Abstract

In this research, an analytical model is developed for the study of thermal effects on transient uptake of moisture by wood exposed to a stepwise relative humidity (RH) change. This model specifically addresses the effect of the latent heat injection (withdrawal) during adsorption (desorption) on the equilibrium wood moisture content. It is explained that this inherent effect associated with wood moisture changes dominates at high RH in slow kinetic processes having time constants up to a few hundred minutes in 20 mg wood samples. In this dynamic range, the predicted RH dependence of the time constant is confirmed by dynamic vapour sorption experiments.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The calculation of the diffusion of heat and moisture through wooden walls is a topic in building physics to analyse the performance of buildings with respect to moisture-related damage, energy use, health and living comfort (Trechsel and Bomberg 2009), requiring appropriate heat and moisture transfer equations with associated material parameters.

While the moisture diffusion coefficient of wood can be reliably determined by direct analysis of stationary moisture flow measurements, transient (i.e. non-stationary) measurements have remained poorly understood (Engelund et al. 2013). More specifically, when comparing the time dependence of the gain/loss of a fixed unit of water in a wood sample, corresponding to a sudden change in relative humidity (RH) of the environment, the rate of moisture content (MC) change appears markedly reduced at increasing levels of initial RH. This has been observed for various wood species without exception (Christensen and Kelsey 1959; Kelly and Hart 1970; Wadsö 1994; Zaihan et al. 2010). Paradoxically, the stationary moisture diffusion coefficient of wood generally increases at higher RH (Skaar 1988; Wadsö 1994), suggesting faster kinetics at high RH. It is obvious that this issue needs scientific attention to improve physical models of wood moisture dynamics.

Krabbenhøft and Damskilde (2004) simulated realistic moisture transients by simultaneous diffusion equations for bound moisture and water vapour, coupled by a water sorption rate equation that accounts for the local conversion of bound water in the wood cell wall into water vapour in the cell lumen (and vice versa). However, the used sorption rate equation was entirely empirical, lacking an independent experimental verification or theoretical justification.

Anomalous diffusion has been observed in swelling polymer films (De Kee et al. 2005), exhibiting t c-kinetics (½ < c ≤ 1) associated with a sharp moving front of liquid diffusant. In contrast, wood moisture diffusion kinetics in the hygroscopic range (RH < 95%) obey c ≤ ½ with gradual MC gradients. On the other hand, wood swelling/shrinkage induces a significant effect on the equilibrium moisture content (EMC), responsible for moisture sorption hysteresis (Engelund et al. 2013). It remains obscure how and to what extent mechanical relaxations interact in transient MC-kinetics. Hill et al. (2012) tentatively associated MC transients with mechanical relaxations in the wood cell wall, using a Kelvin–Voigt lumped parameter model and the thermodynamic swelling pressure equation, which will be discussed later.

Kelly and Hart (1970) observed that the slow kinetic part of MC changes follows the time dependence of the wood sample temperature (deviation from ambient temperature). This temperature deviation results from the exchange of the large amount of latent enthalpy associated with MC changes. Kelly and Hart (1970) reasoned that the temperature deviation changes the local RH, which in turn changes the EMC of wood. Both the moistening and the drying transient may thus become decelerated by the self-inflicted EMC-change. Christensen and Kelsey (1959) had previously declined the possibility of a thermal origin for slow transient MC, concluded from their notion that at high RH, there is hardly any temperature deviation. Their conclusion was adopted by later authors (Wadsö 1984; Engelund et al. 2013) in reviews on retarded kinetics at high RH but will be challenged in the present paper. In addition, Engelund et al. (2013) argued that the results of Kelly and Hart (1970)—obtained under vacuum conditions, like Christensen and Kelsey (1959)—are less relevant for the MC transient studies in atmospheric conditions where a much better heat convection between wood and the ambient was expected. On the other hand, under atmospheric conditions, a viscous gas layer at the surface of the wood sample might well act as a transfer resistance for heat and moisture under low to medium air flow conditions (Bergman et al. 2011). Moving from vacuum to atmospheric conditions, thermal transfer may thus be slightly improved at the cost of an increased moisture transfer resistance, with an uncertain effect on the MC-kinetics. A final judgment on the significance of thermally limited kinetics may therefore still be premature, calling for further theoretical and experimental assessments.

The objective of this paper is to assess the feasibility of thermally limited moisture transfer as a significant effect on the slow kinetics of MC changes at high RH by theoretical analysis of the mechanism described by Kelly and Hart (1970). The derived model will be preliminary verified by recently acquired moisture transients (Altgen et al. 2016) by the method of dynamical vapour sorption (DVS), (Engelund et al. 2010). A rigorous model verification is outside the scope of this article, requiring a dedicated experimental study.

Theory

To understand the context of thermally limited moisture transfer, some important results from the standard theory of diffusion as well as a simple empirical model approach to moisture transfer are reviewed, before deriving the new model.

Fickian diffusion

Diffusion is characterised by a coefficient D (m2 s−1), the proportionality constant between the flow rate of the diffusant and its concentration gradient. Applied to the wood moisture content u (kg moisture/kg dry wood), together with the conservation law of moisture mass, the well-known second law of Fick is obtained, which reads in one spatial dimension x (m) and time t (s), with a uniform and constant D:

The diffusion equation is treated in numerous textbooks of mathematical physics, for example Crank (1975), with various geometries, boundary conditions and (non)linear extensions. The solution of Eq. (1) requires the specification of the space that is occupied by wood and its initial moisture content u 0 , while the moisture content at the wood surface may be set equal to u eq, the EMC, which is mainly controlled by RH (Engelund et al. 2013). Throughout this paper, the numerical value of RH will be expressed in either % or its fractional value equivalent h = RH%/100%. Similarly, MC is expressed in either % or its fractional value u = MC%/100%.

In this paper, the initial h = h 0 is chosen (conditioned) such that u eq(h 0 ) = u 0 and the response of the wood moisture content to a stepwise RH change h 0 →h 1 is studied until a new equilibrium u 1 = u eq(h 1 ) is established. To compare the theoretical solutions u(x,t) from Eq. (1) with gravimetric experiments, the MC average ū(t) across the sample volume must be calculated.

Crank (1975) gives a solution of Eq. (1) for the theoretical case of “wood” occupying the entire half-space (x > 0). The total amount of moisture transferred across the wood–air interface at x = 0 after the RH step at t = 0 then appears proportional to t ½. Since it requires a finite time t l for moisture to diffuse to a certain depth x = l, this t ½-dependence is also found for the moisture change for t < t l in a planar wood sample, with surfaces located at x = ±l. It is therefore customary to plot results from transient diffusion experiments as a function of t ½, allowing the determination of an effective diffusion coefficient from the maximal slope (dū/dt ½) of the response (Simpson 1974; Skaar 1988). For t > t l , the time derivative of ū decreases gradually to zero, letting ū reach u 1 asymptotically.

More complex boundary conditions at the wood surface have been studied by various authors (e.g. Liu 1989; Olek et al. 2011), accounting for a significant impedance of mass transfer passing the wood surface, causing deviations from initial t ½-kinetics. Crank (1975) calculated the effect of a linear transfer coefficient a at the surfaces, controlling the moisture flux at the surfaces:

The corresponding solution for the RH-step response, ū(t)−u 0 , is presented in normalised form ω(t), obtained by division with the step size u 1 −u 0 , having the appearance of an infinite cascade of independent first-order systems (Crank 1975):

where the β n are the positive roots (in ascending order for increasing n) of

ω(t) is plotted as a function of √(Dt/l 2) in Fig. 1 for three values of L. The corresponding logarithmic dω/dt of versus Dt/l 2 appear to be nearly linear (Fig. 1), by the dominance of the n = 1 term. The convergence of Eq. (3) is rather poor for L ≫ 1, requiring many terms to approach the final condition ω = 1.

a RH-step response (Eq. 3) for three values of L as a function of t ½. b The corresponding logarithmic time derivative of the responses versus time

For the case without surface resistance (L→∞, β n = (2n−1)π/2), an increasing diffusion constant D with higher RH (Skaar 1988; Wadsö 1994) yields faster moisture kinetics instead of the observed slow kinetics at high RH. A decreasing surface transfer coefficient a at constant D (i.e. decreasing L) reduces the moisture transfer rate and introduces a settling period at the beginning of the response.

Overall heat and mass transfer coefficients

The description of moisture transfer by a sophisticated partial differential equation (Eq. 1) is not always necessary. The slow process of lumber drying has been satisfactorily modelled by Ananias et al. (2009) using a simple moisture transfer rate, proportional to ū−u 1 . This leads to first-order kinetics:

where A is the wood surface area (m2) and K (kg m−2 s−1) is the overall mass transfer coefficient. Ananias et al. (2009) describe the overall moisture transfer resistance 1/K as the sum of the diffusion resistance and the surface resistance. Their empirical expression for 1/K, accounts for the sample thickness in the diffusion resistance and the RH dependence in the surface resistance part.

This simple model (Eq. 5) fails to reproduce the initial settling period and the adjacent t ½-kinetics of moisture transients of Eq. (3). Only when L is small, hence β 1 is small, tan β 1 ≈ β 1 and L ≈ β 21 , ω(t) is independent of D, and the pre-exponential factor of the n = 1 term is close to unity, reducing Eq. (3) to:

which is functionally equivalent to Eq. (5).

In this paper, the response Eq. (5) from the model of Ananias et al. (2009) is regarded as a first-order approximation of Eq. (3), representing only the slowest diffusion component (n = 1). A second-order approximation, containing two exponential components, is known to accurately fit wood moisture transients (Kohler et al. 2003; Hill et al. 2010).

Since heat transfer in wood and with the ambient can be described by very similar equations as for moisture transfer, the model of Ananias et al. (2009) has a thermal counterpart with an overall heat transfer coefficient, α, defined for the heat flow, driven by the difference in ambient temperature and the volume-averaged sample temperature. This thermal model is accurate when heat transfer is dominated by surface emission at sufficiently large t.

Thermally limited moisture transfer

In this subsection, the mechanism of thermally limited moisture transfer, as explained by Kelly and Hart (1970), is physically modelled. The exploratory text is written for moisture gain, but is straightforwardly adaptable to moisture loss. In both directions, the kinetics are decelerated with an increasing h 0 .

Heat and mass transfer are described by the moisture transfer model of Ananias et al. (2009) and its analogue for heat transfer. However, the RH dependence of kinetics is not accounted for empirically in the overall mass transfer coefficient K but will emerge in the model owing to the coupled heat and moisture exchange of wood with the ambient. Hence, a modified overall mass transfer coefficient k, without RH dependence, is used instead of K. Other parameters in the model will also be considered RH-independent, taking a fixed mid-range value, enabling an analytical evaluation. This is justified by the dominance of the RH dependence of the mechanism of thermally limited moisture transfer, overriding the effect of the RH dependence of any of the model parameters, as has been verified a posteriori by numerical evaluation (not shown).

Consider a wood sample with dry mass m 0 (kg) at relative humidity h 0 (−) and temperature T 0 (300 K), having an equilibrium moisture content u 0 = u eq(h 0 ). At time t = 0, h increases isothermally from h 0 to h 1 in the environment, corresponding to a new equilibrium moisture content u 1 = u eq(h 1 ). The accumulation of moisture (m 0 du/dt) releases latent heat of water vapour, H 0 (44 kJ mol−1), neglecting the additional RH-dependent heat of adsorption, raising the temperature T of the wood with a heat capacity m 0 c p (J K−1), neglecting the additional heat capacity of the adsorbed moisture. The excess temperature (T−T 0 ) will disappear over time by heat transfer into the ambient [across the surface area A (m2)] with an overall heat transfer coefficient α (W m−2K−1). The energy balance reads:

The accumulated moisture (m 0 du/dt) is described by the simple rate equation of Ananias et al. (2009) with the modified overall moisture transfer coefficient k:

where h s is the local RH at the wood surface. u eq (EMC) is considered explicitly temperature-independent; however indirectly, u eq(h s ) is sensitively dependent on T via h s . Neglecting the small partial pressure gradient required for the water vapour flux in the air layer near the sample, h s follows from the equality of partial vapour pressures h s p sat(T) = h 1 p sat(T 0 ), where p sat is the saturated water vapour pressure (Pa) at the specified temperature.

making use of p sat(T) ≈ constant·exp(−H 0 /RT) and its linearisation around T 0 , where R = 8.31 (J mol−1K−1) is the universal gas constant. To close the model, u eq(h s ) can now be expressed in u 1 and (T−T 0 ):

Substituted in Eq. (8):

Equations (7) and (11) constitute two simultaneous ordinary differential equations (ODEs) with presumed constant coefficients, which can be solved analytically. First, the following variables are defined:

Here, φ is a measure of the EMC deviation owing to the temperature deviation T−T 0 , ω is the step-normalised MC, and τ is the dimensionless time variable—obtained by division of t by a time constant (m 0 /kA) for moisture transfer in the absence of the thermally limited rate effect (Eq. 5). The ODEs can then be rewritten in dimensionless form,

capturing the physics by just two independent parameters, W and X, given by

W is the dimensionless ratio between heat and moisture transfer rates, which controls the disappearance rate of a moisture deviation from EMC. X determines the temperature increase by the adsorption of moisture.

The initial conditions at t = 0, just after the RH change from h 0 to h 1 , are: φ = 0 and ω = 0. The model solutions, valid for both adsorption and desorption, are then given by (see the information in the Supplementary Material):

where

having the associated time constants t 1,2 = −m 0 /(kA b 1,2 ), assuming that (W+X)2 > 4 W, which would otherwise lead to oscillatory solutions that have not been experimentally reported. The practically relevant case that (W+X)2 ≫ 4 W and W+X ≫ 1 allows the simplification

The following time constants are then obtained:

t 1 is the time constant associated with a fast response of coupled moisture and heat transfer towards a peak in T−T 0 , and t 2 is time constant associated with the slow response of coupled moisture and heat transfer towards EMC and T 0 . At h = 0, t 1 = m 0 c p /αA and t 2 = m 0 /kA become independent time constants of heating and moistening/drying the sample, respectively. At high RH, t 2 becomes independent of the steady-state moisture transfer coefficient k and inversely proportional to the heat transfer coefficient α, hence the name thermally limited moisture changes.

Materials and methods

The model for thermally limited moisture transfer is verified with the recorded moisture response of small amounts of wood samples to stepwise RH changes, obtained with an automated instrument for dynamic vapour sorption (DVS Advantage, Surface Measurement Systems, London, UK). The DVS data were measured in the study of Altgen et al. (2016) on the swelling and hygroscopicity behaviour of steamed pine sapwood (P. sylvestris). Altgen et al. (2016) noticed significant differences in the swelling properties of native and steamed samples, mainly attributed to modifications in the (static) elastic properties of the steamed wood cell walls, making a further study into the moisture dynamics interesting.

The reader is referred to Altgen et al. (2016) for the full details of the sample treatment procedure. Briefly, all native pine samples were first oven-dried. A part of this material (labelled “Pine ref”) serves as the untreated control. Another part (labelled “Dry pine steam-hydrolysed”) was exposed to saturated steam of 155 °C with a duration of 5 h. Yet another part is labelled “Wet pine steam-hydrolysed” and saturated with water (MC = 140%) with subsequent exposure to saturated steam of 145 °C during 8 h. The steam treatments (dry vs. wet) were shown to result in markedly different dry wood mass losses (3.0 vs. 2.1%) before and (6.6 vs. 15%) after water leaching, while the EMCs after water leaching were similar (Altgen et al. 2016).

All (three types of) samples were adjacently subjected to a measurement of the dimensional changes from the oven-dried to the water-saturated state (maximum swelling), a water-leaching treatment, a second measurement of the maximum swelling, oven-drying, EMC determination at 20 °C and 65% RH and finally milling in a cutter mill with a mesh size of 2 mm.

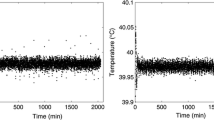

The RH dependence of the moisture dynamics is performed by executing subsequent small RH steps with intermediate stationary periods at h = 0.063, 0.163, 0.255, 0.354, 0.452, 0.547, 0.644, 0.742, 0.840 and 0.933. The “oven-dry” condition corresponds to h = 0.004. A sampling time of 60 s was used for the acquisition of RH, T and MC data. The RH is automatically set in the instrument by mixing mass flow controlled amounts of dry and moist gas streams, for fast switching of RH within one or two sampling intervals. The temperature of humid gas stream is controlled at 20.0 °C. The MC is considered to have reached the EMC, when the derivative dMC/dt is less than 0.002%/min for at least 10 min.

Results and discussion

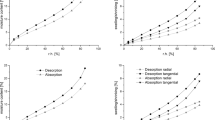

The measured transients near RH = 15, 55 and 95% (Fig. 2a–c) show the trend of decelerated kinetics for increasing RH, in agreement with numerous previous studies (Christensen and Kelsey 1959; Kelly and Hart 1970; Wadsö 1994; Zaihan et al. 2010).

The transient curves were extrapolated (broken lines) using a linear extrapolation of the logarithmic derivative curves (Fig. 2d),

showing that the duration of the stationary RH is too short for accurate determination of the EMC and accurate fitting of Eq. (22). The slope of the regression line equals the reciprocal time constant (τ −1 S ) for the slowest dynamic component of the transient, assuming no interference from other dynamic processes. The intercept of the regression at t = 0 is related to MCS, the amount of “slow” moisture. The residual MC, obtained by the subtraction MC(t)−MC(0)−MCS(1−exp(−t/τ S ), is “fast” moisture, which time dependence can be approximated by a first-order response MCF(1-exp(−t/τ F ), which has become known as the PEK (parallel exponential kinetics) model (Kohler et al. 2003; Hill et al. 2010; Xie et al. 2011), in step-normalised form:

The 4-parameter PEK-model makes very accurate fits to recorded MC transients, except for the settling stage, occurring immediately after the RH step is executed. This was dealt with by omitting the corresponding initial MC points and time-shifting of the entire transient, such that the extrapolation of the MC(t) towards t = 0 equals the initial MC. Without such a pre-treatment of the data, the settling behaviour can result in an “unwanted” negative fast component (Himmel and Mai 2016). On the other hand, Fig. 1a shows that a settling stage can be physically entailed in the transient in case of a limiting surface moisture flow rate. In the present work, no effort was made to find the “perfect” PEK-fit of the transient, in view of the empirical stature of the PEK-model. The emphasis was put on the determination of the slow moisture parameters (ω S = MCS/(MCS + MCF) and τ S ) from linear regressions as in Fig. 2d. τ S is the only parameter that can be meaningfully verified by the derived value (Eq. 21) for thermally limited moisture transfer, because of the limitations in the used moisture transfer model of Ananias et al. (2009).

All parameters that were evaluated from the transient MC gain data are represented in Fig. 3. The determined parameters reasonably agree with those of Zaihan et al. (2010) for six Malaysian hardwood species.

Analysis with Fickian diffusion theory

Intriguingly, the slow and fast moisture components do not seem to be independent: the ratio of the time constants, τ S /τ F ≈ 3.7, and the fraction of slow moisture, ω S ≈ 0.6, are similar for nearly all RH and all samples. Dependent slow and fast moisture components are typical for Fickian diffusion, which can be understood as follows. Recalling that the initial t ½-kinetics of diffusion are associated with a moisture profile that moves progressively deeper beneath the sample surface into “untouched volume”, slow exponential kinetics arise when the moisture profile has reached all parts of the sample volume. This situation has been schematically drawn in Fig. 4 for a hypothetical case of oven-drying, representing the transformation of an initially uniform MC into a parabolic MC distribution in a plane sample with its central part still at the initial MC.

The average MC in the sample is then 2/3 of the initial MC. Hence, 1/3 of the initial MC has left the sample with fast kinetics, while the remaining 2/3 will leave the sample with slow kinetics. This is consistent with the slow moisture fraction of about 0.6 (Fig. 3b) and the fact that the fast and slow time constants are correlated, which is governed by the sample geometry. For different geometries to planar, Eq. (3) can be generalised to:

Table 1 gives the τ S /τ F -ratio and the slow moisture fraction, derived from expressions given by Crank (1975) for the respective geometries without surface resistance. Note that the ratios given in Table 1 are only governed by the geometrical shapes and are independent of the size and the diffusion coefficient of the sample.

The τ S /τ F -ratio becomes progressively smaller for the geometries that allow moisture entrance from more directions focussing the moving moisture profile to the core of the sample. These geometries have a higher surface-to-volume ratio, which is also reflected in the lower slow moisture fraction, since most fast moisture is located near the surfaces. The spherical (powder) geometry gives ratios that are close to the experimental values. However, this does not resolve the origin of the increase of τ S at high RH. Repairing this flaw with the introduction of an (unexplained) increasing surface resistance at high RH, the τ S /τ F -ratio will dramatically increase with RH, while the slow moisture fraction will approach unity, which is inconsistent with the observations. A higher surface resistance at high RH would also contribute to the overall transfer rate in stationary vapour diffusion measurements, contrary to experience. In accordance with Wadsö (1994) and others, one must conclude that the standard Fickian diffusion theory with the surface resistance extension cannot fully explain wood moisture transients. Moreover, slow moisture transfer at high RH is evident in the studies of Christensen and Kelsey (1959) and Kelly and Hart (1970) under vacuum conditions, assuring a negligible surface resistance for moisture transfer.

Considerations on cell wall mechanics

There is an undeniable interplay between moisture and the wood cell wall mechanics. The reader is referred to specialised literature on this subject, for example the textbook of Skaar (1988) or the review of Engelund et al. (2013) and references therein. However, wood–water relations are still under scientific investigation. Even in the simplest case of equilibrium, u eq(h), the influence of cell wall mechanics on the shape of the moisture adsorption isotherm (Fig. 3a) is unclear. The steep increase of u eq at high RH is accompanied by a softening transition of the wood cell walls, changing their rheology from elastic to viscoelastic behaviour (Engelund et al. 2013). In the same RH range, the time constants of moisture dynamics dramatically increase with RH (Fig. 3c + d).

The Kelvin–Voigt-model is an attempt to relate the dynamics of the expansion of the (visco)elastic cell wall to the rate of MC change via mechanical stresses (Hill et al. 2012; Xie et al. 2011). However, the softening transition in the calculated storage modulus occurs below 40% RH, whereas it is expected around 70% RH (Engelund et al. 2013). The calculated storage and loss moduli of elasticity from MC transients by this method generally show decreasing trends of both moduli with RH. This result breaches the fundamental Kramers–Kronig relationship between these dynamic moduli, requiring a loss modulus peak at the RH where the softening transition takes place. An increased loss modulus must account for the dissipation in viscoelastic shear, which is totally absent in the results of Hill et al. (2012) and like.

It seems that the direct (thermodynamic) influence of the elastic swelling stresses on EMC is rather limited to the highest RH range, near h = 1 (Willems 2014a; Bertinetti et al. 2016). This is exemplified by the DVS data on three samples used in this study, having a different maximum volume swelling (15% for pine reference, 13.5% for steamed dry pine and 20% for steamed wet pine, Altgen et al. 2016), while the EMC (Fig. 3a) and the dynamic moisture parameters (Fig. 3b–d) are rather similar over the RH range from h = 0.05 to 0.93.

One may speculate that there is an additional indirect influence of swelling stresses on EMC via hydrogen-bonded polymer links in the cell wall matrix, controlling the number of active water sorption sites in the cell wall, having a directly proportional EMC effect on the entire RH range (Willems 2014b). The relaxation of the induced hygro-mechanical stresses in the hydrogen-bond network may be involved in extremely slow EMC changes associated with mechanical creep. This might explain the findings of Christensen and Hergt (1969) with oven-dry samples, showing the influence of the duration of a pre-conditioning step at h = 0.53 on the adsorption kinetics in response to a subsequent RH step to h = 0.69 or 0.80. The results with a long (>24 h) pre-conditioning time cannot be explained by thermally limited moisture transfer and do have the characteristics of creep relaxation in the cell wall at h = 0.53, increasing the number of active water sorption sites.

Analysis with thermally limited moisture transfer model

While the cell wall mechanics certainly deserve attention in slow moisture dynamics, there is a mechanism described in the literature (Kelly and Hart 1970) that has the potential to explain the kinetic trends in the DVS transients of Fig. 2 on its own. Mechanical relaxations will become more important at elevated temperatures (well above room temperature) or with prolonged observation times (Christensen and Hergt 1969; Olek et al. 2016; Glass et al. 2016).

The gain of wood moisture from the ambient is thermodynamically associated with the release of heat, leaving an immediate and measurable effect on the sample temperature (Christensen and Kelsey 1959; Kelly and Hart 1970). To appreciate the significance of this thermal effect, one could calculate the wood temperature rise ΔT owing to the injection of the latent heat of water vapour (H v = 2500 kJ/kg) in a wood sample with a specific heat capacity (c p = 1.7 kJ/kg.K) by an instantaneous and uniform adsorption of 1% moisture (Δu = 0.01), without heat loss to the ambient. In a wood sample of mass m, (mH v )Δu = (mc p )ΔT, which yields ΔT = 14.7 K for each % moisture change, independent of m. In practice, ΔT will be less, because the moisture change is not instantaneous and there is heat loss to the ambient, which is accounted for in the model. The remaining ΔT = T−T 0 causes the sample becoming a “hot spot” in the ambient, where the local RH, h s , hence also u eq(h s ), is decreased with respect to u 1 . The relation between (T−T 0 ) and [u 1 −u eq(h s )] is modelled by Eq. (10), directly determined by saturated water vapour pressure data and the moisture sorption isotherm of the sample (Fig. 5). It can be observed from Fig. 5 that a small temperature difference of for example T−T 0 = 0.5 K at h 1 = 0.95 causes the wood to strive for a MC, u eq, that is more than 0.02 (ΔEMC = 2%) below the actual EMC, u 1 , after thermal equalisation.

Effect of a temperature difference between sample and environment T−T 0 on u 1 −u eq(h s ). The curves are calculated by h s = h 1 p sat(T 0 )/p sat(T) (Eq. 9), used in u eq(h 1 )−u eq(h s ) as a function of T−T 0 at fixed T 0 = 293 K and for each h1 = 0.1, 0.4, 0.75 and 0.95. The ueq(h) data correspond to the adsorption isotherm of the Pine ref sample

u 1 is reached via cascaded kinetics of (1) u eq(t) towards u 1 and (2) u(t) towards u eq(t). Thermal equalisation of T towards T 0 will bring u eq(t) towards u 1 , but the momentary moisture content u(t) always lags in the cascade with respect to u eq(t). New latent heat is injected when u(t) moves towards u eq(t), which must leak into the ambient, delaying the disappearance of (T−T 0 ), etcetera. The combined effect of heat and mass coupling and cascading thus leads to an increase in the simple mass transfer time constant m 0 /kA (Eq. 5) with the additional term in Eq. (21), which increases steeply with RH by the factor h 1 (du 1 /dh 1 ). The increased sensitivity for high RH is explained by the larger effect of a temperature deviation on the local RH deviation, h 1 −h s , combined with a correspondingly larger MC deviation, u 1 −u eq(h s ), (with latent heat exchange) by the steepness of the moisture sorption isotherm at high RH.

Time constant of slow kinetics

The model result (Eq. 21) has been verified by fitting to the measured τ S data of Altgen et al. (2016), by linear regression of τ S versus h 1 (du 1 /dh 1 ), represented by the drawn line in Fig. 3c, showing a reasonable fit. Figure 6 shows a similar fit, obtained with the τ S data from Jalaludin (2012) for six Malaysian hardwoods. The linear regression parameters of τ S vs. h 1 (du 1 /dh 1 ) are given by:

With m 0 = 20 mg, H 0 = 44 kJ mol−1, R = 8.3 J mol−1 K−1, M w = 18 g mol−1, T 0 = 293 K and estimating A = 1 cm2 from the dimensions of the sample cup, the fitted transfer coefficients are k = 1.2 (2.1) 10−4 kg m−2s−1 and α = 2.3 (2.0) W m−2K−1, for the fit in Fig. 3c, with values in brackets for the fit in Fig. 6. At this point, the simplification step from Eqs. (18) to (19) is confirmed by evaluation of the dimensionless parameters W = 6.4 and (RH-dependent) X ranging from 1 to 70. The maximum relative difference in t 2 calculated by Eq. (18) and the simplified Eq. (19) is 4% over the entire RH range.

The fitted correlation between τ S and h in Fig. 3c. has been plotted in Fig. 6 (broken line) for comparison, suggesting a good agreement between the studies of Altgen et al. (2016) and Jalaludin (2012). The determined moisture transfer coefficients, k, correspond to values given by Ananias et al. (2009) for thin samples in the lower RH range. The thermal transfer coefficients α are also realistic, being at the lower limit for gas–solid heat transfer (Bergman et al. 2011), noting that α must also account for heat transfer inside the sample, giving lower values than for a boundary layer alone.

The model predicts that the retardation of moisture dynamics at high RH is less pronounced in modified woods, having a markedly reduced hygroscopicity (du 1 /dh 1 ) compared to normal wood (Hill 2006). This effect is too small to confirm in the relatively mildly steam-treated samples used in this study. A preliminary inspection of the published τ S data on thermally modified acacia and sesendok (Jalaludin 2012) and on acetylated birch wood (Popescu et al. 2014) seems to confirm a significantly reduced τ S by wood modification. In contrast, Olek et al. (2016) determined for thermally modified wood a τ S of around 100 h, being larger than for normal wood. When wood is subjected to thermal modification the time constant of mechanical relaxations is increased by the lack of shear movement in hemicelluloses (González-Penã et al. 2005). Mechanical relaxations manifest themselves outside the chosen observation time window of the DVS experiments referred to in this paper (Glass et al. 2016).

Adsorption–desorption asymmetry

When comparing τ S data from adsorption and desorption transients, it is important to note that τ S is associated with the final h = h 1 of the RH step (see Eqs. 9 and 10) and that there are shape differences in the adsorption and desorption isotherms (not shown). Hence, τ S is plotted as a function of h 1 (du 1 /dh 1 ) in Fig. 7. According to Eq. (24), the slope of this relation is determined by the heat transfer coefficient α, which is expected to be the same for all three samples and for adsorption as well as desorption. This is confirmed for h 1 (du 1 /dh 1 ) < 0.2 (roughly, h 1 < 0.8), but τ S seems to saturate for larger RH, which is not understood. The keruing and ramin DVS adsorption τ S data of Jalaludin (2012) exhibit similar saturation behaviour, whereas it is absent for the other four wood species (Fig. 6). Upon inspection of the raw DVS data of Altgen et al. (2016), the scattered and relatively low τ S values at high RH coincide with too short hold times of the RH level of less than 1.8 times τ S , compared to more than 2.8 times τ S in the well-correlated range.

Comparison of slow kinetics time constant τS in adsorption (closed symbols) and desorption (open symbols) transients of the pine samples of Altgen et al. (2016): pine ref (circles), wet pine—hydrolysed (triangles), dry pine—hydrolysed (squares)

For h < 0.8, the moisture transfer rate is systematically higher for adsorption than for desorption. Interpreted with Eq. (24), the intercepts for adsorption and desorption correspond to different (steady-state) moisture transfer coefficients, k ads and k des, with k ads/k des ≈ 2.5, agreeing with reported ratios between 2.5 and 3.0 in the literature (Choong and Fogg 1968; Absetz et al. 1993). Since the steady-state transfer of moisture is independent of the direction of flow, it is concluded that the polymer matrix is in a different state during desorption than adsorption. This asymmetry between adsorption and desorption can be understood from glassy polymer dynamics (Engelund et al. 2013).

Time constant of fast kinetics

The model for thermally limited moisture transfer predicts a second time constant, t 1 , given by Eq. (20), which is associated with the thermal response time, wherein the sample is heated by the initial moisture gain after the RH step. At low RH, t 1 = m 0 c p /αA ≈ 2.2 min (taking c p = 1.5 kJ kg−1K−1), becoming smaller at higher RH. This RH dependence is incompatible with the fast component of the measured transient (Fig. 3d). Moreover, the fractional contribution of the t 1 component in ω appears negligible, as follows from a numerical evaluation of (Eq. 20). The actual fast component cannot be found from the present thermally limited transfer model, owing to the limitations in the used moisture transfer model of Ananias et al. (2009), as pointed out in the Theory section.

The fixed ratio between τ S and τ F (Fig. 2d) for all RH is a strong indication for Fickian diffusion hence, an improved model for thermally limited moisture transfer should incorporate the diffusion equation (Eq. 1) for the moisture transfer in the sample. An interesting result from the application of the present model is that u eq(h s ) can be represented as a time-dependent boundary condition for the diffusion equation:

where the RH-dependent t 2 (h) must be used according to Eq. (21). Equation (25) follows from Eqs. (10) and (12) with ϕ ≈ exp(−t/t 2 ), owing to t 1 ≪ t 2 . A first-order time-dependent boundary condition (Eq. 25) has been independently proposed by Olek et al. (2011) in a phenomenological approach to account for transient mechanical relaxation of the wood polymers during EMC changes. These authors pointed out that this type of time-dependent EMC resolves the issues with the diffusion equation with a surface resistance that fail to correctly describe both steady-state and non-steady-state diffusion. The present paper provides a derivation of the boundary condition Eq. (25), based on a completely different mechanism of thermally limited moisture transfer, accompanied by an expression for the RH dependence of t 2 , derived within the same model and quantitatively verified by experiment.

Remarks on the thermal transient

Thermal and moisture transients are coupled. The experimental access to this important quantity is highly recommended in future experiments that are aimed at full understanding moisture dynamics. Ironically, thermal transients have been measured in a previous study of Christensen and Kelsey (1959) and led to their conclusion of disproof of thermally limited moisture transfer. It seems that these authors based their conclusion on observations of the pronounced temperature deviation peak that develops shortly after the RH step. However, thermally limited moisture transfer at high RH is rather the result of the prolonged duration of a small temperature deviation.

At low RH, the injection of heat associated with adsorption can freely develop into a large temperature peak without significant effect on EMC (Fig. 5) and hence on the moisture transfer rate. In contrast, at high RH, the temperature deviation is limited by its strong effect on EMC, since a little amount of transferred moisture (with latent heat release) is sufficient to reduce the moisture flow driving gradient (u−u eq) close to zero [see Eq. 25 with the initial u(0) = u 0 , hence u eq (0) ≈ u 0 ], explaining slow moisture transfer rate.

Conclusion

It is confirmed in this study that the kinetics of wood moisture transients are decelerated at increasing levels of RH. This trend is observed in both time constants of the parallel exponential kinetics describing the MC transient. The slowest component, with a time constant roughly ranging from 20 min at low RH to 200 min at high RH, as obtained from DVS experiments on 20 mg wood powder samples, can be quantitatively explained by a physical model for thermally limited moisture transfer, developed in this work. The main achievement of this model is the prediction of the correct RH dependence of the slow kinetic component of transient MC changes that is independent of the stationary moisture transfer properties. The latter property makes the theory a good candidate for the explanation of the unsolved paradox of the opposite RH trends in stationary versus non-stationary wood moisture transfer rates.

However, a future dedicated study may verify the model more rigorously by addressing the associated thermal transient of the moisture transient and justifying the used stationary heat and mass transfer coefficients in the model fits to the DVS data. The essential elements of the developed model might be incorporated in numerical simulations of moisture transients based on the diffusion equation. The latter is found to be indispensable for the prediction of the fast-kinetic component in MC changes, which is not feasible within the present simplified model for moisture transients.

Further research into thermally limited moisture transfer is urged for quantifying its effects in: (1) sorption hysteresis obtained from DVS measurements with limited equilibration time, (2) simultaneous thermal transients and mechanical relaxations and (3) moisture dynamics in modified wood.

References

Absetz I, Koponen S, Lehtinen M (1993) Effects of cell and cell wall structure on mechanical and moisture physical properties of wood. Annual report, Helsinki University of Technology, Laboratory of Structural Engineering and Building Physics

Altgen M, Hofmann T, Militz H (2016) Wood moisture content during the thermal modification process affects the improvement in hygroscopicity of Scots pine sapwood. Wood Sci Technol 50:1181–1195

Ananias RA, Mougel E, Zoulalian A (2009) Introducing an overall mass transfer coefficient for predicting of drying curves at low-temperature drying rates. Wood Sci Technol 43:43–56

Bergman TL, Lavine AS, Incropera FP, DeWitt DP (2011) Fundamentals of heat and mass transfer, 7th edn. Wiley, New York

Bertinetti L, Fratzl P, Zemp T (2016) Chemical, colloidal and mechanical contributions to the state of water in wood cell walls. New J Phys 18:083048

Choong ET, Fogg PJ (1968) Moisture movement in six wood species. Forest Prod J 18:66–70

Christensen GN, Hergt HFA (1969) Effect of previous history on kinetics of sorption by wood cell wall. Polym Sci A1(7):2427–2430

Christensen GN, Kelsey KE (1959) Die Geschwindigkeit der Wasserdampfsorption durch Holz (The rate of sorption of water vapor by wood) (In German). Holz Roh Werkst 17:178–188

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, New York

De Kee D, Liu Q, Hinestroza J (2005) Viscoelastic (non-Fickian) diffusion. Can J Chem Eng 83:913–929

Engelund ET, Klamer M, Venås TM (2010) Acquisition of sorption isotherms for modified woods by the use of dynamic vapour sorption instrumentation. Principles and Practice. In: The international research group on wood protection, document no IRG/WP 10-40518, Stockholm

Engelund ET, Thygesen LG, Svensson S, Hill CAS (2013) A critical discussion of the physics of wood–water interactions. Wood Sci Technol 47:141–161

Glass SV, Boardman CR, Zelinka SL (2016) Short hold times in dynamic vapor sorption measurements mischaracterize the equilibrium moisture content of wood. Wood Sci Technol 51(2):243–260

González-Penã MM, Breese MC, Hale MDC (2005) Studies on the relaxation of heat-treated wood. In: Militz H, Hill C (eds) Wood modification: processes properties and commercialization. Georg August University Press, Göttingen, pp 87–90

Hill CAS (2006) Wood modification—chemical, thermal and other processes. Wiley, Chichester

Hill CAS, Norton A, Newman G (2010) Analysis of the water vapour sorption behaviour of Sitka spruce (Picea sitchensis (Bongard) Carr.) based on the parallel exponential kinetics model. Holzforschung 64:469–473

Hill CAS, Keating BA, Jalaludin Z, Mahrdt E (2012) A rheological description of the water vapour sorption kinetics behaviour of wood invoking a model using a canonical assembly of Kelvin–Voigt elements and a possible link with sorption hysteresis. Holzforschung 66:35–47

Himmel S, Mai C (2016) Water vapour sorption of wood modified by acetylation and formalisation – analysed by a sorption kinetics model and thermodynamic considerations. Holzforschung 70:203–213

Jalaludin Z (2012) The water vapour sorption behaviour of wood. Dissertation, Bangor University

Kelly MW, Hart CA (1970) Water vapor sorption rates by wood cell walls. Wood Fiber Sci 1:270–282

Kohler R, Renate D, Bernhard A, Rainer A (2003) A numeric model for the kinetics of water vapour sorption on cellulosic reinforcement fibers. Compos Interfaces 10:255–257

Krabbenhøft K, Damskilde L (2004) A model for non-Fickian moisture transfer in wood. Mat Struct 37:615–622

Liu JY (1989) A new method for separating diffusion coefficient and surface emission coefficient. Wood Fiber Sci 21:133–141

Olek W, Perré P, Weres J (2011) Implementation of a relaxation equilibrium term in the convective boundary condition for a better representation of the transient bound water diffusion in wood. Wood Sci Technol 45:677–691

Olek W, Rémond R, Weres J, Perré P (2016) Non-Fickian moisture diffusion in thermally modified beech wood analyzed by the inverse method. Int J Therm Sci 109:291–298

Popescu CM, Hill CAS, Curling S, Ormondroyd G, Xie Y (2014) The water vapour sorption behaviour of acetylated birch wood: how acetylation affects the sorption isotherm and accessible hydroxyl content. J Mater Sci 49:2362–2371

Simpson WT (1974) Measuring dependence of diffusion coefficient of wood on moisture concentration by adsorption experiments. Wood Fiber Sci 5:299–307

Skaar C (1988) Wood-water relations. Springer, Berlin

Trechsel HR, Bomberg MT (2009) Moisture control in buildings: the key factor in mold prevention, 2nd edn. ASTM International, West Conshohocken

Wadsö L (1994) Unsteady-state water vapor adsorption in wood: an experimental study. Wood Fiber Sci 26:36–50

Willems W (2014a) Hydrostatic pressure and temperature dependence of wood moisture sorption isotherms. Wood Sci Technol 48:483–498

Willems W (2014b) The water vapor sorption mechanism and its hysteresis in wood: the water/void mixture postulate. Wood Sci Technol 48:499–518

Xie YJ, Hill CAS, Jalaludin Z, Curling SF, Anandjiwala RD, Norton AJ, Newman G (2011) The dynamic water vapour sorption behaviour of natural fibres and kinetic analysis using the parallel exponential kinetics model. J Mater Sci 46:479–489

Zaihan J, Hill CAS, Curling S, Hashim WS, Hamdan H (2010) The kinetics of water vapour sorption: analysis using parallel exponential kinetics model on six Malaysian hardwoods. J Trop For Sci 22:107–117

Acknowledgements

The author wishes to acknowledge Dr. Michael Altgen and Prof. Carsten Mai of the faculty of Forest Sciences and Forest Ecology of the Georg-August University in Göttingen, Germany, for discussions and the provision of valuable DVS data.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Willems, W. Thermally limited wood moisture changes: relevance for dynamic vapour sorption experiments. Wood Sci Technol 51, 751–770 (2017). https://doi.org/10.1007/s00226-017-0905-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-017-0905-x