Abstract

Immobilization is one of the most effective and powerful tools used in industry, which has been studied and improved since the last century. Various immobilization techniques and support materials have been used on both laboratory and industrial scale. Each immobilization technique is applicable for a specific production mostly depending on the cost and sensibility of process. Compared to free biocatalyst systems, immobilization techniques often offer better stability, increased activity and selectivity, higher resistance, improved separation and purification, reuse of enzymes, and consequently more efficient process. Recently, many reviews have been published about immobilization systems; however, most of them have focused on a specific application or not emphasized in details. This review focuses on most commonly used techniques in industry with many recent applications including using bioreactor systems for industrial production. It is also aimed to emphasize the advantages and disadvantages of the immobilization techniques and how these systems improve process productivity compared to non-immobilized systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In almost every industry, the term productivity has a vital significance for every single step of the entire process carried out to produce a specific product. The importance of the productivity increases due to the restriction of production time and final product volume since both can alter total cost of the whole process. Therefore, most of the industries are eager to invest specially on promising innovative systems for more efficient production that eventually will result in high quality products with reduced cost and time consumption. Since the cost of food and drugs is increasing intensely on global scale, consequently, investment on these promising systems becomes more indispensable each day for every industry and now is of global concern.

Every industrial bioprocess is catalyzed by a specific biocatalyst. Therefore, the recovery of these molecules during downstream processes and improving operational stabilities is highly crucial and of high cost. Improving recovery and operational stabilities will result in reduced cost and higher overall bioprocess efficiency.

To reach those aims, immobilization became one of the most innovative and recently well-studied systems to carry out a production on industrial scale with higher productivity. Immobilization systems allow us to overcome most of the process restrictions, improve recovery of biocatalysts for reuse, offer better stability, activity, and selectivity of the molecules, higher resistance against inhibition, help the elimination of unnecessary separation and purification steps, and consequently produce desired products with more efficiency. Various immobilization techniques and materials have been used on both laboratory and industrial scale and have a broad range of use on industries such as food processing, biomedical production, wastewater treatment, textile, detergent industry, and even biodiesel production.

The focus of this review is to outline the importance of immobilization systems to improve overall efficiency and consequently to reduce total cost of bioprocess. The principal techniques and support materials of immobilization systems and their use for production in bioreactors will be brought into focus and several examples from recent studies will be given and discussed to show advantages and disadvantages of these systems in various industrial bioprocesses.

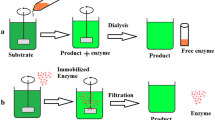

Immobilization, by definition, is the term that expresses of making something immobile or fixed. In the first Enzyme Engineering Conference that was held at Henniker, NH, USA, in 1971, it was defined that immobilized biocatalysts, enzymes, or cells are physically fixed in a defined region in order to catalyze a specific reaction with no loss of catalytic activity and with repeated use (Katchalski-Katzir and Kraemer 2000). Immobilization can also be defined as a key to optimization of the operational performance of biocatalysts in industrial processes (Sheldon 2007). In Table 1, immobilized biocatalytic processes with non-immobilized biocatalytic processes are compared.

Immobilization of enzymes

Most of the enzymes have high cost hence they should be used efficiently, and their capacity to perform same function repeatedly is considered as an important property. Since both enzyme and product are in dissolved state, the separation becomes more difficult, consequently more costly. Some enzymes used in industry are too expensive so the enzymatic process becomes viable and effective only if they can be reused. The immobilization involves the conversion of water-soluble enzyme into a solid form of catalyst, which facilitates the separation, therefore, immobilization techniques should be considered as a powerful tool to use in processes (Kulkarni 2002).

An immobilized enzyme, in some cases such as entrapment and membrane confinement, has free mobility in their fixed regions. This kind of immobilization must offer economic improvement to the production compared to the use of free enzymes; otherwise, it brings additional cost to production (Krishna 2011).

Immobilization of an enzyme might cause certain alterations in its physical and chemical properties, which might complicate the separation. The stability of enzymes, conformational and steric effects, kinetic properties, and diffusional and mass transfer effects are the most important changes observed (Shanmugam and Sathishkumar 2009).

There are two essential functions that any immobilized enzyme must comprise: (1) the non-catalytic functions (NCF), which provide an easier separation and consequently, reusing of the catalysts and control of the process; and (2) the catalytic functions (CF), which convert the substrates into the desired product. It is very important to design a suitable immobilization technique, which immobilized biocatalysts can meet both catalytic and non-catalytic needs (Cao 2006).

The immobilization of enzymes is an emerging technique that involves stabilizing of an enzyme in or on insoluble matrix. Immobilization systems facilitate the entire process by bringing many advantages; nevertheless, these systems have some difficulties, which might slow down the process since there are no certain techniques to be applied for each enzyme in industry.

The importance of enzyme immobilization is to make it possible to use the same enzyme repeatedly. This prevents possible loss at the end of each batch and facilitates the design of continuous systems, which will make the entire process more feasible. Since the immobilization causes more stable activity for biocatalysts, it is easier to control the process. In immobilization systems, enzyme-substrate ratio is also very high, so additional use of substrate can be avoided (Kulkarni 2002). At the end of each process, enzyme can be easily removed from the reaction mixture, which eliminates possible threats for bioprocess coming from contamination (Mishra and Champagne 2009).

Immobilization systems allow us to work at high substrate concentration and prevent the product inhibition. Immobilization, in overall, is economically advantageous due to increased productivity, enhanced enzyme stability, and reduced adverse effects. Savings on space and labor, controlling process in an effective way, giving more uniform quality, and having acceptable costs are other principal benefits of immobilization systems (Krishna 2011). Considering all these benefits mentioned above that immobilization brings along, the most significant advantage would be overall cost-effectiveness since it is, probably, the most important point of interest in industry.

Free enzymes in a reaction mixture have total mobility and there is no physical obstacle that prevents them to get into reaction with a substrate. When enzymes are immobilized, their mobility becomes dependent on the particle, which is used to immobilize. However, particles used for immobilization have certain fragility and diffusion limitations. In some cases, application of nanoparticles can improve the process, facilitating the immobilization of the cells. Such nanostructured systems can be prepared using different types of materials, such as biodegradable polymers (Amaral and Felipe 2013). Therefore, choosing suitable particles is essential to eliminate this issue. Depending on the harshness of the immobilization technique, some considerable alteration in enzyme conformation and loss of catalytic activity may occur. Causing great stress on the enzyme is one of the encountered disadvantages of immobilization by covalent binding (Reis and Román 2004).

Every free enzyme has its kinetic model; however, when an enzyme is immobilized, since certain factors or parameters like temperature, pH, K m, and reaction mixture will be altered; consequently, kinetic model will change and there will be a new model to be defined, which might make the process control difficult.

The importance of using enzyme reactors has been increased dramatically. Immobilized enzymes are not ready-to-use for every type of bioreactors. A specific type of bioreactor equipment is required to work with immobilized enzymes to obtain higher efficiency. Necessity for special reactors might have a higher cost than free cell systems. This requires high engineering skills and designs.

Immobilization of enzymes onto polymeric microfiltration-type membranes might block the active side of enzyme and this blocking might restrict accessibility of enzyme to its substrate and as a result decreases enzyme activity and causes multiple points binding which might denature the enzyme (Ramakrishna et al. 2011).

In some cases, the matrix used for immobilization might favor the microbial growth since some matrices have polymeric structures that can be consumed by microorganisms as nutrient source. If the substrates used in process are insoluble or substrate diffusion problems to enzyme persist during process, immobilization might be inconvenient to use (Krishna 2011).

Immobilization of cells

The nature of cells (mainly prokaryotic cells) is lean to be mobile to access the free nutrients for its metabolism in its microenvironment. In some phase of their life cycles, some of them tend to attach themselves onto surface. Since immobilization can be described as any technique that limits the free movement of cells, the technique could enforce them to stay against their nature. Most microbial cells, by its very nature, tend to attach themselves onto a solid surface in some growth phase of their life cycles. In nature, cell immobilization occurs naturally by adhesion of cells to solid surfaces. In some industrial bioprocess flocculation, pellet formation and surface attachment can be considered as immobilization forms (Akin 1987).

Immobilization of cells must have properties such as a high biocatalytic activity, long-term stability of cells, possibility of regenerating biocatalyst, and low loss of activity during immobilization and fermentation. In addition, it also has low leakage of cells, non-compressible particles, and high resistance to abrasion. It is also very desirable to be economic support matrix with high resistance to microbial degradation, with low diffusional limitation, high surface area, and appropriate density for the reactor type (Nussinovitch 1997).

The production carried out in most industry with cell immobilization systems has a specific area of application in industry and immobilization techniques vary from cell to cell.

Biocatalyst reactions by immobilized microbial cells, compared to immobilized purified enzyme systems, have numerous advantages such as less expense on separation, advantageous isolation and purification method, allows multistep reactions, enhanced stability of the enzyme in its native state, longer enzyme activity in the presence of co-factors, and continued biosynthesis by cell (Jack and Zajic 1997). Immobilization allows the cells to be used repeatedly and continuously, which helps the maintenance the high cell density during process and consequently reduces the cost of bioprocess. Immobilized cells are more resistant to shear stress since there is an additional support material to provide protection (Akin 1987).

Biocatalysts often suffer many disadvantages compared to simple inorganic catalysis. Concentration of active biomass is sometimes lower than expected to carry out the reaction and this mostly leads to low reaction rates and increase the cost of recovery. However, immobilization can store more active biocatalyst per unit of reactor volume; as a result, it can reduce the cost and allow more efficient reactor design (Atkinson et al. 1980).

Cell immobilization systems also present disadvantages depending on the area of application. The cells to be immobilized might have different activity and be in different growth phase to avoid their unrestrained growth, which can burst the thin layer of support matrix used for mostly entrapment of organism and this might contaminate the product in production media. This matrix might also cause a diffusion barrier so it is very essential to choose a matrix that is capable of holding high cell density and allows the diffusion between entrapped cells and culture media (Akin 1987).

Comparative analysis of advantages and disadvantages of biocatalyst immobilization is shown in Fig. 1.

Support material for biocatalyst immobilization

The immobilization process involves several steps such as choosing appropriate support material and technique with suitable biocatalysts. Each step must be carried out meticulously for a successful immobilization.

Support material has to achieve high cell loading capacity, and mechanical and chemical stability to avoid possible damage on matrix during the process. Mechanical and chemical stability mostly offer regeneration ability to the support. Since it directly affects cost-effectiveness of the entire process, preparation must include simple procedure. Scale-up process is very essential for large-scale production; therefore, support material must have suitability for possible production in bioreactor. Most of the time downstream process takes too much time and is costly. An ideal support material must allow easy separation of carriers with immobilized cells from media and retention of immobilized cell and enzyme viability. Each support material is made of a compound that must be approved for food and pharmaceutical applications (Aguilera et al. 2010).

There are number of support material available for industrial application. Depending on the sensibility of the production, each support material is chosen for a specific reason such as its overall cost to process, its product specificity, biocompatibility, and availability.

Collagen

Collagen is used for immobilization mostly due to its biocompatibility, availability in nature, and its ability to attach cells, which makes it a promising material for immobilization. The tissues like tendon, skin, bone, and cartilage are abundant sources for isolation of collagen. This natural polymer can be integrated with porous sponges and films by processing. Its ability of attaching cells strongly makes it prominent for immunological use. High costly purification process of collagen is a main challenge to choose collagen as a support material for biocatalyst immobilization (Nedovic and Willaert 2004).

Alginate

Alginic acid is a hetero-polymer of l-guluronic acid and d-mannuronic acid. The alginates are extracted mostly from seaweed like marine algae and become available as water-soluble sodium salts after processing. Depending on the proportions of these two acids, alginate tends to give a different internal pore size to the gel beads (Tampion and Tampion 1987). Alginate has widely been used for cell immobilization due to its high biocompatibility and simple gelation with calcium ions. Alginate gels might suffer uncontrollable and unexpected dissolution by the loss of divalent ions into surrounding fluids and limit its use for immobilization. Alginate gels has limited use for protein adsorption, hence it is modified to be used with lectin to control cell adhesion (Nedovic and Willaert 2004).

κ-carrageenan

κ-carrageenan can be used as an alternative support matrix for cell immobilization since κ-carrageenan gels are less sensitive to chelating agents than alginate. However, κ-carrageenan beads can be fragile and cause disruption of immobilized material into the medium. κ-carrageenan beads can be strengthened by incorporation of small amounts of locust bean gum. The presence of high potassium concentration directly affects the rigidity of κ-carrageenan, which limits its application to animal cell immobilization due to their sensibility and also physiological problems (Goosen 1992).

Chitosan

Chitosan is obtained by deacetylation of chitin, which is abundantly found in crustacean shells, fungi, insects, and mollusks. Chitosan can form hydrogels by ionic or chemical cross-linking with glutaraldehyde and can be hydrolyzed enzymatically. Chitosan have been widely used for pharmaceutical, food, and mainly on biotechnological applications. Chitosan has great biocompatibility; therefore, it can be used easily for many biological applications. Besides that, chitosan has weak mechanical properties compared to other support materials; therefore, it is common to combine chitosan with other materials such as calcium phosphate or collagen to improve its mechanical strength (Nedovic and Willaert 2004). Production with bacterial cells immobilized in chitosan is more efficient compared to other ionotropic gels such as calcium alginate and κ-carrageenan (Wukasch 1994).

Agar and agarose

Agarose is a gel form of agar and prepared by its purification. Both polysaccharides are commonly used in cell encapsulation. Agarose gel contains pentagonal pores with proportional size to allow diffusional access of many proteins. Agarose gel does not have a strong mechanical structure, which is a property that limits its use for immobilization (Dumitrriu 2004). Agar and agarose gel tend to have solid form in cold temperature. The preparation of beads is carried out by dripping the warm agar-cell or agarose-cell suspension into cold buffer for sudden solidification (Brodelius and Nilsson 1980). Agarose has also the ability to form thermally reversible gels and allow the design of microporous gels seeded with chondrocytes to repair of cartilages that have defects (Nedovic and Willaert 2004).

Polyacrylamide and polyanhydrides

Polyacrylamides are synthetic polymers that are often used for separation of molecules with different sizes and shapes (Tampion and Tampion 1987). Polyacrylamide can also be used for whole-cell immobilization for binding and selective recovery of metal ions like Au3+, Cu2+, Hg2+, and Zn2+ (Darnall et al. 1986).

Polyanhydrides is used for cell immobilization due to their high strength compared to other support materials. Its degradation can be controlled by surface erosion, which makes these polymers attractive for design of micro- and macroporous structures. Controllable surface erosion can be used for controlled drug delivery system where it maintains structural integrity for desired time (Nedovic and Willaert 2004).

Immobilization techniques

Each production requires a specific operational condition since process pathway varies for each product. Hence, selecting proper immobilization technique becomes more important for overall process yield. Additionally, when industrial scale is in the question, choosing the right immobilization technique saves time and money to industry. Immobilization techniques improve enzyme properties by increasing stabilization and rigidity of 3D structure, causing chemical modification, generating hyper-hydrophilic microenvironments and reducing enzyme inhibitions (Cho et al. 1981).

Physical adsorption

Physical adsorption occurs by dipole-dipole and hydrophobic interactions, van der Waals forces, or hydrogen bonding, and one of these interactions is used for immobilization depending on the natural properties of the substrate surface and the adsorbate (Ligler and Taitt 2011). Physical adsorption is the one of the easiest techniques used for immobilization in industry (Cao 2006).

Physical adsorption is a simple and less expensive technique, which retains high catalytic activity; therefore, it is used more commonly than other methods. This technique also allows the reuse of expensive support materials; as a result, this reusability of the support material brings economic advantages for industrial productions. On the other hand, this technique does not offer high stability and might cause loss of biomolecules that is immobilized during washing and operation (Salleh et al. 2006).

Encapsulation and entrapment

The encapsulation process is based on the entrapment of the biomolecule in a polymeric matrix. The main advantage of this technique is that it allows the transport of low molecular weight (LMW) compounds through the permeable matrix (Guisan 2006). Entrapment matrix is generally formed during the immobilization process. Therefore, the properties of the gel matrix and the conditions used for the encapsulation should be compatible with the enzyme to be immobilized (Cao 2006). Among the immobilization methods applicable to plant cells, the most common and effective methods are entrapment or encapsulation of cells within a gel or in a solid support (Kuhtreiber et al. 1999).

Cross-linking method

Cross-linking is an immobilization technique that combines both covalent bonding and entrapment (Taylor and Schultz 1996). Immobilization by this method requires cross-linking agents such as glutaraldehyde and bisisodiacetamide (Panesar et al. 2010). The enzyme activity of immobilized preparations cross-linked with these reagents is dependent upon the degree of cross-linking (Arora 2003).

Covalent binding

Covalent binding is based on the formation of a covalent bond between the biomolecule and the support material (Kök et al. 2001a, b). Covalent binding causes a tight binding so the biomolecule to be immobilized does not separate from supports during utilization. Because of this strong interaction between enzyme molecules and supports, there is high heat stability. However, this interaction, unfortunately, does not allow the enzyme molecules to have free movement, resulting in decreased enzyme activity. Enzymes immobilized with this technique also can easily contact with substrates since the enzymes are localized on the surface of the support material. This technique is less effective for immobilization of cells, and support materials are not renewable (Aehle 2006).

Advantages and disadvantages of most commonly known immobilization techniques are demonstrated in Table 2.

Production systems designed with immobilized biocatalysts

Most of the bioprocess has no great significance if it is not applicable on industrial scale. Therefore, it is very crucial to scale-up a laboratory production into industrial production. Bioreactor is the main equipment that allows us to increase the production volume. Furthermore, as it was mentioned before, immobilization systems improve process quality, and therefore, using immobilization systems with bioreactors will increase overall process yield to the maximum values since a bioreactor allows us to have control on bioprocess variables. The selection and specific design of a bioreactor system include a series of decisions to take into consideration.

Immobilized enzymes are suitable to use in continuous systems and have easiness in separation from product for reuse or recycling. This easiness makes it possible to design continuously operated reactors with great advantage. Some of the continuously operated flow reactors, which are used frequently in bioprocess, are continuous stirred tank reactors, packed bed reactors, plug-flow reactors, and fluidized bed reactors.

Besides most commonly known reactor types as mentioned above, biocatalytic membrane reactors, immobilized liquid membrane systems, and biphasic systems are also very important for production by using immobilized biocatalysts. Each of these reactors has a specific use for a different process. It is essential to use appropriate reactor in order to get maximum performance (Rao 2010). Some examples of the use of immobilization biocatalysts in different production systems are listed below.

Continuous stirred tank reactors

The continuous stirred tank reaction (CSTR) consists of a well-stirred tank into which reactants flow continuously in a steady state. When CSTR is connected in series, it becomes more advantageous since there is considerably good mixing in each vessel, which consequently ensures that the volume in reactor is completely utilized for reaction, with no dead space (Denbigh and Turner 1984). The CSTR is widely used for industrial-scale production; however, in case of small-scale operations batch processing is preferred for a better production. Moreover, the continuous operation results in more stable products, better energy consumption, and higher productivity.

In a recent study, pretreated sludge was inoculated into a CSTR as an activated sludge immobilized bioreactor by using granular activated carbon as support material for biohydrogen production (Wei et al. 2012). It was found that both biogas and hydrogen yields in CSTR increased with organic loading rate at the range of 8–24 days. The granular activated carbon offered a stable biohydrogen-producing system and could be used as efficient support material for fermentative biohydrogen production with CSTR.

Another comparative study was done by using immobilized bioreactor system and CSTR with suspended cell culture. Production of biohydrogen by immobilized cells on ceramic balls showed higher volumetric hydrogen production and had more resistance to cell-washout, whereas CSTR with suspended cells lost high amount of biomass. Five-fold more volumetric hydrogen production was achieved in 8-fold smaller bioreactor with immobilization system (Keskin et al. 2012).

Packed bed reactors

A packed bed reactor is, by far, the most commonly used immobilized cell reactor in industry (Katchalski-Katzir 1993). These reactors have a simple design and consist of a column, which is packed with biocatalysts and is continuously perfused by the liquid phase. Consequently, many different materials for cell adsorption, even those that are fragile, can be used in packed bed reactors (Nedovic and Willaert 2004).

Clostridium beijerinckii cells were immobilized on ceramic rings and pumice stones in a packed bed bioreactor for production of 1,3-propanediol (1,3-PDO) by using raw glycerol as substrate obtained from a biodiesel production process. Another control bioreactor was operated with suspended cells for comparative analysis. It was observed that cell immobilization had better robustness and reliability compared to suspended cells. Production in packed bed bioreactor designed with immobilization system achieved 2.5-fold higher productivity compared to free system, which had advantageous properties over free cell system (Gungormusler et al. 2011). The production of lactose with β-d-galactosidase in a packed bed bioreactor was studied with immobilized yeast cells in calcium alginate gel (Panesar et al. 2010). It was observed that immobilization helped to overcome the problem of poor permeability of the cell membrane to lactose. The designed bioreactor system was economically viable and allowed high hydrolysis of milk lactose.

A horizontal packed bed bioreactor with a free space above the gel bed was designed to reduce CO2 gas hold-up in the continuous production of ethanol by immobilized yeast cells. It was concluded that the horizontal packed bed bioreactor was 1.5 times more productive than vertical one during continuous operational conditions. Immobilized yeast cells also reached steady state much earlier. Results showed that the horizontal packed bed bioreactor could be utilized as a very promising bioreactor system for the economic production of ethanol (Shiotani and Yamane 1981).

Plug-flow reactors

In a plug-flow reactor (PFR), all reactants are assumed to move through the reactor with no mixing and each particle at constant velocity (Harriott 2002). Concentration rate varies along the length of the reactor and can be related to reaction time. The plug-flow reactors yield higher conversions and this gives equal residence times; however, the plug-flow reactor is more difficult to control. Recycle reactors are mostly plug-flow reactors and are used for faster conversion (Bronzino 2000).

There are a few studies done with immobilization systems in plug-flow bioreactors; however, most of them are not up-to-date due to other novel immobilized reactor systems, which have gained importance recently. β-galactosidase was immobilized in cobalt alginate beads by entrapment for production in plug-flow reactor. The immobilization method in this reactor system resulted in high activity and good physical-chemical characteristics. The use of this method also was considered cheap and applicable for industry by appropriate optimization of reactor (Ateş and Mehmetoğlu 1997). Alcohol dehydrogenase from Lactobacillus brevis was immobilized on amino-epoxy support to evaluate storage and process stability during production in a plug-flow reactor. Production of (R)-phenylethanol from acetophenone could be operated over 10 weeks with great enzyme utilization in a plug-flow reactor (Hildebrand and Lutz 2006).

Fluidized bed reactors

In fluidized bed reactor, the catalysts are placed in a vessel that has a porous plate at the bottom, in which reactant gases pass. As the gas velocity is increased, the bed becomes fluidized and as a result, the volume is increased and gas bubbles become invisible. Different from fixed bed reactors, fluidized bed reactors allow feeding additional catalyst at the top of the reactor (Ross 2011). The excellent heat transfer is considered as one of the main benefits of this type of reactor that allows a safe and efficient reactor operation even for highly exothermic reactions (Tóta et al. 2010).

Fluidized bed reactor was operated for the removal of estrogens by immobilized laccase on Eupergit® supports in order to increase the degradation yields and enzyme stability as a comparative analysis with packed bed reactors. During 16 days of run time, high removal level and significantly improved stability of the biocatalysts were achieved with this reactor system (Lloret et al. 2012). A comparative analysis was performed for the biodiesel production by immobilized lipase from Rhizopus oryzae in magnetic chitosan microspheres in a magnetically stabilized fluidized bed reactor (MSFBR) and conventional fluidized bed reactor. MSFBR showed better reusability of magnetic particles and higher productivity compared with traditional reactor. The magnetic applied in the MSFBR improved the yield of microsphere for a more efficient immobilization (Zhou et al. 2014).

Biocatalytic membrane reactors

Compared to inorganic catalysts, biocatalysts such as enzymes and cells offer better catalytic action and enhanced stability under extreme conditions like pH, pressure, and temperature. After the solid-phase biochemistry became common, the use of immobilized biocatalysts for homogeneous phase systems increased for cheap novel bioprocesses.

Synthetic membranes are ideal supports for immobilization of biocatalysts owing to their greater surface per volume ratio (Drioli and Giorno 1998). Immobilized enzymes have been used primarily in fixed bed reactors. The membrane reactors have a great use with enzyme immobilization. The system has a semipermeable membrane, which physically separates the enzyme from the substrate and product. This function of membrane reactors allows the microbial contamination to be controlled due to its high degree of permeability. These systems can be designed as it permits the passage of product through the membrane, while keeping the enzyme with sufficient substrate in the reaction vessel or it permits limited passage of substrate and product through the membrane as the enzyme circulates on the catalysts side of the membrane. The last design of this system, which might be the most important for immobilization, permits the enzyme to be immobilized within the membrane and reaction takes place as the substrate passes through the membrane with no diffusion limits (Uhlig 1998).

Compared to fixed or fluidized bed reactors, biocatalytic membrane reactors present several advantages as described by Mohanty and Purkait (2011). Since the product is continuously taken out from the system, it makes it more suitable against product inhibition. The membranes used in these systems have enough thickness compared to the bed length of bed reactors; therefore, the pressure difference through the membrane is reduced. The mass transfer is also increased due to interaction between enzyme and substrate because of controlled convection.

A novel approach was proposed for the treatment of biomass by using immobilized lipase in polyether sulfone hollow fiber membrane in order to develop a two separate phase biocatalytic submerged membrane reactor. Besides this membrane system, the submerged biocatalytic membrane reactor was run for the production of valuable components from waste biomass. After the optimization of parameters, immobilized enzyme-loaded membrane showed high performance and worked efficiently with waste oils production while same system separated glycerides hydrolysis reaction products successfully (Chakraborty et al. 2012).

The tetracycline as a recalcitrant pollutant was eliminated from aqueous solutions by immobilized laccase from Trametes versicolor in a biocatalytic membrane reactor. The degradation yield of tetracycline in water solutions was 56 % in membrane reactor system with immobilized biocatalysts, while it was only 30 % with free laccase. Immobilized enzyme represented good reactivity and stability. Additionally, the biocatalytic membrane reactor had a constant degradation rate of 0.34 mg/h of tetracycline during 10 days of operation without activity loss (Cazes et al. 2014).

Immobilized liquid membranes

A polymer support integrated with a viscous solution of carrier is the main components of immobilized liquid membrane systems. Various polymer supports have been used for immobilized liquid membranes such as cellulose acetate reverse osmosis membrane, microporous polypropylene ultra filtration membrane, polyvinylchloride filter, or hollow fiber membranes. Two critical problems have to be considered in design of immobilized liquid membranes: loss of solvent and loss of carrier (Araki and Tsukube 1990).

Immobilized liquid membranes can be designed in different geometrical forms. Flat sheet Industrial Laser Module can be handy for small-scale applications; however, the surface area-to-volume ratio is considerably low for industrial use. Spiral-wound and hollow-fiber industrial laser modules have bigger surface area-to-volume ratio compared to flat sheet industrial laser modules, which makes it viable for industrial use. The chemical stability of carrier and mechanical stability of porous support are two important parameters to take into consideration for immobilized liquid membrane design (Kislik 2009).

An immobilized liquid membrane system was designed by using ionic liquid and polyvinylidene fluoride (PVDF) hollow fiber as a support material to improve the CO2 permeability and stability of the liquid membrane for CO2/N2 separation. PVDF presents favorable characteristics such as electrical and chemical resistance, stability, and low superficial energy (Akashi and Kuroda 2015). The support material used for immobilization affected the feed pressure of system differently. The system used showed high CO2 permeability. Immobilized membrane system also showed good stability at increasing pressure values (Kim et al. 2011).

Biphasic systems with immobilized biocatalysts

The aqueous biphasic system (ABS) has been used as an alternative to conventional liquid-liquid extraction techniques (Albertsson 1986). ABS consists of two aqueous phases based on polymer-polymer, polymer-salt, or salt-salt combinations (Freire et al. 2012). ABS is mostly composed of water, which this property drives attentions to these systems as they are biocompatible media for biocatalysts and can be easily used for the separation and purification of these biocatalysts (Zaslavsky 1994).

Design of pure organic solvent systems have become very important since undesired non-enzymatic reactions in water/organic solvent systems occur all the time. As most of the proteins are insoluble in organic solvents, working with immobilized biocatalysts in liquid biphasic systems becomes necessary. Immobilization, besides enhancing stability of enzyme, also makes the separation of enzyme from reaction mixture easier (Carrea and Riva 2008). In most cases, the production carried out by using biocatalysts is limited because of low water solubility of substrate and product, which might also have high toxicity to the biocatalysts. Therefore, using biphasic systems with immobilized biocatalysts is often advantageous in order to enhance the efficiency of the biocatalytic process and the operational stability of the biocatalyst (Zhang et al. 2012a, b).

Diketoreductase from Acinetobacter baylyi is a carbonyl reductase that can reduce ethyl-6-(benzyloxy)-3,5-dioxohexanoate to ethyl 3R,5S-6-(benzyloxy)-3,5-dihydroxy-hexanoate, which can be used as an advanced intermediate for statin drugs. An aqueous-organic biphasic reaction system was created for an efficient use of this enzyme. This aqueous-organic biphasic system resulted in more efficiency in the reduction of ethyl-6-(benzyloxy)-3,5-dioxohexanoate than the simple aqueous system (Wu et al. 2011). Biphasic system presents excellent stereo selectivity resulting in high yield.

Dai and co-authors studied another biphasic system with n-octane-water (10:90, v/v) that was built for the biodesulfurization by immobilized Brevibacterium lutescens cells. Moreover, magnetic nano Fe3O4 particles with calcium alginate were also used for immobilization of these cells for biphasic system for enhancing the effect of biodesulfurization. n-Octane-water biphasic system with immobilized cells could be reused at least four times and could be applicable to other area of biocatalytic processes (Dai et al. 2014).

Industrial applications of the immobilized biocatalysts

Food industry

Immobilization of enzymes has a great importance in the processing and analyzing of foods (Khan and Alzohairy 2010). The numbers of the enzymes and biocatalysts have been used intensely in food industry mainly for starch processing, cheese making, food preservation, lipid hydrolysis and other applications. Immobilization of these enzymes has been recognizable for commercial use since immobilization improves yield of food processes and consequently, minimizing process cost (Breguet et al. 2010).

α-Amylase is an important industrial enzyme, mainly used in food industry for starch liquefaction process. The enzyme used in this process can suffer a lack of long-term operational stability and difficulty in recovery. α-Amylase immobilized onto ion-exchange resin beads showed better stability, and time required for starch liquefaction was improved significantly (Gupta et al. 2013). Another thermostable α-amylase from Bacillus licheniformis was immobilized by six different cross-linked enzyme aggregates for starch liquefaction. Among all, tert-butanol used as precipitant showed best performance for starch liquefaction. Immobilization technique did not alter V max of enzyme, however, increased the affinity of enzyme to substrate significantly (Torabizadeh et al. 2014).

The major problem in fruit industry is the browning of fruits and this is the main reason for quality loss during fruit juice processing, which is mostly caused by enzymatic reactions (Quevedo et al. 2009). Immobilization of pectinase using calcium alginate (Rehman et al. 2013), entrapment in polyvinyl alcohol (PVA) sponge (Esawy et al. 2013), immobilization in silica-coated magnetite nanoparticles (Mosafa et al. 2014), and magnetic cornstarch microspheres (Wang et al. 2013) were studied for juice production. It is showed that for immobilization stability, pH and temperature tolerance of enzyme were enhanced. Immobilization system also allowed the enzyme to be reused several times for juice production.

β-galactosidase is an important enzyme for food industry, and since it is an intracellular enzyme, the cells must be treated with chemical and physical agents to increase permeability prior to immobilization (Numanoğlu and Sungur 2004). β-Galactosidase was entrapped into calcium alginate for hydrolysis of lactose from milk and whey in batch process and as well as in continuous packed bed columns. Entrapped cross-linked concanavalin A-β-galactosidase complex offered high stability against physical and chemical denaturants. Retention of immobilized enzyme was found to be more efficient and this immobilization system could be employed efficiently in a reactor for the continuous conversion of lactose in the presence of milk and whey for food industry (Haider and Husain 2009).

Recombinant form of β-galactosidase originated from Bacillus stearothermophilus, was immobilized on a chitosan matrix using tris (hydroxymethyl) phosphine (THP) and glutaraldehyde to hydrolyze lactose of milk. As a result, THP-immobilized recombinant β-galactosidase had high thermostability and showed great advantage for potential industrial use to produce lactose-hydrolyzed milk (Chen et al. 2009).

Proteases are widely used in the food industry for deproteinization of protein-containing foods. Alkaline protease immobilization on cross-linked chitosan beads was performed for deproteinization of natural rubber. Compared to other techniques, using immobilized alkaline protease reduced the total nitrogen level in the rubber up to 96 % and enzyme system could be used five times without losing more than 10 % of the initial enzyme activity (Praserkittikul et al. 2013). A novel cysteine protease, Procerain B, was immobilized on glutaraldehyde-activated chitosan matrix by covalent attachment for use in food industry. The capacity of substrate loading and reusability were improved and even after tenth use, 50 % of enzyme activity remained (Singh et al. 2011).

Brewing industry

Brewing is considered as one of the oldest known fermentation process since 8,000 years ago. Then, in recent years, microbiologists concentrated on brewing process to understand the process more efficiently and helped us to develop the brewing industry, as we know it today (Leskosek-Cukalovic and Nedovic 2005). Brewing industry has already replaced traditional batch brewing operations with continuous batch, and the use of immobilized yeast cell systems in this industry became more common recently for a better industrial yield (Mensour et al. 1996).

Engineering problems like optimization of process or bioreactor geometry, unbalanced beer flavor that might alter cell physiology and cell aging, and unrealized cost of immobilization can be the possible reasons for failure of continuous production of beer by immobilized yeast cells in bioreactor systems (Branyik et al. 2005). Hence, there have been several studies to achieve these problems for beer production with high efficiency.

Immobilization systems have been used for high quality beer production. Using immobilization technology could favor the characteristics of beer such as color, flavor, and headspace compounds of stout beer. A comparative study was carried out for beer fermentation by using free and microencapsulated yeast cells in alginate. The velocity of the fermentation was not altered by immobilization. At the end of third day of batch fermentation, the amount of free viable biomass in the bioreactor with microencapsulated yeast had more secondary metabolism activity than free cells. However, immobilization does not alter the sensorial quality of the beer (Almonacid et al. 2012).

A cryotolerant Saccharomyces cerevisiae was immobilized on porous cellulosic material for maltose fermentation at 5–10 °C. Immobilized yeast cells completed the fermentation, while FC was unable to ferment maltose at this temperature. The presence of tubular cellulose as support material increased maltose uptake rate due to attraction by hydrogen bonding on cellulose surface (Ganatsios et al. 2014).

The use of cheap support material for immobilization is very essential for industrial production. S. cerevisiae was immobilized on winemaking residues and corncobs as support material for ethanol production. It was found that the support materials used for immobilization of yeast released nutrients into the medium, which favored the yeast development and ethanol production. Since the support materials are of low cost and available in large amounts, this immobilization could be an alternative and cheap technique for winemaking (Genisheva et al. 2011). The yeast S. cerevisiae was also immobilized in calcium alginate-magnetic nanoparticles, on chitosan-magnetite microparticles, and cellulose-coated magnetic nanoparticles for ethanol fermentation. The use of magnetic particles helped the cells to have more stability during extended fermentation time. Each support material altered the production differently; however, immobilization, in general, improved the ethanol yield in bioreactor (Ivanova et al. 2011).

Pharmaceutical

The pharmaceutical industry is eventually approving the importance of enzyme immobilization for its applications principally those related to biotechnology. Chemical industry that mostly processes heavy and non-sensible materials always tried to avoid the use of biocatalysts, which are considered sensible; however, it has concentrated on studies related with immobilized enzymes for biotechnological products (Katchalski-Katzir 1993).

There are several important enzymes used in pharmaceutical industry like cysteine proteinases, asparaginase, streptokinase, urokinase, deoxyribonuclease I, hyaluronidase, pegademase, and glucocerebrosidase. Immobilization of penicillin amidase is the major applications of immobilized enzymes used in this industry (Parmar et al. 2000; Brar et al. 2014).

Penicillin is the most widely used antibiotics, due to their great spectrum of antibacterial activity, low toxicity, and inhibitory effect on bacterial cell wall synthesis and it shares about 19 % of the estimated worldwide antibiotic market (Parmar et al. 2000). Therefore, penicillin G acylase (PGA) that catalyzes the hydrolysis of penicillin G to produce 6-aminopenicillanic acid (6-APA) is very essential for the production of semisynthetic penicillin. It is also important to create efficient methods for immobilization of PGA for high activity and stability to make it viable for industrial applications. Immobilization of PGA on immobilized metal affinity membrane (IMAM) showed more PGA activity compared to those immobilized metal affinity resin. Immobilization gave stability to PGA in the pH range from 7 to 9 and for temperatures from 40 to 60 °C. Immobilization also allowed the enzyme to be reused 16 times and caused very little activity loss after 40 days of storage (Chen et al. 2011).

Penicillin G acylase was also immobilized in macro-mesoporous silica spheres prepared with a micro-device. The silica spheres containing PGA were placed into a packed bed reactor in order to perform penicillin G production (Zhao et al. 2011). Macropores of silica spheres allowed high enzyme loading amount and lower internal mass transfer resistance. Immobilized enzymes also showed great stability during production (Zhao et al. 2011). The production of 6-aminopenicillanic acid was also carried out by isolated bacterial cells immobilized on κ-carrageenan. The system allowed the continuous production of 6-APA from penicillin G by repeated use of bacterial cells (Dolui et al. 2011).

Besides 6-APA, the production of 7-aminodeacetoxycephalosporanic acid (7-ADCA), 7-aminocephalosporanic acid (7-ACA), and deacetyl-7-aminocephalosporanic acid (D-7-ACA) has great importance since they can be utilized to synthesize almost all semisynthetic antibiotics of penicillins or cephalosporins. It should also be noted that synthesis of these antibiotics has been performed via biocatalysts instead of chemical methods because of health and environmental issues (Sio and Quax 2004).

Enzymatic production of D-7-ACA was performed from cephalosporin C (CPC) by using immobilized cephalosporin C acylase and deacetylase. Cephalosporin C acylase (CPCA) and cephalosporin C deacetylase (CAH) were immobilized by coupling. In order to complete the process, immobilized CPCA was used for hydrolysis of CPC to 7-ACA, then immobilized CAH was used for deacetylation of 7-ACA to D-7-ACA. As a result, 78.39 % of yield for D-7-ACA was achieved in 30 min in a single reactor. The specific productivity of D-7-ACA was increased 4-fold, and this enzymatic process was repeatable and stable. The half-times of immobilized CPCA and CAH were 18 and 534 h, respectively. Results obtained showed that the industrial application of this process could be feasible and advantageous (Ma et al. 2014).

d-Amino acid oxidase is an important industrial enzyme for the synthesis of fine chemicals. Free d-Amino acid oxidase from Trigonopsis variabilis (TvDAO) is very sensitive to exposure to gas–liquid interfaces. Immobilization systems can enhance stability under bubble aeration and eliminate this challenge. In order to achieve this challenge, a fusion protein between TvDAO and the positively charged module Zbasic2 was generated, and attached to oppositely charge of functionalized silica carrier. The immobilized enzyme was not sensitive anymore to bubble aeration and had over 10-fold enzyme activity stabilization compared to free enzyme. The system created also allowed the reuse of the enzyme for d-amino acid oxidation (Bolivar and Nidetzky 2012).

d-Amino acid oxidase was also immobilized in a calcium alginate matrix by entrapment. The immobilized enzyme allowed the complete conversion of CPC. This entrapment technique also gave good operational stability to enzyme and retained 90 % of its initial activity. It can be concluded that entrapment in Ca-alginate matrix appeared to be an efficient method for antibiotics industry. Because of the availability of Ca-alginate and simplicity of the immobilization technique, this production can be considered economically viable (Wong et al. 2011).

Amino acids produced by biological methods are in the l-forms, whereas amino acids produced chemically are racemic mixtures of l- and d-isomers. One of the first studies on l-amino acid production by using aminoacylase immobilized on DEAE-sephadex by ionic binding, on iodoacetyl cellulose by covalent binding, and in polyacrylamide gel by entrapping. The production was compared between these three immobilized enzyme and free form of enzyme. The K m and V max values of free aminoacylase were 5.7 mM and 1.52 μmol/h, while these values were 8.7 mM and 3.33 μmol/h, 6.7 mM and 4.65 μmol/h, and 5.0 mM and 2.33 μmol/h for the enzyme immobilized on DEAE-Sephadex, on iodoacetyl cellulose and in polyacrylamide gel, respectively (Chibata et al. 1976).

l-Asparaginase is an important enzyme for pharmaceutical industry for acute lymphoblastic leukemia and lymphosarcoma treatment. l-Asparaginase and microorganisms that produce the enzyme have been immobilized in various support material for industrial use: Immobilization of the enzyme on polyaniline nanofibers matrix (Ghosh et al. 2012); immobilization of marine fungi in silica gel carrier (Sundaramoorthi et al. 2012); nanoencapsulation of the enzyme in chitosan-tripolyphosphate nanoparticles (Bahreini et al. 2014). All these studies showed that immobilization system decreased K m value of the enzyme and improved the reuse for further applications.

Another important enzyme for pharmaceutical industry is streptokinase, which is widely used in the treatment of deep vein thrombosis, pulmonary embolism, and acute myocardial infarction. The main challenge for the use of this enzyme is its short half-life in blood. Some immobilization systems have been tested to overcome this limitation: in chitosan nanoparticles (Modaresi et al. 2014), coupled onto PVC-g-PEGMA (Arenas et al. 2012).

Biomedical application

Use of enzymes in biomedical has been increasing since the mid-1950s. Recently, many enzymes have been isolated and purified for several productions, which has clinical importance. The immobilization of biocatalysts has been very attractive for biomedical applications (Reis and Román 2004). The use of immobilized enzymes in applied medicine has many promising advantages. The use of enzyme in natural form might have limitations for clinical use since they are unstable, have a short lifetime, cause toxic and immune reactions, and are expensive; however, immobilization techniques can eliminate these difficulties stated above (Torchilin 1987).

Polyphosphazenes are hybrid inorganic–organic polymers with tunable physicochemical and biocompatible properties, which give them a promising role in biomedical industry as biosensors, controlled release, drug delivery, scaffolding materials, and enzyme immobilization. A core/sheath nanofiber membrane was prepared by using poly [bis(p-methylphenoxy)] phosphazene (PMPPh) via a coaxial electrospinning process to investigate the system as a support material for enzyme immobilization because of its high biocompatibility, high surface/volume ratio, and large porosity. Lipase was immobilized on the nanofiber membrane by adsorption. With the adsorption capacity of 20.4 mg/g and activity retention of 63.7 % of the immobilized lipase, the nanofiber membrane system with polyphosphazenes showed great results to use for biomedical applications (Wang et al. 2012).

Egg-white lysozyme was immobilized onto electrospin chitosan nanofiber via cross-linked enzyme aggregates to use as for effective antibacterial applications. Chitosan nanofibers were designed from a mixed chitosan/PVA solution by the electrospinning method. Chitosan/PVA was treated with NaOH solution to increase stability of nanofibers. The immobilized lysozyme retained more than 75.4 % of its initial activity after 80 days of storage, whereas free lysozyme lost all of its activity under the same conditions. Immobilization also allowed the reuse of lysozyme 100 times. Immobilized lysozyme showed high antibacterial activity against four pathogenic bacteria (Park et al. 2013).

Acetylcholinesterase (AChE) and choline oxidase (ChO) were co-immobilized on poly-2-hydroxyethyl methacrylate (pHEMA) membrane for biosensor construction. Membranes prepared in the presence of SnCl4 showed good porosity and permeability to be used as the immobilization matrix. Immobilization of the enzymes was carried out both by entrapment and surface attachment via epichlorohydrin (Epi) and Cibacron Blue F36A (CB) activation. Activity of the enzymes was increased by immobilization significantly (Kök et al. 2001a, b).

Wastewater treatment

Biological wastewater treatment has been applicable in industry since the twentieth century. Immobilization of biocatalysts, especially microbial adhesion to surfaces, has been studied intensely for water pollution treatment (Bhamidimarri 1990).

Three bacterial strains were immobilized on a unique biofilm for acetonitrile-containing wastewater treatment. The biofilm system exhibited high resistance against acetonitrile loading and completely depleted the initial concentration of acetonitrile within 24 h in a bed-biofilm reactor. Results demonstrated that bacteria immobilized on biofilm can improve the degradation of contaminants in wastewater and can be considered as a novel technique for enhancing biological oxidation of toxic pollutants in wastewater (Li et al. 2013).

Horseradish peroxidase was immobilized in chitosan-halloysite hybrid nanotubes with cross-linking by using glutaraldehyde. Structure analysis showed that the hybrid nanotubes formed three-dimensional nanocomposites with high porosity. With this new support material, the maximum enzyme loading reached 21.5 mg/g, which is higher than the capacity of raw halloysite (3.1 mg/g). Immobilized horseradish peroxidase did not have loss in activity after 35 days of storage, while free enzyme retained only 27 % of its original activity in the same storage conditions. The results showed that the immobilized horseradish represented high overall phenol removal from wastewater (Zhai et al. 2013).

Support matrices used for immobilization might have high cost for process; therefore, it is important to choose economic matrices. The use of bagasse, coconut coir, loofah sponge, and gunny bag (Jute) as cheap matrices for immobilization of Aspergillus terreus viz had positive results. A. terreus immobilized on the listed matrices showed great reduction in biological oxygen demand (BOD) and chemical oxygen demand (COD). Among all matrices, gunny bag (Jute) was the most efficient immobilizing material for A. terreus to decrease the pollution level and remediation of the effluent. Results showed that the strain A. terreus was not only useful for discoloration (dye adsorption) but also for degradation of other organic wastes that are present in the effluent (Jogdand et al. 2012).

Textile industry

The use of enzymes in textile industry is a fast-growing market and gaining importance due to their non-toxic and ecological properties (Mojsov 2011). Principal enzyme used in textile is cellulase for denim finishing and cotton softening, amylase for de-sizing, pectate lyase for scouring, catalase for bleach termination, laccase for bleaching, and peroxidase for excess dye removal (Kirk et al. 2002).

Commercial acid cellulases were immobilized on chemically modified pumices particles by ZrOCl2—adsorbed efficiently to abrade indigo dyed denim fabrics. The immobilization, in all treatments, increased process efficiency and allowed the enzyme to be used repeatedly (Pazarlioğlu et al. 2005).

Lipase is an industrially important enzyme, which is commercially available, for its applications in textile industry. Immobilization of lipase from porcine-pancreas onto zirconia coated alkylamine glass beads by glutaraldehyde coupling was carried out for better washing of cotton cloth. Immobilization process altered its physical properties compared to natural form and the chosen support material resulted in maximum enzyme activity for this production (Malik et al. 2000).

Peroxidase is widely used for treatment of industrial effluent. Bitter gourd peroxidase obtained from Momordica charantia entrapped into calcium alginate-starch for the treatment of a textile industrial effluent in batch and continuous reactor showed great effectiveness for this type process. Entrapped enzyme retained 59 % effluent decolorization ability even after its tenth repeated use. This immobilization system can be applied with success for treating industrial effluents at large scale (Matto and Husain 2009).

Laccase originated from T. versicolor was immobilized reversibly by adsorption on poly (4-VP) grafted and/or Cu (II) ions chelated magnetic beads. The reusability of the magnetic beads as support can provide economic advantages for large-scale applications (Bayramoğlu et al. 2010).

Detergent industry

The use of enzymes in detergent industry has been increasing and most of the detergents recently produced by industry contain enzymes. The use of enzymes as detergent additives represents the largest application of industrial enzymes (Kirk et al. 2002).

One enzyme used in detergent industry is the alkaline protease produced from bacterial sources, and mutations that occurred in bacteria can lead to newer protease preparations with higher catalytic efficiency and more stability in high temperatures or in presence of oxidizing agents and consequently more efficient wash conditions (Gupta et al. 2002). Enzymes like amylases (Gupta et al. 2003), lipases (Hasan et al. 2006) and cellulases (Cullinan et al. 2000) are the most commonly used enzymes in detergent industry since they comprise high catalytic activity.

α-Amylase was immobilized on the silica nanoparticles to evaluate cleaning performance as a detergent powder for removal of starch soils. Since a detergent contains several compounds that might affect activity, stability, and cleaning performance of enzymes negatively, therefore, using immobilization techniques might prevent this problem. Immobilized α-amylase on silica nanoparticles showed increased cleaning efficiency for starch soil removal from cotton fabrics compared whereas free enzyme had small effect on the enzyme activity against the same soil. Immobilization also enhanced stability of enzyme against temperature and humidity (Soleimani et al. 2012).

An alkaline protease production from Bacillus megaterium MTCC2444 immobilized in Ca-alginate by entrapment was studied to enhance enzyme production to use in detergent industry. Protease produced by immobilized cells presented good stability in the presence of oxidants, surfactants, and commercial detergents. Immobilized cells produced enzyme with 1.5-fold more yield compared to free cells. Gel concentration and bead diameter were important parameters that affect the production of enzyme (Mrudula and Shyam 2012).

In other study, commercial α-amylase from Aspergillus niger, cellulase from Trichoderma viride, protease and lipase from porcine pancrease, as a mixture of enzymes mostly used in detergent industry, have been co-immobilized covalently onto a plastic bucket and brush for evaluation of their performance in cloth washing (Pundir and Chauhan 2012). Optimal pH, incubation temperature, maximum activity, and K m were altered due to the immobilization process. The higher conjugation yield was achieved on the brush than on beaker wall since brush had more surface area. In order to evaluate the performance, immobilized enzymes were utilized to wash starch, grass, egg albumin, and oil-stained cotton cloth pieces, and their performance was compared with detergents with no presence of immobilized enzymes. The combination of any detergent containing immobilized enzymes gave better washing (Pundir and Chauhan 2012).

Biodiesel production

The energy demand is increasing significantly in whole world due to technological developments that favor our life. Since fossil fuels are limited and running out, new researches are compulsorily directed toward alternative energy sources.

Biodiesel is an alternative diesel fuel, which is produced by renewable biological sources such as vegetable oils and animal fats (Ma and Hanna 1999). More technical definition of biodiesel would be the mono alkyl esters of long fatty acids derived from renewable lipid feedstock such as vegetable oils or animal fats, for use in compression ignition (diesel) engines (National Biodiesel Board 1996). Transesterification process, which involves altering the chemical properties of the oil by using methanol, is the most common method to produce biodiesel among other processes: blending, microemulsions, and thermal cracking, respectively (Ma and Hanna 1999). Transesterification of plant oils with methanol is a relatively simple process that yields high conversions with only glycerin as a by-product (Conley 2006).

The necessity of bringing down the cost of an enzymatic production is very high if enzymes are to be competitive on the worldwide enzyme market. Free enzymes are cheaper than immobilized ones due to the difficulties of immobilization process. It is crucial to know if the enzymes used for biodiesel production require immobilization (Fjerbaek et al. 2009).

Several immobilized enzymes have been commercialized to use for biodiesel production: Novozym 435 from Candida antarctica immobilized on a macroporous acrylic resin; Lipozyme RM IM from Rhizomucor miehei immobilized on an anionic resin; and Lipozyme TL 1 M from Thermomyces lanuginosus immobilized on a gel of granulated silica (Zhang et al. 2012a, b). In addition, immobilized lipases, as an important enzyme used for biodiesel production, have been used commercially.

Lipase was immobilized synthesized meso-structured onion-like silica for biodiesel production in Nanoscale Enzyme Reactors (NERs). Immobilization was performed via adsorption and subsequent enzyme cross-linking. As a result, NERs increased the enzyme stability and enzyme loading. Immobilized lipase in NERs represented more stability during 40 days but free cells showed a rapid inactivation. Specific activity of immobilized lipase was higher than free cells (Jun et al. 2012).

Immobilization by using multiple support material can increase the efficiency of biodiesel production process. Immobilization of lipase from Burkholderia cepacia for the first time by cross-linking with glutaraldehyde followed by entrapment in a hybrid matrix of equal proportions of alginate and κ-carrageenan had advantageous results. At the optimal conditions, 100 % yield of fatty acid ethyl esters was achieved. The immobilized lipase was stable and even continued with 73 % relative transesterification activity after six cycles of reuse. It can be conclude that the immobilized lipase in alginate/κ-carrageenan matrix has a potential and environmental friendly use for biodiesel industry (Abdulla and Ravindra 2013).

Lipase, for being the most known enzyme for biodiesel production, has been tested with various support material for immobilization: Immobilization of microbial lipase on PVDF membrane (Kuo et al. 2013); onto olive pomace by covalent binding (Yucel 2011); and on hydrophobic magnetic particles (Liu et al. 2012a, b). In each study after biodiesel production, immobilized lipase showed no or negligible activity loss and high biodiesel yield was obtained.

Besides enzyme immobilization, cells also have been immobilized for biodiesel production. R. oryzae ATCC 9374 was immobilized as a whole-cell biocatalyst within biomass support particles (BSPs), and process efficiency was compared with Novozym 435, which is considered as the most effective extracellular immobilized lipase for methanolysis of soybean oil in solvent free system for biodiesel production. The maximum methyl esters content in the reaction mixture was obtained by using R. oryzae as whole-cell biocatalyst, which was significantly comparable with yield of biodiesel obtained with Novozym 435. The immobilized R. oryzae was available for reuse in different batch cycles. As a conclusion, the use of whole-cell biocatalysts immobilized within BSPs and treated with glutaraldehyde solution might favor industrial biodiesel fuel production (Hashemizadeh et al. 2011).

Pulp and paper industry

Pulp and paper industry, as well as in wastewater treatment, generate by-products with high amount of BODs and CODs. There are specific challenges that have not yet been eliminated such as the removal of brown color of the effluent, which might cause decreased oxygen concentration (Kingstad and Lindstom 1984). Biological treatment has several advantages over the physical and chemical methods since these methods have high cost (Ragunathan and Swaminathan 2004).

Immobilized biocatalysts can enhance the removal of many effluents in pulp and paper industry. Two basidiomycetous fungi and a deuteromycetous fungus isolated from effluents of a pulp and paper mill were immobilized on a nylon mesh, as a study reported the first time to analyze the bioremediation efficiency in a continuously bench-top bioreactor. Within the first 24 h of the treatment, immobilized fungi reduced the color, lignin, and COD of the effluent with high efficiency (Malaviya and Rathore 2007).

Chlorophenols are considered as important pollutants in industrial wastewater treatment especially from the pulp and paper industry. Peroxidases from horseradish and soybean were immobilized covalently onto aldehyde glass through their amine groups. Activity of free and immobilized peroxidases was compared for their ability to remove chlorophenol from aqueous solutions. It was found that immobilized enzymes had higher removal percentages than free cells and needed shorter treatment time (Bódalo et al. 2008).

Another study for phenol removal was performed by using laccase from Streptomyces psammoticus immobilized in alginate beads by entrapment method in batch experiments using packed bed bioreactor. The immobilized system removed most of the color and total phenol and maintained 50 % of its efficiency after eight runs (Niladevi and Prema 2008).

Removal of pitch particles originating from alkaline peroxide from whitewater during papermaking is a critical issue to be solved. In order to degrade pitch particles, lipase was immobilized on chitosan beads. The immobilized lipase showed high operational stability and reduced pitch particles present in whitewater. Immobilization increased V max of free lipase (46.7 U/ml) to 2,500 U/ml (Liu et al. 2012a, b).

Oxalate is a by-product in bleaching processes and forms calcium oxalate, which causes problems in the pulp and paper industry. Oxalate decarboxylase, an oxalate degradation enzyme, was covalently immobilized to Eupergit® C in order to decrease oxalate level in paper industry. The immobilized enzyme showed more stability at lower pH and higher temperatures compared to soluble enzymes (Lin et al. 2011).

Conclusions

Instability and high sensibility of enzymes or biocatalysts led to many bioprocess difficulties since the beginning of modern biotechnology. Immobilization has been a promising technology for both laboratory research and industrial-scale production and proposed several commercial solutions in order to eliminate these difficulties and achieve a long-term profit for industry. Through the recent intelligent design in techniques and support material, immobilization technology will enable a rapid fascinating advance in several industrial applications by bringing down the overall cost and increase the yield. Indeed, immobilization can be improved for the production of molecules with industrial importance. As a result, all these future advances in immobilization will allow us to have innovative solutions against the problems that make production difficult.

References

Abdulla R, Ravindra P (2013) Immobilized Burkholderia cepacia lipase for biodiesel production from crude Jatropha curcas L. oil. Biomass Bioenergy 56:8–13

Aehle W (2006) Enzymes in industry: products and applications. John Wiley & Sons pp 73

Aguilera JM, Barbosa-Cánovas GV, Simpson R, Welti-Chanes J, Bermúdez-Aguirre D (2010) Food engineering interfaces. Springer pp 121

Akashi N, Kuroda S (2015) Preparation and characterization of protein A-immobilized PVDF and PES membranes. Express Polym Lett 9(1):2–13

Akin C (1987) In: Russell GE (ed) Biotechnology and Genetic engineering reviews: biocatalysis with immobilized cells 5(1):319–367

Albertsson PA (1986) Partitioning of cell particles and macromolecules, 3rd edn. Wiley, New York

Almonacid SF, Nájera AL, Young ME, Simpson RJ, Acevedo CA (2012) A comparative study of stout beer batch fermentation using free and microencapsulated yeasts. Food Bioprocess Technol 5(2):750–758

Amaral AC, Felipe MS (2013) Nanobiotechnology: an efficient approach to drug delivery of unstable biomolecules. Curr Protein Pept Sci Curr 14:588–594

Araki T, Tsukube H (1990) Liquid membranes: chemical applications. CRC Press pp 35

Arenas E, Castillón FF, Farías MH (2012) EDC and sulfo-NHS functionalized on PVC-g-PEGMA for streptokinase immobilization. Des Monomers Polym 15(4):369–378

Arora DK (2003) Handbook of fungal biotechnology. CRC Press pp 294

Ateş S, Mehmetoğlu Ü (1997) A new method for immobilization of β-galactosidase and its utilization in a plug flow reactor. Process Biochem 32(5):433–436

Atkinson B, Black GM, Pinches A (1980) Process intensification using cell support systems. Process Biochem 15:24–32

Bahreini E, Aghaiypour K, Abbasalipourkabir R, Mokarram AR, Goodarzi MT, Saidijam M (2014) Preparation and nanoencapsulation of l-asparaginase II in chitosan-tripolyphosphate nanoparticles and in vitro release study. Nanoscale Res Lett 9(1):1–13

Bayramoğlu G, Yilmaz M, Arica YM (2010) Reversible immobilization of laccase to poly-4-vinylpyridine grafted and Cu (II) chelated magnetic beads: biodegradation of reactive dyes. Bioresour Technol 101(17):6615–6621

Bhamidimarri SMR (1990) In: Tyagi RD, Vembu K (ed) Wastewater treatment by immobilized cells. CRC Press pp 30

Bódalo A, Bastida J, Máximo MF, Montiel MC, Gómez M, Murcia MD (2008) A comparative study of free and immobilized soybean and horseradish peroxidases for 4-chlorophenol removal: protective effects of immobilization. Bioprocess Biosyst Eng 31(6):587–593

Bolivar JM, Nidetzky B (2012) Oriented and selective enzyme immobilization on functionalized silica carrier using the cationic binding module Zbasic2: design of a heterogeneous d‐amino acid oxidase catalyst on porous glass. Biotechnol Bioeng 109(6):1490–1498

Branyik T, Vicente AA, Dostalek P, Teixeira JA (2005) Continuous beer fermentation using immobilized yeast cell bioreactor systems. Biotechnol Prog 21(3):653–663

Brar SK, Dhillon GS, Fernandes M (2014) Biotransformation of waste biomass into high value biochemicals. Das D, Goyal AIn: (ed) Pharmaceutical enzymes Springer pp 367–387

Breguet V, Vojinovic V, Marison IW (2010) In: Zuidam NJ, Nedovic V (ed) Encapsulation technologies for active food ingredients and food processing pp 367

Brodelius P, Nilsson K (1980) Entrapment of plants cells in different matrices: a comparative study. FEBS Lett 122(2):312–316

Bronzino JD (2000) Biomedical engineering handbook. Vol 2 CRC press pp X4

Cao L (2006) Carrier-bound immobilized enzymes: principles, applications and design. John Wiley & Sons pp 131

Carrea G, Riva S (2008) Organic synthesis with enzymes in non-aqueous media. John Wiley & Sons pp 216–222

Cazes M, Belleville MP, Petit E, Llorca M, Rodriguez-Mozaz S, Gunzbrurg J, Barcelo D, Sanchez-Marcano J (2014) Design and optimization of an enzymatic membrane reactor for tetracycline degradation. Catal Today 236:146–152

Chakraborty S, Drioli E, Giorno L (2012) Development of a two separate phase submerged biocatalytic membrane reactor for the production of fatty acids and glycerol from residual vegetable oil streams. Biomass Bioenergy 46:574–583

Chen C, Ko YM, Shieh CJ, Liu YC (2011) Direct penicillin G acylase immobilization by using the self-prepared immobilized metal affinity membrane. J Membr Sci 380(1):34–40

Chen W, Chen H, Xia Y, Yang J, Zhao J, Tian F, Zhang HP, Zhang H (2009) Immobilization of recombinant thermostable β-galactosidase from Bacillus stearothermophilus for lactose hydrolysis in milk. J Dairy Sci 92(2):491–498

Chibata I, Tosa T, Sato T, Mori T (1976) Production of ʟ-amino acids by aminoacylase adsorbed on DEAE-sephadex. Methods Enzymol 44:746–759

Cho GH, Cha YC, Yang DC, Moon HH (1981) Continuous ethanol production by immobilized yeast in a fluidized reactor. Biotechnol lett 11(3):667–671

Conley SP (2006) What is biodiesel? Purdue Extension Bioenerg series ID-336-337

Cullinan P, Harris JM, Taylor AJ, Hole AM, Jones M, Barnes F, Jolliffe G (2000) An outbreak of asthma in a modern detergent factory. Lancet 356(9245):1899–1900

Dai Y, Shao R, Qi G, Ding BB (2014) Enhanced dibenzothiophene biodesulfurization by immobilized cells of Brevibacterium lutescens in n-octane–water biphasic system. Appl Biochem Biotechnol 174(6):2236–2244

Darnall DW, Greene B, Henzl MT, Hosea JM, McPherson RA, Sneddon J, Alexander MD (1986) Selective recovery of gold and other metal ions from an algal biomass. Environ Sci Technol 20(2):206–208

Denbigh KG, Turner JCR (1984) Chemical reactor theory: an introduction. CUP Archive pp 64

Dolui AK, Sahana S, Kumar A (2011) Studies on production of 6-aminopenicillanic acid by free and κ-carrageenan immobilized soil bacteria. Indian J Pharm Educ Res 46(1):70–74

Drioli E, Giorno L (1998) Biocatalytic membrane reactors: applications in biotechnology and the pharmaceutical industry. CRC Press pp 51–52

Dumitriu S (2004) Polysaccharides: structural diversity and functional versatility. CRC Press pp 868

Esawy MA, Gamal AA, Kamel Z, Ismail AMS, Abdel-Fattah AF (2013) Evaluation of free and immobilized Aspergillus niger NRC1ami pectinase applicable in industrial processes. Carbohydr Polym 92(2):1463–1469

Fjerbaek L, Christensen KV, Norddahl B (2009) A review of the current state of biodiesel production using enzymatic transesterification. Biotechnol Bioeng 102(5):1298–1315

Freire MG, Claudio AFM, Araujo JMM, Coutinho JAP, Marrucho IM, Lopes JNC, Rebelo LPN (2012) Aqueous biphasic systems: a boost brought about by using ionic liquids. Chem Soc Rev 41(14):4966–4995

Ganatsios V, Koutinas AA, Bekatorou A, Kanellaki M, Nigam P (2014) Promotion of maltose fermentation at extremely low temperatures using a cryotolerant Saccharomyces cerevisiae strain immobilized on porous cellulosic material. Enzym Microb Technol 66:56–59

Genisheva Z, Mussatto SI, Oliveira JM, Teixeira JA (2011) Evaluating the potential of wine-making residues and corn cobs as support materials for cell immobilization for ethanol production. Ind Crop Prod 34(1):979–985

Ghosh S, Chaganti SR, Prakasham RS (2012) Polyaniline nanofiber as a novel immobilization matrix for the anti-leukemia enzyme l-asparaginase. J Mol Catal B Enzym 74(1):132–137

Goosen MFA (1992) Fundamentals of animal cell encapsulation and immobilization. CRC Press pp 301

Guisan JM (2006) Immobilization of enzymes and cells. Humana Press, Totowa, pp 5–78

Gungormusler M, Gonen C, Azbar N (2011) Continuous production of 1, 3-propanediol using raw glycerol with immobilized Clostridium beijerinckii NRRL B-593 in comparison to suspended culture. Bioprocess Biosyst Eng 34(6):727–733

Gupta R, Beg Q, Lorenz P (2002) Bacterial alkaline proteases: molecular approaches and industrial applications. Appl Microbiol Biotechnol 59(1):15–32

Gupta R, Gigras P, Mohapatra H, Goswami VK, Chauhan B (2003) Microbial α-amylases: a biotechnological perspective. Process Biochem 38(11):1599–1616