Abstract

Health hazards of artificial antioxidants have motivated use of natural phenolic compounds in food industry. Olive-waste cake, resulted from olive oil extraction, is accounted as a rich resource of phenolic compounds. In this study, extraction of phenolic compounds through sonication process was investigated. In this respect, effects of sample weight to solvent ratio (in three levels of 1:10, 1:30 and 1:50) and sonication time (in three levels of 10, 30 and 50 min) were evaluated on total phenolic content, antioxidant activity and color parameters of L* and a* of the extracts. Results showed that changing the independent variable of sample weight to solvent ratio from 1:50 to 1:10 results in a significant increase in total phenolic content and antioxidant activity parameters (P ≤ 0.01) and a significant reduction of L* color parameter (P ≤ 0.01) of the extracts. Also, the results of this study demonstrated that prolonging sonication time from 10 to 50 min provides significant increase of L* color parameter (P ≤ 0.01) and insignificant enhancement of total phenolic content and antioxidant activity (P > 0.05) while it reduces a* color parameter of the extracts, significantly (P ≤ 0.01). Based on Fourier transform infrared spectra of the treatments, ultrasound waves do not impose any destructive impact on functional groups of the extracts. Moreover, scanning electron microscopy images of the olive-waste cake powders showed higher porosity in the microstructure of the sonicated solid residues, specifically when longer ultrasonic times were applied.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Antioxidants are effectively and widely used in foods to reduce lipid oxidation, prolong shelf life of foods and prevent decline of their apparent and nutritional qualities [1]. Since artificial antioxidants can result in health hazards on humans, e.g. tumor and liver damage [2], tendency towards employing natural antioxidants has increased in food, pharmaceutical and cosmetics industries, recently [3]. Many studies have shown that application of phenolic compounds in foods, as a category of natural antioxidants, can play an important role in prevention of low-density lipoprotein increase, atherosclerosis and osteoporosis increase, and also different types of cancer [4]. Moreover, it is reported that these compounds function as anti-tumor, metabolism regulator [5], and protector agents of neural and gastric cells [6].

Olive is rich in phenolic compounds [7] and its bitter taste is associated with these compounds, basically [4]. The important point is that just about 2% of its phenolic content enters the oil phase during oil extraction while about 45% of olive’s phenolic compounds enter olive-waste cake [7]. Phenolic compounds of olive-waste cake are solid, colorless, water soluble with considerable environmental resistance and they decompose hardy. Therefore, entrance of waste cake from olive oil extraction plants, and in fact the entrance of their phenolic compounds to underground water and soil is hazardous. Consequently, these compounds should be extracted and removed from the olive waste cake [8]. Furthermore, extraction and production of phenolic compounds are economically important due to their applications in chemical, pharmaceutical and food industries.

Conventional extraction methods, such as Soxhlet, have many disadvantages including noticeable chemical solvent consumption and prolonged extraction time [9]. In recent years, higher efficiency and lower extraction time of modern extraction techniques, e.g. extraction by ultrasonic waves, have motivated employing this method to extract natural compounds [10]. Ultrasound is a specific kind of sound waves that is beyond human hearing range. During this extraction process, a considerable part of energy of ultrasonic waves converts into thermal energy. Ultrasonic waves pass through a conductive medium by putting pressure on the medium. In this process, a phenomenon called cavitation occurs, that is accompanied with generation, growth and destruction of bubbles. In general, sonication improves mass transfer and solvent accessibility to plant cells [9, 11]. To date, sonication has been used to extract phenolic compounds from different resources, such as strawberry [12], rosemary [13], red grape peel [14], cotton seed [15], wheat bran [16] and olive leaf [17].

To the best of our knowledge, no study has investigated the effect of ultrasonic process on extraction of phenolic compounds from olive-waste cake. Thus, this research attempts to explore extraction of phenolic compounds from olive-waste cake through ultrasonic extraction approach. In this respect, the effect of sample to solvent ratio (at three levels of 1:10, 1:30 and 1:50) and sonication time (at three levels of 10, 30 and 50 min) and also their mutual impact on dependent variables of phenolic content, antioxidant activity and color parameters of L* and a* of the extracts were studied. Moreover, decomposition possibility of the functional groups of extracts during sonication was investigated using Fourier transform infrared (FT-IR) spectroscopy. Changes in the microstructure of olive-waste cake during the selected extraction treatments were studied by scanning electron microscopy (SEM) to investigate the relationship between structural variations and the amounts of extracted phenolic compounds.

Materials and methods

Chemicals and reagents

In this study, olive-waste cake was provided by Sadr olive oil plant located in Roodbar, Iran. Also, all utilized chemicals including ethanol, 1,1-diphenyl-2-picryl hydrazyl (DPPH) radical powder, Folin–Ciocalteu indicator, potassium bromide (KBr), sodium carbonate powder and gallic acid were purchased from Merck, Darmstadt, Germany.

Sample preparation

Semi-dried olive-waste cake was dried up to fixed final moisture amount (8.14 ± 0.13%) using a fan at room temperature (25 ± 2 °C). In the next step, the dried waste cake was ground by a domestic mill (Model National, Osaka, Japan). To obtain a homogenous powder, particles were separated through a 20-mesh filter. The resultant powder was conserved in a plastic container wrapped with an aluminum foil to protect the samples from light and was refrigerated at − 15 °C, prior to later application.

Ultrasonic extraction method

Ultrasonic extraction was carried out in an ultrasonic bath (Model 300, Pulse, Italy) at constant frequency of 40 kHz and at temperature of 50 ± 5 °C. To start extraction, three ratios of sample (dried olive-waste cake powder) to ethanol solvent of 1:10, 1:30 and 1:50 were prepared with fixed solvent volumes (10 mL) in glass beakers. The beakers were sonicated for 10, 30 and 50 min in the ultrasonic bath. After sonication, the beakers were removed out of the ultrasonic bath and the resulting mixtures were filtered through Whatman papers (No. 40, England), in the dark. Then, the solutions were centrifuged at 3000 rpm for 15 min using a centrifuge equipment (Model CE 148, Shimiran Company, Tehran, Iran) to acquire a purer extract. Finally, the resulted extract was kept in a dark for further experiments.

Physicochemical analysis

Determination of total phenolic content

Total phenolic compounds existing in the extracts obtained from olive-waste cake were measured based on Folin–Ciocalteu assay. For this test, 0.5 mL of the olive-waste cake extract was poured into a test tube. Then, 3.75 mL distilled water and 0.25 mL Folin–Ciocalteu indicator (diluted two-fold in distillated water) were added to the extract. In the next step, 0.5 mL of 10% (w/v) sodium carbonate solution was mixed with the extract solution. The prepared mixture was kept in the dark for 1 h. Then, absorbance of the mixture was recorded by a UV visible spectrophotometer (Rayleigh-UV 9200, Beijing, China) at 765 nm [18]. In this method, the total amount of phenolic compounds is usually stated based on a selected phenolic compound such as gallic acid. To obtain the standard curve of gallic acid, 10–1100 ppm gallic acid solutions were prepared and their absorbances were measured by the spectrophotometer [17]. The regression equation regarding the relationship between gallic acid concentration and its absorbance at 765 nm is presented in Eq. 1:

To use Eq. 1, absorption of the extract was replaced with Y parameter to find the value of X, that is gallic acid concentration in ppm. In this study, total phenolic contents are reported as mg of gallic acid in 100 mL of extract (mg/100 mL).

Determination of antioxidant activity

The basis of this method is reduction of DPPH radical by the antioxidants of extract in absence of any other free radical in the reaction medium. The outcome of this reaction is decreased color intensity of DPPH solution, which can be quantified by the spectrophotometer [19]. For this assay, 0.1 mL of the extract was mixed with 3 mL DPPH solution with 40 ppm concentration (in ethanol solvent) in a test tube. The tube contents were mixed for 3 min using a spatula. Then, the tube was positioned in a dark place for 60 min and after that its absorbance was measured by the spectrophotometer at 517 nm. The antioxidant activity (% inhibition of DPPH) was calculated according to the following formula [20]:

In Eq. 1, A1 is absorption of the blank solution (DPPH solution without the extract) and A2 refers to absorption of DPPH solution containing the extract.

Determination of color parameters of L* and a*

L* and a* color parameters were measured using a colorimeter (TES-135A, Taiwan). It should be noted that color parameter of L* indicates lightness–darkness intensity of the sample and ranges from 0 (equivalent to black color) to 100 (equivalent to white color). The color parameter of a* defines intensities of red and green colors in the range of − 60 (greenness) to + 60 (redness) [21, 22].

Scanning electron microscopy (SEM) images

SEM images of the olive-waste cake powders after the following four selected treatments were taken by a scanning electron microscope (Model EM3200, KYKY, Beijing, China) with 25 kV voltage, 500 times magnification and 10 μm scale length. The four selected treatments were sample to solvent ratio of 1:50—sonication time of 10 min, sample to solvent ratio of 1:50—sonication time of 50 min, sample to solvent ratio of 1:10—sonication time of 10 min, and sample to solvent ratio of 1:10—sonication time of 50 min. The images of four mentioned treatments were compared with that of the initial untreated olive-waste cake powder.

Fourier transform infrared (FT-IR) spectroscopy

FT-IR spectroscopy was employed to characterize functional groups of the extracts and investigate if they were altered or decomposed during the extraction treatments. For this test, first a potassium bromide (KBr) disk was prepared. Then, 1 up to 2 drops of the extract were dropped on the KBr disk using a capillary tube. The tablet was inserted in the FT-IR instrument (Model Spectrum 65, Norwalk, Connecticut, PerkinElmer, U.S.A) and its spectrum was recorded in the region of 450–4000 cm−1 with a spectral resolution of 4 cm−1 [23].

Statistical analysis

Statistical analysis was performed via a factorial experiment in a completely randomized design (CRD) with three repeatitions. Variance analysis of the data were conducted by SAS 8.0 statistical software. Comparison of the data averages was done using the least significant difference (LSD) method at 5% probability (P \(\le \hspace{0.17em}\)0.05). The presented data of this study are reported as mean ± standard error (SE).

Results and discussion

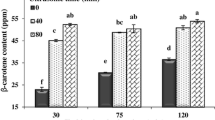

The effect of process variables on total phenolic content

According to Table 1, independent variable of sample to solvent ratio has a significant effect on total phenolic content of the extracts (P \(\le \hspace{0.17em}\)0.01) while independent variable of sonication time and the mutual effect of sample to solvent ratio and sonication time do not have significant impacts on total phenolic content (P \(>\hspace{0.17em}\)0.05). Table 2 shows that varying sample to solvent ratio from 1:50 to 1:10 has enhanced (P\(\hspace{0.17em}\le \hspace{0.17em}\)0.01) total phenolic content from 24.41 ± 1.12 to 64.30 ± 4.00 mg/100 mL, respectively. This finding is consistent with study on extraction of phenolic compounds from powdered tomato peel [24].

Table 3 implies that though prolonging sonication time from 10 to 50 min has promoted extracted total phenolic content from 38.0 ± 4.23 to 49.2 ± 4.05 mg/100 mL, respectively, sonication time influence on total phenolic content is insignificant (P > 0.05). Improved extraction of phenolic compounds demonstrates that increased ultrasonic process time has destroyed cell walls more. Consequently, more phenolic compounds have diffused into the solvent. Promoted phenolic content of the samples simultaneous with applying longer ultrasonic process time has been also reported by Wang et al. in extraction of phenolic compounds from wheat [16].

The effect of process variables on antioxidant activity

As Table 1 shows, sample to solvent ratio has a significant impact on antioxidant activity of the extracts (P ≤ 0.01). However, sonication time effect and mutual effect of the sample to solvent ratio and sonication time on antioxidant activity were insignificant (P > 0.05). Based on Table 2, changing sample to solvent ratio from 1:50 to 1:10 has significantly increased (P ≤ 0.01) antioxidant activity from 12.7 ± 0.7 to 41.21 ± 3.41%, respectively, while no significant difference (P > 0.05) is observed between sample to solvent ratios of 1:30 and 1:50, with respect to antioxidant activity of the extracts. Antioxidant activity has significantly increased by varying sample to solvent ratio from 1:30 to 1:10 and from 1:50 to 1:10 (P ≤ 0.01). This observation can be attributed to increased weight of the olive-waste cake powder in ethanol solvent, and consequently, improved entrance of phenolic compounds of powder to the solvent. It is noteworthy that as antioxidant activity is improved with the increase of sample to solvent ratio from 1:50 to 1:10, it can be concluded that the solvent is not saturated with phenolic compounds of the olive-waste cake in the investigated ratios. Similar results have been found by Şahin and Şamlı during evaluation of olive leaf antioxidant capacity [17].

As Table 3 reveals, even though antioxidant activity of the extracts has enhanced from 22.7 ± 2.45 to 34.2 ± 4.32% and from 19.0 ± 1.74 to 34.2 ± 4.32% by prolonging sonication time from 10 to 50 min and from 30 to 50 min, respectively, independent variable of sonication time does not have a significant effect on antioxidant activity of the extracts (P > 0.05). It should be noted that increasing sonication time enhances diffusion of phenolic compounds with great antioxidant properties from the cells to the solvent due to rupturing cell walls and promoting solvent penetration into the sample. A study by Ghafoor et al. on extraction of phenolic compounds from grape seed reported that increasing sonication time can provide higher antioxidant activity [25], which is in agreement with findings of this study.

L* color parameter

Table 1 exhibits significant effects of sonication time, sample to solvent ratio and their mutual influence on L* color parameter (brightness measure) (P ≤ 0.01). As it can be observed in Table 2, varying sample to solvent ratio from 1:50 to 1:10 is accompanied with reduction of L* color parameter and brightness of the extracts from 17.79 ± 0.12 to 16.63 ± 0.2. The reason is that phenolic compounds of the extract increase with the weight increase of olive-waste cake in the solvent, and as phenolic compounds and olive pigments such as chlorophyll are dark colored, L* color parameter decreases [26].

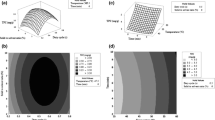

According to Table 2, increasing sonication time from 10 to 50 min elevates L* color parameter from 16.45 ± 0.24 to 17.48 ± 0.12 (P ≤ 0.01). The reason might be due to reduced activity of polyphenol oxidase enzyme of the extracts with prolonged sonication time and, therefore, darkening of the solution and reduction of L* color parameter resulted from polyphenol oxidase enzyme were prevented. A study by Amaral et al. on storage time of fresh potato slices has shown that 5 min of sonication process resulted in reduction of enzymatic activities and inactivation of some enzymes [27]. Furthermore, Costa et al. have compared pineapple juices exposed to sonication process with untreated juices and have concluded that activity of polyphenol oxidase enzyme has declined, noticeably [28]. Moreover, study of Cabezas-Serrano et al. on different types of potato have declared that the relationship between L* color parameter and enzymatic activity of the samples, specifically activity of polyphenol oxidase enzyme, is inverse [29]. These studies are consistent with findings of this section. Mutual effect of sonication time and sample to solvent ratio variables on L* color parameter is exhibited in Fig. 1. The lowest L* color parameter of 15.32 ± 0.24, and the highest L* color parameter of 18.23 ± 0.09 are observed for 1:10 sample to solvent ratio—10 min sonication time and 1:50 sample to solvent ratio—10 min sonication time, respectively.

a* color parameter

Table 1 demonstrates significant effect of sonication time on color parameter of a* (P ≤ 0.01). However, sample to solvent ratio and the mutual effect of sonication time and sample to solvent ratio have insignificant effects on color parameter of a* (P > 0.05). Based on Table 3, the observed color parameter of a* is the lowest for 50 min and the highest for 10 min sonication time with − 4.25 ± 0.68 and − 0.82 ± 0.29 values, respectively. This difference is statistically significant (P ≤ 0.01). In other words, increasing sonication time from 10 to 50 min has reduced the a* color parameter as much as 418.29%. The underlying reason can be associated with more chlorophyll pigment extraction and, thus, intensification of green color with more sonication time. This result is in agreement with Adekunte et al. who reported reduction of a* color parameter of tomato juice upon sonication time prolongation [30].

SEM images

SEM images of the olive-waste cake samples after treatments of 1:50 sample to solvent ratio—10 min sonication, 1:50 sample to solvent ratio—50 min sonication, 1:10 sample to solvent ratio—10 min sonication, and 1:10 sample to solvent ratio—50 min sonication were obtained to investigate their microstructure changes. SEM images of these four samples were compared with the initial untreated olive-waste cake powder. It is evident that all treated samples (Fig. 2a–d) are consisted of ruptured and decomposed cells, as an outcome of sonication process compared to Fig. 2e. At fixed sonication times of 10 min (Fig. 2a, c) and 50 min (Fig. 2b, d), it can be observed that treatment with 1:10 sample to solvent ratio (Fig. 2c, d) has induced more noticeable rupture to the cells, compared to 1:50 sample to solvent ratio. As aforementioned, greater ruptures by employing 1:10 sample to solvent ratio, compared with 1:50 sample to solvent ratio, facilitates extraction of more phenolic compounds and promotes antioxidant activity of the extract (Table 2). Also, at this condition, presence of higher phenolic content and chlorophyll pigments in the 1:10 sample to solvent ratio treated extracts provided darker extracts with lower L* color parameter (Table 2).

Scanning electron microscopy images of a the remained solids air-dried after treatment with sample to solvent ratio of 1:50—ultrasonic time of 10 min, b the remained solids air-dried after treatment with sample to solvent ratio of 1:50—ultrasonic time of 50 min, c the remained solids air-dried after treatment with sample to solvent ratio of 1:10—ultrasonic time of 10 min, d the remained solids air-dried after treatment with sample to solvent ratio of 1:10—ultrasonic time of 50 min and e untreated olive waste powder

Comparison of Fig. 2c, d (both treatment having 1:10 sample to solvent ratio) and Fig. 2a, b (both treatment having 1:50 sample to solvent ratio) indicates that using 50 min sonication time (Fig. 2b, d) results in more cellular rupture in the olive-waste cake samples, with respect to 10 min sonication (Fig. 2a, c). It means that prolonging sonication time from 10 to 50 min disrupts cellular walls more severely, since it intensifies cavitation phenomenon. This phenomenon promotes solvent penetration into the cell structure and enhances diffusion of cell contents into the solvent [15]. As outlined, this phenomenon provides greater phenolic contents and improves antioxidant activity of the extracts with increased sonication time (Table 3). Moreover, longer sonication time and greater cellular damage releases more chlorophyll pigments from the olive-waste cake powders, which results in reduced a* color parameter and increased greenish color of the extracts (Table 3).

FT-IR

FT-IR spectroscopy of the 9 treated samples was carried out to study the functional groups of the extracts and their possible changes (Fig. 3). All FT-IR spectra of Fig. 3 match each other. In the FTIR spectra, the peaks observed at 3668 and 3384 cm−1 are ascribed to hydroxyl group (O–H stretch) [31, 32]. The peak positioned at 2974 cm−1 relates to the C–H asymmetric stretch of –CH3 and the peak positioned at 2923 cm−1 refers to CH2 antisymmetric stretch of methyl groups [33, 34]. In the phenol-rich fraction, the band positioned at 1742 cm−1 is indicative of the carbonyl C=O stretching of protonated carboxylic acids [34, 35]. In addition, the peak at 1404 cm−1 belongs to the symmetric –CH3 bending [33, 36, 37], the clear peak of 1250.30 cm−1 is assigned to the C–O stretching of phenols [37], 1052 cm−1 peak is attributed to the C–OH stretching band [38], the peak of 883 cm−1 signify presence of R–CH=CH–R [39], and the bandwidth centered at 617 cm−1 is associated with CH=CH stretching vibration on the aromatic ring [40]. In general, the results of FT-IR spectra demonstrate that sonication did not destroy the functional groups of phenolic compounds of the extracts treating with ultrasonic waves for various time of 10, 30 and 50 min, since the position and type of functional groups did not change.

Conclusions

In this research, ultrasonic extraction of phenolic compounds from olive-waste cake was investigated for the first time and the effects of sonication time, sample weight to solvent volume ratio and also their mutual impacts on total phenolic contents, antioxidant activity and L* and a* color parameters were evaluated. The most remarkable findings of this research include:

-

Variations of sample weight to solvent ratio variable from 1:50 to 1:10 resulted in significant increase of total phenol content and antioxidant activity (P ≤ 0.01) and decrease of L* color parameter (P ≤ 0.01) of the extracts.

-

Prolonging sonication time from 10 to 50 min enhanced L* color parameter (P ≤ 0.01) while it reduced a* color parameter (P ≤ 0.01) of the extracts.

-

According to FT-IR spectra of the sonicated extracts, increasing sonication time from 10 to 50 min does not disturb functional groups of the sonicated extracts.

-

Based on the SEM images of the olive-waste cake powder relating to the selected treatments, applying ultrasound waves to extraction of phenolic compounds for a longer period and changing sample to solvent ratio from 1:50 to 1:10 results in greater rupturing of the microstructures of the olive-waste cake powder and provides more porous textures.

Finally, as the presented results demonstrate, employing sonication method is an efficient and effective method to extract phenolic compounds from agricultural wastes to produce products that are economically highly valued and reduce environmental issues of agricultural waste disposal.

References

S. Djilas, J. Canadanovic-Brunet, G. Cetkovic, Antioxidants in food. Hem. Ind. 56, 105–112 (2002)

D. Bera, D. Lahiri, A. Nag, Studies on a natural antioxidant for stabilization of edible oil and comparison with synthetic antioxidants. J. Food Eng. 74, 542–545 (2006)

A. Tafesh et al., Synergistic antibacterial effects of polyphenolic compounds from olive mill wastewater. Evid. Based Complement. Altern. Med. 2011, 1–9 (2011)

F. Alagna et al., Olive phenolic compounds: metabolic and transcriptional profiling during fruit development. BMC Plant Biol. 12, 162 (2012)

F. Aouidi et al., Rapid quantitative determination of oleuropein in olive leaves (Olea europaea) using mid-infrared spectroscopy combined with chemometric analyses. Ind. Crops Prod. 37, 292–297 (2012)

F. Mazzotti et al., Assay of tyrosol and hydroxytyrosol in olive oil by tandem mass spectrometry and isotope dilution method. Food Chem. 135, 1006–1010 (2012)

E. Marco, De et al., Characterization and fractionation of phenolic compounds extracted from olive oil mill wastewaters. Food Chem. 104, 858–867 (2007)

N.S. Kumar, K. Min, Phenolic compounds biosorption onto Schizophyllum commune fungus: FTIR analysis, kinetics and adsorption isotherms modeling. Chem. Eng. J. 168, 562–571 (2011)

J. Azmir et al., Techniques for extraction of bioactive compounds from plant materials: a review. J. Food Eng. 117, 426–436 (2013)

Y. Picó, Ultrasound-assisted extraction for food and environmental samples. TrAC Trends Anal. Chem. 43, 84–99 (2013)

Y. Tao, Z. Zhang, D.-W. Sun, Kinetic modeling of ultrasound-assisted extraction of phenolic compounds from grape marc: influence of acoustic energy density and temperature. Ultrason. Sonochem. 21, 1461–1469 (2014)

M.C. Herrera, M.D. Luque de Castro, Ultrasound-assisted extraction for the analysis of phenolic compounds in strawberries. Anal. Bioanal. Chem. 379, 1106–1112 (2004)

G. Zu et al., Ultrasound-assisted extraction of carnosic acid and rosmarinic acid using ionic liquid solution from rosmarinus officinalis. Int. J. Mol. Sci. 13, 11027–11043 (2012)

C. Carrera, A. Ruiz-rodríguez, M. Palma, C.G. Barroso, Ultrasound assisted extraction of phenolic compounds from grapes. Anal. Chim. Acta 732, 100–104 (2012)

C. Corbin et al., Development and validation of an efficient ultrasound assisted extraction of phenolic compounds from flax (Linum usitatissimum L.) seeds. Ultrason. Sonochem. 26, 176–185 (2015)

J. Wang, B. Sun, Y. Cao, Y. Tian, X. Li, Optimisation of ultrasound-assisted extraction of phenolic compounds from wheat bran. Food Chem. 106, 804–810 (2008)

S. Şahin, R. Şamli, Optimization of olive leaf extract obtained by ultrasound-assisted extraction with response surface methodology. Ultrason. Sonochem. 20, 595–602 (2013)

C. Soto, E. Caballero, E. Pérez, M. Elvira, M.E. Zúñiga, Effect of extraction conditions on total phenolic content and antioxidant capacity of pretreated wild Peumus boldus leaves from Chile. Food Bioprod. Process 92, 328–333 (2014)

S. Chanda, R. Dave, In vitro models for antioxidant activity evaluation and some medicinal plants possessing antioxidant properties: an overview. Afr. J. Microbiol. Res. 3, 981–996 (2009)

A. El-Abbassi, H. Kiai, A. Hafidi, Phenolic profile and antioxidant activities of olive mill wastewater. Food Chem. 132, 406–412 (2012)

S. Haji Heidari, S. Taghian Dinani, The study of ultrasound-assisted enzymatic extraction of oil from peanut seeds using response surface methodology. Eur. J. Lipid Sci. Technol. (2017). https://doi.org/10.1002/ejlt.201700252

S. Taghian Dinani, N. Hamdami, M. Shahedi, M. Havet, D. Queveau, Influence of the electrohydrodynamic process on the properties of dried button mushroom slices: a differential scanning calorimetry (DSC) study. Food Bioprod. Process 95, 83–95 (2015)

Y. Sun, G. Ma, X. Ye, Y. Kakuda, R. Meng, Stability of all-trans-β-carotene under ultrasound treatment in a model system: effects of different factors, kinetics and newly formed compounds. Ultrason. Sonochem. 17, 654–661 (2010)

D.L. Luthria, Optimization of extraction of phenolic acids from a vegetable waste product using a pressurized liquid extractor. J. Funct. Foods 4, 842–850 (2012)

K. Ghafoor, Y.H. Choi, J.Y. Jeon, I.H. Jo, Optimization of ultrasound-assisted extraction of phenolic compounds, antioxidants, and anthocyanins from grape (Vitis vinifera) seeds. J. Agric. Food Chem. 57, 4988–4994 (2009)

M. Brenes-Balbuena, P. Garcia-Garcia, A. Garrido-Fernandez, Phenolic compounds related to the black color formed during the processing of ripe olives. J. Agric. Food Chem. 40, 1192–1196 (1992)

R.D.A. Amaral, B.C. Benedetti, M. Pujola, I. Achaerandio, M.L. Bachelli, B. Effect of ultrasound on quality of fresh-cut potatoes during refrigerated storage. Food Eng. Rev. 7, 176–184 (2015)

M.G.M. Costa et al., High-intensity ultrasound processing of pineapple juice. Food Bioprocess Technol. 6, 997–1006 (2013)

A.B. Cabezas-Serrano, M.L. Amodio, R. Cornacchia, R. Rinaldi, G. Colelli, Suitability of five different potato cultivars (Solanum tuberosum L.) to be processed as fresh-cut products. Postharvest Biol. Technol. 53, 138–144 (2009)

A.O. Adekunte, B.K. Tiwari, P.J. Cullen, A.G.M. Scannell, C.P. O’Donnell, Effect of sonication on colour, ascorbic acid and yeast inactivation in tomato juice. Food Chem. 122, 500–507 (2010)

B. Saberi, S. Chockchaisawasdee, J.B. Golding, C.J. Scarlett, C.E. Stathopoulos, Physical and mechanical properties of a new edible film made of pea starch and guar gum as affected by glycols, sugars and polyols. Int. J. Biol. Macromol. 104, 345–359 (2017)

T. Suganya, S. Renganathan, Optimization and kinetic studies on algal oil extraction from marine macroalgae Ulva lactuca. Bioresour. Technol. 107, 319–326 (2012)

X. Lu, C.F. Ross, J.R. Powers, D.E. Aston, B.A. Rasco, Determination of total phenolic content and antioxidant activity of garlic (Allium sativum) and elephant garlic (Allium ampeloprasum) by attenuated total reflectance–Fourier transformed infrared spectroscopy. J. Agric. Food Chem. 59, 5215–5221 (2011)

X.N. Lu, C.F. Ross, J.R. Powers, B.A. Rasco, Determination of quercetins in onion (Allium cepa) using infrared spectroscopy. J. Agric. Food Chem. 59, 6376–6382 (2011)

J. He, L.E. Rodriguez-Saona, M.M. Giusti, Midinfrared spectroscopy for juice authentication-rapid differentiation of commercial juices. J. Agric. Food Chem. 55, 4443–4452 (2007)

X. Lu et al., Infrared and Raman spectroscopic studies of the antimicrobial effects of garlic concentrates and diallyl constituents on foodborne pathogens. Anal. Chem. 83, 4137–4146 (2011)

H. Sohrabi, E. Ameri, Adsorption equilibrium, kinetics, and thermodynamics assessment of the removal of the reactive red 141 dye using sesame waste. Desalin. Water Treat. 57, 18087–18098 (2016)

X. Lu et al., Determination of total phenolic content and antioxidant capacity of onion (Allium cepa) and shallot (Allium oschaninii) using infrared spectroscopy. Food Chem. 129, 637–644 (2011)

M.M. Kamil, G.F. Mohamed, M.S. Shaheen, Fourier Transformer Infrared spectroscopy for quality assurance of tomato products. J. Am. Sci. 27, 253–260 (2011)

K. Sinha, P. Saha, S. Das, Datta, Extraction of natural dye from petals of Flame of forest (Butea monosperma) flower: process optimization using response surface methodology (RSM). Dyes Pigm. 94, 212–216 (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khalili, F., Taghian Dinani, S. Extraction of phenolic compounds from olive-waste cake using ultrasonic process. Food Measure 12, 974–981 (2018). https://doi.org/10.1007/s11694-017-9712-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-017-9712-1