Abstract

Bioprocess development is a current requirement to enhance the global production of D-lactic acid. Herein, we report a new bioprocess for D-lactic acid production directly from starch using engineered Lactococcus lactis NZ9000. To modify L. lactis as a D-lactic acid producer, its major endogenous L-lactate dehydrogenase (L-Ldh) gene was replaced with a heterologous D-Ldh gene from Lactobacillus delbrueckii subsp. lactis JCM 1107. The resulting strain AH1 showed a somewhat slower growth rate but similar lactic acid production compared to those of the intact strain when cultivated with glucose as a carbon source. The chemical purity of D-lactic acid produced by L. lactis AH1 was 93.8%, and the enzymatic activities of D- and L-Ldh in AH1 were 1.54 U/mL and 0.05 U/mL, respectively. Next, a heterologous α-amylase gene from Streptococcus bovis NRIC 1535 cloned into an expression vector pNZ8048 was introduced into AH1. The resulting strain AH2 showed an amylolytic activity of 0.26 U/mL in the culture supernatant. Direct production of D-lactic acid from starch as the carbon source was demonstrated using L. lactis AH2, resulting in D-lactic acid production at a concentration of 15.0 g/L after 24 h cultivation. To our knowledge, this is the first report on D-lactic acid production in engineered L. lactis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lactic acid bacteria (LAB) fermentatively produce lactic acid, which is a renewable versatile chemical [1,2,3]. Lactic acid shows two optically active isomers, D-lactic acid and L-lactic acid. L-lactic acid has been used as a building block for the well-studied bioplastic poly(L-lactic acid) that possesses unique properties such as transparency, biocompatibility, and biodegradability [4]. The melting temperature (Tm) of crystallized poly(L-lactic acid) is around 180 °C whereas that of crystallized stereocomplex poly(lactic acid) consisting of poly(L-lactic acid) and poly(D-lactic acid) at a ratio of 1:1 is around 230 °C [5,6,7], meaning that the stereocomplex polymer is a preferable commodity plastic. However, global production of poly(D-lactic acid) is very low because the global market for D-lactic acid is currently less than that for L-lactic acid. To promote the stereocomplex poly(lactic acid) as a commodity bioplastic, development of a bioprocess to enhance the global production of D-lactic acid is highly desired.

LAB are classified into two groups, homofermentative and heterofermentative LAB, and these are further divided into subgroups harboring D-lactate dehydrogenase (D-Ldh) and/or L-Ldh [8]. Homofermentative LAB produce two molecules of lactic acid from one molecule of glucose without any by-product, whereas heterofermentative LAB produce one molecule of lactic acid from one molecule of glucose with by-products such as acetic acid and ethanol. LAB harboring D- and L-Ldh produce D- and L-lactic acids respectively, but LAB harboring both enzymes can produce both lactic acids. Therefore, it is desired that industrial production of lactic acids is performed using homofermentative LAB harboring either D- or L-Ldh [9,10,11,12]. Some homofermentative LAB harboring only L-Ldh have been found in nature, such as Lactococcus lactis, where there is no homofermentative LAB harboring only D-Ldh except for Lactobacillus delbrueckii.

L. lactis is one of the most well-studied LAB. To date, many reports on genetic engineering of L. lactis have been published as L. lactis can be easily transformed using appropriate vectors with very high efficiency [13] and many genetic tools for gene expression in L. lactis [14,15,16,17]. The NICE system is one of the best known gene expression systems in L. lactis based on a combination of L. lactis hosts encoding nisRK genes with the expression vectors harboring a nisin-inducible strong promoter [18,19,20,21]. On the contrary, there are only a few reports on genetic engineering of L. delbrueckii because it can be transformed with low efficiency compared to L. lactis [22,23,24]. These data suggest that L. lactis is preferable for D-lactic acid production rather than L. delbrueckii. Because homofermentative LAB can produce lactic acid without by-products and show tolerance to lactic acid produced by themselves, it is reasonable to engineer homofermentative LAB for lactic acid production compared to non-LAB such as Escherichia coli [25, 26]. For example, Okano et al. [27] have demonstrated production of D-lactic acid at 86.0 g/L from 100 g/L glucose for 36 h cultivation in a fermenter using engineered L-Ldh gene-deficient Lactobacillus plantarum.

In this study, we developed a new bioprocess for D-lactic acid production using engineered L. lactis. The engineered strain producing D-lactic acid was constructed by replacement of its major endogenous L-Ldh gene with a heterologous D-Ldh gene from L. delbrueckii subsp. lactis JCM 1107. The cell growth and lactic acid production of the resulting strain L. lactis AH1 were characterized. To reduce production costs, it is beneficial if D-lactic acid can be directly produced using starch as the substrate, instead of glucose. In fact, some related studies on lactic acid production directly from starch by the expression of a heterologous amylase from Streptococcus bovis 148 (corresponding to NRIC 1535) in LAB have been published [27,28,29]. In this study, we demonstrated the direct production of D-lactic acid from starch using a further engineered strain based on the NICE system. A heterologous α-amylase gene from S. bovis NRIC 1535 was introduced into the L. lactis AH1 strain, resulting in L. lactis AH2, and the amylolytic activity and D-lactic acid production of L. lactis AH2 from starch were then characterized.

Materials and Methods

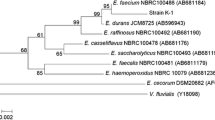

Strains, Media, and Culture Conditions

L. lactis NZ9000 (NIZO Food Research, Netherlands) [30] and S. bovis NRIC 1535 [31] were grown in M17 medium (Difco Laboratories, MI, USA) supplemented with 0.5% glucose (GM17) at 30 °C. L. delbrueckii subsp. lactis JCM 1107 (corresponding to CNRZ 327) was grown in MRS medium (Oxoid, Hampshire, UK) at 30 °C. E. coli JM109 (Toyobo, Osaka, Japan)) and TOP10 (Thermo Fisher Scientific, MA, USA) were grown in LB medium at 37 °C. For fermentation tests, the recombinant L. lactis were grown in 5 mL M17 medium with 2% glucose or soluble starch in the presence of 0.5 M 3-(N-morpholino)propanesulfonic acid) (MOPS, pH 7.0) at 30 °C for 24 h. When required, 50 mg/L kanamycin and 20 mg/L chloramphenicol were added to the media for E. coli and L. lactis transformants, respectively.

Genetic Engineering

Restriction and ligation enzymes were purchased from Thermo Fisher Scientific (Waltham, MA, USA) and Toyobo, respectively. Genomic DNA isolation from LAB was performed using ISOPLANT (Nippon gene, Tokyo, Japan). Plasmid DNA isolation from E. coli and L. lactis was performed using the MagExtractor Plasmid (Toyobo) and a protocol described elsewhere [32], respectively.

Replacement of the L-Ldh gene encoded on the genome of L. lactis NZ9000 with the D-Ldh gene from L. delbrueckii subsp. lactis JCM 1107 by homologous recombination is illustrated in Fig. 1. The pfk-pyk and the nupC-nupB regions from L. lactis NZ9000 were amplified by polymerase chain reaction (PCR) with primer sets, pfk-F1 (5′-ctggtggtgatgccccagggatgaatgcgg-3′) and pyk-R1 (5′-agatctgtcgacatatgtttctttaattcctttcaaattataaacg-3′); and nupB-F1 (5′-acaagatctgtcctcgttcctctcattgcc-3′) and nupC-R1 (5′-aagtcgacagagttagtagaaaatttcaac-3′), respectively, with L. lactis NZ9000 genomic DNA (accession no. CP002094) as a template, and KOD plus DNA polymerase (TOYOBO). The amplified pfk-pyk fragment was cloned into a plasmid pCR-BluntII-TOPO in the same direction as the lacZ gene via TOPO cloning using E. coli JM109 as the host, followed by cloning of the amplified nupC-nupB fragment into the resulting plasmid at the SalI and BglII restriction enzyme sites, resulting in the pAH2 plasmid. To clone the D-Ldh gene from L. delbrueckii subsp. lactis JCM 1107 and the erythromycin resistance gene (Emr) into pAH2, these genes and the pAH2 fragment were amplified by PCR using primer sets D-ldh-F1 (5′-aggaattaaagaaaatcatgactaaaatttttgcttacgc-3′) and D-ldh-R1 (5′-tatctgtgtcgacaaagcggctagattagccaacc-3′); Em-F1 (5′-ttgtcgacacagatagcgacagagaaggcg-3′) and Em-R1 (5′-ctgtcgacctctttagctccttggaagctg-3′); and pAH2-F1 (5′-ttttctttaattcctttcaaattataaacg-3′) and pAH2-R1 (5′-taaagaggtcgacagagagttagtagaaaatttcaac-3′), respectively, with L. delbrueckii subsp. lactis JCM 1107 genomic DNA (accession no. CCDV01000001), pNZ9520 plasmid [33], and pAH2 as respective templates, and KOD plus DNA polymerase, followed by fragment assembling using the Generates Seamless Cloning and Assembly Kit (Thermo Fisher Scientific) with E. coli TOP10 as a host, resulting in the pAH4 plasmid.

a A scheme of replacement of the L-Ldh gene encoded on the genome of L. lactis NZ9000 with the D-Ldh gene from L. delbrueckii subsp. lactis JCM 1107 by homologous recombination using the pAH4 plasmid. pfk, 6-phosphofructokinase gene; pyk, pyruvate kinase; nupB and nupC, ABC transporter permease gene. D-Ldh gene and erythromycin resistance gene (Emr) were cloned into the intergenic region between pfk-pyk and nup-nupC on pAH4. b Comparison of nucleotide and amino acid sequences between the 5′ flanking regions of L-Ldh and D-Ldh genes of L. delbrueckii subsp. lactis JCM 1107 and L. lactis NZ9000, respectively. By homologous recombination, the D-Ldh gene was inserted in-frame downstream of the endogenous L-Ldh gene encoded on the genome of L. lactis NZ9000, resulting in AH1. The shaded sequences are nucleotides encoding D-/L-Ldh and identical amino acids are indicated in bold letters

To replace the L-Ldh gene with the D-Ldh gene, L. lactis NZ9000 was transformed with pAH4 by electroporation according to a protocol described elsewhere [15]. The cells were subsequently incubated at 30 °C for 18 h on GM17 agar medium supplemented with 1 mg/L erythromycin, resulting in L. lactis AH1. To confirm the desired mutant, agarose gel electrophoresis was performed using PCR amplicons of respective deleted regions using mutant genomic DNA as the template with the following primer sets: L-ldh-F1 (5′-agttatccttgttggtgacggtgctgtagg-3′) and L-ldh-R1 (5′-gtaatacgagcaagggctacagccacaccg-3′), and D-ldh-F1 and D-ldh-R1.

Plasmid construction for heterologous α-amylase expression in L. lactis NZ9000 was performed in the following manner. The α-amylase gene amyA from S. bovis was amplified by PCR using KOD plus DNA polymerase, S. bovis NRIC 1535 genomic DNA (accession no. AB000829) as a template, and a primer set of amyA-F1 (5′-ccctcatgacatttcagaataaagtaaatt-3′) and amyA-R1 (5′-ctgctgcagaagctacttcttagggaaagg-3′). After The amplified amyA fragment containing the region encoding the leader peptide was digested with PagI and PstI, the resulting fragment was cloned into pNZ8048 at NcoI and PstI sites, resulting in pNZ8048-amyA. L. lactis NZ9000 was transformed with pNZ8048-amyA by electroporation, resulting in L. lactis AH2.

Characterization of the Engineered L. lactis

The chirality of lactic acid in the supernatant of L. lactis cells (optical density at 600 nm (OD600) of 1) incubated in 50 mM potassium phosphate buffer (pH 7.0) containing 1% glucose at 30 °C for 24 h was determined using a Prominence HPLC system (Shimadzu, Kyoto, Japan) equipped with a MCI GEL CRS10 W column (Mitsubishi Chemical, Tokyo, Japan) and monitored at 254 nm using 1 mM copper(II) sulfate solution as the mobile phase at a 0.5 mL/min flow rate. Commercial D-/L-sodium lactate reagents (Sigma-Aldrich, St. Louis, USA) were used as controls for lactic acid quantification. Lactic acid produced in the culture supernatant of L. lactis was quantified using the HPLC system equipped with a SCR-102H column (Shimadzu). Lactic acid was eluted using 0.1% perchloric acid solution. The flow rate was 0.9 mL/min, and the eluate was monitored by absorbance at 210 nm. D-lactic acid production in GM17 was obtained by multiplying the lactic acid concentration determined using HPLC by the chemical purity.

Glucose in the culture supernatant was measured using the commercial kit, Glucose CII-Test Wako (Wako Pure Chemical Industries, Osaka, Japan). Sugar concentration in the culture supernatant was determined by the phenol-sulfuric acid method [34].

Recombinant L. lactis cultivated in GM17 medium at 30 °C for 18 h was inoculated in fresh GM17 medium, and was cultured to an optical density at OD600 of 0.1. After the cultures were subsequently grown at 30 °C until they reached an OD600 of 0.5–0.7, the cells were washed twice with a resuspension buffer (50 mM Tris-HCl (pH 8.0), 100 mM NaCl, 2 mM EDTA, 1 mM DTT, 0.5 mM PMSF) [35]. The washed cells were resuspended in 90 µL of resuspension buffer containing 0.5 g/L Labiase (Ozeki Corp., Hyogo, Japan) and lysozyme (Wako) and then incubated at 37 °C for 30 min. After adding 10 µL of BugBuster 10X Protein Extraction Reagent (Merck Millipore, MA, USA) to the cell suspension, the suspension was incubated at a room temperature for 20 min. The cell extract was centrifuged and its protein concentration was then measured using the protein assay reagent in the TaKaRa BCA Protein Assay Kit (Takara Bio Inc., Shiga, Japan), based on the BCA method [36], with bovine serum albumin as a standard. D-/L-Ldh specific activities in recombinant L. lactis were assayed in the following manner: 10 µL of the cell extract was incubated with 200 µL of substrate solution (100 mM Tris-HCl (pH 8.0), 15 mM NAD+, 500 mM D-/L-sodium lactate, 10 mM fructose 1,6-bisphosphate) at 37 °C for 10 min. The released NADH was measured at 340 nm using a spectrophotometer. One unit (U) corresponds to 1 µmol of NADH formed per min.

Recombinant L. lactis cultivated in GM17 medium at 30 °C for 18 h was inoculated in fresh GM17 medium, and cultured to OD600 of 0.1. After the cultures were subsequently grown at 30 °C until they reached an OD600 of 0.4–0.6, 5 μg/L nisin A (Sigma-Aldrich) was added to the cultures and then incubated at 30 °C for 18 h for amyA expression. The α-amylase activity in the culture supernatant of recombinant L. lactis was determined using a commercial kit, α-Amylase Assay Kit (Kikkoman Corp., Chiba, Japan) with 2-chloro-4-nitrophenyl 65-azido-65-deoxy-β-maltopentaoside as the substrate according to the manufacturer’s instructions. One unit (U) of α-amylase activity was defined as the release of 1 μmol of 2-chloro-4-nitrophenol within 1 min. The plate assay for α-amylase activity was performed as follows: L. lactis NZ9000 cells harboring pNZ8048-amyA or pNZ8048 were inoculated on GM17 agar plate supplemented with 1% soluble starch. After incubation for 18 h at 30 °C, the plate was stained with iodine solution (0.12% iodine + 0.4% potassium iodide). Appearance of a clear zone around the recombinant colony indicates starch hydrolysis.

Results and Discussion

Characterization of L. lactis AH1

By double crossover recombination between the pfk-pyk and nupC-nupB regions, the major L-Ldh gene on the genome of L. lactis NZ9000 was replaced with the fragment containing the D-Ldh gene from L. delbrueckii subsp. lactis JCM 1107, resulting in L. lactis AH1 (Fig. 1a). The D-Ldh gene was inserted in-frame downstream of the endogenous promoter of the L-Ldh gene (Fig. 1b). To check the gene replacement, the chirality of lactic acid produced by AH1 was analyzed. The cells were incubated in a phosphate buffer containing 1% glucose and the supernatant was then analyzed because the impurities from M17 medium affected detection of the chirality by HPLC (data not shown). After 24 h incubation, L. lactis AH1 and NZ9000 produced 1.5 ± 0.1 g/L and 0.1 ± 0.1 g/L, and 0.0 ± 0.0 g/L and 1.7 ± 0.1 g/L of D- and L-lactic acids, respectively (Fig. 2a). From this result, the chemical purity of D-lactic acid produced by L. lactis AH1 was calculated as 93.8% with 87.5% optical purity. This indicates that the introduced D-Ldh gene functions in L. lactis AH1 and that the production level of lactic acid was unaffected by the gene replacement. L. lactis AH1 produced 0.1 g/L of L-lactic acid; this is due to the presence of L-Ldh homologue genes that are identical to ldhB, ldhX, and hicD encoded on the genome of L. lactis strains [37,38,39]. This is in good agreement with the result that the enzymatic activities of D- and L-Ldhs in L. lactis AH1 were 1.54 ± 0.00 U/mL and 0.05 ± 0.00 U/mL, respectively (Fig. 2b). Since the titer of L-lactic acid produced by L. lactis AH1 was negligible, the recombinant strain was used as a D-lactic acid producer hereafter. The effect of gene replacement on the growth rate and lactic acid production was characterized by cultivation of the recombinant strain in GM17 at 30 °C. The turbidity of L. lactis AH1 and NZ9000 cultures at the stationary phase was almost the same (OD600 = 2.5), whereas they reached the stationary phase after 12 h and 6 h cultivation, respectively (Fig. 2c). This may be because the D-Ldh gene from L. delbrueckii showing an optimal growth at 40–44 °C [40] was introduced into L. lactis showing an optimal growth at 27–33 °C [41]. This suggested that D-Ldh showing an optimal temperature at 27–33 °C is preferable for cell growth of L. lactis AH1. L. lactis AH1 produced 6.6 ± 0.0 g/L of D-lactic acid after 24 h cultivation; this titer was similar to the L-lactic acid production of L. lactis NZ9000 (7.0 ± 0.0 g/L). This is in good agreement with the result of lactic acid production by AH1 cells incubated in the buffer.

a D-/L-lactic acid production by the cells of L. lactis AH1 and L. lactis NZ9000 incubated in 50 mM potassium phosphate buffer (pH 7.0) containing 1% glucose at 30 °C for 24 h. b Specific D-/L-Ldh activities in the cell extract of L. lactis AH1. Ten microliters cell extract were incubated with 200 µL of substrate solution (100 mM Tris-HCl (pH 8.0), 15 mM NAD+, 500 mM D-/L-sodium lactate, 10 mM fructose 1,6-bisphosphate) at 37 °C for 10 min. The released NADH was measured at 340 nm. c Cell growth of L. lactis AH1 (open circles) and NZ9000 (diamonds). These strains were cultivated in GM17 at 30 °C for 24 h. All experiments were performed in duplicate, and the average is represented with error bars

Characterization of L. lactis AH2

A functional assay to determine the activity of α-amylase expressed in L. lactis NZ9000 was demonstrated by introduction of pNZ8048-amyA into L. lactis NZ9000. The α-amylase from S. bovis NRIC 1535 showed amylolytic activity (0.26 ± 0.01 U/mL) in the culture supernatant of L. lactis NZ9000 harboring pNZ8048-amyA, whereas L. lactis NZ9000 harboring pNZ8048 as a control showed no amylolytic activity (Fig. 3a). A similar result (Fig. 3b) was observed on the plate assay, indicating that heterologous α-amylase was secreted from L. lactis NZ9000 harboring pNZ8048-amyA and starch was then utilized in the L. lactis strain after hydrolysis by α-amylase.

Expression of AmyA from S. bovis NRIC 1535 in L. lactis NZ9000. a Specific AmyA activities in culture supernatants of L. lactis NZ9000 harboring pNZ8048-amyA or pNZ8048. This assay was performed at 30 °C in duplicate, and the mean value is presented with error bars. b Iodine staining of 1% starch-containing agar plates after inoculation with L. lactis NZ9000 harboring pNZ8048-amyA or pNZ8048. Clear zones indicate hydrolysis of starch around the recombinant colonies

Lactococcus lactis AH2 was obtained by introduction of pNZ8048-amyA into L. lactis AH1. Using the resulting strain, the direct production of D-lactic acid from starch was demonstrated for 24 h with 2% soluble starch as the carbon source. To reduce the effect of pH decrease by lactic acid produced on cell growth, 0.5 M MOPS (pH 7.0) was supplemented in the culture medium. To normalize the effect of harboring the plasmid, L. lactis AH1 harboring pNZ8048 was used as a control. Cultivation of L. lactis AH1 harboring pNZ8048 with 2% glucose resulted in maximal cell growth (OD600 = 5.10 ± 0.53) and maximal L-lactic acid production of 23.5 ± 0.2 g/L after 18 h cultivation, the levels of which remained unchanged thereafter (Fig. 4a). L. lactis AH2 showed a similar profile when cultivated with 2% glucose, showing the maximal cell growth (OD600 = 6.85 ± 0.25; specific growth rate (µ) = 1.05) and maximal D-lactic acid production of 23.3 ± 0.1 g/L (D-lactic acid productivity (P) = 1.14 g/L/h) (Fig. 4b). Compared to a related report using engineered L-Ldh gene-deficient L. plantarum cultivated in the presence of 100 g/L glucose [27], the production level obtained was about four times lower, possibly because this study used 20 g/L glucose. In the presence of 2% soluble starch, L. lactis AH2 didn’t reach a stationary phase even after 24 h cultivation (OD600 = 2.78 ± 0.06, µ = 0.12) but showed maximal D-lactic acid production of 15.0 ± 0.5 g/L (P = 0.63 g/L/h) (Fig. 4c). It has been reported that soluble starch was hydrolyzed to maltose (62.9%) and glucose (37.1%) when treated with α-amylase from S. bovis 148 [29, 42]. This is probably why the growth rate and D-lactic acid production rate were slower than when glucose was used. This suggests that maltose consumption was the rate-limiting step in starch fermentation. In fact, a similar phenomenon was observed in a previous related study [29], suggesting that D-lactic acid production by L. lactis from starch can be enhanced by improving this step (e.g., expression of maltase).

Production of lactic acid in L. lactis AH1 harboring pNZ8048 and L. lactis AH2 in different culture media. aL. lactis AH1 harboring pNZ8048 was cultivated in M17 supplemented with 2% glucose, and bL. lactis AH2 was cultivated in M17 supplemented with b 2% glucose and c 2% soluble starch at 30 °C for 24 h. All media contain 0.5 M MOPS (pH 7.0). Open squares, cell growth; open triangles, residual glucose/sugar concentration; open circles, D-/L-lactic acid concentration. This cultivation was performed in duplicate, and the average is represented with error bars

In conclusion, this study showed that replacement of L-Ldh gene with D-Ldh gene is useful for engineering LAB for D-lactic acid production. To our knowledge, this is the first report on D-lactic acid production in engineered L. lactis. The technique described herein for D-lactis acid production from starch by L. lactis expressing α-amylase may reduce the total incurred costs including production costs due to the carbon source. As L. lactis can be genetically modified easily and the NICE system provides strong gene expression in L. lactis, it is possible to perform further metabolic engineering of recombinant L. lactis as an easily engineerable host such as E. coli for bioproduction of a series of versatile chemicals such as propionic acid [43] and 1,2-propanediol [44], using D-lactic acid as the platform chemical.

References

Rathin D, Henry M (2006) Lactic acid: recent advances in products, processes and technologies—a review. J Chem Technol Biotechnol 81:1119–1129

Litchfield JH (2009) Lactic acid, microbially produced. In: Schaechter MO (ed) Encyclopedia of microbiology. Oxford Academic Press, Oxford, pp 362–372

Martinez FAC, Balciunas EM, Salgado JM, González JMD, Converti A, de Souza Oliveira RP (2013) Lactic acid properties, applications and production: a review. Trends Food Sci Technol 30:70–83

Henton DE, Gruber P, Lunt J, Randall J (2005) Polylactic acid technology. In: Mohanty AK, Misra M, Drzal LT (eds) Natural fibers, biopolymers, and biocomposites. Taylor & Francis, Boca Raton, pp 527–577

Garlotta D (2001) A literature review of poly (lactic acid). J Pol Environ 9:63–84

Tsuji H (2005) Poly(lactide) stereocomplexes: formation, structure, properties, degradation, and applications. Macromol Biosci 5:569–597

de Vos S (2008) Improving heat-resistance of PLA using poly(d-lactide). Bioplast Mag 3:21–25

Axelsson L (2004) Lactic acid bacteria: classification and physiology. In: Salminen S, Von Wright A (eds) Lactic acid bacteria. Microbiological and functional aspects, 3rd edn. Marcel Dekker, New York, pp 1–72

Chao GAO, Cuiqing MA, Ping XU (2011) Biotechnological routes based on lactic acid production from biomass. Biotechnol Adv 29:930–939

Abdel-Rahman MA, Tashiro Y, Sonomoto K (2013) Recent advances in lactic acid production by microbial fermentation processes. Biotechnol Adv 31:877–902

Ghaffar T, Irshad M, Anwar Z, Aqil T, Zulifqar Z, Tariq A, Kamran M, Ehsan N, Mehmood S (2014) Recent trends in lactic acid biotechnology: a brief review on production to purification. J Radiat Res Appl Sci 7:222–229

Eş I, Mousavi Khaneghah A, Barba FJ, Saraiva JA, Sant’Ana AS, Hashemi SMB (2018) Recent advancements in lactic acid production—a review. Food Res Int 107:763–770

Holo H, Nes IF (1989) High-frequency transformation, by electroporation, of Lactococcus lactis subsp. cremoris grown with glycine in osmotically stabilized media. Appl Environ Microbiol 55:3119–3123

McKay LL, Kathleen AB (1990) Applications for biotechnology: present and future improvements in lactic acid bacteria. FEMS Microbiol Rev 7:3–14

van de Guchte M, Kok J, Venema G (1992) Gene expression in Lactococcus lactis. FEMS Microbiol Rev 8:73–92

de Vos WM (1999) Gene expression systems for lactic acid bacteria. Curr Opin Microbiol 2:289–295

Morello E, Bermudez-Humaran LG, Llull D, Sole V, Miraglio N, Langella P, Poquet I (2008) Lactococcus lactis, an efficient cell factory for recombinant protein production and secretion. J Mol Microbiol Biotechnol 14:48–58

de Ruyter PG, Kuipers OP, Beerthuyzen MM, van Alen-Boerrigter I, de Vos WM (1996) Functional analysis of promoters in the nisin gene cluster of Lactococcus lactis. J Bacteriol 178:3434–3439

Mierau I, Kleerebezem M (2005) 10 years of the nisin-controlled gene expression system (NICE) in Lactococcus lactis. Appl Microbiol Biotechnol 68:705–717

Mierau I, Olieman K, Mond J, Smid EJ (2005) Optimization of the Lactococcus lactis nisin-controlled gene expression system NICE for industrial applications. Microbial Cell Fact 4:16

Mierau I, Leij P, Van Swam I, Blommestein B, Floris E, Mond J, Smid EJ (2005) Industrial-scale production and purification of a heterologous protein in Lactococcus lactis using the nisin-controlled gene expression system NICE: the case of lysostaphin. Microbial Cell Fact 4:15

Zink A, Klein JR, Plapp R (1991) Transformation of Lactobacillus delbrueckii ssp. lactis by electroporation and cloning of origins of replication by use of a positive selection vector. FEMS Microbiol Lett 78:207–212

Serror P, Sasaki T, Ehrlich SD, Maguin E (2002) Electrotransformation of Lactobacillus delbrueckii subsp. bulgaricus and L. delbrueckii subsp. lactis with various plasmids. Appl Environ Microbiol 68:46–52

Palomino MM, Allievi MC, Prado-Acosta M, Sanchez-Rivas C, Ruzal SM (2010) New method for electroporation of Lactobacillus species grown in high salt. J Microbiol Methods 83:164–167

Zhou S, Shanmugam KT, Ingram LO (2003) Functional replacement of the Escherichia coli d-(-)-lactate dehydrogenase gene (ldhA) with the l-(+)-lactate dehydrogenase gene (ldhL) from Pediococcus acidilactici. Appl Environ Microbiol 69:2237–2344

Aso Y, Tsubaki M, Long BHD, Murakami R, Nagata K, Okano H, Phuong Dung NT, Ohara H (2019) Continuous production of d-lactic acid from cellobiose in cell recycle fermentation using β-glucosidase-displaying Escherichia coli. J Biosci Bioeng 127:441–446

Okano K, Zhang Q, Shinkawa S, Yoshida S, Tanaka T, Fukuda H, Kondo A (2009) Efficient production of optically pure d-lactic acid from raw corn starch by using a genetically modified l-lactate dehydrogenase gene-deficient and α-amylase-secreting Lactobacillus plantarum strain. Appl Environ Microbiol 75:462–467

Narita J, Okano K, Kitao T, Ishida S, Sewaki T, Sung M, Fukuda H, Kondo A (2006) Display of α-amylase on the surface of Lactobacillus casei cells by use of the PgsA anchor protein, and production of lactic acid from starch. Appl Environ Microbiol 72:269–275

Okano K, Kimura S, Narita J, Fukuda H, Kondo A (2007) Improvement in lactic acid production from starch using α-amylase-secreting Lactococcus lactis cells adapted to maltose or starch. Appl Microbiol Biotechnol 75:1007–1013

Kuipers OP, de Ruyter PG, Kleerebezem M, de Vos WM (1998) Quorum sensing-controlled gene expression in lactic acid bacteria. J Biotechnol 64:15–21

Satoh E, Niimura Y, Uchimura T, Kozaki M, Komagata K (1993) Molecular cloning and expression of two alpha-amylase genes from Streptococcus bovis 148 in Escherichia coli. Appl Environ Microbiol 59:3669–3673

O’sullivan DJ, Klaenhammer TR (1993) Rapid mini-prep isolation of high-quality plasmid DNA from Lactococcus and Lactobacillus spp. Appl Environ Microbiol 59:2730–2733

Kleerebezem M, Beerthuyzen MM, Vaughan EE, de Vos WM, Kuipers OP (1997) Controlled gene expression systems for lactic acid bacteria: transferable nisin-inducible expression cassettes for Lactococcus, Leuconostoc, and Lactobacillus spp. Appl Environ Microbiol 63:4581–4584

DuBois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Lapierre L, Germond JE, Ott A, Delley M, Mollet B (1999) D-Lactate dehydrogenase gene (ldhD) inactivation and resulting metabolic effects in the Lactobacillus johnsonii strains La1 and N312. Appl Environ Microbiol 65:4002–4007

Smith PK, Krohn RI, Hermanson GT, Mallia AK, Gartner FH, Provenzano M, Fujimoto EK, Goeke NM, Olson BJ, Klenk DC (1985) Measurement of protein using bicinchoninic acid. Anal Biochem 150:76–85

Makarova K, Slesarev A, Wolf Y, Sorokin A, Mirkin B, Koonin E, Pavlov A, Pavlova N, Karamychev V, Polouchine N, Shakhova V, Grigoriev I, Lou Y, Rohksar D, Lucas S, Huang K, Goodstein DM, Hawkins T, Plengvidhya V, Welker D, Hughes J, Goh Y, Benson A, Baldwin K, Lee JH, Díaz-Muñiz I, Dosti B, Smeianov V, Wechter W, Barabote R, Lorca G, Altermann E, Barrangou R, Ganesan B, Xie Y, Rawsthorne H, Tamir D, Parker C, Breidt F, Broadbent J, Hutkins R, O’Sullivan D, Steele J, Unlu G, Saier M, Klaenhammer T, Richardson P, Kozyavkin S, Weimer B, Mills D (2006) Comparative genomics of the lactic acid bacteria. Proc Natl Acad Sci USA 103:15611–15616

Wegmann U, O’Connell-Motherway M, Zomer A, Buist G, Shearman C, Canchaya C, Ventura M, Goesmann A, Gasson MJ, Kuipers OP, van Sinderen D, Kok J (2007) Complete genome sequence of the prototype lactic acid bacterium Lactococcus lactis subsp. cremoris MG1363. J Bacteriol 189:3256–3270

Gaspar P, Neves AR, Gasson MJ, Shearman CA, Santos H (2011) High yields of 2, 3-butanediol and mannitol in Lactococcus lactis through engineering of NAD + cofactor recycling. Appl Environ Microbiol 77:6826–6835

Germond JE, Lapierre L, Delley M, Mollet B, Felis GE, Dellaglio F (2003) Evolution of the bacterial species Lactobacillus delbrueckii: a partial genomic study with reflections on prokaryotic species concept. Mol Biol Evol 20:93–104

Lee DA, Collins EB (1976) Influence of temperature on growth of Streptococcus cremoris and Streptococcus lactis. J Dairy Sci 59:405–409

Satoh E, Uchimura T, Kudo T, Komagata K (1997) Purification, characterization, and nucleotide sequence of an intracellular maltotriose-producing alpha-amylase from Streptococcus bovis 148. Appl Environ Microbiol 63:4941–4944

Kandasamy V, Vaidyanathan H, Djurdjevic I, Jayamani E, Ramachandran KB, Buckel W, Jayaraman G, Ramalingam S (2013) Engineering Escherichia coli with acrylate pathway genes for propionic acid synthesis and its impact on mixed-acid fermentation. Appl Microbiol Biotechnol 97:1191–1200

Niu W, Kramer L, Mueller J, Liub K, Guo J (2019) Metabolic engineering of Escherichia coli for the de novo stereospecific biosynthesis of 1,2-propanediol through lactic acid. Metab Eng Commun 8:e00082

Acknowledgements

We thank the NIZO Food Research (Netherlands) for providing us with L. lactis NZ9000 and pNZ8048. We also thank NODAI Culture Collection Center (Tokyo University of Agriculture, Japan) for providing us with S. bovis NRIC 1535. This work was supported by JSPS KAKENHI Grant Number 24580110.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest for this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aso, Y., Hashimoto, A. & Ohara, H. Engineering Lactococcus lactis for D-Lactic Acid Production from Starch. Curr Microbiol 76, 1186–1192 (2019). https://doi.org/10.1007/s00284-019-01742-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-019-01742-4