Abstract

Nanotechnology is widely used in biomedical applications, engineering sciences, and food technology. The application of nanocompounds play a pivotal role in food protection, preservation, and increasing its shelf life. The changing lifestyle, use of pesticides, and biological and/or chemical contaminants present in food directly affect its quality. Metallic nanoparticles (MNPs) are useful to develop products with antimicrobial activity and with the potential to improve shelf life of food and food products. Due to the prevention of microbial growth, MNPs have attracted the attention of researchers. Biopolymers/polymers can be easily combined with different MNPs which act as a vehicle not only for one type of particles but also as a hybrid system that allows a combination of natural compounds with metallic nanocompounds. However, there is a need for risk evaluation to use nanoparticles in food packaging. In this review, we aim to discuss how MNPs incorporated into polymers/biopolymers matrices can be used for food preservation, considering the quality and safety, which are desirable in food technology.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

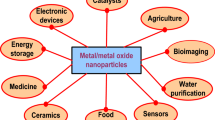

Nanotechnology is a wide platform in biomedical applications, engineering sciences, food, and agriculture. In this context, nanomaterials play a crucial role in protection and preservation of food and also in developement of sensors (Santos et al. 2007, 2011, 2014; Singh and Sahareen, 2017; Pandit et al. 2017; Suryavanshi et al. 2017; Ahmed et al. 2018; Bhardwaj et al. 2020). The frequent use of pesticides and biological/chemical contaminants present in food directly affects the quality of nutrition in food. The packing materials are important for the protection of food products because they prevent deterioration of food products owing to physico-chemical or biological factors and maintain the overall quality during storage and handling (Youssef et al. 2015). Metallic nanoparticles (MNPs) are useful to develop antimicrobial products with potential to enhance the shelf life of food by prevention of microbial growth and hence, they have attracted tremendous attention. They interact with different microbial cells, kill them, and have potential to inhibit biofilms formation (Rai et al. 2009, 2017). These characteristics have made them important in food technology applications. In this relation, MNP-based films, hydrogels, and sensors are emerging as a tool in food science. Various studies have shown application of MNPs in food packaging, which is an intelligent system for food preservation. Moreover, MNP-based sensors are used to detect food contaminants particularly microbes (Yang et al. 2017; Sarwar et al. 2018).

Polymer nanocomposites are considered as major technological break-through for many engineering applications. Nanoparticles incorporated into polymers can enhance chemical and electrical properties (Rossi et al. 2017; Wrona et al. 2017). The MNPs are also useful for enhancing conductivity of sensors (Malekzad et al. 2017). Biopolymers and polymers can be easily combined with different MNPs, which act as a vehicle not only for one type of particles but also act as a hybrid system that allows the combination of natural compounds with MNPs (Vasile 2018).

It is well known that nanotechnology plays an important role in food industries, particularly in the processing and packaging of food and food products. In this context, various studies have been performed and some of the good reviews are also published. However, there is no review available in the current year which specifically focuses on nanoparticles incorporated nano products like nanofilms, hydrogel, nanosensors, and application of hybrid nanomaterials. This will enable scientists to develop newer technology. Therefore, we believe that the present review is timely and hence considering the necessity of these aspects, various above-mentioned topics have been incorporated. In addition, some other important aspects like toxicological concerns and regulations for human biosafety have also been discussed.

Silver nanoparticles in films/hydrogels as novel antimicrobials

Silver nanoparticles (AgNPs) have already demonstrated its potent antimicrobial activities (Rai et al. 2009; Rai et al. 2012; Siddiqi et al. 2018; Shanmuganathan et al. 2019) and therefore, they can be used in food packaging materials. In this context, Incoronato et al. (2011) evaluated the efficacy of an antimicrobial packaging system containing active AgNPs on the quality deterioration of Fior di Latte cheese. The authors used three different concentrations of silver montmorillonite embedded in agar. It was found that the active packaging system significantly enhanced the shelf life of Fior di Latte cheese. The authors claimed that the active packaging system developed in their study could be used to increase the shelf life of Fior di Latte. In another study, Wang and Rhim (2015) prepared ternary blend agar/alginate/collagen hydrogel films with AgNPs and grape-fruit seed extract. The hydrogel film thus developed was highly transparent and showed activity against food-borne Gram-positive (Listeria monocytogenes) and Gram-negative (Escherichia coli) bacteria.

Ahmed et al. (2018) reported that the utilization of polylactic acid (PLA) biopolymers incorporated with MNPs can enhance the physico-mechanical properties of PLA natural constitution, promoting more flexibility and better mechanical structures. The increase in barrier properties was modified by the addition of cinnamon oil and MNPs. The antimicrobial efficacy against Salmonella typhimurium, Campylobacter jejuni, and L. monocytogenes inoculated in chicken samples was evaluated and it was found that the films loaded with Ag-CuNPs and 50% CEO demonstrated significant activity against the bacteria. The study reinforces the importance of combined natural bioactives and MNPs in films to obtain biomaterials with biological effectiveness. In fact, the polymer blend is influenced not only by the natural constitution but also due to ligands composition. In a similar study by Li et al. (2017a, b), PLA was impregnated with AgNPs and titanium dioxide that showed no effect of nanoparticles on the glass transition parameters but they caused an increase in the cold crystallization with effective PLA nano-blend films to antimicrobial activity against E. coli and L. monocytogenes. Cao et al. (2018) developed integrated polypropylene nanocomposite with AgNPs and evaluated antimicrobial effectiveness against E. coli and S. aureus as a model. The authors believe that in this process, reactive oxygen species (ROS) enrolled as polypropylenes are extensively used for food packaging applications by improving mechanical and biological properties against food contamination. However, they found a limiting factor that the migration in food directly raises a question of biosafety. Further, the study showed that migration is directly related to temperature, time, and constitution. The food simulant property for food packing application was in the following order: acid food > oily food > alcoholic food > water food. The total Ag migration values ranged between 1.8 and 24.5 μg/cm2.

The packaging by the intelligent nanosystem allows to control oxygen limits, microorganism proliferation, and add sensors to evaluate food security. In this context, Olmos et al. (2018) evaluated the efficacy of low-density polyethylene/Ag (LDPE/Ag) nanocomposites in food preservation against biofilm-forming E. coli. The results showed that the thermal properties or the surface properties of polyethylene were not altered after incorporation of AgNPs. Moreover, LDPE/Ag nanocomposites also demonstrated efficacy against E. coli and its biofilm. Therefore, the LDPE/Ag nanocomposites can be used as storage materials or general-purpose containers. Recently, Bahrami et al. (2019) developed an interesting antibacterial film for food packaging. They used biocomposite film which consists of tragacanth/hydroxypropylmethylcellulose/beeswax impregnated with AgNPs. The authors evaluated activity of this film against Gram-positive (Bacillus cereus ATCC-1247, S. aureus ATCC-25923, Streptococcus pneumoniae ATCC-49615, and L. monocytogenes ATCC-7644) and Gram-negative (E. coli ATCC-8739, S. typhimorum ATCC-14028, Pseudomonas aeruginosa ATCC-9027, and Klebsiella pneumoniae ATCC-10031) bacteria and reported that both Gram-positive and Gram-negative bacteria demonstrated inhibitory effect in a dose-dependent manner. Considering these facts, the authors claimed that this new nanocomposite film can be used in food packaging.

Hybrid materials such as PVA/nanocellulose/Ag nanocomposite films can also be used for packaging application to protect against methicilline-resistant S. aureus (MRSA) and E. coli (DH5-alpha). The maximum inhibition zone (14 ± 0.70 mm) was observed at 0.5 g AgNPs with 12 wt% nanocellulose against E. coli (DH5-alpha), whereas the maximum zone of inhibition against MRSA was found to be 13.6 ± 0.68 (Sarwar et al. 2018).

In another study, Shankar et al. (2018) prepared hybrid nanomaterials by one-pot synthesis of AgNPs, copper oxide nanoparticles (CuONPs), and zinc oxide nanoparticles (ZnONPs) during regeneration of cellulose from cotton linter (CL) and microcrystalline cellulose (MCC) which showed potential antibacterial activity against E. coli and L. monocytogenes. This provides evidence that the hybrid material with a variety of MNPs is also an innovative approach in the treatment of food-borne microbes for safety and preservation. In a recent study, Dairi et al. (2019) developed nanobiocomposite films by incorporating AgNPs/gelatin-MMT and thymol. The AgNPs were biogenically synthesized by using Curcuma longa. The film demonstrated antioxidant, antibacterial, and antifungal activities. These novel films can be used for enhancing the shelf life of fruits. Moreover, Kadam et al. (2019) developed chitosan-based nanocomposite films impregnated with biologically synthesized AgNPs by using extract of Nigella sativa plant. Interestingly, the film demonstrated pH-dependent sustained release of AgNPs. Moreover, the authors evaluated efficacy of these nanocomposite films against two Gram-positive (B. subtilis and S. aureus) and two Gram-negative bacteria (E. coli and P. aeruginosa), which showed a remarkable antibacterial activity. Further, the authors reported dose-dependent inhibition of bacterial growth. Simialrly, Vishnuvarthanan and Rajeswari (2019) also prepared nanocomposites of carrageenan/AgNPs/Laponite and coated on the oxygen plasma surface–modified polypropylene film. AgNPs were synthesized by extract of Digitalis purpurea. Further, they assessed adhesion, mechanical barrier, and antimicrobial properties of nanocomposites, which were significantly increased. E. coli and S. aureus demonstrated higher sensitivity to these nanocomposites.

Copper nanoparticle–impregnated films for food packaging

Ebrahimiasl and Rajabpour (2015) reported remarkable antimicrobial activity of biodegradable hydroxypropyl methylcellulose (HPMC) matrix impregnated with copper nanoparticles (CuNPs). The film showed mechanical and water vapor barrier properties due to incorporation of CuNPs. Antimicrobial efficacy of these films was tested against S. aureus, S. epidermidis, B. cereus, E. coli, E. faecalis, Salmonella sp., and P. aeruginosa at different concentrations of CuNPs. The results demonstrated the potential bactericidal activity of nanocomposite films against all tested bacteria. Therefore, the authors proposed that CuNP-impregnated films can be used in the packaging and preservation of food products like meat thereby avoiding microbial growth. Moreover, Tamayo et al. (2016) studied copper-polymer nanocomposite films which have already demonstrated antimicrobial activities. These nanocomposites can be used against S. aureus, E. coli, S. cerevisiae, Streptococcus spp., and Pseudomonas spp., etc.

Similarly, Varaprasad et al. (2017) prepared metal-oxide polymer nanocomposite films using biodegradable poly-ε-caprolactone, disposed of poly(ethylene terephthalate) oil bottles monomer and zinc oxide-copper oxide nanoparticles. The metal-oxide polymer nanocomposite films demonstrated excellent mechanical properties. The authors claimed that this type of film can be used in domestic packaging.

In another study, chitosan (CS) and endogenous Cu nanoclusters (NCs) capped with protein were used (Li et al. 2017a, b). The chitosan/soy protein nanocomposite film improved the tensile strength and elongation of composite films by 118.78% and 74.93%, respectively. The authors claimed that owing to the improved characteristics, these films can be used in food packaging. Arfat et al. (2017a, b) developed silver-copper alloy nanoparticle nanocomposite films based on guar gum. The authors evaluated the influence of Ag-Cu nanoparticles after loading on guar gum and found the improved mechanical strength, and UV light and oxygen barrier efficacy. Moreover, the film thus prepared demonstrated antibacterial activity against L. monocytogenes and S. typhimurium. The Ag-Cu nanoparticles were more effective against Gram-negative than the Gram-positive bacteria.

Ahmed et al. (2016) developed plasticized PLA-based nanocomposite films impregnated with polyethylene glycol (PEG) and two nanoparticles including silver-copper alloy and zinc oxide with the size range of 50–100 nm. The film showed significant tensile strength as compared with the combination of plasticized PLA and PEG. Further, Ahmed et al. (2018) prepared plasticized PLA composite films by using bimetallic nanoparticles of silver-copper (Ag-Cu) and essential oil of cinnamon. The efficacy of the film was evaluated on S. typhimurium, C. jejuni, and L. monocytogenes inoculated chicken. The growth of these pathogens was remarkably reduced to 3.87, 2.59, and 2.42 log CFU/g when 50% cinnamon essential oil was used in packaging.

Copper-based nanocomposites have been reported to have potential antibacterial activity against a wide range of Gram-positive and Gram-negative bacteria. Several possible mechanisms have been proposed for the mode of action of copper-based nanocomposites which are explained in detail by many researchers including Tamayo et al. (2016). Based on all the studies, it can be said that copper-polymer nanocomposites mainly target the bacterial cell through three different steps which mainly include (I) release of copper ions, (II) release of CuNPs from nanocomposites, and (III) inhibition of biofilms. In the first phenomenon, the copper ions interact with cell wall (e.g., amines and carboxyl groups in N-acetylglucosamine and N-acetylmuramic acid in the peptidoglycan layer) and various other biomolecules present in the membrane proteins (e.g., sulfhydryl groups). These interactions destabilize the membrane potential and subsequently disintegrate the bacterial cell wall and membrane. In addition, copper ions released also reported to bind and interact with DNA to disintegrate its helical structures, moreover, ROS generated due to released copper ions lead to bacterial death. In the second phenomenon (i.e., release of CuNPs from nanocomposites), thus released CuNPs bind to the surface of bacterial cells through different adherent forces like electrostatic forces and molecular interactions. Further, these nanoparticles penetrate the cell through the outer cell wall or membrane by endocytosis and direct diffusion. Later, they target the bacterium by similar mechanisms proposed for released copper ions. Similarly, CuNPs inhibit biofilm formation (Applerot et al. 2012; Tamayo et al. 2016). Figure 1 represents the schematic illustration of the antibacterial effects of copper-polymer nanocomposites.

Schematic illustration of antibacterial effects of copper-polymer nanocomposites [Reprinted with permission from Tamayo et al. (2016), copyright permission from Elsevier]

Gold nanoparticles as sensors in food technology

The presence of contaminants in food is a major problem observed by food manufacturer and it is mainly due to the use of toxic chemicals during processing or because of chemical compounds present in packaging materials. Bisphenol A is an example of contaminants present in food that passes through packaging material to food. Yang et al. (2017) developed a surface-enhanced Raman spectroscopy (SERS) system based in gold nanoparticles (AuNPs). In this connection, AuNPs were used to potentialize modification of substrate with the help of aggregation agent able to improve the detection sensitivity of BPA residue in milk. The study showed a good linear relationship (R2 = 0.990) between the intensity of SERS signal and the logarithm of BPA concentration in the range. The recovery of BPA residue is reported between 89.5 and 100.2% with relative standard deviation ranging from 4.6 to 2.7%. The application of AuNPs as sensors is the most promising approach owing to their interesting properties like reactivity, selectivity, and specificity which makes them efficient and sensible against food contaminants.

Shi et al. (2013) in a study explored the optical properties of AuNPs in thin films which allowed to obtain semiconductor fluorescent material. The authors prepared gelatin-SiNP composite thin films and successfully incorporated AuNPs. This composite film is important being portable, flexible, transparent, and free-standing with multiple applications. Fan et al. (2020) developed an electrochemical sensitive sensor to determine the Ca2+ concentration in meat. Oxygen plasma–treated graphene was used with AuNPs. This electrochemical method was used for the detection of pork. The authors believed that this method can be applied for the detection of Ca2+ in meat samples.

Bozkurt et al. (2018) developed SERS-based biosensor for the detection of E. coli through a sandwich immunoassay. This SERS-based biosensor was prepared by coating spherical AuNPs on magnetic nanoparticles (MNPs) to form AuNP-coated MNPs complex (MNPs-Au) followed by its modification using E. coli antibody for immunomagnetic separation. On the other hand, rod-shaped AuNPs were labeled with alkaline phosphatase (ALP) and this complex was also modified by E. coli antibody. Initially, MNPs-Au complex modified by E. coli antibody was added to the medium containing E. coli and subsequently, E. coli were captured on this complex and separated by applying an external magnetic field. Further, another complex already prepared, i.e., ALP labeled and E. coli antibody–modified rod-shaped AuNPs, was added to previously captured and separated E. coli so as to form the sandwich immunoassay. Finally, the specific substrate for ALP enzyme, i.e., BCIP (5-bromo-4-chloro-3-indolyl phosphate), was added which leads to enzymatic hydrolysis of the substrate, the AuNPs present in the sensor enhanced the SERS signal specific to BCIP, the intensity of SERS signal depends on the concentration of E. coli present. Figure 2 represents the schematic illustration of different steps involved in the detection of E. coli using active sandwich immunoassay.

Schematic illustration of different steps involved in detection of E. coli using ALP-labeled SERS active sandwich immunoassay [Reprinted with permission from Bozkurt et al. (2018), copyright permission from Elsevier]

The food is usually contaminated by different pathogenic microbes, and therefore their timely detection is very important. Globally, these microbes are a major threat to human health. Such microbes generally include bacteria, fungi, viruses, and other parasites. Among these, fungi secretes various mycotoxins in food, which are of great importance because they cause severe health problems in humans (Richard 2007). Mycotoxins are toxic secondary metabolites produced by a variety of fungi which mainly include various members of the genus Aspergillus, Fusarium, and Penicillium (Goyal et al. 2017). Mateo et al. (2018) reported that about 25% of the world’s food crops get contaminated every year due to mycotoxins, resulting in the huge industrial and agricultural loss. Among the various mycotoxins, aflatoxin is considered as most potent, strong teratogen, mutagen, and carcinogenic. Aflatoxins are low molecular weight toxic compounds generally produced by different species of Aspergillus such as A. flavus and A. parasiticus. These mycotoxins are commonly found in various food and feed stuffs including cereals, oilseeds, spices, coffee beans, and nuts (Omrani et al. 2016; Negash 2018). Therefore, considering the major health issues caused due to mycotoxins, there is a growing interest among the food technologists to develop the most effective and sensitive approach for the detection of food-borne microbes and their toxins. In this context, various attempts have been made mostly focusing on the development of approaches based on nanotechnology. Pissuwan et al. (2019) reviewed the role of various AuNPs based assays for the detection of food-borne microbes. In another recent study, Bhardwaj et al. (2020) developed surface plasmon resonance (SPR)–based nanosensor (chip) by the incorporation of AuNPs for the detection of aflatoxin in food. The nanobiosensor was developed through three different steps which include (i) Step-I: synthesis of AuNPs and ligand exchange process from CTAB to lipoic acid surface modification, (ii) Step-II: self-assembled monolayer (SAM) of cystamine and lipoic acid on Au sensor chips surface, and (iii) Step-III: in situ activation of SAM-modified chip surface, grafting of protein-A, and immobilization of anti-AFB1 antibodies followed by interaction with AFB1 antigen. Figure 3 represents the schematic illustration of the different steps involved in the biosensor active surface modification. The obtained results revealed that thus developed nanosensors are potentially effective and most sensitive in the detection of aflatoxin.

Schematic representation of the different steps involved in the active surface modification of nanobiosensor. Step-1: synthesis of AuNPs and ligand exchange process from CTAB to lipoic acid surface modification. Step-2: self-assembled monolayer of cystamine and lipoic acid on Au sensor chips surface. Step-3: in situ activation of SAM-modified chip surface, grafting of protein-A, and immobilization of anti-AFB1 antibodies followed by interaction with AFB1 antigen (Reprinted with permission from Bhardwaj et al. (2020), copyright permission from Elsevier)

Hybrid materials in food technology

Hybrid metal-polymer matrices show distinct properties, such as large surface areas, ordered crystalline structures, highly regularized pores, and structure functionalities making them a new class of materials for diverse applications (Zhang et al. 2014). The use of potential MNPs combined with natural compounds is also an approach that needs to be explored. Krishna et al. (2016) and Yang et al. (2017) reported a sensor composed of graphene oxide-nickel nanoparticle biopolymer films that aim to detect glucose concentration. The sensor can be used not only for glucose detection in body fluids, but it can also be used in a food application system, due to biocompatible materials utilized, the low toxicity Ni and low-cost technology.

Oun and Rhim (2017) studied the natural properties of chitin combined with ZnO/AgNPs after their incorporation in carboxymethyl cellulose. Hybrid material originated films exhibited strong antibacterial activity against both Gram-positive and Gram-negative bacteria. As discussed in this review, the combination of nanocomposites exhibits better physico-chemical properties of the films when they are incorporated with nanoparticles. The increased thermal stability by the incorporation of ZnO-AgNPs showed the high UV barrier property. Similarly, the tensile strength and elastic modulus of the composite film were also increased, whereas elongation at break was found to be decreased.

Yaşa et al. (2012) reported antimicrobial activity of nanosized Ag-doped TiO2 colloids against E coli, S. aureus, B. subtilis, S. typhimurium, and C. albicans. Although the study was not focused on food applications, the microorganisms tested show an excellent prognostic in the use of this hybrid in food application process. In chitosan films, the combination of AgNPs and AuNPs showed promising antimicrobial activity against bacteria (S. aureus, P. aeruginosa), fungi (A. niger), and yeast (C. albicans) (Youssef et al. 2014). Later, in another study, Youssef et al. (2015) combined bionanocomposite based on chitosan/poly (vinyl alcohol)/titanium nanoparticles (TiO2NPs) (CS/PVA/TiO2 nanocomposite) which were used as packaging materials for soft white cheese. Chemical and antimicrobial properties were also evaluated showing an increase in storage time and reduced bacteria, yeast, and mold counts compared with the control.

Other bionanocomposites in food technology

Bionanocomposites are considered as one of the most important class of hybrid materials, which are mainly composed of biopolymers and inorganic solids having at least one dimension on the nanometer scale. The discovery of such biodegradable materials is found to be promising gift to present and future generations. To date, various synthetic and natural polymers have been successfully used in the development of bionanocomposite materials. Among the various polymers, natural polymers such as starch, cellulose acetate, chitosan, and different proteins are considered as environment friendly and hence preferably used in the past few years for a wide range of application including food industry. For example, optically transparent plasticized PLA-based bionanocomposite films have been utilized for packaging in the food industry (Mohanty and Swain 2017; Arora et al. 2018).

The combination of starch and clay is considered as the most promising biodegradable nanocomposites having potential applications in food packaging because these bionanocomposites exhibit excellent barrier properties and hence essentially required for any ideal food packaging material (Cyras et al. 2008). In another study, Yu et al. (2009) developed a starch/ZnO-carboxymethylcellulose sodium nanocomposite using ZnONPs stabilized by carboxymethylcellulose sodium (CMC) as the filler in glycerol-plasticized pea starch. These films also found to have promising applications in food industry. Similarly, De Moura et al. (2009) synthesized a bionanocomposite material by incorporating chitosan-tripolyphosphate (CS-TPP) nanoparticles into hydroxypropyl methylcellulose (HPMC) films. It was observed that incorporation of CS–TPP nanoparticles into HPMC films significantly improved its mechanical and barrier properties. Thus, the authors claimed its applications in food industry as a packaging material. Zare et al. (2019) synthesized zinc oxide-silver nanocomposites (ZnO-Ag NCs) using leaf extract of Thymus vulgaris as a stabilizer and a reducing agent through biomimetic hydrothermal decomposition reaction. Later, thus synthesized nanocomposite was incorporated into poly(3-hydroxybutyrate-co-3-hydroxyvalerate)-chitosan (PHBV-CS) as an active agent in a highly precise ratio to develop the novel degradable biopolymer nanocomposite. Further, this bionanocomposite was evaluated for its enhanced mechanical properties and antimicrobial activity to improve the shelf life of poultry items. These findings showed the application of ZnO-Ag NCs as a nano-active agent in the food packaging by controlling its spoilage. Moreover, these bionanocomposites demonstrated potential antimicrobial activity that offers effective and novel replacement of traditional petrochemical-based polymers conventionally used for packaging of poultry items. Moreover, some reports suggested that incorporation of ZnONPs to PHBV enhances antimicrobial activity of ZnONPs, which can be used to increase the shelf life of food. Abdalkarim et al. (2017) demonstrated that PHBV/ZnO nanocomposites possess potential antibacterial activity against E. coli and S. aureus. Further, it was also observed that incorporation of ZnO (ZnONPs) not only positively affects barrier and hydrophilicity of the polymer blend coatings but also improves the tensile strength, Young’s modulus of PHBV and increases its maximum decomposition temperature. As far as ZnONPs-based bionanocomposites are concerned, in addition to above-mentioned PHBV, various other biopolymers like chitosan, poly(3-hydroxybutyrate) (PHB), poly(butylene adipate-co-terephthalate) (PBAT), low-density polyethylene (LDPE), semolina flour, and bovine skin gelatin type-B (BSG) have been used for its incorporation. For instance, Abbas et al. (2019) reviewed the role of ZnONPs bionanocomposites films incorporated with all such biopolymers. The authors proposed that incorporation of ZnONPs in the biopolymer films make them resistant to fire, lightweight, stronger in thermal and mechanical performance, and less permeable to moisture and gases. Hence, due to these improved properties, such bionanocomposite films can be effectively used for food packaging.

Recently, Kaseem et al. (2019) reviewed the recent advances in application of PLA/TiO2 composites for various fields including food preservation and packaging. In this context, Garcia et al. (2018) reported that addition of TiO2NPs into the PLA matrix was highly effective against a wide range of bacterial strains and hence authors suggested the use of these nanocomposites instead of AgNPs. Actually, the migration phenomenon of nanoparticles is considered as a critical factor to evaluate the safety and relevance of the PLA/TiO2 composites (Girdthep et al. 2014). Therefore, Li et al. (2018) studied migration phenomenon of TiO2NPs and AgNPs from PLA/TiO2 and PLA/TiO2 + Ag composite films. The results obtained showed that the amounts of TiO2NPs and AgNPs migrated above-mentioned PLA composite films to cheese specimens were much lower than the migration limit proposed by European Food Safety Agency for food contact materials. Considering all these advantages, it has been confirmed that PLA/TiO2 nanocomposites can be safely used as antimicrobial food packaging films.

Recently, Zubair and Ullah (2019) reviewed the role of various protein-based bionanocomposites in food industry and proposed that such bionanocomposites can be promisingly used for various purposes including food packaging. Kanmani and Rhim (2014) developed gelatin-based active nanocomposite films incorporating AgNPs using a solution casting method. The incorporation of AgNPs into the gelatin-based nanocomposite film promisingly enhanced its antimicrobial activity including. Further, it was observed that thus developed bionanocomposite showed potential antibacterial properties against both Gram-negative and Gram-positive food-borne pathogens. In another study, Shankar et al. (2015) prepared the gelatin/ZnONP nanocomposite films and after evaluation of their antibacterial efficacy it was confirmed that these films considerably more active against Gram-positive food-borne pathogenic bacteria than Gram-negative. Similarly, TiO2NPs at different concentrations (1, 3, and 5 wt%) were used to develop biodegradable whey protein isolate (WPI) films and evaluated their physical and mechanical properties. The results obtained revealed that increase in concentration of TiO2 from 1 to 5% showed a decrease in water barrier permeability as well as water vapor transport rate of films. These properties are considered as important for food packaging materials and hence such films can be effectively used in food packaging to increase its self-life (Zolfi et al. 2014). Arfat et al. (2016) developed effective antimicrobial nanocomposite film using fish protein isolate and fish skin gelatin by the addition of ZnONPs and used an efficient food packaging to prevent the growth of pathogen and spoilage bacteria in foods.

Besides all these bionanocomposites, there are few other bionanocomposites also developed by the incorporation of nanoparticles in different polymers. Due to improved antimicrobial and other properties like moisture and gas barrier, these bionanocomposites have been promisingly used in food industries for various purposes.

Toxicity and biosafety concerns

The applications of important MNPs and other various nanomaterials in food are already described in this review. But the toxicity and biosafety of these materials is a major issue when nanoparticles are in materials especially those in contact with food. The polymers commonly used as films, hydrogels, and sensors are most of the time composed of biopolymers or materials that are ecofriendly and biocompatible for human use. However, nanomaterials like MNPs are described with potential toxicity, depending on exposure factors, time of exposure, and contact. To date, toxicological effects of different nanomaterials have been studied by both in vitro (using various cell lines) and in vivo (using experimental models like zebrafish, mice, etc.) approaches.

From the available reports, it is clear that nanomaterials exert toxicological effects in living organisms, as well as in environmental ecosystems, which is commonly referred as ecotoxicity. The flora and fauna present in the ecosystem helps to maintain the ecological balance and hence, there is ecological connectivity with such living organisms and ecosystem. But, it was found that nanomaterials through their toxicological effects may disturb this ecological balance. Therefore, evaluation of toxicological effects of nanomaterials and the understanding of their interaction with different taxa present in the ecosystem are essentially required. In this context, a number of studies have been performed demonstrating the negative effects of nanomaterials in various trophic levels. Bour et al. (2015) demonstrated the toxicity of cerium dioxide nanoparticles (CeO2NPs) in aquatic environments on living systems from different trophic levels which include four species (i.e., one is diatoms Nitzschia palea, second is the sediment-dwelling invertebrate Chironomus riparius, and the third and fourth are amphibian larvae Xenopus laevis and Pleurodeles waltl). It was found that CeO2NPs inhibit the growth of all above-tested species. Further, the authors observed that in aquatic environment, CeO2NPs tend to aggregate and sediment quickly. These findings suggested that, in the case of water contamination with such nanoparticles, exposure not only affects organisms from the water column but it also harms the benthic organisms. These organisms are of prime importance from an ecological point of view, as they represent the base of the trophic chain.

Apart from this, Ramachandran et al. (2018) used zebrafish as animal model and exposed to AgNPs and AuNPs to evaluate damages and compared both for toxicity when they are used in the same conditions. It was observed that the treatment of AgNPs enhances the secretion of alanine aminotransferase and aspartate aminotransferase enzymes in the cell compared with AuNPs. The enhanced secretion of these enzymes leads to the increase in the ROS generation level and thus caused more damages than AuNPs through oxidative stress and immunotoxicity. Moreover, the formation of micronuclei and nuclear abnormalities was observed in the cells treated with AgNPs, which was not observed in cells treated with AuNPs. From these observations, it can be concluded that AuNPs are relatively safe and less toxic bionanomaterials for possible applications. Similarly, Rajput et al. (2018) demonstrated the toxicological concerns of copper oxide nanoparticles in barley (Hordeum sativum distichum) which is considered as one of the most important staple food crops. The study involves the evaluation of effects of these nanoparticles on stomatal aperture and root morphology, metaxylem size, and changes in cellular organelles (plastids, mitochondria), as well as in plastoglobules, starch granules, protoplasm, and membranes. All the above-mentioned studies confirmed that nanomaterials exert harmful effects in all kinds of living systems present in the environment such as plants, aquatic organisms, terrestrial animals, and human beings.

Regulations for human safety

For assessment of risk concerning the use of nanoparticles in food packaging, the degradation of nanomaterial in the environment for human safety is imperative. Kotsilkov et al. (2018) evaluated the release of graphene carbon nanotubes from poly(lactic) nanocomposite films. Regarding polymer film, the release of nanocompounds and the impact of contaminations are a real concern. The observed limit for migration was estimated at around 0.028–0.053 mg/cm2 and 0.006–0.011 mg/cm2 for PLA films and nanoparticle migration, respectively. Both are below the EU regulation overall limit that was 0.10 mg/cm2.

Dimitrijevic et al. (2015) reported that the effect of nanomaterial on the human body depends on its property. The time of nanoparticles’ circulation increases in the case of hydrophilic and positively charged nanoparticles. Although the exact mechanism is not known, it is believed that the toxicity is based on oxidative stress. Gallocchio et al. (2015) reported that the impact of nanomaterials in food science is very important since early stages until the uptake by living organisms. The authors summarized the principle rules regarding use of nanomaterials in food. If nanomaterials are used as primary ingredients (e.g., nanoemulsions), they fall within the scope of “Novel Food” Regulation (258/97) as “foods and food ingredients with a new or intentionally modified primary molecular structure” and they are subjected to a risk assessment procedure before market approval. If they are used as food additives, a different procedure is applied (Reg 1333/2008) and they are expected to be inserted in the EU register before use (Gallocchio et al. 2015). It is noteworthy to mention that Switzerland seems to be the unique country where nano-specific provisions have been incorporated in existing legislation, while in other countries nanomaterials are regulated more implicitly by mainly building on guidance for industry (Amenta et al. 2015).

Rainieri et al. (2018) emphasized on metallic safety of commercial food products describing “The European Food Safety Authority (EFSA) Scientific Opinion entitled Guidance for risk assessment of engineered nanomaterials which recommends examination of the following conditions: i) the state in which the nanomaterial was produced; ii) the state in which the nanomaterial is used or is present in the food and feed; iii) the state in which the nanomaterial is present in the toxicological studies, and iv) the state of the nanomaterials in biological fluids and tissues.”

Conclusions

The applications and advantages of MNPs and nanocompounds in food preservation and treating contamination are well recognized. The versatile nature of materials, combinations, and hybridization makes them more attractable. The materials that combine nanocompounds with polymers and natural compounds are promising sources that need to be explored. The MNPs such as AgNPs, AuNPs, and CuNPs have already demonstrated a wide antimicrobial activity against pathogenic bacteria, fungi, and yeasts. In addition, the physical properties such as high reactivity, specificity, and selectivity make them an attractive combination with other materials to provide large applicability. There is a greater need of sensors in food technology in order to constantly monitor process, compounds, and nutrients. The risk assessments, biosafety, and regulations concerning these compounds are still a challenge and warrants extensive research. The lack of uniformity in worldwide regulations makes them potentially dangerous when one takes an account of body exposure or the environment impacts.

References

Abbas M, Buntinx M, Deferme W, Peeters R (2019) (Bio)polymer/ZnO nanocomposites for packaging applications: a review of gas barrier and mechanical properties. Nanomaterials 9:1494. https://doi.org/10.3390/nano9101494

Abdalkarim SYH, Yu HY, Song ML, Zhou Y, Yao J, Ni QQ (2017) In vitro degradation and possible hydrolytic mechanism of PHBV nanocomposites by incorporating cellulose nanocrystal-ZnO nanohybrids. Carbohydr Polym 176:38–49

Ahmed J, Arfat YA, Bher A, Mulla M, Jacob H, Auras R (2018) Active chicken meat packaging based on polylactide films and bimetallic Ag-Cu nanoparticles and essential oil. J Food Sci 83(5):1299–1310

Ahmed J, Arfat YA, Castro-Aguirre E, Auras R (2016) Mechanical, structural and thermal properties of Ag-Cu and ZnO reinforced polylactide nanocomposite films. Int J Biol Macromol 86:885–892

Amenta V, Aschberger K, Arena M, Bouwmeester H, Moniz FB, Brandhoff P, Gottardo S, Marvin HJP, Mech A, Pesudo LQ, Rauscher H, Schoonjans R, Vettori MV, Weigel S, Peters RJ (2015) Regulatory aspects of nanotechnology in the agri/feed/food sector in EU and non-EU countries. Regulatory Toxicol Pharmacol 73:463–476

Applerot G, Lellouche J, Lipovsky A, Nitzan Y, Lubart R, Gedanken A, Banin E (2012) Understanding the antibacterial mechanism of CuO nanoparticles: revealing the route of induced oxidative stress. Small 8(21):3326–3337

Arfat YA, Ahmed J, Jacob H (2017a) Preparation and characterization of agar-based nanocomposite films reinforced with bimetallic (Ag-Cu) alloy nanoparticles. Carbohydr Polym 155:382–390

Arfat YA, Benjakul S, Prodpran T, Sumpavapol P, Songtipya P (2016) Physico-mechanical characterization and antimicrobial properties of fish protein isolate/fish skin gelatin-zinc oxide (ZnO) nanocomposite films. Food Bioprocess Technol 9(1):101–112

Arfat YA, Ejaz M, Jacob H, Ahmed J (2017b) Deciphering the potential of guar gum/Ag-Cu nanocomposite films as an active food packaging material. Carbohydr Polym 157:65–71

Arora B, Bhatia R, Attri P (2018) Bionanocomposites: green materials for a sustainable future. In: New polymer Nanocomposites for environmental remediation (Hussain CM, Mishra AK, eds.), Elsevier, UK, pp. 699–712

Bahrami A, Rezaei-Mokarram R, Sowti-Khiabani M, Ghanbarzadeh B, Salehi R (2019) Physico-mechanical and antimicrobial properties of tragacanth/hydroxypropylmethylcellulose/bees-wax edible films reinforced with silver nanoparticles. Int J Biol Macromol 129:1103–1112

Bhardwaj H, Sumana G, Marquette CA (2020) A label-free ultrasensitive microfluidic surface Plasmon resonance biosensor for Aflatoxin B1 detection using nanoparticles integrated gold chip. Food Chem 307:125530. https://doi.org/10.1016/j.foodchem.2019.125530

Bour A, Mouchet F, Verneui L, Evariste L, Silvestre J, Pinelli E, Gauthier L (2015) Toxicity of CeO2 nanoparticles at different trophic levels - effects on diatoms, chironomids and amphibians. Chemosphere 120:230–236

Bozkurt AG, Buyukgoz GG, Soforoglu M, Tamer U, Suludere Z, Boyaci IH (2018) Alkaline phosphatase labeled SERS active sandwich immunoassay for detection of Escherichia coli. Spectrochimica Acta Part A: Mol Biomol Spectr 194:8–13

Cao G, Lin H, Kannan P, Wang C, Zhong Y, Huang Y, Guo Z (2018) The enhanced antibacterial and food simulant activities of silver nanoparticles/polypropylene nanocomposite films. Langmuir 34(48):14537–14545

Cyras VP, Manfredi LB, Ton-That MT, Vazquez A (2008) Physical and mechanical properties of thermoplastic starch/montmorillonite nanocomposite films. Carbohyd Polym 73(1):55–63

Dairi N, Ferfera-Harrar H, Ramos M, Garrigós MC (2019) Cellulose acetate/AgNPs-organoclay and/or thymol nanobiocomposite films with combined antimicrobial/antioxidant properties for active food packaging use. Int J Biol Macromol 121:508–523

De Moura MR, Aouada FA, Avena-Bustillos RJ, McHugh TH, Krochta JM, Mattoso LHC (2009) Improved barrier and mechanical properties of novel hydroxypropyl methylcellulose edible films with chitosan/tripolyphosphate nanoparticles. J Food Eng 92:448–453

Dimitrijevica M, Karabasila N, Boskovica M, Teodorovica V, Vasileva D, Djordjevicb V, Kilibardac N, Cobanovic N (2015) Safety aspects of nanotechnology applications in food packaging. Procedia Food Sci 5:57–60

Ebrahimiasl S, Rajabpour A (2015) Synthesis and characterization of novel bactericidal cu/HPMC BNCs using chemical reduction method for food packaging. J Food Sci Technol 52(9):5982–5988

Fan X, Xing L, Ge P, Cong L, Hou Q, Ge Q, Liu R, Zhang W, Zhou G (2020) Electrochemical sensor using gold nanoparticles and plasma pretreated graphene based on the complexes of calcium and troponin C to detect Ca2+ in meat. Food Chem 307:125645. https://doi.org/10.1016/j.foodchem.2019.125645

Gallocchio F, Bellucoa S, Ricci A (2015) Nanotechnology and food: brief overview of the current scenario. Procedia Food Sci 5:85–88

Garcia CV, Shin GH, Kim JT (2018) Metal oxide-based nanocomposites in food packaging: applications, migration, and regulations. Trends Food Sci Technol 82:21–31

Girdthep S, Worajittiphon P, Molloy R, Lumyong S, Leejarkpai T, Punyodom W (2014) Biodegradable nanocomposite blown films based on poly(lactic acid) containing silver-loaded kaolinite: a route to controlling moisture barrier property and silver ion release with a prediction of extended shelf life of dried longan. Polymer 55:6776–6788

Goyal S, Ramawat KG, Mérillon JM (2017) Different shades of fungal metabolites: an overview. In: Mérillon JM, Ramawat K (eds) Fungal Metabolites. Reference Series in Phytochemistry. Springer, Cham, pp 1–29

Incoronato AL, Conte A, Buonocore GG, Del Nobile MA (2011) Agar hydrogel with silver nanoparticles to prolong the shelf life of Fiordi latte cheese. J Dairy Sci 94(4):1697–1704

Kadam D, Momin B, Palamthodi SS (2019) Physiological and functional properties of chitosan based nanocomposite films incorporated with biogenic silver nanoparticles. Cabohydr Polym 211:124–132

Kanmani P, Rhim JW (2014) Physical, mechanical and antimicrobial properties of gelatin based active nanocomposite films containing AgNPs and nanoclay. Food Hydrocoll 35:644–652

Kaseem M, Hamad K, Rehman ZU (2019) Review of recent advances in polylactic acid/TiO2 composites. Materials 12:3659. https://doi.org/10.3390/ma12223659

Kotsilkov S, Ivanov E, Vitanov NK (2018) Release of graphene and carbon nanotubes from biodegradable poly(lactic acid) films during degradation and combustion: risk associated with the end-of-life of nanocomposite food packaging materials. Materials 11:2346. https://doi.org/10.3390/ma11122346

Krishna R, Campina JM, Fernandes PMV, Ventura J, Titus E, Silva AF (2016) Reduced graphene oxide-nickel nanoparticles/biopolymer composite films for sub-millimolar detection of glucose. Analyst 141(13):4151–4161

Li K, Jin S, Liu X, Chen H, He J, Li J (2017a) Preparation and characterization of chitosan/soy protein isolate nanocomposite film reinforced by cu nanoclusters. Polymers (Basel). 9(7): pii: E247; doi: https://doi.org/10.3390/polym9070247

Li W, Li L, Zhang H, Yuan M, Qin Y (2018) Evaluation of PLA nanocomposite films on physicochemical and microbiological properties of refrigerated cottage cheese. J Food Process Pres 42:e13362. https://doi.org/10.1111/jfpp.13362

Li W, Zhang C, Chi H, Li L, Lan T, Han P, Chen H, Qin Y (2017b) Development of antimicrobial packaging film made from poly(lactic acid) incorporating titanium dioxide and silver nanoparticles. Molecules 22:1170–1185

Malekzad H, Zangabad PS, Mirshekari H, Karimi M, Hamblin MR (2017) Noble metal nanoparticles in biosensors: recent studies and applications. Nanotechnol Rev 6(3):301–329

Mateo EM, Gomez JV, Romera D, Tarazona A, Gimeno-Adelantado JV, Mateo-Castro R, Jimenez M (2018) Environmental temperature and relative humidity, two key factors in maize technology affecting ochratoxin A production and growth of ochratoxigenic species. Int J Food Eng 4(1):51–57

Mohanty F, Swain SK (2017) Bionanocomposites for food packaging applications. In: Nanotechnology applications in food (Oprea AE, Grumezescu AM, eds.), Elsevier, UK, pp. 363–379

Negash D (2018) A review of aflatoxin: occurrence, prevention, and gaps in both food and feed safety. J Appl Microbiol Res 1:35–43

Olmos D, Pontes-Quero GM, Corral A, González-Gaitano G, González-Benito J (2018) Preparation and characterization of antimicrobial films based on LDPE/Ag nanoparticles with potential uses in food and health industries. Nanomaterials 8:60. https://doi.org/10.3390/nano8020060

Omrani NM, Hayat A, Korri-Youssoufi H, Marty JL (2016) Electrochemical biosensors for food security: mycotoxins detection. In: Nikolelis D, Nikoleli GP (eds) Biosensors for security and bioterrorism applications. Advanced Sciences and Technologies for Security Applications. Springer, Cham, pp. 469–490

Oun AA, Rhim JW (2017) Preparation of multifunctional chitin nanowhiskers/ZnO-Ag NPs and their effect on the properties of carboxymethyl cellulose-based nanocomposite film. Carbohydr Polym 169:467–479

Pandit R, Rai M, Santos CA (2017) Enhanced antimicrobial activity of the food-protecting nisin peptide by bioconjugation with silver nanoparticles. Environ Chem Lett 15(3):443–452

Pissuwan D, Gazzana C, Mongkolsuk S, Cortie MB (2019) Single and multiple detections of foodborne pathogens by gold nanoparticle assays. Wiley Interdiscip Rev Nanomed Nanobiotechnol:e1584. https://doi.org/10.1002/wnan.1584

Rai M, Deshmukh S, Ingle A, Gade A (2012) Silver nanoparticles: the powerful nano-weapon against multidrug resistant bacteria. J Appl Microbiol 112(5):841–852

Rai M, Ingle A, Pandit R, Paralikar P, Gupta I, Chaud MV, Santos CA (2017) Broadening the spectrum of small-molecule antibacterials by metallic nanoparticles to overcome microbial resistance. Int J Pharm 532(1):139–148

Rai MK, Yadav AP, Gade AK (2009) Silver nanoparticles as a new generation of antimicrobials. Biotechnol Adv 27(1):76–82

Rainieri S, Olasagasti M, Barranco A (2018) Overview on the safety of commercial products containing metallic nanoparticles in the food sector. Nutr Hosp 35:155–158

Rajput V, Minkina T, Fedorenko A, Sushkova S, Mandzhieva S, Lysenko V, Duplii N, Fedorenko G, Dvadnenko K, Ghazaryan K (2018) Toxicity of copper oxide nanoparticles on spring barley (Hordeum sativum distichum). Sci Total Environ 645:1103–1113

Ramachandran, R, Krishnaraj C, Kumar VKA, Harper SL, Kalaichelvan TP, Yun S (2018) In vivo toxicity evaluation of biologically synthesized silver nanoparticles and gold nanoparticles on adult zebra fish: a comparative study. 3 Biotech 8:441; https://doi.org/10.1007/s13205-018-1457-y

Richard JL (2007) Some major mycotoxins and their mycotoxicoses: an overview. Int J Food Microbiol 119(1–2):3–10

Rossi M, Passeri D, Sinibaldi A, Angjellari M, Tamburri E, Sorbo A, Carata E, Dini L (2017) Nanotechnology for food packaging and food quality assessment. Adv Food Nutr Res 82:149–204. https://doi.org/10.1016/bs.afnr.2017.01.002

Santos CA, Mazzola PG, Silva PH, Cholewa O, Penna TCV (2007) Preliminary study on the potential utility of GFP as a biosensor for drug stability in parenteral solutions. Biotechnol Prog 23(4):979–984

Santos CA, Ribeiro GB, Knirsch MC, Pessoa Junior A, Penna TCV (2011) Influence of Pluronic® F68 on ceftazidime biological activity in parenteral solutions. J Pharma Sci 2:715–720

Santos CA, Seckler MM, Ingle A, Gupta I, Galdiero S, Galdiero M, Gade A, Rai M (2014) Silver nanoparticles: therapeutical uses, toxicity, and safety issues. J Pharma Sci 7:1931–1944

Sarwar MS, Khan MB, Jahan NZ, Ahmad T, Hussain A (2018) Preparation and characterization of PVA/nanocellulose/Ag nanocomposite films for antimicrobial food packaging. Carbohydr Polym 184:453–464

Shankar S, Xinnan T, Gaobin L, Rhim JW (2015) Preparation, characterization, and antimicrobial activity of gelatin/ ZnO nanocomposite films. Food Hydrocoll 45:264–271

Shankar S, Oun AA, Rhim JW (2018) Preparation of antimicrobial hybrid nano-materials using regenerated cellulose and metallic nanoparticles. Int J Biol Macromol 107(Pt A):17–27

Shanmuganathan R, Karuppusamy I, Saravanan M, Muthukumar H, Ponnuchamy K, Ramkumar VS, Pugazhendhi A (2019) Synthesis of silver nanoparticles and their biomedical applications: a comprehensive review. Curr Pharm Des 25(24):2650–2660

Shi L, Yu T, Sun L, Pia X, Peng X (2013) Optical properties of free-standing gelatin–Si nanoparticle composite films and gelatin–Si–Au nanoparticle composite films. Phys Chem Chem Phys 15:20140–20146

Siddiqi KS, Husen A, Rao RAK (2018) A review on biosynthesis of silver nanoparticles and their biocidal properties. J Nanobiotechnol 16(1):14. https://doi.org/10.1186/s12951-018-0334-5

Singh M, Sahareen T (2017) Investigation of cellulosic packets impregnated with silver nanoparticles for enhancing shelf-life of vegetables. LWT Food Sci Technol 86:116–122

Suryavanshi P, Pandit R, Gade A, Derita M, Zachino S, Rai M (2017) Colletotrichum sp. mediated synthesis of sulphur and aluminium oxide nanoparticles and its in vitro activity against selected food-borne pathogens. LWT-Food Sci Technol 81:188–194

Tamayo L, Azócar M, Kogan M, Riveros A, Páez M (2016) Copper-polymer nanocomposites: an excellent and cost-effective biocide for use on antibacterial surfaces. Mater Sci Eng C Mater Biol Appl 69:1391–1409

Varaprasad K, Pariguana M, Raghavendra GM, Jayaramudu T, Sadiku ER (2017) Development of biodegradable metaloxide/polymer nanocomposite films based on poly-ε-caprolactone and terephthalic acid. Mater Sci Eng C Mater Biol Appl 70:85–93

Vasile C (2018) Polymeric nanocomposites and nanocoatings for food packaging: A review. Materials 11:1834. https://doi.org/10.3390/ma11101834

Vishnuvarthanan M, Rajeswari N (2019) Preparation and characterization of carrageenan-silver nanoparticles-Laponite nanocomposite coating on oxygen plasma surface modified polypropylene for food packaging. J Food Sci Technol 56(5):2545–2552

Wang LF, Rhim JW (2015) Preparation and application of agar/alginate/collagen ternary blend functional food packaging films. Int J Biol Macromol 80:460–468

Wrona M, Cran MJ, Nerín C, Bigger SW (2017) Development and characterization of HPMC films containing PLA nanoparticles loaded with green tea extract for food packaging applications. Carbohydr Polym 156:108–117

Yang L, Chen Y, Shen Y, Yang M, Li X, Han X, Jiang X, Zhao B (2017) SERS strategy based on the modified au nanoparticles for highly sensitive detection of bisphenol a residues in milk. Talanta 179:37–42

Yaşa I, Lkhagvajav N, Koizhaiganova M, Celik E, Sarı O (2012) Assessment of antimicrobial activity of nanosized Ag doped TiO(2) colloids. World J Microbiol Biotechnol 28(7):2531–2539

Youssef AM, Abdel-Aziz MS, El-Sayed SH (2014) Chitosan nanocomposite films based on AgNP and AuNP biosynthesis by Bacillus subtilis as packaging materials. Int J Biol Macromol 69:185–191

Youssef AM, El-Sayed SM, Salam HH, El-Sayed HS, Dufresne A (2015) Evaluation of bionanocomposites as packaging material on properties of soft white cheese during storage period. Carboydr Polym 132:274–285

Yu J, Yang J, Liu B, Ma X (2009) Preparation and characterization of glycerol plasticized-pea starch/ZnO–carboxymethylcellulose sodium nanocomposites. Bioresour Technol 100:2832–2841

Zare M, Namratha K, Ilyas S, Hezam A, Mathur S, Byrappa K (2019) Smart fortified PHBV-CS biopolymer with ZnO–Ag nanocomposites for enhanced shelf life of food packaging. ACS Appl Mater Interfaces 11(51):48309–48320

Zhang W, Lu G, Li S, Liu Y, Xu H, Cui C, Yan W, Yang Y, Huo F (2014) Controlled incorporation of nanoparticles in metal–organic framework hybrid thin films. Chem Commun 50:4296–4298

Zolfi M, Faramarz K, Mohammad M, Maryam H (2014) Development and characterization of the kefiran-whey protein isolate-TiO2 nanocomposite films. Int J Biol Macromol 65:340–345

Zubair M, Ullah A (2019) Recent advances in protein derived bionanocomposites for food packaging applications. Crit Rev Food Sci Nutr. https://doi.org/10.1080/10408398.2018.1534800

Funding

MKR received financial support from CNPq (National Council for Scientific and Technological Development, Brazil) (process number 403888/2018-2).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

dos Santos, C.A., Ingle, A.P. & Rai, M. The emerging role of metallic nanoparticles in food. Appl Microbiol Biotechnol 104, 2373–2383 (2020). https://doi.org/10.1007/s00253-020-10372-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-020-10372-x