Abstract

This article focuses on engineering Corynebacterium glutamicum to produce L-lysine efficiently from starch using combined method of “classical breeding” and “genome breeding.” Firstly, a thermo-tolerable L-lysine-producing C. glutamicum strain KT45-6 was obtained after multi-round of acclimatization at high temperature. Then, amylolytic enzymes were introduced into strain KT45-6, and the resultant strains could use starch for cell growth and L-lysine production except the strain with expression of isoamylase. In addition, co-expression of amylolytic enzymes showed a good performance in starch degradation, cell growth and L-lysine production, especially co-expression of α-amylase (AA) and glucoamylase (GA). Moreover, L-lysine yield was increased by introducing AA-GA fusion protein (i.e., strain KT45-6S-5), and finally reached to 23.9 ± 2.3 g/L in CgXIIIPM-medium. It is the first report of an engineered L-lysine-producing strain with maximum starch utilization that may be used as workhorse for producing amino acid using starch as the main feedstock.

Key points

• Thermo-tolerable C. glutamicum was obtained by temperature-induced adaptive evolution.

• The fusion order between AA and GA affects the utilization efficiency of starch.

• C. glutamicum with starch utilization was constructed by optimizing amylases expression.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

L-lysine, an essential amino acid for animal and human, has been widely applied in feed industry, food industry and pharmaceutical industry (Xu et al. 2019). According to statistics published by the China Biotech Fermentation Industry Association (http://www.cfia.org.cn/), the yield of L-lysine in China reached an all-time high of 2,533,000 tons in 2019. It is conceivable that the global demands for L-lysine will grow rapidly with the exploitation and extension of L-lysine’s applications in the future. Although there are four methods to use for producing L-lysine (i.e., Proteolysis, Chemical synthesis, Microbial fermentation and Enzymatic synthesis), microbial fermentation is the common method in industry at present. Corynebacterium glutamicum and Escherichia coli as well as their derivatives are generally regarded as workhorses for L-lysine production by microbial fermentation (Sgobba et al. 2018; Xu et al. 2020). The main feedstock for L-lysine production is glucose (Tateno et al. 2007b), which accounts for about 40% to 50% of the whole production costs by microbial fermentation. Glucose is mainly produced from starch by inorganic acids or enzyme catalysis (Karim et al. 2019). However, the costs of energy and/or enzymes are high regardless of glucose produced from starch by acid-catalyzed hydrolysis or by enzyme-catalyzed hydrolysis (Tateno et al. 2007a). Therefore, how to increase the efficiency in the use of starch and/or to simplify the handling procedures of starch have become the key problems which need to be addressed in industrial L-lysine fermentations.

Starches are polysaccharides, which are widely existed in the natural plant. And they are formed from many α-glucose units that are interconnected by α-1,4- and/or α-1,6-glycosidic linkages, thus forming two polymers of glucose, i.e., amylose and amylopectin (Hu et al. 2020). Amylose is a linear polymer only with α-1,4-glycosidic linkages, while amylopectin is a multibranched polymer with α-1,4-glycosidic linkages and α-1,6-glycosidic linkages (Villas-Boas and Franco 2016). Starch coming from different sources possesses different contents of amylose and amylopectin, and the contents of amylopectin (i.e., 75 ~ 85%) is higher than that of amylose (i.e., 15 ~ 25%) in general (Zhao et al. 2020). Based on published research (Karim et al. 2019), more than 70% of starches are used to produce glucose. In the sugar industry, the production of glucose from starch normally involves two working procedures, i.e., liquefaction and saccharification (Guzmanmaldonado and Paredeslopez 1995; Karim et al. 2019). In liquefaction stage, starch is converted into a solution of soluble dextrins and maltose by a series of amylases (e.g., α-amylase, β-amylase, isoamylase and pullulanase), and then this liquefied solution is further hydrolyzed to glucose by glucoamylase in saccharification stage (Karim et al. 2019). It should be noted that these amylolytic enzymes in starch degradation have different function ways (Guzmanmaldonado and Paredeslopez 1995). α-Amylase (i.e., AA, EC 3.2.1.1, encoded by amyA gene) is an endo-type enzyme that randomly cleaves the α-1,4-glycosidic linkages in the interior of starch thus producing soluble maltodextrins as the main end product, while β-amylase (i.e., BA, EC 3.2.1.2, encoded by amyB gene) is an exo-type enzyme that cuts the α-1,4-glycosidic linkages from non-reducing end thus producing maltose as the end product (Das et al. 2018; Roy et al. 2013; Villas-Boas and Franco 2016). Isoamylase (i.e., IA, EC 3.2.1.9, encoded by amyX gene) and pullulanase (i.e., Pul, EC 3.2.1.41, encoded by pulA gene) specifically cleave the α-1,6-glycosidic linkages (Bi et al. 2020; Ghosh et al. 2020). Glucoamylase (i.e., GA, EC 3.2.1.3, encoded by glaA gene) not only cleaves the α-1,4-glycosidic linkages from non-reducing end but also slowly cuts the α-1,6-glycosidic linkages, thus producing glucose as the end product (Ghani et al. 2013; Karim et al. 2019; Lincoln et al. 2019). It should be noted that the above mentioned amylolytic enzymes show the optimally active at weak acidity (i.e., pH 4.5 ~ 7.0) and high temperature (i.e., > 50 °C) (Guzmanmaldonado and Paredeslopez 1995). Thus, the procedure of glucose production from starch is set at high temperature, whether in liquefaction stage (i.e., 90 ~ 110 °C) or in saccharification stage (i.e., 55 ~ 65 °C)(Parashar and Satyanarayana 2018; Zhao et al. 2007).

As the main workhorse for producing L-lysine in microbial fermentation, C. glutamicum grows on a variety of materials as carbon source (e.g., mono-/di-saccharides, n-alkane, ethanol and organic acids) besides starch (Seibold et al. 2006; Xu et al. 2020), because it intrinsically lacks any amylolytic enzymes (Seibold et al. 2006). Many studies have attempted to modify C. glutamicum to directly utilize starch as a key resource for producing value-added chemicals, including L-lysine (Seibold et al. 2006; Sgobba et al. 2018; Tateno et al. 2007a, 2009; Tsuge et al. 2013). Tateno et al. (2007b) and Tsuge et al. (2013) have produced L-lysine and organic acids by cell surface-engineered C. glutamicum with α-amylase activity using starch as carbon source. In addition, heterologous over-expression and secretion of α-amylase in C. glutamicum could also be applied to produce L-lysine using starch as carbon source (Chen et al. 2020; Seibold et al. 2006; Tateno et al. 2007a, 2009). In recent years, researchers are trying to co-culture various strain combinations for value-added chemicals production from starch, for example, co-culturing E. coli-C. glutamicum for L-lysine production (Sgobba et al. 2018). Although these studies have obtained a series of meaningful results, it is hard to obtain the satisfactory L-lysine production from starch. Because the optimal temperature of amylolytic enzymes (i.e., > 50 °C) is higher than the growth temperature of C. glutamicum (i.e., 25 ~ 37 °C) (Abe et al. 1967).

At present study, C. glutamicum K-8 was improved by a series of strategies that allow it to grow at high temperature and to produce L-lysine from starch. Firstly, we isolated a thermo-tolerable C. glutamicum KT45-6 derived from strain K-8 using temperature-induced mutagenesis-based adaptive laboratory evolution. And the effect of the adaptive strategy on fermentation performance of mutant strains was investigated at different culture temperature. Furthermore, different amylolytic enzymes were introduced into the thermotolerant mutant, and their effects on L-lysine production using corn starch as carbon source were studied. As a result, a high-temperature strain C. glutamicum KT45-6S-5 (i.e., C. glutamicum KT45-6 ΔsigH::amyA-glaA) derived from C. glutamicum K-8 was obtained, which produced 23.9 ± 2.3 g/L of L-lysine using corn starch as the main carbon source at 45 °C. As compared with existing strains reported by previous studies (Tateno et al. 2007a, 2007b, 2009), strain KT45-6S-5 shows good high temperature tolerance and homologous expression of AA-GA fusion enzyme thus giving strain with maximum starch utilization for producing L-lysine.

Material and methods

Strains, growth medium, and conditions

Strains used in present study are listed in Table 1. C. glutamicum and E. coli were cultivated at Luria–Bertani (LB) medium and LBG (LB + Glucose) medium, respectively (Xu et al. 2014). Epo medium and LBHIS (LB + Brain Heart Infusion + Sorbitol) medium used in genetically modifying C. glutamicum were prepared based on the methods described by van der Rest et al. (1999). Unless stated otherwise, C. glutamicum was cultivated at 30 °C.

Batch shake-flask fermentation was referred to the methods reported by Xu et al. (2014). The modified CgXII-medium (i.e., CgXIIIP; CgXII + 0.25 g/L l-methionine + 0.6 mg/L biotin) without carbon source was applied as basal medium to produce L-lysine. The culture was operated in 50 mL CgXIIIP-medium with 40 g/L of glucose (i.e., CgXIIIPG-medium) or 10 g/L of glucose and 30 g/L of starch (i.e., CgXIIIPM-medium) or 40 g/L of starch (i.e., CgXIIIPS-medium), respectively. These medium were adjusted to pH 7.0 with 20% (w/v) NaOH.

Thermal tolerance assays

Tolerance for high temperature was examined by evaluating the growth of strain in LBG medium at different temperature. Cells in mid-log phase were scribed on LBG-plate or 1% (v/v) of cells in mid-log phase were inoculated in LBG liquid medium, and then cultivated at 30 ~ 45 °C for 24 h.

Adaptive laboratory evolution for improving thermo-tolerance of C. glutamicum

LBG medium was applied to adaptive laboratory evolution. The procedure was according to the descriptions reported by Oide et al. (2015). In the first round of evolution, the initial temperature was set at 30 °C and eventually up to 35 °C as bacterial adaptation proceeded. On the 90th day, aliquots of the culture were spread on LBG-plate and incubated at 35 °C for 24 h. The colonies with big size were selected for fermentation test in shake flasks at 35 °C. Mutant with better fermentation performance was isolated and used as original strain for the next round of evolution. The second round (from 35 °C to 38 °C), the third round (from 38 °C to 41 °C), the fourth round (from 41 °C to 43 °C) and the fifth round (from 43 °C to 45 °C) of evolution were executed according to the abovementioned procedure.

Construction of recombinant C. glutamicum strains

The plasmids are listed in Table 1 and oligonucleotides are listed in Table S1. The modifications of C. glutamicum chromosome were referred to the published method (Xu et al. 2016). The cassettes of α-amylase (from Streptococcus bovis, Accession No. MZ821032), β-amylase (from Bacillus aryabhattai, Accession No. MZ821033), glucoamylase (from Aspergillus niger, Accession No. MZ821034), isoamylase (from Bacillus lentus, Accession No. MZ821035) and pullulanase (from Bacillus thermoleovorans, Accession No. MZ821036) with Ptac-M promoter (Xu et al. 2011), signal sequence of gene cspB from C. glutamicum (Tateno et al. 2007a) and rrnBT1T2 terminator were optimized for expression in C. glutamicum and were synthesized by GENEWIZ (Suzhou), Inc. (Suzhou, China). The procedure for construction of recombinant plasmids and strains was referred to the published methods (van der Rest et al. 1999; Xu et al. 2016), and the detail procedure was stated in Supplementary material and the building process was referred to Figure S1.

Enzyme activity assay

The qualitative analysis of enzyme activity was carried out by Iodine–Starch chromogenic assay (Seibold et al. 2006). Strains were cultivated on LBG-plate containing 5 g/L starch for 24 h, and then added the right amount of 0.1 mol/L of Lugol’s solution to color. The colonies showing a colourless zone indicated the strain with amylolytic enzyme activity. The quantitative analysis of enzyme activity was performed using spectrophotometry. The activity of AA, BA, IA, GA and Pul in culture supernatants was determined using the method provided by Seibold et al. (2006), Duan et al. (2019), Chen et al. (1998), Karim et al. (2019), and Bi et al. (2020), respectively.

Analysis of the fermentation performance of different strains

Aliquots (200 μL) of the culture were taken from flasks every 2 or 4 h to analyze the biomass (i.e., dry cell weight; DCW) and L-lysine production. Total sugars were analyzed according to phenol–sulfuric acid method (Masuko et al., (2005). Biomass was assayed by spectrophotometer at 600 nm. Based on the previous results (Xu et al. 2014), 1 OD600 is the equal of 0.318 g DCW. Half of sample was diluted 100-fold, and then used to determine L-lysine concentration by SBA-40E immobilized enzyme biosensor (Shandong, China) (Xu et al., (2020).

Results

Temperature-induced mutagenesis-based adaptive evolution of C. glutamicum K-8

The optimal growth temperature of C. glutamicum and its relatives is between 25 °C and 37 °C (Abe et al. 1967). Thus, we first investigated thermotolerance of C. glutamicum K-8, its parental strain C. glutamicum JL-6 (Xu et al. 2018) and the wild-type strain C. glutamicum ATCC13032 on LBG-plate at various temperatures (Fig. 1a). All strains grew rapidly at 30 °C, and strain ATCC13032 even showed vigorous growth at 41 °C. However, strain K-8 and JL-6 exhibited no growth at 38 °C and above, implying that the intrinsic thermotolerance of strain JL-6 was lost after multiple rounds of random mutagenesis. The growth performance of these strains was also compared by cultivating them in shake flasks (Fig. 1b). Consistent with the results of LBG-plate assay, all strains grew well at 30 °C despite strain K-8 and JL-6 did worse than strain ATCC13032. While the growth of strain ATCC13032 was not significantly affect during temperature up to 41 °C, the growth of strain K-8 and JL-6 was significantly inhibited at 35 °C and above. All these results indicate that strain K-8 and JL-6 are not able to grow well at 35 °C and above.

To give strain K-8 with thermo-tolerance, adaptive laboratory evolution by gradually increasing temperature was carried out in strain K-8. In the first round of evolution, about 80 colonies were isolated after 60 days of unintermittent evolution. Whether grown in LBG-medium or in CgXIIIPG-medium, these evolved strains showed increased growth at 35 °C compared to the strain K-8 (Fig. 2a and Table 2). Among these evolved strains, however, more than half of mutants showed an obvious decrease of L-lysine production. The negative mutants accounted for about 64% of all evolved strains (Fig. 2b). Among these evolved strains, strain C. glutamicum KT35-48 showed a slight increase of L-lysine production (from 26.7 ± 3.5 g/L to 27.4 ± 2.9 g/L), thus it was used as the original strain for the next round of evolution. In a follow-up experiment, 57 colonies, 29 colonies, 32 colonies, and 18 colonies were isolated in the second round, the third round, the fourth round, and the fifth round of evolution, respectively (Fig. 2c–f). It should be noted that the final DCW and the maximal growth rates (μmax) of the evolved strains at the elevated temperatures were lower than that of strain K-8 at 30 °C (Fig. 2 and Table 2). Especially, DCW of 18 candidate strains from the fifth round of evolution at 45 °C was limited to about 67% of strain K-8 at 30 °C (Fig. 2f). Unexpectedly, the L-lysine production of all 18 candidate strains at 45 °C was decreased as compared with strain K-8 at 30 °C (Fig. 2b). Strain C. glutamicum KT45-6 grew well at 45 °C and exhibited a little decrease of L-lysine production in comparison with strain K-8 at 30 °C after 48 h of batch fermentation (23.8 ± 3.2 g/L vs. 26.7 ± 3.5 g/L; Fig. 2b). In addition, there were no notable differences in cell shape or size between the strain KT45-6 and the parental strain K-8 (Fig. 3). Therefore, the thermo-tolerable strain KT45-6 was used as the initial strain for producing L-lysine from starch.

Temperature-induced adaptive evolution to endow C. glutamicum K-8 with the thermo-tolerance. a and c–f The dry cell weight (DCW) of evolved strains at 35 °C (a), at 38 °C (c), at 41 °C (d), at 43 °C (e), and at 45 °C (f). The red column represents the candidate strain in this study. b The L-lysine production of evolved strains and original strain K-8 at elevated temperature. The black dot represents the L-lysine production of original strain K-8 at 30 °C. The red dot represents the L-lysine production of evolved strains at elevated temperatures. The blue diamond represents the candidate strain in this study. The purple dot line represents the level of L-lysine production in strain K-8 at 30 °C. The data are mean values obtained from three independent experiments with error bar

Expression of heterologous amylolytic enzymes in the thermotolerant C. glutamicum KT45-6

To produce L-lysine from starch, we modified C. glutamicum KT45-6 to obtain a recombinant C. glutamicum strain with amylolytic enzymes activity. For the stable expression of enzymes in cells, a gene was constructed for integration into the C. glutamicum KT45-6 chromosome using the recombinant mobilizable plasmid derived from pK18mobsacB (Xu et al. 2016). The amylolytic enzyme-coding gene was expressed under the constitutive promoter tacM (Xu et al. 2011). The recombinant mobilizable plasmids with different amylolytic enzyme-coding gene cassettes were introduced into C. glutamicum KT45-6 to achieve two round of homologous recombination (see “Materials and methods”), and the resultant transformants were named strain KT45-6 ΔsigH::amyA, KT45-6 ΔsigH::amyB, KT45-6 ΔsigH::amyX, KT45-6 ΔsigH::pulA and KT45-6 ΔsigH::glaA, respectively. To investigate the expression of heterologous amylolytic enzyme-coding gene, the abovementioned transformants and strain KT45-6 were grown on starch-containing LBG-plate at 45 °C for 24 h and then dipped in Lugol’s solution. All of transformants could degrade starch, but not for strain KT45-6 (Fig. 4a). There results indicated that all of transformants express the amylolytic enzyme-coding gene and secrete amylolytic enzyme into the medium. The expression of heterologous amylolytic enzyme-coding gene in these transformants was also tested by SDS-PAGE analysis and enzyme analysis. The results of SDS-PAGE analysis showed a prominent protein band at molecular mass (Fig. 4b), and the mass of these proteins was consistent with the estimated size of the amylolytic enzymes. In addition, all of transformants exhibited an activity of amylolytic enzymes in the culture supernatants besides strain KT45-6 (Table 3). Furthermore, we also found the activity of amylolytic enzymes in the cell pellet of all transformants (Table 3).

Analyzing the enzyme activity in strain C. glutamicum KT45-6 with single expression of amylolytic enzyme. a The starch degradation of different C. glutamicum strains on LBG-plate containing 0.5% (w/v) starch at 45 °C. b SDS-PAGE analyses of amylolytic enzymes in culture supernatant from different C. glutamicum strains. Lane M: protein molecular weight marker; Lane 1: strain KT45-6, Lane 2: strain KT45-6 ΔsigH::amyA, Lane 3: strain KT45-6 ΔsigH::amyB, Lane 4: strain KT45-6 ΔsigH::amyX, Lane 5: strain KT45-6 ΔsigH::pulA, and Lane 6: strain KT45-6 ΔsigH::glaA. The red arrows represent the target protein

To investigate the effect of heterologous amylolytic enzymes on growth in the thermotolerant L-lysine-producing strain KT45-6 using starch as substrate, the abovementioned transformants and strain KT45-6 were cultivated in CgXIIIPG-medium, CgXIIIPM-medium and CgXIIIPS-medium, respectively. In CgXIIIPG-medium and CgXIIIPM-medium, all of strains showed vigorous growth (Fig. 5a, b). However, strain KT45-6 did not grow in CgXIIIPS-medium, while transformants exhibited the poor growth vigor in CgXIIIPS-medium as compared with in CgXIIIPG-medium and CgXIIIPM-medium (Fig. 5c). It should be noted that transformants showed the highest final DCW (> 8.0 g/L) and μmax (~ 0.22 h−1) in CgXIIIPM-medium except strain KT45-6 ΔsigH::amyX (Fig. 5a–c). As expected, starch in CgXIIIPM-medium was completely degraded at 12 h, whereas the starch in CgXIIIPS-medium was completely degraded at 36 h because of the poor growth vigor of transformants in CgXIIIPS-medium (Data not shown). These results implied the ability of all of transformants to use starch as substrate for growth. Among these transformants, the strain with heterologous expression of β-amylase (i.e., strain KT45-6 ΔsigH::amyB) showed the highest final DCW and the μmax in CgXIIIPM-medium and CgXIIIPS-medium, closely followed by strain KT45-6 ΔsigH::amyA and KT45-6 ΔsigH::glaA, while strain KT45-6 ΔsigH::amyX had the worst cell growth (Fig. 5b, c).

The growth performance of different C. glutamicum strains using different sugar as carbon source. a Strains in CgXIIIPG-medium containing 4% (w/v) glucose. b Strains in CgXIIIPM-medium containing 1% (w/v) glucose plus 3% (w/v) starch. c Strains in CgXIIIPS-medium containing 4% (w/v) starch. The data are mean values obtained from three independent experiments

To investigate whether these transformants could use starch as feedstock for L-lysine production, different strains were cultivated in CgXIIIPG-medium, CgXIIIPM-medium and CgXIIIPS-medium at 45 °C to analyze the concentration of L-lysine. In CgXIIIPG-medium, all of strains begun to produce L-lysine after 10 h and accumulated about 23 g/L of L-lysine (Fig. 6a). In contrast, only strains with amylolytic enzymes activity were able to produce L-lysine in CgXIIIPM-medium and CgXIIIPS-medium, except strain KT45-6 ΔsigH::amyX (Fig. 6b, c). This result indicated that strain KT45-6 ΔsigH::amyA, KT45-6 ΔsigH::amyB, KT45-6 ΔsigH::glaA and KT45-6 ΔsigH::pluA can use starch as feedstock for L-lysine production. Strain KT45-6 ΔsigH::amyA exhibited the best L-lysine production, followed by strain KT45-6 ΔsigH::amyB, whereas strain KT45-6 ΔsigH::pluA was the worst (Fig. 6b, c). Strain KT45-6 ΔsigH::amyA begun to produce L-lysine after 16 h and accumulated about 19.3 ± 2.1 g/L of L-lysine in CgXIIIPM-medium, which were worse than those of strain KT45-6 in CgXIIIPG-medium (Fig. 6a, b). However, the consumption rate of sugar of all strains in CgXIIIPM-medium and CgXIIIPS-medium was lower than that in CgXIIIPG-medium, particularly in CgXIIIPS-medium (Fig. 6d–f). As expected, strain KT45-6 ΔsigH::amyA showed the highest consumption rate of sugar, and 34.7 g of total sugar was consumed after 48 h during cultivated in CgXIIIPM-medium (Fig. 6e).

The L-lysine production and total sugar consumption of different C. glutamicum strains using different sugar as carbon source. a–c L-lysine production in CgXIIIPG-medium, CgXIIIPM-medium and CgXIIIPS-medium, respectively. d–f Total sugar in CgXIIIPG-medium, CgXIIIPM-medium and CgXIIIPS-medium, respectively. The data are mean values obtained from three independent experiments with error bar

Co-expression of different amylolytic enzymes enhanced starch degradation and L-lysine production

Based on the procedure of glucose production from starch in industry, AA, BA, IA and Pul are usually used in liquefaction stage to produce soluble dextrins, while GA is often used for producing glucose from dextrins in saccharification stage (Karim et al. 2019). To simulate the production requests of industrial glucose production in microorganism, we co-expressed the enzymes used in liquefaction stage and in saccharification stage (i.e., co-expression of AA and GA, BA and GA, IA and GA or Pul and GA), and the resultant transformants were named strain KT45-6 ΔsigH::amyA ΔptsG::glaA (i.e., strain KT45-6S-1), KT45-6 ΔsigH::amyB ΔptsG::glaA (i.e., strain KT45-6S-2), KT45-6 ΔsigH::amyX ΔptsG::glaA (i.e., strain KT45-6S-3) and KT45-6 ΔsigH::pulA ΔptsG::glaA (i.e., strain KT45-6S-4), respectively. All of these strains were able to degrade starch (Fig. 7a) and exhibited an activity of amylolytic enzymes in the culture supernatants (Table 3). In addition, a prominent protein band was observed at the appropriate locations from SDS-PAGE through analyzing the culture supernatants of these strains (Fig. 7b). These results suggested that the amylolytic enzymes-coding genes in strain were expressed and secreted into the medium. As expected, all of strains could grow in CgXIIIPM-medium and CgXIIIPS-medium, but they are the worse in CgXIIIPS-medium (Fig. 8a, b). However, it is worth noting that the growth of strains with co-expression of amylolytic enzymes is higher than that of strains with single-expression of amylolytic enzymes in CgXIIIPS-medium (Fig. 5c and Fig. 8b). In addition, the highest final DCW (10.2 ± 1.0 g/L) and μmax (0.23 h−1) in CgXIIIPM-medium were observed in strain KT45-6S-1, which were higher than that of strain KT45-6 ΔsigH::amyA (8.9 ± 0.7 g/L and 0.22 h−1, respectively) and KT45-6 ΔsigH::glaA (8.5 ± 0.3 g/L and 0.20 h−1, respectively; Fig. 5b and Fig. 8a).

Analyzing the enzyme activity in strain C. glutamicum KT45-6 with co-expression of amylolytic enzyme. a The starch degradation of strains on LBG-plate containing 0.5% (w/v) starch at 45 °C. b SDS-PAGE analyses of amylolytic enzymes in culture supernatant from different C. glutamicum strains. Lane M: protein molecular weight marker; Lane 1: strain KT45-6, Lane 2: strain KT45-6S-1, Lane 3: strain KT45-6S-2, Lane 4: strain KT45-6S-3, Lane 5: strain KT45-6S-4. The red arrows represent the target protein

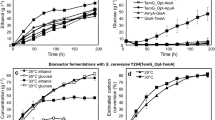

The fermentation performance of different C. glutamicum strains using different sugar as carbon source. a, b The cell growth in CgXIIIPM-medium (a) and CgXIIIPS-medium (b). c, d The L-lysine production in CgXIIIPM-medium (c) and CgXIIIPS-medium (d). e, f Total sugar in CgXIIIPM-medium (e) and CgXIIIPS-medium (f). The data are mean values obtained from three independent experiments with error bar

To investigate the effect of co-expression of amylolytic enzymes on L-lysine production using starch as substrate, the abovementioned strains were cultivated in CgXIIIPG-medium, CgXIIIPM-medium and CgXIIIPS-medium, respectively. As a control, strains with single-expression of amylolytic enzymes did the same. Interestingly, strains with co-expression of amylolytic enzymes produced more L-lysine than strains with single-expression of amylolytic enzymes in CgXIIIPM-medium and CgXIIIPS-medium (Fig. 6b, c and Fig. 8c, d). The L-lysine production is the best in strain KT45-6S-1, followed by strain KT45-6S-4 (Fig. 8c, d). Strain KT45-6S-1 accumulated 21.7 ± 1.8 g/L of L-lysine in CgXIIIPM-medium, which was only about 8.8% lower than that of strain KT45-6 in CgXIIIPG-medium (Fig. 6a and Fig. 8c). Although strain KT45-6S-3 exhibited the worst fermentation performance, the L-lysine yield of this strain was higher than that of strain KT45-6 ΔsigH::amyX and KT45-6 ΔsigH::glaA (Fig. 6c, d and Fig. 8c, d). Not surprisingly, more total sugar was consumed in strains with co-expression of amylolytic enzymes (Fig. 8e, f). This result indicated that co-expression of amylolytic enzymes is beneficial to give strain with strong hydrolysis ability of starch. However, it is important to point out that the fermentation performance of all the abovementioned strains in CgXIIIPM-medium is better than that in CgXIIIPS-medium (Fig. 8c, d).

The effect of AA-GA and GA-AA fusion enzymes on starch degradation and L-lysine production

Based on the above results, co-expression of AA and GA in strain KT45-6 has a significant impact on starch degradation and L-lysine production. Considering that recombinant multifunctional fusion enzyme has several advantages in catalyzing sequential reactions (Wang et al. 2007), genes encoding AA and GA were fused with a linker and expressed in the thermotolerant L-lysine-producing strain KT45-6. In the AA-GA fusion enzyme, the C terminus of AA was fused with the N terminus of GA in frame. By contrast, the GA-AA fusion enzyme was inverted (Fig. 9a). And the corresponding strains were named C. glutamicum KT45-6S-5 and C. glutamicum KT45-6S-6, respectively. Recombinant enzymes produced in strain KT45-6S-5 and KT45-6S-6 was used to analyze by SDS-PAGE (Fig. 9b), which matched the theoretical molecular mass from the deduced amino acid sequence. Strain KT45-6S-5 had similar or even better biodegradability of starch than strain KT45-6S-1, whereas KT45-6S-6 did worse (Fig. 9c). In addition, enzyme activity assay once again showed that strain KT45-6S-5 exhibited the highest activity of amylolytic enzymes (97.3 ± 8.4 U/L of AA and 51.4 ± 6.2 U/L of GA) while KT45-6S-6 had only 108.5 U/L of amylolytic enzyme activity (i.e., 69.8 ± 5.7 U/L of AA and 38.7 ± 3.4 U/L of GA) in culture supernatants (Table 3). As anticipated, strain KT45-6S-5 and KT45-6S-6 could use starch as carbon source for cell growth and L-lysine production (Fig. 9c, d). However, strain KT45-6S-5 showed the best performance of growth and L-lysine production in CgXIIIPM-medium and CgXIIIPS-medium. In CgXIIIPM-medium, strain KT45-6S-5 begun to produce L-lysine after 10 h and accumulated 23.9 ± 2.3 g/L of L-lysine (Fig. 9f). Encouragingly, expression of AA-GA fusion enzyme could significantly promote performance of growth and L-lysine production in CgXIIIPS-medium (Fig. 9e, g). The highest final DCW (9.4 ± 0.3 g/L) and μmax (0.15 h−1) in CgXIIIPS-medium were observed in strain KT45-6S-5, which were higher than that of strain KT45-6S-1 (8.7 ± 0.5 g/L and 0.12 h−1, respectively; Fig. 8b and Fig. 9e). In addition, L-lysine was firstly accumulated at 16 h and finally to about 13.5 ± 1.0 g/L in strain KT45-6S-5 during cultivated in CgXIIIPS-medium (Fig. 9g). It is worth noting that strain KT45-6S-5 showed the better fermentation performance during cultivated in CgXIIIPS-medium and CgXIIIPM-medium at 45℃ that of at 30℃ (Fig. S2a-f). In addition, it showed the similar fermentation performance with the parental strain K-8 during cultivated in CgXIIIPG-medium at 30℃ (Fig. S2g-i). Strangely, expression of GA-AA fusion enzyme seems to be slanted against starch degradation. Strain KT45-6S-6 showed the worst performance of growth and L-lysine production during used starch as carbon source (Fig. 9e, g).

Starch degradation and fermentation performance of different C. glutamicum strains with AA-GA or GA-AA fusion enzyme. a Construction process of the recombinant plasmids for expression fusion protein. b SDS-PAGE analyses of amylolytic enzymes in culture supernatant from different C. glutamicum strains. Lane M: protein molecular weight marker; Lane 1: strain KT45-6S-1, Lane 2: strain KT45-6S-5, Lane 3: strain KT45-6S-6. c The starch degradation of strains on LBG-plate containing 0.5% (w/v) starch at 45 °C. d, e The cell growth in CgXIIIPM-medium (d) and CgXIIIPS-medium (e). f, g The L-lysine production in CgXIIIPM-medium (f) and CgXIIIPS-medium (g). The data are mean values obtained from three independent experiments with error bar

Discussion

Starches are natural polysaccharides, and they are closely related to sugar industry (Karim et al. 2019). Although C. glutamicum cannot utilize starch directly (Tateno et al. 2007b), many studies have attempted to modify C. glutamicum to directly utilize starch as a key resource for producing value-added chemicals (Chen et al. 2020; Sgobba et al. 2018; Tsuge et al. 2013). However, the present achievements are also hard to obtain the satisfactory L-lysine production from starch in industry. In this study, we devote to improve C. glutamicum strain for efficiently producing L-lysine using raw corn starch as the key carbon source. In order to improve cell growth and L-lysine production on starch, an L-lysine-producing strain C. glutamicum K-8 was consecutively modified to give strain K-8 with high-efficiency degradability of starch at high temperature, for example temperature-induced mutagenesis-based adaptive laboratory evolution, introduction of different amylolytic enzymes as well as optimization of combinations and expressing systems of amylolytic enzymes. As a result, a high-temperature strain C. glutamicum KT45-6S-5 was obtained, which produced 23.9 ± 2.3 g/L of L-lysine using starch as the main carbon source at 45 °C. It is the first report that the classically derived mutant strain was modified to improve temperature tolerance and to co-expression of amylolytic enzymes and thus to increase starch utilization for producing L-lysine.

The optimal growth temperatures of C. glutamicum and its relatives are between 25 °C and 37 °C (Abe et al. (1967). However, the L-lysine-producing strain used in this work (i.e., C. glutamicum K-8) exhibited the bad growth at 35 °C and above (Fig. 1). The parental strain of K-8 is C. glutamicum JL-6, which was derived from C. glutamicum ATCC 13,032 by “classical breeding” (Xu et al. 2018). Ohnishi et al. (2003) also found that strains modified by “classical breeding” showed a worse growth at elevated temperatures (e.g., 35 °C) than strains modified by “genome breeding.” One possible reason is that the intrinsic thermo-tolerance was lost in classically derived strains after random mutagenesis. However, many studies pointed out that high-temperature fermentation could accelerate fermentation progress, increase the yield of target products and reduce the dosage of cooling water, thus cutting the cost of production (Eiichiro et al. 1996; Hou et al. 2012; Ohnishi et al. 2003). In addition, improving the thermotolerance of strain K-8 should help increase the yield and productivity of L-lysine during used starch as carbon source because amylolytic enzymes are optimal activity at high temperature (i.e., > 50 °C)(Leveque et al. 2000). Stress-induced mutagenesis-based adaptive evolution is a valid method in improving microbial stresses-tolerance and generating robust microbial strains (Zhu et al. 2014). Strain C. glutamicum KT45-6 was obtained after 5 round of temperature-induced mutagenesis-based adaptive evolution, which grows well at 45 °C and accumulates 23.8 ± 3.2 g/L of L-lysine after 48 h of batch fermentation at 45 °C (Fig. 2b). It may be due to the DNA-repair mechanisms in cell and disruption of metabolic pathways (Leszczewicz and Walczak 2019; Oide et al. 2015; Wang et al. 2019a), the positive mutants are no more than 30% of all mutants (Fig. 2).

Previous study demonstrated that wild-type C. glutamicum cannot utilize starch directly (Tateno et al. 2007b), whereas the recombinant C. glutamicum strains with α-amylase activity exhibited the ability to degrade starch (Seibold et al. 2006; Tateno et al. 2007a, 2007b). Except for α-amylase, many amylolytic enzymes are also widely used in starch degradation, such as β-amylase, glucoamylase, isoamylase, and pullulanase (Guzmanmaldonado and Paredeslopez 1995; Karim et al. 2019). Our results indicated that all recombinant strains with different amylolytic enzymes can degrade starch at different levels (Fig. 4b), but not all recombinant strains can used starch as the only carbon source for cell growth and L-lysine production (Fig. 5a–c and Fig. 6). Based on the data published by Guzmanmaldonado and Paredeslopez (1995), these amylolytic enzymes in starch degradation have a different function way. IA is a glycogen-/starch-debranching enzyme that hydrolyzes the α-1,6-glucosidic linkage specific in α-glucans with more than 3 glucose residues to only produces amylose (Park et al. 2007). This might be why strain KT45-6 ΔsigH::amyX cannot grow and produce L-lysine in CgXIIIPS-medium (Fig. 5c and Fig. 6c). In contrast, Pul, as another debranching enzyme, can hydrolyze the α-1,6-glucosidic linkage in α-glucans with lower than 3 glucose residues to produce maltose and maltotriose (Wang et al. 2019b), which in turn could help strain KT45-6 ΔsigH::pulA grow in CgXIIIPS-medium (Fig. 5c). Since maltose is the main degradation products of starch after BA hydrolysis (Duan et al. 2019), strain KT45-6 ΔsigH::amyB with BA activity showed the best performance of growth in CgXIIIPM-medium and CgXIIIPS-medium (Fig. 5b, c). However, the L-lysine production of strain KT45-6 ΔsigH::amyB is lower than that of strain KT45-6 ΔsigH::amyA in CgXIIIPM-medium (Fig. 6b). That may be because more carbon source in strain KT45-6 ΔsigH::amyB are used to cell growth rather than L-lysine production (Moon et al. 2005; Seibold et al. 2006). It should be noted that all recombinant strains showed the worse performance of growth and L-lysine production in CgXIIIPS-medium than in CgXIIIPM-medium (Fig. 5b, c and Fig. 6b, c). Similar results were achieved in another research reported by Seibold et al. (2006). A possible explanation could be that some of starch hydrolysis products are not usable for growth and L-lysine production (Seibold et al. 2006). In addition, the results of phenol–sulfuric acid colorimetric assay indicated that the consuming rate of total sugar by strains in CgXIIIPS-medium is lower than that in CgXIIIPM-medium (Fig. 6b, c). This might be another possible reason.

In sugar industry, two kinds of amylolytic enzymes are used to degrade starch for producing glucose (Karim et al. 2019). Some studies also pointed out that co-expression of amylolytic enzymes in yeast or in Aspergillus niger is beneficial to starch degradation and cell growth (Inokuma et al. 2015; Juge et al. 2006; Murai et al. 1999). In this study, GA was co-expressed with AA, BA, IA and Pul in a thermotolerant L-lysine-producer C. glutamicum KT45-6. As shown in Fig. 4a and Fig. 7a, all of recombinant strains with co-expression or single-expression of amylolytic enzymes are able to degrade starch, but the recombinant strains with co-expression of amylolytic enzymes showed the better degradability than strains with single-expression of amylolytic enzymes. More strikingly, the growth and L-lysine production of strains with co-expression of amylolytic enzymes in CgXIIIPM-medium and CgXIIIPS-medium is higher than that of strains with single-expression of amylolytic enzymes, especially in CgXIIIPS-medium (Fig. 5b, c, Fig. 6b, c, and Fig. 8a–d). These similar results were also obtained in previous studies (Inokuma et al. 2015; Murai et al. 1999). As is known to all, GA from Aspergillus niger possesses the non-catalytic substrate binding domains (SBD), which accelerates the rate of hydrolysis of substrate (Juge et al. 2006). In addition, soluble dextrin is believed to be the best substrate for GA (Karim et al. 2019; Shigechi et al. 2004). Murai et al. (1999) also pointed out that the recombinant S. cerevisiae with expression of GA only forms a small colourless zone around the colony. Therefore, strain KT45-6S-1 (i.e., co-expression of AA and GA in strain KT45-6) showed the biggest colourless zone as well as the best cell growth and L-lysine production using starch as carbon source (Fig. 7 and Fig. 8). Seo et al. (2000) pointed out that recombinant multifunctional fusion enzyme is beneficial to improve catalytic activities of freestanding enzymes because of a proximity effect. And our results also indicated that expression of AA-GA fusion enzyme in strain KT45-6 (i.e., strain KT45-6S-5) significantly increases catalytic activities and promotes the performance of growth and L-lysine production using starch as carbon source (Table 3 and Fig. 9c–g). This is because the efficiency of hydrolyzing starch to fermentable sugars was greatly improved (Juge et al. 2006). However, expression of GA-AA fusion enzyme seems to be slanted against starch degradation (Fig. 9e, g). Similar results were also obtained in previous studies, in which bifunctional fusion enzyme TSBA (i.e., Trehalose synthase-β-amylase fusion protein) showed higher catalytic activities than that of BA/TS, but BATS showed similar activities with BA/TS because of the different Km value and kcat value for starch (Wang et al. 2007). Therefore, we speculate that AA-GA fusion enzyme showed the best catalytic efficiencies (i.e., kcat/Km), whereas GA-AA fusion enzyme showed the worst catalytic efficiencies for starch.

In conclusion, a thermotolerant L-lysine producer C. glutamicum KT45-6 has been achieved by temperature-induced mutagenesis-based adaptive laboratory evolution. Additionally, this thermotolerant L-lysine producer KT45-6 can be used to produce L-lysine from corn starch with high efficiency by introduction of AA and GA. Furthermore, a recombinant bifunctional fusion enzyme AA-GA can increase the efficiency of hydrolyzing starch to fermentable sugars, thus improving the performance of growth and L-lysine production of the recombinant strain. These results provide a convenient and efficient way to produce L-lysine direct from raw starch for industrial applications.

Data availability

Data and materials will be made available on reasonable request.

References

Abe S, Takayama K, Kinoshita S (1967) Taxonomical studies on glutamic acid-producing bacteria. J Gen Appl Microbiol 13:279–301

Bi JH, Chen SH, Zhao XH, Nie Y, Xu Y (2020) Computation-aided engineering of starch-debranching pullulanase from Bacillus thermoleovorans for enhanced thermostability. Appl Microbiol Biot 104(17):7551–7562. https://doi.org/10.1007/s00253-020-10764-z

Chen JZ, Wang Y, Guo X, Rao DM, Zhou WJ, Zheng P, Sun JB, Ma YH (2020) Efficient bioproduction of 5-aminolevulinic acid, a promising biostimulant and nutrient, from renewable bioresources by engineered Corynebacterium glutamicum. Biotechnol Biofuels 13(1):41–53. https://doi.org/10.1186/s13068-020-01685-0

Chen PH, Lin LL, Hsu WH (1998) Expression of Pseudomonas amyloderamosa isoamylase gene in Saccharomyces cerevisiae. Biotechnol Lett 20(8):735–739. https://doi.org/10.1023/A:1005382602683

Das R, Talat M, Srivastava ON, Kayastha AM (2018) Covalent immobilization of peanut β-amylase for producing industrial nano-biocatalysts: a comparative study of kinetics, stability and reusability of the immobilized enzyme. Food Chem 245:488–499. https://doi.org/10.1016/j.foodchem.2017.10.092

Duan XG, Shen ZY, Zhang XY, Wang YS, Huang Y (2019) Production of recombinant β-amylase of Bacillus aryabhattai. Prep Biochem Biotechnol 49(1):88–94. https://doi.org/10.1080/10826068.2018.1536987

Eiichiro K, Yoshimi K, Yoshio K (1996) Stress-tolerant microorganism and method of the production of fermentation product. US patent, EP96901978A

Ghani M, Aman A, Rehman HU, Siddiqui NN, Qader SAU (2013) Strain improvement by mutation for enhanced production of starch-saccharifying glucoamylase from Bacillus licheniformis. Starch-Starke 65(9–10):875–884. https://doi.org/10.1002/star.201200278

Ghosh B, Lahiri D, Nag M, Dash S, Ray RR (2020) Bio characterization of purified isoamylase from Rhizopus oryzae. Prep Biochem Biotechnol 50(5):453–459. https://doi.org/10.1080/10826068.2019.1706561

Guzmanmaldonado H, Paredeslopez O (1995) Amylolytic enzymes and products derived from starch-a review. Crit Rev Food Sci 35(5):373–403. https://doi.org/10.1080/10408399509527706

Hou XH, Ge XY, Wu D, Qian H, Zhang WG (2012) Improvement of L-valine production at high temperature in Brevibacterium flavum by overexpressing ilvEBNrC genes. J Ind Microbiol Biot 39(1):63–72. https://doi.org/10.1007/s10295-011-1000-1

Hu B, Li YM, Zhu SN, Zhang HR, Jing YY, Jiang DP, He C, Zhang ZP (2020) Evaluation of biohydrogen yield potential and electron balance in the photo-fermentation process with different initial pH from starch agricultural leftover. Bioresource Technol 305:122900. https://doi.org/10.1016/j.biortech.2020.122900

Inokuma K, Yoshida T, Ishii J, Hasunuma T, Kondo A (2015) Efficient co-displaying and artificial ratio control of α-amylase and glucoamylase on the yeast cell surface by using combinations of different anchoring domains. Appl Microbiol Biot 99(4):1655–1663. https://doi.org/10.1007/s00253-014-6250-1

Juge N, Nohr J, Le Gal-Coeffet MF, Kramhoft B, Furniss CSM, Planchot V, Archer DB, Williamson G, Svensson B (2006) The activity of barley alpha-amylase on starch granules is enhanced by fusion of a starch binding domain from Aspergillus niger glucoamylase. BBA-Proteins Proteom 1764(2):275–284. https://doi.org/10.1016/j.bbapap.2005.11.008

Karim KMR, Husaini A, Sing NN, Tasnim T, Sinang FM, Hussain H, Hossain MA, Roslan H (2019) Characterization and expression in Pichia pastoris of a raw starch degrading glucoamylase (GA2) derived from Aspergillus flavus NSH9. Protein Expres Purif 164. https://doi.org/10.1016/j.pep.2019.105462

Leszczewicz M, Walczak P (2019) Selection of thermotolerant Corynebacterium glutamicum strains for organic acid biosynthesis. Food Technol Biotech 57(2):249–259. https://doi.org/10.17113/ftb.57.02.19.5980

Leveque E, Janecek S, Haye B, Belarbi A (2000) Thermophilic archaeal amylolytic enzymes. Enzyme Microb Tech 26(1):3–14. https://doi.org/10.1016/S0141-0229(99)00142-8

Lincoln L, More VS, More SS (2019) Purification and biochemical characterization of extracellular glucoamylase from Paenibacillus amylolyticus strain. J Basic Microbiol 59(4):375–384. https://doi.org/10.1002/jobm.201800540

Masuko T, Minami A, Iwasaki N, Majima T, Nishimura SI, Lee YC (2005) Carbohydrate analysis by a phenol-sulfuric acid method in microplate format. Anal Biochem 339(1):69–72. https://doi.org/10.1016/j.ab.2004.12.001

Moon MW, Kim HJ, Oh TK, Shin CS, Lee JS, Kim SJ, Lee JK (2005) Analyses of enzyme II gene mutants for sugar transport and heterologous expression of fructokinase gene in Corynebacterium glutamicum ATCC 13032. FEMS Microbiol Lett 244(2):259–266. https://doi.org/10.1016/j.femsle.2005.01.053

Murai T, Ueda M, Shibasaki Y, Kamasawa N, Osumi M, Imanaka T, Tanaka A (1999) Development of an arming yeast strain for efficient utilization of starch by co-display of sequential amylolytic enzymes on the cell surface. Appl Microbiol Biot 51(1):65–70. https://doi.org/10.1007/s002530051364

Ohnishi J, Hayashi M, Mitsuhashi S, Ikeda M (2003) Efficient 40 °C fermentation of L-lysine by a new Corynebacterium glutamicum mutant developed by genome breeding. Appl Microbiol Biot 62(1):69–75. https://doi.org/10.1007/s00253-003-1254-2

Oide S, Gunji W, Moteki Y, Yamamoto S, Suda M, Jojima T, Yukawa H, Inui M (2015) Thermal and solvent stress cross-tolerance conferred to Corynebacterium glutamicum by adaptive laboratory evolution. Appl Environ Microb 81(7):2284–2298. https://doi.org/10.1128/Aem.03973-14

Parashar D, Satyanarayana T (2018) An insight into ameliorating production, catalytic efficiency, thermostability and starch saccharification of acid-stable α-amylases from acidophiles. Fron Bioeng Biotechnol 6(3):125–138. https://doi.org/10.3389/fbioe.2018.00125

Park HS, Park JT, Kang HK, Cha H, Kim DS, Kim JW, Park KH (2007) TreX from Sulfolobus solfataricus ATCC 35092 displays isoamylase and 4-α-glucanotransferase activities. Biosci Biotechnol Biochem 71(5):1348–1352. https://doi.org/10.1271/bbb.70016

Roy JK, Borah A, Mahanta CL, Mukherjee AK (2013) Cloning and overexpression of raw starch digesting α-amylase gene from Bacillus subtilis strain AS01a in Escherichia coli and application of the purified recombinant α-amylase (AmyBS-I) in raw starch digestion and baking industry. J Mol Catal B-Enzym 97:118–129. https://doi.org/10.1016/j.molcatb.2013.07.019

Schafer A, Tauch A, Jager W, Kalinowski J, Thierbach G, Puhler A (1994) Small mobilizable multipurpose cloning vectors derived from the Escherichia coli plasmids pK18 and pK19-selection of defined deletions in the chromosome of Corynebacterium glutamicum. Gene 145(1):69–73. https://doi.org/10.1016/0378-1119(94)90324-7

Seibold G, Auchter M, Berens S, Kalinowski J, Eikmanns BJ (2006) Utilization of soluble starch by a recombinant Corynebacterium glutamicum strain: growth and lysine production. J Biotechnol 124(2):381–391. https://doi.org/10.1016/j.jbiotec.2005.12.027

Seo HS, Koo YJ, Lim JY, Song JT, Kim CH, Kim JK, Lee JS, Choi YD (2000) Characterization of a bifunctional enzyme fusion of trehalose-6-phosphate synthetase and trehalose-6-phosphate phosphatase of Escherichia coli. Appl Environ Microb 66(6):2484–2490. https://doi.org/10.1128/Aem.66.6.2484-2490.2000

Sgobba E, Stumpf AK, Vortmann M, Jagmann N, Krehenbrink M, Dirks-Hofmeister ME, Moerschbacher B, Philipp B, Wendisch VF (2018) Synthetic Escherichia coli-Corynebacterium glutamicum consortia for L-lysine production from starch and sucrose. Bioresource Technol 260:302–310. https://doi.org/10.1016/j.biortech.2018.03.113

Shigechi H, Fujita Y, Koh J, Ueda M, Fukuda H, Kondo A (2004) Energy-saving direct ethanol production from low-temperature-cooked corn starch using a cell-surface engineered yeast strain co-displaying glucoamylase and alpha-amylase. Biochem Eng J 18(2):149–153. https://doi.org/10.1016/j.bej.2003.08.003

Tateno T, Fukuda H, Kondo A (2007a) Direct production of L-lysine from raw corn starch by Corynebacterium glutamicum secreting Streptococcus bovis α-amylase using cspB promoter and signal sequence. Appl Microbiol Biot 77(3):533–541. https://doi.org/10.1007/s00253-007-1191-6

Tateno T, Fukuda H, Kondo A (2007b) Production of L-lysine from starch by Corynebacterium glutamicum displaying α-amylase on its cell surface. Appl Microbiol Biot 74(6):1213–1220. https://doi.org/10.1007/s00253-006-0766-y

Tateno T, Okada Y, Tsuchidate T, Tanaka T, Fukuda H, Kondo A (2009) Direct production of cadaverine from soluble starch using Corynebacterium glutamicum coexpressing α-amylase and lysine decarboxylase. Appl Microbiol Biot 82(1):115–121. https://doi.org/10.1007/s00253-008-1751-4

Tsuge Y, Tateno T, Sasaki K, Hasunuma T, Tanaka T, Kondo A (2013) Direct production of organic acids from starch by cell surface-engineered Corynebacterium glutamicum in anaerobic conditions. AMB Express 3. https://doi.org/10.1186/2191-0855-3-72

van der Rest ME, Lange C, Molenaar D (1999) A heat shock following electroporation induces highly efficient transformation of Corynebacterium glutamicum with xenogeneic plasmid DNA. Appl Microbiol Biot 52(4):541–545. https://doi.org/10.1007/s002530051557

Villas-Boas F, Franco CML (2016) Effect of bacterial β-amylase and fungal α-amylase on the digestibility and structural characteristics of potato and arrowroot starches. Food Hydrocolloid 52:795–803. https://doi.org/10.1016/j.foodhyd.2015.08.024

Wang JH, Tsai MY, Lee GC, Shaw JF (2007) Construction of a recombinant thermostable β-amylase-trehalose synthase bifunctional enzyme for facilitating the conversion of starch to trehalose. J Agr Food Chem 55(4):1256–1263. https://doi.org/10.1021/jf062355t

Wang SH, Hou YR, Chen XL, Liu LM (2019a) Kick-starting evolution efficiency with an autonomous evolution mutation system. Metab Eng 54:127–136. https://doi.org/10.1016/j.ymben.2019.03.010

Wang XY, Nie Y, Xu Y (2019b) Industrially produced pullulanases with thermostability: discovery, engineering, and heterologous expression. Bioresource Technol 278:360–371. https://doi.org/10.1016/j.biortech.2019.01.098

Xu DQ, Tan YZ, Li Y, Wang XY (2011) Construction of a novel promoter-probe vector and its application for screening strong promoter for Brevibacterium flavum metabolic engineering. World J Microbiol Biotechnol 27(4):961–968. https://doi.org/10.1007/s11274-010-0539-8

Xu JZ, Han M, Zhang JL, Guo YF, Zhang WG (2014) Metabolic engineering Corynebacterium glutamicum for the L-lysine production by increasing the flux into L-lysine biosynthetic pathway. Amino Acids 46(9):2165–2175. https://doi.org/10.1007/s00726-014-1768-1

Xu JZ, Ruan HZ, Yu HB, Liu LM, Zhang WG (2020) Metabolic engineering of carbohydrate metabolism systems in Corynebacterium glutamicum for improving the efficiency of l-lysine production from mixed sugar. Microb Cell Fact 19(1):1–15. https://doi.org/10.1186/s12934-020-1294-7

Xu JZ, Wu ZH, Gao SJ, Zhang WG (2018) Rational modification of tricarboxylic acid cycle for improving L-lysine production in Corynebacterium glutamicum. Microb Cell Fact 17(1):105. https://doi.org/10.1186/s12934-018-0958-z

Xu JZ, Yu HB, Han M, Liu LM, Zhang WG (2019) Metabolic engineering of glucose uptake systems in Corynebacterium glutamicum for improving the efficiency of l-lysine production. J Ind Microbiol Biot 46(7):937–949. https://doi.org/10.1007/s10295-019-02170-w

Xu JZ, Zhang JL, Han M, Zhang WG (2016) A method for simultaneous gene overexpression and inactivation in the Corynebacterium glutamicum genome. J Ind Microbiol Biot 43(10):1417–1427. https://doi.org/10.1007/s10295-016-1806-y

Zhao GZ, Liu XL, Liu ZF (2007) The process and key technics in starch sweetening. Cereals and Oils 10:4–8 ((in Chinese))

Zhao JK, Xu YJ, Zhang M, Wang DH (2020) Integrating bran starch hydrolysates with alkaline pretreated soft wheat bran to boost sugar concentration. Bioresource Technol 302:122826. https://doi.org/10.1016/j.biortech.2020.122826

Zhu LJ, Cai Z, Zhang YP, Li Y (2014) Engineering stress tolerance of Escherichia coli by stress-induced mutagenesis (SIM)-based adaptive evolution. Biotechnol J 9(1):120–127. https://doi.org/10.1002/biot.201300277

Funding

This work was supported by the National Key Research and Development Program of China (2021YFC2100900), the Key Laboratory of Industrial Biotechnology, Ministry of Education, Jiangnan University (KLIB-KF 202004), the Top-Notch Academic Programs Project of Jiangsu Higher Education Institutions, the 111 project (Grant number 111–2-06), and the National First class Discipline Program of Light Industry Technology and Engineering (LITE2018-08). National Basic Research Program of China (973 Program),2021YFC2100900,Jian-Zhong Xu,National Natural Science Foundation of China,31601459,Jian-Zhong Xu

Author information

Authors and Affiliations

Contributions

LML and JZX conceived and designed the experiments. WGZ contributed new reagents or analytical tools. CLL and HZR performed the experiments and analyzed the data. CLL, HZR and JZX wrote the paper. All authors read and approved the final manuscript.

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, CL., Ruan, HZ., Liu, LM. et al. Rational reformation of Corynebacterium glutamicum for producing L-lysine by one-step fermentation from raw corn starch. Appl Microbiol Biotechnol 106, 145–160 (2022). https://doi.org/10.1007/s00253-021-11714-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-021-11714-z