Abstract

Recently, the dynamic vapor sorption (DVS) technique has been used to measure sorption isotherms and develop moisture-mechanics models for wood and cellulosic materials. This method typically involves measuring the time-dependent mass response of a sample following step changes in relative humidity (RH), fitting a kinetic model to the data, and extrapolating the asymptotic mass. A series of steps covering the full RH range is used to generate the sorption isotherm. The majority of prior DVS data were taken with hold times of either 60 min or until the change in moisture content was <0.002% per minute over a 10-min period. Here, DVS measurements on wood and isolated wood polymers are presented where the hold times at certain relative humidity steps were much longer, ranging between 24 and 50 h. The data clearly show that the criteria for hold time in previous DVS measurements result in significant errors in prediction of the asymptotic mass. Although the data at short times are consistent with previous measurements, the data exhibit slow sorption behavior with characteristic times on the order of 500–2000 min that cannot be identified with shorter hold times. The results suggest that new hold time criteria need to be developed for dynamic vapor sorption measurements in wood.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The hygroscopic nature of wood strongly influences its properties and performance. Wood moisture content affects a host of properties such as the strength, stiffness, size (dimensional stability), thermal conductivity, heat capacity, electrical conductivity, and coefficient of friction (Tiemann 1906; Stamm 1964; Skaar 1988; Siau 1995; Glass and Zelinka 2010). Wood moisture content, M (expressed as a percentage), can be defined as M = (m tot − m dry)/m dry × 100, where m tot is the total mass (including water in any of its phases) and m dry is the mass of ovendry wood.

In the absence of liquid water, wood moisture content at a fixed temperature depends upon the relative humidity (RH) and the specimen’s history. The moisture sorption isotherm is the curve that relates the equilibrium moisture content (EMC) to a constant RH at a given temperature. The phrase “equilibrium moisture content” describes the moisture content at which the wood has no net gain or loss of moisture, which is attained after some period of time at a given RH. It should be noted that this is not a true thermodynamic equilibrium since the sorption isotherm of wood is path dependent (hysteresis); that is, different equilibrium moisture contents are found at a given RH depending on whether the RH was reached from a lower value (adsorption) or a higher value (desorption). Sorption isotherms are important both for fundamental understanding of wood–water interactions and for practical use of wood. Sorption data for wood were reported as early as 1896 by Volbehr (as cited by Stamm 1964) and have appeared in the Wood Handbook since 1935 (Glass et al. 2014). The nature of the time dependence of the moisture sorption process in wood has long been a topic of investigation, as discussed by Engelund et al. (2013).

Water vapor sorption isotherms have traditionally been characterized manually. In these experiments, macroscopic samples with masses on the order of grams and dimensions on the order of centimeters are placed in a vacuum apparatus or in a desiccator, chamber, or room with near-constant RH, attained with a saturated salt solution or mechanical humidification/dehumidification. The samples are either weighed in situ or removed from the environment periodically for weighing. The samples are considered to have reached their equilibrium moisture content when successive readings are equal or within a certain range. For example, Zelinka and Glass (2010) used an equilibrium criterion of a change <0.2 mg over successive readings spaced at least 48 h apart on samples with an ovendry mass of 1100 mg. Spalt (1957, 1958) used a criterion of three identical successive readings; readings were taken 2–8 h apart, the resolution of the balance was 1 mg, and the average sample mass was 1000 mg.

Computer-automated gravimetric vapor sorption methods were developed beginning in the 1980s with vacuum-based systems (Rasmussen and Akinc 1983; Astill et al. 1987; Benham and Ross 1989). Similar methods were developed in the 1990s for measurements at atmospheric pressure using continuous flow of vapor in a carrier gas (Bergren 1994; Marshall et al. 1994; Williams 1995). This technique is commonly known as dynamic vapor sorption (DVS). A sample with mass in the milligram range is suspended from a microbalance along with a reference (or counterweight). The sample is located in a chamber maintained at constant temperature. Vapor mixed with inert carrier gas (such as nitrogen) is continuously flowed through the sample chamber. In the case of water vapor, the relative humidity is controlled by mixing dry and humidified streams of carrier gas in the desired ratio using mass flow controllers. The method thus allows for rapid step changes in relative humidity and gravimetric measurement of time-dependent moisture sorption or desorption.

Within the last decade, a number of papers have used DVS to examine wood and related cellulosic materials (Kohler et al. 2003; Olsson and Salmén 2004). Wood samples may be ground or cut into small sections. Differences in sample preparation may not have a large effect on EMC but may affect the time to reach equilibrium. In DVS measurements, the balance has a much higher precision than manual measurements, and the operator needs to make a decision about how much time is needed to determine an equilibrium condition. Commonly used criteria for wood (and cellulosic materials) are a change in moisture content of 0.002% per minute over a 10-min period (e.g., Hill et al. 2009) or a constant hold time of 60 min per RH step (Driemeier et al. 2012; Patera et al. 2013), although several other criteria have also been used (Kohler et al. 2003, 2006; Yakimets et al. 2007; Sun et al. 2009; Paes et al. 2010; Ceylan et al. 2012; Volkova et al. 2012; Williams and Hodge 2013). The EMC is either taken as the last measured moisture content (Sharratt et al. 2010) or taken as the asymptotic moisture content from a kinetic model fit to the moisture content versus time data (Hill et al. 2009). Determination of EMC from DVS measurements is thus sensitive to (1) the amount of data collected and potentially (2) the model used to extrapolate the data. Proper selection of the hold time in DVS measurements therefore requires a priori knowledge of the full mass versus time curve for a given material at each RH step to make sure the EMC prediction is correct.

The most commonly cited method for determining when sufficient data have been collected for EMC determination is a change in moisture content of 0.002% per minute over a 10-min period (Hill et al. 2009, 2010a, b, 2012, 2013; Zaihan et al. 2009; Engelund et al. 2010; Jalaludin et al. 2010a, b; Sharratt et al. 2010; Xie et al. 2010, 2011b; Zaihan et al. 2010; Thybring et al. 2011; Keating et al. 2013; Popescu et al. 2013). In these papers, it is unclear whether the reference mass is total mass \(({\frac{100}{{m_{\text{tot}} }}\frac{{{\text{d}}m_{\text{tot}} }}{{{\text{d}}t}}})\) or dry mass \(( {\frac{{{\text{d}}M}}{{{\text{d}}t}} = \frac{100}{{m_{\text{dry}} }}\frac{{{\text{d}}m_{\text{tot}} }}{{{\text{d}}t}}})\). We interpreted it as the latter (i.e., \(|{\text{d}}M/{\text{d}}t|\, = \,0.002\% \min^{ - 1}\)), which is the case if the reference mass is updated right after the sample is dried in the first step (as is commonly done by most DVS users). In some cases, data were then extrapolated with the parallel exponential kinetics (PEK) model to determine the equilibrium moisture content (Hill et al. 2010a, b). The PEK model, first proposed for cellulosic materials by Kohler et al. (2003, 2006), is an extension of a single exponential model. The PEK model can be described by

with n = 2 where M(t) is the time-dependent moisture content, M 0 is the moisture content prior to the RH step change (at time t = 0), \(\Delta M_{i}\) are the asymptotic changes in moisture content for the parallel processes, and \(\tau_{i}\) are their characteristic times. The single exponential kinetics (SEK) model and triple exponential kinetics (TEK) model can be described by the same equation when n = 1 and n = 3, respectively. A key feature of the PEK model is that there are two time constants that describe two sorption processes. Researchers who have used the \({\text{d}}M/{\text{d}}t = 0.002\% \min^{ - 1}\) criterion have reported time constants on the order of 1–50 min for \(\tau_{1}\) and 5–250 min for τ 2 (Hill et al. 2010a, b; Zaihan et al. 2010). Where reported, the time needed to reach the criterion at a given RH step varied but in many cases was <60 min, especially at low RH (Kohler et al. 2003, 2006; Hill et al. 2010b, 2012; Jalaludin et al. 2010a; Sharratt et al. 2010; Zaihan et al. 2010; Thybring et al. 2011; Xie et al. 2011a, b; Popescu et al. 2013). The total isotherms could be collected in less than 3 days using these criteria (Kohler et al. 2003, 2006; Hill et al. 2009, 2010a; Engelund et al. 2010; Jalaludin et al. 2010b; Zaihan et al. 2010; Xie et al. 2011a, b; Volkova et al. 2012).

Interestingly, no data were found presented to support the claim that \({\text{d}}M/{\text{d}}t = 0.002\% \min^{ - 1}\) is sufficient for an accurate determination of EMC. Most papers state that this criterion has been shown to yield asymptotic values within 0.1% MC of the equilibrium value measured in long-term exposure experiments; however, the extended time data have not been shown, even when citations are given to previous work (Hill et al. 2009, 2010a). Furthermore, it is unclear how the equilibrium value at extended time was determined (DVS or manually), how long the extended time was, and whether it was sufficient for the samples to reach equilibrium. In cases where the data were not extrapolated, and the last measured moisture content when \({\text{d}}M/{\text{d}}t = 0.002\% \min^{ - 1}\) was taken as EMC, it is useful to compare this to criteria previously used in manual measurements. For example, the dM/dt criterion of the manual measurements of Zelinka and Glass (2010) was 0.00006% min−1 and that of Spalt (1958) ranged between 0.0002% min−1 at low RH and 0.00007% min−1 at high RH. These differences in criteria may have an effect on the reported EMC; Willems (2015) noted that in some cases the isotherms obtained with DVS over a few days appear different from those collected manually over many weeks.

Here, for the first time, it was shown that wood, holocellulose, and lignin exhibit much longer time constants (on the order of 500 min or longer) that are not captured by previous DVS measurements. This long-time behavior has an appreciable effect on the predicted equilibrium moisture content. This paper models DVS data at long hold times and shows how short hold times can lead to incorrect predictions of the equilibrium moisture content.

Materials and methods

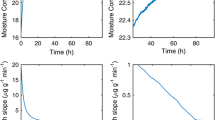

Sorption data were collected on a gravimetric dynamic vapor sorption analyzer (IGAsorp, Hiden Isochema, Warrington, UK). The instrument has a microbalance with a resolution of 0.1 µg, located within a thermostatically controlled chamber purged with dry nitrogen. The sample is placed in a stainless-steel mesh basket suspended from the balance inside a separate chamber with controlled temperature and RH, and sample mass is continuously recorded. The humidity is controlled by mixing dry and water vapor-saturated nitrogen streams at a total flow of 250 mL min−1 using electronic mass flow controllers, with feedback provided by a RH sensor placed in the chamber near the sample. In a typical experiment, the sample was first held at the experimental temperature for 10 h or longer under flow of dry nitrogen and then exposed to a series of relative humidity steps, from 0% RH to 95% RH in increments of 5% RH, followed by the same steps in reverse order. Sample dry mass was determined after completion of adsorption and desorption steps under flow of dry nitrogen at 105 °C to constant mass, which was typically reached in about 3 h. Data were typically collected under constant temperature and relative humidity for times varying from 600 min (10 h) to as long as 1440 min (24 h). For certain RH steps, data collection was arbitrarily extended for as long as 3000 min (50 h) when the change in moisture content with time after the initial 24 h was 0.0001% min−1 or greater. Data were recorded at intervals of 1 min or less. The temperature and RH in the sample chamber were extremely stable throughout these long hold times; an example is shown in Fig. 1.

Data from three materials are presented: southern pine (believed to be slash pine, Pinus elliottii) cut to a 300-μm-thick transverse section with a sliding microtome, lignin extracted from Loblolly pine (Pinus taeda), and holocellulose extracted from Loblolly pine (Pinus taeda). Sample dry mass was between 4.0 and 11.6 mg. The materials were part of a larger study on wood moisture relations and fiber saturation (Zelinka et al. 2012, 2016a, b). Details on the extraction methods for the lignin and holocellulose can be found elsewhere (Yelle et al. 2008; Zelinka et al. 2012).

Various RH steps with long hold times were selected for curve fitting, and three methods were used. Data from the first 60 min following a RH step change were fit to the PEK model (Eq. 1 with n = 2), which is denoted “PEK-I.” A second PEK fit was done using data until the change in moisture content with time was less than 0.002% per minute over a 10-min period, which is denoted “PEK-II.” In addition, data at the full hold times were fit to a triple exponential kinetics (TEK) (Eq. 1 with n = 3).

Model parameters were optimized with software that minimized the residual sum of squares using the generalized reduced gradient nonlinear algorithm (Microsoft Excel 2013 Solver). The fits excluded data at early times before the RH had fully adjusted to the new condition (about 1 min). Instead of shifting the time axis when removing these data points at early time and constraining M 0 to be equal to the first data point used for curve fitting (as was done, for example, by Hill et al. 2010a), the approach used here was to leave the time axis unaltered when deleting data at early times but allow M 0 to be a fit parameter in the optimization. Comparison of the two different approaches on the same data (not shown) indicates that the fits yield essentially the same EMC, characteristic times, and root-mean-square error (RMSE).

Results

Figure 2 illustrates a step change from 90 to 95% RH in southern pine where data were collected for 2050 min (34 h) at 40 °C; the subfigures (a–c) illustrate the effects of different hold time criteria. In Fig. 2a, the first 60 min of the data is shown along with the PEK fit to the data (PEK-I). Figure 2b plots the first 258 min of the adsorption step, which corresponds to dM/dt = 0.002% MC min−1 along with the PEK fit to the data (PEK-II). For comparison, the PEK fit from Fig. 2a is included. Importantly, the PEK-I fit diverges from the actual data and under-predicts the moisture content at 258 min by 0.4% MC. Figure 2c contains the full 2050 min of data, with the triple exponential kinetic model fit to the data; the PEK-I and PEK-II fits are included for comparison. Both PEK fits under-predict the final moisture content of 18.18% MC found by extrapolation of the TEK fit. The PEK models flatten off shortly outside of the region of data they fit; they are unable to capture the slow increase at extended times.

Moisture content as a function of time for southern pine in adsorption from 90 to 95% RH at 40 °C. The white overlay represents the PEK fit (a, b) or the TEK fit (c) to the data shown in the subfigure. a The data truncated at 60 min, b the data truncated at dM/dt = 0.002% MC min−1, c all the data collected (2050 min) with the fits from a and b overlaid. d–f The residuals of the PEK or TEK fit to the data in (a–c), respectively

The residuals of the PEK and TEK fits are given in Fig. 2d–f. Interestingly, they are all roughly equal in magnitude regardless of the amount of data used in the fits. The residuals are generally less than ±0.02% MC after the first 10 min. The root-mean-square error (RMSE) of the residuals is 0.0064, 0.0078, and 0.0058% MC for the PEK-I, PEK-II, and TEK fits, respectively. The slightly higher RMSE for the PEK-II fit reflects the visible oscillation in the residuals (Fig. 2e), which suggests that this model is not fully successful at fitting behavior at intermediate- to long-time scales.

Figure 3 shows an example in desorption for southern pine, taken from a step change from 95 to 90% RH where data were collected for 1440 min (24 h) at 40 °C. Like Figs. 2 and 3a shows the data from the first 60 min of the test and Fig. 3b shows the data truncated when |dM/dt| = 0.002% MC min−1. However, in this example the criterion was reached at 30 min, so Fig. 3b contains less data than Fig. 3a. Figure 3c shows the entire 1440 min of data with the TEK fit overlaid along with the PEK fits from Fig. 3a, b overlaid. The residuals are shown in Fig. 3d–f. Similar to the residuals in Fig. 2, the residuals are small after the first 10 min, generally remaining under ± 0.02% MC no matter the curve fit or amount of data used. Again the RMSEs are comparable for the three criteria (0.0071, 0.0085, and 0.0066% MC, for figure d–f, respectively). The PEK extrapolations from the truncated data sets under-predict the change in moisture content and thus predict a higher moisture content than is predicted from the TEK fit to 1440 min of data. The PEK fits in Fig. 3a, b both extrapolate to an equilibrium moisture content of 17.32%, whereas the TEK fit to the larger data set predicts an equilibrium moisture content of 16.97%.

Moisture content as a function of time for southern pine in desorption from 95 to 90% RH at 40 °C. The white overlay represents the PEK fit (a, b) or the TEK fit (c) to the data shown in the subfigure. a The data truncated at 60 min, b The data truncated at |dM/dt| = 0.002% MC min−1, c all the data collected (1440 min) with the (almost identical) fits from a and b overlaid. d–f The residuals of the PEK or TEK fit to the data in (a–c), respectively

Both Figs. 2 and 3 examine steps between high RH conditions, where it has long been known that the kinetics are slower (Spalt 1957, 1958). Figure 4 shows a desorption step for southern pine from 10 to 5% RH at 40 °C where data were collected for 1440 min (24 h). Figure 4a plots the first 60 min of data; Fig. 4b plots the first 38 min of data (|dM/dt| = 0.002% MC min−1); and Fig. 4c plots the full 1440 min of data with a fit of the TEK model overlaid and the PEK fits from Fig. 4a, b added for comparison. Even under these low RH conditions, both the PEK-I and PEK-II fits under-predict the change in moisture content corresponding to this change in RH (extrapolated EMC is 2.6% for a and b as opposed to 2.4% in c). The residuals are shown in Fig. 4d–f. It should be noted that the residuals are much lower in magnitude than the residuals in Figs. 2 and 3; this is not surprising since the absolute value of the moisture content is lower. However, as in Figs. 2 and 3, the residuals are similar for all three fits (RMSEs of 0.0027, 0.0022, and 0.0031% MC for d–f, respectively). The data in Figs. 2, 3, and 4 show that previously used criteria for stopping data collecting in DVS can lead to errors in the extrapolated moisture content over a range of relative humidities in both adsorption and desorption for southern pine.

Moisture content as a function of time for southern pine in desorption from 10 to 5% RH at 40 °C. The white overlay represents the PEK fit (a, b) or the TEK fit (c) to the data shown in the subfigure. a The data truncated at 60 min, b The data truncated at |dM/dt| = 0.002% MC min-1, c all the data collected (1440 min) with the fits from a and b overlaid. d–f represent the residuals of the PEK or TEK fit to the data in (a–c), respectively

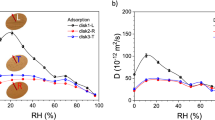

Similar trends were also observed for wood cell wall components. Figure 5 presents data from lignin at different RH steps at 25 °C. Figure 5a presents data from an adsorption step from 90 to 95% RH where data were collected for about 2900 min along with PEK-I, PEK-II, and TEK fits. Likewise, Fig. 5b shows the same material in desorption from 95% to 90% RH. Figure 5c, d shows desorption steps (1440 min of data) from 55 to 50% RH and 10 to 5% RH, respectively. In all subfigures, the long-time constant in the TEK fit for lignin is much higher than the corresponding time constant for southern pine. For example, τ 3 = 593 min for southern pine adsorption from 90 to 95% RH, whereas it is equal to 1790 min for the same RH step in lignin. Because the kinetics are so much slower, it is not surprising that the errors in the EMC prediction are also greater; the difference between TEK and PEK-II extrapolations for lignin is 2.8% MC at 90–95% RH, whereas it is only 0.4% MC for southern pine at that RH step.

Moisture content of lignin as a function of time measured over RH steps from a 90 to 95%, b 95 to 90%, c 55 to 50%, d 10 to 5%. The white curve represents a TEK fit to the entire data set. In each figure, the gray dashed curve and solid curve represent the PEK fits to the first 60 min of data and the data truncated at dM/dt = 0.002% min−1, respectively

Figure 6 presents data for holocellulose that was isolated from southern pine for three RH steps: adsorption from 90 to 95% RH (Fig. 6a), desorption from 95 to 90% RH (Fig. 6b), and desorption from 55 to 50% RH (Fig. 6c). The adsorption step from 90 to 95% RH displayed unusual kinetics. The PEK-I fit to the first 60 min of data significantly overestimated the change in moisture content, rather than underestimating as in previously shown data. The PEK-II fit based on the 0.002% min−1 criterion (350 min) resulted in a single exponential fit (ΔM 1 went to 0). The TEK fit to the full data set resulted in a double exponential fit (ΔM 1 also went to 0). The PEK-II and TEK extrapolations were very similar. The desorption steps from 95 to 90% RH (Fig. 6b) and 55 to 50% RH (Fig. 6c), however, show behavior closer to that shown previously for southern pine and lignin in that the PEK-I and PEK-II fits underestimate the actual change in moisture content.

Moisture content of holocellulose as a function of time measured over RH steps from a 90 to 95% b 95 to 90% c 55 to 50%. The white curve represents a TEK fit to the entire data set. In each figure, the gray dashed curve and solid curve represent the PEK fits to the first 60 min of data and the data truncated at dM/dt = 0.002% min−1, respectively. In c, the 60-min and 0.002% min−1 curves overlap

Discussion

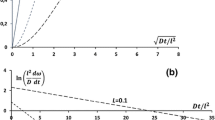

In nearly all cases presented in Figs. 2, 3, 4, 5, and 6, the measured moisture content at long times diverged from PEK model predictions based on shorter hold times. This divergence appears to be a result of a very slow third time constant in the sorption response, which is not captured in the PEK model. This is illustrated in Table 1, which lists the time constants from the TEK fits in Figs. 2, 3, 4, 5, and 6. While τ 1 and \(\tau_{2}\) are very similar to the time constants previously reported with PEK fits to shorter hold times, τ 3 is much larger than any previously reported time constant for sorption in cellulosic materials acquired with DVS. The data clearly show that longer hold times are needed to accurately characterize material behavior when using DVS.

Table 2 shows the differences in predictions that occur from stopping data collection at different time points. The data are compared against the TEK fit to the data at extended time. For the \({\text{d}}M/{\text{d}}t = 0.002\% \min^{ - 1}\) criterion, data are presented for three cases: (1) the EMC is taken as the last data point; (2) the EMC is predicted from a fit of the data to the PEK model; and (3) the EMC is predicted from a fit to a single exponential model. In all cases, the magnitudes of the differences are greater than or equal to 0.15% MC, and in some cases the predictions differ by more than 1% MC. When the magnitudes of the differences are compared on average, the PEK fit to the \({\text{d}}M/{\text{d}}t = 0.002\% \,{ \hbox{min} }^{ - 1}\) criterion comes the closest to predicting the asymptotic data based on long hold times.

While the previously used criteria are insufficient for accurate extrapolation, using longer hold times in DVS is not without drawbacks. The biggest limitation is the time needed to take measurements. Most DVS instruments do not allow measurements to be taken in parallel. With a 24-h hold time at each RH step, a single isotherm takes several weeks for a single replicate of a single material.

In addition to measurement duration, at long hold times, the stability of the temperature and RH control are very important. Figure 1 shows an example of the stability of the temperature and RH at long hold time, under high RH conditions. Although the temperature and RH were stable, it was found that a potential concern with collecting data at long times is the appearance of random fluctuations in sample mass or sudden step changes in sample mass (Fig. 7). These mass fluctuations are likely a result of large floor vibrations affecting the instrument despite attempts at vibration isolation. The longer the hold time at a given step, the higher the probability that a large vibration would occur. The fluctuation shown in Fig. 7a did not require any systematic correction, but data that appeared “bumpy” were arbitrarily excluded from the TEK fit (330–600 min). The data in Fig. 7c illustrate a shift in mass at approximately 320 min. This shift was corrected by a simple offset: Each data point at times greater than 320 min was lowered by 0.02% MC (Fig. 7e). Comparing the TEK fits (not shown) to the uncorrected and corrected data, the correction lowered the RMSE from 0.0042 to 0.0033% MC but resulted in only a small change in predicted EMC (12.47 vs. 12.55% MC).

Examples of mass fluctuations that can occur during long hold times. a “Bump” in data with TEK fit excluding the values between the vertical lines (330–600 min); c one time offset in the data; e data in (c) showing a correction to the data consisting of (a) −0.02% MC offset applied to data at times greater than 320 min (solid line). Residuals are shown in (b), (d), and (f)

Given that the dM/dt = 0.002% min−1 and the 60-min criteria yield faulty predictions in the extrapolated equilibrium moisture content, it is logical to examine other potential criteria to determine valid hold times. Figure 8 plots dM/dt curves versus time for all of the data presented in the paper. The curves were generated by taking an analytical derivative of the TEK fit instead of the actual data to reduce noise and better illustrate the trends in the data. In general, the absolute value of the change in moisture content with respect to time decreases as time progresses, consistent with the moisture content gradually approaching an asymptote. The various curves, however, display a wide range of behavior. The steepness of the slopes of these curves (i.e., d2 M/dt 2) is a measure of how fast the curves are converging to the asymptote at a given time and dM/dt.

Absolute value of the change in the moisture content with respect to time as a function of time for the first 6 h of adsorption and desorption data shown in Figs. 2, 3, 4, 5, and 6, as calculated from the analytical derivative of the TEK fit to the data. Previously used criteria (60 min and dM/dt = 0.002% min−1) are plotted with bold solid lines. The dashed curves were both collected for lignin and are highlighted to show the differences in dM/dt behavior within a given material at different RH steps

To illustrate the difficulties in determining appropriate hold time criteria, two of the curves in Fig. 8 are highlighted with different line types. Both of these curves were collected on lignin isolated from southern pine. The dashed (–) curve in Fig. 8 (55–50% RH step, corresponding to data in Fig. 5c) very quickly reaches 0.002% min−1 and |dM/dt| continues to decrease rapidly, consistent with the moisture content rapidly approaching an asymptote. EMC predicted by the PEK-II and TEK fits in this case differs by only 0.2% MC. In contrast, the dot-dash curve (·-) (90–95% RH step, corresponding to data in Fig. 5a) reaches 0.002% min−1 less rapidly and then continues to have a similar dM/dt for a long time afterward. In this case, the EMCs predicted by the PEK-II and TEK fits differ by a much larger value of 2.8% MC. Selecting an appropriate hold time criterion for accurate extrapolation will require more information than just dM/dt or an arbitrary amount of time. In actuality, the numerical derivatives are noisy particularly below 0.001% min−1 and the second derivatives are impractical because they are even noisier. While these curves give insight into how cellulosic materials can approach equilibrium, a more expansive analysis including more data is needed to develop robust equilibrium criteria.

In summary, these data force us to rethink how DVS is used to measure sorption isotherms for wood and other cellulosic materials. While the data show that previously used criteria cause faulty predictions in the extrapolated moisture content, it is still unclear whether the data in Figs. 2, 3, 4, 5, and 6 are sufficient to properly extrapolate to equilibrium. Further research is needed to confirm that these materials are truly approaching equilibrium and to develop robust hold time criteria, ensuring that DVS data are sufficient to yield accurate extrapolations of EMC.

Conclusion

DVS measurements at extended hold times indicate that previously used criteria for hold time mischaracterize the equilibrium moisture content for southern pine, lignin, and holocellulose. Criteria for hold time examined here were (1) a fixed time of 60 min, (2) a variable time, until the change in moisture content was 0.002% per minute over a 10-min period, and (3) a range of variably long hold times. Although the data at short times are consistent with previous measurements showing sorption processes with two characteristic times, the data at extended times (24–50 h) exhibit slow sorption behavior that has a significant effect on the final moisture content. Data collected at extended times can be fit with a TEK model, with the third time constant on the order of 500–2000 min. While the previously used criteria result in extrapolations that deviate from the data at long hold times, more data are needed to develop new robust criteria. Importantly, the criteria should account for cases where the moisture content changes very slowly with time and does not quickly converge to an equilibrium value.

References

Astill D, Hall P, McConnell J (1987) An automated vacuum microbalance for measurement of adsorption isotherms. J Phys E Sci Instrum 20:19

Benham M, Ross D (1989) Experimental determination of absorption–desorption isotherms by computer-controlled gravimetric analysis*. Z Phys Chem 163:25–32

Bergren MS (1994) An automated controlled atmosphere microbalance for the measurement of moisture sorption. Int J Pharm 103:103–114

Ceylan Ö, Landuyt L, Meulewaeter F, Clerck K (2012) Moisture sorption in developing cotton fibers. Cellulose 19:1517–1526

Driemeier C, Mendes FM, Oliveira MM (2012) Dynamic vapor sorption and thermoporometry to probe water in celluloses. Cellulose 19:1051–1063

Engelund ET, Klamer M, Venås TM (2010) Acquisition of sorption isotherms for modified woods by the use of dynamic vapour sorption instrumentation: principles and practice. In: 41st annual meeting of the international research group on wood protection, Biarritz, France, 9–13 May 2010. IRG Secretariat

Engelund ET, Thygesen LG, Svensson S, Hill CAS (2013) A critical discussion of the physics of wood–water interactions. Wood Sci Technol 47:141–161

Glass SV, Zelinka SL (2010) Moisture relations and physical properties of wood. In: Ross RJ (ed) Wood handbook, wood as an engineering material. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison

Glass SV, Zelinka SL, Johnson JA (2014) Investigation of historic equilibrium moisture content data from the Forest Products Laboratory. General technical report FPL–GTR–229. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, p 34

Hill CAS, Norton A, Newman G (2009) The water vapor sorption behavior of natural fibers. J Appl Polym Sci 112:1524–1537

Hill CAS, Norton AJ, Newman G (2010a) The water vapour sorption properties of Sitka spruce determined using a dynamic vapour sorption apparatus. Wood Sci Technol 44:497–514

Hill CAS, Norton A, Newman G (2010b) The water vapor sorption behavior of flax fibers—Analysis using the parallel exponential kinetics model and determination of the activation energies of sorption. J Appl Polym Sci 116:2166–2173

Hill CAS, Keating BA, Jalaludin Z, Mahrdt E (2012) A rheological description of the water vapour sorption kinetics behaviour of wood invoking a model using a canonical assembly of Kelvin-Voigt elements and a possible link with sorption hysteresis. Holzforschung 66:35–47

Hill CAS, Ramsay J, Laine K, Rautkari L, Hughes M (2013) Water vapour sorption behaviour of thermally modified wood. Int Wood Prod J 4:191–196

Jalaludin Z, Hill CAS, Samsi HW, Husain H, Xie Y (2010a) Analysis of water vapour sorption of oleo-thermal modified wood of Acacia mangium and Endospermum malaccense by a parallel exponential kinetics model and according to the Hailwood-Horrobin model. Holzforschung 64:763–770

Jalaludin Z, Hill CAS, Xie Y, Samsi HW, Husain H, Awang K, Curling SF (2010b) Analysis of the water vapour sorption isotherms of thermally modified acacia and sesendok. Wood Mat Sci Eng 5:194–203

Keating BA, Hill CAS, Sun D, English R, Davies P, McCue C (2013) The water vapor sorption behavior of a galactomannan cellulose nanocomposite film analyzed using parallel exponential kinetics and the Kelvin-Voigt viscoelastic model. J Appl Polym Sci 129:2352–2359

Kohler R, Dück R, Ausperger B, Alex R (2003) A numeric model for the kinetics of water vapor sorption on cellulosic reinforcement fibers. Compos Interfaces 10:255–276

Kohler R, Alex R, Brielmann R, Ausperger B (2006) A new kinetic model for water sorption isotherms of cellulosic materials. Macromol Symp 244:89–96

Marshall PV, Cook PA, Williams DR (1994) A new analytical technique for characterising the water vapour sorption properties of powders. Paper presented at the international symposium on solid oral dosage forms, Stockholm

Olsson AM, Salmén L (2004) The association of water to cellulose and hemicellulose in paper examined by FTIR spectroscopy. Carbohydr Res 339:813–818

Paes SS, Sun S, MacNaughtan W, Ibbett R, Ganster J, Foster TJ, Mitchell JR (2010) The glass transition and crystallization of ball milled cellulose. Cellulose 17:693–709

Patera A, Derome D, Van den Bulcke J, Carmeliet J (2013) 3D Experimental investigation of the hygro-mechanical behaviour of wood at cellular and sub-cellular scale: detection of local deformations. In: 1st international conference on tomography of materials and structures (ICTMS 2013). pp 55–58

Popescu C-M, Hill CAS, Curling S, Ormondroyd G, Xie Y (2013) The water vapour sorption behaviour of acetylated birch wood: how acetylation affects the sorption isotherm and accessible hydroxyl content. J Mat Sci 49:2362–2371

Rasmussen M, Akinc M (1983) Microcomputer-controlled gravimetric adsorption apparatus. Rev Sci Instrum 54:1558–1564

Sharratt V, Hill CAS, Zaihan J, Kint DPR (2010) Photodegradation and weathering effects on timber surface moisture profiles as studied using dynamic vapour sorption. Polym Degrad Stab 95:2659–2662

Siau JF (1995) Wood: influence of moisture on physical properties. Department of Wood Science and Forest Products, Virginia Polytechnic Institute and State University, Blacksburg

Skaar C (1988) Wood–water relations. Springer, New York

Spalt H (1957) The sorption of water vapor by domestic and tropical woods. For Prod J 7:331

Spalt H (1958) The fundamentals of water vapor sorption by wood. For Prod J 8:288–295

Stamm AJ (1964) Wood and cellulose science. The Ronald Press Co., New York

Sun S, Mitchell JR, MacNaughtan W, Foster TJ, Harabagiu V, Song Y, Zheng Q (2009) Comparison of the mechanical properties of cellulose and starch films. Biomacromolecules 11:126–132

Thybring EE, Klamer M, Venås TM (2011) Adsorption boundary curve influenced by step interval of relative humidity investigated by Dynamic Vapour Sorption equipment. In: 42nd annual meeting of the international research group on wood protection, Queenstown, New Zealand. IRG Secretariat, pp Paper IRG/WP 11-40547

Tiemann HD (1906) Effect of moisture upon the strength and stiffness of wood. US Department of Agriculture, Forest Service Bulletin 70, Government Printing Office, Washington

Volkova N, Ibrahim V, Hatti-Kaul R, Wadsö L (2012) Water sorption isotherms of Kraft lignin and its composites. Carbohydr Polym 87:1817–1821

Willems W (2015) A critical review of the multilayer sorption models and comparison with the sorption site occupancy (SSO) model for wood moisture sorption isotherm analysis. Holzforschung 69:67–75

Williams D (1995) The characterisation of powders by gravimetric water vapour sorption. Int Labmate 20:40–42

Williams DL, Hodge DB (2013) Impacts of delignification and hot water pretreatment on the water induced cell wall swelling behavior of grasses and its relation to cellulolytic enzyme hydrolysis and binding. Cellulose 21:221–235

Xie Y, Hill CA, Xiao Z, Jalaludin Z, Militz H, Mai C (2010) Water vapor sorption kinetics of wood modified with glutaraldehyde. J Appl Polym Sci 117:1674–1682

Xie Y, Hill C, Jalaludin Z, Curling S, Anandjiwala R, Norton A, Newman G (2011a) The dynamic water vapour sorption behaviour of natural fibres and kinetic analysis using the parallel exponential kinetics model. J Mat Sci 46:479–489

Xie Y, Hill CA, Jalaludin Z, Sun D (2011b) The water vapour sorption behaviour of three celluloses: analysis using parallel exponential kinetics and interpretation using the Kelvin-Voigt viscoelastic model. Cellulose 18:517–530

Yakimets I, Paes SS, Wellner N, Smith AC, Wilson RH, Mitchell JR (2007) Effect of water content on the structural reorganization and elastic properties of biopolymer films: a comparative study. Biomacromolecules 8:1710–1722

Yelle DJ, Ralph J, Frihart CR (2008) Characterization of nonderivatized plant cell walls using high-resolution solution-state NMR spectroscopy. Magn Reson Chem 46:508–517

Zaihan J, Hill CAS, Curling S, Hashim WS, Hamdan H (2009) Moisture adsorption isotherms of Acacia mangium and Endospermum malaccense using dynamic vapour sorption. J Trop For Sci 21:277–285

Zaihan J, Hill C, Curling S, Hashim W, Hamdan H (2010) The kinetics of water vapour sorption: analysis using parallel exponential kinetics model on six Malaysian hardwoods. J Trop For Sci 22(2):107–117

Zelinka SL, Glass SV (2010) Water vapor sorption isotherms for southern pine treated with several waterborne preservatives ASTM. J Test Eval 38:80–88

Zelinka SL, Lambrecht MJ, Glass SV, Wiedenhoeft AC, Yelle DJ (2012) Examination of water phase transitions in Loblolly pine and cell wall components by differential scanning calorimetry. Thermochim Acta 533:39–45

Zelinka SL, Glass SV, Boardman CR, Derome D (2016a) Moisture storage and transport properties of preservative treated and untreated southern pine wood. Wood Mat Sci Eng 11:228–238

Zelinka SL, Glass SV, Jakes JE, Stone DS (2016b) A solution thermodynamics definition of the fiber saturation point and the derivation of a wood–water phase (state) diagram. Wood Sci Technol 50:443–462

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Glass, S.V., Boardman, C.R. & Zelinka, S.L. Short hold times in dynamic vapor sorption measurements mischaracterize the equilibrium moisture content of wood. Wood Sci Technol 51, 243–260 (2017). https://doi.org/10.1007/s00226-016-0883-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-016-0883-4