging sector due to its improved performance and ease of degradation. ZnO/poly(butylene adipate-co-terephthalate) (PBAT) has been reported by Venkatesan et al. (2017) for food packaging. Based on PBAT and ZnO NPs, antimicrobial films were developed. The mechanical and thermal stability of the nanocomposites have significantly increased. The PBAT/ZnO nanofilms have excellent antibacterial activity against Staphylococcus aureus and Escherichia coli. Jamali et al. (2023) investigated the efficacy of a biodegradable film for food packaging comprised of PVA and ZnO. The results indicate that introducing ZnO-NPs to PVA biofilms increases the stability of the biofilms. Physical and mechanical properties were significantly improved. An in-depth analysis of fruit quality, related features, and biofilm stability was discussed. Li and coworkers (2011) studied in vitro and in vivo the antimicrobial packing of ZnO/polyvinyl chloride (PVC) films against Escherichia coli. The film’s inhibitory action increased with the amount of ZnO nanostructure. On the basis of these findings, the nano-ZnO-coated film shows great potential for making antimicrobial packaging resistant to Escherichia coli and lowering the risk of microbial growth on freshly cut fruit. Ali and Hameed 2022) reported the food packaging capability of ZnO/TiO2/cellulose acetate-based nanocomposite film. The developed films’ superior wettability and antibacterial activity suggest they may be used in the packaging industry. Rihayat et al. (2019) studied the role of PLA (poly lactic acid)/ZnO/chitosan nanocomposite in antimicrobial food packaging. Nanocomposites were found to be efficient for inactivating Escherichia coli and Staphylococcus aureus, based on antimicrobial evaluation.

Al2O3

The common forms of aluminium oxides are α-, β-, and γ- Al2O3. α-Al2O3 is also known as alumina; on heating aluminium hydroxides approximately at 400 °C, γ-Al2O3 is formed. The irreversible transformation from γ- to α-Al2O3 takes place after heating at temperatures greater than 1100 0C. β-Al2O3 is a mixture of aluminates of alkali and alkaline earth metals. It contains a comparatively higher amount of aluminium oxide (Gudkov et al., 2022). Nano-aluminium oxide-based materials are also a potential candidate for food packaging in the food industry (Tavakolian et al., 2021; Yakdoumi et al., 2020; Simakin et al., 2022; Shittu et al., 2014; Burmistrov et al., 2022). Al2O3, SiO2, and carboxymethyl cellulose (CMC)-based nanofilms were investigated by Tavakolian et al. (2021) for their potential as food packaging materials. The effectiveness of food packaging systems has been shown to be improved by incorporating core-shell NPs into the matrix of polymeric films (CMC). Yakdoumi and others (2020) reported polylactic acid (PLA), aluminium oxide (Al2O3), and titanium dioxide (TiO2)-based nanofilms. The nanofilm was more efficient than each of its two components in inhibiting the development of Pseudomonas aeruginosa and Escherichia coli, respectively. Eco-friendly and biodegradable packaging materials based on poly(lactic)-co-glycolic acid (PLGA) and Al2O3 NPs have been reported by Simakin et al. (2022). The developed nanocomposite is a desirable option for use as a food packaging material due to its regulated mechanical characteristics, excellent antibacterial activity, and high biocompatibility. Chitosan and alumina-based nanocomposite for food packaging have been reported by Shittu et al. (2014). The films’ resistance under high moisture conditions to microbial degradation has been improved by the incorporation of Al2O3. The availability and outstanding biocompatibility of aluminium oxide nanoparticles make them a viable choice for coatings (Burmistrov et al., 2022). These coatings are intended to prevent the inevitable micro-damages to surfaces that take place during food processing, in addition to giving surfaces an antibacterial surface effect.

Ag

Silver nanoparticles (Ag NPs) show excellent antimicrobial activities (Siddiqi et al., 2018). Ag NPs are currently used progressively in industrial, consumer, medicinal, food, and other uses. These NPs show improved optical, electrical, thermal, and biological properties (Zhang et al., 2016). In order to be used in food packaging, Ag NPs must exhibit high stability and slow silver ion release rates in stored foods (Zorraquín-Peña et al., 2020). Kowsalya et al. (2021) proposed a biodegradable gelatin/Ag nanocomposite-based film for food packaging. An improvement in the mechanical and barrier characteristics of nanocomposite films has been shown by Ag NPs inclusion. The film based on gelatin and Ag NPs has extended the shelf life of sapodilla fruits. Agar/Ag-based nanocomposite films were developed by Basumatary et al. (2018) for use in food packaging. The antibacterial properties and other physical properties have been improved by the addition of Ag NPs. The composite films may help shield wrapped (packaged) food items from UV radiation. Aeromonas hydrophilla, a Gram-negative foodborne pathogen, was successfully destroyed by the composite films. De Moura and coworkers (2012) reported a nanocomposite made of Ag NPs and hydroxypropyl methylcellulose (HPMC) for food packaging. In a disc diffusion study against E. coli and S. aureus, the antibacterial efficacy of HPMC/Ag thin films was assessed based on the diameter of the inhibitory zone. A hybrid nanocomposite film made of chitosan, gelatin, polyethylene glycol, and Ag NPs was developed by Kumar et al. (2018). Based on the packaging for red grapes, the hybrid film improved the fruit’s shelf life. As a result, the findings of the current study might be investigated more thoroughly for developing effective and economically feasible packaging materials for food applications. Bumbudsanpharoke et al. (2018) reported the use of Ag and low-density polyethylene (LDPE)-based nanocomposite in food packaging. In addition to increased mechanical and other features, the LDPE/Ag nanocomposite film demonstrated efficient antibacterial action against Escherichia coli and Staphylococcus aureus. On the basis of these findings, it may be feasible to employ LDPE/Ag nanocomposite film in food packaging to maintain food quality and increase shelf life.

CuO

CuO nanoparticles (CuO NPs) are used mostly as antibacterial agents. They have attracted a lot of attention due to their applications in energy storage, pharmaceuticals, sensors, catalysis, the food industry, etc. CuO NPs show distinctive electrical, optical, and magnetic properties (Dagher et al., 2014; Devi et al., 2014; Zhang et al., 2014). Sodium alginate (SA)/cellulose nanowhisker (CNW)/CuO-based nanofilm for food packaging applications was reported by Saravanakumar et al. (2020). The film has shown significant antioxidant and antimicrobial activities against Escherichia coli and Staphylococcus aureus, and Candida albicans. The findings indicate that the food sector may employ SA/CNW/CuO in order to reduce the drawbacks of conventional food packaging. The gelatin/CuO-based nanofilm was reported by Gvozdenko et al. (2022). Based on the results, both as an independent nanofilm and as a component of other packaging materials, the gelatin/Cuo-based nanofilm offers great potential for usage in food packaging. Esmailzadeh et al. (2021) have studied nanocomposites based on CuO and ZnO for application in antibacterial food packaging. Bacillus subtilis and Enterobacter aerogenes have been selected as targets of the antimicrobial activities. Nanocomposites comprising ZnO and CuO have a strong antibacterial activity, which makes them suitable for use in food packaging. Bumbudsanpharoke et al. (2023) used the poly(butylene adipate-co-terephthalate) (PBAT)/thermoplastic starch (TPS)/CuO-based nanofilm as eco-friendly and biodegradable food packaging material. The water vapour barrier characteristic of the film was enhanced by the addition of CuO NPs. The bionanocomposite material effectively reduced the growth of Escherichia coli because of its antibacterial properties. The results of the study indicate that it is feasible to manufacture and utilise the PBAT/TPS/CuO bionanocomposite film in food packaging to maintain food quality and increase shelf life.

Active and intelligent food packaging

The term “active packaging” denotes an approach in which the food’s shelf life improves via interaction among the product, packaging, and surrounding environment. Active packaging helps to extend product shelf life as well as prevent microbial growth, oxidation of lipids, moisture loss, food contamination, etc. It involves technologies that actively absorb or release molecules from the food or the headspace of food packaging. Intelligent packaging technologies make accessible to consumers information on the condition of the food or its surroundings. It is a growth in the communication aspect of traditional packaging and communicates with the consumer based on its ability to observe, experience, and maintain track of changes in the environment surrounding the product (Ghoshal, 2018; Papargyri et al., 2005; Pereira de Abreu et al., 2012). Because of their incorporation into packaging systems or materials, active and intelligent packaging systems are expected to have a promising future (Biji et al., 2015). These packaging systems have received a lot of attention in the dairy, bakery, confectionary, meat, and seafood industries (Bhardwaj et al., 2022). An outline diagram of active and smart, or intelligent, packaging systems is presented in Figs. 7 and 8 (Bayram et al., 2021; Velázquez-Contreras et al., 2022; Vilela et al., 2018). Table 3 presents the MNPs-based materials which have been successfully employed in active and intelligent packaging (Abdolsattari et al., 2022; Alghamdi et al., 2022; Ballesteros et al., 2022; Eskandarabadi et al., 2019; Fathi et al., 2022; Liu et al., 2021; Motelica et al., 2020; Mousazadeh et al., 2021; Sarapulova et al., 2015; Sobhan et al., 2020; Wu et al., 2018; Yu et al., 2021).

MNPs and health hazards

The significance of MNPs for a number of industries is widely reported (Khan et al., 2021). Due to their unexpected interactions with many biological systems and cellular processes, the unique characteristics of synthetic nanomaterials not only confer significant advantages but also adverse effects (Gupta and Xie, 2018). MNPs are going to be released into the environment or come into direct contact with humans due to their widespread application. As a consequence, the potential risks they pose to the environment and human health have drawn increased attention. MNPs may enter the body through inhalation, the skin, or the gastrointestinal tract and circulate through the blood or lymphatic system; further, they accumulate in different organs (Sengul and Asmatulu, 2020; Yao et al., 2019). Table 4 presents several major health risks that tend to arise in humans due to MNPs, which are generally used in food processing and packaging.

Future perspectives

Food processing and food packaging have a special role in today’s era. The main objective of all these is to provide hygienic and nutritious food to the people. MNPs-based nanomaterials have made a substantial contribution to the advancement of higher-quality, safer, and healthier food products as well as food packaging. Applications of food processing and packaging are constantly evolving as a result of safety concerns and consumer awareness. There are risks to human health and the environment when certain hazardous materials are frequently used. The advancement of nanotechnology opened up new potential for improvements in a wide range of industrial applications. The food sector has been influenced by nanotechnology in a variety of ways, such as processed and packaged food. Industries have been working on NPs that will impact food safety and provide health benefits. The use of antimicrobial MNPs-based nanomaterials in the food industry helps protect food against harmful and spoilage-causing bacteria, increase shelf life, and enhance freshness. The toxicity risk associated with NPs for human health may exist. Therefore, it is advised that an effective regulatory system be established to deal with any health issues related to applications of nanotechnology.

Growing demand for a broader range of foods has given rise to developments in food processing and packaging technologies. Nanotechnology has given the food sector encouragement with its advancements in food processing and packaging. The use of MNPs in food packaging intends to enhance the safety of food items from different pathogenic microorganisms. MNPs have demonstrated lots of promise for extending the shelf life of food, preserving nutritious content, and enhancing safety. MNPs are the nanomaterials with the best antimicrobial behaviour, therefore receiving great attention in food packaging. These nanoparticles have the potential to be used with other conventional food packaging materials. However, both advantages and hazards need to be carefully considered. Investigation continues to be required to develop regulatory frameworks and provide techniques for biosafety risk assessment.

Data availability

Data is contained within the article.

References

Abdolsattari P, Rezazadeh-Bari M, Pirsa S. Smart film based on polylactic acid, modified with polyaniline/ZnO/CuO: Investigation of physicochemical properties and its use of intelligent packaging of orange juice. Food and Bioprocess Technology. 15: 2803-2825 (2022)

Adeyemi JO, Fawole OA. Metal-based nanoparticles in food packaging and coating technologies: a review. Biomolecules. 13: 1092 (2023)

Adeyeye SAO, Ashaolu TJ. Applications of nano-materials in food packaging: A review. Journal of Food Process Engineering. 44: e13708 (2021)

Agriopoulou S, Stamatelopoulou E, Skiada V, Tsarouhas P, Varzakas T. Emerging nanomaterial applications for food packaging and preservation: safety issues and risk assessment. Sroceedings. 7: 70 (2020)

Ahmed S, Ahshan KN, Mondal MNA, Hossain S. Application of metal oxides-based nanofluids in PV/T systems: a review. Frontiers in Energy. 16, 397-428 (2022)

Ajmal N, Saraswat K, Bakht MA, Riadi Y, Ahsan MJ, Noushad M. Cost-effective and eco-friendly synthesis of titanium dioxide (TiO2) nanoparticles using fruit’s peel agro-waste extracts: characterization, in vitro antibacterial, antioxidant activities. Green Chemistry Letters and Reviews. 12: 244-254 (2019)

AlAli M, Alqubaisy M, Aljaafari MN, AlAli AO, Baqais L, Molouki A, Abushelaibi A, Lai K-S, Lim S-HE. Nutraceuticals: transformation of conventional foods into health promoters/disease preventers and safety considerations. Molecules. 26: 2540 (2021)

Alamu EO, Mooya A. (2017) Food processing technologies and value addition for improved food safety and security. In: Smart Technologies for Sustainable Smallholder Agriculture. Academic Press, Cambridge, pp. 201-210.

Alghamdi HM, Abutalib MM, Mannaa MA, Nur O, Abdelrazek EM, Rajeh A. Modification and development of high bioactivities and environmentally safe polymer nanocomposites doped by Ni/ZnO nanohybrid for food packaging applications. Journal of Materials Research and Technology. 19: 3421-3432 (2022)

Ali HA, Hameed NJ. Preparation of cellulose acetate nanocomposite films based on TiO2-ZnO nanoparticles modification as food packaging applications. Journal of Applied Science and Nanotechnology. 2: 115-125 (2022)

Anand S, Bharadvaja N. Potential benefits of nutraceuticals for oxidative stress management. Revista Brasileira de Farmacognosia. 32: 211-220 (2022)

Ashfaq A, Khursheed N, Fatima S, Anjum Z, Younis K. Application of nanotechnology in food packaging: Pros and Cons. Journal of Agriculture and Food Research. 7: 100270 (2022)

Baig N, Kammakakam I, Falath W. Nanomaterials: A review of synthesis methods, properties, recent progress, and challenges. Materials Advances. 2: 1821-1871 (2021)

Ballesteros LF, Lamsaf H, Sebastian CV, Cerqueira MA, Pastrana L, Teixeira JA. Active packaging systems based on metal and metal oxide nanoparticles. pp. 143-181. In: Nanotechnology-Enhanced Food Packaging. Parameswaranpillai J, Krishnankutty RE, Jayakumar A, Rangappa SM, Siengchin S. Wiley, India. (2022)

Basumatary K, Daimary P, Das SK, Thapa M, Singh M, Mukherjee A, Kumar S. Lagerstroemia speciosa fruit-mediated synthesis of silver nanoparticles and its application as filler in agar based nanocomposite films for antimicrobial food packaging. Food Packaging and Shelf Life. 17: 99-106 (2018)

Bayram B, Ozkan G, Kostka T, Capanoglu E, Esatbeyoglu T. Valorization and application of fruit and vegetable wastes and by-products for food packaging materials. Molecules. 26: 4031 (2021)

Bereka MM. Nanotechnology in food industry; advances in food processing, packaging and food safety. International Journal of Current Microbiology and Applied Sciences. 4: 345-357 (2015)

Berk Z. Food packaging. Food process engineering and technology. Elsevier, Amsterdam, pp. 621-636 (2013)

Bhakya S, Muthukrishnan S, Sukumaran M, Muthukumar M. Biogenic synthesis of silver nanoparticles and their antioxidant and antibacterial activity. Applied Nanoscience. 6: 755-766 (2016)

Bhardwaj K, Dhanjal DS, Sharma A, Nepovimova E, Kalia A, Thakur S, Kuča K. Conifer-derived metallic nanoparticles: Green synthesis and biological applications. International Journal of Molecular Sciences. 21: 9028 (2020)

Bhardwaj A, Sharma N, Sharma V, Alam T, Shafia S. Smart Food Packaging Systems. In: Smart and Sustainable Food Technologies. Sehgal S, Singh B, Sharma V. Springer, Singapore. (2022)

Biji KB, Ravishankar CN, Mohan CO, Srinivasa Gopal TK. Smart packaging systems for food applications: a review. Journal of Food Science and Technology. 52: 6125-6135 (2015)

Biswas R, Alam M, Sarkar A, Haque MI, Hasan MM, Hoque M. Application of nanotechnology in food: Processing, preservation, packaging and safety assessment. Heliyon. 8: e11795 (2022)

Bodaghi H, Hagh ZG. Application of clay-TiO2 nanocomposite packaging films on pears (Prunus communis L. cv. Williams) under cold storage. Journal of Food Measurement and Characterization. 13: 2377-2388 (2019)

Bumbudsanpharoke N, Lee W, Ko S. A comprehensive feasibility study on the properties of LDPE-Ag nanocomposites for food packaging applications. Polymer Composites. 39: 3178-3186 (2018)

Bumbudsanpharoke N, Harnkarnsujarit N, Chongcharoenyanon B, Kwon S, Ko S. Enhanced properties of PBAT/TPS biopolymer blend with CuO nanoparticles for promising active packaging. Food Packaging and Shelf Life. 37: 101072 (2023)

Burmistrov DE, Serov DA, Simakin AV, Baimler IV, Uvarov OV, Gudkov SV. A polytetrafluoroethylene (PTFE) and Nano-Al2O3 based composite coating with a bacteriostatic effect against E. coli and low cytotoxicity. Polymers. 14: 4764 (2022)

Cassano A, Conidi C, Castro-Muñoz R. Current and future applications of nanofiltration in food processing. In: Galanakis CM (ed). Separation of functional molecules in food by membrane technology. . Academic Press, Cambridge, pp 305-348 (2019)

Chadha U, Bhardwaj P, Selvaraj SK, Arasu K, Praveena S, Pavan A, Khanna M, Singh P, Singh S, Chakravorty A, Badoni B, Banavoth M, Sonar P, Paramasivam V. Current trends and future perspectives of nanomaterials in food packaging application. Journal of Nanomaterials. (2022) https://doi.org/10.1155/2022/2745416

Chaudhary P, Fatima F, Kumar A. Relevance of nanomaterials in food packaging and its advanced future prospects. Journal of Inorganic and Organometallic Polymers and Materials. 30: 5180-5192 (2020)

Chen H, Weiss J, Shahidi F. Nanotechnology in nutraceuticals and functional foods. Food Technology. 60: 30-36 (2006)

Coman C. Nanostructured colloids in food science. In: Milani JM (ed). Some New Aspects of Colloidal Systems in Foods. IntechOpen, London (2019)

Couto C, Almeida A. Metallic nanoparticles in the food sector: A mini-review. Foods. 11: 402 (2022)

Cruz-Luna AR, Cruz-Martínez H, Vásquez-López A, Medina DI. Metal nanoparticles as novel antifungal agents for sustainable agriculture: Current advances and future directions. Journal of Fungi. 7: 1033 (2021)

Dagher S, Haik Y, Ayesh AI, Tit N. Synthesis and optical properties of colloidal CuO nanoparticles. Journal of Luminescence. 151: 149-154 (2014)

Dash KK, Deka P, Bangar SP, Chaudhary V, Trif M, Rusu A. Applications of inorganic nanoparticles in food packaging: A Comprehensive Review. Polymers. 14: 521 (2022)

De A, Ghosh S, Chakrabarti M, Ghosh I, Banerjee R, Mukherjee A. Effect of low-dose exposure of aluminium oxide nanoparticles in Swiss albino mice: Histopathological changes and oxidative damage. Toxicology and Industrial Health. 36: 567-579 (2020)

De Moura MR, Mattoso LH, Zucolotto V. Development of cellulose-based bactericidal nanocomposites containing silver nanoparticles and their use as active food packaging. Journal of Food Engineering. 109: 520-524 (2012)

Devi AB, Moirangthem DS, Talukdar NC, Devi MD, Singh NR, Luwang MN. Novel synthesis and characterization of CuO nanomaterials: Biological applications. Chinese Chemistry Letters. 25: 1615-1619 (2014)

Didi MA. Treatment of wastewater by nanofiltration. In: Moujdin IM, Summers JK (ed). Promising Techniques for Wastewater Treatment and Water Quality Assessment. IntechOpen, London (2021)

Dobrucka R. Antioxidant and catalytic activity of biosynthesized CuO nanoparticles using extract of galeopsidis herba. Journal of Inorganic and Organometallic Polymers and Materials. 28: 812-819 (2018)

Dos Santos CA, Ingle AP, Rai M. The emerging role of metallic nanoparticles in food. Applied Microbiology and Biotechnology. 104: 2373-2383 (2020)

Ealias AM, Saravanakumar MP. A review on the classification, characterisation, synthesis of nanoparticles and their application. In: IOP Conference Series: Material Science and Engineering. (2017)

Elshama SS, Abdallah ME, Abdel-Karim RI. Zinc oxide nanoparticles: therapeutic benefits and toxicological hazards. The Open Nanomedicine and Nanotechnology Journal. 5: 16-22 (2018)

Eskandarabadi SM, Mahmoudian M, Farah KR, Abdali A, Nozad E, Enayati M. Active intelligent packaging film based on ethylene vinyl acetate nanocomposite containing extracted anthocyanin, rosemary extract and ZnO/Fe-MMT nanoparticles. Food Packaging and Shelf Life. 22: 100389 (2019)

Esmailzadeh H, Sangpour P, Shahraz F, Eskandari A, Heijazi J, Khaksar R. CuO/LDPE nanocomposite for active food packaging application: a comparative study of its antibacterial activities with ZnO/LDPE nanocomposite. Polymer Bulletin. 78: 1671-1682 (2021)

Espitia PJP, Otoni CG, Soares NFF. Zinc oxide nanoparticles for food packaging applications. In: Barros-Velázquez J (ed). Antimicrobial food packaging. Academic Press, Cambridge, pp. 425-431. (2016)

Fathi M, Samadi M, Abbaszadeh S, Nourani MR. Fabrication and characterization of multifunctional bio-safe films based on carboxymethyl chitosan and saffron petal anthocyanin reinforced with copper oxide nanoparticles for sensing the meat freshness. Journal of Polymers and the Environment. 30: 4538-4549 (2022)

Ferdous Z, Nemmar A. Health impact of silver nanoparticles: A review of the biodistribution and toxicity following various routes of exposure. International Journal of Molecular Sciences. 21: 2375 (2020)

Ge X, Cao Z, Chu L. The antioxidant effect of the metal and metal-oxide nanoparticles. Antioxidants (Basel). 11: 791 (2022)

Ghoshal G. Recent trends in active, smart, and intelligent packaging for food products. pp. 343–374. In: Food packaging and preservation. Grumezescu AM, Holban AM. Academic Press. (2018)

Grande F, Tucci P. Titanium dioxide nanoparticles: A risk for human health? Mini Reviews in Medicinal Chemistry. 16: 762-769 (2016)

Gudkov SV, Burmistrov DE, Serov DA, Rebezov MB, Semenova AA, Lisitsyn AB. A mini review of antibacterial properties of ZnO nanoparticles. Frontiers in Physics. 9: 641481 (2021)

Gudkov SV, Burmistrov DE, Smirnova VV, Semenova AA, Lisitsyn AB. A mini review of antibacterial properties of Al2O3 nanoparticles. Nanomaterials (Basel). 12: 2635 (2022)

Guo HH, Hong ZA, Yi RZ. Core-shell collagen peptide chelated calcium/calcium alginate nanoparticles from fish scales for calcium supplementation. Journal of Food Science. 80: N1595-N1601 (2015)

Guo H, Li X, Yang W, Yao Z, Mei Y, Peng LE, Yang Z, Shao S, Tang CY. Nanofiltration for drinking water treatment: a review. Frontiers of Chemical Science and Engineering.16: 681-698 (2022)

Gupta SM, Tripathi M. A review of TiO2 nanoparticles. Chinese Science Bulletin. 56: 1639-1657 (2011)

Gupta R, Xie H. Nanoparticles in daily life: Applications, toxicity and regulations. Journal of Environmental Pathology, Toxicology and Oncology. 37: 209-230 (2018)

Gupta RK, Dudeja P, Minhas S. (2017) Food safety in the 21st century. Academic Press, Cambridge, pp. 71-81

Gvozdenko AA, Siddiqui SA, Blinov AV, Golik AV, Nagdalian AA, Maglakelidze DG, Statsenko EN, Pirogov MA, Blinova AA, Sizonenko MN, Simonov AN, Zhukov RB, Kolesnikov RO, Ibrahim A. Synthesis of CuO nanoparticles stabilized with gelatin for potential use in food packaging applications. Scientific Report. 12: 12843 (2022)

He Y, Ingudam S, Reed S, Gehring A,Strobaugh Jr TP, Irwin P. Study on the mechanism of antibacterial action of magnesium oxide nanoparticles against foodborne pathogens. Journal of Nanobiotechnology. 14: 54 (2016)

Helal NA, Eassa HA, Amer AM, Eltokhy MA, Edafiogho I, Nounou MI. Nutraceuticals’ novel formulations: the good, the bad, the unknown and patents involved. Recent Patents on Drug Delivery and Formulation. 13: 105–156 (2019)

Hosseinzadeh S, Partovi R, Talebi F, Babaei A. Chitosan/TiO2 nanoparticle/Cymbopogon citratus essential oil film as food packaging material: Physico-mechanical properties and its effects on microbial, chemical, and organoleptic quality of minced meat during refrigeration. Journal of Food Processing and Preservation. 44: e14536 (2020)

Jamali AR, Shaikh AA, Chandio AD. Nano-based biodegradable food packaging of vitis-vinifera synthesized by PVA/ZnO nanocomposites. Physical Chemistry Research. 11: 449-458 (2023)

Jang J, Kang Y, Jang K, Kim S, Chee SS, Kim IS. Ti3C2TX-Ethylenediamine nanofiltration membrane for high rejection of heavy metals. Chemical Engineering Journal. 437: 135297 (2022)

Jeevanandam J, Barhoum A, Chan YS, Dufresne A, Danquah MK. Review on nanoparticles and nanostructured materials: history, sources, toxicity and regulations. Beilstein Journal of Nanotechnology. 9: 1050-1074 (2018)

Jiang CC, Cao YK, Xiao GY, Zhu RF, Lu YP. A review on the application of inorganic nanoparticles in chemical surface coatings on metallic substrates. RSC Advances. 7: 7531-7539 (2017)

Joshi NC, Gururani P, Gairola SP. Metal oxide nanoparticles and their nanocomposite-based materials as photocatalysts in the degradation of dyes. Biointerface Research in Applied Chemistry. 12: 6557-6579 (2021)

Joudeh N, Linke D. Nanoparticle classification, physicochemical properties, characterization, and applications: a comprehensive review for biologists. Journal of Nanobiotechnology. 20: 262 (2022)

Kamari S, Shahbazi A. High–performance nanofiltration membrane blended by Fe3O4@SiO2–CS bionanocomposite for efficient simultaneous rejection of salts/heavy metals ions/dyes with high permeability, retention increase and fouling decline. Chemical Engineering Journal. 417: 127930 (2021)

Khan A, Singh AK. A review on food processing industry in India. Asian Journal of Research and Reviews in Agriculture. 4: 90-97 (2022)

Khan I, Saeed K, Khan I. Nanoparticles: Properties, applications and toxicities. Arabian Journal of Chemistry. 12: 908-931 (2019)

Khan M, Khan MSA, Borah KK, Goswami Y, Hakeem KR, Chakrabartty I. The potential exposure and hazards of metal-based nanoparticles on plants and environment, with special emphasis on ZnO NPs, TiO2 NPs, and AgNPs: A review. Environmental Advances. 6: 100128 (2021)

Khan Y, Sadia H, Ali Shah SZ, Khan MN, Shah AA, Ullah N, Ullah MF, Bibi H, Bafakeeh OT, Khedher NB, Eldin SM, Fadhl BM, Khan MI. Classification, synthetic, and characterization approaches to nanoparticles, and their applications in various fields of nanotechnology: A review. Catalysts. 12: 1386 (2022)

Knorr D, Watzke H. Food processing at a crossroad. Frontiers in Nutrition. 6: 85 (2019)

Kowsalya E, MosaChristas K, Balashanmugam P, Manivasagan V, Devasena T, Jaquline CRI. Sustainable use of biowaste for synthesis of silver nanoparticles and its incorporation into gelatin-based nanocomposite films for antimicrobial food packaging applications. Journal of Food Process Engineering. 44: e13641 (2021)

Kumar S, Shukla A, Baul PP, Mitra A, Halder D. Biodegradable hybrid nanocomposites of chitosan/gelatin and silver nanoparticles for active food packaging applications. Food Packaging and Shelf Life. 16: 178-184 (2018)

Kumar A, Choudhary A, Kaur H, Mehta S, Husen A. Metal-based nanoparticles, sensors, and their multifaceted application in food packaging. Journal of Nanobiotechnology. 19: 256 (2021)

Kumar A, Kumar A, Vats C, Sangwan P, Kumar V, Abhineet A, Chauhan PS, Chauhan R, Chaudhary K. Recent insights into metallic nanoparticles in shelf-life extension of agrifoods: Properties, green synthesis, and major applications. Frontiers in Sustainable Food System. 6: 1-30 (2022)

Kustiningsih I, Ridwan A, Abriyani D, Syairazy M, Kurniawan T, Dhena RB. Development of chitosan-TiO2 nanocomposite for packaging film and its ability to inactive Staphylococcus aureus. Oriental Journal of Chemistry. 35: 1132 (2019)

Li WL, Li XH, Zhang PP, Xing YG. Development of nano-ZnO coated food packaging film and its inhibitory effect onEscherichia coli in vitro and in actual tests. Advanced Material Research. 152: 489-492 (2011)

Li M, Ho KK, Hayes M, Ferruzzi MG. The roles of food processing in translation of dietary guidance for whole grains, fruits, and vegetables. Annual Review of Food Science and Technology.10: 569-596 (2019)

Li Q, Li J, Duan M, Liu L, Fu Y, McClements DJ, Zhao T, Lin H, Shi J, Chen X. Impact of food additive titanium dioxide on the polyphenol content and antioxidant activity of the apple juice. LWT. 154: 112574 (2022)

Liu J, Huang J, Hu Z, Li G, Hu L, Chen X, Hu Y. Chitosan-based films with antioxidant of bamboo leaves and ZnO nanoparticles for application in active food packaging. International Journal of Biological Macromolecules. 189: 363-369 (2021)

Lotha R, Sundaramoorthy NS, Shamprasad BR, Nagarajan S, Sivasubramanian A. Plant nutraceuticals (Quercetrin and Afzelin) capped silver nanoparticles exert potent antibiofilm effect against food borne pathogen Salmonella enterica serovar Typhi and curtail planktonic growth in zebrafish infection model. Microbial Pathogenesis. 120: 109-118 (2018)

Lydia DE, Khusro A, Immanuel P, Esmail GA, Al-Dhabi NA, Arasu MV. Photo-activated synthesis and characterization of gold nanoparticles from Punica granatum L. seed oil: An assessment on antioxidant and anticancer properties for functional yoghurt nutraceuticals. Journal of Photochemistry and Photobiology B: Biology. 206: 111868 (2020)

MacDonald R, Reitmeier C. Understanding food systems. Elsevier, USA (2017).

Majhi KC, Yadav M. Synthesis of inorganic nanomaterials using carbohydrates. In: Boddula R, Asiri AM (ed). Green Sustainable Process for Chemical and Environmental Engineering and Science. Elsevier, Amsterdam, pp. 109-135 (2021).

Massot A, Mietton-Peuchot M, Peuchot C, Milisic V. Nanofiltration and reverse osmosis in winemaking. Desalination. 231: 283-289 (2008)

Mihretie Y. Review on knowledge towards food processing and use of technologies. American Journal Biomedical Science and Research. 2: 78-83 (2019)

Mohammad AW, Teow YH, Ho KC, Rosnan NA. Recent developments in nanofiltration for food applications. In: Rubio AL, Rovira MJF, Sanz MM, Gómez-Mascaraque LG (eds). Nanomaterials for Food Application. Elsevier, Amsterdam, pp 101-120 (2019)

Motelica L, Ficai D, Oprea OC, Ficai A, Andronescu E. Smart food packaging designed by nanotechnological and drug delivery approaches. Coatings. 10: 806 (2020)

Mousazadeh S, Ehsani A, Kia EM, Ghasempour Z. Zinc oxide nanoparticles and periodate oxidation in developing pH-sensitive packaging film based on modified gelatin. Food Packaging and Shelf Life. 28: 100654 (2021)

Nagaich U, Gulati N, Chauhan S. Antioxidant and antibacterial potential of silver nanoparticles: Biogenic synthesis utilizing apple extract. Journal of Pharmaceutics. (2016) https://doi.org/10.1155/2016/7141523

Naseem T, Durrani T. The role of some important metal oxide nanoparticles for wastewater and antibacterial applications: A review. Environmental Chemistry and Ecotoxicology. 3: 59-75 (2021)

Naz S, Gul A, Zia M. Toxicity of copper oxide nanoparticles: a review study. IET Nanobiotechnology. 14: 1-13 (2020)

Negrescu AM, Killian MS, Raghu SNV, Schmuki P, Mazare A, Cimpean A. Metal oxide nanoparticles: Review of synthesis, characterization and biological effects. Journal of Functional Biomaterials. 13: 274 (2022)

Nikolic MV, Vasiljevic ZZ, Auger S, Vidic J. Metal oxide nanoparticles for safe active and intelligent food packaging. Trends in Food Science and Technology. 116:655-668 (2021)

Nikolova MP, Chavali MS. Metal oxide nanoparticles as biomedical materials. Biomimetics. 5: 27 (2020)

Othman SH, Salam NRA, Zainal N, Basha RK, Talib RA. Antimicrobial activity of TiO2 nanoparticle-coated film for potential food packaging applications. International Journal of Photoenergy. (2014) https://doi.org/10.1155/2014/945930

Papargyri S, Tsipas DN, Papargyris DA, Botis AI, Papargyris AD. Review on the production and synthesis of nanosized SnO2. Solid State Phenomena. 106: 57-62 (2005)

Pereira de Abreu DA, Cruz JM, Paseiro Losada P. Active and intelligent packaging for the food industry. Food Reviews International. 28: 146-187 (2012)

Pop OL, Mesaros A, Vodnar DC, Suharoschi R, Tăbăran F, Magerușan L, Todor IS, Diaconeasa Z, Balint A, Ciontea L, Socaciu C. Cerium oxide nanoparticles and their efficient antibacterial application in vitro against gram-positive and gram-negative pathogens. Nanomaterials. 10: 1614 (2020)

Pushpalatha C, Suresh J, Gayathri VS, Sowmya SV, Augustine D, Alamoudi A, Zidane B, Albar NHM, Patil S. Zinc oxide nanoparticles: a review on its applications in dentistry. Frontiers in Bioenergy and Biotechnology. 10: 1-9 (2022)

Reig M, Vecino X, Cortina JL. Use of membrane technologies in dairy industry: An overview. Foods. 10: 2768 (2021)

Rihayat T, Suryani S, Ismi AS, Nurhanifa N, Riskina S. PLA-ZnO nanocomposite paper for antimicrobial packaging application. Jurnal Polimesin, 17: 55-60 (2019)

Robertson GL. Food packaging: principles and practice. 3rd ed. CRC press, Boca Raton (2005)

Robertson GL. Food Packaging. In: Alfen NKV (ed). Encyclopedia of Agriculture and Food Systems. Academic Press, Cambridge, pp 232-249 (2014)

Sagadevan S, Imteyaz S, Murugan B, Anita Lett J, Sridewi N, Weldegebrieal GK, Fatimah I, Oh WC. A comprehensive review on green synthesis of titanium dioxide nanoparticles and their diverse biomedical applications. Green Processing and Synthesis. 7: 44-63 (2022)

Sánchez-López E, Gomes D, Esteruelas G, Bonilla L, Lopez-Machado AL, Galindo R, Cano A, Espina M, Ettcheto M, Camins A, Silva AM, Durazzo A, Santini A, Garcia ML, Souto EB. Metal-based nanoparticles as antimicrobial agents: an overview. Nanomaterials (Basel). 10: 292 (2020)

Sarapulova O, Sherstiuk V, Shvalagin V, Kukhta A. Photonics and nanophotonics and information and communication technologies in modern food packaging. Nanoscale Research Letters. 10: 229 (2015)

Saravanakumar K, Sathiyaseelan A, Mariadoss AVA, Xiaowen H, Wang MH. Physical and bioactivities of biopolymeric films incorporated with cellulose, sodium alginate and copper oxide nanoparticles for food packaging application. International Journal of Biological Macromolecules. 153: 207-214 (2020)

Sengul AB, Asmatulu E. Toxicity of metal and metal oxide nanoparticles: a review. Environmental Chemistry Letter. 18: 1659-1683 (2020)

Shamprasad BR, Lotha R, Nagarajan S, Sivasubramanian A. Metal nanoparticles functionalized with nutraceutical Kaempferitrin from edible Crotalaria juncea, exert potent antimicrobial and antibiofilm effects against Methicillin-resistant Staphylococcus aureus. Scientific Report. 12: 7061 (2022)

Sharif S, Ahmad KS, Memon FH, Rehman F, Soomro F, Thebo KH. Functionalised graphene oxide-based nanofiltration membranes with enhanced molecular separation performance. Material Research Innovations. 26: 373-381 (2022)

Shi H, Magaye R, Castranova V, Zhao J. Titanium dioxide nanoparticles: a review of current toxicological data. Particle and Fibre Toxicology. 10: 15 (2013)

Shi GM, Farahani MHDA, Liu JY, Chung TS. Separation of vegetable oil compounds and solvent recovery using commercial organic solvent nanofiltration membranes. Journal of Membrane Science. 588: 117202 (2019)

Shittu TA, Jayaramudu J, Sivakumar D, Sadiku ER. Physicochemical and engineering properties of nanocomposite films based on chitosan and Pseudoboehmite alumina. Food Bioprocess Technology. 7: 2423-2433 (2014)

Shon HK, Phuntsho S, Chaudhary DS, Vigneswaran S, Cho J. Nanofiltration for water and wastewater treatment–a mini review. Drinking Water Engineering and Science. 6: 47-53 (2013)

Siddiqi KS, Husen A, Rao RAK. A review on biosynthesis of silver nanoparticles and their biocidal properties. Journal of Nanobiotechnology. 16: 14 (2018)

Sim S, Wong NK. Nanotechnology and its use in imaging and drug delivery. Biomedical Reports. 14: 1-9 (2021)

Simakin AV, Sarimov RM, Smirnova VV, Astashev ME, Serov DA, Yanykin DV, Chausov DN, Shkirin AV, Uvarov OV, Rotanov E, Shakhovskoy A, Bruskov VI, Ivanov VE, Dorokhov AS, Izmailov AY. New structural nanocomposite based on PLGA and Al2O3 NPs as a balance between antibacterial activity and biocompatibility with eukaryotic cells. Journal of Composites Science. 6: 298 (2022)

Singh T, Shukla S, Kumar P, Wahla V, Bajpai VK, Rather IA. Application of nanotechnology in food science: perception and overview. Frontiers in Microbiology. 8: 1501 (2017)

Singh M, Singh N, Chandrasekaran B, Deb PK. Nanomaterials in nutraceuticals applications. In: Krishnan A, Chuturgoon A (eds) Integrative nanomedicine for new therapies. Springer, South Africa (2020)

Sobhan A, Muthukumarappan K, Wei L, Van Den Top T, Zhou R. Development of an activated carbon-based nanocomposite film with antibacterial property for smart food packaging. Materials Today Communications. 23: 101124 (2020)

Song D, Ma LW, Pang B, An R, Nie JH, Guo YR, Li S. An active bio-based food packaging material of ZnO@ plant polyphenols/cellulose/polyvinyl alcohol: Design, characterization and application. International Journal of Molecular Sciences. 24: 1577 (2023)

Sunil K, Karunakaran G, Yadav S, Padaki M, Zadorozhnyy V, Pai RK. Al-Ti2O6 a mixed metal oxide based composite membrane: A unique membrane for removal of heavy metals. Chemical Engineering Journal. 348: 678-684 (2018)

Tang S, Wang Z, Li P, Li W, Li C, Wang Y, Chu PK. Degradable and photocatalytic antibacterial Au-TiO2/sodium alginate nanocomposite films for active food packaging. Nanomaterials. 8: 930 (2018)

Tavakolian S, Ahari H, Givianrad MH, Hosseini H. Improving the barrier properties of food packaging by Al2O3@TiO2 & Al2O3@SiO2 nanoparticles. Food Bioprocess Technology. 14: 1287-1300 (2021)

Tiwari S, Yadav G, Sharma S, Srivastava P, Kumar A. Inorganic nanoparticles: A review on method and material for fabrication. Indian Journal of Pharmacy and Pharmacology. 9: 158-163 (2022)

Torabally NB, Rahmanpoor HA. Nutraceuticals: Nutritionally functional foods: An Overview. Biomedical Journal of Scientific and Technical Research. 15:1-3 (2019)

Uresti-Porras JG, Cabrera-De-La Fuente M, Benavides-Mendoza A, Olivares-Sáenz E, Cabrera RI, Juárez-Maldonado A. Effect of graft and nano ZnO on nutraceutical and mineral content in bell pepper. Plants (Basel). 10: 2793 (2021)

Valcárcel M, López-Lorente AI. Gold nanoparticles in analytical chemistry. Elsevier, Spain (2014)

Valgimigli L, Baschieri A, Amorati R. Antioxidant activity of nanomaterials. Journal of Material Chemistry B. 6: 2036-2051 (2018)

Van Nguyen S, Lee BK. PVA/CNC/TiO2 nanocomposite for food-packaging: Improved mechanical, UV/water vapor barrier, and antimicrobial properties. Carbohydrate Polymers. 298: 120064 (2022)

Velázquez-Contreras F, Zamora-Ledezma C, López-González I, Meseguer-Olmo L, Núñez-Delicado E, Gabaldón JA. Cyclodextrins in polymer-based active food packaging: A fresh look at nontoxic, biodegradable, and sustainable technology trends. Polymers. 14: 104 (2022)

Venkatesan R, Rajeswari N. ZnO/PBAT nanocomposite films: Investigation on the mechanical and biological activity for food packaging. Polymers and Advanced Technology. 28: 20-27 (2017)

Vilela C, Kurek M, Hayouka Z, Röcker B, Yildirim S, Antunes MD, Nilsen-Nygaard J, Pettersen MK, Freire CS. A concise guide to active agents for active food packaging. Trends in Food Science and Technology. 80: 212-222 (2018)

Wu Z, Huang X, Li YC, Xiao H, Wang X. Novel chitosan films with laponite immobilized Ag nanoparticles for active food packaging. Carbohydrate Polymers. 199: 210-218 (2018)

Yadav D, Karki S, Ingole PG. Nanofiltration (NF) membrane processing in the food industry. Food Engineering Reviews. 14: 579-595 (2022)

Yakdoumi, Zohra F, Hadj-Hamou, Siham A. Effectiveness assessment of TiO2-Al2O3 nano-mixture as a filler material for improvement of packaging performance of PLA nanocomposite films. Journal of Polymer Engineering. 40: 848-858 (2020)

Yang X, Liu Y, Hu S, Yu F, He Z, Zeng G, Feng Z, Sengupta A. Construction of Fe3O4@ MXene composite nanofiltration membrane for heavy metal ions removal from wastewater. Polymers for Advanced Technology. 32: 1000-1010 (2021)

Yao Y, Zang Y, Qu J, Tang M, Zhang T. The toxicity of metallic nanoparticles on liver: the subcellular damages, mechanisms, and outcomes. International Journal of Nanomedicine. 14: 8787-8804 (2019)

Youssef AM, Abd El-Aziz ME, Morsi SMM. Development and evaluation of antimicrobial LDPE/TiO2 nanocomposites for food packaging applications. Polymer Bulletin. 80: 5417-5431 (2023)

Yu F, Fei X, He Y, Li H. Poly (lactic acid)-based composite film reinforced with acetylated cellulose nanocrystals and ZnO nanoparticles for active food packaging. International Journal of Biological Macromolecules. 186: 770-779 (2021)

Zandi M, Almasi H, Dardmeh N. Evaluation of nanocomposite packaging containing TiO2 and ZnO on shelf life and quality changes of apple and grape. Innovative Food Technology. 8: 63-82 (2020)

Zhang Q, Zhang K, Xu D, Yang G, Huang H, Nie F, Liu C, Yang S. CuO nanostructures: Synthesis, characterization, growth mechanisms, fundamental properties, and applications. Progress in Material Science. 60: 208-337 (2014)

Zhang XF, Liu ZG, Shen W, Gurunathan S. Silver nanoparticles: Synthesis, characterization, properties, applications, and therapeutic approaches. International Journal of Molecular Sciences. 17: 1534 (2016)

Zhang W, Xu H, Xie F, Ma X, Niu B, Chen M, Zhang H, Zhang Y, Long D. General synthesis of ultrafine metal oxide/reduced graphene oxide nanocomposites for ultrahigh-flux nanofiltration membrane. Nature Communication. 13: 471 (2022)

Zhu L, Ji J, Wang S, Xu C, Yang K, Xu M. Removal of Pb(II) from wastewater using Al2O3-NaA zeolite composite hollow fiber membranes synthesized from solid waste coal fly ash. Chemosphere. 206: 278-284 (2018)

Zorraquín-Peña I, Cueva C, Bartolomé B, Moreno-Arribas MV. Silver nanoparticles against foodborne bacteria. Effects at intestinal level and health limitations. Microorganisms. 8: 132 (2020)

Acknowledgements

We are thankful to the Division of Research and Innovation for their encouragement and support during the writing of the manuscript.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Conceptualization, data collection, writing-review and editing, supervision: NCJ Writing and editing, supervision: PBN Editing, data curation, writing: PG All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Joshi, N.C., Negi, P.B. & Gururani, P. A review on metal/metal oxide nanoparticles in food processing and packaging. Food Sci Biotechnol 33, 1307–1322 (2024). https://doi.org/10.1007/s10068-023-01500-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-023-01500-0