Abstract

α-Ketoglutarate (α-KG), one of short-chain carboxylates of high commercial relevance, has been widely used in food, medicine, chemical, and cosmetic fields. Compared to other carboxylates, α-KG occupies key positions in the tricarboxylate cycle (TCA cycle) and amino acid metabolic pathway, the over-accumulation of α-KG is restricted both by tighter carbon and nitrogen regulation process. Biotechnology production of α-KG on large industrial level has been impeded by many obstacles. This review aims at highlighting and stating recent efforts toward improving the yield and titer of α-KG in the strains of Yarrowia lipolytica to reach industrial relevance. Fermentation process optimization concerning feedstock utilization, dissolved oxygen controlling, pH manipulation and establishment of fed-batch process, have been assessed and evaluated. Moreover, pathway engineering routes have been applied for enhancing carbon commitment to α-KG, blocking competing pathways, regenerating of co-factors and regulating of carboxylate transporters to facilitate production and accumulation of α-KG. Although no engineered strain can satisfy the requirements of industrial production relevance to date, these strategies provide many clues for accelerating strain development for α-KG production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The increasing depletion of fossil resources and environment-damaged production processes stress the concern about traditional fossil resource-based chemical routes (Hatti-Kaul et al. 2007). Therefore, the renewable biomass-based production has recently gained tremendous interests and attentions (Yu et al. 2011). Although bio-based industry products currently only contribute few in global supply (Chisti 2007; Kallio et al. 2014), the market share of bio-based chemicals is expanding by a rate of 5–20 % driven from chemical and economic point of view (Sauer et al. 2008). Compared to fossil-based conversion processes, bio-based chemical production is still in its infancy and faces many challenges (Bozell and Petersen 2010), but a promising prospect that bio-based chemicals will occupied all aspects in our daily life can be envisioned.

Short-chain carboxylates have fundamental roles in food, pharmacy and many other aspects in our daily life, especially serve as chemical precursors for bulk chemicals and important polymers (Alonso et al. 2015; Holladay et al. 2007). Therefore, the markets for microbial production of short-chain carboxylates have been expanded (Chen and Nielsen 2016). Because of the sensitivity among industrial competitors, accurate demand of carboxylates is not available (Sauer et al. 2008); however, the estimated annual production can still be acquired from literatures. From 2008 to 2011, the annual production of lactic acid increased from 150,000 to 370,000 tons, the annual production of citric acid increased from 1.6 million tons to 1.7 million tons, succinic acid increased from 16,000 tons to a scale of 30,000–50,000 tons (Chen and Nielsen 2016; Sauer et al. 2008). Nevertheless, commercial application of bio-catalysis for short-chain carboxylates still faces the challenges of low productivity, low yield, low titer, pH and inhibitor tolerance (Bozell and Petersen 2010).

α-Ketoglutarate (α-KG), an important intermediate in the TCA cycle with high commercial value, could be utilized as building block for synthesis of N-heterocyclic compounds, nutraceuticals and antioxidant in cosmetic (Kamzolova et al. 2012a). α-KG occupies key position in carbon and nitrogen pathways and plays crucial roles in various cellular metabolic processes. Mediated by ketoglutarate dehydrogenase complex, α-KG is catalyzed to form succinic acid and NADH which directly participates in cellular electron transport chain. As carbon skeleton, α-KG is also attached by NH4 + to form glutamate (Fendt et al. 2013). These features of α-KG have contributed to diverse roles in maintaining of cellular homeostasis. In cells of human, α-KG and its amino acid derivatives possess functions of immuno-enhancing and prolonging life. In cells of animal, α-KG can modulate protein synthesis and bone development (Wu et al. 2016). Consequently, light have been shed on α-KG as a nutraceutical for food supplement, cosmetics and animal feed supplement (Yin et al. 2015).

Compared to commercialized lactic acid, citric acid and succinic acid, no bio-based production of α-KG on industrial scale has been established. Cost-effective production of α-KG is still restricted by challenges of low titer, low productivity, synthesis of non-targeted carboxylates and maneuverability for industry. Presently, advances in the development of robust and efficient bio-based production of α-KG, including fermentation process optimization and pathway engineering, were highlighted and discussed.

Current α-KG production routes

Multiple chemical synthesis process

Currently, α-KG is synthesized via multiply chemical processes on industry scale, and the dominating chemical route utilized succinic acid and oxalic acid diethyl esters with a yield of 75 %, also with high risk of manipulation of hazardous chemicals (Stottmeister et al. 2005). Whereas, another route relies on oxidation of glyoxylic acid with sodium glutamate using a copper catalyst which is absent of selectivity (Verseck et al. 2009). The drawbacks of these chemical routes were low yield, high risk of manipulation of harsh chemicals and generation of environmental hazards. These drawbacks sharply increased downstream cost of refine and restricted utilization of α-KG in fields of food, the medicine and cosmetics, which driven the light on seeking for biotechnology routes (Yin et al. 2015).

Overproduce of α-KG by microorganisms

It has been reported that some species of microorganism could overproduce α-KG for many decades. Some bacteria, including Arthrobacter paraffineus, Pseudomonas fluorescens, Serratia marcescens, Corynebacterium glutamicum and Bacillus ssp, could accumulate α-KG with titer of no more than 70 g·L−1 (Otto et al. 2011). Whereas, these strains were proven to be insufficient in ATP generation for cellular homeostasis maintenance under condition of acidogenosis (Yuzbashev et al. 2010). This inherited property has restricted these strains for α-KG production. Compared to bacteria species, yeast species are more efficient for ATP generation. Theoretically, cells of yeast strains are more effective for α-KG accumulation.

Some yeast species have also been reported as α-KG producers, including of Torulopsis glabrata (Hua et al. 1999), Y. lipolytica (Tsugawa et al. 1969) and some strains from Candida and Pichia (Chernyavskaya et al. 1997). Strains of these yeast species have been proven to be multivitamin auxotrophic cells: strains of T. glabrata were simultaneously auxotrophic mutants for thiamine, biotin, nicotinic acid and pyridoxine (Liu et al. 2007), strains from Candida and Pichia were simultaneously auxotrophic mutants for thiamine and biotin (Otto et al. 2011), cells of Y. lipolytica were auxotrophic mutants for thiamine. As co-factors, these vitamins played key roles on activity of enzymes which located in TCA cycle, and exogenous level of these vitamins also played key roles on α-KG accumulation. Compared with other yeast species, Y. lipolytica is more efficient for accumulation of α-KG and also represents the optimal strain for α-KG production, due to the simplest cultivation nutrition demand and vitamin supplement (Otto et al. 2011).

Fermentation process optimization and controlling

Expanding feedstock range

As Y. lipolytica were isolated from environments of oil-contained soils and waters, the strains of Y. lipolytica can readily utilize hydrophobic substrates, which is the most distinguishing characteristics of the yeast from other yeast species (Fickers et al. 2005). Consequently, petroleum-based alkane, paraffin and ethanol have been investigated to be utilized as solo carbon and energy sources by the strains of Y. lipolytica to accumulate products with biological and commercial relevance for decades (Bankar et al. 2009). Maintaining high concentration of carbon source (alkanes, paraffin and ethanol) and limited nitrogen source (C to N from 40:1 to 400:1) in the medium is one of the required conditions for α-KG production. When a hyper producer, Y. lipolytica H355, was utilized, 195 g·L−1 α-KG was synthesized on the medium containing a mixture of n-paraffins (C12–C18). An α-KG productivity of 1.3 g·L−1 h−1 was also achieved during the fermentation process (Weissbrodt et al. 1989). Integrated with optimization of exogenous thiamine and nitrogen content, α-KG with the titer of 49 g·L−1 can be accumulated on medium containing ethanol by Y. lipolytica N1(Otto et al. 2011). A maximum α-KG yield of 120 % (petrolatum, w/w, 108.7 g·L−1) can be achieved on medium containing n-alkanes (Finogenova et al. 2005).

Although considerable amounts of α-KG have been synthesized in fermentation processes utilizing petroleum and its derivate as substrates, the geopolitical instability in petroleum-producing areas and finite nature of fossil fuels cemented with the notion of exploration of alternative carbon source. The industrial and agricultural wastes, including raw glycerol and rapeseed oil, were measured and used. The raw glycerol, as by-product of bio-diesel industry, was initially utilized as substrate for production of citric acid (Papanikolaou et al. 2002) and lipids (Papanikolaou and Aggelis 2002) by strains of Y. lipolytica. It was reported that α-KG could be converted from raw glycerol, but production on industry-scale was still prohibited by accumulation of by-products (Yovkova et al. 2014). A comprehensive comparison between pharmaceutical glycerol and raw glycerol was performed in shake flask and bioreactor using Y. lipolytica H355 and its mutants. It was demonstrated that 36.2 % more α-KG was accumulated in the medium containing pharmaceutical glycerol, whereas the maximal titer of 138 g·L−1 α-KG was obtained from raw glycerol in a 1.4-L bioreactor (Otto et al. 2012).

Similarly, conversion from rapeseed oil, as a renewable source, to valuable products was initially concentrated in production of citric/isocitric acid and lipids in the yeast strains (Papanikolaou et al. 2003). When Y. lipolytica VKMY-2373 was cultured with rapeseed oil, the cellular growth and yield of citric acid were comparable to those parameters obtained when raw glycerol was utilized (Kamzolova et al. 2007). The route for production of α-KG from rapeseed oil was also devised when Y. lipolytica VKMY-2412 was used, and the titer of α-KG reached 103 g·L−1 accompanied by the productivity of 0.8 g·L−1·h−1(Kamzolova and Morgunov 2013).

Cellulose, as the most abundant renewable feedstock, has been intensively engineered and explored for production of many chemicals with high-value by microbial strains (Lynd et al. 2002). However, cells of Y. lipolytica could not consume cellulose directly. Facilitated with commercial cellulase, a microbial biocatalyst system using cells of Y. lipolytica was constructed and optimized to convert cellulose to α-KG (Ryu et al. 2015). Under optimized condition, the biocatalyst system produced 5.5 g·L−1 α-KG, up to 92 % of the maximum theoretical yield. The strains of Y. lipolytica were engineered for utilizing cellobiose via expressing the cellodextrin transporter (cdt-1) and intracellular β-glucosidase (gh1-1) (Lane et al. 2015). Moreover, efforts of heterogeneous expression of cellulase (Wei et al. 2014), xylanase (Wang et al. 2014) and β-glucosidase (Guo et al. 2015b) also have been orchestrated to utilize cellulose. Whereas, the goal of consuming cellulose directly by engineered strains of Y. lipolytica has been achieved, but these efforts proposed potential clues for engineering cells of Y. lipolytica to synthesize α-KG.

Sucrose, as a large component of molasses and glucose syrup, was widely utilized for bio-production of many chemicals of industrial and commercial relevance. However, it was excluded from the substrate spectrum of wild-type strains of Y. lipolytica (Kruse et al. 2004). Although previous studies were only concentrated in citric acid production, the hyper acidogenic yeast strains were constructed to qualify for sucrose utilization by introduction of invertase (encoded by SUC2) for α-KG production (Föerster et al. 2007). Protein waste, the by-product of biofuel refineries, is another interesting feedstock for keto acids conversion (Huo et al. 2011). Specifically, it was reported that α-KG was converted from L-glutamic acid by engineered strains of Escherichia coli or Bacillus subtilis, in which L-amino acid deaminase of Proteus mirabilis was heterogeneous expressed respectively (Hossain et al. 2014).

Manipulating dissolved oxygen level

The cells of Y. lipolytica are obligate aerobes in which oxidative phosphorylation and TCA cycle are ultimately utilized (Yuzbashev et al. 2010). Theoretically, all oxygen atoms in metabolites and cell components were derived from dissolved oxygen (DO) in fermentation broths. Consequently, the level of DO plays crucial roles in cellular growth and metabolites accumulation. High DO demand (0.26–0.56 mmol·L−1 min−1 O2) was observed for α-KG production in the medium containing ethanol in shake flasks. Once the DO level was lower than 0.2 mmol·L−1·min−1 O2, the excretion of the carboxylate was ceased (Kamzolova et al. 2012a). The similar correlation between DO level and α-KG accumulation was also observed when rapeseed oil was utilized as carbon source. If DO level was extremely low (5 % air saturation), the production of α-KG also reduced (Kamzolova and Morgunov 2013). Accordingly, the DO level in fermentation broths was maintained at a high and constant level (50–60 % air saturation) in fermenter.

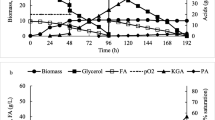

Whereas, low oxygen concentration (5 % air saturation) was favorable for cellular growth. The biomass increased by 25 % and nitrogen assimilation was also accelerated under condition of low oxygen concentration (5 % air saturation) (Chernyavskaya et al. 2000). Based on these observations, a two-stage DO control strategy was designed and widely utilized to enhance α-KG production. When Y. lipolytica H222 and its mutants were engineered for α-KG production, the air concentration was shifted from 50 to 10 % air saturation after initial growth phase (12–13 h) in the medium containing raw glycerol in a 1.4-L bioreactor (Holz et al. 2011).

Applying pH control strategies

pH is one of the fundamental physicochemical factors, which is involved in many biological processes including survival of bacteria and the virulence of some fungi. Moreover, for microorganism species, which can grow over a wide range of pH, ambient pH tailors gene expression to respond to the variation of the ambient pH conditions (Blanchin-Roland 2011). For acidogenic species of Y. lipolytica, the pH was initiated at 5.0–5.5 and maintained in cellular growth phase. Once cellular growth ceased owing to exogenous thiamine deficiency, the pH was lowered and controlled to the end of fermentation process (Morgunov et al. 2013). Such pH control strategies were universally utilized for enhancing α-KG accumulation among several strains of Y. lipolytica. Using such pH control strategy, 45.5 % more α-KG was synthesized by cells of Y. lipolytica WSH-Z06 in batch fermentation process (Yu et al. 2012). Similarly, the titer, yield and productivity of α-KG were also enhanced resulted from such pH control strategies in cells of Y. lipolytica H222 and Y. lipolytica VKM Y-2412 (Kamzolova and Morgunov 2013; Yovkova et al. 2014).

Endeavors were made to uncover the underlining mechanisms of environmental pH stress and cellular responses by several groups. Under acidic environmental stress, extracellular protons can pass through cellular membrane freely without energy cost (Orij et al. 2011). The influx of proton mainly triggered acidification of cytosolic matrix and organelles (Casey et al. 2010). As a cellular defensing strategy for intracellular pH homeostasis, proton extrudation relied on proton-ATPase pumps and proton-pumping respiration chain were promoted to extrude protons (Krulwich et al. 2011). In cells of Y. lipolytica, NADH generated from proton-pumping respiration chain and concomitantly contributed to prime source of intracellular reactive oxygen species (ROS) (Pastor et al. 2009). Metabolic flux was redirected to α-KG to cope with high level intracellular ROS under such condition (Rui et al. 2010). Furthermore, the α-KG was converted to γ-aminobutyric acid to cope with acidic environmental stress and prevent cytosolic matrix from acidification (Boonburapong et al. 2015).

Establishing fed-batch fermentation process

As classic fermentation control strategy, fed-batch process originally was designed for heterologous protein production in recombinant strains of Y. lipolytica (Chang et al. 1998). Empirically, α-KG synthesis would be ceased when exogenous carbon source was exhausted. It was demonstrated that the cells of Y. lipolytica WSH-Z06 still had potential for α-KG production in later phase of batch fermentation process, whereas more carboxylate production was hampered by the unavailability of glycerol. Therefore, different glycerol feeding strategies were investigated for enhancing α-KG production. A fed-batch strategy, which integrated with pH-shifting control strategy, was designed and established (Yu et al. 2012). Compared to batch fermentation process, maximum α-KG titer was improved up to 66.2 g·L−1 and 0.5 g·g−1 of α-KG yield was achieved when the feeding strategy was integrated.

Applying pathway engineering to produce carboxylates

Accumulation of untargeted carboxylates (pyruvic, citric, succinic, fumaric and malic acid) was the Achilles’s Heel of α-KG production on industrial scale (Otto et al. 2012). Enhanced production of target metabolite is always benefited from overexpression of enzymes from assimilation pathway. Similarly, the roles of enzymes in α-KG synthesis route were assessed and evaluated, and production of α-KG was benefited from some of these targets (Table 1). Current studies are concentrated on enhancing α-KG production and reduction of untargeted carboxylates.

Enhance carbon commitment to targeted carboxylates

Since all of the strains of Y. lipolytica could not synthesize the pyrimidine structure of the thiamine molecule, the yeast cells were proven to be auxotrophic mutation for thiamine (Kamzolova et al. 2012b). Deficiency of thiamine is the main trigger for acidogenosis in cells of Y. lipolytica, thiamine also participates in catalysis of both pyruvate dehydrogenase and ketoglutarate dehydrogenase. Based on this thiamine profiling, α-KG synthesis was accompanied by pyruvate accumulation under condition of limiting exogenous thiamine (Guo et al. 2014). The accumulation of pyruvate not only impaired carbon flux to α-KG, also sharply increased the cost of the following isolation and refining processes. Enhanced carbon commitment from pyruvate into TCA cycle was designed and engineered by overexpression of pyruvate carboxylase or pyruvate dehydrogenase complex.

A comparison between pyruvate carboxylase from Saccharomyces cerevisiae (encoded by ScPYC1) and Rhizopus oryzae (encoded by RoPYC2) was constructed through heterologous expression to replenish carbon flux into TCA cycle in Y. lipolytica WSH-Z06 (Yin et al. 2012). The engineered strain, harboring RoPYC2, gained advantages on reduction of pyruvate and accumulation of α-KG over its counterparts of engineered strain harboring ScPYC1. Finally, 35.3 % more α-KG and 69.8 % less pyruvate were synthesized in shake flask in Y. lipolytica-RoPYC2. 62.5 g·L−1 α-KG was accumulated, which was accompanied by the QαKG of 35.8 mg·g−1·h−1 (the biomass-specific rate of α-KG) in 3 L bioreactor fermentation process. Since introduction of pyruvate carboxylation pathway into the yeast cells have been evidenced to be beneficial for reduction of pyruvate, the question, whether regulation of this target can synergistically effect with other key enzymes to redirect carbon flux toward α-KG, should be proven.

Therefore, pyruvate carboxylase (encoded by PYC1) and fumarase (encoded by FUM1) were targeted and co-expressed in the strain of Y. lipolytica (Otto et al. 2012). When pyruvate carboxylase or fumarase was separately expressed, the titer of α-KG was 134.1 and 126.9 g·L−1 in cells of Y. lipolytica H355(FUM1) and Y. lipolytica H355(PYC1) respectively, which was comparable to 133.0 g L−1 in parental strain Y. lipolytica H355. The reduction of by-products (from 6.3 to 2.9 g·L−1) was only observed when pyruvate carboxylase was expressed. Whereas, by-products increased by 53.9 % (from 6.3 to 9.6 g·L−1) was observed in Y. lipolytica H355(PYC1). Nevertheless, no synergistic effects were observed neither for α-KG production nor reduction of by-products when co-expression of both of enzymes was engineered. When pyruvate carboxylase (encoded by PYC1) and fumarase (encoded by FUM1) were co-expressed, 138.0 g·L−1 of α-KG and 8.6 g·L−1 of by-products were observed in mutant strain Y. lipolytica H355(FUM1-PYC1).

Pyruvate dehydrogenase complex was assembled by multi-copy of E1, E2 and E3 components, and the balanced assembling stoichiometry among each component was prerequisite for finely orchestrated and sophisticated catalysis process of the enzyme complex (Balakrishnan et al. 2012). A metabolic strategy for the separate overexpression of the α and β subunit of pyruvate dehydrogenase E1, E2 and E3 components was designed to reduce pyruvate accumulation (Guo et al. 2014). Only elevation of α subunit of pyruvate dehydrogenase E1 component was proved to be beneficial for α-KG production, whereas elevated protein level of β subunits of pyruvate dehydrogenase E1, E2 or E3 component impaired the balanced assembling of structure core of the enzyme complex and invalid for reduction of by-products. Compared to wild-type strain, 19.9 % more α-KG (from 34.6 to 43.3 g·L−1) was synthesized by engineered strain in which α subunit of pyruvate dehydrogenase E1 component was overexpressed. The pyruvate decreased from 34.2 to 20.1 g·L−1 when subunit of pyruvate dehydrogenase E1 component was expressed. The increased intracellular level of acetyl-CoA was verified and concluded for elevation of synthesis of α-KG.

Since elevation of intracellular acetyl-CoA content could contribute to increase of α-KG accumulation, supply of the acetyl-CoA was engineered and regulated for α-KG synthesis. Acetyl-CoA synthase from S. cerevisiae (encoded by ACS1) and ATP-citrate lyase from Mus musculus (encoded by ACL1) was expressed respectively in Y. lipolytica WSH-Z06, resulting in engineered strain of Y. lipolytica-ACS1 and Y. lipolytica-ACL1 (Zhou et al. 2012). More than one order of magnitude higher enzyme activities of ACS and ACL were detected, which also resulted in increased intracellular level of acetyl-CoA from 2.2 to 5.8 and 6.0 nmol mg−1·DCW in cells of Y. lipolytica-ACS1 and Y. lipolytica-ACL1 respectively. Increasing the availability of intracellular acetyl-CoA contributed to 24.1 and 33.3 % higher α-KG titer respectively in Y. lipolytica-ASC1 and Y. lipolytica-ACL1 in 3 L fermentation process. These heterogeneous expressions also resulted in pyruvate decrease from 35.1 to 25.4 g·L−1 and 20.2 g·L−1 in cells of Y. lipolytica-ACS1 and Y. lipolytica-ACL1 respectively.

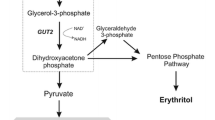

Blockage of competing pathways

In order to achieve the goal of high titer and high productivity of target metabolite, blockage of competing pathways has always been manifested and employed to control carbon flux. Empirically, carbon flux branches from α-KG mediated by ketoglutarate dehydrogenase and glutamate dehydrogenase (Fig. 1). Genomic disruption of glutamate dehydrogenase have been undertaken and proven to be beneficial for α-KG production in C. glutamicum (Jo et al. 2012). Whereas, as an obligate aerobe, Y. lipolytica use oxidative phosphorylation and the TCA cycle ultimately for cellular growth, genomic disruption of these key dehydrogenases would result in high risk for cellular lethality (Yuzbashev et al. 2010).

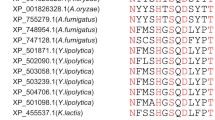

The metabolic strategies for α-KG production in Y. lipolytica BLG1 and BLG2 β-glucosidase from Y. lipolytica, CBH1 cellobiohydrolase, cdt-1 cellodextrin transporter from Neurospora crassa, gh-1 β-glucosidase from Neurospora crassa, XlnD exo-1,4-b-xylosidase from Aspergillus niger, XynII endo-1, 4-b-xylanases from Trichoderma harzianum, SUC2 invertase from S. cerevisiae, ASC1 acetyl-CoA synthase from S. cerevisiae, ACL1 ATP-citrate lyase from M. musculus, PDA1 α subunit of E1 component of pyruvate dehydrogenase, PDB1 β subunit of E1 component of pyruvate dehydrogenase, LPD1 E2 component of pyruvate dehydrogenase, LAT1 E3 component of pyruvate dehydrogenase, PYC1 pyruvate carboxylase from S. cerevisiae, PYC2 pyruvate carboxylase from R. oryzae, FUM1 fumarase from Y. lipolytica, LDP1 NADP+-dependent isocitrate dehydrogenase, KGD1 E1 component of ketoglutarate dehydrogenase, KGD2 E2 component of ketoglutarate dehydrogenase, JEN1-6 keto acid transporters from Y. lipolytica

As an alternative route, the catabolism of α-KG via TCA cycle was regulated by assembly of ketoglutarate dehydrogenase complex (Guo et al. 2016). Two conserved active site residues (His419 and Asp423) of dihydrolipoamide succinyltransferase (DLST), which served as catalytic and structural core of ketoglutarate dehydrogenase complex in Y. lipolytica, were identified through homolog alignment and docking calculations. Subsequently, mutagenesis of His419 and Asp423 residues reduced the enzyme catalytic efficiency by impairing catalysis activity and substrate binding respectively. Moreover, overexpression of the mutants of DLST also impaired the balanced assembly of the enzyme complex by variation the stoichiometry among components. The engineered strains with mutated DLST overexpressed individually accumulated highest content of α-KG of 50.4 g·L−1, which was 40 % higher titer when compared to parental strain. Whereas, co-expression of E1(KGD1), E2 (KGD2) and E3 (LPD1) components of ketoglutarate dehydrogenase complex increased the overall specific activity of ketoglutarate dehydrogenase complex, which resulted in reduction of α-KG (Holz et al. 2011).

Co-factor regeneration to facilitate synthesis of targeted carboxylates

Regulation of intracellular co-factors content was comparable with the effects of overexpression of key enzymes in the pathways on α-KG synthesis. The synthesis of α-KG would be facilitated by increase of intracellular content of NAD+ and NADP+. Dynamic analysis of intracellular content of NAD+ illustrated that the co-factor decreased sharply (22.0 to 3.8 mM) from growth phase to acid accumulation phase, while the specific activity of NAD+-depended isocitrate dehydrogenase remained constant level (0.15–0.17 μmol·L−1 per mg protein) (Morgunov et al. 2004). Nevertheless, the specific activity of NADP+-depended isocitrate dehydrogenase decreased by 20 %, which should be owed to low content of NADP+. Therefore, the supply of NADP+ was engineered by overexpression of isocitrate dehydrogenase (encoded IDP1) (Yovkova et al. 2014). Owing to integration of multicopy vector-derived of IDP1 in genomic DNA of cells of Y. lipolytica, six times higher specific activity of isocitrate dehydrogenase was observed in engineered strains. This integration also contributed to 6.8 % higher titer of α-KG, when co-expressed with pyruvate carboxylase, 186.0 g·L−1 (29.1 g·L−1 higher) of α-KG was accumulated in 3 L fermentation process which was accompanied by a QαKG of 50.7 mg·g−1·h−1(Yovkova et al. 2014).

Regulation of targeted carboxylates transportation

Under physiological conditions, the intracellular pH of eukaryotic cells is maintained near neutrality (Orij et al. 2011). According to Henderson-Hasselbalch equation pH = pka + log (A−/HA), the short-chain carboxylates predominately distributed in the form of anions (Skory et al. 2010). These carboxylic anions cannot be transported across cellular membrane freely without specific transporters, and carboxylate transporters should play crucial role on accumulation of α-KG accordingly. Previous phylogenetic analysis suggested that the roles of six putative carboxylate transporters, Jen1-6p (YALI0B19470p, YALI0C15488p, YALI0C21406p, YALI0D24607p, YALI0D20108p and YALI0E32901p) from Y. lipolytica, distinguished from identified Jen1 and Jen2 subfamily members (Lodi et al. 2007). To assess and characterize the role of each putative transporter, sextuple-deletion mutant strain ΔYLjen1-6 was constructed. Combined with the growth profiles of engineered strains in which each of YlJen1-6p was introduced into cells of ΔYLjen1-6 individually, it was concluded that all these transporters were responsible for carboxylates transport but with different substrate specificity (Dulermo et al. 2015).

Based on the expression profiles on mRNA level, it was concluded that YlJen1p (YALI0C15488p) and YlJen5p (YALI0B19470p) were mainly in charge of carboxylates transport during pyruvate and α-KG up-taking processes (Guo et al. 2015a). Individual heterologous expression of these transporters in a carboxylate-transport-deficient strain of S. cerevisiae could restore the cell growth of the carboxylate-transport-deficient strain on all tested carboxylate containing medium. Accordingly, these restoral suggested that all transporters possessed carboxylate-transporting characteristics and flexibly of substrate spectrum. Six engineered strains of Y. lipolytica WSH-Z06 were constructed in which additional genomic copy of each transporter was added via integration of vector-derived of each gene. The engineered line of Y. lipolytica harboring YlJen5p showed advantage over other five mutant lines on α-KG production, with 30.6 % less pyruvate content (12.3 g·L−1) and 27.6 % higher titer (46.7 g·L−1) (Guo et al. 2015a).

Although biotechnology production of α-KG has been achieved with the highest titer of 195 g·L−1 and the maximal volumetric productivity of 1.75 g·L−1·h−1, the production was restricted on laboratory scale with a working volume of 600 mL (Yovkova et al. 2014). The largest working volume reported in literatures was 4 L from literatures (Yu et al. 2012), and the biotechnology production of α-KG on industry scale was mainly limited by complicated nutrition demand of the species of the yeast, especially for thiamine, which was crucial for accumulation of α-KG but difficult for manipulation in industry.

For industrial production, lights should be shed on establishing novel metabolic strategies to promote α-KG accumulation, which is independent on thiamine supply. Compared to other model yeast species, metabolic engineering toward cells of Y. lipolytica was impeded by less engineering tools at translating and transcription levels, which also limited the application of metabolic perturbation and remolding on global levels. Light also should be shed on modeling and flux analysis in silicon to identify key regulating nodes and bottlenecks for α-KG accumulation. Although much of progress has been made through applying these strategies, the goal of high titer and productivity has not been achieved. Nevertheless, these efforts provide many clues for accelerating strain development for α-KG production.

References

Alonso S, Rendueles M, Diaz M (2015) Microbial production of specialty organic acids from renewable and waste materials. Crit Rev Biotechnol 35(4):497–513. doi:10.3109/07388551.2014.904269

Balakrishnan A, Nemeria NS, Chakraborty S, Kakalis L, Jordan F (2012) Determination of pre-steady-state rate constants on the Escherichia coli pyruvate dehydrogenase complex reveals that loop movement controls the rate-limiting step. J Am Chem Soc 134(45):18644–18655. doi:10.1021/ja3062375

Bankar A, Kumar A, Zinjarde S (2009) Environmental and industrial applications of Yarrowia lipolytica. Appl Microbiol Biotechnol 84(5):847–865. doi:10.1007/s00253-009-2156-8

Blanchin-Roland S (2011) Identical domains of Yarrowia lipolytica Vps23 are required for both ESCRT and Rim pathways, but the latter needs an interaction between the Vps23 UEV domain and Rim8/PalF. FEMS Yeast Res 11(6):473–486. doi:10.1111/j.1567-1364.2011.00735.x

Boonburapong B, Laloknam S, Incharoensakdi A (2015) Accumulation of gamma-aminobutyric acid in the halotolerant cyanobacterium Aphanothece halophytica under salt and acid stress. J Appl Phycol 28(1):141–148. doi:10.1007/s10811-015-0523-7

Bozell JJ, Petersen GR (2010) Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy’s “Top 10” revisited. Green Chem 12(4):539. doi:10.1039/b922014c

Casey JR, Grinstein S, Orlowski J (2010) Sensors and regulators of intracellular pH. Nat Rev Mol Cell Biol 11(1):50–61. doi:10.1038/nrm2820

Chang CC, Ryu DD, Park CS, Kim JY (1998) Improvement of heterologous protein productivity using recombinant Yarrowia lipolytica and cyclic fed-batch process strategy. Biotechnol Bioeng 59(3):379–385. doi:10.1002/(sici)1097-0290(19980805)59:3<379::aid-bit15>3.0.co;2-9

Chen Y, Nielsen J (2016) Biobased organic acids production by metabolically engineered microorganisms. Curr Opin Biotechnol 37:165–172. doi:10.1016/j.copbio.2015.11.004

Chernyavskaya OG, Shishkanova NV, Finogenova TV (1997) Biosynthesis of α-ketoglutaric acid from ethanol by yeasts. Appl Biochem Microbiol 33(3):261–265

Chernyavskaya OG, Shishkanova NV, Il'chenko AP, Finogenova TV (2000) Synthesis of α-ketoglutaric acid by Yarrowia lipolytica yeast grown on ethanol. Appl Microbiol Biotechnol 53(2):152–158. doi:10.1007/s002530050002

Chisti Y (2007) Biodiesel from microalgae. Biotechnol Adv 25(3):294–306. doi:10.1016/j.biotechadv.2007.02.001

Dulermo R, Gamboa-Meléndez H, Michely S, Thevenieau F, Neuvéglise C, Nicaud J-M (2015) The evolution of Jen3 proteins and their role in dicarboxylic acid transport in Yarrowia. Microbiology Open 4(1):100–120. doi:10.1002/mbo3.225

Fendt S-M, Bell EL, Keibler MA, Olenchock BA, Mayers JR, Wasylenko TM, Vokes NI, Guarente L, Heiden MGV, Stephanopoulos G (2013) Reductive glutamine metabolism is a function of the α-ketoglutarate to citrate ratio in cells. Nat Commun 4:2236. doi:10.1038/ncomms3236

Fickers P, Benetti PH, Wache Y, Marty A, Mauersberger S, Smit MS, Nicaud JM (2005) Hydrophobic substrate utilisation by the yeast Yarrowia lipolytica, and its potential applications. FEMS Yeast Res 5(6–7):527–543. doi:10.1016/j.femsyr.2004.09.004

Finogenova TV, Morgunov IG, Kamzolova SV, Chernyavskaya OG (2005) Organic acid production by the yeast Yarrowia lipolytica: a review of prospects. Appl Biochem Microbiol 41(5):418–425

Föerster A, Aurich A, Mauersberger S, Barth G (2007) Citric acid production from sucrose using a recombinant strain of the yeast Yarrowia lipolytica. Appl Microbiol Biotechnol 75(6):1409–1417. doi:10.1007/s00253-007-0958-0

Guo H, Madzak C, Du G, Zhou J, Chen J (2014) Effects of pyruvate dehydrogenase subunits overexpression on the α-ketoglutarate production in Yarrowia lipolytica WSH-Z06. Appl Microbiol Biotechnol 98(16):7003–7012. doi:10.1007/s00253-014-5745-0

Guo H, Liu P, Madzak C, Du G, Zhou J, Chen J (2015a) Identification and application of keto acids transporters in Yarrowia lipolytica. Sci Rep 5:8138–8147. doi:10.1038/srep08138

Guo ZP, Duquesne S, Bozonnet S, Cioci G, Nicaud JM, Marty A, O'Donohue MJ (2015b) Development of cellobiose-degrading ability in Yarrowia lipolytica strain by overexpression of endogenous genes. Biotechnol Biofuels 8:16. doi:10.1186/s13068-015-0289-9

Guo H, Madzak C, Du G, Zhou J (2016) Mutagenesis of conserved active site residues of dihydrolipoamide succinyltransferase enhances the accumulation of α-ketoglutarate in Yarrowia lipolytica. Appl Microbiol Biotechnol 100(2):649–659. doi:10.1007/s00253-015-6995-1

Hatti-Kaul R, Tornvall U, Gustafsson L, Borjesson P (2007) Industrial biotechnology for the production of bio-based chemicals - a cradle-to-grave perspective. Trends Biotechnol 25(3):119–124. doi:10.1016/j.tibtech.2007.01.001

Holladay J, Bozell J, White J, Johnson D (2007) Top value-added chemicals from biomass. Volume II–Results of Screening for Potential Candidates from Biorefinery Lignin, Report prepared by members of NREL, PNNL and University of Tennessee

Holz M, Otto C, Kretzschmar A, Yovkova V, Aurich A, Potter M, Marx A, Barth G (2011) Overexpression of α-ketoglutarate dehydrogenase in Yarrowia lipolytica and its effect on production of organic acids. Appl Microbiol Biotechnol 89(5):1519–1526. doi:10.1007/s00253-010-2957-9

Hossain GS, Li J, H-d S, Chen RR, Du G, Liu L, Chen J (2014) Bioconversion of l-glutamic acid to α-ketoglutaric acid by an immobilized whole-cell biocatalyst expressing l-amino acid deaminase from Proteus mirabilis. J Biotechnol 169:112–120. doi:10.1016/j.jbiotec.2013.10.026

Hua Q, Yang C, Shimizu K (1999) Metabolic flux analysis for efficient pyruvate fermentation using vitamin-auxotrophic yeast of Torulopsis glabrata. J Biosci Bioeng 87(2):206–213. doi:10.1016/s1389-1723(99)89014-8

Huo Y-X, Cho KM, Rivera JGL, Monte E, Shen CR, Yan Y, Liao JC (2011) Conversion of proteins into biofuels by engineering nitrogen flux. Nat Biotechnol 29(4):346–U160. doi:10.1038/nbt.1789

Jo JH, Seol HY, Lee YB, Kim MH, Hyun HH, Lee HH (2012) Disruption of genes for the enhanced biosynthesis of α-ketoglutarate in Corynebacterium glutamicum. Can J Microbiol 58(3):278–286. doi:10.1139/w11-132

Kallio P, Pásztor A, Thiel K, Akhtar MK, Jones PR (2014) An engineered pathway for the biosynthesis of renewable propane. Nat Commun:5. doi:10.1038/ncomms5731

Kamzolova SV, Morgunov IG (2013) α-Ketoglutaric acid production from rapeseed oil by Yarrowia lipolytica yeast. Appl Microbiol Biotechnol 97(12):5517–5525. doi:10.1007/s00253-013-4772-6

Kamzolova SV, Finogenova TV, Lunina YN, Perevoznikova OA, Minachova LN, Morgunov IG (2007) Characteristics of the growth on rapeseed oil and synthesis of citric and isocitric acids by Yarrowia lipolytica yeasts. Microbiology 76(1):20–24. doi:10.1134/S0026261707010031

Kamzolova S, Chiglintseva M, Lunina J, Morgunov I (2012a) α-Ketoglutaric acid production by Yarrowia lipolytica and its regulation. Appl Microbiol Biotechnol 96(3):783–791. doi:10.1007/s00253-012-4222-x

Kamzolova SV, Chiglintseva MN, Yusupova AI, Vinokurova NG, Lysanskaya VY, Morgunov IG (2012b) Biotechnological potential of Yarrowia lipolytica grown under thiamine limitation. Food Technol Biotechnol 50(4):412–419

Krulwich TA, Sachs G, Padan E (2011) Molecular aspects of bacterial pH sensing and homeostasis. Nat Rev Micro 9(5):330–343. doi:10.1038/nrmicro2549

Kruse K, Förster A, Mauersberger S, Barth G (2004) Method for the biotechnological production of citric acid by means of a genetically modified yeast Yarrowia lipolytica

Lane S, Zhang SY, Wei N, Rao C, Jin YS (2015) Development and physiological characterization of cellobiose-consuming Yarrowia lipolytica. Biotechnol Bioeng 112(5):1012–1022. doi:10.1002/bit.25499

Liu L, Li Y, Zhu Y, Du G, Chen J (2007) Redistribution of carbon flux in Torulopsis glabrata by altering vitamin and calcium level. Metab Eng 9(1):21–29. doi:10.1016/j.ymben.2006.07.007

Lodi T, Diffels J, Goffeau A, Baret PV (2007) Evolution of the carboxylate Jen transporters in fungi. FEMS Yeast Res 7(5):646–656. doi:10.1111/j.1567-1364.2007.00245.x

Lynd LR, Weimer PJ, van Zyl WH, Pretorius IS (2002) Microbial cellulose utilization: fundamentals and biotechnology. Microbiol Mol Biol Rev 66(3):506–577. doi:10.1128/mmbr.66.3.506-577.2002

Morgunov IG, Solodovnikova NY, Sharyshev AA, Kamzolova SV, Finogenova TV (2004) Regulation of NAD+-dependent isocitrate dehydrogenase in the citrate producing yeast Yarrowia lipolytica. Biochemistry-Moscow 69(12):1391–1398. doi:10.1007/s10541-005-0086-3

Morgunov IG, Kamzolova SV, Samoilenko VA (2013) Enhanced α-ketoglutaric acid production and recovery in Yarrowia lipolytica yeast by effective pH controlling. Appl Microbiol Biotechnol 97(19):8711–8718. doi:10.1007/s00253-013-5170-9

Orij R, Brul S, Smits GJ (2011) Intracellular pH is a tightly controlled signal in yeast. BBA-Gen Subjects 1810(10):933–944. doi:10.1016/j.bbagen.2011.03.011

Otto C, Yovkova V, Barth G (2011) Overproduction and secretion of α-ketoglutaric acid by microorganisms. Appl Microbiol Biotechnol 92(4):689–695. doi:10.1007/s00253-011-3597-4

Otto C, Yovkova V, Aurich A, Mauersberger S, Barth G (2012) Variation of the by-product spectrum during α-ketoglutaric acid production from raw glycerol by overexpression of fumarase and pyruvate carboxylase genes in Yarrowia lipolytica. Appl Microbiol Biotechnol 95(4):905–917. doi:10.1007/s00253-012-4085-1

Papanikolaou S, Aggelis G (2002) Lipid production by Yarrowia lipolytica growing on industrial glycerol in a single-stage continuous culture. Bioresour Technol 82(1):43–49

Papanikolaou S, Muniglia L, Chevalot I, Aggelis G, Marc I (2002) Yarrowia lipolytica as a potential producer of citric acid from raw glycerol. J Appl Microbiol 92(4):737–744

Papanikolaou S, Muniglia L, Chevalot I, Aggelis G, Marc I (2003) Accumulation of a cocoa-butter-like lipid by Yarrowia lipolytica cultivated on agro-industrial residues. Curr Microbiol 46(2):124–130. doi:10.1007/s00284-002-3833-3

Pastor MM, Proft M, Pascual-Ahuir A (2009) Mitochondrial function is an inducible determinant of osmotic stress adaptation in yeast. J Biol Chem 284(44):30307–30317. doi:10.1074/jbc.M109.050682

Rui B, Shen T, Zhou H, Liu J, Chen J, Pan X, Liu H, Wu J, Zheng H, Shi Y (2010) A systematic investigation of Escherichia coli central carbon metabolism in response to superoxide stress. BMC Syst Biol 4:122. doi:10.1186/1752-0509-4-122

Ryu S, Labbe N, Trinh CT (2015) Simultaneous saccharification and fermentation of cellulose in ionic liquid for efficient production of α-ketoglutaric acid by Yarrowia lipolytica. Appl Microbiol Biotechnol 99(10):4237–4244. doi:10.1007/s00253-015-6521-5

Sauer M, Porro D, Mattanovich D, Branduardi P (2008) Microbial production of organic acids: expanding the markets. Trends Biotechnol 26(2):100–108. doi:10.1016/j.tibtech.2007.11.006

Skory CD, Hector RE, Gorsich SW, Rich JO (2010) Analysis of a functional lactate permease in the fungus Rhizopus. Enzym Microb Technol 46(1):43–50. doi:10.1016/j.enzmictec.2009.08.014

Stottmeister U, Aurich A, Wilde H, Andersch J, Schmidt S, Sicker D (2005) White biotechnology for green chemistry: fermentative 2-oxocarboxylic acids as novel building blocks for subsequent chemical syntheses. J Ind Microbiol Biotechnol 32(11−/12):651–664. doi:10.1007/s10295-005-0254-x

Tsugawa R, Nakase T, Kobayash T, Yamashit K, Okumura S (1969) Fermentation of n-paraffins by yeasts. I. Fermentative production of a-ketoglutaric acid by Candida lipolytica. Appl Biochem Microbiol 33(2):158

Verseck S, Karau A, Weber M (2009) Fermentative production of alpha-ketoglutaric acid. Evonik Degussa GmbH Patent WO2009053489

Wang W, Wei H, Alahuhta M, Chen XW, Hyman D, Johnson DK, Zhang M, Himmel ME (2014) Heterologous expression of xylanase enzymes in lipogenic yeast Yarrowia lipolytica. PLoS One 9(12). doi:10.1371/journal.pone.0111443

Wei H, Wang W, Alahuhta M, Wall TV, Baker JO, Taylor LE, Decker SR, Himmel ME, Zhang M (2014) Engineering towards a complete heterologous cellulase secretome in Yarrowia lipolytica reveals its potential for consolidated bioprocessing. Biotechnol Biofuels:7. doi:10.1186/s13068-014-0148-0

Weissbrodt E, Gey M, Barth G, Weber H, Stottmeister U, Düresch R, Richter H (1989) Verfahren zur Herstellung von 2-Oxoglutarsäure durch Hefen. Patent DD 267999

Wu N, Yang M, Gaur U, Xu H, Yao Y, Li D (2016) α-Ketoglutarate: physiological functions and applications. Biomol Ther 24(1):1–8. doi:10.4062/biomolther.2015.078

Yin XX, Madzak C, Du GC, Zhou JW, Chen J (2012) Enhanced α-ketoglutaric acid production in Yarrowia lipolytica WSH-Z06 by regulation of the pyruvate carboxylation pathway. Appl Microbiol Biotechnol 96(6):1527–1537. doi:10.1007/s00253-012-4192-z

Yin X, Li JH, Shin HD, Du GC, Liu L, Chen J (2015) Metabolic engineering in the biotechnological production of organic acids in the tricarboxylic acid cycle of microorganisms: advances and prospects. Biotechnol Adv 33(6):830–841. doi:10.1016/j.biotechadv.2015.04.006

Yovkova V, Otto C, Aurich A, Mauersberger S, Barth G (2014) Engineering the α-ketoglutarate overproduction from raw glycerol by overexpression of the genes encoding NADP+-dependent isocitrate dehydrogenase and pyruvate carboxylase in Yarrowia lipolytica. Appl Microbiol Biotechnol 98(5):2003–2013. doi:10.1007/s00253-013-5369-9

Yu C, Cao YJ, Zou HB, Xian M (2011) Metabolic engineering of Escherichia coli for biotechnological production of high-value organic acids and alcohols. Appl Microbiol Biotechnol 89(3):573–583. doi:10.1007/s00253-010-2970-z

Yu ZZ, Du GC, Zhou JW, Chen J (2012) Enhanced α-ketoglutaric acid production in Yarrowia lipolytica WSH-Z06 by an improved integrated fed-batch strategy. Bioresour Technol 114:597–602. doi:10.1016/j.biortech.2012.03.021

Yuzbashev TV, Yuzbasheva EY, Sobolevskaya TI, Laptev IA, Vybornaya TV, Larina AS, Matsui K, Fukui K, Sineoky SP (2010) Production of succinic acid at low pH by a recombinant strain of the aerobic yeast Yarrowia lipolytica. Biotechnol Bioeng 107(4):673–682. doi:10.1002/bit.22859

Zhou JW, Yin XX, Madzak C, Du GC, Chen J (2012) Enhanced α-ketoglutarate production in Yarrowia lipolytica WSH-Z06 by alteration of the acetyl-CoA metabolism. J Biotechnol 161(3):257–264. doi:10.1016/j.jbiotec.2012.05.025

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Funding

This work was supported by the National Natural Science Foundation of China (grant numbers: 31130043, 21276109, 21576108, 21476093), the Author of National Excellent Doctoral Dissertation of PR China (grant number: FANEDD, 201256), the Program for New Century Excellent Talents in University (grant number: NCET-12-0876), the Fundamental Research Funds for the Central Universities (grant number: JUSRP51307A), the 111 Project (grant number: 111-2-06), and the Scientific Research Funds of Huaqiao University (16BS103).

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Guo, H., Su, S., Madzak, C. et al. Applying pathway engineering to enhance production of alpha-ketoglutarate in Yarrowia lipolytica . Appl Microbiol Biotechnol 100, 9875–9884 (2016). https://doi.org/10.1007/s00253-016-7913-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-016-7913-x