Abstract

Identification and quantification of microplastics (MP) in environmental samples is crucial for understanding the risk and distribution of MP in the environment. Currently, quantification of MP particles in environmental samples and the comparability of different matrices is a major research topic. Research also focusses on sample preparation, since environmental samples must be free of inorganic and organic matrix components for the MP analysis. Therefore, we would like to propose a new method that allows the comparison of the results of MP analysis from different environmental matrices and gives a MP concentration in mass of MP particles per gram of environmental sample. This is possible by developing and validating an optimized and consistent sample preparation scheme for quantitative analysis of MP particles in environmental model samples in conjunction with quantitative 1H-NMR spectroscopy (qNMR). We evaluated for the first time the effects of different environmental matrices on identification and quantification of polyethylene terephthalate (PET) fibers using the qNMR method. Furthermore, high recovery rates were obtained from spiked environmental model samples (without matrix ~ 90%, sediment ~ 97%, freshwater ~ 94%, aquatic biofilm ~ 95%, and invertebrate matrix ~ 72%), demonstrating the high analytical potential of the method.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the next few years, MP content in marine and freshwater ecosystems is expected to continuously increase. Over the next two decades, plastic production is expected to double or possibly even quadruple by 2050 [1]. Because 79% of plastic waste ends up in landfills or in the environment, the increase in environmental MP is the direct consequence of growing global plastic production [2]. In some locations, plastic abundance in marine ecosystems already exceeds that of zooplankton [3, 4]. It is therefore not surprising that focus on MP in the scientific and public communities has been expanding. The term MP was first introduced in 2004 in the context of small plastic fragments [5]. At present, plastic with a size distribution of 1 μm–5 mm is defined as MP [6, 7]. Due to their small size, MP enter aquatic systems in many ways, including through rain, wind, and wastewater treatment [8,9,10,11]. The small size of such plastics also hides the danger to the environment, since MP can be incorporated by aquatic organisms and in the worst case can lead to starvation [8, 12].

Identification and quantification of MP in environmental samples is crucial for understanding the risk of MP to the environment and to humans. Identification and counting of MP particles (MPP) is mainly performed by FTIR and Raman techniques. Advantages and disadvantages of these methods are described in detail in literature [13, 14]. Detection of MP in environment often focuses on samples taken from sediments, water, and biota in either marine or freshwater systems, though the latter systems have only been extensively studied in recent years [15]. Sediments of the Elbe, Moselle, Neckar, and Rhine (Germany) were analyzed for MP and were found to contain 34–64 items MP per kilogram dry weight (DW) [4]. MP can also be detected in freshwater organisms. The guts of wild gudgeons (Gobio gobio) sampled in 11 French rivers contained MP consisting of hard and colored fibers [16]. The number of studies focusing on MP content in sediment and water samples in freshwater systems has risen sharply in recent years [13]. In contrast, studies observing biota in freshwater systems are not so frequently performed [15, 17]. In order to be able to identify and quantify MP in environmental samples, many analytical detection methods require that MP particles be free of inorganic and organic matrix constituents. Literature detailing the removal of inorganic material from the MP particles mainly describes the method of density separation [18]. For this purpose, the Munich Plastic Sediment Separator (MPSS), which can process a sample volume of up to 6 L, was developed [19]. In order to remove MP particles from inorganic material, solutions with different densities, such as NaCl 1.2 kg/L, ZnCl2 1.7 kg/L, or NaI 1.6 kg/L, are used [20]. A solution with a density > 1.6 kg/L has to be used to be able to separate all commercially available polymers [19]. In most cases, an additional step is required after density separation to remove organic material from MP particles. The method of choice for this additional step is often chemical or enzymatic digestion of organic matrix. Oxidizing agents such as hydrogen peroxide (H2O2), strong acids, and bases can be used for chemical digestion. However, some of these chemicals might also affect or even completely dissolve or decompose MP particles [13, 21]. Enzymes such as protease, cellulase, and/or chitinase are used for enzymatic digestion. The disadvantage of enzymatic digestion is that it can take about 10 times longer than chemical digestion [22].

Nevertheless, there still is a great need for research regarding both sample preparation and quantification of MP in environmental samples. In most reviews on this topic, authors repeatedly report the problem of non-comparability of studies and analytical methods [7, 13, 21]. Therefore, we would like to propose a solution that allows different environmental matrices consisting of sediment, water, and/or organisms to be compared and to specify a plastic concentration in mass of particles per gram of environmental sample. This is possible by validating an optimized and consistent sample clean-up scheme. Quantification of MP particles can be carried out by 1H-NMR spectroscopy using the integration method combined with the calibration curve method (INT-qNMR). The successful application of this method for quantitative analysis of MP particles has already been described [23]. In this paper, we present first results concerning the influence of different matrices on the quantification of PET particles, used as an example of MP particles, by qNMR spectroscopy. For this purpose, we wanted to clarify whether there are disturbing matrix effects after chemical digestion (1) and if these matrix effects negatively influence the quantification of PET particles using the INT-qNMR method (2). Furthermore, we designed a new sample clean-up scheme for the qNMR method (3), checked whether chemical digestion affects PET particles or not (4), and determined recovery rates for different environmental samples for method validation (5).

Materials and methods

Environmental model samples

Environmental samples collected from the Moselle River in Germany included water samples collected at position 50° 21′ 49.8″ N 7° 33′ 54.6″ E, aquatic biofilm, representing an important food source for grazing macroinvertebrates or fish, collected at position 50° 21′ 49.8″ N 7° 33′ 54.6″ E and the amphipod (Gammarus roeselii), representing macroinvertebrates in inland waters. The following matrices were tested: Deionized water as a blank, sand as a model for a sediment matrix, Moselle water to represent a freshwater matrix, and aquatic biofilm as well as invertebrates to represent common biological matrices.

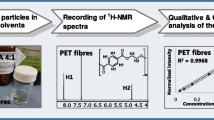

qNMR of PET fibers

Quantification of PET fibers (colorless with a length of approx. 500 μm and a diameter of approx. 10–20 μm, produced by Schwarzwälder-Textil-Werke, Germany) was carried out by quantitative 1H-NMR spectroscopy using the calibration curve method. For 1H-NMR analysis of PET particles, deuterated chloroform (99.8 atom %D, stab. with Ag) from Deutero and trifluoroacetic acid (TFA) from Carl ROTH were used. Solutions of different concentrations of PET particles used for calibration were prepared from a stock solution (PET fibers in CDCl3/TFA 4:1 at RT). For 1H-NMR measurements, 700 μL of the sample solution was transferred into 5 mm NMR tubes. A JEOL® 500 spectrometer with a 500 MHz 5 mm TH ATM probe head was used for the 1D 1H-NMR experiments. Recorded spectra were loaded into the NMR program MestReNova as an FID file. Phase correction was performed manually, whereas baseline correction of the recorded spectra was performed with the Whittaker Smoother. The integral of the signal regions is proportional to the H atoms and thus to the concentration of analyte in the solution [24]. For quantification, the signal range of 8.20–8.00 ppm was integrated and normalized using the residual solvent signal as an internal standard (for more details, see Peez et al. 2019) [23].

Sample clean-up

All environmental samples were dried in an oven at 60 °C and then placed into their own glass beaker with an agitator. Ten milliliters of approx. 50% sulfuric acid (96% from Lach-Ner) and 10 mL of hydrogen peroxide solution (30% from Carl ROTH) per 150 mg dry weight (DW) of the sample (at least 10 mL of the chemical digestion solution regardless of the DW of the sample) were added for chemical digestion for 48 h under constant stirring, optimized according to Imhof et al. [25]. The resulting mixture containing solid residues and MP was then diluted with the same volume of deionized water, filtered under vacuum via a filter, in this case via a P4 frit, and rinsed with deionized water. The filter cake was completely transferred into a glass jar with deionized water and then dried in an oven at 60 °C. If the filter cake consisted largely of inorganic components, like sediment, they were separated from the MP particles. For this separation, the filter cake was dissolved in a suitable solvent for the MP particles to be analyzed and was stirred until a suspension formed (2–4 h). The suspension was then allowed to stand until the non-dissolved sediment matrix components had settled and a well-defined amount of the clear MP solution could be removed. The MP solution was then dried before being dissolved in a suitable deuterated solvent appropriate for the MP polymer species [23]. For determination of digestion efficiency, the DW of environmental samples was determined before and after chemical digestion. Efficiency was then calculated as weight after chemical digestion/weight before chemical digestion × 100%. This procedure was performed on three replicates of each sample type to determine the mean digestion efficiency and standard deviation.

Recovery rates

Recovery rates of the above described sample preparation method were determined using colorless PET fibers, as an example for MP particles. For this purpose, the different environmental samples were spiked with a defined amount (in a spike concentration range of 0.70–2.80 mg/mL) of PET fibers either before digestion (steps 1–5), after digestion (steps 2–5), or after filtration (step 5), to determine the mean recovery rate and standard deviation (n = 3). Recovery rates were determined using the normalized content of PET in the sample. A model sample was used for normalization to minimize measurement inaccuracies caused by shimming or measurement conditions (see Eq. 1).

- [calculated]:

-

calculated value of the PET concentration in mg/mL of the sample

- [calculated]Model Sample:

-

calculated value of the PET concentration in mg/mL of the model sample

- [spike]:

-

weighted value of PET in mg/mL of the sample

- [spike]Model Sample:

-

weighted value of PET in mg/mL of the sample of the model sample

- [Normalized MP]:

-

normalized content of PET in mg/mL in the sample

All glassware were washed with water, acetone, and distilled water before being dried at 60 °C for > 24 h to avoid contamination of the samples. During sample preparation, samples were covered whenever possible. In addition, care was taken to wear closed lab coats (100% cotton) when working with the samples in order to avoid contamination with polymer fibers from clothes. A negative control (n = 3) was carried out to exclude possible contamination during sample preparation.

μFTIR and SEM

In order to check whether chemical digestion had an influence on PET fibers, additional μFTIR and scanning electron microscopy (SEM) measurements of PET fibers were carried out before and after chemical digestion. μFTIR measurements were performed using a Bruker Hyperion 2000 FTIR microscope in attenuated total reflectance (μATR) mode (wavenumber range 4000–600 cm−1). Afterwards, obtained spectra were compared with the Bruker database using the software OPUS 7.5. Moreover, surface morphologies of raw and chemically digested PET fibers were examined by scanning electron microscopy (SEM, SEM515, Philips, Amsterdam, The Netherlands). Both PET types were covered with a gold layer to avoid charging. The micrographs were recorded at least at three different positions operating with an acceleration voltage of 10 kV, 20 mm distance.

Results and discussion

Matrix effects of environmental model samples

Organic matrices might cause interfering matrix signals in 1H-NMR spectra and thus problems concerning quantitative analysis of MP particles might be envisaged. Therefore, it must be checked whether NMR-active matrix components are still present after chemical digestion (see section “Sample clean-up method”) and what influence they have on qualitative and quantitative analysis of MP particles. Figure 1 shows the recorded 1H-NMR spectra of PET fibers and of the environmental model samples (biofilm, invertebrate, and freshwater matrix) after chemical digestion (without PET fibers). The sediment matrix showed no significant signals in the range of 0–9 ppm, except for the solvent signal at 7.26 ppm; the freshwater matrix showed signals of low intensity at 2.45 and 1.25 ppm; and the biofilm and invertebrate matrices showed signals of high intensity at 2.45, 1.65, 1.25, and 0.85 ppm. These signals are typical for fatty acids, long-chain ketones, and aldehydes which may result from the chemical digestion of lipids and lignin. The signal at 1.56 ppm is caused by water. Nevertheless, irrespective of the kind of matrix, areas with potentially disturbing matrix effects (highlighted light gray) were clearly separated from the signal range used for qualitative and quantitative analysis of PET (highlighted dark gray and gray). It is therefore confirmed that qualitative and quantitative analysis of PET particles from environmental samples can be performed by INT-qNMR even if there still were contaminations by traces of the corresponding matrix after chemical digestion.

1H-NMR spectra of PET fibers, biofilm (after chemical digestion), invertebrate (after chemical digestion), freshwater (after chemical digestion), and sediment in CDCl3/TFA 4:1 at RT. Dark gray and gray indicate the ppm range for qualitative analysis of PET particles, gray for quantitative analysis, and light gray for environmental matrix effects

Nevertheless, even in cases of matrix signal overlays, quantification of the MP particles in environmental samples is theoretically possible by applying the peak-fitting method (PF-qNMR) as an alternative quantification method. This is a mathematical method by which overlapping signals are deconvoluted and, thus, area integration of the extracted signals becomes possible [26,27,28]. The PF-qNMR method is not as widespread as the INT-qNMR method because it is more time-consuming and thus is not used for routine analytics [26]. Nevertheless, both methods offer the possibility to qualitatively and quantitatively determine MP particles in different environmental samples.

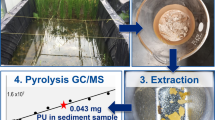

This is a big advantage compared with other detection methods used in MP analytics. FTIR spectroscopy is highly sensitive to matrix effects when detecting MP particles due to signal overlap of many organic matrix materials. Such signal overlap results from CH stretching vibration, CH deformation vibration, or CO stretching vibration [17]. Therefore, it is not possible to identify MP particles with FTIR if biofilm is present on the surface of the particles because the measurement is limited to the surface [13]. For the qNMR method reported herein, this limitation does not apply. Another advantage of qNMR analysis is that samples do not have to be absolutely water-free since water shows a signal at 1.56 ppm in CDCl3 and therefore falls within the existing matrix range of 1.8–0.7 ppm. In comparison, water interferes strongly with FTIR spectroscopy [17]. Raman microspectroscopy (RM) has the advantage of insensitivity to the water content of samples [17]. Nevertheless, RM also has a major disadvantage compared with other analytical techniques, namely the overlap of fluorescence. This overlap can be caused by the presence of inorganic compounds such as clay minerals or organic compounds such as humic acid [17, 29]. In the case of pyrolysis GC-MS analysis, matrix effects are also disturbing. In general, pyrolysis GC-MS identifies the so-called indicator components of specific polymers and identifies the type of polymer being examined, using these indicators [30]. Since these indicators are often aromatic or aliphatic compounds which also often occur in constituents of the organic matrix, identification issues arise [30]. To what extent this has a significant impact on qualitative and quantitative determination of MP using pyrolysis GC-MS still has to be investigated in more detail [17].

We have shown for the first time which NMR-active matrix signals from different environmental samples can still be detected after chemical digestion by 1H-NMR spectroscopy and therefore might complicate quantitative analysis of MP particles. Nevertheless, qNMR spectroscopy compared with FTIR and RM methods has the advantage of being insensitive to inorganic matrix components such as clay minerals and to organic matrix components in the signal ranges of 0.0–0.7 ppm, 1.8–2.4 ppm, and 2.5–10.0 ppm.

qNMR of PET fibers: influence of matrix effects

To quantify the amount of PET fibers in environmental model samples, we used the INT-qNMR method combined with the calibration curve method. Since our study has shown that NMR-active matrix components do not interfere with the quantification of PET particles, we assumed that quantitative analysis can be performed with only one single matrix calibration, as previously shown by Dümichen et al. for PE particles [31]. To verify this, four different environmental samples were chemically digested (except for sediment samples) and spiked with a known amount of PET. The PET content was then calculated using the calibration without matrix. Figure 2 shows a representative calibration line of PET fibers which was used for quantification (for more information, see Peez et al. 2019) [23]. In Table 1, the quantification results for four different environmental matrices (freshwater, biofilm, invertebrate, and sediment) and without matrix are presented.

Calibration line for PET fibers with the appropriate confidence interval (CI). The concentration in mg/mL is plotted against the normalized intensity. The signal range from 8.20–8.00 ppm was integrated and the residual solvent signals serves as an internal standard. Regression factor of the calibration line: R2 = 0.9990

According to our previous investigations, the calculated values of PET content without matrix determined with the qNMR method correspond to the real values [23]. Furthermore, the calculated values of freshwater, biofilm, and sediment matrix are within the error range of real values of the samples. However, for invertebrate matrix, calculated values are lower than for real values. This may be due to inorganic residues still being present after chemical digestion consisting mainly of calcium carbonate, because we chose a model organism for aquatic invertebrates (G. roeselii) which exhibits an exoskeleton. The presence of these inorganic residues may make it more difficult to dissolve PET fibers because of interactions of the basic carbonate with TFA. Nevertheless, our results show that only one calibration line (without matrix effects) is sufficient to determine the PET content in different environmental matrices which include inorganic components like sediments or organic components after chemical digestion.

Sample clean-up

To analyze MP in environmental samples using qNMR spectroscopy, we first had to develop a suitable sample preparation scheme (see Fig. 3). In addition, we wanted to develop a sample preparation that could be used for different environmental matrices to ensure comparability of the analytical results. Four different sample matrices were tested: freshwater, aquatic biofilm, macroinvertebrates, and sediment samples. These environmental matrices were selected and tested because most studies for the investigation of MP in environmental samples mainly refer to these types of samples [32]. For samples consisting of water or organisms, sample preparation is identical. First, the organic material in the sample has to be removed by chemical digestion (step 1). As chemical digestion reagent, we used 50% sulfuric acid and 30% hydrogen peroxide solution in a ratio of 1:1 with a digestion efficiency (mean ± SD) of 82.8 ± 4.3% for invertebrate samples and 97.6 ± 1.3% for biofilm samples (for more information, see ESM section “Chemical Digestion” and Fig. S2). Step 2 involves filtering the remaining solid material consisting of MP particles and undissolved matrix components such as inorganic or poorly soluble organic compounds. These steps (steps 1 and 2) are commonly applied to prepare samples for analyses directly measuring MP particles on a filter using FTIR or RAMAN spectroscopy [33, 34]. For qNMR spectroscopy to be used for MP analytics, however, it is essential to dissolve MP particles. Therefore, MP particles (and undissolved matrix components) must be rinsed off a P4 frit (step 3) in order to be subsequently dissolved. Rinsing and transfer of the residue are done with deionized water, which is afterwards removed at 60 °C (step 4). The residue consisting of MP then has to be dissolved in 1 mL of a suitable deuterated solvent and transferred into a NMR tube, before analysis by qNMR (step 5). This has already been described by some of us for LDPE, PET, and PS particles and will not be explained here in detail [23].

A positive side effect of step 5 is that by dissolving the sample in 1 mL of the deuterated solvent, the MP content of the environmental sample is concentrated. Thus, even small amounts of MP particles in environmental samples can be analyzed by this method. Steps 4a–4c must be performed after step 4 depending on the amount of insoluble matrix components such as sediment or poorly soluble organic or inorganic compounds. The volume of the solid residue has to be so small (~ 50 mg) that if 1 mL deuterated solvent is added, 700 μL can still be taken for 1H-NMR measurement. Using more than 1 mL of deuterated solvent is not an appropriate procedure because the advantage of concentrating MP would be lost. In the case of larger amounts of insoluble matrix components at the end of step 4, they must be separated by solving the residue in just enough undeuterated solvent to form a suspension. After stirring for 2–4 h, it is allowed to settle (step 4a). A defined volume of the solution is then removed (step 4b) without transferring any solid material, and is then evaporated to dryness at 60 °C (step 4c).

This procedure was varied according to Ceccarini et al., who described the solvent extraction of MP particles from sand samples for the first time [35]. If only small amounts of organic material are present in the sediment samples, only steps 4a–5 may be used. This is an alternative to the density separation method [17,18,19]. The density method is sometimes very time-consuming, taking approximately 12 h, especially if very small particles have to be separated according to their density [13]. Furthermore, despite increased efforts, not all polymer types can be separated from inorganic matrix components by different separation liquids [17]. The advantage of the density separation method is that MP particles can be separated from sediment without the loss of information on MP size. Depending on the desired analytical information, either the method described by us or the density separation method is more suitable. Nevertheless, both methods are compatible with quantitative analysis of MP by qNMR.

We therefore consider the sample preparation scheme for MP analysis shown in Fig. 3 to be suitable for a wide range of environmental samples providing analytical results that are completely comparable with respect to each other. This could be a first step towards a routine analytical method for rapid analysis of MP content in environmental samples.

Chemical digestion: effects on PET fibers

In addition to the high digestion efficiency and short reaction time, the optimized chemical digestion method presented here has the further advantage that no highly concentrated acid which might affect MP particles is used [36, 37]. In order to check whether the digestion reagents used in our study attack PET fibers, we used 1H-NMR spectroscopy and μFTIR investigations to determine potential changes in the chemical structure of the particles. Moreover, the surface of the fibers was examined with respect to possible differences before and after chemical digestion using SEM images. Figure 4 shows 1H-NMR spectra (4a, 4d), μFTIR spectra (4b, 4e) and SEM images (4c, 4f) of PET fibers before (4a–c) and after (4d–f) chemical digestion. According to 1H-NMR and μFTIR measurements, the chemical structure of the PET fibers did not change due to digestion since no additional signals are present and no signals are missing. In addition, PET fibers after digestion were clearly identified by OPUS software with a high hit quality of over 950 (max. hit quality 1000). SEM images display morphological changes of the PET fibers after chemical digestion (4f) compared with the raw material (4c) (for more information, see ESM Fig. S3). The surface of the pure PET fibers clearly presents a homogenous and smooth texture revealing a closed surface without any (stress) cracking on the outside. The chemically digested fibers, on the other hand, show a rough surface with crystalline residues, potentially originating from contact with the applied solvents. These residues may be fillers or other additives in the PET released by leaching, or impurities or crystalline residues from the solutions after drying. Nevertheless, the overall shape and main structure of the digested fibers is intact and shows no significant damages (peeling off, cracking, etc.). Lower recovery rates of MP after chemical digestion also are indicative of chemical reactions of MP particles that occur during chemical digestion. Avio et al. state that the reason for their very low recovery rates of 4% for PE and PS particles after chemical digestion was the highly acidic digestion procedure, which seemed to be too aggressive [36]. In this study, however, the recovery rates of PET fibers before and after chemical digestion were similar (t test, p = 0.378, n = 3, Fig. 5), with a recovery rate of 92.7 ± 1.3% (before chemical digestion) and a recovery rate of 89.6 ± 3.9% (after chemical digestion).

Recovery rates of sample clean-up. Mean and standard deviation (SD) obtained from 3 replicates in the spike concentration range of 0.70–2.80 mg/mL. Recovery rate of step 5 (except of sediment sample steps 4a–5), steps 2–5, and steps 1–5 for the respective matrices: without, freshwater, biofilm, invertebrates, and sediment

A falsification of analytical results after having applied the chemical digestion method described herein which might have been caused by an attack of the chemicals used can thus be ruled out. In summary, we provide a fast and effective chemical digestion method which does not attack PET fibers and still has a digestion efficiency > 83% for environmental samples except freshwater samples (see ESM).

Recovery rates of sample clean-up

To determine the efficiency of the sample clean-up procedure, recovery rates were determined for steps 1–5, steps 2–5, and step 5, except for samples with a high sediment content for which steps 4a–5 were carried out, using colorless PET fibers (length of approx. 500 μm, diameter of approx. 10–20 μm) as a model for MP particles. The samples were analyzed by quantitative 1H-NMR spectroscopy according to Peez et al. and recovery rates were determined using Eq. 1 [23]. Recovery rates were determined for a PET concentration in the range of 0.70–2.80 mg/mL (for more information, see ESM Table S1). First, recovery rates for PET fibers without matrix effects were determined. Step 5 (PET fibers dissolved in 1 mL deuterated solvent and measured) had a recovery rate of 96.3 ± 2.0%, steps 2–5 (PET fibers filtered via a P4 frit, dissolved, and measured) had a recovery rate of 92.7 ± 1.3%, and steps 1–5 (complete sample clean-up procedure) had a recovery rate of 89.6 ± 3.9%. For steps 1–5, recovery rates for an even lower spike concentration (0.38–0.62 mg/mL) were also determined to check whether there is an effect on the quality of the method. Steps 1–5 for this lower concentration had a recovery rate of 86.0 ± 5.0% and, therefore, no significant difference can be observed compared with the recovery rate for the higher spike concentration range (t test, p = 0.474, n = 3). Additionally, recovery rates for the environmental model samples were determined to detect potential losses during sample preparation caused by different matrices. Recovery rates for freshwater samples are as follows: 90.6 ± 2.9% (step 5), 91.8 ± 3.1% (steps 2–5), 93.5 ± 5.7 (steps 1–5); for biofilm samples: 94.7 ± 6.4% (step 5), 98.2 ± 5.0% (steps 2–5), 96.4 ± 7.5% (steps 1–5); for invertebrate samples: 72.2 ± 8.7% (step 5), 79.4 ± 17.1% (steps 2–5), 72.1 ± 4.6% (steps 1–5); and sediment samples: 96.8 ± 4.3% (steps 4a–5) and 104.5 ± 3.7% (steps 1–5) (Fig. 5, Table 2). Furthermore, a negative control for steps 1–5 was carried out to check for contamination of the samples during sample clean-up procedure. No signals could be detected in the area to be analyzed (see ESM Fig. S1). Thus, a contamination of the samples with plastic particles can be excluded.

Recovery rates of the sediment matrix are striking since they are beyond 100%. This could be due to the fact that steps 4a–4c have to be added to the sample clean-up procedure for a sediment matrix. In step 4a, it is conceivable that solvent may have evaporated during dissolution of the PET fibers despite careful closure of the glass vessel. This results in an artificially increased concentration of MP particles and thus a recovery rate > 100% is observed. Nevertheless, the standard deviation of 3.7% is very low and the procedure (steps 4a–4c) is reproducible. Moreover, it is not conspicuous that recovery rates for invertebrate samples (> 72%) are approx. 20% lower compared with other matrices (> 90%) due to inorganic residues such as calcium carbonate (see section “qNMR of PET fibers: influence of matrix effects”).

In order to be able to estimate the quality of recovery rates presented here, recovery rates already published and those presented here have been summarized in Table 2 according to Zhao et al. [38]. Recovery rates for sand/sediment samples are in the range of 50–100% [19, 39,40,41,42], and for fish tissue and mussel samples are in the range of 57–95% [30, 36, 37]. These recovery rates are mainly influenced by two factors. On one hand, high recovery rates for optical or FTIR methods might be related to systematic errors caused by the fact that the exact number of spiked particles is known by those performing the experiments. It is therefore an advantage of the qNMR method validation that the exact number of particles is not known, leading to a low probability of unconsciously falsified results. On the other hand, in many studies, colored pellets or granules with a size distribution of 0.1–5.0 mm were used as MP (see Table 1). These particles are easily visible to the naked eye due to their color and size. Hanvey et al. have already noted that higher recovery rates are achieved when samples are spiked with larger MP particles [44]. Hurley et al. have compared small and large PE particles as well as PET fibers and showed that the recovery rate for fibers is lower than the more spherical PE particles independent of their size (see Table 1) [43]. Although PET fibers used for this investigation are hardly visible to the naked eye, we achieved recovery rates > 90% (except for invertebrate samples > 72%) for the complete sample clean-up procedure (steps 1–5) for all matrix conditions.

High recovery rates, low standard deviations for different environmental matrices, and the absence of contamination during sample preparation (cf. negative control) suggest that this sample clean-up method allows for consistent and reproducible results from environmental samples. However, there is still a need for research to improve quantification of PET in matrices containing large amounts of calcium carbonate, indicated by the recovery rates within the analyzed invertebrate matrix (i.e., the amphipod G. roeselii). Therefore, our current research also includes the improvement of the PET quantification in samples with matrices consisting partly of inorganic residues such as calcium carbonate. Nevertheless, it can be summarized that the optimized sample clean-up method presented by us for qualitative and quantitative analysis of MP particles in environmental samples using qNMR presented here offers a very good alternative for MP analysis compared with typically used methods.

Change history

18 November 2019

The original version of this article contained a mistake.

References

World Economic Forum. The New Plastics Economy: Rethinking the future of plastics. 2016. https://www.ellenmacarthurfoundation.org/publications/the-new-plastics-economy-rethinking-the-future-of-plastics. Accessed 6 Mar 2019.

Geyer R, Jambeck JR, Law KL. Production, use, and fate of all plastics ever made. Sci Adv. 2017;3:e1700782.

Moore CJ, Moore SL, Leecaster MK, Weisberg SB. A comparison of plastic and plankton in the North Pacific central gyre. Mar Pollut Bull. 2001;42:1297–300.

Wagner M, Scherer C, Alvarez-Munoz D, Brennholt N, Bourrain X, Buchinger S, et al. Microplastic in freshwater ecosystems: what we know and what we need to know. Environ Sci Eur. 2014;26:12.

Thompson RC, Olsen Y, Mitchell RP, Davis A, Rowland SJ, John Anthony WG, et al. Lost at sea: where is all the plastic? Science. 2004;304:838.

Thompson RC, Moore CJ, Vom Saal FS, Swan SH. Plastics, the environment and human health: current consensus and future trends. Philos Trans R Soc B. 2009;364:2153–66.

Wagner M, Lambert S, editors. Freshwater microplastics: emerging environmental contaminants? SpringerOpen. 2018.

Wright SL, Thompson RC, Galloway TS. The physical impacts of microplastics on marine organisms: a review. Environ Pollut. 2013;178:483–92.

Klein S, Worch E, Knepper TP. Occurrence and spatial distribution of microplastics in river shore sediments of the Rhine-Main area in Germany. Environ Sci Technol. 2015;49:6070–6.

Eerkes-Medrano D, Thompson RC, Aldridge DC. Microplastics in freshwater systems: a review of the emerging threats, identification of knowledge gaps and prioritisation of research needs. Water Res. 2015;75:63–82.

Derraik JGB. The pollution of the marine environment by plastic debris: a review. Mar Pollut Bull. 2002;44:842–52.

Ziajahromi S, Kumar A, Neale PA, Leusch FDL. Impact of microplastic beads and fibers on waterflea (Ceriodaphnia dubia) survival, growth, and reproduction: implications of single and mixture exposures. Environ Sci Technol. 2017;51:13397–406.

Wendt-Potthoff K, Imhof HK, Wagner M, Primpke S, Fischer D, Scholz-Böttcher BM, Laforsch C. Mikroplastik in Binnengewässern. Handbuch Angewandte Limnologie. 2017.

Käppler A, Fischer D, Oberbeckmann S, Schernewski G, Labrenz M, Eichhorn K-J, et al. Analysis of environmental microplastics by vibrational microspectroscopy: FTIR, Raman or both? Anal Bioanal Chem. 2016;408:8377–91.

Mai L, Bao L-J, Shi L, Wong CS, Zeng EY. A review of methods for measuring microplastics in aquatic environments. Environ Sci Pollut Res Int. 2018;25:11319–32.

Sanchez W, Bender C, Porcher J-M. Wild gudgeons (Gobio gobio) from French rivers are contaminated by microplastics: preliminary study and first evidence. Environ Res. 2014;128:98–100.

Ivleva NP, Wiesheu AC, Niessner R. Microplastic in aquatic ecosystems. Angew Chem Int Ed. 2017;56:1720–39.

Hidalgo-Ruz V, Gutow L, Thompson RC, Thiel M. Microplastics in the marine environment: a review of the methods used for identification and quantification. Environ Sci Technol. 2012;46:3060–75.

Imhof HK, Schmid J, Niessner R, Ivleva NP, Laforsch C. A novel, highly efficient method for the separation and quantification of plastic particles in sediments of aquatic environments. Limnol Oceanogr Methods. 2012;10:524–37.

Dris R, Imhof H, Sanchez W, Gasperi J, Galgani F, Tassin B, et al. Beyond the ocean: contamination of freshwater ecosystems with (micro-) plastic particles. Environ Chem. 2015;12:539–50.

Vandermeersch G, van Cauwenberghe L, Janssen CR, Marques A, Granby K, Fait G, et al. A critical view on microplastic quantification in aquatic organisms. Environ Res. 2015;143:46–55.

Löder MGJ, Imhof HK, Ladehoff M. Enzymatic purification of microplastics in environmental samples. Environ Sci Technol. 2017;51:14283–92.

Peez N, Janiska M-C, Imhof W. The first application of quantitative 1H-NMR-spectroscopy as a simple and fast method of identification and quantification of microplastic particles (PE, PET and PS). Anal Bioanal Chem. 2019;411:823–33.

Alves Filho EG, Silva LMA, Araújo NVP, Alves EG, Lião LM, Alcantara GB. Qualitative and quantitative control of pediatric syrups using nuclear magnetic resonance and chemometrics. J Pharm Biomed Anal. 2018;153:29–36.

Imhof HK, Ivleva NP, Schmid J, Niessner R, Laforsch C. Contamination of beach sediments of a subalpine lake with microplastic particles. Curr Biol. 2013;23:R867–8.

Monakhova Y, Diehl B. Practical guide for selection of 1H qNMR acquisition and processing parameters confirmed by automated spectra evaluation. Magn Reson Chem. 2017:996–1005.

Bharti SK, Roy R. Quantitative 1H NMR spectroscopy. TrAC. 2012;35:5–26.

Barding G, Salditos R, Larive C. Quantitative NMR for bioanalysis and metabolomics. Anal Bioanal Chem. 2012;404:1165–79.

Elert AM, Becker R, Duemichen E, Eisentraut P, Falkenhagen J, Sturm H, et al. Comparison of different methods for MP detection: what can we learn from them, and why asking the right question before measurements matters? Environ Pollut. 2017;231:1256–64.

Fischer M, Scholz-Böttcher BM. Simultaneous trace identification and quantification of common types of microplastics in environmental samples by pyrolysis-gas chromatography–mass spectrometry. Environ Sci Technol. 2017;51:5052–60.

Dümichen E, Barthel A-K, Braun U, Bannick CG, Brand K, Jekel M, et al. Analysis of polyethylene microplastics in environmental samples, using a thermal decomposition method. Water Res. 2015;85:451–7.

Silva AB, Bastos AS, Justino CIL, da Costa JP, Duarte AC, Rocha-Santos TAP. Microplastics in the environment: challenges in analytical chemistry - a review. Anal Chim Acta. 2018;1017:1–19.

Catarino AI, Thompson R, Sanderson W, Henry TB. Development and optimization of a standard method for extraction of microplastics in mussels by enzyme digestion of soft tissues. Environ Toxicol Chem. 2017;36:947–51.

Caron AGM, Thomas CR, Berry KLE, Motti CA, Ariel E, Brodie JE. Validation of an optimised protocol for quantification of microplastics in heterogenous samples: a case study using green turtle chyme. MethodsX. 2018;5:812–23.

Ceccarini A, Corti A, Erba F, Modugno F, La Nasa J, Bianchi S, et al. The hidden microplastics: new insights and figures from the thorough separation and characterization of microplastics and of their degradation byproducts in coastal sediments. Environ Sci Technol. 2018;52:5634–43.

Avio CG, Gorbi S, Regoli F. Experimental development of a new protocol for extraction and characterization of microplastics in fish tissues: first observations in commercial species from Adriatic Sea. Mar Environ Res. 2015;111:18–26.

Claessens M, van Cauwenberghe L, Vandegehuchte MB, Janssen CR. New techniques for the detection of microplastics in sediments and field collected organisms. Mar Pollut Bull. 2013;70:227–33.

Zhao S, Zhu L, Gao L, Li D (eds). Limitations for microplastic quantification in the ocean and recommendations for improvement and standardization. Microplatic Contamination in Aquatic Environments: Elsevier Inc. 2018.

Nuelle M-T, Dekiff JH, Remy D, Fries E. A new analytical approach for monitoring micrplastics in marine sediments. Environ Pollut. 2014;184:161–9.

Fries E, Dekiff JH, Willmeyer J, Nuelle M-T, Ebert M, Remy D. Identification of polymer types and additives in marine microplastic particles using pyrolysis-GC/MS and scanning electron microscopy. Environ Sci: Processes Impacts. 2013;15:1949–56.

Nor NHM, Obbard JP. Microplastics in Singapore's coastal mangrove ecosystems. Mar Pollut Bull. 2014;79:278–83.

Stolte A, Forster S, Gerdts G, Schubert H. Microplastic concentrations in beach sediments along the German Baltic coast. Mar Pollut Bull. 2015;99:216–29.

Hurley RR, Lusher AL, Olsen M, Nizzetto L. Validation of a method for extracting microplastics from complex, organic-rich, environmental matrices. Environ Sci Technol. 2018;52:7409–17.

Hanvey JS, Lewis PJ, Lavers JL, Crosbie ND, Pozo K, Clarke BO. A review of analytical techniques for quantifying microplastics in sediments. Anal Methods. 2017;9:1369–83.

Acknowledgments

The authors thank Prof. Dr. B. Hahn and M. Albanna (University of Applied Science, RheinAhrCampus, Remagen, Germany) for SEM support. Furthermore, we thank Lana Vuleta for proofreading.

Funding

The authors gratefully acknowledge the financial support of the Deutsche Forschungsgemeinschaft (INST 366/6-1) for the purchase of the NMR spectrometer. The authors also acknowledge financial support of the research fund of University Koblenz - Landau.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised: The word “sediment” 20 was accidentally removed in Figure 5 due to a technical error.

Electronic supplementary material

ESM 1

(PDF 428 kb)

Rights and permissions

About this article

Cite this article

Peez, N., Becker, J., Ehlers, S.M. et al. Quantitative analysis of PET microplastics in environmental model samples using quantitative 1H-NMR spectroscopy: validation of an optimized and consistent sample clean-up method. Anal Bioanal Chem 411, 7409–7418 (2019). https://doi.org/10.1007/s00216-019-02089-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-019-02089-2