Abstract

With the rapid development of society, it is of paramount importance to expeditiously assess environmental pollution and provide early warning of toxicity risks. Microbial fuel cell–based self-powered biosensors (MFC-SPBs) have emerged as a pivotal technology, obviating the necessity for external power sources and aligning with the prevailing trends toward miniaturization and simplification in biosensor development. In this case, vigorous advancements in MFC-SPBs have been acquired in past years, irrespective of whether the target identification event transpires at the anode or cathode. The present article undertakes a comprehensive review of developed MFC-SPBs, categorizing them into substrate effect and microbial activity effect based on the nature of the target identification event. Furthermore, various enhancement strategies to improve the analytical performance like accuracy and sensitivity are also outlined, along with a discussion of future research trends and application prospects of MFC-SPBs for their better developments.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biosensor is an analysis and detection device composed of molecular recognition elements and signal conversion elements and has been successfully applied to environmental monitoring, disease diagnosis, food safety, and military fields. At present, biosensors not only require accurate, reliable, and sensitive detection of targets, but also tend to be able to perform quick and convenient on-site detection step by step [1, 2]. Electrochemical biosensors based on bioelectrical interfaces are the key to achieve these visions. It responds to target analytes through biological recognition elements, converting the biological responses into a measurable electrical signal proportional to the concentration of target analytes [3]. To generate a measurable signal proportional to the concentration of the analyte, the transducer is also essential as an electrically powered device. The external power source and costly equipment severely limit its application in remote and long-term environmental monitoring [4].

Self-powered biosensors (SPBs) utilize biofuel cells both as a simultaneous power source and biosensor, streamlining the biosensor system and offering a viable approach for constructing miniaturized, implantable, or portable devices. Various types of fuel cells, such as enzymatic biofuel cells (EBFCs), microbial fuel cells (MFCs), and photocatalytic fuel cells (PFCs), can adjust their output in response to changes in analyte concentrations, using the catalytic properties of enzymes, microorganisms, and semiconductor materials for sensitive detection, respectively. The first report of self-powered sensors was in 2001 when Wilner and Katz constructed two EBFCs, glucose and lactate. They proposed the concept of a SPB that detects the fuel concentration depending on the open-circuit voltage [5]. EBFC-SPBs, utilizing enzymes as catalysts and biofuels like alcohols, saccharides, and amines commonly found in nature, exhibit high sensitivity and good selectivity but suffer from poor enzyme stability. MFC-SPBs can operate stably for a long time in complex environments without changing microbe, but their sensitivity is relatively low. PFC-SPBs offers high sensitivity and fast response when under light irradiation, but their preparation costs are relatively higher [6]. Considering comprehensively, MFC-SPBs with enhanced performance present advantages such as affordability, robust environmental adaptability, and long-term stability, thus holding significant potential for widespread application in the realm of SPBs.

MFC-SPBs rely on microorganisms to generate electricity, interpret signals, and convert them into usable forms [7, 8]. They typically consist of anode, cathode, and diaphragm materials, along with electrogenic microorganism, recognition elements, and signal conversion components. The fundamental detection principle of MFC-SPBs involves translating the concentration of the target analyte into changes in voltage, current, and power output of the biofuel cell [9, 10]. Factors such as substrate type, microbial species, and concentration influence battery performance, thereby reflecting variations in the target analyte [11]. MFC-SPBs prioritize monitoring changes in cell output performance across diverse conditions, offering promising applications in environmental monitoring [12, 13]. The biofilm formed on the MFC anode can be directly used as a sensing element during current generation. As the anode sensing strategy is relatively simple, it was first applied in the field of the MFC-SPB field [14, 15]. Anode sensing hinges on a biofilm adhering to the anode surface and is primarily effective when analyte components interact with microorganisms. Consequently, the detection mechanism mainly involve substrate effects and microbial activity effects, including the monitoring of biochemical oxygen demand (BOD), chemical oxygen demand (COD), toxic substances, heavy metal ions (HMIs), and antibiotics et al. [16,17,18,19]. However, the reliance of anode sensing on biofilms renders it susceptible to disturbance during sensing, typically suitable only for anaerobic water environments. Oxygen diffusion in the cathode chamber would limit sensor sensitivity. Moreover, the presence of organic substances alongside toxic compounds often leads to unreliable sensing signals, constraining the applicability of anode sensing mode [20, 21].

In recent years, the cathode-based sensing mode has also gradually attracted the attention of researchers on MFC-SPBs. Various substances, including dissolved oxygen (DO), transition metal compounds, and inorganic salts, serve as the final electron acceptor at the cathode. The sensing signal has a linear relationship with the electron concentration within a certain range, which can be regarded as a substrate effect of the cathode [22, 23]. Besides, with the development of bio-cathodes, many target analytes like toxicant would affect microbial activity and thus the output signal from the MFC-SPBs, which is also a sensing strategy based on the microbial activity effect. Different from anode sensing mode, the false alarms caused by the organic matter/toxicity combination shock can be avoided in bio-cathode. However, the cathodic sensing mode depends on the stability of the anode performance, and the cathodic sensing signal can only be referenced when the anode output is stable. In addition, during long-term operation, the oxygen supply environment in most cases of the cathode chamber may lead to the growth and reproduction of aerobic bacteria, which will greatly affect the cathodic sensing performance. Consequently, considerable research opportunities persist in the realms of application development and performance optimization for cathodic sensing.

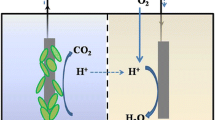

With the rapid development of MFC-SPBs in recent years, various subfields have been comprehensively reviewed. Varshney et al. have presented an overview of the most intriguing new applications of MFC-SPBs for detecting pollutants [24]. Similarly, Chung et al. have provided a comprehensive evaluation of recent advances in optimizing MFC biosensors in terms of configurations, sizes, electrochemical operating modes, sensing biofilms, and other operating parameters to aid the MFC biosensor’s applications to recalcitrant contaminants [25]. To date, most of the published reviews focused on the applications of MFC-SPBs (e.g., COD, BOD) based on different substrate materials in anode-based sensing mode, while losing sight of MFC-SPBs in cathode-based sensing mode, let alone the behind connection between these two modes in terms of sensing mechanisms. In this review, we summarize the recently important strides toward the building of MFC-SPBs in both anode and cathode sensing modes and innovatively integrate or categorize them based on whether the target identification event pertains into substrate effect or microbial activity effect, as shown in Fig. 1. Furthermore, the improvement strategies for the accuracy and sensitivity of MFC-SPBs have also been highlighted. Hopefully, this review will further intensify the research on the exploration of novel sensing strategies to advance the development on the increasing the reliability and improve signal transmission aspects of MFC-SPBs, as well as provide references to the guidance on the future researches and real-world applications.

Substrate effect

Substrate effect stands as the earliest and most prevalent design principle of SPBs, which reflects the alteration of substrate concentration through the variations of output performance parameters of the fuel cell. Understanding this effect is pivotal in discerning how MFC-SPBs react to specific substances or analytes [24]. Generally, within the anode, substrate organics serve as the electron donor for microbial metabolism, initiating a series of electrochemical reactions that generate a measurable signal. Similarly, within the cathode, the detection of substrate concentration as an electron acceptor can be encapsulated within the broader concept of the substrate effect. Investigating the substrate effect in both anode and cathode modes provide valuable insights into optimizing the biosensor's sensitivity, selectivity, and overall performance.

Anode sensing mode

The anode sensing mode based on the substrate effect stands out as the most prevalent strategy in MFC sensing. Leveraging this approach, researchers often advocate for the efficacy of MFC-SPBs in detecting organic pollutants in water, soil, and atmospheric air, which holds significant importance for advancing environmental monitoring efforts. During operation, the organic analyte enters the anode chamber, then the electroactive microorganisms populating the anode produce electrons by microbial oxidation. The released electrons are then transferred to the anode electrode through the process of extracellular electron transport, and an external circuit driven by a potential gradient between the two electrodes moves further from the anode to the cathode. Thus, the electrical signals generated by the MFC-SPBs, such as voltage and current, are a function of the oxidation rate of the organic analyte [15].

Based on this strategy, MFC-SPBs exhibit the capability to discern alterations in a diverse array of biodegradable organic matters (BOM). Tornt et al. employed a MFC-SPB for in situ monitoring lactate concentration during bioremediation. Bioelectricity served as a metric for quantifying lactate availability and the oxidation rate. As a result, the electrical signals manifested a linear correlation with lactate concentration (R2 = 0.9) [26]. In the same year, this research group further investigated the use of acetate by Geobacter sulfurreducens, observing a robust correlation between acetate concentrations and electrical signals [27]. As a prototypical volatile fatty acid (VFA), acetate concentrations are crucial for monitoring, controlling, evaluating, and optimizing the anaerobic digestion process. In addition, a myriad of emerging pollutants may serve as substrates for SPB detection, such as bisphenol A [28], polyhydroxyalkanoates (PHAs) [29], and linear alkylbenzene sulfonate (LAS) [30]. In addition to the detection of pure substances, MFC-SPBs lends themselves to the comprehensive evaluation of various the total amount of different BOMs, such as BOD [31, 32], COD [28], and assimilable organic carbon (AOC) [33], attributing to the limited specificity of microorganisms to substrates.

MFC-SPBs may additionally find utility when integrated with other waste management procedures. For example, the emerging integrated platform consisting of constructed wetlands (CWs) and MFCs has been preliminarily developed and has attracted much attention [34, 35]. Xu et al. undertook the pioneering investigation into the feasibility of employing MFCs for the sense of COD in CWs [36]. Corbella et al. presented a study to assess the potential use of constructed CW-MFC as a domestic wastewater COD assessment tool. Four lab-scale CW-MFCs were established, revealing significant linear relationships between inlet COD concentrations and CW-MFC outputs particularly when the contact time exceeded 10 h (Fig. 2a) [37]. By integrating MFC with upflow anaerobic sludge blanket (UASB), Jia et al. established a novel hybrid system for online monitoring the internal reaction condition in UASB reactors. The UASB reactor functioned as the anode chamber of the MFC-SPB, and the voltage could respond to COD concentrations [38]. It provides a new idea for a rapid and stable real-time monitoring of COD. Nonetheless, the application of MFC-SPBs at the anode is chiefly constrained by considerations of accuracy and upper detection limits.

Anode sensing mode based on substrate effect in applications of MFC-SPBs. a Scheme and pictures of the CW-MFC biosensor. (A) graphite felt cathode; (B) cathode overflow; (C) anodic recirculation; (D) external circuit; (E) data logger and external resistance; (F) water level [37]. b Mechanism of BOD concentration detection and correction [40]. c Schematic of a MFC-SPB system and the training lines of both SCG and time series with R2 value 0.98802 and 0.99115 [52]

The strategy to improve the accuracy is to increase the efficiency of electrogenic microorganisms to extract electrons from the BOM and transfer electrons to the anode. Manipulating the metabolic activity of electrogenic and non-electrogenic microorganisms represents an effective avenue. Feng et al. demonstrated that employing a methanogenesis inhibitor (2-bromoethanesulfonate) could heighten the utilization of organic substrates by electrogenic microorganisms to 1.8 times, thereby refining the precision of MFC-SPBs [39]. Besides, substances with high redox potential (e.g., nitrate, oxygen) can serve as electron acceptors, competing with the anode for electrodes and compromising the detection accuracy of sensors. Chang et al. employed chemical additives such as trinitride and cyanide in the anode chamber to counteract these effects. Respiratory inhibitors curbed denitrification and aerobic respiration in MFCs without impeding electron flow to the electrode, thereby mitigating nitrate and oxygen on inhibition on generated current [16]. Guo et al. explored the heterotrophic denitrification in the presence of nitrate, rectifying BOD concentrations through graphical and mathematical methods. By analyzing the nitrogen elements in both the anode and cathode chambers, they quantified electron consumption during nitrate reduction, devising an error correction methodology (Fig. 2b) [40]. Except for the water sample itself, oxygen diffusion through the membrane is also a major source of oxygen present in the anode chamber. Therefore, the use of a low gas-permeable membrane may be an effective way to improve the detection accuracy of MFC-SPB. The oxygen permeability of the sulfonated poly ether ether ketone (SPEEK) membrane was one order lower than that of the conventional Nafion membrane [41]. Consequently, a BOD MFC-SPB equipped with the SPEEK membrane exhibited a lower substrate loss and internal resistance, ultimately leading to a 62.5% improvement in sensing range. Furthermore, the addition of other cathodic electron acceptors (e.g., KMnO4 [42], persulfate [43], ferrocyanide [44,45,46], potassium dichromate [47]) to replace the dissolved oxygen should be a more attractive choice, as it not only fundamentally avoids the involvement of oxygen in MFC, but can also improve the electricity generation.

The strategy to extend the detection limit involves overcoming constraints posed by the sensing apparatus and microbial population density. When the concentration of BOM exceeds the upper detection threshold, the oxidation rate will reach a saturation point, resulting in a plateau in the signal (current) response [48]. To address this challenge, Spurr et al. constructed a multi-stage MFC-SPB. Excess substrate in the previous MFC could flow into the subsequent cells, with the cumulative BOD content reflected by the sum of current outputs from multiple MFCs. By normalizing the total current output against the BOD concentrations, the linear range was extended to 720 mg/L at a flow-rate of 0.52 mL/min [49]. Furthermore, improving the coulombic yield (CY) can increase the BOD upper limit of detection but increases the reaction time [33]. Modin et al. demonstrated that by applying an external voltage, microorganisms at the anode are enabled to generate current at their maximum capacity. The detection time of MFC-SPB was extended from 5 to 20 h for BOD concentrations ranging from 32 to 1280 mg/L [50]. Moon et al. found that by reducing the external resistance from 100 to 10 Ω, the response time could be reducing from 2.1 to 1.4 h [51]. Moreover, optimization through deep learning methodologies offers a promising avenue. Naik et al. developed a dual chambered MFC-SPBs for phenol detection, as shown in Fig. 2c. The topologies of artificial neural networks (ANNs) were analyzed to get the best model to predict the power output of MFCs. The training algorithms were compared with their convergence rates in test results. Scaled conjugate gradient (SCG) algorithm and time-series model were trained with 44 experimental data of varying phenol concentration and varying synthetic wastewater concentration to optimize the biosensor performance, with R2 value of 0.98802 and 0.99115, respectively [52]. Additionally, Kaur et al. developed a simple and low-cost MFC-SPB for short-chain VFA. Employing a functional polypyrrole coating to modify the carbon surface facilitated bacterial adherence and catalytic augmentation, resulting in enhanced detection efficacy [53]. With the further optimization of the BOM MFC-SPB, they are poised to become potent tool for environmental online monitoring processes.

Cathode sensing mode

The concentration of electron acceptors within the cathode chamber can significantly impact the overall response of the MFC-SPB. Certain oxidizable target analytes can be reduced by electrons and protons in the cathode chamber. Assuming the anode’s performance remains consistent, the electrical signal can thus serve as an indicator of the target analyte within the cathode chamber.

Oxygen from the air is frequently employed as an electron acceptor in MFC cathode due to its low cost and easy availability. Theoretically, the number of electrons accepted by the cathode should correspond to the electrons reacting with oxygen. Therefore, the electricity generated can also be a proxy of dissolved oxygen (DO). Leveraging this principle, Zhang et al. developed a submersible MFC-SPB to monitor DO in water in situ. Experimental results demonstrated a linear increase in current density with DO concentration ranging from 0 to 8.8 mg/L (regression coefficient, R2 = 0.9912), achieving a response time of less than 4 min [54]. Similarly, Song et al. integrated a multi-cathode, single-anode MFC-SPB to assess DO concentrations at different depths in lake water (Fig. 3a). With an external resistance of 1000 Ω, the detection range of DO extended from 0 to 9 mg/L [55]. Based on the influence of target analytes on DO, Dai et al. also used MFC-SPBs for oil monitoring. Employing an upward open-channel MFC and a vertically floating/rolling cathode, they observed that the presence of oil hindered the dissolution of oxygen in water, resulting in a reduction in the MFC's output signal (Fig. 3b) [56]. The research group also applied this technology to surface water for online monitoring of minor oil spills (Fig. 3c) [57].

Cathode sensing mode based on substrate effect in applications of MFC-SPBs. a Illustration of a single-anode and multi-cathode MFC-SPB for DO detection [55]. Schematic of the oil spill monitoring through MFC-SPBs in b lab and c natural water body [56, 57]. d Schematic of the two-chamber MFC-SPBs for Cr (VI) and detecting. e Illustration of CoMn2O4 nanoparticles decorated MFC-SPB cathode for detecting H2O2 [59]. f Schematic of two MFCs for enhanced nitrate detecting [61]

When the cathode chamber is in an anaerobic environment, MFC-SPBs can also monitor other electron acceptors. For instance, Chung et al. utilized the MFC-SPB with traditional two-chamber configurations for the detection of Cr (VI). They observed significant changes in the voltage of the MFC-based Cr(VI) sensor with increasing concentrations of Cr(VI) at pH levels 1 and 2 (Fig. 3d) [58]. Notably, the electroreduction processes involved in these reactions can effectively mitigate the toxicity of heavy metal ions (HMIs). Similarly, Liu et al. used the MFC-SPB to detect H2O2 based on the electroreduction effect. The graphite cathode of the MFC was regarded as a sensing element modified by CoMn2O4 nanoparticles (CoMn2O4@GE) to enhance H2O2 reduction and extend the surface area. As a result, the biosensor showed a very wide detection range (1–1000 mM) and a fast response to H2O2 within 5 s (Fig. 3e) [59]. Moreover, anaerobic biofilms in bio-cathode have been reported to possess the capability to reduce inorganic salts [60]. Yang et al. developed an MFC-SPB consisting of two MFC units to detect nitrate, as shown in Fig. 3f. One traditional MFC (ferricyanide cathode and bioanode) was used as the electrical power supply, and the other MFC with biocathode was used as the sensing system. Finally, the minimal detection limit of this sensor could reach 0.11 μM, and it showed a wide linear detection range for nitrate monitoring [61].

The strategy to enhance cathodic sensing is mainly to weaken the limitation of the mass transfer process on the reduction kinetics. Therefore, identifying efficient catalysts for the reduction process is paramount. Traditionally, noble metal catalysts such as Pt and Ag are usually introduced to reduce the activation energy barrier [62, 63]. Considering the prohibitive cost, much attention has been developed in recent years to explore non-noble oxygen reduction reaction (ORR) catalysts, such as activated carbon [64], carbon nanotubes [65], porphyrins [66], and phthalocyanines [67]. Alternatively, Mohan et al. proposed the use of aerobic biofilms on the cathode to catalyze oxygen reduction, likely due to the stimulation of bio-electrochemical processes by higher bio-potentials. MFC operation with aerobic biocathode showed significant increment in both TDS (cathode, 90.2 ± 1%; anode, 39.7 ± 0.5%) and substrate (cathode, 98.07 ± 0.06%; anode, 96.2 ± 0.3%) removal compared to anaerobic biocathode and abiotic cathode operations (COD, 80.25 ± 0.3%; TDS, 30.5 ± 1.2%) [68]. Li et al. added a small amount of shuttle medium (Cu2+) to the cathode chamber to alleviate charge repulsion between Cr2O72− and the cathode. The result showed that the reduction rate of Cr (VI) was increased by 1.17 times [69]. The main comparisons and performances of these anode and cathode mode MFC-SPBs based on substrate effect were listed in Table 1. Compared with the anode sensing mode, the cathode sensing can realize the integration of sensing and repair for HMIs, which provides a convenient method for the monitoring and removing heavy metals in the environment.

Microbial activity effect

In the context of toxicity, the microbial activity effect becomes a critical aspect of MFC-SPBs, especially in applications related to environmental monitoring and early detection of toxic agents. Various target analytes have the potential to modulate microbial activity, consequently influencing the output signal of MFC-SPBs. Factors influencing microbial activity can be delineated into two categories: environmental and matrix-related. Under non-extreme conditions, the influence of environmental factors (e.g., temperature and pH) on microbial activity is usually reversible, affecting the absorption of nutrients and the secretion of metabolites by microorganisms [72,73,74]. The effect can be reduced by controlling the temperature and adding buffer solution. In the following discussion, we will focus on the role of substances in the matrix on the biological activity of the anode and cathode. In the anode mode, the microbial activity effect manifests as a vital component of the biosensor’s functionality. The presence of toxic substances can impede or alter microbial processes, affecting the electron transfer dynamics and subsequently influencing the biosensor’s electrical output. Analogously, the electroactive biofilm can act as the cathode to form a biocatalyst and promote the reduction reaction. In addition, both organic and toxic substances may inhibit the electron transfer of the cathode, which effectively solves the problem of the coexistence of two substances in the process of anode sensing.

Anode sensing mode

Typically, biological anodes serve as sensitive components for elucidating the microbial activity mechanisms. The impact of toxicants in the matrix, such as HMIs [75, 76], herbicides [77], surfactants [78, 79], antibiotics [19, 80], and volatile organic toxicants [81], is usually irreversible on microbial activity. Yu et al. then tested the toxicity of six heavy metal ions (Cu2+, Hg2+, Zn2+, Cd2+, Pb2+, and Cr3+) at a concentration of 2 mg/L in a two-chamber MFC system. They observed inhibition rates on current output were found to be 12.56%, 13.99%, 8.81%, 9.29%, 5.59%, and 1.95%, respectively [75]. Naik et al. presented a simple and convenient single-chamber cylindrical MFC-SPB to detect four toxic heavy metal ions in wastewater, as shown in Fig. 4a. The toxicity order based on the inhibition ratio was found as Cr6+ > Cu2+ > Zn2+ > Ni2+, with a recovery time of 3–4 days based on the concentration toxicant injected to system [82]. Lu et al. demonstrated that the organic solvent (formaldehyde) could denature proteins and nucleic acids and destroy cell membranes, causing damage to microbial activity. Their investigation into microbial responses to three formaldehyde concentrations in MFCs revealed an inverse correlation between microbial activity and both exposure time and formaldehyde concentration [83]. Additionally, Zeng et al. constructed a single chamber MFC based on FePO4 to examine levofloxacin (LEV). The current output had a good linear relationship with LEV over a concentration range of 0.1–100 µg/L. The MFC sensor was in stable operation for more than 14 months, showing the advantages of MFC sensors for antibiotic detection in long-time operation [80]. In sewage detection, Do et al. established double-chamber MFC in a continuous mode under different influent ammonium concentrations ranging from 5 to 40 mg/L. Results indicated that excess ammonium would inhibit the activity of electrogenic bacteria in the anode chamber and consequently affect electricity production. An inverse linear relationship between concentration and voltage generation, achieving an R2 coefficient of 0.99, and the NH4+-N detecting was up to 40 mg/L [84]. However, the sensitivity of an toxicity sensor is typically inadequate, resulting in detection limits differing by several orders of magnitude from water quality standards established by organizations such as the WHO, significantly constraining their potential applications [48]. For instance, certain poison HMIs would stimulate the power generation process of MFCs at low concentrations, leading to a false signal [85]. Thus, urgent exploration of methodologies to enhance the sensitivity of MFC-based toxicity sensors is warranted.

Anode sensing mode based on microbial activity effect in applications of MFC-SPBs. a Schematic of the simple one chamber MFC-SPB for heavy metals detection [82]. b Influence of different culture on the sensitivity of MFC sensors [87]. c Mechanism of a cross-section of the toxicity biosensor using G. sulfurreducens as the biological sensing element [93]. d Schematic illustration of the toxicity detection based on the MFC-SPBs with a PB cathode [94]

Sensitivity is mainly limited by the biological mechanisms and the mass transfer of toxic substances. Controlling the microbial community structures could theoretically be used to enhance the toxicity responses of MFC-based toxicity biosensors. Yi et.al. studied the influence of different culture methods on the sensitivity of MFC sensors. The result showed that the anode biofilm formed with Shewanella loihica PV-4 had a lower content of extracellular polymeric substances (EPS) compared with mixed culture, which is clearly advantageous for the sensing of poisons. However, after a longer period of incubation (more than 6000 min), the mixture begins to have a higher voltage output (238 mV) [86]. For mixed culture microorganisms, Pan et. al. applied commercially available QS autoinducers (AHLs) to MFC-SPB to manipulate anode biofilm for better sensing performance. The results showed that the enhanced anode widened the sensing range of Pb2+ and had better recovery ability to Cu2+ shock. It was found that higher live/dead cells ratio and increased exoelectrogen Geobacter abundance were responsible for the superior sensing linearity and recovery capability of MFC toxicity sensor (Fig. 4b) [87]. Furthermore, MFC-SPBs usually operate in the mode of an external resistor. By adjusting the resistance of the resistor, both anode potential and the composition of the microbial community can be controlled. Yi et. al. found that optimal detection of avermectin, tetracyclines, and heavy metals corresponded to resistances of 100 Ω, 330 Ω, and 680 Ω, respectively [88].

The mass transfer of toxicants in the bioanode is diffusion-controlled, and thus, the biosensor sensitivity can be improved by reducing the thickness of the biofilm or increasing its pores size. Li et al. proposed that a two-dimensional carbon felt and indium tin oxide (ITO) film as the anode of MFC could form a thinner biofilm compared to traditional carbon felt (CF) anode, thereby expediting the mass transfer process. The average sensitivity of ITO-MFC was 3.9 times that of CF-MFC, showing a better performance in toxicity detection [17]. Additionally, cultivation under low nutrient concentrations is conducive to obtaining a thinner biofilm. For example, a tenfold reduction in acetate concentration resulted in a 10% reduction in biofilm thickness, thereby enhancing the response to 1 mg/L formaldehyde [89, 90]. Additionally, the flow mode can also affect the mass transfer process. Jiang et al. optimized the flow configurations and control modes, revealing that sensors operated under controlled anode potential (CP) mode exhibited superior sensitivity compared to those operated under constant external resistance (ER) mode across a broad range of anode potentials from − 0.41 V to + 0.1 V. Electrodeposition of Cu (II) was found to bias the toxicity measurement at low anode potentials [91].

During the long-time operation of MFC-SPB, biofilm may develop resistance to toxic substances, resulting in a decrease in sensitivity of sensors [92]. To address this issue, Davila et al. constructed a silicon-based MFC-SPB. The anode biofilm was replaced after each toxicity test to ensure the sensitivity of the sensor, and the detection range of formaldehyde concentration was up to 0.1 to 4% (Fig. 4c) [93]. In addition, Stein et al. studied the performance of MFC sensors in different control mechanisms, revealing that resistance-controlled sensors outperformed anode potential control and current control counterparts, displaying enhanced sensitivity and shorter recovery times. This superiority may be due to the less damage to the bacteria in this mechanism, allowing them to rebuild the anodic potential and current more quickly during the recovery process [79]. In addition to electrical signal-based sensing methods, color can also be developed using the redox process. Yu et al. constructed a MFC-SPB containing a bioanode and Prussian blue (PB) cathode [94]. When the wastewater containing heavy metals enters the anode chamber, the cathodic reducibility is reduced due to the decrease in microbial activity, and the electrochromic PB shows a different color, as shown in Fig. 4d. Thus, the toxicities of heavy metal ions, such as Co2+, Cd2+, Pb2+, and Cu2+, were sensitively detected by the MFC-based biosensor using colorimetric detection. The inhibition absorbances values were 28.4%, 11.0%, 33.8%, and 66.6% for the samples with 1 mg/L Cd2+, 1 mg/L Co2+, 1 mg/L Pb2+, and 1 mg/L Cu2+, respectively, and the toxicity was in the order of Co2+ < Cd2+ < Pb2+ < Cu2+.

Cathode sensing mode

When the bioanode as the sensitive element, the MFC-based toxicity sensor can be easily disturbed by organic matter. By employing the biocathode, false alarms caused by the organic matter/toxicity combination shock can be avoided. Biocathodes can use electrons and protons to promote the reduction of various electron acceptors. Since the sensing process of the biocathode is no longer affected by organic matter, the application range of the MFC-SPBs can be expanded by using the biocathode as the sensing element compared with traditional bioanode. Specifically, the detection range can be extended from anaerobic/organic-rich water environment to aerobic/organic-deficient ones. Therefore, biocathode sensing elements are more suitable to monitor complex aquatic environment.

Biocathode sensing predominantly relies on electroautotrophic bacteria with a bidirectional electron transport pathway, such as Shewanella oneidensis MR-1 [95]. Toxicants in the cathode chamber could affect the electrons-accepting process and trigger an early warning. Jiang et al. first used the biocathode attached by electroactive microorganisms as a sensing element in MFC-SPB to monitor toxic substances in the water environment. The result showed that the sensitivity of the biosensor was much higher than that of the traditional MFC-SPB with bioanode as the element, and the minimum detection limit of formaldehyde could reach 0.0005%, which is the lowest value reported to date using MFC-SPBs (Fig. 5a) [96]. Jiang et al. also evaluated the sensing performance of biocathodes for gaseous pollutants. They initially assembled the cultured bioanode with a commercial waterproof breathable membrane to achieve sufficient biomass loading. Then, by polarity reversal, the above bioanode can be used as the gas diffusion (GD)-biocathode. The lowest minimum detection limit of the GD-biocathode MFC sensor for formaldehyde was 20 ppm. This study confirmed the feasibility of monitoring gaseous pollutants by MFC-SPB and expanded its scope of application (Fig. 5b) [97]. In addition to monitoring formaldehyde, another report indicated a more sensitive response of biocathodes to heavy metals (Hg(II), Cr(VI), or Pb(II)), 2,4-dichlorophenol, and benzalkonium chloride, compared with previous bioanode [98].

Cathode sensing mode based on microbial activity effect in applications of MFC-SPBs. a Schematic of a biocathode attached by electroactive microorganisms as a sensing element in MFC-SPB [96]. b Preparation of GD-biocathode MFC sensor and the process monitoring air pollutants [97]. c Illustration of an algae-assisted cathode used to detect herbicides [101]. d Schematic of algae absorbing gas produced by the anode in the cathode chamber [102]

Algae can also serve as a source of electron acceptors for cathodes [99]. According to Amesh et al., the oxygen aeration provided by algae facilitated the generation of the maximum power density, which was 32% higher than that generated by mechanical aeration [100]. The advantageous sensitivity of algae toward numerous pollutants results in a decline in DO levels due to the existence of toxins in the catholyte, thereby causing changes in MFC-SPB output signals. Lola Gonzalez Olias et al. first used the algae-assisted cathode as a DO probe to detect herbicides in water. The presence of these toxicants the activity of phototrophic microorganisms, resulting in reducing oxygen in cathode chamber. The lowest detection limit of herbicides by p-MFC constructed in this work is 0.1 μg/L, demonstrating that the potential to warn the herbicide pollution in water [101] (Fig. 5c). In addition, based on the utilization of CO2 by phototrophic microorganisms, MFC-SPB is expected to decrease emission of CO2. Wang et al. designed a novel MFC assembly capable of directing anodic CO2 into the cathode chamber for microalgae growth. The results demonstrated that all the CO2 produced in the anode was completely removed in the cathode while the system operated [102] (Fig. 5d).

Currently, limited researches had been conducted on the factors affecting biocathode sensing. Liao et al. and Prévoteau et al. identified several putative electroautotrophic bacterial populations by exploding the composition of microbial communities of biocathode, most of which are categorized under the Proteobacteria and Bacteroidetes phyla [95, 103]. Optimizing the electrode potential configuration can enhance the sensitivity. At a cathode potential of − 0.2 V, the biosensor sensitivity of the biosensor was 6 times higher than that at 0 V and 64 times higher than that at − 0.4 V, attributed to the selection of microbial communities at different cathode potentials. Safwat et al. conducted a study on the efficacy of MFC-SPBs for the detection of benzene, phenol, chromium, and copper, using different catholyte solutions. Following an initial period, the MFC with aerated tap water (MFC-T) as the catholyte solution generated a voltage higher than that with ferricyanide (MFC-F). Chromium > benzene > phenol > copper for MFC-T and chromium > copper > phenol > benzene for MFC-F were determined to be the orders of toxicity based on the inhibition ratio [104].

However, the effects of other operating parameters on cathodic sensing and the interaction between toxicants and electrotrophic bacteria remain unclear. It should be noted that the response of microbial communities in the bioanode and biocathode to toxicants may be remarkably different. As mentioned above, heavy metal ions can inhibit the abundance of microorganisms in the anode. But in a recent study, Wang et al. found that Zn (II) could play a positive role in the bioanode of a constructed wetland-MFC reactor [105]. Therefore, further research should be devoted to studying the biocathode as a toxicity sensing element and understanding the interaction between toxicants and microorganisms. Moreover, the performance of biocathode-based sensors, such as sensitivity, detection limits, and time response, should also be improved from the aspects of electrode materials, sensor structure, and operating parameters. Biocathode-based sensors will reach full potential for toxicity monitoring when all these elements are integrated into the feature. The performance comparison of MFC-SPBs based on microbial activity effect with both anode and cathode were listed in Table 2.

Concluding remarks and outlook

In this review [106], the recently important strides toward the bio-sensing in both anode and cathode of MFC are reviewed. By identifying the nature of target-recognition events, we concluded that the mechanisms of anode sensing and cathode sensing modes through substrate effects and toxicity effects and highlighted the reinforcement strategies used for the accuracy and sensitivity of MFC-SPBs. Although MFC-SPBs have come a long way in recent years, some limitations still need to be addressed in the future.

-

1)

Regardless of whether anodic sensing or cathodic sensing modes are used, the MFC-SPBs lack selectivity and specificity for monitoring analytes of interest. To address this issue, future research efforts could focus on improving their specificity by developing microorganisms that can distinguish between different kinds of toxicants in the environment. Recent research has moved in this direction, increasing the sensitivity of biosensors by using a single strain of natural or genetically modified bacteria.

-

2)

Studies have shown that the use of a biocathode as the sensing component can show higher sensitivity and a lower false-negative rate compared with a bioanode. However, the operating parameters and toxicity sensing mechanism of biocathodes are still unclear, and the recovery ability of biosensors after toxic stress has not been explored. Therefore, further efforts are still needed to improve the performance of the cathode sensing mode.

-

3)

The sensing signal enhancement strategy of MFC-SPBs need to be further expanded. The technologies such as single-cell modification can be used to improve the electron transport ability of bacteria to enhance the sensing signal, while the combination of supercapacitors or optoelectronic materials can increase the instantaneous output or realize the multiple energy conversion for a better sensing signal. Aside from these strategies from the optimization of MFC output performance, it is also possible to integrate DNA or other bio-amplification technologies for recycling the analyte.

Finally, the application researches of MFC-SPBs should be strengthened. In addition to the detection of some water quality parameters, it is encouraged to be designed for the detection of soil samples, anesthetic drugs, persistent pollutant, and so on. To broaden the application range of MFC-SPBs, more efforts should be devoted to exploit novel sensing strategies that beyond the scope of substrate or toxicity effects. For examples, the steric effect or the biocatalyst variation effect developed in other biofuel cell-based SPBs can be taken into consideration.

References

Pasternak G, Greenman J, Ieropoulos I. Self-powered, autonomous biological oxygen demand biosensor for online water quality monitoring. Sens Actuators B. 2017;244:815–22. https://doi.org/10.1016/j.snb.2017.01.019.

Zhou J, Battig MR, Wang Y. Aptamer-based molecular recognition for biosensor development. Anal Bioanal Chem. 2010;398(6):2471–80. https://doi.org/10.1007/s00216-010-3987-y.

Zhu J, Wang B, Zhang Y, Wei T, Gao T. Living electrochemical biosensing: engineered electroactive bacteria for biosensor development and the emerging trends. Biosens Bioelectron. 2023;237:115480. https://doi.org/10.1016/j.bios.2023.115480.

Lei ZL, Guo B. 2D Material-based optical biosensor: status and prospect. Adv Sci. 2022;9(4):2102924. https://doi.org/10.1002/advs.202102924.

Katz E, Bückmann FA, Willner I. Self-powered enzyme-based biosensors. J Am Chem Soc. 2001;123:10752–3. https://doi.org/10.1021/ja0167102.

Gu C, Gai P, Li F. Construction of biofuel cells-based self-powered biosensors via design of nanocatalytic system. Nano Energy. 2022;93:106806. https://doi.org/10.1016/j.nanoen.2021.106806.

Kurniawan TA, Othman MHD, Liang X, Ayub M, Goh HH, Kusworo TD, Mohyuddin A, Chew KW. Microbial fuel cells (MFC): a potential game-changer in renewable energy development. Sustainability. 2022;14(24):16847. https://doi.org/10.3390/su142416847.

Wang L, Wu Y, You Z, Bao H, Zhang L, Wang J. Electrochemical impedance spectroscopy (EIS) reveals the role of microbial fuel cell-ceramic membrane bioreactor (MFC-CMBR): Electricity utilization and membrane fouling. Water Res. 2022;222:118854. https://doi.org/10.1016/j.watres.2022.118854.

Nakamura H. Current status of water environment and their microbial biosensor techniques - Part II: Recent trends in microbial biosensor development. Anal Bioanal Chem. 2018;410(17):3967–89. https://doi.org/10.1007/s00216-018-1080-0.

Gu C, Bai L, Pu L, Gai P, Li F. Highly sensitive and stable self-powered biosensing for exosomes based on dual metal-organic frameworks nanocarriers. Biosens Bioelectron. 2021;176:112907. https://doi.org/10.1016/j.bios.2020.112907.

ElMekawy A, Hegab HM, Pant D, Saint CP. Bio-analytical applications of microbial fuel cell-based biosensors for onsite water quality monitoring. J Appl Microbiol. 2018;124(1):302–13. https://doi.org/10.1111/jam.13631.

Gai P, Gu C, Hou T, Li F. Integration of biofuel cell-based self-powered biosensing and homogeneous electrochemical strategy for ultrasensitive and easy-to-use bioassays of microRNA. ACS Appl Mater Interfaces. 2018;10(11):9325–31. https://doi.org/10.1021/acsami.8b01001.

Guo D, Wei HF, Song RB, Fu J, Lu X, Jelinek R, Min Q, Zhang JR, Zhang Q, Zhu JJ. N, S-doped carbon dots as dual-functional modifiers to boost bio-electricity generation of individually-modified bacterial cells. Nano Energy. 2019;63:103875. https://doi.org/10.1016/j.nanoen.2019.103875.

Sun JZ, Peter Kingori G, Si RW, Zhai DD, Liao ZH, Sun DZ, Zheng T, Yong YC. Microbial fuel cell-based biosensors for environmental monitoring: a review. Water Sci Technol. 2015;71(6):801–9. https://doi.org/10.2166/wst.2015.035.

Chung TH, Dhar BR. Paper based platforms for microbial electrochemical cell-based biosensors: a review. Biosens Bioelectron. 2021;192:113485. https://doi.org/10.1016/j.bios.2021.113485.

Chang IS, Moon H, Jang JK, Kim BH. Improvement of a microbial fuel cell performance as a BOD sensor using respiratory inhibitors. Biosens Bioelectron. 2005;20(9):1856–9. https://doi.org/10.1016/j.bios.2004.06.003.

Li J, Hu J, Yang C, Pu W, Hou H, Xu J, Liu B, Yang J. Enhanced detection of toxicity in wastewater using a 2D smooth anode based microbial fuel cell toxicity sensor. RSC Adv. 2019;9(15):8700–6. https://doi.org/10.1039/c8ra10337b.

Sivasankar P, Poongodi S, Seedevi P, Sivakumar M, Murugan T, Loganathan S. Bioremediation of wastewater through a quorum sensing triggered MFC: a sustainable measure for waste to energy concept. J Environ Manage. 2019;237:84–93. https://doi.org/10.1016/j.bios.2021.113485.

Catal T, Yavaser S, Enisoglu-Atalay V, Bermek H, Ozilhan S. Monitoring of neomycin sulfate antibiotic in microbial fuel cells. Bioresour Technol. 2018;268:116–20. https://doi.org/10.1016/j.biortech.2018.07.122.

Chang IS, Jang JK, Gil GC, Kim M, Kim HJ, Cho BW, Kim BH. Continuous determination of biochemical oxygen demand using microbial fuel cell type biosensor. Biosens Bioelectron. 2004;19(6):607–13. https://doi.org/10.1016/s0956-5663(03)00272-0.

Peixoto L, Min B, Martins G, Brito AG, Kroff P, Parpot P, Angelidaki I, Nogueira R. In situ microbial fuel cell-based biosensor for organic carbon. Bioelectrochemistry. 2011;81(2):99–103. https://doi.org/10.1016/j.bioelechem.2011.02.002.

Xia X, Tokash JC, Zhang F, Liang P, Huang X, Logan BE. Oxygen-reducing biocathodes operating with passive oxygen transfer in microbial fuel cells. Environ Sci Technol. 2013;47(4):2085–91. https://doi.org/10.1021/es3027659.

Zhu TJ, Lin CW, Liu SH. Sensitivity and reusability of a simple microbial fuel cell-based sensor for detecting bisphenol A in wastewater. Chemosphere. 2023;320:138082. https://doi.org/10.1016/j.chemosphere.2023.138082.

Varshney A, Sharma L, Pandit C, Gupta PK, Mathuriya AS, Pandit S, Lahiri D, Nag M, Upadhye VJ. Microbial fuel cell–based biosensors and applications. Appl Biochem Biotechnol. 2023;195(5):3508–31. https://doi.org/10.1007/s12010-023-04397-x.

Chung TH, Meshref MN, Dhar BR. A review and roadmap for developing microbial electrochemical cell-based biosensors for recalcitrant environmental contaminants, emphasis on aromatic compounds. Chem Eng J. 2021;424:130245. https://doi.org/10.1016/j.cej.2021.130245.

Tront JM, Fortner JD, Plotze M, Hughes JB, Puzrin AM. Microbial fuel cell technology for measurement of microbial respiration of lactate as an example of bioremediation amendment. Biotechnol Lett. 2008;30(8):1385–90. https://doi.org/10.1007/s10529-008-9707-4.

Tront JM, Fortner JD, Plotze M, Hughes JB, Puzrin AM. Microbial fuel cell biosensor for in situ assessment of microbial activity. Biosens Bioelectron. 2008;24(4):586–90. https://doi.org/10.1016/j.bios.2008.06.006.

Do MH, Ngo HH, Guo W, Chang SW, Nguyen DD, Liu Q, Nghiem DL, Thanh BX, Zhang X, Hoang NB. Performance of a dual-chamber microbial fuel cell as a biosensor for in situ monitoring Bisphenol A in wastewater. Sci Total Environ. 2022;845:157125. https://doi.org/10.1016/j.scitotenv.2022.157125.

Dong H, Wang X, Lu S, Ma Y, Song C, Wang S, Liu H. Microbial fuel cell-based biosensor for monitoring anaerobic biodegradation of poly (3-hydroxybutyrate-co-4-hydroxybutyrate). Polym Degrad Stab. 2023;214:110409. https://doi.org/10.1016/j.polymdegradstab.2023.110409.

Askari A, Vahabzadeh F, Mardanpour MM. Quantitative determination of linear alkylbenzene sulfonate (LAS) concentration and simultaneous power generation in a microbial fuel cell-based biosensor. J Cleaner Prod. 2021;294:126349. https://doi.org/10.1016/j.jclepro.2021.126349.

Karube I, Matsunaga T, Mitsuda S, Suzuki S. Microbial electrode BOD sensors. Biotechnol Bioeng. 1977;19(10):1535–47. https://doi.org/10.1002/bit.260191010.

Wang C, Yin L, Wang S, Jin X, Yang J, Liu H. Role played by the physical structure of carbon anode materials in MFC biosensor for BOD measurement. Sci Total Environ. 2023;856:158848. https://doi.org/10.1016/j.scitotenv.2022.158848.

Quek SB, Cheng L, Cord-Ruwisch R. Microbial fuel cell biosensor for rapid assessment of assimilable organic carbon under marine conditions. Water Res. 2015;77:64–71. https://doi.org/10.1016/j.watres.2015.03.012.

Xu L, Yu W, Graham N, Zhao Y. Revisiting the bioelectrochemical system based biosensor for organic sensing and the prospect on constructed wetland-microbial fuel cell. Chemosphere. 2021;264:128532. https://doi.org/10.1016/j.chemosphere.2020.128532.

Lu R, Chen Y, Wu J, Chen D, Wu Z, Xiao E. In situ COD monitoring with use of a hybrid of constructed wetland-microbial fuel cell. Water Res. 2022;210:117957. https://doi.org/10.1016/j.watres.2021.117957.

Xu L, Zhao Y, Fan C, Fan Z, Zhao F. First study to explore the feasibility of applying microbial fuel cells into constructed wetlands for COD monitoring. Bioresour Technol. 2017;243:846–54. https://doi.org/10.1016/j.biortech.2017.06.179.

Corbella C, Hartl M, Fernandez-Gatell M, Puigagut J. MFC-based biosensor for domestic wastewater COD assessment in constructed wetlands. Sci Total Environ. 2019;660:218–26. https://doi.org/10.1016/j.scitotenv.2018.12.347.

Jia H, Yang G, Wang J, Ngo HH, Guo W, Zhang H, Zhang X. Performance of a microbial fuel cell-based biosensor for online monitoring in an integrated system combining microbial fuel cell and upflow anaerobic sludge bed reactor. Bioresour Technol. 2016;218:286–93. https://doi.org/10.1016/j.biortech.2016.06.064.

Feng Y, Harper WF Jr. Biosensing with microbial fuel cells and artificial neural networks: laboratory and field investigations. J Environ Manage. 2013;130:369–74. https://doi.org/10.1016/j.jenvman.2013.09.011.

Guo F, Liu H. Impact of heterotrophic denitrification on BOD detection of the nitrate-containing wastewater using microbial fuel cell-based biosensors. Chem Eng J. 2020;394:125042. https://doi.org/10.1016/j.cej.2020.125042.

Ayyaru S, Dharmalingam S. Enhanced response of microbial fuel cell using sulfonated poly ether ether ketone membrane as a biochemical oxygen demand sensor. Anal Chim Acta. 2014;818:15–22. https://doi.org/10.1016/j.aca.2014.01.059.

Wang S, Tian S, Zhang P, Ye J, Tao X, Li F, Zhou Z, Nabi M. Enhancement of biological oxygen demand detection with a microbial fuel cell using potassium permanganate as cathodic electron acceptor. J Environ Manage. 2019;252:109682. https://doi.org/10.1016/j.jenvman.2019.109682.

Wang Y, Niu CG, Zeng GM, Hu WJ, Huang DW, Ruan M. Microbial fuel cell using ferrous ion activated persulfate as a cathodic reactant. Int J Hydrogen Energy. 2011;36(23):15344–51. https://doi.org/10.1016/j.ijhydene.2011.08.071.

Nakamura H, Abe Y, Koizumi R, Suzuki K, Mogi Y, Hirayama T, Karube I. A chemiluminescence biochemical oxygen demand measuring method. Anal Chim Acta. 2007;602(1):94–100. https://doi.org/10.1016/j.aca.2007.08.050.

Oota S, Hatae Y, Amada K, Koya H, Kawakami M. Development of mediated BOD biosensor system of flow injection mode for shochu distillery wastewater. Biosens Bioelectron. 2010;26(1):262–6. https://doi.org/10.1016/j.bios.2010.06.040.

Wei L, Han H, Shen J. Effects of cathodic electron acceptors and potassium ferricyanide concentrations on the performance of microbial fuel cell. Int J Hydrogen Energy. 2012;37(17):12980–6. https://doi.org/10.1016/j.ijhydene.2012.05.068.

Sindhuja M, Harinipriya S, Bala AC, Ray AK. Environmentally available biowastes as substrate in microbial fuel cell for efficient chromium reduction. J Hazard Mater. 2018;355:197–205. https://doi.org/10.1016/j.jhazmat.2018.05.030.

Jiang Y, Yang X, Liang P, Liu P, Huang X. Microbial fuel cell sensors for water quality early warning systems: fundamentals, signal resolution, optimization and future challenges. Renew Sust Energ Rev. 2018;81:292–305. https://doi.org/10.1016/j.rser.2017.06.099.

Spurr MWA, Yu EH, Scott K, Head IM. Extending the dynamic range of biochemical oxygen demand sensing with multi-stage microbial fuel cells. Environ Sci Water Res Technol. 2018;4(12):2029–40. https://doi.org/10.1039/c8ew00497h.

Modin O, Wilen BM. A novel bioelectrochemical BOD sensor operating with voltage input. Water Res. 2012;46(18):6113–20. https://doi.org/10.1016/j.watres.2012.08.042.

Moon H, Chang IS, Kang KH, Jang JK, Kim BH. Improving the dynamic response of a mediator-less microbial fuel cell as a biochemical oxygen demand (BOD) sensor. Biotechnol Lett. 2004;26:1717–21. https://doi.org/10.1007/s10529-004-3743-5.

Naik S, Eswari JS. Experimental and validation with neural network time series model of microbial fuel cell bio-sensor for phenol detection. J Environ Manage. 2021;290:112594. https://doi.org/10.1016/j.jenvman.2021.112594.

Kaur A, Ibrahim S, Pickett CJ, Michie IS, Dinsdale RM, Guwy AJ, Premier GC. Anode modification to improve the performance of a microbial fuel cell volatile fatty acid biosensor. Sens Actuators B. 2014;201:266–73. https://doi.org/10.1016/j.snb.2014.04.062.

Zhang Y, Angelidaki I. A simple and rapid method for monitoring dissolved oxygen in water with a submersible microbial fuel cell (SBMFC). Biosens Bioelectron. 2012;38(1):189–94. https://doi.org/10.1016/j.bios.2012.05.032.

Song N, Yan Z, Xu H, Yao Z, Wang C, Chen M, Zhao Z, Peng Z, Wang C, Jiang HL. Development of a sediment microbial fuel cell-based biosensor for simultaneous online monitoring of dissolved oxygen concentrations along various depths in lake water. Sci Total Environ. 2019;673:272–80. https://doi.org/10.1016/j.scitotenv.2019.04.032.

Dai Z, Xu Z, Wang T, Fan Y, Liu Y, Yu R, Zhu G, Lu X, Li B. In-situ oil presence sensor using simple-structured upward open-channel microbial fuel cell (UOC-MFC). Biosens Bioelectron X. 2019;1:100014. https://doi.org/10.1016/j.biosx.2019.100014.

Dai Z, Yu R, Zha X, Xu Z, Zhu G, Lu X. On-line monitoring of minor oil spills in natural waters using sediment microbial fuel cell sensors equipped with vertical floating cathodes. Sci Total Environ. 2021;782:146549. https://doi.org/10.1016/j.scitotenv.2021.146549.

Chung H, Ju WJ, Jho EH, Nam K. Applicability of a submersible microbial fuel cell for Cr(VI) detection in water. Environ Monit Assess. 2016;188(11):613. https://doi.org/10.1007/s10661-016-5625-4.

Liu W, Zhou Z, Yin L, Zhu Y, Zhao J, Zhu B, Zheng L, Jin Q, Wang L. A novel self-powered bioelectrochemical sensor based on CoMn2O4 nanoparticle modified cathode for sensitive and rapid detection of hydrogen peroxide. Sens Actuators B. 2018;271:247–55. https://doi.org/10.1016/j.snb.2018.05.070.

Lin Z, Cheng S, Li H, Li L. A novel, rapidly preparable and easily maintainable biocathode electrochemical biosensor for the continuous and stable detection of nitrite in water. Sci Total Environ. 2022;806(Pt 4):150945. https://doi.org/10.1016/j.scitotenv.2021.150945.

Yu YY, Ding XL, Quan WZ, Niu Q, Fang Z, Dapaah MF, You T, Xiao X, Cheng L. Dynamically controlling the electrode potential of a microbial fuel cell-powered biocathode for sensitive quantification of nitrate. Electrochim Acta. 2021;369:137661. https://doi.org/10.1016/j.electacta.2020.137661.

Wang YJ, Zhao N, Fang B, Li H, Bi XT, Wang H. Carbon-supported Pt-based alloy electrocatalysts for the oxygen reduction reaction in polymer electrolyte membrane fuel cells: particle size, shape, and composition manipulation and their impact to activity. Chem Rev. 2015;115(9):3433–67. https://doi.org/10.1021/cr500519c.

Pu L, Li K, Chen Z, Zhang P, Zhang X, Fu Z. Silver electrodeposition on the activated carbon air cathode for performance improvement in microbial fuel cells. J Power Sources. 2014;268:476–81. https://doi.org/10.1016/j.jpowsour.2014.06.071.

Wang X, Feng C, Ding N, Zhang Q, Li N, Li X, Zhang Y, Zhou Q. Accelerated OH(-) transport in activated carbon air cathode by modification of quaternary ammonium for microbial fuel cells. Environ Sci Technol. 2014;48(7):4191–8. https://doi.org/10.1021/es5002506.

Zhu NW, Lu Y, Liu BW, Zhang TP, Huang JJ, Shi CH, Wu PX, Dang Z, Wang RX. CoMn2O4-supported functionalized carbon nanotube: efficient catalyst for oxygen reduction in microbial fuel cells. 2017;19:331. https://doi.org/10.1007/s11051-017-4023-3.

Huang J, Zhu N, Yang T, Zhang T, Wu P, Dang Z. Nickel oxide and carbon nanotube composite (NiO/CNT) as a novel cathode non-precious metal catalyst in microbial fuel cells. Biosens Bioelectron. 2015;72:332–9. https://doi.org/10.1016/j.bios.2015.05.035.

Costa de Oliveira MA, Mecheri B, D’Epifanio A, Zurlo F, Licoccia S. Optimization of PGM-free cathodes for oxygen reduction in microbial fuel cells. Electrochim Acta. 2020;334:135650. https://doi.org/10.1016/j.electacta.2020.135650.

Mohan SV, Srikanth S. Enhanced wastewater treatment efficiency through microbially catalyzed oxidation and reduction: synergistic effect of biocathode microenvironment. Bioresour Technol. 2011;102(22):10210–20. https://doi.org/10.1016/j.biortech.2011.08.034.

Li M, Zhou S. Efficacy of Cu(II) as an electron-shuttle mediator for improved bioelectricity generation and Cr(VI) reduction in microbial fuel cells. Bioresour Technol. 2019;273:122–9. https://doi.org/10.1016/j.biortech.2018.10.074.

Askari A, Vahabzadeh F, Mardanpour MM. Quantitative determination of linear alkylbenzene sulfonate (LAS) concentration and simultaneous power generation in a microbial fuel cell-based biosensor. J Clean Prod. 2021; 294. https://doi.org/10.1016/j.jclepro.2021.126349.

Yu YY, Ding XL, Quan WZ, Niu Q, Fang Z, Dapaah MF, You T, Xiao X, Cheng L. Dynamically controlling the electrode potential of a microbial fuel cell-powered biocathode for sensitive quantification of nitrate. Electrochimica Acta. 2021; 369. https://doi.org/10.1016/j.electacta.2020.137661.

Min B, Roman OB, Angelidaki I. Importance of temperature and anodic medium composition on microbial fuel cell (MFC) performance. Biotechnol Lett. 2008;30(7):1213–8. https://doi.org/10.1007/s10529-008-9687-4.

Ma Y, Deng D, Zhan Y, Cao L, Liu Y. A systematic study on self-powered microbial fuel cell based BOD biosensors running under different temperatures. Biochem Eng J. 2022;180:108372. https://doi.org/10.1016/j.bej.2022.108372.

Tran TTT, Kannoorpatti K, Padovan A, Thennadil S. Sulphate-reducing bacteria’s response to extreme pH environments and the effect of their activities on microbial corrosion. Appl Sci. 2021;11(5):2201. https://doi.org/10.3390/app11052201.

Yu D, Bai L, Zhai J, Wang Y, Dong S. Toxicity detection in water containing heavy metal ions with a self-powered microbial fuel cell-based biosensor. Talanta. 2017;168:210–6. https://doi.org/10.1016/j.talanta.2017.03.048.

Zhang K, Cao H, Chen J, Wang T, Luo H, Chen W, Mo Y, Li L, An X, Zhang X. Microbial fuel cell (MFC)-based biosensor for combined heavy metals monitoring and associated bioelectrochemical process. Int J Hydrogen Energy. 2022;47(49):21231–40. https://doi.org/10.1016/j.ijhydene.2022.04.225.

Stein NE, Hamelers HV, van Straten G, Keesman KJ. Effect of toxic components on microbial fuel cell-polarization curves and estimation of the type of toxic inhibition. Biosensors. 2012;2(3):255–68. https://doi.org/10.3390/bios2030255.

Li T, Wang X, Zhou L, An J, Li J, Li N, Sun H, Zhou Q. Bioelectrochemical sensor using living biofilm to in situ evaluate flocculant toxicity. ACS Sens. 2016;1(11):1374–9. https://doi.org/10.1021/acssensors.6b00571.

Stein NE, Hamelers HVM, Buisman CNJ. The effect of different control mechanisms on the sensitivity and recovery time of a microbial fuel cell based biosensor. Sens Actuators B. 2012;171–172:816–21. https://doi.org/10.1016/j.snb.2012.05.076.

Zeng L, Li X, Shi Y, Qi Y, Huang D, Tade M, Wang S, Liu S. FePO(4) based single chamber air-cathode microbial fuel cell for online monitoring levofloxacin. Biosens Bioelectron. 2017;91:367–73. https://doi.org/10.1016/j.bios.2016.12.021.

Santoro C, Mohidin AF, Grasso LL, Seviour T, Palanisamy K, Hinks J, Lauro FM, Marsili E. Sub-toxic concentrations of volatile organic compounds inhibit extracellular respiration of Escherichia coli cells grown in anodic bioelectrochemical systems. Bioelectrochemistry. 2016;112:173–7. https://doi.org/10.1016/j.bioelechem.2016.02.003.

Naik S, Jujjavarapu SE. Self-powered and reusable microbial fuel cell biosensor for toxicity detection in heavy metal polluted water. J Environ Chem Eng. 2021;9(4):105318. https://doi.org/10.1016/j.jece.2021.105318.

Lu H, Yu Y, Xi H, Wang C, Zhou Y. Bacterial response to formaldehyde in an MFC toxicity sensor. Enzyme Microb Technol. 2020;140:109565. https://doi.org/10.1016/j.enzmictec.2020.109565.

Do MH, Ngo HH, Guo W, Chang SW, Nguyen DD, Sharma P, Pandey A, Bui XT, Zhang X. Performance of a dual-chamber microbial fuel cell as biosensor for on-line measuring ammonium nitrogen in synthetic municipal wastewater. Sci Total Environ. 2021;795:148755. https://doi.org/10.1016/j.scitotenv.2021.148755.

Xu YS, Zheng T, Yong XY, Zhai DD, Si RW, Li B, Yu YY, Yong YC. Trace heavy metal ions promoted extracellular electron transfer and power generation by Shewanella in microbial fuel cells. Bioresour Technol. 2016;211:542–7. https://doi.org/10.1016/j.biortech.2016.03.144.

Yi Y, Xie B, Zhao T, Liu H. Comparative analysis of microbial fuel cell based biosensors developed with a mixed culture and Shewanella loihica PV-4 and underlying biological mechanism. Bioresour Technol. 2018;265:415–21. https://doi.org/10.1016/j.biortech.2018.06.037.

Pan J, Hu J, Liu B, Li J, Wang D, Bu C, Wang X, Xiao K, Liang S, Yang J, Hou H. Enhanced quorum sensing of anode biofilm for better sensing linearity and recovery capability of microbial fuel cell toxicity sensor. Environ Res. 2020;181:108906. https://doi.org/10.1016/j.envres.2019.108906.

Yi Y, Xie B, Zhao T, Li Z, Stom D, Liu H. Effect of external resistance on the sensitivity of microbial fuel cell biosensor for detection of different types of pollutants. Bioelectrochemistry. 2019;125:71–8. https://doi.org/10.1016/j.bioelechem.2018.09.003.

Li T, Liao C, An J, Zhou L, Tian L, Zhou Q, Li N, Wang X. A highly sensitive bioelectrochemical toxicity sensor and its evaluation using immediate current attenuation. Sci Total Environ. 2021;766:142646. https://doi.org/10.1016/j.scitotenv.2020.142646.

Li T, Zhou Q, Zhou L, Yan Y, Liao C, Wan L, An J, Li N, Wang X. Acetate limitation selects Geobacter from mixed inoculum and reduces polysaccharide in electroactive biofilm. Water Res. 2020;177:115776. https://doi.org/10.1016/j.watres.2020.115776.

Jiang Y, Liang P, Zhang C, Bian Y, Yang X, Huang X, Girguis PR. Enhancing the response of microbial fuel cell based toxicity sensors to Cu(II) with the applying of flow-through electrodes and controlled anode potentials. Bioresour Technol. 2015;190:367–72. https://doi.org/10.1016/j.biortech.2015.04.127.

Zhou T, Han H, Liu P, Xiong J, Tian F, Li X. Microbial fuels cell-based biosensor for toxicity detection: a review. Sensors. 2017;17(10):2230. https://doi.org/10.3390/s17102230.

Davila D, Esquivel JP, Sabate N, Mas J. Silicon-based microfabricated microbial fuel cell toxicity sensor. Biosens Bioelectron. 2011;26(5):2426–30. https://doi.org/10.1016/j.bios.2010.10.025.

Yu D, Zhang H, Bai L, Fang Y, Liu C, Zhang H, Li T, Han L, Yu Y, Yu H. Visual detection of the toxicity of wastewater containing heavy metal ions using a microbial fuel cell biosensor with a Prussian blue cathode. Sens Actuators B. 2020;302:127177. https://doi.org/10.1016/j.snb.2019.127177.

Santoro C, Babanova S, Cristiani P, Artyushkova K, Atanassov P, Bergel A, Bretschger O, Brown RK, Carpenter K, Colombo A, Cortese R, Erable B, Harnisch F, Kodali M, Phadke S, Riedl S, Rosa LFM, Schroder U. How comparable are microbial electrochemical systems around the globe? An Electrochemical and Microbiological Cross-Laboratory Study. Chemsuschem. 2021;14(11):2313–30. https://doi.org/10.1002/cssc.202100294.

Jiang Y, Liang P, Liu P, Wang D, Miao B, Huang X. A novel microbial fuel cell sensor with biocathode sensing element. Biosens Bioelectron. 2017;94:344–50. https://doi.org/10.1016/j.bios.2017.02.052.

Jiang Y, Liang P, Huang X, Ren ZJ. A novel microbial fuel cell sensor with a gas diffusion biocathode sensing element for water and air quality monitoring. Chemosphere. 2018;203:21–5. https://doi.org/10.1016/j.chemosphere.2018.03.169.

Prevoteau A, Clauwaert P, Kerckhof FM, Rabaey K. Oxygen-reducing microbial cathodes monitoring toxic shocks in tap water. Biosens Bioelectron. 2019;132:115–21. https://doi.org/10.1016/j.bios.2019.02.037.

Zhou M, He H, Jin T, Wang H. Power generation enhancement in novel microbial carbon capture cells with immobilized Chlorella vulgaris. J Power Sources. 2012;214:216–9. https://doi.org/10.1016/j.jpowsour.2012.04.043.

Kakarla R, Min B. Photoautotrophic microalgae Scenedesmus obliquus attached on a cathode as oxygen producers for microbial fuel cell (MFC) operation. Int J Hydrogen Energy. 2014;39(19):10275–83. https://doi.org/10.1016/j.ijhydene.2014.04.158.

Gonzalez Olias L,Cameron PJ,Di Lorenzo M. Effect of electrode properties on the performance of a photosynthetic microbial fuel cell for atrazine detection. Front Energy Res. 2019; 7. https://doi.org/10.3389/fenrg.2019.00105.

Wang X, Feng Y, Liu J, Lee H, Li C, Li N, Ren N. Sequestration of CO2 discharged from anode by algal cathode in microbial carbon capture cells (MCCs). Biosens Bioelectron. 2010;25(12):2639–43. https://doi.org/10.1016/j.bios.2010.04.036.

Liao C, Wu J, Zhou L, Li T, Du Q, An J, Li N, Wang X. Optimal set of electrode potential enhances the toxicity response of biocathode to formaldehyde. Sci Total Environ. 2018;644:1485–92. https://doi.org/10.1016/j.scitotenv.2018.07.114.

Safwat SM, Khaled A, Elawwad A, Matta ME. Dual-chamber microbial fuel cells as biosensors for the toxicity detection of benzene, phenol, chromium, and copper in wastewater: Applicability investigation, effect of various catholyte solutions, and life cycle assessment. Process Saf Environ Prot. 2023;170:1121–36. https://doi.org/10.1016/j.psep.2022.12.088.

Wang Q, Lv R, Rene ER, Qi X, Hao Q, Du Y, Zhao C, Xu F, Kong Q. Characterization of microbial community and resistance gene (CzcA) shifts in up-flow constructed wetlands-microbial fuel cell treating Zn (II) contaminated wastewater. Bioresour Technol. 2020;302:122867. https://doi.org/10.1016/j.biortech.2020.122867.

Fillet R, Nicolas V, Fierro V, Celzard A. A review of natural materials for solar evaporation. Sol Energy Mater Sol Cells. 2021;219:110814. https://doi.org/10.1016/j.solmat.2020.110814.

Funding

This study is funded by the National Natural Science Foundation of China (22174131, 5200161) and National Natural Science Foundation of Henan Province (232300421089).

Author information

Authors and Affiliations

Contributions

Conceptualization, writing—original draft preparation: J.X. and Y.W. Project administration: Y.J. Resources, investigation: X.L. and S.C. Supervision, validation: R.S. Formal analysis, writing—review and editing: Y.X. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Published in the topical collection Emerging Trends in Electrochemical Analysis with guest editors Sabine Szunerits, Wei Wang, and Adam T. Woolley.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xue, J., Wang, Y., Jing, Y. et al. Recent advances in microbial fuel cell–based self-powered biosensors: a comprehensive exploration of sensing strategies in both anode and cathode modes. Anal Bioanal Chem 416, 4649–4662 (2024). https://doi.org/10.1007/s00216-024-05230-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-024-05230-y