Abstract

Planar particle image velocimetry was utilized to investigate the effects of localized blowing (injection) on the turbulent boundary layer over two-dimensional k-type roughness. The experiments were performed at a Reynolds number of 100,000, based on the boundary layer thickness and the free-stream velocity. The roughness was composed of identical transverse square bars at a pitch to height ratio \(p/k = 11\); the bars occupied \(\sim 13-14\%\) of the boundary layer thickness. In addition to a baseline no-injection case, localized blowing through five small spanwise jets was considered at two rates and for two injection locations. The volumetric flow rate through the jets was below 0.12% of the overall flow rate, resulting in a small perturbation to the flow field. As such, the overall flow organization is maintained across the five considered cases (baseline and four injection cases). However, the localized blowing alters the time-averaged streamwise velocity, boundary layer characteristics, Reynolds shear stress, and in-plane turbulent kinetic energy. For example, the localized blowing considered here can induce an increase up to \(\sim 6\%\) in the time-averaged streamwise velocity and a reduction up to \(\sim 20\%\) in the maximum streamwise-averaged Reynolds shear stress and turbulent kinetic energy. The blowing-induced deviations from the baseline case extend far within the boundary layer; however, two-point correlations and proper orthogonal decomposition analyses provide evidence for a similar turbulence structure far above the roughness, despite the blowing-induced deviations in the aforementioned flow quantities.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The turbulent flow over two-dimensional (2D) roughness has been extensively studied to characterize the flow features close to and away from the wall (see, for example, studies by Burattini et al. 2008; Hamed et al. 2015, 2017; Lee et al. 2018; Ismail et al. 2018; Segunda et al. 2018; De Marchis et al. 2020). Significant effort has been focused on the turbulent flow over wall-mounted transverse square bars (rods or ribs). The turbulent flow over such bars has been investigated in the context of (i) channel flow with bars placed on one or both walls (e.g., Krogstad et al. 2005; Ashrafian and Andersson 2006; Ikeda and Durbin 2007; Tachie et al. 2009; Fang et al. 2015); (ii) open channel flow (e.g., Tachie et al. 2007; Roussinova and Balachandar 2011); and (iii) boundary layer flow (e.g., Volino et al. 2009; Lee et al. 2012, 2016; Choi et al. 2020). The effects of an adverse pressure gradient on the turbulent flow over this roughness have also been examined (e.g., Tsikata and Tachie 2013a, b). In addition to these flow-field investigations, numerous studies have focused on the convective heat transfer over walls roughened with transverse bars. In this context, the bars are used to disturb the flow, increase mixing, and, consequently, enhance heat transfer. For more on the heat transfer augmentation by bars and other wall-mounted elements, the reader is referred to reviews by Alam et al. (2014); Sheikholeslami et al. (2015); and Mousa et al. (2021).

As noted in many of the aforementioned studies, the turbulent flow over periodic transverse square bars is highly dependent on the ratio of the streamwise spacing to the bars’ height k. Alternatively, the ratio can be expressed as p/k, where p is the pitch, defined as the distance from the leading edge of one bar to the leading edge of the next. Utilizing direct numerical simulations (DNS), Leonardi et al. (2003, 2004) characterized the flow field over bars with p/k ranging from 1.33 to 20. They noted ‘d-type’ roughness behavior for \(p/k < 8\), where the flow separates at the trailing edge of a bar and reattaches onto the next (i.e., the recirculation zone occupies the entire cavity). For \(p/k \ge 8\), they observed ‘k-type’ roughness behavior with a recirculation zone forming at the trailing edge; however, the flow reattaches to the wall upstream of the next bar. As the attached flow approaches the downstream bar, it separates and forms a smaller recirculation zone at the wall-bar junction. For bars with p/k ranging from 1.5 to 60, Leonardi et al. (2007) further investigated the roughness behavior, noting the importance of the relative contributions of friction drag and pressure (form) drag. They associated d- and k-type behavior with the dominance of friction and pressure drag, respectively. Nadeem et al. (2015) characterized the development of a turbulent boundary layer over bars with p/k ranging from 8 to 128; they reported p/k dependency for various flow quantities including the form drag, friction velocity, and boundary layer growth rate.

Another key parameter governing the flow is the ratio of bar height to boundary layer thickness \(k/\delta\), or k/h for channel flow, where h is the channel’s half-height. \(k/\delta\) is especially important in the context of Townsend’s similarity hypothesis, which states that the turbulent flow sufficiently far above the wall (outer-layer flow) is unaffected by the wall topography, except for the wall’s role in setting the shear velocity \(u_\tau\) and the boundary layer thickness \(\delta\) (Townsend 1976). Jimenez (2004) proposed that the roughness height should be less than 2.5%\(\delta\) for similarity to hold. Numerous studies have provided support for outer-layer similarity in the presence of 3D roughness (see, for example, Flack and Schultz (2014); Chung et al. (2021) and references therein). However, the presence of outer-layer similarity in turbulent boundary layers over transverse square bars exhibiting k-type behavior has been debated. Numerous studies have shown roughness effects extending far from the wall, even for \(k/\delta\) as low as 0.62% (Lee and Sung 2007; Djenidi et al. 2008; Volino et al. 2009, 2011; Lee et al. 2012). The lack of similarity has been associated with the repeated disturbance at each bar due to the periodicity of the roughness and, more so, the significant blockage for 2D roughness, which forces the flow upward at each element (Volino et al. 2011; Flack and Schultz 2014). Moreover, Volino et al. (2009) suggested that the bar roughness generates turbulent motions with length scales larger than k due to the uninterrupted spanwise width of the bars. However, similarity has been shown over 2D bars with \(k/\delta \simeq 0.76\%\), but at a significantly higher Reynolds number than in previous studies (Krogstad and Efros 2012). Additionally, Choi et al. (2020) found similarity over 2D bars with \(k/\delta \simeq 0.4\%\) at a lower Reynolds number than in Krogstad and Efros (2012).

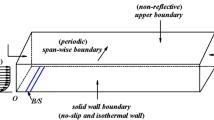

Schematic of the bar-roughened walls with localized blowing: a injection at the downstream face of the 11th bar (cases 2 and 3) and b injection from the wall at a distance 1.5k downstream of the 11th bar (cases 4 and 5). The small jets have a diameter \(d = 2.4\) mm and are spaced 7d apart (center to center). The dashed line indicates the central plane, which coincides with the central jet and the PIV measurement plane

The large body of literature surveyed above provides a well-established flow description for the periodic transverse square bar roughness. The availability of this flow description makes this geometry appealing for the study of flow control strategies superimposed on the rough wall. To this end, we investigate the effects of localized steady blowing (injection) on the turbulent flow over large-scale transverse square bars and compare our results to a baseline case without blowing (the well-studied case). Specifically, the effects of flow injection through small jets arranged in a spanwise-periodic configuration are examined in an otherwise streamwise-periodic flow. It is worth noting that flow control through blowing has been explored for smooth-wall boundary layers (see, for example, investigations by Krogstad and Kourakine 2000; Park et al. 2003; Kim and Sung 2003, 2006; Keirsbulck et al. 2006; Haddad et al. 2006, 2007; Kametani and Fukagata 2011; Kametani et al. 2015; Liu et al. 2017; Xie et al. 2020). These investigations include both uniform blowing and localized blowing from a single streamwise location through a transverse slot, porous strip, or series of jets. However, the superposition of roughness and flow injection has not received significant attention (Miller et al. 2014; Mori et al. 2017; Borchetta et al. 2018). Early studies by Healzer et al. (1974) and Schetz and Nerney (1977) explored the heat transfer and skin friction for rough-wall boundary layers subjected to blowing. Healzer et al. (1974) provided formulation to relate the Stanton number to the blowing rate, and Schetz and Nerney (1977) noted a decrease in skin friction due to blowing. In an experimental study of uniform blowing through a three-dimensional (3D) roughness, Miller et al. (2014) suggested that flow injection has an effect similar to that of increased roughness. Mori et al. (2017) found, through DNS, a decrease in the drag over a 2D irregular roughness due to uniform blowing. Borchetta et al. (2018) experimentally studied the effects of uniform blowing on the coherent structures over a dimpled surface and noted an increase in flow complexity. Djenidi et al. (2019a) and Ghanadi and Djenidi (2021) studied the effects of localized suction through a porous strip on the turbulent boundary layer over a wall roughened by circular transverse rods; the suction affected the mean streamwise velocity and the turbulence intensity even in the outer layer. Motivated by environmental flows in, for example, rivers and streams, seepage through permeable rough beds has also been investigated (e.g., Dey et al. 2011; Singha et al. 2012). Such studies highlight the complexities in the superposition of roughness, permeable wall, and net injection/suction. While less studied, the superposition of roughness and flow injection is relevant to numerous engineering applications (e.g., flow control for drag reduction). To better understand this complex superposition, we examine the effects of localized blowing on the mean flow, turbulence statistics, and turbulence structure in a rough-wall boundary layer. The choice of a well-studied roughness geometry (transverse square bars) provides a benchmark for future experimental and numerical studies.

2 Experimental setup

Planar particle image velocimetry (PIV) was used to experimentally study the effects of localized blowing on the turbulent boundary layer over large-scale 2D roughness. The experiments were conducted in a recirculating water channel with a 0.2 \(\times\) 0.2 \(\times\) 2 m\(^3\) test section. Upstream of the test section and the 6:1 area ratio contraction, the flow is conditioned by a honeycomb section and a series of screens. The reader is referred to Hamed et al. (2019) for additional details on the water channel, which has been previously used for turbulent boundary layer studies (Hamed et al. 2019; Hamed and Peterlein 2020). The 2D roughness was installed on one wall only; the other three walls of the channel were smooth and without any trips. The roughness was composed of 14 identical transverse bars with a square cross section (\(k \times k = 12.7 \times 12.7\) mm\(^2\)). The bars were arranged periodically with a pitch to height ratio \(p/k = 11\), ensuring k-type roughness behavior (Leonardi et al. 2003, 2004, 2007). Flow measurements were made in the central streamwise- wall-normal plane extending from the 11th bar to the 12th; the 11th bar was located \(\sim\)1.45 m from the inlet.

Within the measurement region, the baseline no-injection case has a bar height to boundary layer thickness ratio \(k/\delta\) of approximately 13%. Given this large ratio, outer-layer similarity is not achieved (Flack and Schultz 2014). At the same region, the smooth-wall boundary layers have a thickness of \(\sim 2.4k\), which is significantly thinner than that over the rough wall (8.0k for the baseline case). The streamwise-wall-normal measurement plane is, therefore, \(\sim 5.5k\) away from the edge of the smooth-wall boundary layer on either side. In the wall-normal direction, the edge of the rough-wall boundary layer is \(\sim 4.3k\) from the edge of the smooth-wall boundary layer on the opposite wall. As such, within the measurement region, the rough-wall boundary layer is generally free from the boundary layers formed on the smooth walls. The pressure gradient in the measurement region is near zero as evidenced by a nearly constant free-stream velocity \(U_0\) (\(\lesssim 0.4\%\) change). Additionally, the rough-wall boundary layer approaches a developed stage with a \(\lesssim\) 5% change in the local boundary layer thickness over the measurement region. The experiments were conducted at a Reynolds number \(Re_\delta = U_0 \delta / \nu \simeq 100{,}000\), where \(\nu\) is the kinematic viscosity. Additional characteristics of the turbulent boundary layer are reported in sect. 3.

In addition to the baseline no-injection case (case 1), flow measurements were performed for four additional cases (cases 2–5) to investigate the effects of localized blowing. All cases were studied at \(Re_\delta \simeq 100{,}000\). The roughness configuration described above was unchanged for all five cases, except for the flow injection at a single streamwise location between the 11th and 12th bars (cases 2–5). Five small spanwise jets with diameter \(d= 2.4\) mm were used for flow injection. The central jet was aligned with the center of the test section, and the remaining four jets were arranged symmetrically with center-to-center spacing of 7d. The five jets occupied the central \(\sim 1/3\) of the spanwise extent. For cases 2 and 3, the jets issued from the back face of the 11th bar with their centers vertically aligned to k/2. For cases 4 and 5, the jets are issued from the wall with their centers at a distance 1.5k from the trailing edge of the 11th bar. The two arrangements are illustrated in figure 1. The flow injection was enabled by a secondary frequency-controlled pump, and a flow distributor was used to ensure equivalent flow through each of the five jets. Only five jets were used due to the limited power of the secondary pump. However, spanwise periodicity is expected near the measurement plane coincident with the central jet due to the presence of two jets on each side. Following Liu et al. (2017), who studied localized blowing by spanwise jets in a smooth channel, a severity factor \(\sigma\) is defined as the ratio of the volumetric flow rate through the five jets to the volumetric flow rate within the channel. For each of the two injection locations, two injection rates were utilized, resulting in \(\sigma \simeq 0.05\%\) and 0.12%. These low severity factors are in line with \(\sigma = 0.13\%\) used in Liu et al. (2017), who indicated that such \(\sigma\) represents a small perturbation to the flow. The five experimental cases are summarized in table 1.

For all five cases, flow measurements were made using a TSI planar PIV system consisting of a 4 MP CCD camera and a 200 mJ/pulse double-pulsed laser. The measurements were made in the streamwise-wall-normal (x - y) plane coincident with the center of the bars, which is also coincident with the central jet in cases 2–5. This plane is indicated with a dashed line in figure 1, which also indicates the coordinate system. Hollow glass spheres with a 10-\(\mu\)m average diameter were used as seeding particles; they were illuminated by a 1-mm-thick laser sheet. The resulting field of view extends over \(x \times y \simeq 14k \times 10k\). Image pairs were collected at 1 Hz frequency and were later interrogated with a multipass scheme in Insight 4G (TSI). A 32 \(\times\) 32 pixel final interrogation window was chosen along with 50% overlap, resulting in a final vector grid spacing of 0.09k. To minimize peak-locking bias error, the average particle image diameter was above the 2-pixel limit as recommended by Christensen (2004). Random errors in determining the displacement have been approximated to 5% of the particle image diameter (Prasad et al. 1992); this amounts to \(\sim 1 \%~U_0\). For each of the five cases, 4000 statistically-independent velocity fields were acquired under consistent experimental conditions.

It is important to note that the planar PIV measurements do not capture the out-of-plane velocity component or any spanwise variations in the flow field; such variations are expected near the bars due to the spanwise configuration of the jets. For example, Liu et al. (2017) noted spanwise variations in skin friction coefficient on a smooth channel wall subjected to blowing through spanwise jets. Their numerical results indicate a maximum reduction in the skin friction coefficient in the region near the jets. Here, the measurement plane coincident with the central jet was chosen to highlight the heightened impact of the jets in the near wake region of the 11th bar. While the current effort does not capture the spanwise variations of the flow, the experimental conditions and the location of the planar measurements were consistent across all cases, allowing for meaningful comparisons and providing insight into the effects of injection location and magnitude.

3 Results and discussion

The mean flow field for case 1 (baseline) is illustrated in Fig. 2 through contours of the time-averaged streamwise and wall-normal velocities \(U/U_0\) and \(V/U_0\), respectively. Streamlines and a white contour at \(U/U_0=0\) are superimposed to aid in visualizing the flow and the recirculation zones. In this and subsequent figures, the origin of the x-axis is set at the trailing edge of the 11th bar. Instead of a case-specific lengthscale, the x and y coordinates are normalized by the bar height k to aid in identifying the spatial extent of blowing effects and to facilitate comparisons with previous studies (e.g., Wang et al. 2007; Lee et al. 2008; Djenidi et al. 2008). The case-specific free-stream velocity \(U_0\) is used for normalization; \(U_0\), reported in table 1, was controlled across the five cases (\(\lesssim 1\%\) change). As shown in Fig. 2, the flow separates at the trailing edge of the bars then reattaches to the wall, as expected for k-type roughness. Another recirculation zone, although much smaller, forms at the leading edge of the bars. The flow deflects upward at the leading edge with a maximum wall-normal velocity \(V/U_0\simeq 0.25\). The compact upwash region is followed by a relatively weak and lengthy downwash region with a minimum velocity \(V/U_0\simeq -0.06\). The described flow field is in line with those found in the literature for similar p/k ratios (e.g., Wang et al. 2007; Lee et al. 2008; Djenidi et al. 2008). Moreover, the reattachment length \(X_r/k = 3.3\), determined at the intersection of the \(U/U_0=0\) contour and the wall, is comparable to values found in the literature. For example, Wang et al. (2007) reported \(X_r/k =3.6\) in a channel with bars on one wall (\(p/k = 12\), \(k/h = 0.15\), and \(Re_h = 22,000\)). It is worth noting that the reattachment length is dependent on p/k, the Reynolds number, and \(k/\delta\) or k/h; therefore, a range of reattachment lengths (\(X_r/k \simeq 3-6\)) can be found in the literature for k-type roughness composed of identical transverse square bars.

For cases 2–5 (roughness with localized blowing), the mean flow field, which is not shown for brevity, exhibits a similar organization to that of the baseline case described above. Specifically, the overall flow features, including the two recirculation zones, the compact intense upwash region, and the relatively weak downwash region, persist in all cases. The similarity in flow organization suggests that localized blowing at low severity factors (\(\sigma \simeq 0.05\%\) and 0.12%) represents a small perturbation to the flow field, as noted by Liu et al. (2017). However, multiple flow quantities are affected by blowing; for example, the reattachment length \(X_r/k\), reported in table 2, is altered due to blowing. While increases of 12% and 6% are noted for cases 2 and 4 (\(\sigma \simeq 0.05\%\)), respectively, \(X_r/k\) is reduced by \(\sim 35-40\%\) for cases 3 and 5 (\(\sigma \simeq 0.12\%\)). Here and in subsequent results, it is important to note that the measurements were made at a single spanwise location coincident with the bars’ center line and the central jet in cases 2–5. Although spanwise variations are not captured, the measurement plane and experimental conditions were unchanged for the five cases, allowing for meaningful comparisons.

The effects of the injection location and severity factor \(\sigma\) on \(U/U_0\) are highlighted in Fig. 3 through profiles taken at \(x/k = 1\), 5, and 9. Blowing-induced deviations from the baseline case extend far within the boundary layer, reaching \(y/k =6\), which corresponds to approximately 75% of the boundary layer thickness in case 1. An increase in \(U/U_0\) of up to \(6\%\) occurs in cases 2 and 3 relative to case 1, while a modest difference exists for cases 4 and 5. Through DNS, Mori et al. (2017) studied uniform blowing in a channel with irregular 2D roughness on one wall; they considered blowing rates ranging from 0.1% to 1%, where the blowing rate is defined as the ratio of the injection velocity to the bulk velocity. Similar to the results presented here, they noted variations in the time-averaged streamwise velocity extending far above the wall (past the channel half-height in their case). However, the uniform blowing resulted in a consistent decrease in the time-averaged streamwise velocity, which is in contrast to the increase noted in Fig. 3 for cases 2 and 3. This difference emphasizes the complexities involved in the superposition of roughness and blowing, where the flow field is likely sensitive to the roughness geometry and injection type (localized vs. uniform), rate, and location. Similarly, Djenidi et al. (2019a) and Ghanadi and Djenidi (2021) observed an effect on the velocity profile extending to the outer layer over a rough wall subjected to localized suction through a porous strip.

As shown in Fig. 3, the deviations from case 1 vary with x/k, y/k, \(\sigma\), and injection location. To better quantify these changes, \(U/U_0\) was streamwise averaged over a single pitch (i.e., a spatial average over \(x/k \in [0, 11]\)); a similar streamwise averaging procedure has been employed by, for example, Tachie et al. (2007); Lee et al. (2012); and Tsikata and Tachie (2013a). The streamwise-averaged profiles, shown in Fig. 4, evidence the streamwise persistence of the \(U/U_0\) increase in cases 2 and 3. Moreover, the streamwise-averaged profiles were used to determine the boundary layer thickness \(\delta /k\), displacement thickness \(\delta ^*/k\), and momentum thickness \(\theta /k\), which are reported in table 2. While the flow organization is maintained across the five cases, localized blowing at such low severity factors can, as demonstrated in table 2, alter the boundary layer characteristics. For example, localized blowing results in a \(\sim 10-14\%\) decrease in the boundary layer thickness \(\delta /k\). The sensitivity of the boundary layer to blowing highlights the potential for localized blowing as a flow control strategy in the presence of roughness.

The effects of localized blowing on the flow turbulence are examined through contours of the Reynolds shear stress \(-\langle u'v'\rangle /U_0^2\), shown in Fig. 5. Here, \(\langle .\rangle\) denotes temporal averaging such that \(U = \langle u\rangle\), and primes indicate temporal fluctuations from time-averaged quantities (e.g., \(u' = u - U\)). The \(-\langle u'v'\rangle /U_0^2\) distribution for case 1 is similar to that in the literature (e.g., Wang et al. 2007; Lee et al. 2008; Djenidi et al. 2008), where the elevated \(-\langle u'v'\rangle /U_0^2\) is associated with the shear layer behind the bars. The Reynolds shear stress for cases 2 and 4 (\(\sigma = 0.05\%\)) exhibits similar spatial distribution and magnitude to the baseline case. In contrast, differences are observed for cases 3 and 5 (\(\sigma = 0.12\%\)). The magnitude of \(-\langle u'v'\rangle /U_0^2\) is significantly decreased for case 3, while the spatial distribution is altered for case 5.

The height of the roughness sublayer (the region where the roughness effects are pronounced) is often defined as the vertical location where the turbulence statistics become spatially homogeneous (Lee and Sung 2007; Placidi and Ganapathisubramani 2015). Due to the planar nature of the measurements, the spatial homogeneity of the Reynolds shear stress is examined only in the streamwise direction. Following Placidi and Ganapathisubramani (2015), the height of the roughness sublayer is defined as the location where the Reynolds shear stress varies by less than 10% from its streamwise-averaged value. As an example, the roughness sublayer height \(Y_{RSL}/k\) for case 1 is illustrated in figure 6. There, the Reynolds shear stress profiles are shown for \(x/k \in \{0, 1, 2, ..., 11\}\), and the horizontal line indicates the location where these profiles collapse under the 10% condition (\(Y_{RSL}/k = 2.9\)). Based on this definition, \(Y_{RSL}/k\) was determined for the five cases and is reported in table 2. Overall, \(Y_{RSL}/k\) for the various cases is in line with the \(Y_{RSL}/k \simeq 3 -5\) range found in the literature for k-type roughness composed of transverse square bars (Lee and Sung 2007; Lee et al. 2008; Djenidi et al. 2008). Significant changes in \(Y_{RSL}/k\) are noted for cases 2 and 5. The injection from the bar at \(\sigma =0.05\%\) (case 2) reduces the roughness sublayer height by 0.5k, which is in line with the thinning of the boundary layer for this case (demonstrated in table 2). In contrast, injection from the wall at \(\sigma =0.12\%\) (case 5) increases \(Y_{RSL}/k\) by 0.7k; this increase is likely associated with a weaker downwash region (relative to case 1), which increases the vertical extent of vortical structures shed from the bars. In an investigation of the flow over a dimpled surface, Borchetta et al. (2018) reported a larger vertical extent of the vortical structures due to uniform blowing, which is in line with the extension of the roughness sublayer reported in table 2 for case 5. In addition to the larger vertical extent, they noted that uniform blowing interrupts the shedding of vortical structures. This interruption could be a competing effect resulting in the reduced roughness sublayer height for cases 2–4.

Contours of the two-point correlations \(R_{11}\) and \(R_{22}\) for reference point \((x_{ref}/k = 5, y_{ref}/k = 3)\): a case 1, \(R_{11}\), b case 1, \(R_{22}\), c case 2, \(R_{11}\), and d case 2, \(R_{22}\). White contours at correlation levels 0.4–0.9 are shown in increments of 0.1 to aid in comparisons

Profiles of \(-\langle u'v'\rangle /U_0^2\) taken at \(x/k =1\), 5, and 9 are shown in Fig. 7. Profiles of the in-plane turbulent kinetic energy \(TKE = \langle u'^2 + v'^2 \rangle / 2U_0^2\) exhibit similar trends but are not shown for brevity. A peak in both \(-\langle u'v'\rangle /U_0^2\) and TKE is noted for all cases near \(y/k = 1\). This peak is associated with the separated shear layer downstream of the bars, and its vertical location remains near \(y/k =1\) until the compact upwash region, where the peak location shifts upward. At \(x/k =1\) (Fig. 7a), the secondary peak near \(y/k =2.5\) corresponds to the shear layer from the upstream element. Localized blowing results in deviations from the baseline profiles; these deviations extend far within the boundary layer and vary with x/k, y/k, \(\sigma\), and injection location. As shown in Fig. 7, injection from the bar (cases 2 and 3) appears influential in altering the magnitude of \(-\langle u'v'\rangle /U_0^2\). The streamwise-averaged profiles of \(-\langle u'v'\rangle /U_0^2\) and TKE are provided in Fig. 8; they also highlight the influential role of injection from the bar (cases 2 and 3) in reducing \(-\langle u'v'\rangle /U_0^2\) and TKE. Most notably, the maximum streamwise-averaged \(-\langle u'v'\rangle /U_0^2\) for case 3 is reduced by 24% relative to case 1. Similarly, the maximum streamwise-averaged TKE is reduced by 21%. The decrease for cases 2 and 3 is in contrast to an increase in \(-\langle u'v'\rangle /U_0^2\), \(-\langle u'^2\rangle /U_0^2\), and \(-\langle v'^2\rangle /U_0^2\) reported by Borchetta et al. (2018) due to uniform blowing through a dimpled surface. Obtaining the friction velocity \(u_{\tau }\) for a rough wall without direct wall shear stress measurements is challenging; the reader is referred to Wei et al. (2005) and Djenidi et al. (2019b) for a discussion of the challenge involved in determining \(u_{\tau }\) from the velocity profile. However, an estimate of \(u_{\tau }\) can be obtained from the maximum or plateau of the Reynolds shear stress profile (Flack et al. 2005; Djenidi et al. 2008; Manes et al. 2011; Placidi and Ganapathisubramani 2015). Here, the streamwise-averaged \(-\langle u'v'\rangle /U_0^2\) profiles in Fig. 8a were used to approximate the friction velocity \(u_{\tau }/U_0\) for the various cases. Specifically, \(u_{\tau }/U_0\), reported in table 2, was estimated as the square root of the maximum streamwise-averaged \(-\langle u'v'\rangle /U_0^2\). To facilitate comparisons and due to the approximate nature of the reported \(u_{\tau }\), \(U_0\), rather than \(u_{\tau }\), is used for normalization.

Contours of the two-point correlations \(R_{11}\) and \(R_{22}\) for reference point \((x_{ref}/k = 5, y_{ref}/k = 1.1)\): a case 1, \(R_{11}\), b case 1, \(R_{22}\), c case 2, \(R_{11}\), and d case 2, \(R_{22}\). White contours at correlation levels 0.4–0.9 are shown in increments in 0.1 to aid in comparisons

The turbulence structure is explored through the two-point correlations

where \(u'_1\) and \(u'_2\) denote \(u'\) and \(v'\), respectively. For each case, two reference points are considered: \((x_{ref}/k = 5, y_{ref}/k = 3)\) and \((x_{ref}/k = 5, y_{ref}/k = 1.1)\). The two reference points were chosen to highlight the correlation close to and away from the bars; \(y_{ref}/k = 3\) is at the upper portion of the roughness sublayer and represents \(\sim 38\% - 44\%\) of the boundary layer thickness reported in table 2. The \(R_{11}\) and \(R_{22}\) correlations for the two reference points are shown in Figs. 9, 10; for brevity, the correlations are shown only for cases 1 and 2. In the figures, white contours at correlation levels 0.4 - 0.9 are superimposed at 0.1 increments to facilitate comparisons. For \((x_{ref}/k = 5, y_{ref}/k = 3)\), \(R_{11}\) exhibits an inclined elliptical shape, and \(R_{22}\) exhibits a more circular shape stretched in the vertical direction (Fig. 9). The shape of the correlations and inclination angles are consistent across all five cases and compare well with those in the literature. For example, similar shapes were observed by Volino et al. (2009) at \(y/\delta =0.4\) for the turbulent boundary layer over smooth walls and walls roughened with transverse square bars (\(k/\delta \simeq 0.03\)). Volino et al. (2009) reported an increase in the extent of both \(R_{11}\) and \(R_{22}\) due to the bar roughness. As shown in Fig. 9, the localized blowing does not change the shape of the correlations away from the roughness; however, it modestly affects their spatial extent. For example, the streamwise extent of \(R_{11}\), determined on the 0.5 contour, decreases from 6.5k for the baseline case to 6.1k due to localized blowing from the bar at \(\sigma = 0.05\%\) (case 2). Relative to the baseline case, the maximum change in this extent across the 4 injection cases is below 6%.

The correlations at \((x_{ref}/k = 5, y_{ref}/k = 1.1)\), shown in Fig. 10, exhibit a shorter extent relative to those at \((x_{ref}/k = 5, y_{ref}/k = 3)\). While \(R_{22}\) has a similar shape to the one in Fig. 9, the elliptical shape of \(R_{11}\) appears more inclined on the downstream side possibly due to the presence of the intense upwash region. Both the shape and extent of the correlations appear more sensitive to localized blowing. Specifically, some differences across the five cases are noted in the shape of \(R_{11}\) on the upstream side (Fig. 10). Additionally, the streamwise extent of \(R_{11}\), determined on the 0.5 contour, decreases from 4.9k for the baseline case to 4.2k for case 2. Across the 4 injection cases, the maximum change in the streamwise extent of \(R_{11}\) relative to case 1 is below 14%. Figs. 9 and 10 provide insight into the effects of localized blowing on the flow lengths scales and structure. While a more pronounced effect is observed near the roughness, the shape and spatial extent of \(R_{11}\) are modestly affected by blowing far from the wall. In a study of the turbulent boundary layer over rough walls with various topographies (\(k/\delta = 0.1\)), Placidi and Ganapathisubramani (2018) observed similar \(R_{11}\), \(R_{22}\), and \(R_{12}\) shapes at \(y/\delta = 0.4\) across the various topographies. They suggested that the similar correlation shapes support a similarity in the turbulence structure away from the roughness. In the context of their analysis, the similarity in the shapes of \(R_{11}\) and \(R_{22}\) at \((x_{ref}/k = 5, y_{ref}/k = 3)\) suggests a minor perturbation to the turbulence structure away from the bars due to localized blowing.

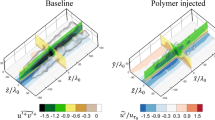

Snapshot proper orthogonal decomposition (POD) analysis was performed to further investigate the effects of localized blowing on the turbulence structure. Following Sirovich (1987), the in-plane fluctuating velocity \(\mathbf {u'}(\mathbf {x},t) = u'(\mathbf {x},t)\hat{i} + v'(\mathbf {x},t)\hat{j}\) is decomposed into a deterministic part \(\varvec{\phi ^n}(\mathbf {x})\) (often referred to as spatial modes, eigenmodes, or POD modes) and time-dependent coefficients \(a^n(t)\) as

Here, N is the total number of velocity fields (snapshots), and the bold symbols denote vectorial quantities. For each of the five cases, \(N=\) 4,000 velocity fields were used in the decomposition. The modes are ranked in descending order based on their individual energy content; the sum of the energy of all modes is representative of the turbulent kinetic energy of the flow. The low-order POD modes (more energetic modes) tend to have larger spatial structure than the high-order modes (less energetic modes). Additionally, it is important to note that the modes themselves are not coherent structures; however, they provide insight into the spatial flow scales and their respective energy. For additional details on the POD procedure and interpretation, the reader is referred to, for example, Hamed and Peterlein (2020); Placidi and Ganapathisubramani (2018, 2015); Liu et al. (2001); Sirovich (1987). The first four streamwise POD modes \(\phi _{u'}\) for cases 1 and 2 are shown in Fig. 11; the modes for cases 3–5 are not shown for brevity. Overall, the first 4 modes exhibit similar shapes across the five cases; however, differences are observed at mode 5 and beyond. As a percentage of the total energy, the first 4 modes contain similar cumulative energy across the five cases (41% - 44%). It is worth noting that the modes shown in Fig. 11 exhibit similar shapes to the respective modes found by Hamed and Peterlein (2020) for a smooth-wall turbulent boundary layer. Additionally, similar shapes were reported by Placidi and Ganapathisubramani (2018, 2015) for a turbulent boundary layer over various large-scale roughness topographies. Relying on the similarity in the shape of the two-point correlations and the low-order energetic POD modes across their various roughness topographies, Placidi and Ganapathisubramani (2018) suggested that the turbulent boundary layer over these topographies exhibits similar spatial turbulence structure, despite the changes in the turbulence statistics. They argued that the large-scale flow structures are the major contributors to the two-point correlations and low-order POD modes. Since these structures are less sensitive to the small-scales generated at the roughness, the overall turbulence structure is maintained away from the roughness as evidenced by the similarity in the two-point correlations and low-order POD modes. In this context, the similarity in the shapes of the two-point correlations (Fig. 9) and the low-order POD modes (Fig. 11) across the five cases considered here suggests that localized blowing has a minimal effect on the turbulence structure away from the bars, despite the modulation noted in, for example, the time-averaged streamwise velocity (Fig. 3), Reynolds shear stress (Fig. 5), and TKE (Fig. 8). A minimal impact on the turbulence structure was also observed by Djenidi et al. (2019a) for a rough wall subjected to localized suction through a porous strip. However, they relied on the skewness and flatness of the streamwise velocity to investigate the turbulence structure. For a similar rough wall with localized suction, Ghanadi and Djenidi (2021) suggested a possible change in the turbulence structure at low Reynolds numbers (\(Re_\tau = \delta u_{\tau }/\nu \sim 1,000\)).

4 Conclusions

Planar PIV was used to experimentally investigate the effects of localized blowing on the turbulent boundary layer over 2D roughness composed of identical transverse square bars. The flow field over the baseline case (no injection, case 1) compares well with that in the literature for similar k-type roughness. The flow separates at the trailing edge of the bars and reattaches to the wall upstream of the next bar; enhanced turbulence levels are associated with the separated shear layer. The overall flow organization, including the recirculation zones and the upwash and downwash regions, persists despite the localized blowing in cases 2–5. Quantitatively, localized blowing alters the time-averaged streamwise velocity, boundary layer characteristics, Reynolds shear stress, and the turbulent kinetic energy. The blowing-induced deviations from the baseline case extend far above the roughness and vary with both the severity factor and injection location. Notably, the localized injection from the downstream face of the bar (cases 2 and 3) increases the streamwise velocity and reduces the Reynolds shear stress and the in-plane turbulent kinetic energy. In the context of previous studies, the two-point correlations and POD analyses suggest that the turbulence structure is minimally perturbed far above the roughness, despite the blowing-induced deviations in the aforementioned flow quantities. The sensitivity of the time-averaged streamwise velocity, Reynolds shear stress, and turbulent kinetic energy to localized blowing highlights the potential for its use as an active control strategy in the presence of roughness. The persistence of the flow organization and turbulence structure despite the blowing suggests that localized injection at low severity factors can be viewed as a small perturbation to the flow field.

Since only one roughness topography was considered in this study, additional investigations are recommended to further characterize the superposition of roughness and flow injection. Key parameters to investigate include the roughness topography, injection location, and injection rate. The effects of the jets’ diameter and spacing on the boundary layer characteristics, flow statistics, and turbulence structure are also in need of further study. Additionally, volumetric or multi-plane measurements are required to better describe the flow field and to characterize the spanwise variations that were not captured in this study. Such measurements can facilitate the quantification of the jet-induced spanwise variations in flow quantities and the streamwise extent of these variations.

References

Alam T, Saini RP, Saini JS (2014) Heat and flow characteristics of air heater ducts provided with turbulators-a review. Renew Sustain Energy Rev 31:289–304

Ashrafian A, Andersson HI (2006) The structure of turbulence in a rod-roughened channel. Int J Heat Fluid Flow 27(1):65–79

Borchetta CG, Martin A, Bailey SCC (2018) Examination of the effect of blowing on the near-surface flow structure over a dimpled surface. Exp Fluids 59(3):36

Burattini P, Leonardi S, Orlandi P, Antonia RA (2008) Comparison between experiments and direct numerical simulations in a channel flow with roughness on one wall. J Fluid Mech 600:403

Choi YK, Hwang HG, Lee YM, Lee JH (2020) Effects of the roughness height in turbulent boundary layers over rod-and cuboid-roughened walls. Int J Heat Fluid Flow 85:108644

Christensen K (2004) The influence of peak-locking errors on turbulence statistics computed from piv ensembles. Exp Fluids 36(3):484–497

Chung D, Hutchins N, Schultz MP, Flack KA (2021) Predicting the drag of roughness. Annu Rev Fluid Mech

De Marchis M, Saccone D, Milici B, Napoli E (2020) Large eddy simulations of rough turbulent channel flows bounded by irregular roughness: Advances toward a universal roughness correlation. Flow Turbul Combust 105

Dey S, Sarkar S, Ballio F (2011) Double-averaging turbulence characteristics in seeping rough-bed streams. J Geophys Res Earth Surf 116(F3)

Djenidi L, Antonia RA, Amielh M, Anselmet F (2008) A turbulent boundary layer over a two-dimensional rough wall. Exp Fluids 44(1):37–47

Djenidi L, Kamruzzaman M, Dostal L (2019a) Effects of wall suction on a 2d rough wall turbulent boundary layer. Exp Fluids 60(3):1–11

Djenidi L, Talluru KM, Antonia RA (2019b) A velocity defect chart method for estimating the friction velocity in turbulent boundary layers. Fluid Dyn Res 51(4):045502

Fang X, Yang Z, Wang BC, Tachie MF, Bergstrom DJ (2015) Highly-disturbed turbulent flow in a square channel with v-shaped ribs on one wall. Int J Heat Fluid Flow 56:182–197

Flack KA, Schultz MP (2014) Roughness effects on wall-bounded turbulent flows. Phys Fluids 26(10):101305

Flack KA, Schultz MP, Shapiro TA (2005) Experimental support for townsend’s reynolds number similarity hypothesis on rough walls. Phys Fluids 17(3):035102

Ghanadi F, Djenidi L (2021) Reynolds number effect on the response of a rough wall turbulent boundary layer to local wall suction. J Fluid Mech 916

Haddad M, Labraga L, Keirsbulck L (2006) Turbulence structures downstream of a localized injection in a fully developed channel flow. J Fluid Eng 128

Haddad M, Labraga L, Keirsbulck L (2007) Effects of blowing through a porous strip in a turbulent channel flow. Exp Therm Fluid Sci 31(8):1021–1032

Hamed AM, Peterlein AM (2020) Turbulence structure of boundary layers perturbed by isolated and tandem roughness elements. J Turbul 21(1):17–33

Hamed AM, Kamdar A, Castillo L, Chamorro LP (2015) Turbulent boundary layer over 2d and 3d large-scale wavy walls. Phys Fluids 27(10):106601

Hamed AM, Castillo L, Chamorro LP (2017) Turbulent boundary layer response to large-scale wavy topographies. Phys Fluids 29(6):065113

Hamed AM, Peterlein AM, Randle LV (2019) Turbulent boundary layer perturbation by two wall-mounted cylindrical roughness elements arranged in tandem: Effects of spacing and height ratio. Phys Fluids 31(6):065110

Healzer J, Moffat R, Kays W (1974) The turbulent boundary layer on a porous, rough plate-experimentalheat transfer with uniform blowing. In: Thermophysics and Heat Transfer Conference, p 680

Ikeda T, Durbin PA (2007) Direct simulations of a rough-wall channel flow. J Fluid Mech 571:235

Ismail U, Zaki TA, Durbin PA (2018) Simulations of rib-roughened rough-to-smooth turbulent channel flows. J Fluid Mech 843:419

Jimenez J (2004) Turbulent flows over rough walls. Annu Rev Fluid Mech 36:173–196

Kametani Y, Fukagata K (2011) Direct numerical simulation of spatially developing turbulent boundary layers with uniform blowing or suction. J Fluid Mech 681:154–172

Kametani Y, Fukagata K, Örlü R, Schlatter P (2015) Effect of uniform blowing/suction in a turbulent boundary layer at moderate reynolds number. Int J Heat Fluid Flow 55:132–142

Keirsbulck L, Labraga L, Haddad M (2006) Influence of blowing on the anisotropy of the reynolds stress tensor in a turbulent channel flow. Exp Fluids 40(4):654

Kim K, Sung HJ (2003) Effects of periodic blowing from spanwise slot on a turbulent boundary layer. AIAA J 41(10):1916–1924

Kim K, Sung HJ (2006) Effects of unsteady blowing through a spanwise slot on a turbulent boundary layer. J Fluid Mech 557:423–450

Krogstad PÅ, Efros V (2012) About turbulence statistics in the outer part of a boundary layer developing over two-dimensional surface roughness. Phys Fluids 24(7):075112

Krogstad PÅ, Kourakine A (2000) Some effects of localized injection on the turbulence structure in a boundary layer. Phys Fluids 12(11):2990–2999

Krogstad PÅ, Andersson HI, Bakken OM, Ashrafian A (2005) An experimental and numerical study of channel flow with rough walls. J Fluid Mech 530:327

Lee J, Kim JH, Lee JH (2016) Scale growth of structures in the turbulent boundary layer with a rod-roughened wall. Phys Fluids 28(1):015104

Lee JH, Seena A, Lee SH, Sung HJ (2012) Turbulent boundary layers over rod-and cube-roughened walls. J Turbul 13(1):N40

Lee SH, Sung HJ (2007) Direct numerical simulation of the turbulent boundary layer over a rod-roughened wall. J Fluid Mech 584:125–146

Lee SH, Kim JH, Sung HJ (2008) Piv measurements of turbulent boundary layer over a rod-roughened wall. Int J Heat Fluid Flow 29(6):1679–1687

Lee YM, Kim JH, Lee JH (2018) Direct numerical simulation of a turbulent couette-poiseuille flow with a rod-roughened wall. Phys Fluids 30(10):105101

Leonardi S, Orlandi P, Smalley RJ, Djenidi L, Antonia RA (2003) Direct numerical simulations of turbulent channel flow with transverse square bars on one wall. J Fluid Mech 491:229

Leonardi S, Orlandi P, Djenidi L, Antonia RA (2004) Structure of turbulent channel flow with square bars on one wall. Int J Heat Fluid Flow 25(3):384–392

Leonardi S, Orlandi P, Antonia RA (2007) Properties of d-and k-type roughness in a turbulent channel flow. Phys Fluids 19(12):125101

Liu C, Araya G, Leonardi S (2017) The role of vorticity in the turbulent/thermal transport of a channel flow with local blowing. Comput Fluids 158:133–149

Liu Z, Adrian RJ, Hanratty TJ (2001) Large-scale modes of turbulent channel flow: transport and structure. J Fluid Mech 448:53–80

Manes C, Poggi D, Ridolfi L (2011) Turbulent boundary layers over permeable walls: scaling and near wall structure. J Fluid Mech 687:141–170

Miller MA, Martin A, Bailey SCC (2014) Investigation of the scaling of roughness and blowing effects on turbulent channel flow. Exp Fluids 55(2):1675

Mori E, Quadrio M, Fukagata K (2017) Turbulent drag reduction by uniform blowing over a two-dimensional roughness. Flow Turbul Combust 99(3–4):765–785

Mousa MH, Miljkovic N, Nawaz K (2021) Review of heat transfer enhancement techniques for single phase flows. Renew Sustain Energy Rev 137:110566

Nadeem M, Lee JH, Lee J, Sung HJ (2015) Turbulent boundary layers over sparsely-spaced rod-roughened walls. Int J Heat Fluid Flow 56:16–27

Park YS, Park SH, Sung HJ (2003) Measurement of local forcing on a turbulent boundary layer using piv. Exp Fluids 34(6):697–707

Placidi M, Ganapathisubramani B (2015) Effects of frontal and plan solidities on aerodynamic parameters and the roughness sublayer in turbulent boundary layers. J Fluid Mech 782:541–566

Placidi M, Ganapathisubramani B (2018) Turbulent flow over large roughness elements: Effect of frontal and plan solidity on turbulence statistics and structure. Boundary-Layer Meteorol 167(1):99–121

Prasad A, Adrian R, Landreth C, Offutt P (1992) Effect of resolution on the speed and accuracy of particle image velocimetry interrogation. Exp Fluids 13(2):105–116

Roussinova V, Balachandar R (2011) Open channel flow past a train of rib roughness. J Turbul 12:N28

Schetz JA, Nerney B (1977) Turbulent boundary layer with injection and surface roughness. AIAA J 15(9):1288–1294

Segunda VM, Ormiston SJ, Tachie MF (2018) Experimental and numerical investigation of developing turbulent flow over a wavy wall in a horizontal channel. Eur J Mech - B/Fluids 68:128–143

Sheikholeslami M, Gorji-Bandpy M, Ganji DD (2015) Review of heat transfer enhancement methods: Focus on passive methods using swirl flow devices. Renew Sustain Energy Rev 49:444–469

Singha A, Al Faruque MA, Balachandar R (2012) Vortices and large-scale structures in a rough open-channel flow subjected to bed suction and injection. J Eng Mech 138(5):491–501

Sirovich L (1987) Turbulence and the dynamics of coherent structures. part i: Coherent structures. Q Appl Maths 45:561–571

Tachie MF, Agelinchaab M, Shah MK (2007) Turbulent flow over transverse ribs in open channel with converging side walls. Int J Heat Fluid Flow 28(4):683–707

Tachie MF, Paul SS, Agelinchaab M, Shah MK (2009) Structure of turbulent flow over 90 and 45 transverse ribs. J Turbul 10:N20

Townsend AA (1976) The structure of turbulent shear flow. Cambridge University Press, Cambridge

Tsikata JM, Tachie MF (2013a) Adverse pressure gradient turbulent flows over rough walls. Int J Heat Fluid Flow 39:127–145

Tsikata JM, Tachie MF (2013b) Effects of roughness and adverse pressure gradient on the turbulence structure. Int J Heat Fluid Flow 44:239–257

Volino RJ, Schultz MP, Flack KA (2009) Turbulence structure in a boundary layer with two-dimensional roughness. J Fluid Mech 635:75–101

Volino RJ, Schultz MP, Flack KA (2011) Turbulence structure in boundary layers over periodic two-and three-dimensional roughness. J Fluid Mech 676:172–190

Wang L, Hejcik J, Sunden B (2007) Piv measurement of separated flow in a square channel with streamwise periodic ribs on one wall. J Fluid Eng 128

Wei T, Schmidt R, McMurtry P (2005) Comment on the clauser chart method for determining the friction velocity. Exp Fluids 38(5):695–699

Xie L, Zheng Y, Zhang Y, Ye Z, Zou J (2020) Effects of localized micro-blowing on a spatially developing flat turbulent boundary layer. Flow Turbul Combust pp 1–29

Acknowledgements

This work was supported by Union College through the start-up funds of Assistant Professor A. M. Hamed, Faculty Research Fund, and Student Research Grant for C. E. Nye. The authors are thankful to GE Global Research (Niskayuna, NY) for the donation of the water channel used in this research. The authors thank undergraduate students N. Rachad and R. Gallary for their assistance with the experiments and the manuscript preparation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hamed, A.M., Nye, C.E. & Hall, A.J. Effects of localized blowing on the turbulent boundary layer over 2D roughness. Exp Fluids 62, 163 (2021). https://doi.org/10.1007/s00348-021-03261-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00348-021-03261-0