Abstract

In the present investigation, the ultrasound-assisted convective drying process for zucchini slices was studied. In this regard, the effects of convective air velocity (in three levels of 1, 2, and 3 m/s) and ultrasonic pretreatment time (in three levels of 0, 15, and 30 min) on drying kinetic, drying time, and qualitative characteristics of the dried product were investigated. Moreover, the effects of these independent variables on functional groups of dried zucchini slices were also studied using Fourier Transform Infrared spectroscopy (FTIR), and those on the microscopic structure of dried zucchini slices were investigated using Scanning Electron Microscopy (SEM). Based on the results obtained in this study, the ultrasonic pretreatment for 30 min and convective air velocity of 2 m/s are recommended for drying zucchini slices with optimal product quality and short drying time. Compared to untreated samples, less wrinkled tissues and more microscopic channels were observed in pretreated samples especially at 30 min sonication time. In terms of functional groups, there was no difference in the FTIR spectra at different levels of ultrasonic pretreatment time and convective air velocity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Zucchini (Cucurbita pepo L.) [1], as it is generally known in America, is recognized as “vegetable marrow” in Britain and “courgettes” in parts of Europe [2]. It is a small green squash or summer marrow with a similar shape to a ridged cucumber [1]. Zucchini is very low in calories, but it is rich in nutrients, particularly ascorbic acid, vitamins A and E, folic acid, calcium, potassium, iron, sodium, phosphorus, and magnesium [3]. Since zucchini is highly perishable [2], as one of the ancient procedures of food preservation, drying can extend its shelf life [4].

Drying process reduces the water activity of the dried product and consequently, its microbiological and chemical degradations. This process decreases the volume and weight of the product; as a result, the transportation and storage of the product will be simplified and also the cost of the transportation and storage will decrease [5, 6]. Dried zucchini snack can be considered as a functional food type with high amounts of fiber and bioactive compounds and with low level of lipid; moreover, it can diversify vegetable consumption [5]. In addition, dried zucchini can be consumed as seasoning mixes, soup mixes, casseroles [4], ready-made sacks, rice mixtures, bulgur, pet and bird food [3]. Another advantage of zucchini drying process is that when being fried, the dried zucchini slices consume less amount of oil than the non-dried ones do [7].

Convective drying with air at elevated temperatures [8] is the most common dehydration technique due to its control simplicity [9]. It offers the lowest investment cost and generally a simple setup, compared to any other available drying technique [8]. Nonetheless, convective drying speed is commonly very low [9] so, it takes a long period of time. Consequently, convective drying process is extremely energy consuming [10] with very high operating costs [11]. In other words, usual convective drying process consumes more than 25% of the energy used by industries in the developed countries [12]. In addition, it results in the cell structure breakdown of samples [13], and causes a negative impact on nutritional, physical, and chemical qualities of the final products [10]. Therefore, some developments are still required either in the drying process or in the applied pretreatments [14]. Convective hybrid drying assisted by additional processes, in particular, ultrasound pretreatment, can be used to overcome the problems associated with convective drying [9].

Ultrasound is sound waves with frequencies (from 20 kHz to 100 MHz [5]) above the audible frequency range of human [8]. The ultrasound waves with high power and low frequency (frequencies from 20 to 40 kHz) [15] lead to cavitation phenomenon (implosion of bubbles) in a liquid, resulting in micro mixing [5]. In addition, ultrasound pretreatment in solid–liquid systems can lead to various phenomena such as sponge effect (alternative expansions and compressions in the solid sample) [16], acoustic streaming [6], high shear forces [15], heating effect [17] and membrane damage of cells [15].

The central goal of this investigation was to study the effects of two independent variables of ultrasonic pretreatment time (0, 15, and 30 min) and air velocity (1, 2 and, 3 m/s) in an ultrasound-assisted convective drying method on the drying kinetics, drying time, and quality indicators of the dried zucchini slices. These quality indicators included the water absorption ability (WAA), the dried matter holding ability (DMHA), the rehydration capacity (RC), and the total color difference (ΔE). To the best of our knowledge, there has been no investigation on the interaction of these two independent variables in the drying process. In addition, Fourier Transform Infrared spectroscopy (FTIR) was applied to examine possible changes of functional groups of the dried zucchini slices processed by various treatments, and scanning electron microscopy (SEM) was used to investigate their microstructure.

2 Materials and methods

2.1 Sample preparation

To perform experiments, zucchinis were procured from a local market in Isfahan. The zucchinis were manually peeled using a knife. Then, they were cut by a food slicer (model Delmonti DL 610, Italy) to slices with a thickness of 5 mm. Blanching process was performed to prevent enzymatic browning reactions in boiling water (with a ratio of sample to boiling water equal to 1 to 6) for 6 min. The blanching time was obtained based on the peroxidase (Guaiacol) test [18]. In the end, samples were cooled down quickly to the ambient temperature with cold water. It should be noted that the initial moisture content of zucchinis slices was 95.50 ± 2.12%.

2.2 Ultrasonic pretreatment process

300 g of the blanched zucchini slices were put in a 1000 ml beaker, with a ratio of zucchini slices to distilled water equal to 1 to 3. Subsequently, the beaker containing the zucchini slices and distilled water was processed by the ultrasonic probe (Model UIP1000hd, Germany) with the constant frequency of 20 kHz, the ultrasound power of 1000 W at the temperature of 25 ± 5 °C and at the two ultrasonic time levels of 15 and 30 min. The beaker containing the zucchini slices and distilled water was put in a water container so that during the ultrasonic process, the temperature of the beaker content could be regulated by adding ice cubes to the water in the container. During the ultrasonic process, the ultrasound probe was placed to the depth of 1.5 cm into distilled water in the beaker. Moreover, the zucchini slices were put in a convective dryer immediately after blanching for treatments without ultrasonic pretreatment process (0 min ultrasound).

2.3 Convective drying treatment

After eliminating the surface moisture of the zucchini slices with tissue paper, about 200 g of the zucchini slices were placed on two metal perforated plates of the convective dryer as a single layer. The convective drying process continued at the temperature of 70 °C until a constant weight was obtained (final moisture content of 12.00 ± 2.83%). During drying process, the zucchini slices were weighted every 15 min by a digital balance (Kern, Germany with 0.01 g accuracy). In addition, the air velocity was checked by an anemometer (Model TES 1341, Taipei, Taiwan). In this study, three air velocity levels of 1, 2, and 3 m/s were investigated. Moreover, all the drying treatments were repeated at least in triplicate.

2.4 Procedures

2.4.1 Determination of moisture content (MC) and drying rate (DR)

To calculate the MC of the zucchini slices before and after each drying treatment, the hot air oven (Model ALFA INC 55, Iran) method was used at 70 °C until a constant weight was obtained. The MC was calculated based on a dry basis (kg water/kg dried matter) using Eq. (1) [19]:

where, W0 and Wd are the initial and the final sample weights (kg), respectively. The Eq. 2 was used to calculate the drying rate (DR) of the zucchini slices in kg water/ kg dry matter. Min [20]:

where, ∆t is the time changes (min), MCt and MCt + Δt stand for the moisture content (kg water/ kg dry matter) at the times t and t+∆t respectively. The dimensionless moisture ratio (MR) of the zucchini slices was calculated using Eq. (3) [19]:

where, MCt and MC0 are the moisture contents at time t and at the initial time (kg water/kg dry matter), respectively.

2.4.2 Shrinkage

Applying the liquid displacement technique with distilled water, the volume of the zucchini slices both before entry into the dryer and after finishing each convective drying treatment was investigated. Then, volume shrinkage was measured by Eq. (4) [21]:

where, V0 and Vf are the volume (cm3) of the zucchini slices before entry into dryer and after each convective drying treatment was finished.

2.4.3 Rehydration properties

To measure the rehydration parameters of the dried zucchini, the dried zucchini slices from each treatment were weighed. After that, they were immersed in distilled water (500 ml) with the temperature of 50 °C in a beaker with a volume of 1000 ml. The beaker was put in a water bath (Shimifan, Iran) with the temperature of 50 °C for 60 min. Next, the zucchini slices were separated from distilled water and their surface moisture content was removed using tissue paper. The zucchini slices were weighed and finally, in order to determine their dry matter content (S) (in percentage), they were dried in the oven at 70 °C [22]. Using Eqs. 5, 6 and 7, the water absorption ability (WAA), the dried matter holding ability (DMHA) and the rehydration capacity (RC) were calculated, respectively [23]:

where, S is the dry matter content of the dried zucchini slices (%), W denotes the weight of the dried zucchini slices, and the subscripts 0, d and r symbolize before dehydration, dehydrated and rehydrated modes of the zucchini slices, respectively. The range of WAA, DMHA and RC is from zero to one. It is interesting to mention that the more changes and destruction of product during drying, the smaller these indices will be [24].

2.4.4 Total color difference (ΔE) parameter

A chromameter (Model TES-135A, Taiwan) was used to measure the L, a, and b color scales of the above surface of the zucchini slices before entry into dryer and after each convective drying treatment was finished. The L color parameter is in the range of 0 (blackness) to 100 (whiteness). Furthermore, the color parameter of a ranges from -a (greenness) to +a (redness), and the color parameter of b is in the range of -b (blueness) to +b (yellowness) [25]. In this study, the total color difference (ΔE) was measured using Eq. 8 [21]:

where, Δ indicates the L, a, and b color parameter differences of the zucchini slices before entry into dryer and after each convective drying treatment was finished. It should be noted that for maximum accuracy, at least six zucchini slices were used for color determination of each treatment.

2.4.5 Fourier transform infrared spectroscopy (FTIR)

The FTIR test was performed to determine the functional groups of the dried zucchini slices and to study the probability of destruction of these functional groups during sonication pretreatment at three time levels of 0, 15, and 30 min, and during convective drying treatment at three air velocity levels of 1, 2, and 3 m/s. In order to perform this test, potassium bromide (KBr) and the powder of the dried zucchini slices were mixed together with the ratio of 100:1, and a pallet of them was prepared. The resulting pallet was then placed in a FTIR apparatus (Spectrum 65, PerkinElmer, U.S.A). The spectra of the samples were obtained in a region of 450–4000 cm−1 with 4 cm−1 spectral resolution [26] .

2.4.6 Scanning Electron microscopy (SEM)

SEM images were prepared in order to study both the microscopic structure of the dried zucchini slices and the possible microscopic changes obtained from selected treatments using SEM instrument (EM3200, KYKY, Beijing, China) at 25 kV voltage with magnification of 500 times [27]. A gold deposition device (Model SBC12, KYKY, Beijing, China) was used to deposit a thin layer of gold on the surface of the dried zucchini slices [28] before taking the SEM images.

2.5 Statistical procedure

Statistical examination was conducted using a factorial design with two independent variables, the first of which consisted of 3 levels of ultrasonic pretreatment time (0, 15 and 30 min) and the second one included 3 levels of air velocity (1, 2 and 3 m/s). Statistical software of SAS 8.0 was used for variance analysis of the data. Moreover, a comparison of the means of dependent variables was made using the Least Significant Difference (LSD) technique at 5% probability level (p ≤ 0.05). It is worth mentioning that treatments were repeated three times, and the presented data are presented as mean ± standard error (SE).

3 Results and discussion

3.1 Drying time

According to Table 1, the effects of ultrasonic pretreatment time (p≤0.001), air velocity (p≤0.001) and interaction of ultrasonic time and air velocity (p≤0.01) on the drying time of the zucchini slices are statistically significant. As observed in Table 2, those without ultrasonic pretreatment time (0 min) have the highest drying time (161 ± 4.35 min), and the ones with 30 min ultrasonic pretreatment time have the lowest drying time (134 ± 2.66 min). Therefore, by increasing the ultrasound time from 0 to 30 min, the drying time decreased by 16.77% (p≤0.001). This phenomenon is explained in some other papers. For example, it is reported that by applying ultrasound for eggplant drying, the convective drying time was significantly reduced due to an intense inducing stress in the internal microstructure of eggplant, which could result in a faster rate of moisture removal from the matrix and the noteworthy increase in the effective diffusivity [35]. Furthermore, the reduction in the drying time when ultrasound is applied can be linked to mild destruction in the protein structure, leading to less hardening degree of the tissue [36]. Moreover, it was reported that the sonication process for convective drying of apple [37] and strawberry [12] decreased drying time by 13–17% [37] and by 13 to 44% [12], respectively, in comparison to the untreated samples. The results of these studies are in accordance with those obtained in the current study.

Based on Table 3, by increasing the air velocity from 1 to 3 m/s, the drying rate decreased significantly by 24.74% (from 173 ± 2.86 min to 125 ± 2.17 min) (p≤0.001). Chandramohan and Talukdar (2017) investigated the drying rate of potato slices in a hot air drier at different air velocities of 2, 4, and 6 m/s. They also reported low drying time at air velocities of 4 and 6 m/s in comparison to air velocity of 2 m/s. When the air velocity increased, the mass and heat transfer coefficients and the diffusion coefficient increased proportionally [38]. Increasing the air velocities from 1.5 to 2.5 m/s in a tray dryer for drying fresh and osmotically pretreated pineapple slices also led to shorter drying times [39]. The results of these studies are in accordance with those obtained in the current study.

The interaction between the ultrasonic time and the air velocity on the drying time of the zucchini slices, presented in Fig. 1, shows that among all treatments, the treatment of 0 min ultrasonic time- 1 m/s air velocity has the highest drying time (188.33 ± 8.78 min). Although this treatment is not statistically different from those of 15 min ultrasonic time-1 m/s air velocity, 30 min ultrasonic time-1 m/s air velocity, and 0 min ultrasonic time- 2 m/s air velocity (p > 0.05), it is a significantly different from the rest of treatments (p≤0.01). Moreover, among all treatments, the treatment of 30 min ultrasonic time- 3 m/s air velocity has the lowest drying time (115.00 ± 0.11 min); this treatment is statistically different from all treatments shown in this graph (p≤0.01).

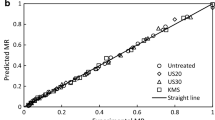

3.2 Drying rate

Convective drying rate of the zucchini slices based on the moisture ratio at three air velocity levels of 1, 2, and 3 m/s and with ultrasonic pretreatment at three time levels of 0, 15, and 30 min has been provided in Fig. 2. This figure shows that the drying treatments had only falling rate periods. Diamante and Yamaguchi (2012) also reported that the hot air drying of infused apple cubes consisted of two falling rate periods; this observation is consistent with the results of this study [29]. As shown in Fig. 2, for each air velocity, among all treatments, the treatments with 30 min ultrasonic pretreatment time have the highest drying rate and those with no ultrasonic pretreatment (0 min sonication) have the lowest drying rate. Nowacka et al. (2012) provided ultrasonic process prior to the apple drying at the frequency of 35 kHz for durations of 10, 20, and 30 min in an ultrasound bath. They reported that the ultrasonic treatment resulted in a high apple drying rate compared to the untreated process [30]. Moreover, it was reported that application of ultrasonic process improved the drying rate of desalted cod slices [31] and orange peel [32]. These studies are well consistent with those obtained in this part of the present study.

Fig. 2 also shows that for each ultrasonic pretreatment time, the drying rate at the air velocity of 3 m/s is more than that at the air velocity of 2 m/s. It should be noted that the treatments with the air velocity of 1 m/s have a low drying rate compared to those with other two levels of air velocity. This observation can be explained in the following. As the air velocity increased, the difference in humidity between the sample and air [33] and between the internal and the surface parts of the sample increased [34]. In this condition, the boundary layer thickness decreased, and the mass and the heat transfer coefficients as well as the water evaporation and drying rate improved [33]. It was proved that the higher the air velocity was, the more the drying rate of a model food (consisting of starch, cellulose, water, and fructose) was [8]. Generally, Fig. 2 shows that a high air velocity and a long time of ultrasonic pretreatment result in a high drying rate, so that among all treatments, the treatment of 30 min ultrasonic time- 3 m/s air velocity treatment has the highest drying rate, and that of 0 min ultrasonic time– 1 m/s air velocity has the lowest drying rate (Fig. 2).

3.3 Shrinkage

The results in Table 1 indicate that the effects of ultrasonic time (p ≤ 0.001) and air velocity (p ≤ 0.01) on the shrinkage variable of the dried zucchini slices were significant, but the interaction of these two parameters has no significant effect on the shrinkage variable of the dried zucchini slices (p > 0.05). Table 2 demonstrates that the shrinkage of the dried zucchini slices decreased significantly (p < 0.001), by 14.92%, with the ultrasonic time increasing from 0 min (0.67 ± 0.01) to 30 min (0.57 ± 0.01). Considerably less shrinkage and more porosity of the dried zucchini slices pretreated by the ultrasonic process, were confirmed by SEM images presented in Section 3–7. Gamboa-Santos et al. (2014) described that the application of ultrasound in the convective drying of strawberry did not significantly affect the shrinkage of the dried product [12]. It is important to mention that the effect of ultrasound process on the tissue of different samples varies because of both the kinds of composition and structure of the tissue and the processing parameters [40].

Table 3 shows that, as air velocity increased from 1 to 2 m/s, the amount of shrinkage of the dried zucchini slices was significantly decreased by 12.31% (from 0.65 ± 0.01 to 0.57 ± 0.01, respectively) (p ≤ 0.01). In addition, as air velocity increased from 1 to 3 m/s, the amount of shrinkage of the dried zucchini slices decreased by 6.15% (p > 0.05). It should be noted that the highest and the lowest amounts of shrinkage of the dried zucchini slices were attained at the air velocities of 1 m/s and 2 m/s, respectively (Table 3). The low shrinkage at the higher air velocities of 2 and 3 m/s compared to the air velocity of 1 m/s can be attributed to casehardening. At a high air velocity, the surface moisture was quickly reduced because of both the high mass and heat transfer and the high drying rate. Thus, the dried surface became rigid, and the final volume was fixed in the first stage of drying; this phenomenon led to a restrictive shrinkage and to an improved pore formation and porosity [41]. It was reported that shrinkage of hawthorn fruit (Crataegus spp.) dried by convective process decreased as air velocity increased from 0.5 to 0.9 and 1.3 m/s because of the reduction in the drying time and because of an improvement in the porous structure of the dried product in this condition [42]. The results of their study are in a good agreement with those of the current study.

3.4 Rehydration properties

According to Table 1, the effects of the ultrasonic time (p≤0.01) and air velocity (p≤0.05) on the water absorption ability (WAA) were significant, but the interaction of these two factors were not significant in WAA (p≤0.01). According to Table 2, WAA of the treatment with 30 min ultrasonic time (0.31 ± 0.01) has increased by 29.17% compared to that with no ultrasonic pretreatment (0.24 ± 0.01). It should be noted that the treatment with no ultrasonic pretreatment and that with ultrasonic time of 15 min are not significantly different in terms of WAA (p > 0.05). According to the results in Table 3, the highest WAA corresponds to the treatment with the air velocity of 2 m/s (0.30 ± 0.10) and the lowest one corresponds to that with the air velocity of 1 m/s (0.25 ± 0.10).

Based on Table 1, the effects of ultrasonic time, air velocity and their interaction on the dried matter holding ability (DMHA) are not statistically significant (p > 0.05). Table 2 shows that with an ultrasonic time increase from 0 min to 30 min, the DMHA increased by 28.59% (from 0.42 ± 0.01 to +0.54 ± 0.03) (p > 0.05). Moreover, according to Table 3, with an air velocity increase from 1 to 3 m/s, the DMHA increased by 26.83% (from 0.41 ± 0.01 to 0.52 ± 0.03) (p > 0.05).

In Table 1, it can be seen that the effect of the ultrasonic time on the rehydration capacity (RC) of the dried zucchini slices is significant (p ≤ 0.01), but that of the air velocity and the interaction of air velocity and ultrasonic time on RC are not significantly different (p > 0.05). According to Table 2, with an increase in ultrasonic time from 0 min to 30 min, RC of the zucchini slices increased significantly from 0.10 ± 0.004 to 0.17 ± 0.01, (increases by 70%) (p≤0.01). It should be noted that two treatments with 15 and 30 min ultrasonic process time did not show any significant difference in terms of RC (p > 0.05). According to the previous results, it can be argued that less shrinkage of the dried zucchini slices pretreated by ultrasonic process for 30 min (Table 2) has led to a better water retention ability of samples during rehydration process [43]. This result indicates that the tissue of the samples pretreated by ultrasound, especially with 30 min of ultrasound, has wider microchannels (refer to Section 3–8) than the tissue of any other sample does; the microchannels of the tissue of these samples have been degraded less than that of other samples because of the shorter drying time of the samples through this treatment than that of other samples (Table 2). Therefore, it has a great potential for rehydration ability. Similarly, enhancements in rehydration characteristics of the dried okra slices pretreated by ultrasound were observed by Tüfekçi and Özkal (2017). They reported that the developed rehydration ratio using ultrasonic process could be attributed to the increase in superior internal stresses and thus, formation of more pores in the sample structure [44]. In other words, ultrasound can result in disruption of sample parenchyma and cell walls, creation of microchannels, and cellular adhesion loss, leading to lower water diffusion resistance and to an enhanced RC [40]. According to Table 3, although none of the three levels of air velocity (1, 2, and 3 m/s) are significantly different in terms of RC (p > 0.05), the dried zucchini slices at the air velocity of 2 m/s have the highest RC (0.15 ± 0.01). Based on Table 3, more RC of the dried zucchini slices at the air velocity of 2 m/s is probably due to the less shrinkage of these samples.

3.5 Total color difference (ΔE)

Based on Table 1, effects of the ultrasonic time, the air velocity, and their interaction on the dependent variable of ΔE are not significant (P > 0.05). Table 2 shows that with an increase in the ultrasonic time from 0 min to 30 min, the variation in the parameter of ΔE is not constant, so that with a growth in the ultrasonic pretreatment time from 0 to 15 min, the ΔE parameter insignificantly decreased by 4.74% (p > 0.05) and with a growth in ultrasonic time from 15 to 30 min, ΔE insignificantly increased by 6.61% (p > 0.05). This table shows that the dried zucchini slices pretreated by 15 min ultrasonic pretreatment have the lowest ΔE value (29.32 ± 0.37). Similar to this study, Kadam et al. (2015) reported no consistent tendency in the color of either untreated or ultrasound treated brown seaweed of Ascophyllum nodosum dried in a convective drier [45]. Horuz et al. (2017) reported that ΔE values of the dried tomato slices pretreated by ultrasonic process for 20 min were lower than those pretreated by ultrasound for either 0 or 40 min [46]; this observation is in good agreement with our study.

In addition, Table 3 shows that the air velocity does not have a statistically significant effect on ΔE of the zucchini slices. With an increase in the wind velocity from 1 to 3 m/s, the value of ΔE increased from 29.10 ± 0.84 to 30.71 ± 0.49 (5.54%); this increase was not significant (p > 0.05). This observation may be due to the fact that pigments of zucchini slices are sensitive to temperature; nevertheless, prolonging the drying process under constant temperature and various air velocities was not effective in the color of the dried product [47]. Galvez et al. (2012) studied the color changes in the apple slices. They stated that with an increase in the wind velocity from 0.5 to 1.5 m/s, although the magnitude of ΔE increased, this change was not statistically significant [48]. The results of their study are consistent with those in the current study.

3.6 FTIR analyses

FTIR spectroscopy was used to determine the functional groups of the samples and the probable changes of these functional groups over ultrasonic pretreatment and convective drying treatment. This test was performed for all 9 treatments of 0 min ultrasonic time-1 m/s air velocity, 0 min ultrasonic time-2 m/s air velocity, 0 min ultrasonic time-3 m/s air velocity, 15 min ultrasonic time-1 m/s air velocity, 15 min ultrasonic time-2 m/s air velocity, 15 min ultrasonic time-3 m/s air velocity, 30 min ultrasonic time-1 m/s air velocity, 30 min ultrasonic time-2 m/s air velocity, and 30 min ultrasonic time-3 m/s air velocity. The obtained results have been presented in Fig. 3.

As observed in Fig. 3, all investigated FTIR spectra match each other. The entire spectra of FTIR had the absorption peaks at the indicated wave numbers. The peak at 3413 cm−1 is attributed to the hydroxyl group (O–H stretch) of water and carbohydrates, whereas that at 2928 cm−1 denotes CH2 antisymmetric stretch from methyl groups, existing mostly in lipids [49]. The peak of 2157 cm−1 is the sign of C ≡ C symmetry stretching vibration [50] and that at 1744 cm−1 is a sign for the carbonyl (C=O) stretching of protonated carboxylic acids [27]. The 1639 cm−1 band is due to the α-helix structure of amide I of protein [51], and that at wavenumber of 1411 cm−1 is because of CH3 asymmetric deformation. The small band at 1246 cm−1 is due to amide III (random coil) components of protein [49], while that at 1149 cm−1 is allocated to υ (CC) ring of cellulose and polysaccharides [52]. The shoulder peak at 1107 cm−1 is because of carbohydrate, while the band at 1058 cm−1 is due to vibrational frequency of -CH2OH groups in the carbohydrates [49].The bands at both 920 and 869 cm−1 can be attributed to the left-handed helix DNA. The 820 cm−1 band is produced by ring CH deformation, and it can reveal information about structure of polyphenols [49]. The peak at 778 cm−1 denotes -CH2 [53], and the bandwidth positioned at 706 cm−1 is attributed to C–H weak rocking/ alkanes [54]. The bandwidth positioned at 629 cm−1 is related to CH=CH stretching vibration on the aromatic ring [27]. Finally, the 522 cm−1 peak is related to O–H broad bend/ alcohol [54].

Thus, the FTIR spectra prove that sonication at various times of 0, 15, and 50 min and convective drying at various air velocities of 1, 2, and 3 m/s did not destroy the functional groups of the zucchini slices, since the type and the position of the functional groups were not modified. FTIR analyses for both untreated and ultrasound-pretreated wood samples in distilled water for 30, 60, and 90 min were conducted by He et al. (2016). These researchers reported that the intensity of the hydroxyl band in FTIR spectra grew weaker as ultrasound pretreatment time increased from 30 to 90 min. It is worth noting that the spectra of both untreated and ultrasound-pretreated wood for 30 min match each other properly [55]. Therefore, as the results in their paper and in our paper show, ultrasonic pretreatment for 30 min or for a shorter duration did not abolish the functional groups of the samples.

3.7 SEM images

SEM images provided from treatments of 0 min ultrasonic time-1 m/s air velocity, 30 min ultrasonic time-1 m/s air velocity, 0 min ultrasonic time-2 m/s air velocity, 30 min ultrasonic time-2 m/s air velocity, 0 min ultrasonic time-3 m/s air velocity, and 30 min ultrasonic time– 3 m/s air velocity, are observed in Fig. 4. The microstructure of the untreated dried zucchini samples without ultrasound (0 min ultrasonic time- 1 m/s air velocity (Fig. 4a), 0 min ultrasonic time- 2 m/s air velocity (Fig. 4c), and 0 min ultrasonic time- 3 m/s air velocity (Fig. 4e) were characterized by high shrinkage. However, the microstructure of the convective dried zucchini samples subjected to ultrasound process (Fig. 4b, d, and f) had more open spaces in comparison to the untreated dried zucchini slices (Fig. 4a, c, and e). Ultrasonic pretreatment for 20 and 30 min before drying zucchini slices resulted in cavitation phenomenon, causing both the breakdown of cells and longer and deeper microscopic channels. As explained before, formation of microscopic channels led to shortening the drying time (Table 2) since water can be evaporated more rapidly and effectively [13] and also since water diffusivity increases [40]. It should be noted that changes in the microscopic structure also increased the rehydration strength of the dried samples (Table 2).

Scanning electron microscopy images of zucchini slices dried by treatments of (a) 0 min ultrasonic time-1 m/s convective air velocity, (b) 30 min ultrasonic time-1 m/s convective air velocity, (C) 0 min ultrasonic time- 2 m/s convective air velocity, (d) 30 min ultrasonic time- 2 m/s convective air velocity, and (e) 0 min ultrasonic time- 3 m/s convective air velocity, and (f) 30 min ultrasonic time- 3 m/s convective air velocity

4 Conclusions

In this study, ultrasound pretreatment was used for zucchini slices prior to convective drying treatment. In this regard, the effects of the ultrasonic pretreatment time in three levels of 0, 15, and 30 min and the air velocity of the dryer in three levels of 1, 2, and 3 m/s on the drying kinetic, the drying time and physicochemical characteristics of the dried zucchini slices were studied. Moreover, FTIR spectroscopy and SEM were used to study the probable changes in functional groups of the samples and their microscopic structure, respectively. The most important results of this study include:

-

Considering the drying kinetics, with an air velocity increase from 1 to 3 m/s and with an increase in the ultrasonic pretreatment time from 0 to 30 min, the drying rate of the zucchini slices improved and consequently, the drying time of the samples decreased.

-

With an increase in the ultrasonic pretreatment time from 0 to 30 min, the water absorption ability (WAA), the dried matter holding ability (DMHA), the rehydration capacity (RC) and the total color difference (ΔE) of the dried zucchini slices increased and the shrinkage of these samples decreased.

-

The highest amount of WAA, RC, and ΔE and the lowest amount of shrinkage of the dried zucchini slices were obtained at the air velocity of 2 m/s. Meanwhile, the highest amount of DMHA was obtained at the air velocity of 3 m/s.

-

The FTIR spectrum showed that increasing the ultrasonic pretreatment time from 0 to 30 min and increasing the air velocity from 1 to 3 m/s did not affect the type and the location of the functional groups in the FTIR spectra of the dried zucchini slices.

-

SEM images of either the samples treated or those not treated by the ultrasonic process have shown that ultrasonic waves caused more porosity and microscopic channels in the tissues of the samples.

References

Neves FIG, Vieira MC, Silva CLM (2012) Inactivation kinetics of peroxidase in zucchini (Cucurbita pepo L.) by heat and UV-C radiation. Innov Food Sci Emerg Technol 13:158–162. https://doi.org/10.1016/j.ifset.2011.10.013

Lucera A, Costa C, Mastromatteo M et al (2010) Influence of different packaging systems on fresh-cut zucchini (Cucurbita pepo). Innov Food Sci Emerg Technol 11:361–368. https://doi.org/10.1016/j.ifset.2009.08.002

Dhanushkodi S, Wilson VH, Sudhakar K (2017) Mathematical modeling of drying behavior of cashew in a solar biomass hybrid dryer. Resour Technol:616–621. https://doi.org/10.1016/j.reffit.2016.12.002

Kutlu N, Isci A (2017) Drying characteristics of zucchini and empirical modeling of its drying process. Int J Food Stud 6:232–244. https://doi.org/10.7455/ijfs/6.2.2017.a9

Bromberger Soquetta M, Schmaltz S, Wesz Righes F et al (2018) Effects of pretreatment ultrasound bath and ultrasonic probe, in osmotic dehydration, in the kinetics of oven drying and the physicochemical properties of beet snacks. J Food Process Preserv 42:e13393. https://doi.org/10.1111/jfpp.13393

Wang L, Xu B, Wei B, Zeng R (2018) Low frequency ultrasound pretreatment of carrot slices: effect on the moisture migration and quality attributes by intermediate-wave infrared radiation drying. Ultrason Sonochem 40:619–628. https://doi.org/10.1016/j.ultsonch.2017.08.005

Pedreschi F, Moyano P (2005) Effect of pre-drying on texture and oil uptake of potato chips. LWT - Food Sci Technol 38:599–604. https://doi.org/10.1016/j.lwt.2004.08.008

Beck SM, Sabarez H, Gaukel V, Knoerzer K (2014) Enhancement of convective drying by application of airborne ultrasound - a response surface approach. Ultrason Sonochem 21:2144–2150. https://doi.org/10.1016/j.ultsonch.2014.02.013

Bantle M, Eikevik TM (2014) A study of the energy efficiency of convective drying systems assisted by ultrasound in the production of clipfish. J Clean Prod 65:217–223. https://doi.org/10.1016/j.jclepro.2013.07.016

Vallespir F, Cárcel JA, Marra F et al (2018) Improvement of mass transfer by freezing pre-treatment and ultrasound application on the convective drying of beetroot (Beta vulgaris L.). Food Bioprocess Technol 11:72–83. https://doi.org/10.1007/s11947-017-1999-8

Kowalski SJ, Pawłowski A, Szadzińska J et al (2016) High power airborne ultrasound assist in combined drying of raspberries. Innov Food Sci Emerg Technol 34:225–233. https://doi.org/10.1016/j.ifset.2016.02.006

Gamboa-Santos J, Montilla A, Cárcel JA et al (2014) Air-borne ultrasound application in the convective drying of strawberry. J Food Eng 128:132–139. https://doi.org/10.1016/j.jfoodeng.2013.12.021

Sledz M, Wiktor A, Nowacka M, Witrowa-Rajchert D (2017) Drying kinetics, microstructure and antioxidant properties of basil treated by ultrasound. J Food Process Eng 40:e12271. https://doi.org/10.1111/jfpe.12271

Eissa HA, Bareh GF, Ibrahim AA et al (2013) The effect of different drying methods on the nutrients and non-nutrients composition of zucchini (green squash) rings. J Appl Sci Res 9:5380–5389

Zhang Z, Niu L, Li D et al (2017) Low intensity ultrasound as a pretreatment to drying of daylilies: impact on enzyme inactivation, color changes and nutrition quality parameters. Ultrason Sonochem 36:50–58. https://doi.org/10.1016/j.ultsonch.2016.11.007

Tao Y, Wang P, Wang Y et al (2016) Power ultrasound as a pretreatment to convective drying of mulberry (Morus alba L.) leaves: impact on drying kinetics and selected quality properties. Ultrason Sonochem 31:310–318. https://doi.org/10.1016/j.ultsonch.2016.01.012

Szadzińska J, Łechtańska J, Kowalski SJ, Stasiak M (2017) The effect of high power airborne ultrasound and microwaves on convective drying effectiveness and quality of green pepper. Ultrason Sonochem 34:531–539. https://doi.org/10.1016/j.ultsonch.2016.06.030

Kingsly ARP, Balasubramaniam VM, Rastogi NK (2009) Influence of high-pressure blanching on Polyphenoloxidase activity of peach fruits and its drying behavior. Int J Food Prop 12:671–680. https://doi.org/10.1080/10942910801993841

Taghian Dinani S, Hamdami N, Shahedi M, Havet M (2014) Mathematical modeling of hot air/electrohydrodynamic (EHD) drying kinetics of mushroom slices. Energy Convers Manag 86:70–80. https://doi.org/10.1016/j.enconman.2014.05.010

Taghian Dinani S, Havet M (2015) The influence of voltage and air flow velocity of combined convective-electrohydrodynamic drying system on the kinetics and energy consumption of mushroom slices. J Clean Prod 95:203–211. https://doi.org/10.1016/j.jclepro.2015.02.033

Taghian Dinani S, Havet M (2015) Effect of voltage and air flow velocity of combined convective-electrohydrodynamic drying system on the physical properties of mushroom slices. Ind Crop Prod 70:417–426. https://doi.org/10.1016/j.indcrop.2015.03.047

Taghian Dinani S, Hamdami N, Shahedi M, Havet M (2015) Quality assessment of mushroom slices dried by hot air combined with an electrohydrodynamic (EHD) drying system. Food Bioprod Process 94:572–580. https://doi.org/10.1016/j.fbp.2014.08.004

Taghian Dinani S, Hamdami N, Shahedi M, Keramat J (2014) Optimization of Carboxymethyl cellulose and calcium chloride dip-coating on mushroom slices prior to hot air drying using response surface methodology. J Food Process Preserv 38:1269–1278. https://doi.org/10.1111/jfpp.12088

Lewicki PP (1998) Some remarks on rehydration of dried foods. J Food Eng 36:81–87

Ghasemi YZ, Taghian Dinani S (2018) Optimization of ultrasound-assisted enzymatic extraction of walnut kernel oil using response surface methodology. J Food Process Eng:e12696. https://doi.org/10.1111/jfpe.12696

de Souza VB, Thomazini M, de Carvalho Balieiro JC, Fávaro-Trindade CS (2015) Effect of spray drying on the physicochemical properties and color stability of the powdered pigment obtained from vinification byproducts of the Bordo grape (Vitis labrusca). Food Bioprod Process 93:39–50

Khalili F, Taghian Dinani S (2018) Extraction of phenolic compounds from olive-waste cake using ultrasonic process. J Food Meas Charact 12:974–981. https://doi.org/10.1007/s11694-017-9712-1

Mirheli M, Taghian Dinani S (2018) Extraction of β-carotene pigment from carrot processing waste using ultrasonic-shaking incubation method. J Food Meas Charact. https://doi.org/10.1007/s11694-018-9796-2

Diamante LM, Yamaguchi Y (2012) Response surface methodology for optimisation of hot air drying of blackcurrant concentrate infused apple cubes. Int Food Res J 19:353–362

Nowacka M, Wiktor A, Śledź M et al (2012) Drying of ultrasound pretreated apple and its selected physical properties. J Food Eng 113:427–433. https://doi.org/10.1016/j.jfoodeng.2012.06.013

Santacatalina JV, Guerrero ME, Garcia-Perez JV et al (2016) Ultrasonically assisted low-temperature drying of desalted codfish. LWT - Food Sci Technol 65:444–450. https://doi.org/10.1016/j.lwt.2015.08.023

Ortuño C, Pérez-Munuera I, Puig A et al (2010) Influence of power ultrasound application on mass transport and microstructure of orange peel during hot air drying. Phys Procedia 3:153–159. https://doi.org/10.1016/j.phpro.2010.01.022

Zhu A, Xia K (2013) Dynamics of convective hot air drying of filiform Lagenaria siceraria. Chem Ind Chem Eng Q 19:485–492. https://doi.org/10.2298/CICEQ120313082Z

Huang YW, Chen MQ, Jia L (2016) Assessment on thermal behavior of municipal sewage sludge thin-layer during hot air forced convective drying. Appl Therm Eng 96:209–216. https://doi.org/10.1016/j.applthermaleng.2015.11.090

Puig A, Perez-Munuera I, Carcel JA et al (2012) Moisture loss kinetics and microstructural changes in eggplant (Solanum melongena L.) during conventional and ultrasonically assisted convective drying. Food Bioprod Process 90:624–632. https://doi.org/10.1016/j.fbp.2012.07.001

Ozuna C, Cárcel JAA, Walde PMM, Garcia-Perez JVV (2014) Low-temperature drying of salted cod (Gadus morhua) assisted by high power ultrasound: kinetics and physical properties. Innov Food Sci Emerg Technol 23:146–155. https://doi.org/10.1016/j.ifset.2014.03.008

Fijalkowska A, Nowacka M, Wiktor A et al (2016) Ultrasound as a pretreatment method to improve drying kinetics and sensory properties of dried apple. J Food Process Eng 39:256–265. https://doi.org/10.1111/jfpe.12217

Chandramohan VP, Talukdar P (2017) Estimation of equilibrium moisture content and drying time of potato through hot air drying. In: Fluid Mech. Fluid Power–Contemporary Res. Springer, pp 205–213

Nicoleti JF, Telis-Romero J, Telis VRN (2001) Air-drying of fresh and osmotically pre-treated pineapple slices: fixes air temperature versus fixed slice temperature drying kinetics. Dry Technol 19:2175–2191. https://doi.org/10.1081/DRT-100107493

Fonteles TV, Leite AKF, Silva ARA et al (2016) Ultrasound processing to enhance drying of cashew apple bagasse puree: influence on antioxidant properties and in vitro bioaccessibility of bioactive compounds. Ultrason Sonochem 31:237–249. https://doi.org/10.1016/j.ultsonch.2016.01.003

Supmoon N, Noomhorm A (2013) Influence of combined hot air impingement and infrared drying on drying kinetics and physical properties of potato chips. Dry Technol 31:24–31. https://doi.org/10.1080/07373937.2012.711792

Aral S, Beşe AV (2016) Convective drying of hawthorn fruit (Crataegus spp.): effect of experimental parameters on drying kinetics, color, shrinkage, and rehydration capacity. Food Chem 210:577–584. https://doi.org/10.1016/j.foodchem.2016.04.128

Karam MC, Petit J, Zimmer D et al (2016) Effects of drying and grinding in production of fruit and vegetable powders: a review. J Food Eng 188:32–49. https://doi.org/10.1016/j.jfoodeng.2016.05.001

Tüfekçi S, Özkal SG (2017) Enhancement of drying and rehydration characteristics of okra by ultrasound pre-treatment application. Heat Mass Transf und Stoffuebertragung 53:2279–2286. https://doi.org/10.1007/s00231-017-1983-x

Kadam SU, Tiwari BK, O’Donnell CP (2015) Effect of ultrasound pre-treatment on the drying kinetics of brown seaweed Ascophyllum nodosum. Ultrason Sonochem 23:302–307. https://doi.org/10.1016/j.ultsonch.2014.10.001

Horuz E, Jaafar HJ, Maskan M (2017) Ultrasonication as pretreatment for drying of tomato slices in a hot air–microwave hybrid oven. Dry Technol 35:849–859. https://doi.org/10.1080/07373937.2016.1222538

Xiao HW, Bai JW, Xie L et al (2015) Thin-layer air impingement drying enhances drying rate of American ginseng (Panax quinquefolium L.) slices with quality attributes considered. Food Bioprod Process 94:581–591. https://doi.org/10.1016/j.fbp.2014.08.008

Vega-Gálvez A, Ah-Hen K, Chacana M et al (2012) Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. granny smith) slices. Food Chem 132:51–59. https://doi.org/10.1016/j.foodchem.2011.10.029

Lu X, Wang J, Al-Qadiri HM et al (2011) Determination of total phenolic content and antioxidant capacity of onion (Allium cepa) and shallot (Allium oschaninii) using infrared spectroscopy. Food Chem 129:637–644. https://doi.org/10.1016/j.foodchem.2011.04.105

Sinha K, Das SP, Datta S (2012) Extraction of natural dye from petals of flame of forest (Butea monosperma) flower: process optimization using response surface methodology (RSM). Dyes Pigments 94:212–216. https://doi.org/10.1016/j.dyepig.2012.01.008

Lu X, Rasco BA, Jabal JMF et al (2011) Investigating antibacterial effects of garlic (Allium sativum) concentrate and garlic-derived organosulfur compounds on campylobacter jejuni by using fourier transform infrared spectroscopy, Raman spectroscopy, and electron microscopy. Appl Environ Microbiol 77:5257–5269. https://doi.org/10.1128/AEM.02845-10

Lu X, Ross CF, Powers JR et al (2011) Determination of total phenolic content and antioxidant activity of garlic ( Allium sativum ) and elephant garlic ( Allium ampeloprasum ) by attenuated Total reflectance–Fourier transformed infrared spectroscopy. J Agric Food Chem 59:5215–5221. https://doi.org/10.1021/jf201254f

Zahir E, Saeed R, Hameed MA, Yousuf A (2017) Study of physicochemical properties of edible oil and evaluation of frying oil quality by Fourier transform-infrared (FT-IR) spectroscopy. Arab J Chem 10:S3870–S3876. https://doi.org/10.1016/j.arabjc.2014.05.025

Onukwuli DO, Emembolu LN, Ude CN et al (2016) Optimization of biodiesel production from refined cotton seed oil and its characterization. Egypt J Pet:0–7. https://doi.org/10.1016/j.ejpe.2016.02.001

He Z, Zhang Y, Wang Z et al (2016) Reducing wood drying time by application of ultrasound pretreatment. Dry Technol 34:1141–1146. https://doi.org/10.1080/07373937.2015.1099107

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bagheri, N., Dinani, S.T. Investigation of ultrasound-assisted convective drying process on quality characteristics and drying kinetics of zucchini slices. Heat Mass Transfer 55, 2153–2163 (2019). https://doi.org/10.1007/s00231-019-02573-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02573-6