Abstract

The production of waxy rice wine (WRW) usually requires multiple strains for fermentation. However, information about the contributions of individual strains to the quality of WRW remains limited. In this study, WRWs were produced through fermentation with three strains (Saccharomyces cerevisiae H1 [Sc], Hansenula sp. H3 [Hs] and Pichia kudriavzevii H6 [Pk]), and the quality of the WRWs was evaluated. The results indicated that Sc wine produced high levels of phenylethyl alcohol and 3-methyl-1-butyl acetate, reaching 31,622.78 μg/L and 351.67 μg/L, respectively; Hs wine produced the highest contents of ethyl acetate and lactic acid, reaching 69,535.58 μg/L and 17.46 g/L, respectively, and had the highest score for “acidic”; Pk wine produced high contents of 2-methyl-1-propanol, 3-methyl-1-butanol and 2-methyl-1-butanol, reaching 46,951.56 μg/L, 163,674.83 μg/L and 52,238.51 μg/L, respectively. The average concentrations of ethyl acetate, 2-methyl-1-propanol, and 3-methyl-1-butanol in mixed fermentation products increased by 126.80%, 25.82% and 17.02% compared to Sc wine, respectively, thus increasing the sensory scores for “malty” and “acidic”. In addition, high ethanol content resulted in higher scores for “winey” in WRWs. These results reveal the potential of S. cerevisiae H1 to produce ethanol, Hansenula sp. H3 to produce esters and P. kudriavzevii H6 to produce alcohols in WRW. Simultaneously, advantages of mixed fermentation for integrating the characteristics of various pure cultures were observed, namely increasing the number of volatile organic compounds (VOCs) and appropriately extending the fermentation time. The application of mixed fermentation has the potential to enrich the flavour and improve the quality of WRWs.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Chinese rice wine (CRW) is an alcoholic beverage that originated in China and has been used for thousands of years. CRW is favoured by consumers due to its unique flavour and sweet taste. However, sales of CRW are significantly lower than those of other liquors (such as Chinese baijiu and beer); the unique sensory qualities of CRW and the complexity of fermentation in an open environment are the reasons for this difference [1]. It is necessary to ameliorate the production processes and improve the CRW flavour.

CRW is brewed from grains, yeast and jiuqu (a “saccharifying starter”) [2]. The production procedure involves jiuqu mixing, fermentation, filtration, clarification, and sterilization, followed by storage and aging [3]. Fermentation is the main process of aroma formation in CRW, which usually takes 10–25 days [4]. The brewing methods [5], raw materials [6] and fermentation strains affect the types and contents of volatile organic compounds (VOCs) in CRW. The use of jiuqu is conducive to the convenience of production. However, due to the diversity of microbial species in jiuqu, it is easy to lead to the flavour difference in different batches of products. Therefore, the selection and combination of appropriate fermentation strains as starters is instrumental in controlling the formation of CRW flavour compounds [7, 8].

Members of microbial communities including yeasts, bacteria and moulds make different contributions to the flavour and quality of CRW during fermentation [9, 10]. Yeasts and filamentous fungi are involved in saccharification, liquefaction and alcohol fermentation, and contribute VOCs [7]. Starch and protein in the raw materials are saccharified and hydrolysed under the action of amylase and protein hydrolase enzymes from filamentous fungi, and thereby produce glucose and amino acids. Under the action of yeast, pyruvic acid produced from glucose through anaerobic respiration is converted to lactic acid, acetaldehyde and ethanol through alcohol fermentation. Amino acids are converted into higher alcohols through the Ehrlich pathway, and then into esters. Phenylethyl alcohol is a representative VOC in CRW; its substrate is L-aminopropionic acid. Corn, sorghum and other grains with high contents of L-aminopropionic acid can produce higher amounts of phenylethyl alcohol [1]. However, the influence of various VOCs contents on the overall flavour of CRW is nonlinear. VOCs have different effects on the sensory quality of CRW in different concentration ranges. Therefore, it is necessary to research the fermentation characteristics of different yeasts, which is conducive to controlling the production of specific VOCs in CRW.

Modern brewing industry usually selects specific S. cerevisiae for fermentation to control the fermentation process and maintain reliable and predictable quality [11], but pure cultures can cause a lack of flavour complexity in fermented products [12]. Non-Saccharomyces species can persist through all stages of natural fermentation, carry out alcohol fermentation, and alter the fermentation characteristics of wine [13]. Satora et al. [14] reported that the content of esters in wine produced with a monoculture of S. cerevisiae was only 74.8 mg/L, which is significantly lower than the level produced with monocultures and mixed cultures of other strains, while the wine fermented by S. cerevisiae had higher ethanol content. Aplin, & Edwards [15] found that wine fermented by a monoculture of Hanseniaspora uvarum had a lower ethanol content than wine produced with a monoculture of S. cerevisiae. However, the residual sugar contents were similar, which was related to the high levels of acetic acid and other products produced by H. uvarum during the fermentation process. In addition, Pichia sp. had the ability to increase the contents of esters and mercaptans, and improve the complexity of liquor aroma [16]. Anfang et al. [17] found that the co-fermentation of Pichia kudriavzevii and S. cerevisiae increased the content of 3-mercaptohexyl acetate in Sauvignon Blanc, and the two yeasts coexisted well during the fermentation process; therefore, P. kudriavzevii is considered an excellent fermentation partner for S. cerevisiae. However, little research has been done on the fermentation characteristics of these specific yeasts in CRW, especially the contribution of different yeast combinations to flavour.

In addition, sugar, organic acids and other non-VOC substances play roles in enriching the unique taste of CRW [18]. Wang et al. [19] demonstrated that the contents of organic acids increased continuously during the fermentation of CRW. Lactic acid, acetic acid, citric acid, succinic acid and tartaric acid accounted for 94% of the total organic acids, and the total content of organic acids exceeded 10,000 mg/L. Certainly, the formation of these organic acids is closely related to microorganisms. Appropriate organic acid content improves the sensory characteristics of CRW, and organic acid gradually transforms into aromatic esters [20].

Waxy rice is an excellent raw material for brewing CRW. Waxy rice provides a good fermentation substrate to increases the types and contents of VOCs, due to its high contents of protein and amylopectin [21]. In this study, we investigated the fermentation potential of various yeasts (S. cerevisiae H1, Hansenula sp. H3 and P. kudriavzevii H6), and the performance of various fermentation combinations, in waxy rice wine (WRW) through measurement of the contributions and synergy of these strains with VOCs. This study provides a reference for the selection and combination of yeast for WRW fermentation to improve the flavour quality of WRW.

Materials and methods

Materials and reagents

Waxy rice was purchased online from Yihai Kerry (Jilin) Oils, Grains & Foodstuffs Industries Co., Ltd. (Shanghai, China).

Standards with purity > 98% were purchased. n-Alkane mixtures (C7–C40) were purchased from ANPEL (Shanghai, China). Ethyl acetate (≥ 99.7%), 2-methyl-1-propanol (> 99.0%), 3-methyl-1-butanol (≥ 99.8%), 2-methyl-1-butanol (98%), 2,3-butanediol (98%), 3-methyl-1-butyl acetate (≥ 99.5%), 3-methylmercapto-1-propanol (99%), phenylethyl alcohol (> 99.0%) and 2-octanol (≥ 99%) were purchased from Aladdin (Shanghai, China).

Determination of sugar and ethanol tolerance

S. cerevisiae H1, Hansenula sp. H3 and P. kudriavzevii H6 were used in this study; these strains were isolated from jiuqu and maintained as glycerol freezer stocks at − 80 °C. The yeasts were diluted, applied to potato dextrose agar (PDA) medium (0.6 g/L potato extract, 2 g/L glucose, 2 g/L agar), and then cultured at 30 °C. The purified strains were cultured in potato dextrose broth (PDB) medium, with various concentrations of glucose (100, 200, 300, 400, and 500 μg/L) and ethanol (4, 8, 12, 16, and 20%), for 2 days and then transferred to PDA medium for observation of the growth state.

Fermentation experiments

The strains were activated and cultured to 107 CFU/mL for fermentation.

A substrate of 10 g waxy rice, 0.2 g white granulated sugar and 20 mL double-distilled water was soaked overnight for 12 h and sterilized at 121 °C for 15 min. After cooling, 0.1 g of sweet rice leaven containing only Rhizopus (Angel, Hubei, China) and 20 ml of sterile water were added. Finally, 500 μL of single-strain fermentation or mixed-strain fermentation cultures were added. Single-strain fermentation WRWs were designated as Sc, Hs and Pk. The mixed-strain fermentation WRWs were labelled Sc/Hs, Sc/Pk, Hs/Pk and Sc/Hs/Pk. The sample indexes were determined on days 2, 4, 6, 8 and 10.

Determination of oenological characteristics

The ethanol content, residual sugar, pH and titratable acid content of WRWs were analysed according to methods described in previous studies [22]. The ethanol content and residual sugar were determined using an external standard, and the content of titratable acid was calculated based on acid–base titration.

High performance liquid chromatography (HPLC) analysis

Organic acid contents were determined through HPLC with reference to previously published methods [23]. Briefly, 20 μL of filtrate produced using a 0.45-μm nylon membrane was analysed with an Acclaim OA column (4.0 mm × 250 mm, 5 μm). The column box temperature was 30 °C, 0.1 mol/L Na2SO4 (pH 2.65) was used as the mobile phase with a flow rate of 0.5 mL/min, and the detection wavelength was 210 nm. The organic acid contents were calculated from the standard curve.

Gas chromatography-mass spectrometry (GC–MS) analysis

VOCs were extracted via liquid–liquid extraction (LLE) following previously reported methods [24] with slight alterations. Briefly, 5 mL WRWs, 10 μL 2-octanol (800 mg/L) and 2 g NaCl were mixed in a 50-mL centrifuge tube and extracted twice with dichloromethane (15.0 mL each time). The subnatant and 3 g anhydrous sodium carbonate were vortexed and left to stand for 5 h, and then evaporated to 1 mL at 30 °C.

VOCs were separated using a DB-5 UI capillary column (30 m × 0.25 mm × 0.25 μm) and helium at a flow rate of 2.3 mL/min as the carrier gas, with a split ratio of 1:5. The GC oven temperature was first held at 40 °C for 5 min, increased to 150 °C at a rate of 5 °C/min (held for 1 min), and then increased further to 230 °C at 10 °C/min (held for 3 min). The ionization voltage, ion source temperature, interface temperature and scanning range were 70 eV, 230 °C, 250 °C and 30–550 m/z, respectively. The types, quantities and names of the VOCs in the samples were determined from the mass spectra and retention indices (RIs) provided in the NIST database and NIST Chemistry Webbook. The RIs were computed using n-alkanes (C7–C40) under the same chromatographic conditions used for VOC detection. The contents of VOCs were preliminarily quantified using the internal standard method [25]. Eight VOCs with flavour intensity ≥ 1 were quantified by external standard method. The standard curve was drawn with the ratio of the concentration of the standard to 2-octanol as the abscissa (x) and the ratio of the peak area of the standard to 2-octanol as the ordinate (y).

Gas chromatography–olfactometry (GC-O) analysis

GC-O analysis and aroma extract dilution analysis (AEDA) were performed by eight people (four men and four women; average age = 25 years) with professional knowledge and training [26]. A 6-point intensity scale ranging from 0 to 5 was used to evaluate odour intensity, wherein "0" represents no odour, "3" represents moderate odour, and "5" represents extreme odour. The retention time, intensity value and odour description were recorded. The aroma intensity of each substance is presented as the average value of the eight team members’ scores.

AEDA

The samples were serially diluted (two-fold), resulting in ratios of 1:2, 1:4, 1:8, 1:16, etc. [27]. The diluted samples were analysed with GC-O until they no longer presented an odour [28]. The ratio of the concentration of an aroma compound in the initial sample to its concentration in the maximally diluted sample, also known as the dilution multiple, was designated as the dilution factor (FD).

Sensory evaluation

The samples were further analysed using quantitative descriptive analysis (QDA) [29]. The sensory evaluation team was composed of 10 people (5 men and 5 women) with professional knowledge and training. Each sample (20 ml) was put into a glass bottle and labelled with a random 3-digit code. The team members described and recorded the sensory characteristics of each sample over 4–6 academic terms. According to the results of the discussion among the team members, six sensory descriptors were derived: winey, sweet, malty, milky, pleasant and acidic. Group members were asked to quantify these six sensory descriptors on a scale of 1 to 9 (minimum and maximum intensity, respectively).

Statistical analysis

Significance analysis was performed using SPSS software (ver. 20.0; SPSS Inc., Chicago, IL, USA). Principal component analysis (PCA) and correlation analysis were conducted with Origin 2021b software (OriginLab Corporation, Northampton, MA, USA). The clustering heatmap was created using TBtools software. Partial least-squares regression (PLSR) was conducted using SIMCA 14.0 software (Umetrics, Umeå Sweden). Charticulator (https://charticulator.com) was used to create the chord diagram.

Results and discussion

Sugar and ethanol tolerance of yeast

During the process of brewing, sugar is the energy source for alcohol fermentation, but excessive sugar concentrations inhibit the growth of yeast. Table 1 shows that when the concentration of glucose was 100–300 g/L, all three tested strains grew well. When the concentration of glucose was 500 g/L, S. cerevisiae H1 and P. kudriavzevii H6 exhibited better sugar tolerance than Hansenula sp. H3.

Yeasts produce ethanol during fermentation, but excessive high ethanol contents inhibit yeast growth and limit the ethanol content of the finished wine. All three strains could grow in medium containing 20% ethanol by volume. However, tolerance to different volume fractions of ethanol differed among the three strains, with P. kudriavzevii H6 showing the highest ethanol tolerance. The growth rate of Hansenula sp. H3 decreased when the ethanol content reached 12%. This finding is consistent with the generally low ethanol tolerance of non-Saccharomyces strains [16].

Oenological characteristics

Eight fermentation experiments were conducted with various inoculation combinations, including one control (CK wine), three pure cultures (Sc wine, Hs wine and Pk wine) and four mixed cultures (Sc/Hs wine, Sc/Pk wine, Hs/Pk wine and Sc/Hs/Pk wine). The changes in residual sugar (Fig. 1a), ethanol (Fig. 1b) and titratable acid (Fig. 1c) are presented. The results showed that the residual sugar content of WRWs showed a downward trend in all treatments except CK wine, while the ethanol content and titratable acid content gradually increased.

On the tenth day, the residual sugar contents of Sc wine and mixed fermentation samples were lower than 15 g/L, which was considered the fermentation end point [30]. During the process of fermentation, the tested yeasts showed differences in fermentation kinetics. Compared with Sc wine and Pk wine, Hs wine had a longer fermentation cycle (> 10 d) and produced more acid. These observations verified the low fermentation capacity of non-Saccharomyces yeasts [31]. The results for Sc wine, Sc/Hs wine and Sc/Hs/Pk wine indicated that the addition of Hansenula sp. effectively prolonged the fermentation time of WRW. The slower fermentation process was beneficial, as it reduced the loss of flavour compounds [32].

The main brewing parameters of WRWs during fermentation of the tenth day are listed in Table 2. No significant differences in ethanol and titratable acid contents were found between Sc wine and mixed-strain WRWs, indicating that mixed fermentation did not reduce the ethanol and titratable acid contents of WRWs under the test conditions. These results demonstrate the weak competitiveness of non-Saccharomyces strains and are consistent the conclusion that S. cerevisiae was mainly responsible for alcohol fermentation [33].

Organic acid contents

Organic acids play an important role in the sensory characteristics of wines and lead to the gradual formation of esters. The types and contents of organic acids in WRWs are listed in Table 2. The low contents of tartaric acid and oxalic acid may be caused by Aspergillus present in jiuqu during the initial stage of fermentation [19]. Lactic acid was the most important organic acid in WRWs, and the content of lactic acid in mixed fermentation WRWs ranged from 8.79 to 13.91 g/L. Compared with Sc wine, WRWs resulting from mixed fermentation had higher lactic acid contents, and the highest content of 17.46 g /L was measured in Hs wine. This result demonstrates the excellent lactic acid production capacity of Hansenula sp. H3. The content of malic acid in pure-culture WRWs decreased significantly relative to CK wine, but no significant change in malic acid content between Sc wine and mixed fermentation WRWs was observed. According to previous research, reducing malic acid levels can reduce sour and tannic flavours [34].

Contents of VOCs

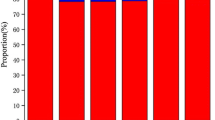

The changes in VOC contents were detected through GC–MS. From the results, a total of 29 compounds were identified using GC–MS. The effects of yeast strain on the VOCs in WRWs are illustrated in Fig. 2a. From these results, the change in volatile compound profiles between CK wine and other WRWs is apparent. Six compounds were present across all fermentation groups, and mixed fermentation improved the variety of compounds (Fig. 2b). The WRWs involved in fermentation by yeast, especially the combination of yeast, contain more types of VOC. The number of VOC types present in WRWs produced through mixed fermentation were elevated by more than 43.75% relative to pure-culture WRWs, which was consistent with the conclusion that pure S. cerevisiae fermentation produces wine with a simple flavour [12].

In addition, the contents of VOCs differed significantly (p < 0.05). In Sc wine, the contents of 3-methyl-1-butyl acetate, 3-methylmercapto-1-propanol and phenylethyl alcohol were higher. Hs wine produced higher concentrations of ethyl acetate, ethyl lactate and other compounds, but a lower content of phenylethyl alcohol. This observation is in accordance with previous findings [35]. Pk wine had high contents of alcohols, including 2-methyl-1-propanol, 3-methyl-1-butanol, 2-methyl-1-butanol, 3-methylmercapto-1-propanol, phenylethyl alcohol and 4-hydroxyphenethyl alcohol. This observation was consistent with previous observations that Pichia sp. could produce high alcohols contents [17].

In Sc/Hs wine, the contents of fatty alcohols, phenols and ethyl esters reached 45.50%, 1.53% and 13.02%, respectively (Fig. 2c). Sc/Pk wine and Sc/Hs/Pk wine presented more types of VOCs and high contents of fatty alcohols. In addition, Sc/Hs/Pk wine contained 12.84% ethyl esters. These observations support previous studies demonstrating that co-fermentation of yeasts improved the aromatic complexity of wines [16], and showed fermentation characteristics of the individual yeasts, while also reflecting synergism between yeasts.

Eight compounds with strong flavour intensity were identified through GC-O and analysed quantitatively. The quantitative analysis results of these eight VOCs in WRWs are presented in Table 3. According to previous studies, ethyl acetate, 2-methyl-1-propanol, 3-methyl-1-butanol, 2-methyl-1-butanol, 2,3-butanediol, 3-methyl-1-butyl acetate, 3-methylmercapto-1-propanol and phenylethyl alcohol are common aromatic compounds in rice wine [7, 36].

Large amounts of higher alcohols were responsible for flavour complexity in WRWs. The contents of higher alcohols in mixed fermentation groups were lower than the content of 331.26 mg/L observed in Pk wine. According to previous reports, higher alcohol contents lower than 300 mg/l impart a pleasant sensory component to wines [37]. The contents of 2-methyl-1-propanol, 3-methyl-1-butanol and 2-methyl-1-butanol in Sc/Hs/Pk wine were significantly elevated by 32.35%, 31.01% and 12.82%, respectively, compared to Sc wine. These higher alcohols brought characteristics of malt and whisky and enriched the aroma of WRWs. The formation of phenethyl alcohol, 3-methylmercapto-1-propanol and other higher alcohols occurs mainly through the Ehrlich pathway [38]. In addition, the content of phenylethyl alcohol was significantly reduced in mixed fermentation WRWs. This difference was mainly due to the significantly lower capacities of Hansenula sp. and P. kudriavzevii to produce phenylethyl alcohol compared to S. cerevisiae, and this observation was consistent with previous findings that Hansenula sp. could modulate the flavour of wines by decreasing the content of phenylethyl alcohol [35].

The main esters in wine include acetate ester and ethyl ester [22]. Mixed fermentation WRWs had significantly higher ester contents than Sc wine. This difference was mainly due to a significant difference in the content of ethyl acetate. The content of ethyl acetate in Sc/Hs wine and Sc/Hs/Pk wine reached 67.08 and 56.14 mg/L, respectively. These results confirm the capacity of Hansenula sp. to increase the content of ethyl acetate, which improves fruity flavour and increases overall complexity [39]. In addition, an appropriate ethyl acetate concentration lower than 80 mg/L was reported to improve the flavour of wine and enhance fruitiness, whereas a high content of ethyl acetate above 150 mg/L produces a sour or vinegary off odour [13].

PCA of aroma-active compounds

In general, odour activity values (OAVs) have been used to measure the contribution of VOCs to the overall flavour of samples. Compounds with OAV > 1 are generally considered aroma-active compounds [40, 41]. Table 4 lists the FD values and OAVs of eight aroma-active compounds in WRWs. The OAVs were calculated using thresholds obtained from the literature [42].

The principal components of these compounds were analysed to distinguish the characteristics of WRWs produced by different strains. Eight aroma-active compounds in WRWs were analysed, including ethyl acetate, 2-methyl-1-propanol, 3-methyl-1-butanol, 2-methyl-1-butanol, 2,3-butanediol, 3-methyl-1-butyl acetate, 3-methylmercapto-1-propanol and phenylethyl alcohol.

PCA of WRWs produced using pure cultures and the CK wine (Fig. 3a) explained 87.6% of the variability in the data. Principal component (PC)1 accounted for 61.3% of the total variability, and PC2 for an additional 26.3%. The contents of 2-methyl-1-propanol, 3-methyl-1-butanol, 2-methyl-1-butanol, 2,3-butanediol, 3-methyl-1-butyl acetate, 3-methylmercapto-1-propanol and phenylethyl alcohol were positively correlated with PC1. The samples were well separated, indicating that differences in aroma-active compounds in WRWs produced with different yeasts are driven by differences in fermentation abilities. Hs wine was also affected by variables positively related to PC2, due to its high concentrations of ethyl acetate and 2,3-butanediol. The fruity and sour sensory characteristics of these two compounds in Hs wine led to a significant difference among the pure fermentation groups.

In addition, PCA of mixed fermentation WRWs showed that PC1 and PC2 explained 60.5% and 23.5% of the total variance, respectively. In these samples, ethyl acetate, 2-methyl-1-propanol, 3-methyl-1-butanol and 2-methyl-1-butanol were closely and positively correlated with PC1. In addition, 2,3-butanediol, 3-methylmercapto-1-propanol and phenylethyl alcohol were positively correlated with PC2. As shown in Fig. 3b, Sc, Sc/Pk and Hs/Pk wines overlapped with Sc/Hs/Pk wine, with Sc/Pk and Sc/Hs/Pk wine having higher PC1 scores. Combined with the results from single-strain fermentation samples, the potential of P. kudriavzevii H6 to enhance the contents of 2-methyl-1-propanol, 3-methyl-1-butanol and 2-methyl-1-butanol was demonstrated. Sc wine was characterized by high contents of 3-methyl-1-butyl acetate and phenylethyl alcohol, but Sc/Hs wine and Sc/Hs/Pk wine had higher contents of ethyl acetate. This result demonstrates that mixed fermentation with Hansenula sp. H3 had a strong influence on the content of ethyl acetate in WRWs.

Sensory evaluation

The aroma characteristics of eight samples were analysed using QDA. The average scores of the six sensory descriptors of WRWs are shown in Fig. 4a. Compared with CK wine, other WRWs had better sensory scores. Among the tested wines, Sc wine was characterized by high “sweet”, “pleasant”, and “winey” scores, and a low score for “acidic”. Hs wine was distinguished by a higher “acidic” score, which may be associated with the production of more acids [16]. The descriptive scores of Pk wine were generally moderate, but it had the highest “malty” score due to its high content of 3-methyl-1-butanol. Sc/Hs/Pk wine produced through mixed fermentation scored highest for “sweet”, and also had high scores for the other descriptors. These results reveal the sensory characteristics of WRWs fermented by three strains, and demonstrate the effect of mixed fermentation on sensory characteristics.

Sensory analysis. (a) Organoleptic assessments of WRWs. (b) Correlation loadings plot of the PLSR model between VOCs and sensory attributes. Green circle 1-8 represent aroma-active compounds in Table 3. (c) Chordal diagram of correlation analysis. Red lines represent positive correlations and blue lines represent negative correlations. Light color indicates significant correlation (p < 0.05) and dark color indicates extremely significant correlation (p < 0.01)

PLSR of sensory attributes and aroma-active compounds

The relationships between sensory attributes and VOCs were studied using PLSR. In total, eight aroma-active compounds (X variables) and six aroma descriptors (Y variables) were used to generate a new set of models (Fig. 4b), which explained 81.8% of the variance in X variables and 86.7% of that in Y variables.

The variance explained in aroma descriptors and VOCs was between 50 and 100%, indicating that the PLSR model had good explanatory power [43]. According to the results of PLSR and correlation analysis (Fig. 4c), varying degrees of positive and negative correlations exist between aroma-active compounds and aroma descriptors [22]. The strong “winey”, “milky” and “pleasant” characteristics of Sc wine could be associated with high contents of 3-methyl-1-butanol acetate (banana, sweet), 3-methyl-1-butanol (malty), 3-methylmercapto-1-propanol (onion, sweet) and ethanol. Hs wine had the highest rating for “acidic” due to its strong correlation with ethyl acetate (pine) and high content of titratable acid. Pk wine had the highest “malty” score due to its strong correlations with 3-methyl-1-butanol (malty) and 2-methyl-1-butanol (malty). In addition, due to the correlations between sensory descriptors and these factors, the mixed fermentation group had higher sensory scores. For example, Sc/Hs/Pk wine had the highest rating for “sweet” due to its strong correlations with 3-methyl-1-butanol acetate (banana, sweet), phenylethyl alcohol (honey, sweet) and 3-methylmercapto-1-propanol (onion, sweet). This finding is consistent with the previous conclusion that 3-methyl-1-butanol acetate and phenylethyl alcohol enhance the “fruity” and “floral” sensory characters of wine [22].

Conclusion

In this study, the metabolic compounds and sensory characteristics produced during pure fermentation and mixed fermentation were studied using S. cerevisiae H1, Hansenula sp. H3 and P. kudriavzevii H6. Sc wine had the fastest fermentation rate, highest ethanol content (15.77%) and highest pH (3.80) among pure cultures. S. cerevisiae also had greatest potential to increase the contents of phenylethyl alcohol and 3-methyl-1-butanol acetate, thereby contributing to the “sweet”, “winey” and "pleasant" characteristics of WRWs. Hs wine had the highest ethyl acetate content (69,535.58 μg/L), leading to the perception of “acidic” flavour. The presence of P. kudriavzevii H6 reduced the content of total titratable acid to 2.90 g/L, and Pk wine had the highest 3-methyl-1-butanol content of 163,674.83 μg/L, thereby providing the sensation of “malty”. Sensory analysis showed that mixed fermentation improved the “sweet” and “winey” tones of WRWs. The positive effects of mixed fermentation, in terms of the metabolism and sensory characteristics of WRWs, demonstrated the contribution of mixed fermentation to improved sensory qualities of WRWs. In addition, the relationships between aromatic compounds and sensory descriptors were established using PLSR and correlation analysis. The results explained the sensory differences among WRWs identified through QDA, and revealed the contributions of various factors to sensory scores. Overall, these results reveal the capacity of S. cerevisiae H1 to shorten the fermentation cycle of WRW and produce a large amount of phenylethyl alcohol, as well as the potential of Hansenula sp. H3 to produce esters and lactic acid, and the ability of P. kudriavzevii H6 to produce large amounts of higher alcohols and mercaptans. Combining different yeasts can improve the quality and complexity of WRWs.

Data availability

All data generated or analysed during this study are included in this published article.

References

Yang Y, Hu W, Xia Y et al (2020) Flavor formation in Chinese rice wine (Huangjiu): impacts of the flavor-active microorganisms, raw materials, and fermentation technology. Front Microbiol 11:580247. https://doi.org/10.3389/fmicb.2020.580247

Varela C, Dry PR, Kutyna DR et al (2015) Strategies for reducing alcohol concentration in wine. Aust J Grape Wine Res 21(1):670–679. https://doi.org/10.1111/ajgw.12187

Yu H, Xie T, Xie J et al (2019) Characterization of key aroma compounds in Chinese rice wine using gas chromatography-mass spectrometry and gas chromatography-olfactometry. Food Chem 293:8–14. https://doi.org/10.1016/j.foodchem.2019.03.071

Yang Y, Xia Y, Wang G et al (2019) Effects of boiling, ultra-high temperature and high hydrostatic pressure on free amino acids, flavor characteristics and sensory profiles in Chinese rice wine. Food Chem 275:407–416. https://doi.org/10.1016/j.foodchem.2018.09.128

Wang X, Tian R, Yang H et al (2022) Effect of baking technique for rice wine production and the characteristics of baked rice wine. J Sci Food Agric 102(4):1498–1507. https://doi.org/10.1002/jsfa.11484

Yang Y, Zhong H, Yang N et al (2022) Effects of the proteins of indica rice and indica waxy rice on the formation of volatiles of sweet rice wine. Int J Food Sci Technol Adv. https://doi.org/10.1111/ijfs.15684 (online publication)

Chen C, Liu Y, Tian H et al (2020) Metagenomic analysis reveals the impact of JIUYAO microbial diversity on fermentation and the volatile profile of Shaoxing-jiu. Food Microbiol 86:103326. https://doi.org/10.1016/j.fm.2019.103326

Chen L, Li D, Ren L et al (2020) Effects of simultaneous and sequential cofermentation of Wickerhamomycesanomalus and Saccharomyces cerevisiae on physicochemical and flavor properties of rice wine. Food Sci Nutr 9(1):71–86. https://doi.org/10.1002/fsn3.1899

Zhu J, Lin JL, Palomec L et al (2015) Microbial host selection affects intracellular localization and activity of alcohol-o-acetyltransferase. Microb Cell Fact 14(1):35. https://doi.org/10.1186/s12934-015-0221-9

Huang ZR, Hong JL, Xu JX et al (2018) Exploring core functional microbiota responsible for the production of volatile flavour during the traditional brewing of wuyi hong qu glutinous rice wine. Food Microbiol 76:487–496. https://doi.org/10.1016/j.fm.2018.07.014

Comitini F, Gobbi M, Domizio P et al (2011) Selected non-Saccharomyces wine yeasts in controlled multistarter fermentations with Saccharomyces cerevisiae. Food Microbiol 28(5):873–882. https://doi.org/10.1016/j.fm.2010.12.001 (450)

Berbegal C, Khomenko I, Russo P et al (2020) PTR-ToF-MS for the online monitoring of alcoholic fermentation in wine: assessment of VOCs variability associated with different combinations of Saccharomyces/non-Saccharomyces as a case-study. Fermentation 6:55. https://doi.org/10.3390/fermentation6020055

Ciani M, Beco L, Comitini F (2006) Fermentation behaviour and metabolic interactions of multistarter wine yeast fermentations. Int J Food Microbiol 108(2):239–245. https://doi.org/10.1016/j.ijfoodmicro.2005.11.012

Satora P, Semik-Szczurak D, Tarko T et al (2018) Influence of selected Saccharomyces and Schizosaccharomyces strains and their mixed cultures on chemical composition of apple wines. J Food Sci 83(2):424–431. https://doi.org/10.1111/1750-3841.14042

Aplin JJ, Edwards CG (2021) Impacts of non-Saccharomyces species and aeration on sequential inoculation with Saccharomyces cerevisiae to produce lower alcohol Merlot wines from Washington state. J Sci Food Agric 101(4):1715–1719. https://doi.org/10.1002/jsfa.10769

Maria T, Mariagiovanna F, Joana P et al (2021) Influence of non-Saccharomyces on wine chemistry: a focus on aroma-related compounds. Molecules 26(3):644. https://doi.org/10.3390/molecules26030644

Anfang N, Brajkovich M, Goddard MR (2009) Co-fermentation with Pichia kluyveri increases varietal thiol concentrations in Sauvignon Blanc. Aust J Grape Wine Res 15:1–8. https://doi.org/10.1111/j.1755-0238.2008.00031.x

He WJ, Liu SX, Heponiemi P et al (2021) Effect of Saccharomyces cerevisiae and Schizosaccharomyces pombe strains on chemical composition and sensory quality of ciders made from Finnish apple cultivars. Food Chem 345:128833. https://doi.org/10.1016/j.foodchem.2020.128833

Wang P, Mao J, Meng X et al (2014) Changes in flavour characteristics and bacterial diversity during the traditional fermentation of Chinese rice wines from Shaoxing region. Food Control 44:58–63. https://doi.org/10.1016/j.foodcont.2014.03.018

Ji ZW, Jin JS, Yu GS et al (2018) Characteristic of filamentous fungal diversity and dynamics associated with wheat Qu and the traditional fermentation of Chinese rice wine. Int J Food Sci Technol 53(7):1611–1621. https://doi.org/10.1111/ijfs.13743

Min G, Zhou Z, Jin J et al (2020) Effects of soaking on physicochemical properties of four kinds of rice used in Huangjiu brewing. J Cereal Sci 91:102855. https://doi.org/10.1016/j.jcs.2019.102855

Liu C, Li M, Ren T et al (2022) Effect of Saccharomyces cerevisiae and non-Saccharomyces strains on alcoholic fermentation behavior and aroma profile of yellow-fleshed peach wine. LWT Food Sci Technol Adv. https://doi.org/10.1016/j.lwt.2021.112993 (online publication)

Han Y, Du J, Li J et al (2019) Quantification of the organic acids in hawthorn wine: a comparison of two HPLC methods. Molecules (Basel, Switzerland) 24(11):2150. https://doi.org/10.3390/molecules24112150

Wang J, Ming Y, Li Y et al (2021) Characterization and comparative study of the key odorants in Caoyuanwang mild-flavor style Baijiu using gas chromatography-olfactometry and sensory approaches. Food Chem 347:129028. https://doi.org/10.1016/j.foodchem.2021.129028

Alvarez MG, Gonzalez-Barreiro C, Cancho-Grande B et al (2011) Relationships between Godello white wine sensory properties and its aromatic fingerprinting obtained by GC-MS. Food Chem 129(3):890–898. https://doi.org/10.1016/j.foodchem.2011.05.040

De La Fuente BA, Ferreira V (2020) Gas chromatography olfactometry (GC-O) for the (semi) quantitative screening of wine aroma. Foods (Basel, Switzerland) 9(12):1892. https://doi.org/10.3390/foods9121892

Lan Y, Guo J, Qian X et al (2021) Characterization of key odor-active compounds in sweet Petit Manseng (Vitis vinifera L.) wine by gas chromatography-olfactometry, aroma reconstitution, and omission tests. J Food Sci 86(4):1258–1272. https://doi.org/10.1111/1750-3841.15670

Kaneko S, Kumazawa K (2015) Aroma compounds in Japanese sweet rice wine (Mirin) screened by aroma extract dilution analysis (AEDA). Biosci Biotechnol Biochem 79(3):484–487. https://doi.org/10.1080/09168451.2014.980218

Zhu LX, Zhang MM, Xiang XF et al (2021) Aromatic characterization of traditional Chinese wine Msalais by partial least-square regression analysis based on sensory quantitative descriptive and odor active values, aroma extract dilution analysis, and aroma recombination and omission tests. Food Chem 361:129781. https://doi.org/10.1016/j.foodchem.2021.129781

Ye Y, Wang L, Zhan P et al (2021) Characterization of the aroma compounds of millet huangjiu at different fermentation stages. Food Chem 366:130691. https://doi.org/10.1016/j.foodchem.2021.130691

Morata A, Escott C, Loira I et al (2019) Influence of Saccharomyces and non-Saccharomyces yeasts in the formation of pyranoanthocyanins and polymeric pigments during red wine making. Molecules 24:4490. https://doi.org/10.3390/molecules24244490

Binati RL, Lemos WJF, Luzzini G et al (2020) Contribution of non-Saccharomyces yeasts to wine volatile and sensory diversity: a study on Lachanceathermotolerans, Metschnikowia spp. and Starmerellabacillaris strains isolated in Italy. Int J Food Microbiol 318:108470. https://doi.org/10.1016/j.ijfoodmicro.2019.108470

Berbegal C, Spano G, Tristezza M et al (2017) Microbial resources and innovation in the wine production sector. S Afr J Enol Vitic 38:156–166. https://doi.org/10.21548/38-2-1333

Liu SX, Laaksonen O, Kortesniemi M et al (2018) Chemical composition of bilberry wine fermented with non-Saccharomyces yeasts (Torulasporadelbrueckii and Schizosaccharomyces pombe) and Saccharomyces cerevisiae in pure, sequential and mixed fermentations. Food Chem 266:262–274. https://doi.org/10.1016/j.foodchem.2018.06.003

Capozzi V, Berbegal C, Tufariello M et al (2019) Impact of co-inoculation of Saccharomyces cerevisiae, Hanseniaspora uvarum and Oenococcusoeni autochthonous strains in controlled multi starter grape must fermentations. LWT Food Sci Technol 109:241–249. https://doi.org/10.1016/j.lwt.2019.04.045

Chen S, Xu Y (2010) The influence of yeast strains on the volatile flavour compounds of Chinese rice wine. J Inst Brew 116(2):190–196. https://doi.org/10.1002/j.2050-0416.2010.tb00417.x

Luan Y, Zhang B, Duan C et al (2018) Effects of different pre-fermentation cold maceration time on aroma compounds of Saccharomyces cerevisiae co-fermentation with Hanseniaspora opuntiae or Pichia kudriavzevii. LWT-Food Sci Technol 92:177–186. https://doi.org/10.1016/j.lwt.2018.02.004

Gu Y, Ma J, Zhu Y et al (2020) Refactoring ehrlich pathway for high-yield 2-phenylethanol production in Yarrowialipolytica. ACS Synth Biol 9(3):623–633. https://doi.org/10.1021/acssynbio.9b00468

Löser C, Urit T, Bley T (2014) Perspectives for the biotechnological production of ethyl acetate by yeasts. Appl Microbiol Biotechnol 98(12):5397–5415. https://doi.org/10.1007/s00253-014-5765-9

Wang X, Xie K, Zhuang H et al (2015) Volatile flavor compounds, total polyphenolic contents and antioxidant activities of a China gingko wine. Food Chem 182:41–46. https://doi.org/10.1016/j.foodchem.2015.02.120

Dein M, Kerley T (2021) Characterization of odorants in a 10-year-old riesling wine. J Agric Food Chem 69(38):11372–11381. https://doi.org/10.1021/acs.jafc.1c04196

Van Gemert LJ (2011) Odour thresholds. In: Compilations of odour threshold values in air, water and other media, 2nd ed. Oliemans Punter & Partners BV, Oliemans Punter & Partners BV, The Netherlands

Yin M, Shao SJ, Zhou ZL et al (2020) Characterization of the key aroma compounds in dog foods by gas chromatography-mass spectrometry, acceptance test, and preference test. J Agric Food Chem 68(34):9195–9204. https://doi.org/10.1021/acs.jafc.0c03088

Funding

This work was sponsored in part by the science and technology research planning project (JJKH2024) from Jilin provincial department of education, and the scholar climbing project (ZKP202006 and ZKP202016) from Changchun University.

Author information

Authors and Affiliations

Contributions

Conceptualization, funding acquisition, project administration, resources, supervision, validation, and review and editing of the manuscript: DL and XL. Data curation, formal analysis, methodology, software, and drafting of the manuscript: YH, MZ, SM, YH, and YS.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, Y., Zhong, M., Mu, S. et al. Assessment of the contributions of Saccharomyces cerevisiae, Hansenula sp. and Pichia kudriavzevii to volatile organic compounds and sensory characteristics of waxy rice wine. Eur Food Res Technol 249, 685–697 (2023). https://doi.org/10.1007/s00217-022-04165-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-04165-x