Abstract

New triazolium Schiff bases (TSBs) were synthesised via a simple and high throughput process. The new salts were successfully characterised. When reacted with Cu(CH3CN)4PF6, the TSB salts formed mononuclear triazole Schiff base copper(I) complexes and dinuclear complexes that were also characterised. The copper complexes were generated in situ (mixtures of TSB salts with Cu(CH3CN)4PF6) and applied as homogeneous catalysts for the C–C coupling of a variety of aryl ketones with aryl alcohols, from which significant reactivity was observed. Reaction conditions were optimised, and the results indicate that the catalyst systems are very robust. A catalyst concentration of 10 mol% efficiently and selectively catalysed the α-alkylation of methyl phenyl ketone and its derivatives to afford up to 94% yield of 1,3-diphenylpropan-1-one and its analogues. The process is adaptable with analogues of acetophenone and benzyl alcohol bearing various regulating substituents tolerated.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

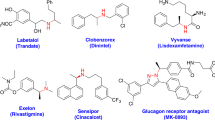

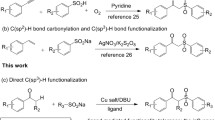

Carbon–carbon (C–C) bond formation is a very important transformation in organic synthesis; as it provides a viable route to the functionalization, chain extension, and even dipole inversion of organic molecules. Various routes are available for achieving the C–C coupling reaction. However, traditional reaction methods of C–C bond coupling suffer from the generation of unfavourable organic waste from side reactions [1]. Recently, homogeneous catalysis-driven C–C coupling via the α-alkylation of ketones with alcohols, has become an attractive and environmentally sustainable way of achieving saturated C–C bond formation in organic synthesis. The metal-centred catalyst activated coupling reaction is mechanistically characterized by hydride abstraction (from the alcohol) and donation to the derived chalcone [2], a process that is widely considered unique due to its excellent atom efficiency and greenness with H2O as the only by-product.

The α-alkylation of ketones with alcohols has traditionally been conducted with the aid of catalyst systems based on expensive heavy metals such as iridium [3,4,5], ruthenium [6,7,8,9,10,11], or rhodium [12,13,14,15]. And, only a handful of catalytic systems based on environmentally benign earth-abundant metal complexes have been reported to date. These include homogeneous systems based on Fe [16, 17], Mn [18], and Co [19]. Also, some heterogeneous catalysts such as CuHT (HT = hydrotalcites) [20], NiNP (NP = nanoparticles) [21], and Ag/Mo oxides [22] have also been reported for C–C coupling reactions via the α-alkylation of ketones with alcohols. Due to a shortage of catalyst systems that are both selective and high yielding for this important chemical transformation, a recent promising paper [23] that reported the β-alkylation of secondary alcohols with primary alcohols catalysed by homogeneous Cu-NHT (NHT = N-heterocyclic thiolates) complexes serve as an inspiration for this study. We hypothesize that adapting a similar green process; the C–C coupling of ketones with alcohols with improvements in product selectivity could be achieved with appropriately designed ligands and complexes as catalysts. In this respect, we herein report the synthesis of new triazolium Schiff bases (TSBs), and for the first time, the application of their in situ generated Cu(I)-TSB complexes as catalysts for the selective C–C coupling of ketones with alcohols.

Results and discussion

Synthesis and characterization

The general synthetic procedure to the title triazole Schiff base compounds is presented in Scheme 1, of which details on compounds 1, 2, and 6 have been reported elsewhere [24, 25]. The properties shown by all the new compounds; 3–5 are similar to that reported for 2 and consistent with previous reports [26,27,28]. Formation of each TSB was confirmed by the disappearance of the aldehyde singlet proton at 10 ppm and the appearance of distinct singlet signals between 8.30–8.89 ppm and 8.25–8.37 ppm in their proton NMR spectra assigned to the C-5 triazolium and imine protons, respectively. NMR spectra of all the salts gave aromatic and aliphatic signals within the expected regions [29]. In the 13C NMR spectra, the characteristic imine carbon resonance appeared as expected downfield at 160–162 ppm. Further characterization of the TSB salts was achieved with IR and MS analysis. Attempts to obtain microanalytical data were unsuccessful due to varying moisture contents, as they easily absorbed atmospheric moisture once exposed or during handling [30].

The copper complexes were synthesized by the reaction of each respective TSB salt with Cu(CH3CN)4PF6. Formation of the copper complexes was confirmed by proton NMR spectroscopy via the significant downfield shifts of the imine proton signals that appear at circa 10 ppm in their 1H NMR spectra. This is accompanied by corresponding far downfield shifts of the imine carbon (CH=N) signals (circa 191 ppm) in their 13C NMR spectra as compared to that of the triazolium salts (Figs. 1, 2). All the copper complexes are soluble in acetonitrile, THF, methanol, and DMSO. They gradually decomposed on exposure to air and moisture. Their gradual decomposition upon exposure to air made it practically challenging to obtain full spectroscopic characterization data, which is common for highly reactive and unstable Cu(I) complexes [31].

However, the NMR data yielded important evidence on the coordination environments of the ligands to the copper metal centres. For instance, a comparative analysis of the 1H NMR data of ligand 6 (Fig. 1, top) and its corresponding copper complex 11 (Fig. 1, bottom) shows that only the imine nitrogen (Cu–N) was coordinated to the copper in 11. This is evidenced by the significant far downfield shift of the imine proton (a, Fig. 1, from 8.3 to 10 ppm) while the triazolium C5-proton (b, Fig. 1) remained virtually unaffected by the coordination at 8.9 ppm. There is also a corresponding downfield shift of the imine carbon from 160 to 191 ppm (Fig. 2). Literature reports have observed similar trend when Schiff base ligands coordinate to metal centres, which results in the deshielding of the coordinated imine (HC=N) protons in the 1H NMR data as we earlier noted [32,33,34,35,36].

The FT-IR spectra of the salts showed characteristic Schiff base imine C=N stretches at 1642–1692 cm−1. This was observed to slightly shift with coordination of the imine to Cu in all the complexes. The shifts in frequencies to higher wavenumbers point to coordination to the metal centres, as shown in Scheme 1 for complexes 7–11. Similarly, broad absorption bands around 3200 cm−1 in the FT-IR spectra of the Cu-TSB complexes are due to absorbed moisture, an inevitable characteristic of the highly hygroscopic compounds. The complexes remain stable in dry acetonitrile solution for a few days, but dried samples gradually decomposed upon storage. This also made it difficult to obtain acceptable CHN analyses data or suitable crystals for single-crystal X-ray diffraction despite several attempts [31]. However, based on the spectroscopic evidence available, 2-coordinate linear geometries are proposed for all the complexes in the solid-state (Scheme 1). Essentially, in all the complexes, the ligands coordinated to the copper metal via the N-donor atom(s) of the Schiff base Cu–N(SB), with no evidence of Cu–C(carbene) binding via the triazole N-heterocycle.

C–C coupling of aryl ketones with benzyl alcohol

The homogenous C–C coupling of aryl ketones and primary aromatic alcohols has mostly been achieved by the use of acetophenone and benzyl alcohol as starting materials with Ir, Ru, or Rh metal complexes as catalysts under basic conditions (usually KOH) in solvents such as dioxane or toluene at 80–120 °C for 4–24 h. One of the mildest conditions reported for this transformation was by Donohoe and coworkers on a Rh complex used for the alkylation of valerophenone at temperatures as low as 65 °C over a period of 48 h [12]. However, in the case of earth-abundant metal (Fe, Co, or Mn) complex based catalyst systems, the mildest conditions were 110–140 °C for not less than 22 h [16, 18, 19]. Hence, we set out in this project to develop new Cu-based catalysts capable of operating under mild reaction conditions. To achieve this objective, we began with the choice of acetophenone and benzyl alcohol as model substrates and used milder THF as a solvent to substitute for the higher boiling and environmentally harsher dioxane or toluene utilized by previous researchers [12, 16, 18, 19].

At the beginning of this catalytic process, it was necessary to determine if any of the in situ generated metal complexes obtained by mixing equimolar quantities of the ligand precursor salt 2 and Cu(CH3CN)4PF6 is any good as a catalyst system and to compare its efficiency to that of an isolated and characterized metal complex bearing the same ligand. Hence, the catalytic activity of complex 7 and its in situ generated equivalent were first trialed on acetophenone (12a) and benzyl alcohol (13a) (Table 1). It is interesting to note that both the in situ generated catalyst and the isolated complex 7 (Table 1, entries 1, 2) gave quite similar activities (45% vs. 43%) and also both methods exclusively yielded the desired 1,3-diphenylpropan-1-one product 14a with no evidence of any base promoted chalcone formation. Henceforth, in keeping with the overall objective of simplifying the catalytic process, for the remainder of this study only in situ generated catalysts were utilized. It is important to emphasize that in situ generated species have been widely employed in homogeneous catalysis as viable alternatives to isolated molecular species. This is due to the advantages they offer that include their ease of preparation, potential stability in the catalytic medium (this is especially important for unstable complexes such as those in this study) and cost-effectiveness through the elimination of often laborious and time-consuming catalyst synthesis and isolation procedures. Specifically, in situ generated Cu catalyst systems have been reported for use in many important homogeneous transformations that include for the transfer hydrogenation of unsaturated substrates [37], coupling reactions [38], and cyclohexane oxidation reactions [31].

The choice of KOH as the base for the optimization trials is because it is readily available, cheap and is commonly used in reactions that require a simple basic medium. It is also readily used as an auxiliary in transfer hydrogenation, base activated coupling reactions and Cu catalyzed Ullman reactions [29, 39]. Investigation of the influence of the base on the catalytic process (entries 2–6) indicates that more exotic and organic bases are less effective than KOH with lowered (KOtBu to K3PO4) or zero isolated product yields (K2CO3 and trimethylamine). Obviously, in the absence of a catalyst system (i.e. absence of both the Cu(I) salt and ligand precursor salt), a base promoted chalcone formation was observed (24% isolated yield of chalcone). On the other hand, a significant drop in isolated yield of the desired product was observed when either only the metal precursor salt Cu(NCCH3)4PF6 or the ligand precursor salt 2 was used in isolation (entries 7 and 8, respectively).

A gradual increase in catalyst concentration (entries 10–12) from 4 mol%, 8 mol% through to 10 mol% led to steady improvements (56%, 72% and 94%, respectively) in isolated yields of 14a. On the other hand, an attempt to improve the efficiency of the base only resulted in lower isolated yields at reduced KOH concentrations (entries 13, 14). This observation is anticipated, as the base is the auxiliary species in the catalyst system responsible for the initial abstraction of a proton from the methyl ketone. The formed enolate eventually condenses with the in situ generated aldehyde (from the benzyl alcohol) to yield the desired product, hence the use of an excess of the base is standard in these reactions [16, 19]. The result presented in entry 15, is our attempt to utilize some of the reported advantages of highly concentrated green reactions by eliminating the need for a solvent. However, only a modest yield of the 14a was recorded which helps to establish the positive influence of the THF in catalyst generation and ensuring its homogeneity with the substrates, leading to high conversions to the desired product.

Further optimization trials using the same reaction conditions but varying the ligand precursor salt 3–6 for the generation of the in situ catalyst led to moderate to good isolated yields of 14a (entries 16–19). Additional azolium functionality on the ligand framework as in 4, led to the lowest yield (66%, entry 17), which was in part due to its relatively lower solubility in the solvent THF. Likewise, the bifunctional 1,2,3-triazolium Schiff base compounds 5 and 6 gave lower yields when compared to 2 (entries 18, 19) which could be attributed to steric hindrance due to their bulky multifunctional ligand frameworks. The main difference between ligand precursor salts 3–6 and the more active precursor 2 is the additional potentially N-chelating pyridyl moiety on the imino Schiff base backbone of 2, which played a role in stabilizing the metal centre as a hemilabile N-donor. Thus, the optimized reaction conditions were found to be refluxing a mixture of in situ generated copper complex 7 (10 mol% each of Cu(CH3CN)4PF6 and 2) as the catalyst, the substrates (acetophenone, 1 mol equiv.; benzyl alcohol, 1.5 mol equiv.), and 2 equivalents of KOH (base, 2 mol equiv.) in THF at reflux for 24 h.

Adopting the optimum reaction conditions presented above, the scope and limitations of the catalyzed α-alkylation reaction were further studied with the results presented in Table 2.

A variety of substituted ketone and alcohol substrates bearing electronic and steric regulating groups on their structural backbones were used to evaluate the overall efficiency and generality of the in situ catalysis based on 7. The obtained results show that the system is highly efficient for catalyzing the coupling of various substituted aryl ketones with benzyl alcohols to achieve the required α-alkylated ketone products in moderate to excellent isolated yields. For instance, electron-rich acetophenone derivatives, such as 4-methoxy-, 4-nitro-, 4-methyl-, and 2-methylacetophenone reacted smoothly with benzyl alcohol and 4-chlorobenzyl alcohol to form a series of α-alkylated ketones with good to excellent isolated yields (66–86%). Similarly, 4-aminoacetophenone was tolerated due to the high selectivity of the catalyst system, since there is the possibility of the amino group reacting with the aldehyde group formed in situ to give a Schiff base product, but that was not observed. However, an exception was recorded for 4-chlorobenzyl alcohol, as the chalcone product was obtained in an excellent yield (92%; Table 2, 14l). Besides, electron-deficient acetophenones were also alkylated to their corresponding desired products with good isolated yields. Also, 2-Phenylacetophenone was not tolerated due to steric hindrance. Cyclic and alkyl ketones were however not tolerated. These observations were attributed to ring strain in the former and aromatic stability in the latter cases [40, 41]. Simple alkanols like ethanol or octanol as well as other primary and tertiary alcohols were not tolerated by the catalyst system, as all attempts led to the isolation of only the substrates, even with an extended reaction time of 3 days. This was not exactly unexpected as cyclic and aliphatic alcohols have been reported to portray poor reactivity toward α-alkylation with ketones [15].

Proposed reaction mechanism

The hydrogen auto-transfer (or hydrogen borrowing) mechanism is generally accepted as the most plausible path for the α-alkylation of ketones with alcohols [2]. The activities of the catalyst systems reported herein are rationalized based on the steps presented in Scheme 2. Thus, as an example, benzyl alcohol (A) is first dehydrogenated to benzaldehyde (B) by the Cu(I) catalyst pre-formed in situ to form the protonated Cu(II)–H intermediate. Subsequent Aldol condensation with the methyl ketone promoted by the base produces the α,β-unsaturated ketone (C), which is then hydrogenated to the desired α-alkylated ketone (D) by the Cu(II)–H intermediate hence completing the cycle. Along with the metal, the imine N-coordinated TSB ligand serves to provide a stable metal–ligand cooperative environment involving the Cu(II)–H intermediate that provides the needed steric and electronic control of product yield and selectivity as proposed by Tan et al. [23]. This is justified by the scope and selectivity of substrates presented herein.

Conclusion

In this report, we have reported for the first time, a new set of triazolium Schiff bases and fully characterized them by spectroscopic techniques. Combinations of the salts with a copper precursor salt [Cu(CH3CN)4PF6] were tested as in situ catalysts for the α-alkylation of a series of functionalized aryl ketones with aryl alcohols. The catalyst systems proved to be simple to prepare, mild and cost-effective, with high isolated yields and selectivity to the 1,3-diphenylpropan-1-one analogue products.

Experimental

All substrates and reactants were purchased from Sigma-Aldrich and used as received. All the solvents (acetonitrile, tetrahydrofuran, methanol, and diethyl ether) were purchased from Merck and purified using a commercially available MBraun MB-SP Series solvent purification system equipped with activated alumina columns. The methods of Lal and Diez-Gonzalez [42] was adopted in the preparation of the triazole synthon 4-(2-formylphenyl)-3-methyl-1-propyl-1H-1,2,3-triazol-3-ium iodide (1, Scheme 1). Also, the triazolium Schiff bases (E)-3-methyl-1-propyl-4-[2-[[[2-(pyridin-2-yl)ethyl]imino]methyl]phenyl]-1H-1,2,3-triazol-3-ium hexafluorophosphate(V) (2) and 4,4′-[[(1E)-[butane-1,4-diylbis(azanylylidene)]bis(methanylylidene)]bis(2,1-phenylene)]bis(3-methyl-1-propyl-1H-1,2,3-triazol-3-ium) hexafluorophosphate(V) (6) were prepared following our methods [24, 25]. Unless otherwise stated, all syntheses were performed under a dinitrogen atmosphere using standard Schlenk line techniques. NMR spectra were recorded on a Bruker Avance 400 MHz spectrometer operated at ambient temperature with δ values reported in ppm and referenced to Me4Si as the internal standard for both 1H and 13C NMR data. Infrared spectra were recorded on a Perkin Elmer universal ATR Spectrum 100 FT-IR spectrophotometer. Mass spectrometry and elemental analysis (where applicable) were recorded on a Waters Micromass LCT Premier TOF MS-ES+ and ThermoScientific Flash2000 Elemental Analyzer, respectively.

General procedure for the synthesis of the TSB salts

The Schiff base-functionalized triazolium salts were synthesized by the adaptation of published procedures [43]. Hence, to a 20 cm3 Schlenk tube equipped with a stirrer bar and condenser was added methanol solution of 0.357 g 1 (1 mmol). The solution was then refluxed for 4 h with the respective equivalents of either mono- (for salts 2, 3, and 4) or diamines (for salts 5 and 6) as shown in Scheme 1. Afforded crude products were then allowed to cool to room temperature and after washing with dry ethyl acetate and diethyl ether (3 × 20 cm3), yielded the corresponding triazolium Schiff bases.

(E)-3-Methyl-4-[2-[(phenethylimino)methyl]phenyl]-1-propyl-1H-1,2,3-triazol-3-ium hexafluorophosphate(V) (3, C21H25F6N4P)

The procedure is similar to that reported for 2 [24, 25]. The quantities used are: 0.357 g 1 (1 mmol) and 0.242 g 2-phenylethanamine (2 mmol). The salt was obtained as a yellow viscous oil. Yield 0.41 g (86%); 1H NMR (CD3CN, 400 MHz): δ = 1.05 (3H, t, J = 7.39 Hz), 2.05 (2H, m, J = 7.25 Hz), 2.80 (2H, t, J = 7.11 Hz), 3.73 (2H, t, J = 3.55 Hz), 3.79 (3H, s), 4.56 (2H, t, J = 7.07 Hz), 7.17 (2H, d, J = 7.29 Hz), 7.23 (1H, t, J = 7.31 Hz), 7.31 (2H, t, J = 7.34 Hz), 7.50 (1H, d, J = 7.54 Hz), 7.69 (1H, t, J = 3.25 Hz), 7.79 (1H, t, J = 3.24 Hz), 7.85 (1H, d, J = 7.67 Hz), 8.27 (1H, s, CH=N, imine), 8.30 (1H, s, triazolium) ppm; 13C NMR (CD3CN, 100.6 MHz): δ = 10.42, 23.24, 37.07, 38.14, 55.84, 62.52, 120.65, 126.67, 128.92, 129.01, 129.27, 131.17, 132.16, 132.16, 132.67, 132.88, 136.12 (C5-triazolium), 140.40, 143.21, 160.52 (CH=N, imine) ppm; IR (ATR): \(\overline{v}\) = 2972 (C–H, sp2), 1692 (C=N), 1587 (C=C), 1137 (N=N), 832 (\({\mathrm{PF}}_{6}^{-}\)), 771 (Ar C–H) cm−1; HRMS: m/z calcd for C21H25N4+ 333.2079, found 333.2088.

(E)-3-Methyl-4-[2-[[[2-(3-methyl-1H-imidazol-3-ium-1-yl)ethyl]imino]methyl]phenyl]-1-propyl-1H-1,2,3-triazol-3-ium hexafluorophosphate(V) (4, C19H26F12N6P2)

To a dry 20 cm3 Schlenk tube charged with excess anhydrous MgSO4 (0.602 g, 5 mmol) was added 0.357 g 1 (1 mmol), and excess DCM solution of in situ liberated 2-aminoethylbromide (0.496 g, 4 mmol). The mixture was then stirred at room temperature for 12 h. At the end of the reaction time, the contents of the tube were filtered under vacuum, and the filtrate concentrated to give a crude TSB salt bearing an ethyl bromide substituent on the N-atom. This was then further refluxed with 0.164 g methylimidazole (2 mmol) in acetonitrile for 12 h to afford an intermediate precursor to 4 bearing bromide counterion to the imidazolium moiety. Subsequent anion metathesis with KPF6 to exchange the Br− for PF6− followed by purification with dry ether (3 × 20 cm3) gave the diazolium hexaflourophosphate salt 4 as a yellow oil. Yield 0.51 g (81%); 1H NMR (CD3CN, 400 MHz): δ = 1.06 (3H, t, J = 7.29 Hz), 2.09 (2H, m, J = 4.36 Hz), 3.73 (6H, s), 3.88 (2H, s), 3.94 (2H, s), 4.67 (2H, t, J = 7.14 Hz), 7.40 (1H, s), 7.44 (1H, s), 7.56 (1H, d, J = 2.85 Hz), 7.73 (1H, t, J = 3.29 Hz), 7.80 (1H, t, J = 3.29 Hz), 8.02 (1H, d, J = 3.89 Hz), 8.37 (1H, s, CH=N, imine), 8.69 (1H, s, triazolium), 8.89 (1H, s, imidazolium) ppm; 13C NMR (CD3CN, 100.6 MHz): δ = 10.41, 23.16, 36.60, 38.52, 50.48, 56.04, 59.58, 121.73, 123.22, 124.05, 129.97, 131.02, 131.84, 132.44, 133.10, 134.91, 135.62 (C5-triazolium), 136.99 (C2-imidazolyl), 141.96, 162.92 (CH=N, imine) ppm; IR (ATR): \(\overline{v}\) = 2970 (C–H, sp2), 1643 (C=N), 1522 (C=C), 1168 (N=N), 832 (\({\mathrm{PF}}_{6}^{-}\)), 751 (Ar C–H) cm−1; LRMS: m/z calcd for C19H26N622+K 188.2211, found 188.1953.

4,4′-[[(1E)-[Ethane-1,2-diylbis(azanylylidene)]bis(methanylylidene)]bis(2,1-phenylene)]bis(3-methyl-1-propyl-1H-1,2,3-triazol-3-ium) hexafluorophosphate(V) (5, C28H36F12N8P2)

The reaction of 2 mol equivalents of 1 (0.714 g, 2 mmol), with 1 mol equivalent of 1,2-diaminoethane (0.060 g, 1 mmol) in refluxing MeOH for 4 h yielded crude 5. The resulting crude product was then concentrated and thoroughly purified with dry ether (3 × 25 cm3). Removal of all volatiles afforded the bis-triazolium hexafluorophosphate salt 5 as a yellow oil. Yield 0.72 g (93%); 1H NMR (CD3CN, 400 MHz): δ = 1.02 (6H, t, J = 7.42 Hz), 2.05 (4H, m, J = 7.25 Hz), 3.59 (4H, s), 3.89 (6H, s), 4.58 (4H, t, J = 7.09 Hz), 7.55 (2H, d, J = 6.93 Hz), 7.71 (2H, t, J = 3.25 Hz), 7.81 (2H, t, J = 3.28 Hz), 7.93 (2H, d, J = 7.71 Hz), 8.35 (1H, s, CH=N, imine), 8.54 (1H, s, triazolium) ppm; 13C NMR (CD3CN, 100.6 MHz): δ = 10.43, 23.26, 38.38, 55.83, 61.59, 120.88, 129.38, 131.36, 131.95, 132.71, 132.90, 135.98 (C5-triazolium), 142.91, 161.17 (CH=N, imine) ppm; IR (ATR): \(\overline{v}\) = 2981 (C–H, sp2), 1644 (C=N), 1588 (C=C), 1174 (N=N), 852 (\({\mathrm{PF}}_{6}^{-}\)), 771 (Ar C–H) cm−1; HRMS: m/z calcd for C28H36F6N8P+ 629.2705, found 629.2687.

General synthetic procedure to the synthesis of the copper complexes

A typical method for the synthesis of the triazole Schiff base [Cu-2]PF6, complex 7, is described for the Cu(I) compounds.

(E)-3-Methyl-1-propyl-4-[2-[(pyridin-2-ylimino)methyl]phenyl]-1H-1,2,3-triazol-3-ium copper(I) hexafluorophosphate(V) ((Cu-2)PF6, 7, C40H48CuF6N10P)

Into a 20 cm3 Schlenk tube with 4 Å molecular sieves, 1 mmol of compound 2 (0.478 g) and 0.5 equivalent of Cu(CH3CN)4PF6 (0.186 g, 0.5 mmol) in 3 cm3 of dry acetonitrile solution were added and stirred at room temperate for 6 h under nitrogen. The resulting mixture was filtered through a short pad of Celite. The solvent was then removed in vacuo and the mixture was washed with dry ether (10 cm3 × 2). Removal of all volatiles yielded 0.354 g (81%) of complex 7 as a gummy light green liquid. 1H NMR (CD3CN, 400 MHz): δ = 1.06 (2 × 3H, t, J = 7.37 Hz), 2.25 (2 × 2H, m, J = 7.58 Hz), 3.20 (2H, t, J = 3.21 Hz), 3.43 (2H, s), 3.97 (2 × 3H, s), 4.61 (2 × 2H, t, J = 7.02 Hz), 7.33 (2 × 3H, m, J = 7.11 Hz), 7.41 (2 × 2H, d, J = 7.45 Hz), 7.65 (2 × 1H, d, J = 7.36 Hz), 7.98 (2 × 2H, m, J = 2.82 Hz), 8.22 (2 × 1H, d, J = 7.19 Hz), 8.39 (2 × 1H, s, triazole), 10.02 (2 × 1H, s, HC=N imine) ppm; 13C NMR (CD3CN, 100.6 MHz): δ = 10.32, 23.16, 33.28, 41.78, 56.10, 121.58, 1227.79, 129.44, 129.48, 129.73, 133.16, 133.47, 134.94, 135.11, 135.53 (C5 triazole), 141.82, 192.84 (HC=N imine) ppm; IR (ATR): \(\overline{v}\) = 3416 (O–H), 2972 (C–H, sp2), 1692 (C=N), 1607 (C=C), 1137 (N=N), 832 (\({\mathrm{PF}}_{6}^{-}\)), 771 (Ar C–H) cm−1; MS (ESI+): m/z (%) = 333 (100, [Ligand]+).

(E)-3-Methyl-4-[2-[(phenethylimino)methyl]phenyl]-1-propyl-1H-1,2,3-triazol-3-ium copper(I) hexafluorophosphate(V) ((Cu-3)PF6, 8, C42H50CuF6N8P)

The complex was synthesized following a procedure similar to 7 with the following quantities of materials: 0.479 g compound 3 (1 mmol) and 0.186 g Cu(CH3CN)4PF6 (0.5 mmol). Gummy dark green liquid. Yield 0.253 g (58%); 1H NMR (CD3CN, 400 MHz): δ = 1.04 (2 × 3H, t, J = 7.42 Hz), 1.83 (2 × 2H, t, J = 3.19 Hz), 2.08 (2 × 2H, m, J = 7.20 Hz), 3.67 (2 × 2H, t, J = 6.40 Hz), 3.95 (2 × 3H, s), 4.61 (2 × 2H, t, J = 7.04 Hz), 7.62 (2 × 1H, d, J = 3.90 Hz), 7.91 (2 × 1H, d, J = 3.18 Hz), 7.93 (2 × 1H, d, J = 3.28 Hz), 7.98 (2 × 4H, m, J = 3.22 Hz), 8.20 (2 × 1H, d, J = 2.91 Hz), 8.36 (2 × 1H, s, triazole), 10.00 (2 × 1H, s, HC=N imine) ppm; 13C NMR (CD3CN, 100.6 MHz): δ = 9.38, 22.24, 24.91, 37.47, 55.14, 66.96, 120.65, 128.77, 132.22, 132.52, 133.96, 134.17, 134.57 (C5 triazole), 140.86, 191.87 (HC=N imine) ppm; IR (ATR): \(\overline{v}\) = 3342 (O–H), 2931 (C–H, sp2), 1695 (C=N), 1603 (C=C), 1169 (N=N), 822 (\({\mathrm{PF}}_{6}^{-}\)), 767 (Ar C–H) cm−1; MS (ESI+): m/z (%) = 396 (0.5, [Cu + Ligand]+), 334 (24, [Ligand]+).

(E)-3-Methyl-4-[2-[[[2-(3-methyl-1H-imidazol-3-ium-1-yl)ethyl]imino]methyl]phenyl]-1-propyl-1H-1,2,3-triazol-3-ium acetonitrilecopper(I) hexafluorophosphate(V) ((Cu-4)PF6, 9, C21H30CuF6N7P)

The complex was synthesized following a procedure similar to 7 with the following quantities of materials: 0.314 g compound 4 (0.5 mmol) and 0.186 g Cu(CH3CN)4PF6 (0.5 mmol). Gummy light green liquid; yield 0.194 g (66%); 1H NMR (CD3CN, 400 MHz): δ = 1.05 (3H, s br), 2.08 (2H, s br), 2.59 (4H, s br), 3.88 (3H, s br), 3.95 (3H, s br), 4.62 (2H, s br), 7.45 (2H, s, br), 7.63 (1H, s, br), 7.97 (2H, s br), 8.19 (1H, s, br), 8.37 (1H, s br, triazole), 8.51 (1H, s br, imidazole), 9.99 (1H, s br, HC=N imine) ppm; 13C NMR (CD3CN, 100.6 MHz): δ = 9.33, 22.16, 37.41, 55.10, 124.02, 128.72, 132.17, 132.46, 133.88, 134.12 (C5 triazole), 134.52 (C2 imidazole), 140.81, 191.82 (HC=N imine) ppm; IR (ATR): \(\overline{v}\) = 3167 (O–H), 2971 (C–H, sp2), 1762 (C=N), 1716 (C=C), 1173 (N=N), 832 (\({\mathrm{PF}}_{6}^{-}\)), 771 (Ar C–H) cm−1; MS (ESI+): m/z (%) = 483 (1, [M + CH3CN + H]+), 172 (8, [Ligand + 2H]2+).

4,4′-[[(1E)-[Ethane-1,2-diylbis(azanylylidene)]bis(methanylylidene)]bis(2,1-phenylene)]bis(3-methyl-1-propyl-1H-1,2,3-triazol-3-ium) acetonitrilecopper(I) hexafluorophosphate(V) ((Cu2-5)2PF6, 10, C32H42Cu2F12N10P2)

The complex was synthesized following a procedure similar to 7 with the following quantities of materials: 0.387 g compound 5 (0.5 mmol) and 0.372 g Cu(CH3CN)4PF6 (1 mmol). Light green solid; yield 0.191 g (39%); m.p.: 112 °C; 1H NMR (CD3CN, 400 MHz): δ = 1.05 (6H, t, J = 7.42 Hz), 1.97 (4H, t, J = 2.46 Hz), 2.08 (4H, q, J = 7.24 Hz), 3.95 (6H, s), 4.62 (4H, t, J = 7.06 Hz), 7.63 (2H, d, J = 7.12 Hz), 7.94 (2H, t, J = 3.29 Hz), 7.98 (2H, t, J = 2.91 Hz), 8.20 (2H, d, J = 2.93 Hz), 8.37 (2H, s, triazole), 10.00 (2H, s, HC=N imine) ppm; 13C NMR (CD3CN, 100.6 MHz): δ = 9.33, 22.21, 37.50, 55.12, 120.64, 128.73, 128.78, 132.21, 132.51, 133.94, 134.16, 134.55 (C5 triazole), 140.84, 191.86 (HC = N imine) ppm; IR (ATR): \(\overline{v}\) = 3351 (O–H), 2920 (C–H, sp2), 1614 (C=N), 1455 (C–H), 1205 (N=N), 833 (\({\mathrm{PF}}_{6}^{-}\)), 768 (Ar C–H) cm−1; MS (ESI+): m/z (%) = 658 (4, [Ligand + 2Cu + CH3CN + Li + H]+), 334 (6, [([Ligand + 2Cu + CH3CN]2+)/2 + Li + H)]), 242 (3, [Ligand + H]2+).

4,4′-[[(1E)-[Butane-1,2-diylbis(azanylylidene)]bis(methanylylidene)]bis(2,1-phenylene)]bis(3-methyl-1-propyl-1H-1,2,3-triazol-3-ium) acetonitrilecopper(I) hexafluorophosphate(V) ((Cu2-6)2PF6, 11, C34H46Cu2F12N10P2)

The complex was synthesized following a procedure similar to 7 with the following quantities of materials: 0.401 g compound 6 (0.5 mmol) and 0.372 g Cu(CH3CN)4PF6 (1 mmol). Gummy light green liquid; yield 0.253 g (50%); 1H NMR (CD3CN, 400 MHz): δ = 0.94 (6H, t, J = 7.39 Hz), 1.72 (4H, m, J = 3.28 Hz), 1.97 (4H, q, J = 7.24 Hz), 3.56 (4H, m, J = 3.29 Hz), 3.85 (6H, s), 4.51 (4H, t, J = 7.06 Hz), 7.52 (2H, d, J = 4.05 Hz), 7.84 (2H, t, J = 2.91 Hz), 7.87 (2H, t, J = 3.69 Hz), 8.09 (2H, d, J = 2.93 Hz), 8.27 (2H, s, triazole), 9.89 (2H, s, CH=N, imine) ppm; 13C NMR (CD3CN, 100.6 MHz): δ = 9.40, 22.34, 27.80, 37.30, 54.92, 60.32, 119.79, 128.18, 130.29, 131.20, 131.78, 132.03, 132.26, 132.53, 133.93 (C5 triazole), 142.50, 191.87 (HC=N imine) ppm; IR (ATR): \(\overline{v}\) = 3350 (O–H), 2927 (C–H, sp2), 1688 (C=N), 1603 (C=C), 1440 (C–H), 1163 (N=N), 848 (\({\mathrm{PF}}_{6}^{-}\)), 766 (Ar C–H) cm−1; MS (ESI+): m/z (%) = 655 (0.4, [Ligand + 2Cu + 2Li + H]+), 328 (10, [(Ligand + 2Cu)/2 + Li + H]+), 256 (2, [Ligand]2+).

General procedure for the α-alkylation of ketones with alcohols

In a 15 cm3 Schlenk tube connected to a condenser were added the substrates [ketones (1.0 mmol), alcohols (1.5 mmol)], 10 mol% of in situ catalyst [2 (10 mol%), Cu(CH3CN)4PF6 (10 mol%)], and base (2.0 mmol). The contents of the flask were then stirred in 3 cm3 tetrahydrofuran and refluxed at 75 °C for 24 h under air. At the end of the reaction time, the reaction mixture was filtered by suction and the filtrate concentrated under vacuum. The resulting solid crude obtained was then purified via column chromatography, yielding isolated products as eluents of DCM/n-hexane solvent mixture. NMR data for the products 14a–14o can be found in the Supplementary Material.

References

Trost BM, Fleming I (1991). In: Schreiber SL (ed) Selectivity, strategy and efficiency in modem organic chemistry. Pergamon Press, Oxford

Obora Y (2014) ACS Catal 4:3972

Shen D, Poole DL, Shotton CC, Kornahrens AF, Healy MP, Donohoe TJ (2015) Angew Chem Int Ed 54:1642

Rueping M, Phapale VB (2012) Green Chem 14:55

Taguchi K, Nakagawa H, Hirabayashi T, Sakaguchi S, Ishii Y (2004) J Am Chem Soc 126:72

Yan F, Zhang M, Wang X, Xie F, Chen M, Jiang H (2014) Tetrahedron 70:1193

Cho CS, Kim BT, Kim T, Shim SC (2002) Tetrahedron Lett 43:7987

Kovalenko, OO, Lundberg H, Hübner D, Adolfsson H (2014) Eur J Org Chem 6639. https://doi.org/10.1002/ejoc.201403032

Kuwahara T, Fukuyama T, Ryu I (2012) Org Lett 14:4703

Martınez R, Brand GJ, Ramon DJ, Yus M (2005) Tetrahedron Lett 46:3683

Martınez R, Ramon DJ, Yus M (2006) Tetrahedron 62:8988

Chan LK, Poole DL, Shen D, Healy MP, Donohoe TJ (2014) Angew Chem Int Ed 53:761

Cho CS, Seok HJ, Shim SC (2005) J Heterocycl Chem 42:1219

Satyanarayana P, Reddy GM, Maheswaran H, Kantam ML (2013) Adv Synth Catal 355:1859

Wang R, Huang L, Du Z, Feng H (2017) J Organomet Chem 846:40

Elangovan S, Sortais JB, Beller M, Darcel C (2015) Angew Chem Int Ed 54:14483

Pan X, Li M, Gu Y (2014) Chem Asian J 9:268

Peria-Lopez M, Piehl P, Elangovan S, Neumann H, Beller M (2016) Angew Chem Int Ed 55:14967

Zhang G, Wu J, Zeng H, Zhang S, Yin Z, Zheng S (2017) Org Lett 19:1080

Dixit M, Mishra M, Joshi PA, Shah DO (2013) Catal Commun 33:80

Alonso F, Riente P, Yus M (2008) Eur J Org Chem 4908. https://doi.org/10.1002/ejoc.200800729

Cui X, Zhang Y, Shi F, Deng Y (2011) Chem Eur J 17:1021

Tan DW, Li HX, Zhu DL, Li HY, Young DJ, Yao JL, Lang JP (2018) Org Lett 20:608

Lawal NS, Bala MD (2020) J Mol Struct 1200:127124

Kadwa E, Friedrich HB, Bala MD (2017) Inorg Chim Acta 463:112

Mathew P, Neels A, Albrecht M (2008) J Am Chem Soc 130:13534

Mncube SG, Bala MD (2016) J Mol Liq 215:396

Dhimba G, Lawal NS, Bala MD (2019) J Mol Struct 1179:100

Abubakar S, Ibrahim H, Bala MD (2019) Inorg Chim Acta 484:276

Lake BRM, Willans CE (2014) Organometallics 33:2027

Mncube SG, Bala MD (2019) Trans Met Chem 44:145

Ihaumeer-Laulloo BS, Bhowon MG (2003) Indian J Chem 42A:2536

Bagihalli GB, Patil SA, Badami PS (2009) J Iran Chem Soc 6:259

Singh K, Singh DP, Barwa MS, Tyagi P, Mirza Y (2006) J Enzyme Inhib Med Chem 21:749

Singh K, Kumar Y, Puri P, Sharma C, Aneja KR (2017) Arab J Chem 10:S978

Grusenmeyer TA, King AW, Mague JT, Rack JJ, Schmehl RH (2014) Dalton Trans 43:17754

Hauwert P, Boerleider R, Warsink S, Weigand JJ, Elsevier CJ (2010) J Am Chem Soc 132:16900

Ibrahim H, Bala MD (2016) New J Chem 40:6986

Chen J, Yuan T, Hao W, Cai M (2011) Tetrahedron Lett 52:3710

Dudev T, Lim C (1998) J Am Chem Soc 120:4450

Aihara J (1992) Sci Am 266:62

Lal S, Diez-Gonzalez S (2011) J Org Chem 76:2367

Cozzi PG (2004) Chem Soc Rev 33:410

Acknowledgements

We acknowledge financial support from the University of KwaZulu-Natal, ESKOM (TESP 2019) and the NRF. NSL thanks Ahmadu Bello University for a paid study fellowship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lawal, N.S., Ibrahim, H. & Bala, M.D. Cu(I) mediated hydrogen borrowing strategy for the α-alkylation of aryl ketones with aryl alcohols. Monatsh Chem 152, 275–285 (2021). https://doi.org/10.1007/s00706-021-02735-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-021-02735-5