Abstract

Drying of food materials is a time consuming activity making the process cost and energy intensive and hence, several pretreatments are used to improve the drying rate. The present study aims to study the effect of potassium metabisulphite (KMS solution, 0.25% w/v) and ultrasound (20 and 30 min) pretreatment on hot air drying characteristics and quality of pineapple slices. The results indicated that pretreated samples provided higher drying rate, enhanced moisture diffusivity, brighter color and lower hardness than that of untreated dried sample. It was observed that KMS and ultrasound pretreatment for 20 and 30 min reduced the drying time by 23.8%, 19% and 14.3%, respectively. Further, ten thin layer drying models were applied to the experimental drying data and logarithmic model was best fitted to explain the drying behavior of pretreated and untreated samples. Additionally, the effect of shrinkage on moisture transfer mechanism was also studied. Results highlighted that instantaneous moisture diffusivity was increased during drying while shrinkage was not accounted. However, shrinkage consideration reduced the average moisture diffusivity values by 72–83%. Overall color change (13.95 ± 0.92) and browning index (36.02 ± 2.45) were found to be lowest in ultrasound (30 min) pretreated dried sample, highlighting better color stability. Scanning electron microscopy presented noticeable effects of pretreatment on alterations of microstructure of pineapple slices. It can be interpreted that KMS pretreatment was found to be more effective for improvement of drying characteristics of pineapple slices as compared to ultrasound pretreatment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pineapple is an important tropical fruit known for its flavor and health benefits, as it is a rich source of fibre, vitamins A, C, and minerals like calcium, magnesium, potassium and iron. It is also a good source of bromelin, a digestive enzyme responsible for anti-inflammatory, antithrombotic and fibrinolytic effects (Cabral et al. 2009). India marks the 5th position for pineapple production in the world and a production of 2.038 million tonnes was recorded during 2016–2017 (Horticultural Statistics Division 2017). During surplus production, there are huge post-harvest losses occurring due to lack of proper processing, storage and transportation facilities. Because of its highly perishable nature, fresh pineapple can neither be stored nor frozen for longer periods (Fasogbon et al. 2013). One of the alternatives for preservation of this fruit is conversion into stable form by reducing moisture through drying process. Commercialization of dried fruits in the form of ready to eat and ready to cook products i.e., minimally processed fruits and chips is growing as an attractive trend in food industries (Ponkham et al. 2012).

Pretreatment aids in drying process by reducing the initial moisture content or by modifying the microstructure of the sample, enhancing drying rate and improves quality of dried products in terms of color, texture, nutritional values and rehydration characteristics (Fijalkowska et al. 2016). Several pretreatments, like chemical treatment with sodium metabisuphite, potassium metabisulphite (KMS), citric acid, ascorbic acid, calcium solution etc. and mechanical treatment like application of ultrasound (US), electric field and high pressure treatment etc. prior to drying are being used to improve the rate of drying and final quality of product (Abano et al. 2011; Mothibe et al. 2011). Sharma et al. (2015) have carried out drying experiments on bell pepper shreds and observed that blanching and KMS pretreatment helped in reducing the drying time and improve color stability. Immersing the samples in KMS solution modifies the micro structure of food matrix in terms of disruption of cell wall, increased tenderness of sample which resulted in enhancing the water removal rate during drying by preventing casehardening. Kingsly et al. (2007) observed higher drying rate and enhanced moisture diffusivity of KMS and ascorbic acid pretreated peach samples than untreated sample, when dried under hot air temperature of 55 and 65 °C. Abano et al. (2011) investigated the effect of citric acid, KMS, Ethylenediamine tetraacetic acid (EDTA) pretreatment on hot air drying kinetics of garlic slices and found Midilli et al. model to be best fitted for untreated sample and Henderson and Pabis model for pretreated samples. It was also observed that KMS pretreatment improved the brightness and inhibited redness of the sample.

Among the mechanical pretreatments being used, ultrasound pretreatment has gained much popularity in recent years and has shown promising result towards improvement of drying characteristics of fruits and vegetables. Generally, frequency range of 20–40 kHz is used for ultrasound pretreatment of food samples prior to drying (Jarahizadeh and Taghian Dinani 2019). Use of ultrasound as a choice of pretreatment helps in improving the drying rate due to the formation of micro channels as a result of rapid expansion and contraction in food matrix, also known as sponge effect generated by acoustic cavitation phenomena. These micro channels aids in increasing the water permeability leading to improved mass transfer during drying. Fernandes et al. (2008) have studied the effect of ultrasound pretreatment on mass transfer attributes of pineapple slices and found that 20 min of ultrasound treatment at 25 kHz frequency resulted in enhancing the moisture diffusivity by 45% during the convective drying period. Zhang et al. (2016) investigated the effect of ultrasound pretreatment at a frequency of 40 kHz prior to hot air and freeze drying of button mushroom slices and observed that the treatment resulted in 9.5% reduction in drying time along with higher moisture diffusivity values. Further, Chen et al. (2016) utilized 40 kHz ultrasound waves in combination with vacuum as the pretreatment option for carrot and achieved 41–53% reduction in drying time. Hence, it was observed from the literatures that chemical as well as mechanical pretreatment have the potential to improve mass transfer characteristics of food products during drying along with positive effects on dried product quality.

Effective moisture diffusivity is an important parameter useful for drying process modelling, equipment design and is dependent on the nature of food product, its moisture content, thermodynamic properties, and also on the degree of shrinkage of the food materials during drying (Chen 2007). Olanipekun et al. (2015) estimated the moisture diffusivity of pineapple slices during hot air drying by using slope method and applied Fick’s second law of diffusion equation to describe the mass transfer process. Although, moisture diffusivity is greatly affected by shrinkage phenomena, still very few researchers have considered shrinkage while calculating the mass transfer parameters (Touil et al. 2014; Dhalsamant et al. 2017). Solution of Fick’s second law involves a series of infinite terms and hence becomes difficult to get analyzed. Therefore, researchers prefer to solve only the first term of the series to estimate diffusivity, but this approach produces result with an error of approximately 20% (Abdul and Vedat 2007). Most of the work carried out in past does not include the estimation of instantaneous moisture diffusivity during drying with changing moisture and dimensions of the product.

From the foregoing literatures, it was noticed that though few research work has been done on ultrasonic and KMS treatment for improving the mass transfer characteristics of different food products, but no research has been attempted yet to compare the effect of chemical and mechanical pretreatment on convective drying behavior and quality attributes of food sample, specifically for pineapple. In order to address this research gap, an attempt was made in the present study to compare the effectiveness of chemical pretreatment using KMS solution and mechanical treatment using ultrasonic pretreatment for improving the mass transfer characteristics along with quality attributes of pineapple. Moreover, studies related to the influence of varying moisture content and shrinkage on moisture diffusivity of pineapple during drying are very scarcely available. Hence, the objectives of the present study are:

-

1.

to study the effect of KMS and ultrasonic pretreatment on drying characteristics, color profile, textural and microstructural characteristics of pineapple slices dried in hot air dryer and

-

2.

to study the influence of moisture content and shrinkage on instantaneous moisture diffusivity during the course of drying.

Materials and methods

Sample procurement and preparation

Fresh and fully ripe pineapples were purchased from the local market of IIT Kharagpur. Pineapples were cut into slices of 10 mm thick and then cored into rings having outer and inner diameter of 90 mm and 30 mm, respectively. The initial moisture content of pineapple slice was estimated by standard AOAC (2002) method and found to lie in the range of 90–92% (wb). The initial total soluble solid of the pineapple was found to be 12 °Brix.

Pretreatment techniques

Pineapple rings were pretreated with KMS and ultrasonic waves prior to hot air drying. The samples dried without any pretreatment were defined as control or untreated (NP) sample.

Ultrasonic pretreatment

Mechanical pretreatment was given to pineapple slices by treating them under ultrasound waves of 40 kHz frequency in an ultrasonic bath (SSE-1151B, Shamboo Scientific Glass work, India) for 20 min (US 20) and 30 min (US 30), respectively. Before the treatment, samples were packed in low-density polyethylene (LDPE) pouches containing distilled water (sample:water = 1:4 on wb) (Fernandes et al. 2008). Packed samples were immersed in ultrasonic bath filled with distilled water up to 2/3rd level of the tank height. Samples were covered using a metal net to avoid floating over the water surface. The water temperature of the ultrasonic bath was initially set at 30 °C.

Chemical pretreatment

Pineapple slices were dipped in 0.25% (w/v) KMS solution for 6 min at room temperature (Ponkham et al. 2012). After the pretreatment, the samples were removed, drained and blotted with absorbent paper to remove extra water from the surface. Individual samples were taken to measure weight and moisture content, which were then used to estimate the water loss (WL) and solid gain (SG) using the following Eqs. 1 and 2 respectively (Fernandes et al. 2008).

where wi: initial fruit mass (g); wf: final fruit mass (g); xi: initial moisture content on wet basis (g water/g); xf: final moisture content on wet basis (g water/g); xsi: initial solid content (g solid/g); xsf: final solid content (g solid/g).

Convective drying experiments

Pretreated pineapple slices were dried in a laboratory scale hot air dryer (SD Instruments, India). Pineapple samples (pretreated and untreated) were placed in a single layer on stainless-steel trays and hot air at a temperature of 70 °C was circulated parallel to the sample surface at a velocity of 0.6 m/s. Before each experiment, the dryer was set to the required temperature and sample was loaded into the dryer once the set temperature was attained. Drying of pineapple samples was continued till final moisture content of 25% (wb) was reached. During the experiment, weight of the sample was recorded at regular time interval of 30 min. The moisture content data obtained from drying experiments were converted into moisture ratio (MR) in order to normalize the initial moisture content (Mo). Equilibrium moisture content (Me) was very less as compared to Mo and hence it was set to zero while calculating MR using Eq. 3 (Ponkham et al. 2012).

Moisture content (M) was plotted with drying time and differentiated using OriginPro 8.5 software to calculate the slope (dM/dt) of the curve. The instantaneous drying rate was calculated at every time interval during drying using Eq. 4 (Geankoplis 1983).

where Ws: weight of dry solid (kg); A: exposed surface area (m2). The average drying rate was estimated by taking average of instantaneous drying rate data.

Thin layer mathematical modelling

To analyze the drying behavior of pineapples slices dried in hot air dryer, experimental moisture ratio and drying time data was fitted to ten empirical/semi-empirical drying models as tabulated in Table 1. Nonlinear regression curve fitting was carried out using OriginPro 8.5 software to determine equation constants and coefficients. All the fitted models were compared on the basis of goodness of fit which was evaluated with higher values of coefficient of determination (R2), lower values of root mean square error (RMSE), and reduced Chi square (χ2) and were calculated using Eqs. 5–7, respectively (Abano et al. 2011).

where MRpred,i: predicted dimensionless moisture ratio; MRexp,i: experimental dimensionless moisture ratio; N: number of observations; z: number of constants.

Determination of moisture diffusion coefficient

Thin layer drying behavior of foods is defined by the solution of Fick’s second law of diffusion, as given in Eq. 8.

D is the effective moisture diffusion coefficient (m2/s)

Taking the assumptions that initial moisture content is uniformly distributed throughout the food product, pineapple slice has been considered as a finite hollow cylinder with 1.5 cm initial inner radius (ri), 4.5 cm outer radius (ro), and height of the cylinder (l) as 1 cm. Moisture is assumed to be migrating from the sample to air through top surface, outer and inner sides by diffusion only, however bottom surface is insulated. The analytical solution of Fick’s second law of diffusion for a finite hollow cylinder is given by multiplication of the solution of infinite slab and solution of infinite hollow cylinder as explained using Eqs. 9–12 (Ponkham et al. 2012).

For Infinite slab

For infinite hollow cylinder

In the above equation, \( \alpha_{n} \) is the positive roots of the following Eq. 11

\( J_{o} (ra_{n})\): bessel function of the first kind of zero order, \( Y_{o} (ra_{n} ) \): bessel function of the second kind of zero order.

Solution for finite hollow cylinder = Solution for infinite slab × solution for infinite hollow cylinder

In order to solve the above series as given in Eq. 12 and to estimate moisture diffusion coefficient (D) at every time interval during drying, a code was written in Engineering Equation Solver (EES). The series was solved up to four terms by substituting first four positive roots \( (\alpha_{n} ) \). The values of \( \alpha_{n} \) were evaluated from EES software using trial and error method. Diffusivity was calculated without and with incorporation of shrinkage effect in the model. For the analysis of diffusivity without considering shrinkage, initial dimensions of pineapple slice were kept constant throughout the drying period. For shrinkage consideration, instantaneous dimensions of the sample during drying were considered for calculation of D. The average effective moisture diffusion coefficient was determined by taking the arithmetic mean of instantaneous diffusivity obtained during the period of drying (Sharma and Prasad 2004).

Shrinkage measurement

The dimensions of pineapple slices were measured at regular time interval of 1 h using a digital vernier caliper (Moore and Wright, Europe, least count 0.01). The dimensions (inner radius, outer radius and thickness) were measured at different positions of the pineapple slice during the course of drying for untreated and pretreated samples. The average values of sample dimensions obtained during drying were used for calculation of instantaneous moisture diffusivity so that shrinkage phenomena could be taken into consideration.

Estimation of quality attributes of pineapple slices

Color analysis

The color of fresh and dried pineapple sample was measured using the CIE colorimeter (KONIKA MINOLTA, Japan). Initially, the instrument was calibrated with black and white plate standards. Measurements of color spaces of the samples were displayed as lightness index (L*), redness/greenness index (a*) and yellowness/blueness index (b*). The total color difference (∆E) and browning index (BI) are expressed in Eqs. (13) and (14) respectively (Velickova et al. 2014).

where

L *s , a *s , b *s : color parameters corresponding to dried sample; L *o , a *o , b *o : color parameters corresponding to fresh sample taken as reference.

where

Texture profile analysis

Texture profile of the fresh and hot air dried pineapple slices were estimated using compression test with the texture analyzer (EZ-SX, SHIMADZU Corp., Japan). Compression test was carried out with a compression plate probe (diameter = 5 cm, thickness = 1 cm) fitted with texture analyzer of 500 N load cell. Samples were placed on a support plate base just below the probe. Pretest speed and test speed of the probe was set as 0.1 mm/s and after penetration of 25% of sample thickness, the probe travelled back at a speed of 0.01 mm/s. Hardness of the sample was evaluated as the maximum force attained (peak) from force–time graph produced in the first compression test (Pieniazek and Messina 2017).

Water activity

Water activity is an important parameter helpful in deciding the storage stability of dried fruits and vegetables. It is generally recommended that water activity of food materials should be less than 0.63 for safe storage (Orsat et al. 2007). The water activity of fresh and dried samples was measured using water activity meter (CX-2, Aqua Lab, USA) at a temperature of 32 ± 2 °C.

Scanning electron microscopy (SEM)

The scanning electron micro images of untreated and pretreated samples were taken to analyze the microstructural changes led by pretreatments. The untreated and pretreated hot air dried samples were cut in longitudinal and vertical direction to produce a 5 cm long and 3 cm thick specimen. Thereafter, the specimen was pasted on a metallic disk and coated with fine layer of gold using a Polaron Range SC7620 Sputter. Gold coated samples were observed for surface morphology at magnification of 500x – 1500x under scanning electron microscope (EVO 60, Carl ZEISS SMT, Germany) operating at an accelerating voltage of 30 kV under vacuum.

Statistical analysis

Statistical analysis of the obtained results was carried out using IBM SPSS Statistics 22 software. Tukey test was applied to the values of color, texture, water activity to check the significant difference in mean values obtained from different pretreatments and untreated sample. All the experiments were done in triplicates and average values with standard deviation are reported.

Results and discussion

Effect of pretreatment on water loss and solid gain

Immersion of freshly cut pineapple slices in KMS solution and distilled water used for ultrasonic pretreatment resulted in changing of water and soluble solid content of the samples. The effect of pretreatment on water loss and solid gain of pineapple slices is shown in Table 2. The samples submitted to ultrasonic waves of 40 kHz for 20 min lost 2.43% moisture, which was increased to 4.14% when treatment time was increased to 30 min. This may be attributed to the fact that the ultrasound treatment caused formation of micro channels which gets intensified with treatment time. Formation of micro capillaries and channels allows the exchange of moisture leading to moisture loss from samples. Furthermore, it was found that the moisture loss from the KMS pretreated sample was 3.52%, which lied between that of US20 and US30 treated samples. It can also be seen from Table 2 that during pretreatment, samples lost soluble solids along with the moisture as indicated by negative sign of solid gain. Solid loss from sample during KMS, US20 and US30 pretreatment was 1.48, 2.80 and 2.51%, respectively. The reason behind the solid loss is detachment of some partially cut pulp on sample surface which remained loosely adhered to the surface. Since pretreatment caused leaching of the soluble solid from sample to the solution, this increased the total soluble solids (TSS) content of the solution. After pretreatment, the TSS of the solution was found as 0.1° Brix. Since, treatment time (20 and 30 min) of ultrasonic exposure was higher as compared to KMS treatment time (6 min), solid loss was found to be more during ultrasonic treatment. Fernandes et al. (2008) have studied the effect of ultrasound pretreatment on convective drying characteristics of pineapple. During the process of pretreatment they observed that pineapple samples lost between 2.1 and 3.2% of its initial moisture, whereas the solid loss was accounted for 23.2% under ultrasonic exposure of 25 kHz frequency. Azoubel et al. (2010) have found that ultrasonic pretreated banana cv Pacovan resulted in water loss and solid loss of 4.2% and 2.4%, respectively, after 30 min of ultrasound pretreatment, which supports the results of present study. Rane and Dabhi (2017) observed the water loss and solid gain of 38.88–43.07% and 4.98–6.07%, respectively, when chemical pretreatment was given to red onion slices by dipping them in solution of calcium chloride and KMS. However, studies related to the effect of KMS pretreatment on mass transfer attributes of food products are very limited.

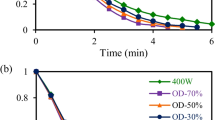

Effect of pretreatment on drying kinetics

As discussed in the previous section, the pretreatment caused loss of moisture from the samples, as a result the initial moisture content at the beginning of drying process was different for untreated and pretreated samples. Hence, in order to normalize the drying curves, moisture data was converted into dimensionless moisture ratio. The untreated and pretreated samples having initial moisture content 90–93% (wb) were dried to safe moisture level of 25% (wb). The drying kinetics of KMS and ultrasonic pretreated pineapple slices dried in hot air dryer is shown in Fig. 1a. It can be seen that both kind of pretreatments was found to affect the mobility of moisture from the samples to hot air during convective drying process of pineapples slices. Plot of MR versus drying time highlighted that samples subjected to chemical pretreatment with KMS solution were dried faster and took 8 h to reach safe moisture content (moisture ratio = 0.025); however the untreated sample took longest drying time (10.5 h). The samples pretreated with ultrasound for 20 and 30 min took 9 and 8.5 h, respectively. It is clear from Table 2 that ultrasound pretreated samples showed improved drying rate and consequently reduced drying time as compared to that of untreated samples. Similar results were observed for other fruits like apple (Fijalkowska et al. 2016), carrot (Ricce et al. 2016), and pineapple (Fernandes et al. 2008). However, the higher drying rate of KMS treated samples indicated better moisture removal ability of chemical treatment over ultrasonic pretreatment.

Mathematical modelling of drying kinetics

Experimental MR and drying time data of pretreated and untreated samples were fitted to ten empirical drying models. Empirical model coefficients and fitted parameters were evaluated for all the samples and are presented in Table 1. It was noticed that all models were successfully fitted with the experimental data; however the best fitted model was identified on the basis of statistical analysis. It was observed that highest values of R2, lowest values of χ2 and RMSE were found for logarithmic model in case of both untreated and pretreated samples. Hence, among all the empirical models fitted, logarithmic model was found to predict the drying kinetics of pineapple slices more accurately as compared to other models. The accuracy of the established model was evaluated by plotting the experimental moisture ratio against model predicted moisture ratio as shown in Fig. 1b. It can be seen that the experimental values and predicted values were bound close to each other as well laid in a straight line (1:1 line) indicating good matching of experimental and predicted data. Zhang et al. (2016) also found logarithmic model to best explain the thin layer drying kinetics of button mushroom slices pretreated with ultrasound of 40 kHz frequency for 3 and 10 min prior to hot air and infrared drying. Some recent studies carried out on hot air drying of pineapple found Midilli et al., Two term and Page model to be best fitted to drying data (Malaikritsanachalee et al. 2018; Izli et al. 2018).

Effective moisture diffusivity with and without shrinkage consideration

The logarithm of moisture ratio, ln(MR) was plotted against drying time for untreated and pretreated samples as illustrated in Fig. 1c. Generally, the plot of ln(MR) vs drying time is found to be linear, and this linear relationship is used for estimation of constant moisture diffusivity using slope method derived from linear regression analysis (Dissa et al. 2011). However in the present study, curve is deviated from linearity and followed second order polynomial relationship. This nonlinear behavior of the curve is due to the non-uniformity in distribution of water within the sample and the extent of shrinkage in pineapple sample during drying (Sharma and Prasad 2004). Results from previous studies have revealed that variation in moisture diffusion coefficient with changing moisture content of the sample during drying also contributed to non-linearity of ln(MR) vs drying time plot (Abano et al. 2011). Hence, variable moisture diffusion coefficient during the course of drying needs to be evaluated.

Effect of moisture content and shrinkage on effective moisture diffusivity

Moisture diffusion coefficient of pineapple slice as a function of moisture ratio during drying without shrinkage consideration is depicted in Fig. 2a. It can be seen that moisture diffusivity was found to rise with the reduction of moisture content as drying progressed. Among all the samples, D of untreated sample was found to be the lowest at every instance during air drying. It is important to mention that during initial period of drying, slight difference was observed in the values of D of pretreated and untreated samples. However, further drying led KMS pretreated sample to present higher moisture diffusivity than other samples till end point of drying. At the end of drying, when moisture ratio reached around 0.025, KMS treated sample showed highest value of instantaneous moisture diffusivity of 1.09 × 10−9 m2/s followed by 9.88 × 10−10 m2/s, 9.79 × 10−10 m2/s and 8.3 × 10−10 m2/s for US30, US20 and untreated sample respectively. Increasing trend of effective moisture diffusivity with reduction in moisture ratio was also observed by Sharma and Prasad (2004) during microwave-convective drying of garlic at operating temperature of 40–70 °C. As far as ultrasound pretreatment is concerned, exposure time did not affect the moisture diffusivity of samples.

Effective moisture diffusivity is dependent on moisture gradient, temperature and path length travelled by moisture while diffusing from the sample to the surface. During air drying, shrinkage of sample is important phenomena occurring and continuously affecting the shape and size of sample and subsequently varying the path length for diffusion throughout the drying process. Hence shrinkage phenomena should be included in the calculation for correct determination of moisture diffusivity (Touil et al. 2014). Incorporation of shrinkage phenomena in the computation of effective moisture diffusivity during the course of drying leads to interesting results as presented in Fig. 2b. Consideration of shrinkage led to initially raise the diffusivity and attained maximum value after 1.5–3 h of drying, followed by decreasing trend till the end of drying. This trend of moisture diffusivity was because of the changing drying mechanism from liquid diffusion during initial period till 2–3 h followed by vapor diffusion in second falling period. Similar behavior of moisture diffusivity as a function of moisture ratio was also observed during infrared drying of pear by Touil et al. (2014). In the present study, relationship of moisture diffusivity and moisture ratio was found almost similar for all samples. However, maximum diffusivity found at peak was highest for KMS pretreated sample (3.94 × 10−10 m2/s) followed by US20 (1.9 × 10−10 m2/s), US30 (1.57 × 10−10 m2/s) and least for untreated sample (1.48 × 10−10 m2/s). Figure 2c presents the comparison between variations in diffusivity of KMS pretreated pineapple slices obtained with and without consideration of shrinkage phenomena. Lower values of moisture diffusivity are clearly depicted from the figure when shrinkage was considered. Similar trend of comparison of moisture diffusivity with and without shrinkage phenomena was also obtained during infrared drying of pears (Touil et al. 2014).

To express the relationship between effective moisture diffusivity and corresponding moisture ratio of pineapple slices during drying, a third order polynomial equation was fitted and is given below in Eq. (15).

where D is the effective instantaneous moisture diffusivity (m2/s); MR is the dimensionless moisture ratio any time t during drying; a, b, c, d are the constants of regression during hot air drying of pineapple slices, whose values are provided in Table 3. High values of R2 indicated that above equation is well fitted to explain the relationship of moisture diffusivity with moisture ratio of pineapple slices with and without shrinkage consideration.

Effect of pretreatment and shrinkage on average effective moisture diffusivity

The average effective moisture diffusivity Davg, was computed by taking the arithmetic mean of the effective moisture diffusivities calculated at various moisture levels during the course of drying (Sharma and Prasad 2004). Average moisture diffusivities with and without shrinkage incorporation was calculated for all the samples and is shown in Table 2. As compared to sample dried without any pretreatment, KMS, US30, US20 pretreatments had the potential to improve the moisture diffusivity (without shrinkage consideration) by 19.2, 10.4 and 10.2%, respectively. It is interesting to notice that average moisture diffusivity of KMS samples was estimated to be 5.71 × 10−10 m2/s and 1.59 × 10−10 m2/s without and with shrinkage, respectively. In other words, neglecting shrinkage phenomena leads to overestimation of diffusivity. Similar type of results were also reported by Dhalsamant et al. (2017) during solar drying of potato cylinders and Ponkham et al. (2012) during far infrared drying of pineapple slices.

Effect of pretreatment on quality attributes of pineapple slices

Table 2 shows the effect of pretreatment on color profile, hardness and water activity of dried pineapple slices.

Color profile analysis

Drying of pineapple slices led an increment in the L* value indicating improvement in brightness of the sample. Samples dried after KMS pretreatment were found brighter than untreated and ultrasound treated dried sample. This result is in good agreement with published studies by Abano et al. (2011). Tukey test revealed that lightness of fresh pineapple sample was changed significantly (p < 0.05) after drying. However, no significant difference was noticed for L* value of untreated and US treated dried sample. It was observed that a* value of fresh sample was − 2.29 ± 0.20 which corresponds to greenish color due to negative sign, however, it shifted to 0.44 ± 0.85 (reddish shade) after drying. Differences among a* values of fresh and pretreated (KMS, US) dried samples were not significant (p > 0.05) indicating capability of ultrasound and KMS pretreatment to protect the greenish shade of the pineapple sample during drying. From the color analysis, it was observed that hot air drying caused a significant increment in b* value, making the samples more yellowish due to non-enzymatic reactions.

Results showed that KMS pretreated dried sample recorded maximum L* value, which consequently produced higher total color change (∆E = 18.21 ± 0.66) during drying as compared to ultrasound treated samples (∆E = 13.95 ± 0.92 for US30; ∆E = 15.43 ± 0.84 for US20). Statistically, overall color change of untreated sample and KMS pretreated sample were not different at p < 0.05. Ultra sonication pretreatment for 30 min was found to cause least total color change as well as lower browning in the sample during drying. Untreated sample showed highest magnitude of browning index (47.26 ± 1.12) followed by US20 (42.07 ± 3.16), KMS (37.60 ± 1.64), and US30 (36.02 ± 2.45) samples. Exposure of samples to KMS and ultrasound waves leads to the inactivation of browning causing enzymes; as a result lower browning was witnessed during drying of KMS and US pretreated samples.

Hardness

Drying phenomena caused changes in the textural profile of food product due to continuous change in shape, size, and mechanical properties of the sample. Hardness of the fresh pineapple slices was found to be 27.66 ± 5.63 N which was drastically increased after drying up to 167.70 ± 11.79 N for untreated sample. It can be noticed from Table 2 that the hardness of untreated dried sample was found quite higher than fresh and pretreated dried samples. Rupturing of the cell membrane and tissue damage during KMS pretreatment makes the sample more tender which prevented the hardening of samples during drying (Sharma et al. 2015; Orikasa et al. 2018). Due to this, hardness of the KMS treated sample was quite less as compared to other samples. US treatment created a number of micro channels that makes sample less dense. This facilitated the lower resistance in moisture transport and lower hardness as compared to untreated sample.

Water activity

Water activity of fresh pineapple was found to be very high, numerically around 0.95 making it difficult to store the fruit at room temperature for longer time. The water availability for chemical reactions gradually decreases during the drying period, resulting in the reduction of water activity of samples. As can be observed from Table 2, the water activity of all samples were found below 0.63 at which chemical reactions and microbial growth is inhibited (Orsat et al. 2007).

SEM analysis

Scanning electron micrographs of dried pineapple slices at magnification of 500x and 1500x are presented in Fig. 3, which clearly showed a noticeable difference among the morphologies of untreated and treated samples. Untreated dried sample showed a porous structure due to pore generation during drying. Moreover, tissues of samples dried without any pretreatment were intact and smooth structured as can be seen in Fig. 3a, b. Ultrasound pretreatment caused the destruction of tissues by mechanical rupturing. Micro images of US20 and US30 treated slices highlighted that cells became small and needle shaped. Additionally, during ultrasound treatment, cells were also flattened and elongated to form micro channels. The micro channels were formed by disruption of tissues due to shear forces resulted from bubble collapse during cavitation (Fernandes et al. 2009). With an increase in exposure time of ultrasonic waves, the degree of cell damage was also intensified as can be observed from Fig. 3e, f. Pineapple slices dried after KMS pretreatment showed homogeneous and higher collapsed cells as compared to untreated sample. It presented the deformation of cell structure in a uniform pattern leading to more porous network due to which higher removal of water during drying was observed (Fig. 3g, h). Results from the microstructure analysis supported increased moisture diffusivity in pretreated samples as compared to untreated ones.

Conclusion

In the current work, influence of KMS and ultrasonic pretreatment on hot air drying characteristics and quality attributes of pineapple slices was investigated. Results highlighted that pineapple samples pretreated with KMS (0.25% w/v solution) resulted into higher drying rate, enhanced moisture diffusivity during convective drying as compared to that of ultrasound pretreated and untreated sample. Apart from this, KMS pretreated dried sample was also found to be brighter in colour and softer in texture than untreated and ultrasound treated dried sample. Ultrasound pretreatment was also found to enhance the mass transfer during drying due to cell rupture and formation of micro channels, however, it was found to be less effective than KMS pretreatment for improving the drying characteristics of pineapple slices. It was observed that KMS, US30 and US20 pretreatments shortened the drying time by 23.8%, 19% and 14.3%, respectively, indicating selection of KMS chemical pretreatment over ultrasound. Drying behavior of untreated and pretreated samples was best interpreted by logarithmic drying model. Consideration of shrinkage lead to the reduction of average diffusivity values by 72–83%. On the other hand, US30 pretreatment produced dried sample with lower color change (13.95 ± 0.92) and lower browning index (36.02 ± 2.45) highlighting better color stability over untreated and KMS pretreated dried sample. Since, ultrasound process is influenced by the applied frequency; therefore, outcomes of the present research are limited to ultrasound frequency of 40 kHz only. Nonetheless, the effect of different frequency ranges are needed to be compared with KMS pretreatment in future studies. Moreover, along with the drying characteristics and quality attributes, shelf life of dried samples is also an important feature that can be studied to analyze the effectiveness of any pretreatment. Hence, the effect of KMS and ultrasonic pretreatment on shelf life stability of dried samples under different storage conditions can be an important subject for future research.

Abbreviations

- \( {\text{J}}_{\text{o}} ({\text{r}}\upalpha_{\text{n}} ) \) :

-

Bessel function of first kind of the zero order

- \( {\text{Y}}_{\text{o}} ({\text{r}}\upalpha_{\text{n}} ) \) :

-

Bessel function of second kind of the zero order

- ∆E:

-

Total color difference

- A:

-

Exposed surface area (m2)

- BI:

-

Browning Index

- D:

-

Effective moisture diffusivity (m2/s)

- dM/dt:

-

Slope of moisture versus drying time curve

- l:

-

Thickness of slice (m)

- L *o , a *o , b *o :

-

Color parameters corresponding to fresh sample

- L *s , a *s , b *s :

-

Color parameters corresponding to dried sample

- M:

-

Moisture content (kg water per kg dry weight)

- Me :

-

Equilibrium moisture content (kg water per kg dry weight)

- Mo :

-

Initial moisture content (kg water per kg dry weight)

- MR:

-

Moisture ratio

- MRexp,i :

-

Experimental dimensionless moisture ratio

- MRpred,i :

-

Predicted dimensionless moisture ratio

- N:

-

Number of observations

- NP:

-

Sample dried without any pretreatment

- R:

-

Drying rate (kg/h.m2)

- R2 :

-

Coefficient of determination

- ri :

-

Inner radius of slice (m)

- ro :

-

Outer radius of slice (m)

- SG:

-

Solid gain (%)

- t:

-

Time (s)

- US20:

-

Ultrasound pretreatment for 20 min

- US30:

-

Ultrasound pretreatment for 30 min

- wb:

-

Wet basis

- wf :

-

Final fruit mass (g)

- wi :

-

Initial fruit mass (g)

- WL:

-

Water loss (%)

- Ws :

-

Weight of dry solid (kg)

- xf :

-

Final moisture content on wet basis (g water/g)

- xi :

-

Initial moisture content on wet basis (g water/g)

- xsf :

-

Final solid content (g solid/g)

- xsi :

-

Initial solid content (g solid/g)

- z:

-

Number of constants

References

Abano EE, Ma H, Qu W, Teye E (2011) Modeling pre-treatments effect on drying kinetics of garlic (Allium sativum L.) slices in a convective hot air dryer. Afr J Food Sci 5:425–435. https://doi.org/10.4172/2157-7110.1000318

Abdul K, Vedat Tuncay (2007) Effective moisture diffusivity from drying data. Tarim Makinalari Bilim Derg 3:249–256

AOAC (2002) Official methods of analysis, 15th edn. Association of Official Analytical Chemists, Arlington, VA

Ayensu A (1997) Dehydration of food crops using a solar dryer with convective heat flow. Sol Energy 59:121–126

Azoubel PM, Barima MAM, Amorim MAR, Oliveira SSB (2010) Effect of ultrasound on banana cv Pacovan drying kinetics. J Food Eng 97(2):194–198

Cabral ACS, Said S, Oliveira WP (2009) Retention of the enzymatic activity and product properties during spray drying of pineapple stem extract in presence of maltodextrin. Int J Food Prop 12:536–548. https://doi.org/10.1080/10942910801942483

Chen XD (2007) Moisture diffusivity in food and biological materials. Dry Technol 25:1203–1213. https://doi.org/10.1080/07373930701438592

Chen Z-G, Guo X-Y, Wu T (2016) A novel dehydration technique for carrot slices implementing ultrasound and vacuum drying methods. Ultrason Sonochem 30:28–34. https://doi.org/10.1016/j.ultsonch.2015.11.026

Chhinnan MS (1984) Evaluation of selected mathematical models for describing thin-layer drying of in-shell pecans. Trans ASABE 27

Dhalsamant K, Tripathy PP, Shrivastava SL (2017) Moisture transfer modeling during solar drying of potato cylinders considering shrinkage. Int J Green Energy 14:184–195. https://doi.org/10.1080/15435075.2016.1256290

Dissa AO, Bathiebo DJ, Desmorieux H et al (2011) Experimental characterisation and modelling of thin layer direct solar drying of Amelie and Brooks mangoes. Energy 36:2517–2527. https://doi.org/10.1016/j.energy.2011.01.044

Fasogbon B, Gbadamosi S, Taiwo K (2013) Studies on the osmotic dehydration and rehydration characteristics of pineapple slices. J Food Process Technol. https://doi.org/10.4172/2157-7110.1000220

Fernandes FAN, Linhares FE, Rodrigues S (2008) Ultrasound as pre-treatment for drying of pineapple. Ultrason Sonochem 15:1049–1054. https://doi.org/10.1016/j.ultsonch.2008.03.009

Fernandes FAN, Gallão MI, Rodrigues S (2009) Effect of osmosis and ultrasound on pineapple cell tissue structure during dehydration. J Food Eng 90:186–190. https://doi.org/10.1016/j.jfoodeng.2008.06.021

Fijalkowska A, Nowacka M, Wiktor A et al (2016) Ultrasound as a pretreatment method to improve drying kinetics and sensory properties of dried apple. J Food Process Eng 39:256–265. https://doi.org/10.1111/jfpe.12217

Geankoplis CJ (1983) Transport processes and unit operations. Allyn and Bacon, Boston

Henderson SM (1974) Progress in developing the thin layer drying equation (for maize). Trans ASAE 17:1167–1172

Horticulture Statistics Division (2017) Horticultural statistics. Department of Agriculture, Cooperation & Farmers Welfare Ministry of Agriculture & Farmers Welfare, Government of Indi, New Delhi

Izli N, Izli G, Taskin O (2018) Impact of different drying methods on the drying kinetics, color, total phenolic content and antioxidant capacity of pineapple. CYTA - J Food 16:213–221. https://doi.org/10.1080/19476337.2017.1381174

Jarahizadeh H, Taghian Dinani S (2019) Influence of applied time and power of ultrasonic pretreatment on convective drying of potato slices. Food Sci Biotechnol 28:365–376. https://doi.org/10.1007/s10068-018-0464-4

Kassem AS (1998) Comparative studies on thin layer drying models for wheat. 13th Int Congress Agri Eng 6:2–6

Kingsly RP, Goyal RK, Manikantan MR, Ilyas SM (2007) Effects of pretreatments and drying air temperature on drying behaviour of peach slice. Int J Food Sci Technol 42:65–69. https://doi.org/10.1111/j.1365-2621.2006.01210.x

Malaikritsanachalee P, Choosri W, Choosri T (2018) Study on kinetics of flow characteristics in hot air drying of pineapple. Food Sci Biotechnol 27:1047–1055. https://doi.org/10.1007/s10068-018-0357-6

Mothibe KJ, Zhang M, Nsor-Atindana J, Wang YC (2011) Use of ultrasound pretreatment in drying of fruits: drying rates, quality attributes, and shelf life extension. Dry Technol 29:1611–1621. https://doi.org/10.1080/07373937.2011.602576

Olanipekun BF, Tunde-Akintunde TY, Oyelade OJ et al (2015) Mathematical modeling of thin-layer pineapple drying. J Food Process Preserv 39:1431–1441. https://doi.org/10.1111/jfpp.12362

Orikasa T, Ono N, Watanabe T et al (2018) Impact of blanching pretreatment on the drying rate and energy consumption during far-infrared drying of Paprika (Capsicum annuum L.). Food Qual Saf 2:97–103. https://doi.org/10.1093/fqsafe/fyy006

Orsat V, Yang W, Changrue V, Raghavan GSV (2007) Microwave-assisted drying of biomaterials. Food Bioprod Process 85:255–263. https://doi.org/10.1205/fbp07019

Page GE (1949) Factors influencing the maximum rates of air drying shelled corn in thin layers. Department of Mechanical Engineering, Purdue University, West Lafayette, IN

Pieniazek F, Messina V (2017) Texture and color analysis of freeze-dried potato (cv. Spunta) using instrumental and image analysis techniques. Int J Food Prop 20:1422–1431. https://doi.org/10.1080/10942912.2016.1211143

Ponkham K, Meeso N, Soponronnarit S, Siriamornpun S (2012) Modeling of combined far-infrared radiation and air drying of a ring shaped-pineapple with/without shrinkage. Food Bioprod Process 90:155–164. https://doi.org/10.1016/j.fbp.2011.02.008

Rane DA, Dabhi MN (2017) Optimization of chemical pretreatment for osmotic dehydrated Talaja red onion slices using response surface methodology. Adv Food Sci Eng 1:152–163. https://doi.org/10.22606/afse.2017.14003

Ricce C, Rojas ML, Miano AC et al (2016) Ultrasound pre-treatment enhances the carrot drying and rehydration. Food Res Int 89:701–708. https://doi.org/10.1016/j.foodres.2016.09.030

Sharaf-Eldeen YI, Blaisdell JL, Hamdy MY (1980) A model for pear-corn drying. Trans ASAE 23:1261–1265

Sharma GP, Prasad S (2004) Effective moisture diffusivity of garlic cloves undergoing microwave-convective drying. J Food Eng 65:609–617. https://doi.org/10.1016/j.jfoodeng.2004.02.027

Sharma R, Joshi VK, Kaushal M (2015) Effect of pre-treatments and drying methods on quality attributes of sweet bell-pepper (Capsicum annum) powder. J Food Sci Technol 52:3433–3439. https://doi.org/10.1007/s13197-014-1374-y

Touil A, Chemkhi S, Zagrouba F (2014) Moisture diffusivity and shrinkage of fruit and cladode of opuntia ficus-indica during infrared drying. J Food Process 2014:1–9. https://doi.org/10.1155/2014/175402

Velickova E, Winkelhausen E, Kuzmanova S (2014) Physical and sensory properties of ready to eat apple chips produced by osmo-convective drying. J Food Sci Technolo 51:3691–3701

Verma LR, Bucklin RA, Endan JB, Wratten FT (1985) Effects of drying air parameters on rice drying models. Trans ASAE 28:296–301

Wang CY, Singh RP (1978) A single layer drying equation for rough rice. Paper No. 78-3001. St. Joseph (MI): American Society of Agri Eng

White GM, Ross IJ, Poneleit CG (1981) Fully-exposed drying of popcorn. Trans ASAE 24:466–468

Yagcioglu A, Degirmencioglu A, Cagatay F (1999) Drying char- acteristic of laurel leaves under different conditions. In: Bascetincelik A (ed) Proceedings of the seventh international congress on agricultural mechanization and energy, Adana, Turkey, pp 565–569

Zhang Z, Liu Z, Liu C et al (2016) Effects of ultrasound pretreatment on drying kinetics and quality parameters of button mushroom slices. Dry Technol 34:1791–1800. https://doi.org/10.1080/07373937.2015.1117486

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rani, P., Tripathy, P.P. Effect of ultrasound and chemical pretreatment on drying characteristics and quality attributes of hot air dried pineapple slices. J Food Sci Technol 56, 4911–4924 (2019). https://doi.org/10.1007/s13197-019-03961-w

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03961-w