Abstract

By expressing wood moisture content data as a function of adsorption energy, an interesting scaling capability is obtained, wherefrom the general hydrostatic pressure and temperature dependence of wood moisture content is determined. The scaling law is fully consistent with the thermodynamics of swelling. It can be used to transform room condition sorption isotherms to other temperatures and hydrostatic pressures, provided that the wood matrix is not irreversibly modified. A special procedure is suggested for the case of an irreversibly changing wood matrix, as in thermal modification and thermo-hydro-mechanical treatments. Using the present scaling theory, several fundamental aspects of wood moisture sorption are explained, such as the absence of a significant quantity of strongly bound wood moisture, the internal stress generation by sorption hysteresis in the wood cell wall, and the reason for the reversible disappearance of the sigmoid shape of the sorption isotherm at higher temperature. The results of this research may be useful (a) for transformation of known sorption data to other conditions, notably where in situ moisture measurements are difficult to perform and (b) to quantify the effects of internal stresses in the ultrastructure of the cell wall on moisture content.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

There is a growing interest in thermo-hydro-mechanical (THM) treatments of wood to obtain thermally modified wood (improved swelling and durability behavior) in combination with improved mechanical properties (Navi and Sandberg 2012). Friction welding of wood (gluing without adhesive application) is another interesting example of THM treatment (Navi and Sandberg 2012). The European Cooperation in Science and Technology (COST Action FP0904) is currently advancing the development of such applications of THM treatments. It is a formidable task to expand and connect all existing knowledge of the physical transport processes, thermochemistry, and hygro-mechanics of wood, to fully understand the nature of THM process.

A key issue in this field of research is the changing moisture content during a THM process, an important factor in the thermochemical process and all involved physical properties of wood. The availability of reliable high-temperature sorption isotherm measurements under high hydrostatic pressure is scarce, if not completely lacking. However, recently developed in situ moisture measurements on wood under THM conditions using neutron beam imaging techniques are becoming available (Mannes et al. 2012). The present paper proposes an interesting route to mathematically transform moisture sorption isotherms, measured at room temperature, to other temperature and hydrostatic pressure.

Experimental studies on the volumetric swelling of wood at the cell wall level show that the volume increment is almost equal to the added liquid volume of water (Hill and Ormondroyd 2004; Hill 2008), indicating that wood moisture below the high-humidity capillary regime is accommodated by void creation inside the dense cell wall matrix, rather than filling up preexisting pores. The hydrostatic pressure dependence of moisture sorption may be understood as the suppressed/facilitated void creation for water in the cell wall. This mechanism was essentially used in the gel theory on the hydrostatic pressure dependence of moisture sorption by Barkas (1949). Some predictions of this theory were experimentally verified by Simpson (1971) and Gunderson (1991), both concluding a reasonable agreement between theory and experiment.

Previous studies on the temperature dependence of wood moisture sorption have been performed with emphasis on finding suitable sorption models with temperature-dependent parameters to acquire empirical equations for the equilibrium moisture content, EMC, as a function of temperature T and relative humidity h (Skaar 1988; Vidal Bastías and Cloutier 2005; Nakano 2006). Activation energy analysis of temperature-dependent sorption model parameters (Nakano 2006) and thermodynamic analysis of experimental data using the Clausius–Clapeyron (CC) equation (Stamm and Loughborough 1935; Skaar 1988; García Esteban et al. 2008) have been used for scientific analysis of the water sorption mechanism, but did not result in a generalized theory on EMC(h, T).

In wood science, the gas adsorption scaling theory of Polanyi (1916) has not caught attention, although it is—under certain conditions—simply capable of predicting EMC(h, T), from just one reference isotherm EMC(h, T 0 ) for a given specimen, as shown in the present article. The Polanyi scaling law has neither been rediscovered in previous temperature-dependent wood moisture sorption studies. This may be explained in the first place by the widespread use of sorption isotherm analysis by surface sorption models, which seem incompatible with Polanyi scaling. Secondly, CC analysis appears to be often used incorrectly, violating the strict conditions of reversibility, a concern already raised by Hill et al. (2010).

The development of a new theory along the lines of Polanyi (1916) with a hydrostatic pressure extension as well as a procedure how to deal with a changing wood cell wall matrix is undoubtedly useful in supporting moisture analysis under THM conditions and may provide improved scientific understanding of wood moisture sorption.

Theory

Polanyi adsorption potential

Polanyi (1916) has treated adsorption from a point of view as a Gibbs molar free energy landscape for the interaction between the solid adsorbent and the vapor. The sorption sites are represented by energy “valleys,” wherein vapor may be condensed. The adsorbed water chemical potential μ determines the occupancy of sorption sites of the distributed adsorption energies ε. Adopting positive sign conventions of Polanyi (1916) for adsorption energy and the chemical potential with respect to bulk liquid water (μ = 0), an increase of μ, will empty more strongly adsorbed moisture (of larger ε). Polanyi (1916) argued that EMC(h, T) represents the thermodynamic equilibrium between the adsorption energy ε and the wood moisture chemical potential μ = RTln(1/h), where R = 8.31 Jmol−1K−1 is the universal gas constant and T/K. Hence, EMC should be a function of ε = RTln(1/h) only, capturing the temperature dependence of sorption.

This general thermodynamic treatment does not need presumptions on the exact nature of the sorption process, e.g., the nature and strength of the binding forces, sorption to primary sites in wood, or to secondary sites on previously adsorbed water molecules. However, capillary water may be best treated as an external phase in thermodynamic contact with the cell wall matrix—which is outside the scope of this paper.

Differential heat of adsorption

Standard thermodynamic analysis of the T dependence of sorption isotherms involves the application of the CC Eq. (1) to calculate the differential heat of adsorption, H s :

It must be kept in mind that this analysis is restricted to systems in thermodynamic equilibrium. In case of EMC being an arbitrary function of the Polanyi adsorption potential ε only, EMC = Φ(ε) with ε = μ, the evaluation of Eq. (1) leads to an important and simple result: When evaluating the total differential dΦ = 0 (Φ = const),

the identity must hold for each μ = RT ln 1/h; hence, the expression between brackets must be zero.

which yields dh/dT = hμ/RT 2, for substitution into Eq. (1):

Hence, the differential heat of adsorption for constant EMC is equal to the wood moisture chemical potential μ.

The energy representation of sorption and its scaling behavior

The water chemical potential can easily be expanded with hydrostatic pressure effects, following Barkas (1949), by accounting for the mechanical work needed for a volume expansion of the cell wall substance against a hydrostatic pressure P, for accommodation of the adsorbed water. The cell wall volumetric swelling per mole of bound moisture uptake is equal to the molar water volume in its liquid state (Hill and Ormondroyd 2004). Possible effects of wood contraction by adsorption of bridging water molecules between polymer chains at low h < 0.05 (Cudinov 1966) or compressed water at crystalline cellulose surfaces (Matthews et al. 2006) do not seem to give significant effects on the magnitude of total volume swelling of the cell wall in the humidity range of interest (0.05–0.95).

The mechanical work for swelling is given by v m P, where v m is the molar volume of liquid water (=1.8·10−5 m3 mol−1). Hence, the moisture chemical potential, representing the tendency for water to evaporate from the cell wall substance, must be accordingly increased to μ = RTln(1/h) + v m P, still being equal to the adsorption energy ε at equilibrium.

At ε = 0, “adsorbed” water molecules are indistinguishable from bulk liquid water; for ε > 0, adsorbed water molecules are bound stronger to the cell wall than in bulk liquid water, needing higher T, higher P, and/or lower h to escape from a binding site in the cell wall. Equation (5) gives the response of this thermodynamic system, described by the specimen specific Φ(ε), to external variables (P, T, h).

P, T, and h are explicitly independent variables in the scaling theory, but may be implicitly related. The pressure P has a contribution from the partial water vapor pressure = h · p sat(T), with p sat(T) being the saturated steam pressure, but has little effect on sorption in the practically relevant partial water vapor pressure range below 3 MPa, as will be shown in “Pressure dependence of the wood moisture sorption isotherm”.

The general scaling law

For a specified moisture content or Φ, the argument in Eq. (5) is determined, fixing the relation between pressure, temperature, and humidity:

Hence, measured isotherm moisture contents Φ(P 0 , T 0 , h) can be directly transferred to a new hydrostatic pressure P and temperature T isotherm Φ(P, T, \( h^{{T_{0}}/T} \)exp(v m P/RT−v m P 0 /RT 0 )). Two special cases will be examined in the next two subsections.

Temperature scaling at constant P 0

At constant P = P 0 , the scaling law (6) simplifies to:

Hence, measured isotherm moisture contents Φ(P 0 , T 0 , h) can be directly transferred to a new isotherm Φ(P 0 , T, h T0/T) for temperature T (Fig. 5).

Note that at h = 0 and at h = 1, there is no shift (Eq. 7): h′ = h for all T 0 /T, meaning that there should be no temperature dependence of moisture content at both outer ends of the sorption isotherm.

Pressure scaling at constant T 0

At constant T = T 0 , the scaling law (6) simplifies to:

Measured isotherm moisture contents Φ(P 0 , T 0 , h) can be directly transferred to a new hydrostatic pressure P isotherm Φ(P, T 0 , h·exp(v m(P−P 0 )/RT 0 )). Equation (8) predicts that there is no pressure dependence of moisture near h = 0. For tensions P < P 0 moisture content values shift to lower h’. Under compression P > P 0 , moisture contents shift to higher h′ ≤ 1.

The swelling pressure Π(h, T 0 ) is defined as the hydrostatic pressure P−P 0 , needed to prevent swelling (i.e., no moisture change, μ = constant) when the water activity is raised from h to h′ = 1, which can be found from (8):

Equation (9) is the well-known thermodynamic equation for the swelling pressure (Skaar 1988).

Results and discussion

Data set used for temperature dependence studies

To evaluate the temperature dependence of moisture sorption, the data from the Forest Product Laboratory Wood Handbook (Glass and Zelinka 2010) on Sitka spruce equilibrium moisture contents have been used, covering a large temperature range (−1.1 to 132.2 °C) at atmospheric pressure. Oscillating humidity was used to simulate service conditions to an averaged moisture sorption isotherm, intermediate between adsorption and desorption. This data set has been used before in numerous theoretical studies on the sorption thermodynamics and temperature dependence of sorption model parameters (Skaar 1988).

The adsorption isotherms were extrapolated to h = 1, to find the apparent fiber saturation point (AFSP) as the limiting moisture content at h = 1, using the Polanyi ln(1/h)-scaling behavior. Luikov (1968) found that sorption isotherm extrapolation to h = 1 may be performed from the linear regression of the reciprocal moisture content versus ln(1/h); a 3rd-order polynomial regression appears to give lower approximation error. The reciprocal AFSP were determined by evaluation of the latter at ln(1/h) = 0. Values of the AFSP found by this method (typ. 25 –30 %) are significantly smaller than the actual fiber saturation point FSP (typ. 40 %, Hill 2008, Hoffmeyer et al. 2011). The differences between FSP and AFSP have been discussed in detail by Siau (1984), assigning AFSP to the moisture content where physical properties (electrical conductivity, mechanical properties, shrinkage, apparent density in benzene, etc.) of wood undergo a trend change. In the present work, it is assumed that AFSP corresponds to the part of FSP moisture that swells the dense cell wall matrix by v m m3/mol, whereas the remaining moisture is non-swelling moisture in molecular layers or clustered in small, stable voids of the cell wall. The scaling theory describes swelling moisture only.

Contrary to the predictions of the scaling theory (“The general scaling law”), the determined AFSP from the Glass and Zelinka (2010) handbook data appears to be clearly temperature-dependent above 30 °C (about −0.13 % K−1, see Fig. 1). Skaar (1988) discussed a number of other studies, all with similar coefficients, attributing this temperature dependence to irreversible hydrogen bonding of cell wall polymers, which may permanently lower the number of accessible water-bonding sites. The tendency to form hydrogen bonds between polysaccharides on heating is illustrated by a thermal increase of cellulose crystallinity in wood (Bhuiyan et al. 2000; Rayirath et al. 2008) and a hydroxyl accessibility loss in 25–80 °C heated wood (Suchy et al. 2010). Hoffmeyer et al. (2011) also found lower adsorption EMC in previously oven-dried specimens compared to room temperature vacuum-dried specimens for h < 0.96, but paradoxically higher adsorption EMC values were found above h = 0.96. Such an increase, approaching h = 1, may be caused by high tensile stresses in the cell wall, caused by oven-drying (see below). The AFSP trend (Fig. 1) is, however, based on moisture content data below h = 0.95.

Temperature dependence of the AFSP, as determined from extrapolated sorption isotherms (data: Sitka spruce, Glass and Zelinka 2010)

To study the reversible temperature dependence of the moisture sorption process, it might have been better to expose all samples equally above the maximum temperature of interest under moist conditions, as a pretreatment prior to the sorption measurements (see “Dealing with irreversible state changes”). For analysis in the present work, the irreversible temperature dependence in the handbook data (Glass and Zelinka 2010) could be removed via a normalization procedure by division of all EMC values by the AFSP at the temperature of measurement. Above 100 °C, the maximum relative humidity is strongly limited by the atmospheric pressure constraint on the water vapor pressure. The isotherm extrapolation procedure to find AFSP, needed for the described normalization of EMC, then becomes unreliable for T > 100 °C, and these data could not be used.

The energy representation of Sitka spruce moisture content

Following Polanyi (1916), the normalized moisture content Φ(h, T) = EMC(h, T)/AFSP(T), evaluated for the Glass and Zelinka (2010) handbook data, now containing only reversible temperature effects, should only depend on the adsorption energy ε = RTln(1/h): Φ(h, T) = Φ(ε). This is confirmed by a master curve (Fig. 2), which may be fitted with—for instance—a stretched exponential function, also known as the Dubinin-Astakhov (DA) function in activated coal sorption studies (Hutson and Yang 1997; Stoeckli 2001):

Equation (10) was obtained from the isotherms under conditions without external hydrostatic pressure (atmospheric P 0 = 0.1 MPa can be neglected, see Fig. 3), but may be used to describe the moisture contents at arbitrary (P, T, h), according to the scaling law (Eq. 5):

Note that Eq. (10) describes the sorption properties of the Sitka spruce specimens, in a fixed state. Irreversible state changes in response to a changed (P, T, h) condition will lead to a different Φ(ε). The irreversible temperature dependence of AFSP could be divided out from the Glass and Zelinka (2010) data set, but more severe thermal degradation of the wood cell wall must be handled in another way (see “Dealing with irreversible state changes”).

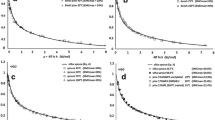

Normalized moisture content Φ data (Glass and Zelinka 2010) fitted with a DA function (broken line) of the adsorption energy ε = RTln(1/h) for 5 temperatures and, for comparison, as a function of the adsorption enthalpy H s (dotted lines, calculated for 3 temperatures using the CC Eq. (1) without normalization)

Pressure dependence of the wood moisture sorption isotherm

Assuming no state changes, the pressure dependence of Eq. (11) may be now theoretically investigated. EMC becomes less than AFSP at h = 1 for P > 0. This means that a definition of AFSP as the limiting moisture content at h = 1 under all circumstances cannot be used here. Equation (9) is an important result, showing the consistency of the scaling theory with the thermodynamics of swelling, derived under conditions where EMC < AFSP(P 0 ) at h = 1. This means that AFSP can only be defined as the extrapolated moisture content at h = 1 with specified P 0 .

Following Barkas (1949), internal and external pressures on the wood cell wall work out similarly and additively determine the volume and the moisture content of the cell wall. At h = 1 and P 0 , moisture is in the bulk liquid state, and hence, all accessible sorption sites are occupied; however, with an applied external pressure, the volume and moisture content of the wood cell wall are reduced via a reduction in the number of accessible sorption sites. This is described by Eq. (11) with constant AFSP(P 0 ).

Likewise, a large tensile stress may lead to an increase in accessible polar sorption sites by increasing the cell wall volume, which would lead to EMC > AFSP(P 0 ), provided that there are extra (polar) sorption sites available. In the case of a constant number of accessible polar sites under tension, EMC cannot increase and the transition regime toward capillary sorption is reached at h′ = h c < 1 (Fig. 3).

Figure 3 gives the calculated sorption isotherms for P = −50, −10, 0, +10, and +50 MPa, using Eq. (11) at room temperature T = 293 K. These isotherms look similar to those given by Skaar (1988), based on a different reference isotherm. Application of the present scaling theory to the latter (not shown) revealed exactly the same results as obtained by the well-established Barkas theory. The equivalence of the Barkas theory with the pressure part of the scaling theory is not surprising, since both are based on same thermodynamic principles of sorption swelling.

Equation (11) predicts that maximum stress effects on the sorption isotherm are experienced by tensile stresses near h = 1, the region where Hoffmeyer et al. (2011) found that EMC is sensitively dependent on the specimen’s preparation procedure. Macroscopic stresses of the order of several MPa, which have been shown to occur in timber drying (Allegretti and Ferrari 2008), are high enough to be seriously considered in possible explanations for this EMC behavior (Fig. 3).

In THM densification and bending, local stresses can reach values above 10 MPa (Navi and Sandberg 2012), where significant effects on equilibrium moisture content are predicted (Fig. 3). It must be realized, however, that P is the pressure (stress) experienced in the cell wall ultrastructure where the swelling takes place, which may be different from macroscopically applied stress. Internal stresses in the cell wall matrix may reach extremely high values (“Wood moisture sorption hysteresis”) with a direct effect on the sorption behavior.

Thermodynamic analysis of wood moisture sorption

The existence of a master curve Φ(ε) validates the premise made in the derivation of Eq. (4), proving the equivalence of μ(=ε) and the differential heat of adsorption. Expressing Φ as a function of H s calculated from Eq. (1) around different temperatures (26.7, 48.9, and 76.6 °C) gives separate lines instead of a master curve (Fig. 2). Moreover, the calculated H s values widely overestimate the true adsorption energies ε at any given Φ, which is graphically explained in Fig. 4.

The Φ(ε) representation (Fig. 2) does contain important information on the state of sorbed water in the wood cell wall. The typical value for the water adsorption energy ε appears to be comparable to the average thermal energy (≈RT = 2.45 kJ/mol at room temperature) in the system and much lower than the molar heat of evaporation of bulk water (≈45 kJ/mol) as well as much lower than the activation energy for bound water diffusion in the cell wall (≈35 kJ/mol, Skaar 1988). This means that most sorbed water is in a state that closely resembles bulk liquid water, but with a restricted mobility range. This is confirmed by 1H-nuclear magnetic resonance measurements on wood below FSP (Almeida et al. 2007, Thygesen and Elder 2009, Cox et al. 2010) showing dominant medium T2 relaxation components (0.5–3 ms) held characteristic for confined mobile water molecules. However, Cox et al. (2010) assigned one T1–T2 correlation peak, unresolved in other studies, to more strongly bound moisture, but with confusing trends and differences between heartwood and sapwood.

A thermodynamic argument for a liquid water-like state of adsorbed water molecules comes from the notion that ε is the molar Gibbs free energy of adsorption referred to liquid water, being equal to the molar enthalpy of adsorption H s referred to liquid water (Eq. 4). The thermodynamic consequence is that there is a negligible difference in entropy (ordering) of adsorbed water in wood compared to liquid water.

Finally, it is noted that a quick calculation on a typical cell wall elastic bulk modulus of 1 GPa, with a typical volumetric strain of 0.3 by liquid water absorption, gives an elastic potential energy of 5.4 kJ/mol, which may be directly obtained from the isothermal chemical potential change (7 kJ/mol) between h = 0.05 and h = 0.95. Hence, the shallow water-binding states, given by the Polanyi potential ε in Fig. 2, are consistent with a mechanism of moisture content control involving elastic forces in the cell wall. This interpretation supports the arguments for moisture sorption hysteresis being related to slow relaxation of the cell wall polymers (Vrentas and Vrentas 1996, Keating et al. 2013), rather than slow desorption from strong-bonding sites.

The effect of temperature scaling on the shape of the sorption isotherm

The final note in “The general scaling law” has an important implication on the change of the sorption isotherm shape by temperature variation. Since the sorption isotherm has fixed end points at h = 0 and 1 and in the intermediate range the moisture contents shift to higher h on higher temperature (Eq. 7), scaling naturally transforms a low temperature sigmoid shape to a high-temperature convex shape (Fig. 5). Applied to the handbook data of equilibrium moisture contents (Glass and Zelinka 2010), the change of shape of the normalized moisture sorption isotherms over the entire temperature range can be completely explained by scaling (hence the master curve in Fig. 2).

The change of a low-temperature sigmoid to a high-temperature convex-shaped sorption isotherm is described by scaling theory, involving a fixed set of adsorption energy states, becoming occupied at higher humidity (Eq. 7) for specified moisture content without water chemical potential change (Eq. 5). This is incompatible with already criticized (Engelund et al. 2013) surface sorption models, which would ascribe this shape transition to a sorption mode transition with water chemical potential change (strongly bound hydration/monolayer → weakly bound dissolution/multi-layer) at a specified moisture content.

Wood moisture sorption hysteresis

Wood moisture sorption hysteresis is the phenomenon that the (apparent) equilibrium moisture content of wood in a humid environment, characterized by (h,T), is dependent on the sign of h change. EMC(h,T) is always higher after desorption than after adsorption. Engelund et al. (2013) have reviewed the current scientific literature on hysteresis emphasizing the relevance of glassy-state phenomena.

It may be interesting to involve swelling pressure effects on sorption in cell wall substance, viewed as a mixture of entangled/cross-linked long polymers of various types. Even without externally applied stress, there can be internal stresses within the cell wall substance between polymeric components with different hygro-mechanical properties. There are many observations of stress interactions between different cell wall components, e.g., the shear deformation of cellulose crystallites, embedded in the lignin-hemicelluloses matrix (Zabler et al. 2010) and the correlated molecular vibrations in different wood cell wall polymers (Åkerholm and Salmén 2004).

Now, taking for example an adsorption isotherm (Fig. 6a), from the Acacia mangium dynamical vapor sorption (DVS) study by Jalaludin et al. (2010), the humidity difference toward the desorption isotherm at a specified moisture content may be used to estimate the internal stress by Eq. (8); this is more directly visualized in a ln(EMC) versus swelling pressure Π(h, T) plot (Fig. 6c). A more or less constant internal stress (≈60 MPa) seems to be responsible for the measured hysteresis in the range 0.1 < h < 0.7, which is gradually relaxed for h > 0.7. The internal stress becomes trivially zero at h = 0.95, the desorption starting point lying on the adsorption line.

a Moisture adsorption/desorption isotherms in native A. mangium at 25 °C, from the DVS study of Jalaludin et al. (2010). b Absolute hysteresis, the moisture content difference of desorption and adsorption isotherms as a function of h, with linear approximation (solid line) for h < 0.7. c Adsorption and desorption isotherms in a ln(EMC) v. RT/v m·ln(1/h) plot, showing an internal hysteresis stress of ≈60 MPa. Isotherm data provided by Prof. C. Hill, Napier University, Edinburgh, with acknowledgement

The volumetric strain, s, of the dry cell wall by moisture sorption to EMC, can be calculated from the true density of the cell wall (1,500 kg m−3, Hill 2008) and the density of the incorporated water (1,000 kg m−3) as s = 0.015·EMC. The absolute hysteresis (the numerical difference between the adsorption and desorption isotherm moisture contents at a given h) may be approximated by ΔEMC(h) ≈ 5.7 h in the range of h = 0.1–0.7 (solid line in Fig. 6b). The required extra strain Δs, to accommodate the nonequilibrium moisture ΔEMC(h), is then given by Δs ≈ 0.086 h. The internal stress of 60 MPa, obtained from Fig. 6c, may then be used to roughly estimate an apparent isotropic bulk elastic modulus K responsible for the restrained stress relaxation of the cell wall, giving values K = 60/0.086 h ranging from 1 GPa (h = 0.7) to 7 GPa (h = 0.1), practically the same magnitudes as found by Keating et al. (2013) from analysis of the slow component in the kinetics of moisture desorption from a galactomannan-cellulose nanocomposite film. The reported estimated transverse elastic modulus of lignin (2 GPa, Salmén 2004) is of the same order of magnitude, and lignin has indeed been indicated to be necessary for the expression of hysteresis (Hill et al. 2009).

Dealing with irreversible state changes

In “Thermodynamic analysis of wood moisture sorption”, it was shown that an irreversible thermal decrease of sorption sites in Sitka spruce (Glass and Zelinka 2010) could be divided out from all data points. More severe heating may bring about irreversible changes in the mechanical properties of the cell wall that cannot be treated in this simple way. To circumvent the irreversible effects, scaling laws may be applied to the irreversibly changed wood specimen when returned to standard temperature pressure (STP) room conditions (see Fig. 7), assuming that the wood specimen is then no longer unstable. The changing chemical and physical wood characteristics under THM conditions may thus be characterized by their respective moisture sorption isotherms at STP, which can be experimentally determined in the laboratory on a large number of specimens prepared at different T i , P i , h i with process time t i . The scaling law allows one to transform isotherm i at STP to any T < T i and pressure P < P i , where the composition and structure of the cell wall matrix will not be (further) irreversibly changed.

Proposed approach toward THM process moisture analysis: collect samples (i = 1…n) from a series of process runs aborted at different times (t i ), reflecting the time evolution of irreversible changes made by THM treatment, characterized by the room temperature moisture sorption isotherm. The moisture content under process conditions (P i , T, h i ) is retrieved by application of scaling relation (Eq. 5) on the low-temperature moisture sorption isotherm of sample i

Conclusion

Provided that irreversible changes in the wood cell are properly avoided, wood moisture sorption isotherms, acquired at room temperature conditions, can be transformed to other temperatures T and hydrostatic pressures P using the simple scaling law derived in this work. The scaling law is fully consistent with the thermodynamics of sorption swelling. Moisture analysis of wood under exotic processing conditions where in situ measurements are impossible to perform or difficult to verify may benefit from the results of this study, offering a different, experimentally better accessible approach.

The scaling mechanism acts on the occupancy of a distribution of adsorption energy states for moisture in wood, controlled by the water chemical potential. The water chemical potential increases linearly with P, in accordance with Barkas (1949), and linearly with T, as described by Polanyi (1916)—promoting the loss of moisture from the cell wall matrix at fixed h. To compensate for this moisture loss, the humidity h must be raised, which mechanism changes the shape of the sorption isotherm, explaining the disappearance of the sigmoid shape of moisture sorption isotherms at increased temperature.

The hydrostatic pressure P relates to the micromechanical pressure acting on the ultrastructure of the cell wall substance, biasing the moisture swelling phenomenon. Macroscopically applied stresses are not directly transferred to P, complicating the application of the theory. Fortunately, for many practically relevant applications, |P| will not exceed 3 MPa, where there is still little effect on moisture sorption. High stresses inside the cell wall, e.g., −60 MPa shown in the case of hysteresis, act directly on the sorption isotherm.

Applying thermodynamic analysis to scaling compliant wood moisture sorption isotherms shows that the moisture adsorption energy range is within thermal energy distance to the cohesion energy of bulk water. The alleged existence of strongly bound moisture in wood concluded from many thermodynamic studies seems to relate to an inappropriate application of the CC equation.

This work strongly supports the hysteresis theories based on slow glassy relaxation of the cell wall matrix in favor of the theories assuming slow release of trapped water strongly bound to the cell wall.

References

Åkerholm M, Salmén L (2004) Softening of wood polymers induced by moisture studied by dynamic FTIR spectroscopy. Appl Polym Sci 94:2032–2040

Allegretti O, Ferrari S (2008) A sensor for direct measurement of internal stress in wood during drying: experimental tests toward industrial application. Drying Technol 26:1150–1154

Almeida G, Gagné S, Hernández RE (2007) A NMR study of water distribution in hardwoods at several equilibrium moisture contents. Wood Sci Technol 41:293–307

Barkas WW (1949) The swelling of wood under stress. HM Stationary Office, London

Bhuiyan MTR, Hirai N, Sobue N (2000) Changes of crystallinity in wood cellulose by heat treatment under dried and moist conditions. Wood Sci 46:431–436

Cox J, McDonald PJ, Gardiner BA (2010) A study of water exchange in wood by means of 2D NMR relaxation correlation and exchange. Holzforschung 64:259–266

Cudinov BS (1966) The phenomenon of ‘negative swelling’ of wood perpendicular to grain during adsorption. In: Svojstva drevesiny, ee zascita, i novye drevesnye materialy. Izdat. Nauka, Moscow, pp 30–50

Engelund E, Thygesen L, Svensson S, Hill CAS (2013) A critical discussion of the physics of wood–water interactions. Wood Sci Technol 47:141–161

García Esteban L, de Palacios P, García Fernández F, Guindeo A, Conde M, Baonza V (2008) Sorption and thermodynamic properties of juvenile Pinus sylvestris L. wood after 103 years of submersion. Holzforschung 62:745–751

Glass SV, Zelinka SL (2010) Moisture relations and physical properties of wood. In: Wood Handbook, Chapter 04: General Technical Report FPL-GTR-190. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, pp 1–19

Gunderson DE (1991) Method for measuring mechanosorptive properties. Pulp Pap Sci 17:J53

Hill CAS (2008) The reduction in the fibre saturation point of wood due to chemical modification using anhydride reagents: a reappraisal. Holzforschung 62:423–428

Hill CAS, Ormondroyd GA (2004) Dimensional changes in Corsican pine (Pinus nigra Arnold) modified with acetic anhydride measured using a helium pycnometer. Holzforschung 58:544–547

Hill CAS, Norton A, Newman G (2009) The water vapor sorption behavior of natural fibers. Appl Polym Sci 112:1524–1537

Hill CAS, Norton AJ, Newman G (2010) The water vapour sorption properties of Sitka spruce determined using a dynamic vapour sorption apparatus. Wood Sci Technol 44:497–514

Hoffmeyer P, Thygesen LG, Engelund ET (2011) Equilibrium moisture content in Norway spruce during the first and second desorptions. Holzforschung 65:875–882

Hutson ND, Yang RT (1997) Theoretical basis for the Dubinin-Radushkevitch (DR) adsorption isotherm equation. Adsorption 3:189–195

Jalaludin Z, Hill CAS, Samsi HW, Husain H, Xie Y (2010) Analysis of water vapour sorption of oleo-thermal modified wood of Acacia mangium and Endospermum malaccense by a parallel exponential kinetics model and according to the Hailwood-Horrobin model. Holzforschung 64:763–770

Keating B, Hill CAS, Sun D, English R, Davies P, McCue C (2013) The water vapor sorption behavior of a galactomannan cellulose nanocomposite film analyzed using parallel exponential kinetics and the Kelvin-Voigt viscoelastic model. Appl Polym Sci 129:2352–2359

Luikov AV (1968) The Theory of Drying. Énergiya, Moscow

Mannes D, Sonderegger W, Pearson H, Lehmann E (2012) On-line monitoring of hygroscopicity changes of wood during thermal modification by means of neutron imaging methods. In: The Sixth European Conference on Wood Modification ECWM6 Proceedings. Ljubljana, Slovenia, pp 489–496

Matthews JF, Skopec CE, Mason PE, Zuccato P, Torget RW, Sugiyama J, Himmel ME, Brady JW (2006) Computer simulation studies of microcrystalline cellulose Iβ. Carbohydr Res 341:138–152

Nakano T (2006) Analysis of the temperature dependence of water sorption for wood on the basis of dual mode theory. Wood Sci 52:490–495

Navi P, Sandberg D (2012) Thermo-hydro-mechanical processing of wood. EFPL Press, Lausanne

Polanyi M (1916) Adsorption of gases (vapors) by a solid non-volatile adsorbent. Verh Dtsch Phys Ges 18:55–80

Rayirath P, Avramidis S, Mansfield SD (2008) The effect of wood drying on crystallinity and microfibril angle in black spruce (Picea mariana). J Wood Chem Technol 28:167–179

Salmén L (2004) Micromechanical understanding of the cell-wall structure. C R Biologies 327:873–880

Siau JF (1984) Transport processes in wood. Springer, Berlin

Simpson WT (1971) Moisture changes induced in red oak by transverse stress. Wood Fiber Sci 3:13–21

Skaar C (1988) Wood-water relations. Springer, Berlin

Stamm AJ, Loughborough WK (1935) Thermodynamics of the swelling of wood. Phys Chem 39:121–132

Stoeckli F (2001) Dubinin’s theory and its contribution to adsorption science. Russ Chem Bull 50:2265–2272

Suchy M, Virtanen J, Kontturi E, Vuorinen T (2010) Impact of drying on wood ultrastructure observed by deuterium exchange and photoacoustic FT-IR spectroscopy. Biomacromolecules 11:515–520

Thygesen LG, Elder T (2009) Moisture in untreated, acetylated, and furfurylated Norway Spruce monitored during drying below fiber saturation using time domain NMR. Wood Fiber Sci 41:194–200

Vidal Bastías M, Cloutier A (2005) Evaluation of wood sorption models for high temperatures. Maderas Ciencia y tecnología 7:145–158

Vrentas JS, Vrentas CM (1996) Hysteresis effects for sorption in glassy polymers. Macromolecules 29:4391–4396

Zabler S, Paris O, Burgert I, Fratzl P (2010) Moisture changes in the plant cell wall force cellulose crystallites to deform. Struct Biol 171:133–141

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Willems, W. Hydrostatic pressure and temperature dependence of wood moisture sorption isotherms. Wood Sci Technol 48, 483–498 (2014). https://doi.org/10.1007/s00226-014-0616-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-014-0616-5