Abstract

Microplastic (0.001–5 mm) is a serious problem for the environment and is globally distributed. It has been detected in marine and limnic waters as well as in organisms. Until now, microplastic (MP) particles in environmental samples are mainly identified by Fourier transform infrared (FTIR) or Raman spectroscopy. Usually, for quantitative detection, time-consuming counting of MP particles in the sample is described. Therefore, a great need for research in the field of size-independent quantitative analysis of MP particles is evident. We present herein the application of quantitative 1H NMR spectroscopy (qNMR) as a new method for the qualitative and quantitative analysis of MP in solution. Polyethylene (PE) granules with a size distribution of < 300 μm, polyethylene terephthalate (PET) fibers with a length of approx. 500 μm, and polystyrene (PS) beads with a size distribution of 0.5–1 mm were qualitatively and quantitatively analyzed as prototypical MP particles in model samples using a calibration curve method. As internal standard, the residual proton signal of the deuterated solvent was used. For all polymer types, linearity of the method is > 0.994 R2, and the precision is in the range of 99.4–99.9%. The limit of detection (LOD) is in the range of 19–21 μg/mL and the limit of the quantification (LOQ) is in the range of 74–85 mg/mL, so the LOD and LOQ are observed in an environmentally relevant size. In this work, we therefore show that size-independent qualitative and quantitative determination of microplastic particles in model samples using qNMR is possible.

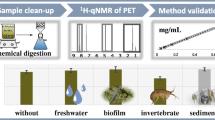

Working flow for the first application of qNMR as a simple and fast method of identification and quantification of microplastic (MP) particles (PE, PET, PS). 338 × 190 mm (96 × 96 DPI)

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microplastic in the environment

Microplastic (MP) is a constantly growing environmental problem as global plastic production continues to increase. By 2015, a total of 6.3 billion ton of plastic waste was produced, of which 79% end up in landfills or in the environment [1]. Therefore, it is not surprising that MP could be detected in significant amounts in marine and limnic systems as it is transported by rain, wind, sewerages, and flow waters [2,3,4,5,6,7,8]. In some cases, plastic abundance exceeds that of zooplankton in oceans [9,10,11]. In Xiangxi River, between 80 and 864 items/m2 were detected in sediment samples and between 55,000 and 880,000 items/km2 in surface water [3]. These examples clearly show that MP particles are abundant in the environment all around the world and will remain there for many years due to the long lifetime of plastic [12, 13].

Particles in a size range of 1 μm to 5 mm are defined as MP particles, which can be subdivided into primary and secondary microplastics [7, 14]. Primary microplastic (PMP) is directly released into the environment such as from industry or private households [14]. For example, PE beads are included in many cosmetics such as scrubs [15, 16]. Each wash cycle can release up to 94,000 MP particles into the environment [17]. On the other hand, secondary microplastic (SMP) is produced by mechanical comminution or chemical, photochemical, and biological decomposition of larger plastic articles [14, 18, 19]. Abrasion of car tires is, according to the Norwegian Environmental Agency, the largest source of SMP in world’s oceans [20]. Textile fibers, which are released into the environment through washes (up to 700,000 fibers per wash), also belong to SMP [2, 5, 21]. Mainly, these are PET, polyamide, and polypropylene (PP) fibers [22].

The small size of MPs contributes significantly to the danger of being absorbed by microorganisms [13, 23, 24]. Through the food chain, MP is taken up by smaller fishes and larger fishes and ultimately by humans [25,26,27]. The effect of MPs on organisms has not been sufficiently clarified yet; nevertheless, it is known that the intestinal tract of microorganisms can be blocked by MP particles [28, 29]. In worst case, this can lead to feelings of fullness and starvation occurs [24, 28, 30]. In addition, SMP particles such as sharp fragments can injure the intestinal tract [30, 31]. It is also known that MP particles absorb persistent organic pollutants (POP) and thus POPs are increasingly absorbed by microorganisms [5, 32, 33]. This can lead to additional side effects [13].

Identification of MP—current methods

In order to be able to identify a correlation between MP and the environmental consequences and to make correct statements, a quantitative detection of MP in environmental samples should be possible [13, 29, 34]. In most studies published on this topic, MP particles have been studied mainly with optical methods such as FTIR or Raman, which allow for a qualitative identification of the respective polymers but provide no quantitative evidence [35, 36]. The advantage of both methods is that they work non-destructively and can detect MP particles with a size down to 0.5 μm (Raman) and 20 μm (FTIR) [37,38,39]. But, instrumentation is very expensive; both methods are very time consuming and labor intensive because of the necessary sample preparation [29, 35, 40]. Nevertheless, Raman and FTIR, in contrast to optical microscopy, in which identification of particles by the human eye takes place are already a great step forward [35, 41]. Studies comparing FTIR or Raman and the optical method (identification with the naked eye) have shown that error rates up to 85% can occur for the optical method [41,42,43]. Due to the lack of alternatives, these methods have almost exclusively been used up to now [29, 43]. Therefore, the focus of published studies has been on the presence of MP particles and their composition. One severe drawback is that studies are not comparable with each other, as inconsistent information on the abundance of MP particles is given, such as the number of particles or particle mass per cubic meter or kilogram of sediment, dry matter, or water [2, 5, 13]. An indication in milligram of MP particles per milligram of environmental sample would be much more useful and would lead to an enhanced comparability of the studies [5, 13, 44]. Therefore, a size-independent quantitative detection of MP particles, which does not lead to “false positive determinations,” is very important for future research in this area. One way to qualitatively and quantitatively detect MP particles is thermoanalytical methods such as thermal desorption gas chromatography-mass spectrometry (TDS-GC-MS) [34, 45]. The advantage of the TDS-GC-MS method is that in a qualitative determination, no sample preparation is needed, it is a fast method, and it is very robust [34]. However, the sample is destroyed, resulting in a loss of particle size information [34, 35]. Dümichen et al. describe the quantitative determination of PE microplastic in environmental model samples using TDS-GC-MS [45]. Another method is the pyrolysis GC-MS method with which the polymer type and organic additives can be determined simultaneously [46,47,48]. Fischer and Scholz-Böttcher describe a simultaneous trace identification and quantification of common types of microplastic [47]. Particularly noteworthy are the good detection limits in the lower microgram range. Nevertheless, this method also has disadvantages as, e.g., the complex sample preparation. For an external calibration curve, MP particles must be weighed individually in an Al2O3 matrix and environmental samples require elaborate sample preparation [47]. Another approach is followed by Hintersteiner et al. They describe the quantitative detection of PE particles in personal care products using high-temperature gel-permeation chromatography [49]. These approaches, published in the last 3 years, underline that just counting of MP particles in environmental samples is not satisfactory and thus there is a great need for research in the field of qualitative and quantitative analysis of MP in environmental samples. Therefore, we describe here a new method to detect MP particles.

Detection of MP particles by qNMR

We suggest herein the use of 1H NMR spectroscopy for quantitative detection of microplastic, by analyzing model samples which exhibit a known content of MP and investigating the question whether a quantitative approach via NMR spectroscopy holds down to quantities as they are expected from environmental samples. To the best of our knowledge, this analytical approach has not yet been described [50,51,52]. Qualitative NMR spectroscopy is well known. By contrast, quantitative NMR spectroscopy has only become increasingly popular in the last 10 years and is widely used in fields of metabolite research, drug toxicity, forensic science, and environmental toxicity [50, 52,53,54]. Quantitative determination by qNMR is based on the proportional relationship of integrated signal area and number of resonant nuclei [53, 55]. qNMR can be described as a precise quantification method since with this method a high quantitative accuracy of > 98% can be achieved [50, 55]. In addition, it is a cost-effective, fast (about 1 min per measurement), non-destructive, size-independent, and simple method.

In principle, various determination methods are possible: relative determination, absolute determination by use of internal or external standards, standard addition, and calibration curve method. Bharti et al. described these methods in connection with qNMR and explained their advantages and disadvantages [50]. For analysis of MP particles in environmental samples, the calibration curve method is best suited because the exact composition of analytes does not need to be known which the case for most MP samples is. Nevertheless, the calibration curve method has some advantages and disadvantages. The calibration curve method is suitable for high sample throughputs, which is fine for routine operations. On the other hand, matrix effects are not correctable and systematic errors are difficult to detect [56]. So in the case of environmental samples, the biological sample matrix must be completely removed from MP particles because signal overlays make quantification difficult [52, 57, 58]. Therefore, a sample preparation step is needed which removes bio-organic components present in the environmental sample. Especially biological samples such as algae or aquatic organisms prove to be challenging since it is very difficult to completely remove the biological matrix [59,60,61].

A disadvantage of quantitative 1H NMR spectroscopy is the dissolution of the analytes in a suitable deuterated solvent leading to a loss of size information of the analytes (in this case the MP particles). Our approach considers only NMR spectroscopy in solution because we assume solid-state NMR spectroscopy not being sensitive enough and not allowing for quantitative results in sufficient accuracy. Therefore, it is important to find suitable conditions for the analysis of MP particles by means of qNMR in order to dissolve different types of polymers (PE, PP, PET, PS, PVC…). This is difficult due to inherent chemical and physicochemical properties of polymers compared with other organic substances [62]. In the literature, there are some conditions under which various polymers dissolve, but these sometimes are not suitable for quantitative determinations [62]. The solvents used and their residual proton signals may fall within the signal range of the respective polymers or measurement temperatures are above the manageable range for quantitative analysis. Sometimes very high temperatures (> 100 °C) are applied which most probably would lead to strong peak broadening which makes, in addition, a quantitative determination difficult [62,63,64]. Thus, a main task was to find solvents suitable for quantitative analysis of MP particles and to validate the calibration curve method for the quantitative analysis of MP particles by qNMR.

In this work, we demonstrate that quantitative determination of microplastic particles using qNMR is possible and also provides a cost-effective, fast, and simple method suitable for routine operation.

Experimental

MP particles

Low-density PE (LDPE) particles manufactured from Versalis, Italy, and broken to granulate with a size distribution of < 300 μm by TER Plastics, Germany, were tested. LDPE is used for large complex moldings, low thickness articles, and artificial flowers. LDPE granules can be considered as SMP. PET fibers with a fiber length of approx. 500 μm, produced by Schwarzwälder-Textil-Werke, Germany, were also tested. These are fibers which are used, for example, in plastics or rubber production and can also be counted as SMP. As PS MP particles, PS beads in a size range of 0.5–1.0 mm from Kissenwelt, Germany, were tested. These PS beads are used as fillers for pillows and bean bags and can be counted as PMP. These three types of polymers make up a total of 23% (14.7% LDPE, 5.5% PET, and 2.8% PS) of the plastic that was processed and recycled in Germany in 2015 [65].

Sample preparation

For 1H NMR analysis of PE particles, deuterated toluene from EURISO-TOP, Chemtrade (99.5 atom %D), and Deutero (99.5 atom %D) was used and was recovered by distillation after the measurements. For PET particles, deuterated chloroform (99.8 atom %D, stab. with Ag) from ARMAR AG and trifluoroacetic acid (≥ 99.9%) from Carl ROTH were used. For the PS particles, deuterated chloroform (99.8 atom %D, stab. with Ag) from ARMAR AG was used. The calibration solutions of different concentrations of MP particles were each prepared from a stock solution (PE granulate in toluene-d8 at 60 °C, PET fibers in CDCl3/TFA 4:1 at r.t., and PS beads in CDCl3 at r.t.). Three model samples of MP particles were used for method validation. For the model sample, a defined amount of PE, PET, or PS particles was transferred to a glass vessel and dissolved in the appropriate solvent at the appropriate temperature. For 1H NMR measurements, 700 μL of the sample solution or calibration solution was transferred to 5-mm NMR tubes and measured. To avoid contamination of the samples, all glassware was washed with water, acetone, and distilled water and was dried at 60 °C for 24 h. In addition, care was taken to close the lab coat (100% cotton) when working with the samples in order to avoid contamination with polymer fibers from clothes.

1H qNMR—quantitative analysis

A JEOL® Delta 500 spectrometer with a 500-MHz 5-mm TH ATM Probe head was used for the 1D 1H NMR experiments (probes marked with an asterisk were measured with a 5-mm FG/RO Digital Auto Tune Probe). The following acquisition parameters for PE samples have been set: receiver gain 56, pulse width 5.15 μs, spectral width 8 ppm, number of scans 8, acquired size 16,384, spectral size 52,430, and the acquisition time 3.28 s. For PET and PS samples, the following acquisition parameters have been set: receiver gain 46, pulse width 5.15 μs, spectral width 10 ppm, number of scans 25, acquired size 32,768, spectral size 52,430, and the acquisition time 5.25 s. The recorded spectra were loaded into the NMR program MestReNova as an FID file. Phase correction was performed manually whereas baseline correction of the recorded spectra was performed manually or with the Whittaker Smoother. For the different MP particles, the same ppm range was manually integrated for all samples. The integral of the signal regions is proportional to the H atoms and thus to the concentration of the analyte in the solution [66]. For method validation of quantitative analysis of MP particles by the calibration curve method, various parameters were checked: linearity, determination and detection limit, accuracy, and precision. In a range of 30–930 μg/mL, a 5-point calibration curve was determined for PE, PET, and PS particles. For this purpose, the stock solution of MP particles was diluted and measured. The concentration was plotted against the normalized area of integration. Linear regression was created with Excel and the coefficient of determination was used for the evaluation of linearity. Detection and quantification limits were determined according to DIN32645 standard [67]. The correctness and precision parameters were determined using three model samples and each spectrum was integrated three times (including phase correction and baseline correction). The confidence interval of the content of the model samples was determined according to DIN38402 standard [68]. The deviation of the calculated value from the true value indicates the degree of correctness (bias in %) and the standard deviation/mean of the calculated value the precision (RSD in %).

Results and discussion

Sample preparation

For quantitative analysis by 1H NMR spectroscopy, it is essential that the MP particles dissolve completely in a suitable deuterated solvent. In the following, the most important requirement criteria for the solvent are presented. The signal(s) of the deuterated solvent should have a chemical shift that significantly differs from signals of the MP particles so that the residual proton signal(s) of the deuterated solvent can function as an internal standard and a quantitative determination is possible. MP particles should completely dissolve at a temperature 50 °C lower than the boiling point of the deuterated solvent. Furthermore, care should be taken that MP particles are completely dissolved and not only swollen, as this makes quantification impossible. In addition, a measuring temperature of > 60 °C is not recommended for a quantitative determination since it is no longer possible to produce a highly accurate calibration straight at higher temperatures. Moreover, economic considerations should be taken into account, because high-priced deuterated solvents would make the establishment of the method for future routine measurements rather unlikely. A selection of various solvents with the corresponding values for boiling point, 1H signals in ppm, and prices is summarized in the Electronic Supplementary Material (ESM).

Table 1 shows the most important types of MP polymers (polyethylene PE, polyethylene terephthalate PET, and polystyrene PS) and the associated 1H signals in ppm in the corresponding deuterated solvent (literature and tested). PE was dissolved and measured according to the literature in a mixture of deuterated dichlorobenzene and trichlorobenzene at 130 °C [62]. The high measurement temperature of 130 °C poses a problem for quantitative analysis since handling of the calibration solutions at such high temperature is problematic and larger signal broadening is to be expected. For this reason, an alternative solvent for PE was required. PE is soluble in toluene at 60 °C and preparation of calibration solutions is thus possible. Toluene-d8 is suitable as a solvent for PE, as there are no signal overlays. Another advantage is that toluene-d8 at a price of 3.7 €/mL is much cheaper than dichlorobenzene. For PET fibers, a solvent mixture consisting of chloroform-D and trifluoroacetic acid (TFA) was chosen. According to the literature, PET dissolves in CDCl3/TFA 8:1 at 25 °C [26, 64]. Trifluoroacetic acid has a signal at about 11 ppm. Chloroform-D has a signal at 7.26 ppm. A signal overlay of solvent and PET is not to be expected since according to the literature, signals of PET occur at 7.6 and 4.3 ppm [64]. In addition, an advantage of this solvent mixture is that PET dissolves at room temperature. This allows for easier operation, such as the application of the calibration solution; the 1H spectra have lower signal broadening; and measurements with an autosampler are possible. In addition, chloroform-D is by far the cheapest deuterated solvent on the market (0.3 €/mL). Chloroform-D is also suitable as a solvent for PS. PS shows signals at chemical shift of 7.5, 7.0, 2.3, and 1.7 ppm. Since the residual proton signal of chloroform-D is at 7.26 ppm, it was checked whether a signal overlay of the signal of chloroform-D and the signals of the aromatic ring of polystyrene at a measurement temperature of 25 °C occurs. Because this is not the case, quantification by means of residual proton signals as an internal standard of PS in chloroform-D as a solvent is possible.

Qualitative and quantitative analysis by 1H NMR

In contrast to routine qualitative NMR spectroscopy, particularities in the measurement and evaluation of the spectra must be considered in quantitative NMR spectroscopy [50, 52]. Nevertheless, it should be noted that special care and accuracy are required by applying phase correction, baseline correction, and integration.

Figure 1 shows typical 1H NMR spectra of PE granules, PET fibers, and PS beads. Each microplastic was dissolved in the corresponding solvent and then measured. The PE granules can be assigned two signals. The signal at 1.33 ppm (H2) corresponds to the protons of the CH2 groups and the signals at 0.93 ppm (H1) to the protons of the CH3 groups, which are present in considerable amount because LDPE is highly branched. Due to the lack of baseline separation of both signals, signals in a range of 1.85–0.60 ppm were integrated together for quantitative determinations. Furthermore, signals at 2.07 ppm can be assigned to the residual proton signal of the CH3 group of toluene-d8. A total of four signals could be assigned to the PET fibers. The signal at 8.11 ppm represents the four protons of the terephthalate ring. The other three signals at 4.77 ppm, 4.62 ppm, and 4.11 ppm are due to the protons of the oxyethylene units (ester or ether functional groups) [64]. For quantitative determinations, the range of 8.20–8.00 ppm was integrated. The signal at 7.25 ppm is caused by the CDCl3 residual proton signal which is also present in the measurement of the PS beads. The signals of the PS beads are in the range of 7.20–6.20 ppm and 2.20–1.10 ppm. The first range belongs to the protons of the aromatic ring and the second range to the protons of the CH2– and CH– groups. For quantitative determinations, the range of 7.20–6.20 ppm was integrated. A qualitative and quantitative determination of the PE, PET, and PS particles is thus possible because a superposition of the respective residual proton signal from the solvent does not occur.

For the quantitative evaluation, special care is required when integrating the signals. In order to minimize possible measurement errors and/or integration errors, the internal standard method was used for all quantitative determinations. An internal standard is the residual proton signal of the deuterated solvent [51, 52]. In order to use the residual proton signals as an internal standard, it must be ensured that the measurements are carried out with the same batch number to rule out possible fluctuations in the residual proton signal [51]. Equation 1 describes the general formula of the normalized intensity calculation. Inormalized indicates the normalized intensity, IMP indicates the integral of the microplastic particles in the sample (absolute value), and IS indicates the intensity of the integral of the internal standard (absolute value), in this case the residual proton signal of the solvent of a chosen sample (in our case the first point of the calibration curve). Isol indicates the intensity of the integral of the residual proton signal of the sample to be normalized (absolute value).

- I normalized :

-

normalized intensity

- I MP :

-

intensity of the microplastic in the sample

- I S :

-

intensity of the internal standard

- I sol :

-

intensity of the residual proton solvent in the sample

Method validation

In order to verify the suitability of NMR spectroscopy for the quantitative analysis of MP particles, various parameters such as linearity, accuracy, precision, and determination and detection limits for the method validation were determined. The calibration curve method was used for the quantitative determination. In Fig. 2, the respective calibration curve of MP particles is indicated in each case for the normalized values in a range of 30–930 μg/mL (Fig. 2a–c) and 0.5–3.2 mg/mL (Fig. 2d–f). Plotted is the concentration of MP particles in the corresponding solvent in milligram per milliliter against the normalized intensity (see Eq. 1). In addition, the upper and lower confidence limits are given for each calibration line.

Calibration curve for the MP particles (PE, PET, and PS) with the appropriate confidence interval (CI). Plotted is the concentration against the normalized intensity (see Eq. 1). For PE particles, the H1–H2 signals; for PET particles, the H1 signals; and for PS particles, the H3-H5 signals are integrated. Solvent toluene-d8 at 60 °C for PE particles, CDCl3/TFA 4:1 at 25 °C for PET fibers, and CDCl3 at 25 °C for PS beads. a–c Calibration curve in the range of 30–930 μg/mL. d–f Calibration curve in the range of 0.5–3.2 mg/mL. In addition, the theoretical  and calculated

and calculated  values of the model samples are given (see Table 3)

values of the model samples are given (see Table 3)

With a coefficient determination of > 0.99, the linearity of a method can be considered as given [69]. For all three MP particles, linearities for the normalized intensities are above 0.994. The linearity data of the normalized and non-normalized values (in parentheses) are shown in Table 2.

The comparison of the coefficients of determination shows that normalization of the values makes sense and leads to a higher linearity of the calibration curve. The difference of the coefficient of determination moves in a range of 0.002–0.0001. From Fig. 2, it becomes clearly evident that the intensity range of the three different types of MP particles is different. The slope of the PE particles is in the range of 18.4–4.8 (difference due to different NMR probe heads), the slope of the PET fibers is in the range of 2.2–2.3, and the slope of the PS beads in a range of 19.2–21.8. The big difference from PET and PS might arise from different solvent compositions. In the PET samples, TFA is added which has a very intense signal at about 11 ppm, because the molar amount of TFA by far exceeds the corresponding value of PET. Thus, the signal intensity of the PET signals can be reduced in contrast to the PS signal. In summary, for all three polymers in the lower and higher concentration ranges, a calibration curve with a coefficient of determination between 0.994 and 0.999 is absolutely comparable compared to the CP pyrolysis GC-MS method, with coefficients of determination for PE, PET, and PS particles between 0.90 and 0.99 [47].

Table 3 gives the data of quantitative qNMR analyses of the model samples for the respective MP polymer species. In each case, theoretical values of the model sample, calculated values, and the corresponding accuracy and precision are listed. For the calculated values, the confidence interval (CI) is additionally given. The accuracy is stated as bias in % and the precision as relative standard derivation in %, in each case for the normalized and non-normalized values (in parentheses). The correctness, in general, is in the range of 81.24–108.09% for PE particles, in the range of 94.13–100.54% for PET particles, and in the range of 97.41–106.43% for PS particles (normalized values). The most accurate results can thus be achieved for the PET particles. The slightly worse values for the PE particles can be attributed to the sample preparation at 60 °C. Thus, the calibration curve in the range of 0.5–3.2 mg/mL for the PE particles has the least coefficient of determination (R2 = 0.9944) compared to the other two types of polymers. Therefore, the confidence interval of this calibration curve is also the largest (± 0. 27 mg/mL). Nevertheless, the results for the PE particles are usable for a quantitative determination of MP-PE particles since the determined values lie within the confidence range of the calibration curve (see Fig. 2d). This applies to all calculated concentrations of the model samples. Thus, the quantitative determination of PE, PET, and PS MP particles by means of qNMR can be considered as given.

For the non-normalized values, the accuracy is between − 52.28 and 104.54%. The value of − 52.28% (PS sample 3) clearly shows that normalization is crucial to minimize such outliners. Thus, the correctness for the normalized values is significantly higher. The precision for normalized values is in a range of 99.38–99.99% and for non-normalized values between 99.14 and 99.99%. This shows that the quantitative analysis of MP particles using qNMR yields very precise results. In summary, it can be stated that the more accurate results are achieved using the internal standard method and an additional advantages arises. When using the same batch of deuterated solvent for calibration solutions and the samples, only one calibration curve needs to be recorded and the samples can be measured at different times. Consequently, for the quantitative analysis of MP particles, a normalization of the intensities according to Eq. 1 should be carried out.

The limits of detection and determination were carried out according to the DIN32645 standard for the calibration curve of normalized values in the range of 30–930 μg/mL. The detection limits (LOD) and quantification limit (LOQ) for PE particles are 19 μg/mL (74 μg/mL), for PET particles 21 μg/mL (81 μg/mL), and for PS particles 19 μg/mL (77 μg/mL). The detection and quantification limits or the three different polymer types are all in a very narrow range. The signal to noise ratio (SNR) can also be used to determine the LOD and LOQ. In our case, for the lowest measured concentration, the SNR could be determined for the PE particles as 403:1, for the PET particles as 337.6:1, and for the PS particles as 9.8:1. For example, Sun et al. defined the LOD as a SNR of 3:1 and the LOQ as a SNR of 10:1 in the application of the qNMR method for the determination of orlistat in tablets [70]. It becomes clear that the lower limit of the LOD has not yet been reached, especially for the PE and PET particles. In comparison, the CP pyrolysis GC-MS method based on the signal to noise ratio showed detection limits of < 4 μg for PE particles, < 5 μg for PET particles, and < 1 μg for PS particles [47]. The measurement limit for the pyrolysis GC-MS method is determined by the properties of the balance used (readability 0.0001 mg) because the particles are individually weighed for the calibration points and recorded and transmitted with the aid of a microscope [47].

With regard to the use of the qNMR method for the quantitative determination of MP particles in environmental samples, it is essential that the detection and quantification limits are at the lower end of the environmentally relevant concentrations. As already described, up to now, concentration data in the literature are mainly given in particle numbers in the environmental sample. Nevertheless, a rough estimate can be drawn from the data for the concentration in milligram of MP particles per kilogram of environmental sample. If it is assumed that a MP particle weight between 2 and 5 μg and 10–1000 particles are counted per kilogram or liter of an environmental sample, this results in a concentration range of 20μg–5 mg per kilogram or liter of the environmental sample [29]. Occasionally, the mass concentration of MP particles has been reported in previously published studies. In the Danube, 4–363 mg/1000 m3 particles could be detected per environmental sample, and in the Los Angeles River, even up to 43 g/m3 for particles in the range of 1.0–4.75 mm [44, 71]. This clearly shows that a limit of quantification for the MP particles in the range of 80 μg/mL (in the NMR samples) is sufficient.

Summary and outlook

This study demonstrates that quantitative 1H NMR spectroscopy provides a way to qualitatively and quantitatively determine LDPE granules, PET fibers, and PS beads. It could be shown that the content of the tested MP particles in model samples can be determined with high precision by means of the calibration curve method. For MP particles, the LOD (19–21 μg/mL) and the LOQ (74–85 g/mL) were calculated using the calibration curve method, demonstrating that the method is capable of quantification of MP particles in environmentally relevant concentrations. The qNMR method is a cost-effective, fast, and simple method that offers a major advantage compared to other detection methods such as pyrolysis GC-MS, FTIR, or Raman spectroscopy: the “size-independent detection limit.” There is no upper or lower limit to the size of the particles since the MP particles are dissolved and can then be determined qualitatively and quantitatively. Nevertheless, application of the method for environmental samples needs additional experiments in advance with the main issue to address being the digestion of the biological matrix as well as the separation of MP from additional constituents of the sample. In our current research, we therefore test several methods of digestion of biological material and have a look at the recovery rates of a known content of MP particles in the sample. Once we have found a straightforward and reliable method of separating MP from biological and inorganic material, all polymers that are to be quantified by qNMR have to be tested under these conditions before we can start to have a look at environmental samples which are expected to exhibit a complex mixture of different MP particles next to inorganic and biological matter. In combination with non-destructive spectroscopic methods, like FTIR or Raman, it is possible to analyze the size distribution and after that the content of MP particles with qNMR in one sample. In addition, other types of polymers (as, e.g., PP or PVC), as well as particle shapes such as fibers, granules, or powders, are tested concerning their solubility in suitable deuterated solvents and will be analyzed the same way.

References

Geyer R, Jambeck JR, Law KL. Production, use, and fate of all plastics ever made. Sci Adv. 2017;3:e1700782.

Eerkes-Medrano D, Thompson RC, Aldridge DC. Microplastics in freshwater systems: a review of the emerging threats, identification of knowledge gaps and prioritisation of research needs. Water Res. 2015;75:63–82.

Zhang K, Xiong X, Hu H, Wu C, Bi Y, Wu Y, et al. Occurrence and characteristics of microplastic pollution in Xiangxi Bay of Three Gorges Reservoir. China Environ Sci Technol. 2017;51:3794–801.

Eriksen M, Mason S, Wilson S, Box C, Zellers A, Edwars W, et al. Microplastic pollution in the surface waters of the Laurentian Great Lakes. Mar Pollut Bull. 2013;77:177–82.

Hidalgo-Ruz V, Gutow L, Thompson RC, Thiel M. Microplastics in the marine environment: a review of the methods used for identification and quantification. Environ Sci Technol. 2012;46:3060–75.

Klein S, Worch E, Knepper TP. Occurrence and spatial distribution of microplastics in river shore sediments of the Rhine-Main Area in Germany. Environ Sci Technol. 2015;49:6070–6.

Wagner M, Lambert S (eds). Freshwater microplastics: emerging environmental contaminants? SpringerOpen. 2018.

Browne MA, Crump P, Niven SJ, Teuten E, Tonkin A, Galloway T, et al. Accumulation of microplastic on shorelines woldwide: sources and sinks. Environ Sci Technol. 2011;45:9175–9.

Moore CJ, Moore SL, Leecaster MK, Weisberg SB. A comparison of plastic and plankton in the North Pacific central gyre. Mar Pollut Bull. 2001;42:1297–300.

Wagner M, Scherer C, Alvarez-Munoz D, Brennholt N, Bourrain X, Buchinger S, et al. Microplastic in freshwater ecosystems: what we know and what we need to know. Environ Sci Eur. 2014;26:12.

Goldstein MC, Titmus AJ, Ford M. Scales of spatial heterogeneity of plastic marine debris in the northeast Pacific Ocean. PLoS One. 2013;8:e80020.

Barnes DKA, Galgani F, Thompson RC, Barlaz M. Accumulation and fragmentation of plastic debris in global environments. Phil Trans R Soc B. 2009;364:1985–98.

Ivleva NP, Wiesheu AC, Niessner R. Microplastic in aquatic ecosystems. Angew Chem Int Ed. 2017;56:1720–39.

Cole M, Lindeque P, Halsband C, Galloway TS. Microplastics as contaminants in the marine environment: a review. Mar Pollut Bull. 2011;62:2588–97.

Zitko V, Hanlon M. Another source of pollution by plastics: skin cleaners with plastic scrubbers. Mar Pollut Bull. 1991;22:41–2.

Grammes F. Mikroplastik-Studie 2016: Codecheck-Studie zu Mikroplastik in Kosmetika. Codecheck AG. 2016. https://corporate.codecheck.info/wp-content/uploads/2016/10/Codecheck_Mikroplastikstudie_2016.pdf. Accessed 15 Oct 2018.

Napper IE, Bakir A, Rowland SJ, Thompson RC. Characterisation, quantity and sorptive properties of microplastics extracted from cosmetics. Mar Pollut Bull. 2015;99:178–85.

Ryan PG, Moore CJ, van Franeker JA, Moloney CL. Monitoring the abundance of plastic debris in the marine environment. Phil Trans R Soc B. 2009;364:1999–2012.

Browne MA, Galloway T, Thompson R. Microplastic - an emerging contaminant of potential concern? Integr Environ Assess Manag. 2007;3:559–66.

Sundt P, Schulze P-E, Syversen F. Sources of microplastic-pollution to the marine environment. Norwegian Environment Agency. 2014. http://www.miljodirektoratet.no/Documents/publikasjoner/M321/M321.pdf. Accessed 15 Oct 2018.

Napper IE, Thompson RC. Release of synthetic microplastic plastic fibres from domestic washing machines: effects of fabric type and washing conditions. Mar Pollut Bull. 2016;112:39–45.

Industrievereinigung Chemiefaser. Weltproduktion von Chemiefasern - Aufteilung der verschiedenen Arten. 2016. https://www.ivc-ev.de/live/index.php?page_id=43. Accessed 10 July 2018.

Fendall LS, Sewell MA. Contributing to marine pollution by washing your face: microplastics in facial cleansers. Mar Pollut Bull. 2009;58:1225–8.

Wright SL, Thompson RC, Galloway TS. The physical impacts of microplastics on marine organisms: a review. Environ Pollut. 2013;178:483–92.

Zarfl C, Matthies M. Are marine plastic particles transport vectors for organic pollutants to the Arctic? Mar Pollut Bull. 2010;60:1810–4.

Rochman CM, Tahir A, Williams SL, Baxa DV, Lam R, Miller JT, et al. Anthropogenic debris in seafood: plastic debris and fibers from textiles in fish and bivalves sold for human consumption. Sci Rep. 2015;5:1–10.

Setälä O, Fleming-Lehtinen V, Lehtiniemi M. Ingestion and transfer of microplastics in the planktonic food web. Environ Pollut. 2014;185:77–83.

Sheavly SB, Register KM. Marine debris & plastics: environmental concerns, sources, impacts and solutions. J Polym Environ. 2007;15:301–5.

Wendt-Potthoff K, Imhof HK, Wagner M, Primpke S, Fischer D, Scholz-Böttcher BM, Laforsch C. Mikroplastik in Binnengewässern. Handbuch Angewandte Limnologie. 2017.

Ogonowski M, Schür C, Jarsen A, Gorokhova E. The effects of natural and anthropogenic microplasticles on individual fitness in Daphnia magna. PLoS One. 2016;11:e0155063.

Welden NAC, Cowie PR. Long-term microplastic retention causes reduced body condition in the langoustine, Nephrops norvegicus. Environ Pollut. 2016;218:895–900.

Browne MA, Niven SJ, Galloway TS, Rowland SJ, Thompson RC. Microplastic moves pollutants and additives to worms, reducing functions linked to health and biodiversity. Curr Biol. 2013;23:2388–92.

Teuten EL, Saquing JM, Knappe DRU, Barlaz MA, Jonsson S, Björn A, et al. Transport and release of chemicals from plastics to the environment and to wildlife. Phil Trans R Soc B. 2009;364:2027–45.

Dümichen E, Eisentraut P, Bannick CG, Barthel A-K, Senz R, Braun U. Fast identification of microplastics in complex environmental samples by a thermal degradation method. Chemosphere. 2017;174:572–84.

Shim WJ, Hong SH, Eo SE. Identification methods in microplastic analysis: a review. Anal Methods. 2017;9:1384–91.

Huppertsberg S, Knepper TP. Instrumental analysis of microplastics-benefits and challenges. Anal Bioanal Chem. 2018;410:6343–52.

Löder MGJ, Kuczera M, Mintenig S, Lorenz C, Gerdts G. Focal plane array detector-based micro-Fourier-transform infrared imaging for the analysis of microplastics in environmental samples. Environ Chem. 2015;12:563.

Käppler A, Windrich F, Löder MGJ, Malanin M, Fischer D, Labrenz M, et al. Identification of microplastics by FTIR and Raman microscopy: a novel silicon filter substrate opens the important spectral range below 1300 cm(-1) for FTIR transmission measurements. Anal Bioanal Chem. 2015;407:6791–801.

Käppler A, Fischer D, Oberbeckmann S, Schernewski G, Labrenz M, Eichhorn K-J, et al. Analysis of environmental microplastics by vibrational microspectroscopy: FTIR, Raman or both? Anal Bioanal Chem. 2016;408:8377–91.

Wang W, Wang J. Investigation of microplastics in aquatic environments: an overview of the methods used, from field sampling to laboratory analysis. TrAC. 2018;108:195–202.

Lenz R, Enders K, Stedmon CA, Mackenzie DMA, Nielsen TG. A critical assessment of visual identification of marine microplastic using Raman spectroscopy for analysis improvement. Mar Pollut Bull. 2015;100:82–91.

Song YK, Hong SH, Jang M, Han GM, Rani M, Lee J, et al. A comparison of microscopic and spectroscopic identification methods for analysis of microplastics in environmental samples. Mar Pollut Bull. 2015;93:202–9.

Hanvey JS, Lewis PJ, Lavers JL, Crosbie ND, Pozo K, Clarke BO. A review of analytical techniques for quantifying microplastics in sediments. Anal Methods. 2017;9:1369–83.

Hohenblum P, Frischenschlager H, Reisinger H, Konecny R, Uhl M, Mühlegger S, Habersack H, Liedermann M, Gmeiner P, Weidenhiller B, Fischer N, Rindler R. Plastik in der Donau: Untersuchung zum Vorkommen von Kunststoffen in der Donau in Österreich. 2015

Dümichen E, Barthel A-K, Braun U, Bannick CG, Brand K, Jekel M, et al. Analysis of polyethylene microplastics in environmental samples, using a thermal decomposition method. Water Res. 2015;85:451–7.

Fries E, Dekiff JH, Willmeyer J, Nuelle M-T, Ebert M, Remy D. Identification of polymer types and additives in marine microplastic particles using pyrolysis-GC/MS and scanning electron microscopy. Environ Sci: Processes Impacts. 2013;15:1949–56.

Fischer M, Scholz-Böttcher BM. Simultaneous trace identification and quantification of common types of microplastics in environmental samples by pyrolysis-gas chromatography–mass spectrometry. Environ Sci Technol. 2017;51:5052–60.

Nuelle M-T, Dekiff JH, Remy D, Fries E. A new analytical approach for monitoring micrplastics in marine sediments. Environ Pollut. 2014;184:161–9.

Hintersteiner I, Himmelsbach M, Buchberger WW. Characterization and quantitation of polyolefin microplastics in personal-care products using high-temperature gel-permeation chromatography. Anal Bioanal Chem. 2015;407:1253–9.

Bharti SK, Roy R. Quantitative 1H NMR spectroscopy. TrAC. 2012;35:5–26.

Letot E, Koch G, Falchetto R, Bovermann G, Oberer L, Roth H-J. Quality control in combinatorial chemistry: determinations of amounts and comparison of the “purity” of LC-MS-purified samples by NMR, LC-UV and CLND. J Comb Chem. 2005;7:364–71.

Pauli GF, Gödecke T, Jaki BU, Lankin DC. Quantitative 1H NMR: development and potential of an analytical method - an update. J Nat Prod. 2012;75:834–51.

Pauli GF, Jaki BU, Lankin DC. Quantitative 1H NMR: development and potential of a method for natural products analysis. J Nat Prod. 2005;68:133–49.

Schoenberger T. Determination of standard sample purity using the high-precision 1H-NMR process. Anal Bioanal Chem. 2012;403:247–54.

Barding G, Salditos R, Larive C. Quantitative NMR for bioanalysis and metabolomics. Anal Bioanal Chem. 2012;404:1165–79.

Schwedt G, Schmidt TC, Schmitz OJ, editors. Analytische Chemie. 3. Auflage. Weinheim: Wiley-VCH; 2016.

Phansalkar RS, Simmler C, Bisson J, Chen S-N, Lankin DC, McAlpine JB, et al. Evolution of quantitative measures in NMR: quantum mechanical qHNMR advances chemical standardization of a red clover (Trifolium pratense) extract. J Nat Prod. 2017;80:634–47.

Monakhova Y, Diehl B. Practical guide for selection of 1H qNMR acquisition and processing parameters confirmed by automated spectra evaluation. Magn Reson Chem. 2017;55:996–1005.

Cole M, Webb H, Lindeque PK, Fileman ES, Halsband C, Galloway TS. Isolation of microplastics in biota-rich seawater samples and marine organisms. Sci Rep. 2015;4:4528.

Löder MGJ, Imhof HK, Ladehoff M. Enzymatic purification of microplastics in environmental samples. Environ Sci Technol. 2017;51:14283–92.

Munno K, Helm PA, Jackson DA, Rochman C, Sims A. Impacts of temperature and selected chemical digestion methods on microplastic particles. Environ Toxicol Chem. 2017;9999:1–8.

Brandolini AJ, Hills DD, editors. NMR spectra of polymers and poylmer additives. New Jersey: Marcel Dekker, Inc.; 2000.

Nukada K. Analysis of the NMR spectrum of isotactic polypropylene. Polym Lett. 1965;3:179–83.

de Ilarduya AM, Muñoz-Guerra S. Chemical structure and microstructure of poly(alkylene terephthalate)s, their copolyesters, and their blends as studied by NMR. Macromol Chem Phys. 2014;215:2138–60.

Wilke S. Anteil Kunststoffsorten an der Verarbeitungsmenge Kunststoffe 2015. 2016. https://www.umweltbundesamt.de/sites/default/files/medien/384/bilder/dateien/3_abb_anteil-kunstst-verarbeitung-arten_2017-01-30_0.pdf. Accessed 10 July 2018.

Alves Filho EG, Silva LMA, Araújo NVP, Alves EG, Lião LM, Alcantara GB. Qualitative and quantitative control of pediatric syrups using nuclear magnetic resonance and chemometrics. J Pharm Biomed Anal. 2018;153:29–36.

DIN 32645:2008-11. https://www.beuth.de/de/norm/din-32645/110729574. Accessed 3 Sept 2018.

DIN 38402-51:2017-05. https://www.beuth.de/de/norm/din-38402-51/272448891. Accessed 3 Sept 2018.

Cerceau CI, Barbosa LCA, Alvarenga ES, Ferreira AG, Thomasi SS. A validated 1H NMR method for quantitative analysis of α-bisabolol in essential oils of Eremanthus erythropappus. Talanta. 2016;161:71–9.

Sun S, Jin M, Zhou X, Ni J, Jin X, Liu H, et al. The application of quantitative 1H-NMR for the determination of orlistat in tablets. Molecules. 2017;22:E1517.

Moore CJ, Lattin GL, Zellers AF. Quantity and type of plastic debris flowing from two urban rivers to coastal waters and beaches of Southern California. J Integr Coast Zone Manag. 2011;11:65–73.

Acknowledgements

The authors gratefully acknowledge support of the Deutsche Forschungsgemeinschaft (INST 366/6-1) for the purchase of the NMR spectrometer.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 77 kb)

Rights and permissions

About this article

Cite this article

Peez, N., Janiska, MC. & Imhof, W. The first application of quantitative 1H NMR spectroscopy as a simple and fast method of identification and quantification of microplastic particles (PE, PET, and PS). Anal Bioanal Chem 411, 823–833 (2019). https://doi.org/10.1007/s00216-018-1510-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-018-1510-z