Abstract

Diluted acids are used as chemical stabilizers in Texas to treat expansive soils for residential projects via deep injection. Due to the proprietary nature of the chemical stabilizers, there are very limited studies on the resilient modulus (MR) of chemically-treated expansive soils. This paper evaluates the effect of a liquid chemical stabilizer on the treatment of expansive soils collected from Texas and Colorado. The chemical solution, called ionic soil stabilizer (ISS) which contain sulfuric acid, phosphoric acid, citric acid, and water was used as an additive and tests were carried out on untreated and treated bulk soil samples in accordance with AASHTO T-307. The treated soil specimens were prepared by hand mixing the dry soils with the chemical stabilizer at three application ratios and two curing periods (7 and 28 days). The experiment results show that the value of resilient modulus increases with the increase of chemical application ratio. The resilient modulus of the treated sample cured for 28 days is much higher that of the untreated sample. Also, MR test results were found to be highly dependent on the compaction, moisture content, chemical ratio and curing time. Finally, MR test results are compared with compressive strength obtained from UCS test to find out the optimum treatment chemical dosage for field application.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction and Background

Resilient modulus (MR) is defined as the ratio of cyclic deviator stress to the recoverable or resilient strain and is considered as one of the important parameters to design flexible pavement (Banerjee 2017; Buchanan 2007; Han and Vanapalli 2016; Rahman and Tarefder 2015; Sun et al. 2016). It is a stiffness measurement that is profoundly influenced by the stress state and moisture content (Rahman and Tarefder 2015).

In general, the MR value of clay soil decreases when the moisture content increases (Buchanan 2007). Expansive soil is the kind of clay that tends to swell or shrink when the moisture content changes (Jones and Jefferson 2012). At least $1 billion per year is spent on rehabilitating U.S. residential homes and pavements (Jones and Jones 1987). To prevent and mitigate the loss, a variety of treatment methods have been developed in the past decades. Essentially traditional chemical stabilizers such as lime, cement and fly ash are utilized to control the swelling and enhance the soil stiffness (Katz et al. 2001; Rauch et al. 2002). Among these stabilizers, lime and fly ash are the most common stabilizer utilized in the U.S. Although the lime treatment increases the optimum water content as compared to the value of the control sample, MR and UCS values of lime treated sample are much higher than those of control samples (Cokca 2001; Kumar et al. 2007; Little 1987; Punthutaecha et al. 2006; Rahman and Tarefder 2015; Sweeney et al. 1988). There is a lack of research on the resilient modulus (MR) testing of liquid chemical-treated expansive soils.

In this study, an ionic soil stabilizer (ISS) is used to treat expansive soil collected from Texas and Colorado. The ISS is composed of sulfuric acid, phosphoric acid, citric acid, water, and surfactant. In the field, engineers dilute the ISS concentrate with water, and then deep inject it into the sublayer. According to the provider, this ISS is environmentally friendly, non-toxic, and efficient to treat expansive soil. Moreover, the transportation fee of the liquid chemical stabilizer is much less than that of traditional soil stabilizer (Katz et al. 2001).

Despite the several benefits as mentioned above, engineers are reluctant to implement the chemical treatment of the expansive soil in general practice. This is primarily due to the lack of literature explaining the mechanisms involved in treating the expansive soils with the chemical, especially the resilient modulus of the soil before and after treatment. In this research, the soil collected from Texas and Colorado were treated with ISS in the laboratory. Furthermore, a series of lab testing including MR and UCS tests on expansive soils before and after treatment with different application ratio was carried out. Finally, the effect of ISS content is evaluated through analysis of MR and UCS test results, and an optimum ISS ratio is recommended.

2 Material Properties

In this study, Texas soils were sampled from Caddo Mills in Dallas area, and the Colorado soils were collected from the state of Colorado. The Dallas soil for laboratory testing was collected at 3 feet below ground surface, and the topsoil above this depth was neglected to avoid the contamination. These soils were excavated in large chunks and transported to the laboratory. Before the specimen preparation for Atterberg Limits and Standard compaction test, the soil sample was oven dried and pulverized through No. 40 sieve. Plasticity index (PI) for Colorado and Texas soil was found to be 42 and 58, respectively.

In the construction site, the suppliers injected ISS provided by TX Prochem via high pressure. The ratio recommended by the supplier was to mix 8 gal of the liquid chemical concentration and 12 oz of surfactant with 6000 gal of water. To simulate the recommended field application ratio, 5 ml of the chemical concentration and 0.057 g of the surfactant were diluted into 1 gallon of water. Apart from this ratio, two other ratios were designed to evaluate the best possible ratio for soil treatment with ISS, and the tested ratios are shown in Table 1.

2.1 Standard Compaction Test

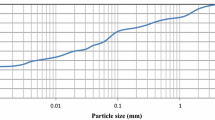

Standard compaction test was conducted according to ASTM D698 to determine the relationship between maximum dry density (MDD) and optimum moisture content (OMC). For treated soils, around 1.8 kg of pulverized dry soils were mixed with various proportions of ISS in separate containers. As liquid chemical may continue to react with the soil after initial mixing, the prepared soil samples were stored in the moisture room at least for 24 h before proctor test. Figure 1 shows the standard compaction test results for Texas and Colorado soils with various ratios of treatment. Unlike control samples, There is an increase in OMC and decrease in MDD with adding ISS. Such behavior could be explained that the soil chemical reaction may not finish without sufficient water, which resulted in OMC increasing.

3 Specimen Preparation

Before UCS and MR tests, both untreated and treated samples were compacted in a split mold to reach the target density of 95% MDD and 100% OMC to simulate the field condition. The sample was 2.8 inches in diameter and 5.8 inches in height. For treated specimens, three different application ratios of ISS were utilized in this study. Dry soil was hand-mixed with ISS uniformly and then put inside a plastic bag and stored in a 100% humidity-controlled moisture room for overnight to ensure that there is sufficient time to allow soil-chemical reaction after initial mixing. After compaction, soil samples were cured in moisture room for 7 and 28 days respectively. At least two samples were prepared for each test for repeatability check.

4 Unconfined Compressive Strength Test

The UCS test was carried out both on untreated, and ISS stabilized specimens. ASTM D2166 is the standard to determine the relationship between unconfined compressive strength and axial strain.

5 Resilient Modulus Test

In this study, resilient modulus test of untreated and treated samples was conducted according to AASHTO T307 (Buchanan 2007; Rahman and Tarefder 2015). The test progress contained 15 stress sequences. Each sequence included a different combination of confining pressure and deviator stress. During the test, 0.1 s of load pulse was followed by 0.9 s of rest period. One loading cycle combined one load pulse and one rest period. Although each sequence includes 100 cycles, resilient modulus was only determined by averaging stress-strain responses of the last five cycles. Figure 2 shows the resilient modulus test equipment used in the lab.

6 Results and Discussions

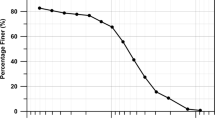

Figure 3 shows the UCS test results for untreated and treated samples with different ISS ratios. For the Texas soil, the sample treated with more ISS revealed higher unconfined compressive strength especially for soil treated by the third ratio. Furthermore, the strength of treated sample curing 28 days was greater than that of treated sample curing seven days. Perhaps the soil and chemical reaction were continuously happening after seven days. For specimen treated by the second ratio, the treated samples were even less than the control one. The decrease may be attributed to the decrease in maximum dry density and increase in optimum water content.

Table 2 shows the resilient modulus of Texas and Colorado soil before and after treatment. The MR value reduced with increasing deviator stress due to stress softening the effect of soils (Rahman and Tarefder 2015). Also, MR value was found to be influenced by OMC. For instance, there was much more ISS content in the third ratio as compared with the first ratio. Texas soil treated by the third ratio after seven days of curing has MR value in the range between 43 to 53.3 MPa. However, Texas soil treated by the first ratio after seven days of curing has MR value between 66.3 and 77.6 MPa. The reduction of MR value is attributed to the fact that OMC of soil treated by the third ratio is nearly 1.5% more than that of soil treated by the first ratio, which could be readily seen from Fig. 1. In sum, to some extent, MR value of treated soil increased in comparison with control samples.

7 Conclusions

The conclusions obtained from the laboratory test before and after treatment are summarized as follows:

After treatment with ISS, soil strength displayed a significant increase, especially for soil treated by the third ratio. In general, the extended curing period for treated sample resulted in higher unconfined strength the sample would perform.

The MR value increased due to the ISS application ratio for both the Texas and Colorado soil. Also, the moisture content in expansive soils has great influence on ISS treatment.

This paper summarizes the effect of ISS dosage on UCS and resilient modulus test results for Colorado and Texas soil. Considering the best fit results among UCS and resilient modulus, the first ratio is recommended for the use in the field.

References

Banerjee, A.: Response of unsaturated soils under monotonic and dynamic loading over moderate suction states. Doctoral Dissertation, University of Texas at Arlington, Arlington, Texas (2017)

Buchanan, S.: Resilient modulus: what, why and how? Technical report, p. 13 (2007)

Cokca, E.: Use of class C fly ashes for the stabilization of an expansive soil. J. Geotech. Geoenviron. Eng. 127(7), 568–573 (2001)

Han, Z., Vanapalli, S.K.: Relationship between resilient modulus and suction for compacted subgrade soils. Eng. Geol. 211, 85–97 (2016)

Jones, D.E., Jones, K.A.: Treating expansive soils. Civ. Eng.—ASCE 57(8), 62–65 (1987)

Jones, L.D., Jefferson, I.: Expansive Soils. ICE Publishing, New York (2012)

Katz, L., et al.: Mechanisms of soil stabilization with liquid ionic stabilizer. Transp. Res. Rec. J. Transp. Res. Board 1757, 50–57 (2001)

Kumar, A., Walia, B.S., Bajaj, A.: Influence of fly ash, lime, and polyester fibers on compaction and strength properties of expansive soil. J. Mater. Civ. Eng. 19(3), 48–242 (2007)

Little, D.N.: Evaluation of structural properties of lime stabilized soils and aggregates (1987)

Punthutaecha, K., Puppala, A.J., Vanapalli, S.K., Inyang, H.: Volume change behaviors of expansive soils stabilized with recycled ashes and fibers. J. Mater. Civ. Eng. 18(2), 295–306 (2006)

Rahman, M.T., Tarefder, R.A.: Assessment of molding moisture and suction on resilient modulus of lime stabilized clayey subgrade soils (2015)

Rauch, A., Harmon, J., Katz, L., Liljestrand, H.: Measured effects of liquid soil stabilizers on engineering properties of clay. Transp. Res. Rec. J. Transp. Res. Board 1787, 33–41 (2002)

Sun, X., Han, J., Crippen, L., Corey, R.: Back-calculation of resilient modulus and prediction of permanent deformation for fine-grained subgrade under cyclic loading. J. Mater. Civ. Eng. 29(5), 4016284 (2016)

Sweeney, D.A., Wong, D.K.H., Fredlund, D.G.: Effect of lime on a highly plastic clay with special emphasis on aging (1988)

Acknowledgements

The authors would like to appreciate TX Prochemical to provide the testing ISS and Mr. Ben Baker for the help of soil sample collection for this study.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

He, S., Yu, X., Gautam, S., Puppala, A.J., Patil, U.D. (2018). Resilient Modulus of Liquid Chemical-Treated Expansive Soils. In: Li, L., Cetin, B., Yang, X. (eds) Proceedings of GeoShanghai 2018 International Conference: Ground Improvement and Geosynthetics. GSIC 2018. Springer, Singapore. https://doi.org/10.1007/978-981-13-0122-3_13

Download citation

DOI: https://doi.org/10.1007/978-981-13-0122-3_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-0121-6

Online ISBN: 978-981-13-0122-3

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)