Abstract

In many parts of the USA, expansive soils pose a significant hazard to infrastructures. These kinds of soils owe their characteristics to the presence of swelling clay minerals. As they get wet, they swell; conversely, as they dry, they shrink. Many stabilization methods have been developed to mitigate the adverse effects of expansive soil. One of them is the use of the ionic additive. In this research, a liquid ionic product is evaluated as a non-traditional stabilizer. Soil samples from a specific construction site in Texas and soil samples from Oklahoma were utilized. The evaluation tests involve the suction measurements, swelling, and plasticity index for treated and untreated soils. Cyclic swelling tests were also carried out on reconstituted specimens. From laboratory tests and analysis, it was found that this additive is effective in reducing swelling of both Texas and Oklahoma soils. It reduces swelling of Texas soils by 0.4–6% and Oklahoma soil by 2–7.4%. The results of swelling cycles reveal a permanent effect of this stabilizer on mitigating the swelling behavior. After the 3rd swelling cycle, the swelling for Oklahoma soils was 5.58% lower than the natural soil, and for Texas soils, it was reduced by 6.02–8.49% for different concentrations of the additive. However, no definitive trend was observed for reducing the shrinkage potential.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

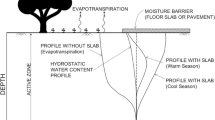

“Stabilization” refers to process where the engineering properties of the soil have been changed significantly (Kalidas 2014). There are two primary types of soil stabilization used today—mechanical stabilization and chemical stabilization. Mixing chemical additives with soil which changes the chemical properties of the soil, thereby upgrading its engineering properties, is known as chemical stabilization (Kalidas 2014). Traditionally, the addition of cement, lime, bituminous, or other agents is referred to as a “chemical” or “additive” method of soil stabilization (Kalidas 2014). Lime is the oldest stabilizer used in the world (Qingquan et al. 2004). Cement was first used as a stabilizer in the twentieth century (Azzam 2014). Other traditional stabilizers include fly ash, gypsum, slag, alum, kiln dust, and stone dust (Zahri and Zainorabidin 2019). But, unfortunately all of these products have been reported to have detrimental effects on the environment related to carbon dioxide (CO2) emission and poor performance during seismic activities (Zahri and Zainorabidin 2019). These issues have led the experts in using some new types of non-traditional stabilizers which are suitable, economical, and come in liquid or powder form (Arabani et al. 2012). These chemical stabilizers can work in different ways—encapsulation of clay minerals, exchange of interlayer cations, breakdown of clay minerals with expulsion of water from the double layer, and interlayer expulsion with subsequent moisture entrapment (Petry and Das 2001). Additives that work by exchanging interlayer cations (also known as ionic stabilizer) stabilize soil by the addition of certain ionizable salts in an aqueous concentration (Graf 1976). In the field, the aqueous solution is distributed throughout the soil by physical diffusion and mass flow (Graf 1976). These chemical stabilizers are usually sold as concentrated liquids and diluted with water at the construction site (Katz et al. 2001). Although these non-traditional soil stabilizers have potential advantages over traditional additives, professionals are reluctant to specify the use of these products due to several reasons like the lack of published studies and field performance data.

Ionic stabilization

The ionic chemical additive used in this research study was supplied by the manufacturers, ESSL, LLC. According to the manufacturers, it contains a mixture of sulfuric acid and naphthalene (Hariharan 2013). This stabilizer is mildly acidic but does not increase the natural soil pH and, as a result, cannot result in sulfate-induced heave (FPA 2007). It changes the characteristics of the negatively charged ions in the clay particles that attract and bind water. It was also found through previous research that this additive destabilizes the silicate structure in clay soil by decreasing negative charge (FPA 2007). It reduces the adsorbed water attached to the clay particles by leaching out the aluminum atoms responsible for the overall negative charge of clay (FPA 2007). Thus, treatment of the soil with this additive in a diluted form results in an electrochemical reaction that breaks the water bonding effect (FPA 2007). This mechanism reduces the shrink-swell potential of the soil and results in an increase in strength due to soil densification which significantly reduces the volume change and subsequently the upheaval movement of all expansive clay soils (FPA 2007).

The main objective of this research study is to understand and evaluate the interaction of an ionic chemical additive with soil and water, mainly in terms of potential reductions in swelling characteristics of expansive soils and also to find out the optimum diluted concentration for the soils used. In this research, soils from Texas and Oklahoma were treated with ionic stabilizer. The ionic stabilization of both soils was evaluated utilizing experimental results of suction measurements, Atterberg limits, free swelling, and swelling cycles.

Materials and laboratory tests

Treated and untreated undisturbed Shelby tube soil samples obtained from SH130 corridor in Texas (supplied by the manufacturer) and undisturbed Shelby tube soil samples from Osage county, Oklahoma (from our laboratory), were tested. Soil depth for Oklahoma soils was unknown. The Texas soil used here was reported to have high swelling and shrinking potential with high plasticity index values by previous research (Hariharan 2013). The Oklahoma soils showed high plasticity index values, similar to the Texas soils. Soil samples from Texas were collected from ground surface up to a depth of 12 feet. The whole depth was divided into 6 groups (0–2 ft, 2–4 ft, 4–6 ft, 6–8 ft, 8–10 ft, and 10–12 ft). After all the tests were completed, the remaining untreated soil (Texas and Oklahoma) was air dried and divided into two parts, one part was treated with ionic additive and the other part was mixed with deionized water (amount of additive and deionized water were adjusted to obtain optimum moisture content by measuring the moisture content of the dried soil so that it does not change the concentration). Shelby tube samples from Oklahoma were used for the same tests that were performed on the Texas soil. The samples were reconstituted and mixed with different concentrations of additive, i.e., 1:50, 1:100, 1:200, and 1:300.

For the Atterberg limits tests, ASTM D-4318, Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils was followed. For liquid limit, mechanical Casagrande device was used, and four points were obtained. Six undisturbed treated and six undisturbed untreated Texas soil samples were tested for their Atterberg limits. Five Oklahoma soil samples were tested, one untreated, and four treated with 1:50, 1:100, 1:200, and 1:300 concentrations.

Suction measurements

Using filter paper method, suction was measured for all undisturbed Texas soil samples (six treated and six untreated), reconstituted Texas soil samples (treated with 1:300 concentration and untreated), and Oklahoma (Osage) soil, untreated with 29% and 35% initial moisture contents and treated with concentrations 1:50, 1:100 (27% and 35% initial moisture contents), 1:200, and 1:300 (29% and 35% initial moisture contents).

Using the same method, osmotic suction measurements were conducted on the 1:50, 1:100, 1:200, and 1:300 concentrations of the ionic stabilizer. Three samples were prepared for each 1:50, 1:100, and 1:300 concentrations and two samples at 1:200 concentration.

Along with filter paper method, WP4 device and tensiometer were used to measure suction at different water contents. Combining the results, soil water characteristic curves (Fredlund et al. 2012) were developed. Soil water characteristic curves (SWCCs) were constructed using Fredlund and Xing (1994) equation for all undisturbed Texas soil samples (six untreated and six treated). For Oklahoma soil, soil water characteristic curves (SWCCs) were constructed for two untreated soils with 35% and 29% initial moisture contents; treated soil with 1:100, 1:200, and 1:300 concentrations with 35% initial moisture content; and treated with 1:50, 1:100, and 1:300 concentrations with 29%, 27%, and 29% initial moisture contents, respectively.

Swelling cycles

Free swell tests were conducted on all undisturbed Texas soils, reconstituted Texas soil (treated with 1:300 concentration and untreated), and Oklahoma (Osage) soil (untreated and treated with 1:50, 1:100, 1:200, and 1:300 concentrations). Using consolidation load frame, one-dimensional swelling was measured. ASTM D 4546, Standard Test Methods for One-Dimensional Swell or Collapse of Cohesive Soils, method B was followed. As free swelling was measured, no vertical pressure was applied. For the first hour, a dial gauge reading was taken at every 10 min, as the rate of swelling is very high in this period. After that, reading was taken at every 2 to 3 h. After the first 24 h, when the swelling slowed down, readings were taken at every 12 h. The test was stopped when there was no more increment in the dial gauge reading.

Swell cycles were conducted on reconstituted Texas soil (treated with 1:300 concentration and untreated) and Oklahoma (Osage) soil (reconstituted) treated with 1:50 (29% initial moisture content), 1:100 (22% initial moisture content), 1:100 (27% initial moisture content), 1:300 (29% initial moisture content) concentrations, and untreated soil (29% initial moisture content). To run swelling cycle test, first the soil samples already used for free swell test were air dried to reach the initial moisture content after being stored for 3 days. The soil samples were kept unwrapped, exposed to air, and placed on aluminum foil. But for most of the soils, after a short period of time, the soil sample started to generate cracks on the surface. To avoid this, the whole drying time was divided into several parts to allow the soil sample not to lose more than 2 gm of weight at a time. After it lost about 2 gm of weight, the soil sample was rapped nicely with plastic wrap and aluminum foil and stored in an ice chest for 24 h. This procedure can reduce the gradient of moisture in the specimen body and decrease the potential for cracking. After that the same procedure was repeated until it reached the desired water content. Then the soil sample was wrapped nicely with plastic wrap and aluminum foil and stored for 3 days. In the meantime, the dimension of the dried, slightly shrunk soil sample was taken. As this shrunk soil sample would not fit anymore in the metal ring used in the consolidation device, a 3D model of a ring was prepared so that the dried soil sample would fit in it and the ring would fit in the swelling test arrangement. Using a 3D printer, the 3D model was printed, and the 2nd swelling cycle test was performed. After the end of the 2nd cycle, the same procedure for air drying and 3D printed ring was followed to start the 3rd swelling cycle. Figure 1 shows a sample of a 3D printed ring.

Electrical conductivity measurements

Electrical conductivity of the liquids collected after swelling cycle tests were measured using a microprocessor-based electrical conductivity meter. Electrical conductivity is the measure of a material’s ability to allow the transport of an electric charge (Smedley 2012). The phenomenon of electric conductivity arises from the movement of ions or electrons through the conducting system. Measured conductivity is a good indicator of the presence or absence of conductive ions in solution (Masliyah and Bhattacharjee 2006).

Results

Plasticity indices

Tables 1 and 2 show the results of liquid limit, plastic limit, and plasticity indices of Texas and Oklahoma soils, respectively. For Texas soils, only the manufacturer supplied soils (1:300 concentration of additive and untreated) were used to observe the difference between treated and untreated soils. From these tables, it can be observed that the ionic stabilizer reduces the plasticity of Texas soils. For Texas soils, the range of plasticity index (PI) was found to be 28–48% for untreated soil. For treated soils, the range drops down to 25–44%. For Oklahoma soils, similar result was not found with the 1:300 concentration of additive. So, different concentrations were tested. The plasticity index (PI) was 39% for the untreated soil. For treated samples with 1:50, 1:100, 1:200, and 1:300 concentrations, the plasticity index (PI) values were found to be 35, 34, 38, and 36%, respectively. The latter means that for Oklahoma soil, the ionic stabilizer is not very effective in reducing plasticity. For treated Texas soils, liquid limit was found to be slightly decreasing. However, no definite pattern was observed in plastic limit test results. For treated Oklahoma soils, plastic limit slightly increases, but no definite pattern was observed in liquid limit test results.

Measurements of total suction

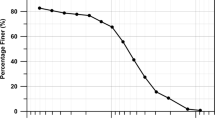

Figure 2 a and b show the results of filter paper tests for total suction of Texas and Oklahoma soils. For Texas soils, suction of untreated soil ranges from 3.65 to 2.98. For treated soils, it drops down to 3.33–2.09. Although there is a reduction in suction for treated soils, the difference between treated and untreated soil for all the depths is very low. For Oklahoma soils, total suction has been reduced for soil treated with 1:100 concentration with 27% initial moisture content (optimum moisture content is 26.5%). The other Oklahoma soil samples have very high initial moisture content, and total suction is higher than untreated soil with the same water content. This could occur because, in high water content, the actual concentration of the additive is much lower than the used concentration. Figure 3 shows the calibration curve developed by Bulut et al. (2001) that was used to determine total suction. From the results of both Oklahoma and Texas soils, it can be observed that, no definite pattern of suction reduction was found using the ionic additive.

Filter paper calibration curve (Bulut and Wray 2005)

Measurements of osmotic suction

The results shown in Table 3 indicate that the increase of ionic stabilizer concentration does not affect the osmotic suction. The difference between the highest and the lowest suction values is 0.14 pF, which is a very low value. These results support the results of total suction of treated and untreated soils presented in Fig. 2. It was also observed that filter paper method was not very effective in measuring suction when the suction value was low. For sample 3 with 1:200 additive concentration, it was not possible to obtain a reasonable suction value after multiple attempts.

Soil water characteristic curve

Soil water characteristic curves (SWCC) were developed using the results obtained from filter paper method, tensiometer, and WP4 device. The empirical equation proposed by Fredlund and Xing (1994) was used to develop SWCCs. The equation is as follows:

where af, nf and mf are curve fitting parameters. The parameter “af” does not affect the overall shape of the curve but shifts the curve toward the higher soil suction region as “af” increases (Fredlund et al. 2005). The parameter “mf” affects the slope of SWCC (Fredlund et al. 2005). Parameter “nf” is related to pore size distribution, the more uniform the pore sizes in the soil, the larger is the value of “nf” (Fredlund et al. 2005). Here, the values of “nf” will be compared as they are more significant than the others. The comparisons are shown in Table 4.

Figures 4 and 5 show two results for Texas and Oklahoma soils. It can be observed that there is no significant change in the soil water characteristic curves (SWCCs) for treated and untreated Texas and Oklahoma soils. However, the treated soils showed increased value of the “nf” parameter by Fredlund and Xing (1994) equation, which indicates that, in treated soils, the pore sizes are more uniform than in untreated soils (Babu et al. 2005). If the largest pore size is relatively small, the air entry value will be relatively large. From the test results (Figs. 4 and 5), treated soils show higher air entry value than untreated soils, which is an indication to the smaller pore size in treated soils (Konyai et al. 2009).

The results of swelling and swelling cycles

From the results of the free swell tests shown in Table 5, for Texas soils from depths 0–2 ft, 6–8 ft, and 10–12 ft and reconstituted soil, the final swelling for treated soil is lower than the untreated soil. For depths 2–4 ft and 4–6 ft although the treated soils show higher swelling than untreated soils, the difference is very low. From Table 6, all the treated Oklahoma soils show decrease in swelling than the untreated soil. For 1:100 concentration, soil with initial moisture content of 27% gave the best result. Since 1:300 is the manufacturer recommended concentration, two specimens at 1:100 and 1:300 concentrations were tested separately. The average of the two tests for each specimen gave equal percentage of swelling for both 1:100 and 1:300 concentrations (3.30%). That means the effect of 1:100 and 1:300 concentrations on swelling is equal and was also better than 1:50 and 1:200. From all the free swell test results, it can be seen that the additive is effective in reducing swelling for both Texas and Oklahoma soils.

A close evaluation of the test results shown in Tables 7 and 8 shows that the ionic additive makes some permanent changes in the soil matrix. For both types of soils, after 3 wetting-drying cycles, the % free swell for treated soils remains much smaller than that of the untreated soils. The additive is working better on Oklahoma soil when 1:300 concentration is used. After the 3rd cycle, the % free swell was increased by only 0.26%. The % free swell for both types of soils increased by a little amount after the 1st cycle. A possible reason for this could be the fact that, the wetting-drying cycles of months were simulated in the laboratory within a few days.

Electrical conductivity measurements

The swelling results show that it is possible that a little amount of additive was leached out of the soil samples. To confirm this hypothesis, electrical conductivity test was performed on the solutions collected after free swelling cycle tests on the Texas reconstituted soil (untreated and treated with 1:300 concentration) and Oklahoma (Osage) soil treated with 1:50, 1:100, and 1:300 concentrations and untreated soil. These results are shown in Table 9, from which we can see that treated soil has higher electrical conductivity than untreated soil. For treated soils, after the second swelling cycle, electrical conductivity is lower than the electrical conductivity found after first cycle. The electrical conductivity after the third cycle is lower than the value obtained after second cycle. This probably indicates that the chemical additive is being leached out of the soil to some extent by each wetting-drying cycle. However, the untreated soil is also showing decrease in electrical conductivity value. This could occur because of the fact that there are natural elements and ions in untreated soil which are also being leached out by wetting-drying cycles.

Conclusion

Based on the laboratory tests performed, it can be concluded that the chemical reduces the plasticity of Texas soils (with plasticity index value lower than 39%) from high to medium level (Sowers 1979). Swelling cycle tests were designed to simulate the effects of seasonal change. The test results show that the ionic stabilizer is very effective in controlling swelling of both Texas and Oklahoma soils. After the 3rd cycle of free swell test, the free swell of treated soil remained much smaller than that of untreated soil, which indicates that the additive is effective in reducing swelling and this mitigation for swelling behavior is permanent. This confirms the findings from the previous research that the additive makes some permanent changes to the soil structure that changes the behavior of the soil making it less prone to swelling. For the purpose of this study, which is to evaluate the performance of the additive in reducing swelling potential of soil, swelling cycle tests shows the effectiveness of the additive more clearly than the other test. The chemical stabilizer reduces suction when the initial moisture content is around the optimum moisture content value. Soil-water characteristic curves developed using Fredlund and Xing (1994) equation show that treated soils have smaller and more uniform pore sizes than untreated soils. Based on the results of different concentrations, 1:300 seems to be economical and the optimum concentration for both soil types tested. This research study was performed in 2016, and the swelling cycle measurement test used in this research is fairly new and can be analyzed and improved further.

References

Arabani M, Haghi AK, Hashemi SA, Karami M, Nikookar M, Bahari M (2012) “Properties of clayey soils stabilized by liquid ionic stabilizer”, 3rd International Conference on new Developments in Soil Mechanics and Geotechnical Engineering. Near East University, Nicosia

ASTM D 4318-10e1, 2014, “Standard test methods for liquid limit, plastic limit, and plasticity index of soils”, ASTM International, West Conshohocken, PA, 2010, DOI: https://doi.org/10.1520/D4318, www.astm.org

ASTM D 4546-08, 2008, “Standard test methods for one-dimensional swell or collapse of cohesive soils”, ASTM International, West Conshohocken, PA, 2008, DOI: https://doi.org/10.1520/D4546-08, www.astm.org

Azzam WR (2014) Utilization of polymer stabilization for improvement of clay microstructure. Appl Clay Sci 93-94:94–101

Babu GLS, Peter J, Mukesh MD, Gartung E (2005) Significance of soil suction and soil water characteristic curve parameters. ASTM Geotechl Test J 28:1

Bulut, R., Lytton, R. L. and Wray, W. K. (2001). “Soil suction measurements by filter paper.” Geotechnical special publication number 115

Bulut R, Wray WK (2005) Free energy of water-suction-in filter papers. ASTM Geotechl Test J 28:4

Foundation Performance Association (FPA) seminar presentation (2007), Houston, Texas.

Fredlund DG, Houston WN, Padilla JM and Perera YY (2005). “A new soil water characteristic curve design.” International Symposium of Advanced Experimental Unsaturated Soil Mechanics, EXPERUS 2005, Trento, Italy, pp 15-22

Fredlund DG, Rahardjo H, Fredlund MD (2012) Unsaturated soil mechanics in engineering practice. John Wiley & Sons, Inc., Hoboken, pp 184–200

Fredlund DG, Xing A (1994) Equations for the soil-water characteristic curve. Can Geotech J 31(3):521–532

Graf ED (1976). “Soil stabilization by ion diffusion.” United States Patent, 600 Dulany Street, Madison East, Concourse Level, Alexandria, VA 22314, US3959975

Hariharan N. (2013). “Effect of ionic stabilization on vertical movement in expansive subgrade soils in Texas”. Master's thesis, Texas A & M University. Available electronically from http://hdl.handle.net/1969.1/151141

Kalidas NS (2014). “Strength characteristic of stabilized embankments using fly ash.” IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE), Volume 11, Issue 4, Version VI, pp 01-34

Katz LE, Rauch AF, Liljestrand HM, Harmon JS, Shaw KS and Albers H (2001). “Mechanisms of soil stabilization with liquid ionic stabilizer.” Transportation Research Record: Journal of the Transportation Research Board, No. 1757, TRB, National Research Council, Washington, D.C., pp 50-57

Konyai S, Sriboonlue V, Trelo-Ges V (2009) The effect of air entry values on hysteresis of water retention curve in saline soil. Am J Environ Sci 5(3):341–345

Masliyah JH, Bhattacharjee S (2006) Electrokinetic and colloid transport phenomena. John Wiley & Sons, Inc., Hoboken, pp 194–196

Petry TM, and Das BM (2001). “Evaluation of chemical modifiers and stabilizers for chemically active soils – clays. Transportation Research Record: Journal of the Transportation Research Board, No. 1757, TRB, National Research Council, Washington, D.C., pp 43-49

Qingquan L, Qing WD and Zhijing G (2004). “The application of Ono-Standard stabilizers to the base course of rural roads.” International Conference on Sustainable Construction Management, Singapore.

Smedley S (2012). “The interpretation of ionic conductivity in liquids.” Plenum Publishing Corporation, 227 West 17th Street, New York, NY 10011

Sowers GF (1979) Introductory Soil Mechanics and Foundations: Geotechnical Engineering, 4th edn. Macmillan & Co., New York

Zahri AM and Zainorabidin A. (2019). “An overview of traditional and non-traditional stabilizer for soft soil.” IOP Conference Series: Materials Science and Engineering, Volume 527, 11th International Conference on Geotechnical Engineering in Tropical Regions (GEOTROPIKA) and 1st International Conference on Highway and Transportation Engineering (ICHITRA), Kuala Lumpur, Malaysia

Acknowledgements

The authors acknowledge the funding support and materials provided by the ESSL, LLC in Texas. The authors also would like to thank for the help with laboratory tests provided by the former graduate student at Oklahoma State University, Dr. Omar Amer and Mr. Harikrishna Kamparajuraman.

Code availability

Not applicable.

Funding

The authors acknowledge the funding support and materials provided by the ESSL, LLC in Texas.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Rights and permissions

About this article

Cite this article

Arefin, S., Al-Dakheeli, H. & Bulut, R. Stabilization of expansive soils using ionic stabilizer. Bull Eng Geol Environ 80, 4025–4033 (2021). https://doi.org/10.1007/s10064-021-02179-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-021-02179-5