Abstract

The authors have synthesized a dummy molecularly imprinted monolith (MIM) in the tip of a micropipette using a sol-gel method. The MIM was applied to selective solid-phase microextraction (SPME) of vanillin (VN) and methyl vanillin (MV) prior to their determination by HPLC. The MIM was characterized by thermogravimetric analysis, scanning electron microscopy and FTIR. Some parameters affecting SPME were optimized. Then, a sensitive SPME/HPLC method was developed for the determination of VN and MV in infant milk powder. Under optimized conditions, the response is linear in the 2 to 3000 μg∙kg−1 VN concentration range and in the 3 to 2000 μg∙kg−1 range for MV. The detection limits (for an S/N ratio of 3) are 0.5 and 1 μg∙kg−1, and the recoveries are between 83 and 110% for VN and between 80 and 101% for MV.

A dummy molecularly imprinting monolith was synthesized and applied for SPME of vanillin and methyl vanillin before HPLC. The detection limits of the method for vanillin and methyl vanillin in milk powder were 0.5 and 1 μg·kg−1, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Vanillin (VN) and methyl vanillin (MV) and many other vanilla-flavor enhancers (VFEs) are important food additives. VN and MV have the pleased and fragrant smell and are widely used as flavoring in sweet food for oatmeal, candies, milk, in perfumes or as a chemical intermediate in the production of pharmaceutical and other fine chemicals. The natural source of VN is the seed pods of Vanilla planifolia which contain about only 2–3%, w/w of vanillin [1]. The extraction of VN from natural seed pods is expensive. So, most of the VN and MV used as flavoring are obtained through chemical synthesis. It has been deemed that these synthetic food additives may have side effects on liver and kidney functions of the body which can trigger migraine headaches, nausea and vomiting. According to the GB 2760–2011 [2], Standardization Administration of China 2014 [3], as well as the FDA and China National Food Safety Standard [4], any flavor enhancers is banned in 0–6 months infant formulas. Therefore, the amount of VFEs should be detected in order to ensure the safety of infant food.

Some methods for the determination of VN and MV in milk powder have been reported, such as HPLC [5, 6], LC-MS [7], UV-vis spectrophotometry [8], capillary electrophoresis (CE) [9], and planar (thin-layer) chromatography [10]. Among these techniques, HPLC has attracted great interest and been widely used for it is a simple and practical technique. However, the complex matrix of milk powder, such as the large amounts of lipids, proteins and many other residues, would interfere the detection of analytes. Therefore, the pretreatment step prior to HPLC determination is required. In recent years, solid-phase microextraction (SPME) is increasingly used for pre-concentration and efficient separation of analytes in the complex matrices due to its flexibility, simplicity and low consumption of reagent [11, 12]. However, lack of selectivity is a serious shortcoming for the conventional SPME process, which influences the separation efficiency [13]. Fortunately, molecularly imprinting have been proved to be a powerful innovation, which is known as a technique for the synthesis of polymers with a predetermined selectivity for preconcentration and efficient separation towards the template molecular in complex matrices [14–18]. Molecularly imprinted polymers (MIPs) are synthetic cross-linked polymers possessing artificial receptor-like binding sites with a “memory” for the shape and functional group positions of the template molecular [19–21]. MIPs combined with monolithic column for sample pretreatment have become the frequently used technique [22–24]. Compared with packed column, monolithic column needed not tedious procedures such as grinding, sieving and packed column and offers lower mass transfer resistance, higher column permeability and better pH tolerance [25–27]. Moreover, molecularly imprinted monolith (MIM) retains binding sites completely. But, the use of MIM as the adsorbent in sample pretreatment faces the problem of template leakage. The dummy imprinting technique, which was developed by using structural analogue as pseudo-template to avoid the leakage of the template, can effectively improve the performance of the MIM material [28].

In this work, a novel dummy MIM was synthesized in a micropipette tip by sol-gel methodfor the SPME of VN and MV. The monolith was prepared by using nonylphenol (NP) as the dummy template, methacrylic acid as the functional monomer, ethylene glycol dimethacrylate as the cross-linker and azobisisobutyronitrile as the initiator. The synthetic conditions were investigated. The synthesized MIM was linked with syringes directly to perform SPME without any other management. A method for the detection of VN and MV in infant milk powder using the MIM-SPME combined with HPLC-UV was established. The strategy aimed to avoid the leakage of the template of MIM and to develop more sensitive quantitative analysis method for trace components in complex matrix samples. The experimental results demonstrated that the method can be applied to the selective and sensitive determination of VN and MV in infant milk powder samples.

Experimental

Reagents and standards

VN (AR, 99%), MV (≥99%), NP (GR), 4-vinyl pyridine (4-VP) were obtained from Aladdin Reagents Company (Shanghai, China). Methacrylic acid (MAA) was purchased from Guoyao Chemical Reagent Company (Shanghai, China). Acrylamide (AM) purchased from Fuchen Chemical Reagent Company (Tianjin, China) was distilled under vacuum prior to use. Ethylene glycol dimethacrylate (EGDMA) purchased from Acros (New Jersey, USA) was extracted with 5% aqueous sodium hydroxide and water to remove the stabilizer, then dried over using anhydrous magnesium sulfate, and kept in refrigerator which was stable for at least one year. Azobisisobutyronitrile (AIBN) was obtained from Shanghai No.4 Chemical Reagent Corp (Shanghai, China) and recrystallized in anhydrous ethanol before use. Methanol and acetonitrile (HPLC grade) were obtained from Tedia Company Inc. (Ohio, USA). Phosphoric acid and other chemical reagents used were all of analytical grade. The water used throughout the experiments was purified on an Ultrapure Water System (Beijing, China).

Stock standard solutions of 1 mg∙mL−1 for VN and MV were prepared in methanol and kept under refrigeration at 4 °C, respectively. Standard working solutions of 0.01–100 μg∙mL−1 for VN and MV were prepared by dilution of the stock standard solutions with ultrapure water.

Instrumentation

All chromatographic analyses were performed with a Dionex Summit U3000 HPLC system equipped with a manual injector, a UV detector (Dionex Technologies, USA) and a temperature controller (Nuohai Technologies, China). A personal computer consisting of a Chromeleon ChemStation program for LC was used to process chromatographic data. A amethyst-C18 column (4.6 mm × 250 mm, 5 μm) from Sepax Technologies Inc. (Newark, USA) was connected with a guard column (cartridge 2.1 mm × 12.5 mm, 5 μm, Agilent Technologies, PaloAlto, CA, USA) filled with the same packing material. An LSP01-1A longer pump (Baoding Longer Precision Pump Co. Ltd., China) was used for pumping. 0.22 μm membrane was obtained from Xingya Scavenging Material Company (Shanghai, China). The measurement of sample pH was achieved by a PH S-25 digital pH meter (Shanghai great instrument Co. Ltd., China). The obtained products were characterized with X-650 scanning electron microscope (SEM) (Hitachi, Japan) and Fourier transform infrared spectrometer (FT-IR) (Perkin Elmer, USA). Thermogravimetric analysis (TGA) experiment was carried out with a Perkin-Elmer TGA-7 thermogravimetric analyzer (PerkinElmer, USA) at a heating rate of 20 °C∙min−1 from 30 °C to 800 °C under nitrogen atmospheres.

Preparation of molecular imprinted monolith

The preparation procedure of the MIM was as follows. First, 0.1 mmol (22 mg) of NP was thoroughly dissolved in 1 mL of methanol. Next, 0.4 mmol (34 μL) of MAA was added. After ultrasonication for 2 h at room temperature, 2 mmol of cross-linker EGDMA (375 μL) and 26 mg of initiator AIBN were added. Then, degassed by ultrasonication for about 5 min. Subsequently, 100 μL of the mixture was transferred into a micro pipette tip which had been sealed at one end. Then, the other end was also sealed immediately. Finally, polymerization was carried out at 60 °C for 24 h. After polymerization, the monolith was washed with methanol to remove the template molecules and other matrices.

A non-imprinted monolith (NIM) was also prepared and treated using the same manner as already described in the absence of the template.

Sample preparation

Three infant milk powder samples were obtained from the local supermarket and pretreated before analysis by the following procedure. First, 50.0 g of milk powder was accurately weighted in a 100.0 mL beaker flask. Then, 30.0 mL of acetonitrile was added and the sample was extracted by ultrasonication for 20 min to remove the precipitated protein. The solution was filtered in a clean tube. This extraction step repeated twice. Then the extraction fractions were merged and evaporated under vacuum at a bath temperature of 50 °C. The residue was diluted to 500.0 mL with ultrapure water. The solution pH was adjusted to 6.0 with phosphoric acid and stored at 4 °C in refrigerator for use.

SPME procedure

The synthetic monolith was washed by 3.0 mL of methanol and 0.5 mL of water, respectively. Then, 3.0 mL of pretreated sample solution was loaded at a flow rate of 0.05 mL∙min−1. 200 μL of water was used to wash the column to remove aqueous matrices. Subsequently, the analytes were eluted with 300 μL of MeOH-ACN (6:4, v/v) at a flow of 0.05 mL∙min−1. Finally, the eluent was filtered through a 0.22 μm membrane filter for further HPLC analysis.

Chromatographic conditions

The fractions eluted from the SPME columns were detected by HPLC with UV detector. The chromatographic separation was carried out as follows: the mobile phase was a mixture of methanol and water (54:46, v/v) with a flow rate of 1.0 mL∙min−1. The column temperature was set at 30 °C. All injections were performed manually with a 20.0 μL sample loop. The wavelength for the UV detector of analytes was set at 224 nm. All tests were performed in triplicate.

Results and discussion

Optimization of synthetic conditions

The synthesize process of MIM is shown in Fig. 1.

To assess the selective recognition performance of the MIM, enrichment factor (EF) and imprinted factor (IF) were calculated as follows:

where Celu is the analyte concentration in eluent and was obtained from calibration of direct of standard solution, C0 is the initial concentration of analyte within the sample, EFMIP and EFNIP refer to the enrichment factors of analyte extracted in MIM and NIM under the same condition, respectively.

To get good permeability and high recognition capacity of the MIM for analytes in SPME, the following synthetic conditions were optimized: (a) Functional monomer; (b) porogen; (c) the amount of initiator. Respective data and Figures are given in the Electronic Supporting Material (ESM). We found the following experimental conditions to give best results: (a) MAA as the monomer; (b) 1.0 mL of MeOH as the porogen solvent; (c) 26 mg of AIBN as the proper amount of initiator.

The characterization of the MIM

The morphology of the MIM was characterized by SEM technique. As it is depicted in Fig. 2a, many macro voids and flow-through channels inlaid in the network skeleton of the MIM is clearly observed, which can provide flow paths for mobile phase to flow through the column with low flow resistance in the SPME process.

In order to evaluate the stability of the MIM, TGA experiment of the MIM was conducted. As shown in Fig. S4 (in ESM), the synthesized monolith is stable up to nearly 300 °C, which demonstrates that the MIM has favorable heat stability.

The infrared spectra of EGDMA, MIM and NIM were monitored to verify the successful synthesis of the MIM. The results are showed in Fig. 2b. Comparing the infrared spectrum of MIM with that of EGDME, the strong peak at 1718 cm−1 attributed to the stretching vibration of C = O in EGDMA still exists in MIM. However, the C = C stretching vibration at 1637 cm−1 almost disappears in infrared spectrum of MIM and NIM. Comparing the infrared spectrum of MIM to that of NIM, the broad absorption of carboxyl group transfers from 3573 to 3445 cm−1, which confirms that hydrogen bonds are formed in the MIP. The data indicates the successful formation of MIM.

Selectivity and binding property of MIM

VN and MV standard solutions were mixed and diluted to 10 ng∙mL−1. The mixed solution was used to assess the selectivity of the MIM. The experimental result shows that the IFs of VN and MV are 3.56 and 2.04, respectively. The data indicates that the MIM possesses high affinity for VN and MV.

So as to evaluate the binding property of MIM, the binding curve of VN and MV were measured by varying the concentration of analytes in the range of 0.1–40 μg∙mL−1, respectively. The results indicate that the adsorption capacities for VN and MV are 456.7 and 320.9 μg∙g−1, respectively. As showed in Fig. 3, the Scatchard plot for the material is not linear, which indicates that the binding sites in the monolith are heterogeneous with respect to the affinity for the analytes.

Optimization of SPME conditions

For evaluating the extraction efficiency of MIM and obtaining the optimized extraction conditions, extraction recovery (ER) was calculated by the following equation:

where nelu is the amount of analyte extracted to the eluent and n0 is the total amount of analyte, Velu and Vaq are the volumes of eluent and sample solution, respectively.

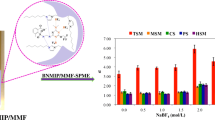

In order to obtain the maximal extraction efficiency, the following parameters were optimized: (a) eluent; (b) eluent flow rate; (c) the volume, pH and ionic strength of sample solution; (d) sample flow rate. Respective Figures are given in Fig. S5 (ESM). We found the following SPME conditions to give best results: (a) a 300 μL of MeOH-ACN (6:4) mixture as the eluent; (b) 0.05 mL∙min−1 as the optimized flow rate of eluent; (c) 3 mL of sample solution (pH = 6, no NaCl added); (d) 0.05 mL∙min−1 as the sample flow rate. The mixture solutions of VN and MV at 10 ng∙mL−1 were used in the SPME optimization (n = 3).

Evaluation and application of the proposed method

Under above optimum conditions, linear ranges, precisions and detection limits of analytes were investigated and the results were listed in Table 1. Working curves were constructed by external standard method using the areas of the chromatographic peaks. Matrix-matched solutions were prepared by addition of the mixed standards to blank sample matrix. Different concentrations of standard mixtures varied in a range of 2–3000 μg∙kg−1 for VN and 3–2000 μg∙kg−1 for MV were prepared as the external standard solutions. Good linearity was obtained for analytes throughout the concentration range, and the regression equations are Y = 72.147X + 418.92 for VN and Y = 62.314X + 153.21 for MV with correlation coefficients (R2) of 0.9947 and 0.9978, respectively. The limit of detection (LOD) and the limit of quantification (LOQ) were calculated at signal-to noise ratios (S/N) of 3 and 10, respectively. The LODs and LOQs of the method are 0.5 and 1.5 μg∙kg−1 for VN, 1 and 3 μg∙kg−1 for MV in infant milk, respectively.

The precision (intra- and inter-day) and accuracy of the method were assessed using milk samples with different concentrations (10, 1000 and 2000 μg∙kg−1) for VN and 10, 500, 1500 μg∙kg−1 for MV. The recoveries of VN and MV in the spiked milk powder samples are 83–110% and 80–101%, respectively. The intra-day precision was proceeded in the same day and the inter-day precision was evaluated in different four days in the same conditions. The intra-day repeatability evaluated as RSD ranges in 0.04–3.55% for VN and 0.11–2.86% for MV, and the inter-day reproducibility is below 3.62% in all cases.

The chromatograms of blank milk sample and spiked milk sample before and after SPME are shown in Fig. 4. It can be seen that MIM had remarkable enrichment ability for VN and MV from milk sample. The method was applied for the detection of VN and MV in three milk powder samples. No MV was detected in three samples and 8.12 and 9.69 μg∙kg−1 of VN were found in two samples, respectively.

Compared with the published methods for the test of VN in the milk powder, LOD of this method is obviously lower than those of the reported methods (Table 2). The experimental results indicate that the method can be applied for the selective and sensitive determination of VN and MV in milk powder samples.

Conclusions

A novel dummy MIM was synthesized in a micropipette tip using NP as the dummy template for the SPME of VN and MV for the first time. The MIM showed high selectivity and enrichment ability for VN and MV. After optimization of the extraction conditions, an SPME-HPLC method was developed for the selective extraction and determination of VN and MV in infant milk powder. A good linear relationship was obtained for analytes in a wide response range. As the result demonstrated, the proposed method was a satisfactory alternative for the separation and detection of VN and MV in infant milk powder.

References

Puzio K, Delépée R, Vidal R, Agrofoglio LA (2013) Combination of computational methods, adsorption isotherms and selectivity tests for the conception of a mixed non-covalent-semi-covalent molecularly imprinted polymer of vanillin. Anal Chim Acta 790:47–55

Wu JH, Yang ZY, Chen N, Zhu WY, Hong JL, Huang CG, Zhou XM (2015) Vanillin-molecularly targeted extraction of stir bar based on magnetic field induced self-assembly of multifunctional Fe3O4@polyaniline nanoparticles for detection of vanilla-flavor enhancers in infant milk powders. J Colloid Interf Sci 442:22–29

Shu M, Man YR, Ma H, Luan F, Liu HT, Gao Y (2016) Determination of vanillin in milk powder by capillary electrophoresis combined with dispersive liquid-liquid microextraction. Food Anal Methods 9:1706–1712

Ma J, Zhang B, Wang YN, Hou XF, He LC (2014) Determination of flavor enhancers in milk powder by one-step sample preparation and two-dimensional liquid chromatography. J Sep Sci 37:920–926

Wang GS, Cao QE, Zhu XF, Hou NB, Ding ZT (2006) Preparation and recognition properties of vanillin-imprinted polymers. Helvetica Chim Acta 89:3032–3040

Waliszewski KN, Pardio VT, Ovando SL (2006) A simple and rapid HPLC technique for vanillin determination in alcohol extract. Food Chem 101:1059–1062

De Jager LS, Perfetti GA, Diahenko GW (2007) Determination of coumarin, vanillin, and ethyl vanillin in vanilla extract products: liquid chromatography mass spectrometry method development and validation studies. J Chromatogr A 1145:83–88

Longares-Patrón A, Canizares-Macías MP (2006) Focused microwaves-assisted extraction and simultaneous spectrophotometric determination of vanillin and p-hydroxybenzaldehyde from vanilla fragans. Talanta 69:882–887

Minematsu S, Xuan GS, Wu XZ (2013) Determination of vanillin in vanilla perfumes and air by capillary electrophoresis. J Environ Sci 25:S8–S14

Gerasimov AV, Gornova NV, Rudometova NV (2003) Determination of vanillin and Ethylvanillin in vanilla flavorings by planar (thin-layer) chromatography. J Anal Chem 58:677–684

Liu XF, Zhu QF, Chen HX, Zhou LZ, Dang XP, Huang JL (2014) Preparation of 2, 4-dichlorophenoxyacetic acid imprinted organic-inorganic hybrid monolithic column and application to selective solid-phase microextraction. J Chromatogr B 951-952:32–37

Guerreiro A, Soares A, Piletska E, Mattiasson B, Piletsky S (2008) Preliminary evaluation of new polymer matrix for solid-phase extraction of nonylphenol from water samples. Anal Chim Acta 612:99–104

Liu J, Song H, Liu J, Liu Y, Li L, Tang H, Li YC (2015) Preparation of molecularly imprinted polymer with double templates for rapid simultaneous determination of melamine and dicyandiamide in dairy products. Talanta 134:761–767

Li YC, Liu J, Liu J, Tang H, Cao C, Zhao DS, Ding Y (2015) Molecularly imprinted polymer decorated nanoporous gold for highly selective and sensitive electrochemical sensors. Sci Rep-UK 2015(5):1–8

Zuo PL, Gao JF, Peng J, Liu JH, Zhao MM, Zhao JH, Zuo PJ, He H (2016) A sol-gel based molecular imprint incorporating carbon dots for fluorometric determination of nicotinic acid. Microchim Acta 183(1):329–336

Narula P, Kaur V, Singh R, Malik AK (2014) Recent progress, challenges and prospects in monitoring plastic derived xenoestrogens using molecularly imprinted sorbents. Chromatographia 77:207–221

Lin ZA, Yang F, He XW, Zhao XM, Zhang YK (2009) Preparation and evaluation of a macroporous molecularly imprinted hybrid silica monolithic column for recognition of proteins by high performance liquid chromatography. J Chromatogr A 1216:8612–8622

Dai H, Xiao DL, He H, Li H, Yuan DH, Zhang C (2015) Synthesis and analytical applications of molecularly imprinted polymers on the surface of carbon nanotubes: a review. Microchim Acta 182(5–6):893–908

Liu ZS, Xu YL, Yan C, Gao RY (2005) Mechanism of molecular recognition on molecular imprinted monolith by capillary electrochromatography. J Chromatogr A 1087:20–28

Yan HY, Tian ML, Row KH (2008) Determination of enfloxacin and ciprofloxacin in mik using molecularly imprinted solid-phase extration. J Sep Sci 31:3015–3020

Lin CI, Joseph AK, Chang CK, Wang YC, Yu DL (2003) Synthesis of molecular imprinted organic-inorganic hybrid polymer binding caffeine. Anal Chim Acta 481:175–180

Lin Z, Lin Y, Sun XB, Yang HH, Zhang L, Chen GN (2013) One-pot preparation of a molecularly imprinted hybrid monolithic capillary column for selective recognition and capture of lysozyme. J Chromatogr A 1284:8–16

Szumski M, Graywinski D, Prus W, Buszewski B (2014) Monolithic molecularly imprinted polymeric capillary columns for isolation of aflatoxins. J Chromatogr A 1364:163–170

Mu LN, Wang XH, Zhao L, Huang YP, Liu ZS (2011) Low cross-linked molecularly imprinted monolithic column prepared in molecular crowding conditions. J Chromatogr A 1218:9236–9243

Wang FQ, Wei AL, Wang XX, Liu HY, Bai LG, Yan HY (2016) Property evaluations and application for separation of small molecules of a nanodiamond-polymer composite monolithic column. Talanta 154:237–248

Zhang H, Bai LG, Wei Z, Liu S, Liu HY, Yan HY (2016) Fabrication of an ionic liquid-based macroporous polymer monolithic column via atom transfer radical polymerization for the separation of small molecules. Talanta 149:62–68

Wang QQ, Sánchez-Lópezb E, Han H, Wu HH, Zhu PJ, Crommen J, Marin ML, Jiang ZJ (2016) Separation of N-derivatized di- and tri-peptide stereoisomers bymicro-liquid chromatography using a quinidine-based monolithic column-analysis of l-carnosine in dietary supplements. J Chromatogr A 1428:176–184

Rao W, Cai R, Yin YL, Long F, Zhang ZH (2014) Magnetic dummy molecularly imprinted polymers based on multi-walled carbon nanotubes for rapid selective solid-phase extraction of 4-nonylphenol in aqueous samples. Talanta 128:170–176

Acknowledgements

This work was supported by the Natural Science Fund for Creative Research Groups of Hubei Province of China (grant no. 2011CDA111), and the Education Commission of Hubei Province of China (grant no. T201101, D20120106), the National Nature Science Foundation of China (grant no. 20975030, 21003034). The authors would like to thank their colleagues for their valuable technical assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no competing interests.

Electronic supplementary material

ESM 1

(PDF 603 kb)

Rights and permissions

About this article

Cite this article

Zhu, J., Chen, D., Ai, Y. et al. A dummy molecularly imprinted monolith for selective solid-phase microextraction of vanillin and methyl vanillin prior to their determination by HPLC. Microchim Acta 184, 1161–1167 (2017). https://doi.org/10.1007/s00604-017-2107-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-017-2107-5