Abstract

The effect of addition of different concentrations of refined coconut oil (CO) and vegetable oil (palm olein oil) (VO) on the mechanical and thermal properties, as well as water absorption, biodegradability and morphology of cassava starch-based TPS films were investigated. Cassava starch-based TPS films were prepared by the solvent casting method using glycerol as the plasticizer incorporation with varying concentrations of CO and VO at 5,10,20, and 40 wt % based on cassava starch. The X-ray diffractometry (XRD), fourier transform infrared (FTIR) spectroscopy, thermogravimetric analysis (TGA), and scanning electron microscopy (SEM) analysis were carried out to observe the interactions between the starch matrix and oil, thermal stability, decomposition temperature and morphology of films. An increase in tensile strength was observed with the increment of both CO and VO concentration while the maximum tensile strength was observed at the oil concentration of 10 wt % for both CO and VO. However, films containing VO have higher tensile strength (4.18 MPa) than the films containing CO (3.56 MPa). Tensile strain at break decreased when increasing the oil concentration up to 10 wt % for both CO and VO. Water absorption of the films increased when increasing the oil concentration. However, the value was less than the reference sample until the oil concentration was 20 wt % for both CO and VO. Moreover, all the samples are biodegradable. Cassava starch, refined coconut oil, and vegetable oil are natural resources that can be used to produce alternative materials that cause minor environmental impact.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Starch is a polymeric carbohydrate containing anhydroglucose units connected by glucosidic bonds. Cereal grains such as corn, wheat and rice and tubers such as potato and cassava, are the main starch sources that can be used for bio-plastics [1, 2]. Production of starch-based bio-plastics which are cheap, and fully biodegradable, could become a possible substitute to non-biodegradable synthetic plastics while creating new markets and reducing environment pollution [3, 4]. The demand for environmentally friendly biodegradable plastics is increasing day by day [5].

Cassava (Manihot esculenta) starch is more suitable to produce thermoplastic starch due to its clarity, low gelatinization temperature and good gel stability. Cassava starch has a carbohydrate content up to 99%, and 17% amylose and 83% amylopectin content [6, 7]. Cassava starch can be transformed into an amorphous thermoplastic by processing with plasticizers such as glycerol under special heat and shear conditions [8]. However, thermoplastic starch has major drawbacks such as poor mechanical properties and water resistance. The hydrophilic nature of starch and plasticizers commonly results in poor mechanical properties of thermoplastic starch [9]

The addition of hydrophobic substances, such as oils and fatty acids, may reduce the hygroscopicity of the thermoplastic starch by increasing the hydrophobic portions in the thermoplastic starch [10]. Current researchers focus on adding plant oil which exhibits admirable hydrophobic properties into thermoplastic starch to improve water resistance properties [11]. Some researchers have focused on using vegetable oil as plasticizers for biodegradable thermoplastics including palm oil [12,13,14], soybean oil [12, 14,15,16], rubber seed oil [17], corn oil [18], olive oil [18], coconut oil [19], canola oil [20], and sunflower oil [21].

Coconut oil which is obtained from the coconut tree and vegetable oil which is produced using palm kernel nuts are some abundant plant oils in the market [22]. The fatty acid content of coconut oil and palm olein oil is listed in Table 1 [22,23,24].

The effect of virgin coconut oil and palm oil on the properties of starch-based thermoplastic was previously studied. To the best of our knowledge, there is no study about the effect of refined coconut oil and palm olein oil (vegetable oil) on the characteristics of cassava starch-based thermoplastic. This research explored the effect of refined coconut oil and palm olein oil (vegetable oil) as hydrophobic components on the properties of cassava starch-based thermoplastics. X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), scanning electron microscopy (SEM), mechanical, water absorption and biodegradability properties of the cassava starch-based thermoplastic thin films were characterized.

2 Materials and Methodology

2.1 Materials

The native cassava starch was purchased from Vilaconic joint stock company, Vietnam. Glycerol was purchased from Research Lab fine chem industry (India). Physically refined coconut oil was purchased from Marina Foods Pvt Ltd and refined palm olein vegetable cooking oil was purchased from NGO Chew Hong Edible Oil Pte Ltd. Freshly prepared distilled water was used.

2.2 Preparation of Thermoplastic Thin Film

Starch-based thin films were prepared by the solvent-casting method after the preparation of film-forming dispersions according to the method adopted by Belibi et al. [25]. Initially, native cassava starch (5 g) was dispersed in an aqueous solution, separately, with the corresponding amount of glycerol and oil at room temperature under continuous stirring for 10 min on a magnetic stirrer. Thereafter, the mixtures were stirred at 80 °C for 45 min to induce starch gelatinization. Afterwards, the films were obtained by casting the hot suspensions into petri dishes. Then, the samples were dried in an oven at 65 °C for 5 h. After that, the dishes were kept in a desiccator and finally, the dry films were carefully removed from the dishes. The sample without oils was prepared as the control sample. Different formulations of cassava starch, glycerol, water and oils are described in Table 2.

2.3 Thickness of the Films

The thickness of thermoplastic thin films was determined using a manual Thickness Gauge by performing at least ten random measurements for each film to the nearest 0.01 mm. The average value for each film was used to calculate the tensile properties.

2.4 Morphology

The surface morphology of thin films was observed using scanning electron microscope (SEM, 259 ZEISS EVO LS15) with accelerating voltage of 10 kV.

2.5 X-ray Diffraction (XRD)

The X-ray diffraction (XRD) patterns of thin films were obtained using a diffractometer (Rigaku Ultima IV). The XRD spectra were recorded over a range (2Ɵ) of 5–45° with a continuous scan rate at 2.0° interval.

2.6 Fourier Transforms Infrared Spectroscopy (FTIR)

Characteristic peaks for thin films were obtained using FTIR spectrometer (PerkinElmer, USA) equipped with a universal Attenuated Total Reflectance (UATR) reflectance cell. Spectra were collected in the wavenumber range of 500–4000 cm−1.

2.7 Thermogravimetric Analysis (TGA)

Thermogravimetric analyzes were performed in a thermal analyzer (PerkinElmer, model 4000) in ceramic pans. Samples (10 g) were heated up from 40 to 700 °C at a rate of 20 °C/min. Nitrogen was used as purge gas (20 mL/min) to avoid thermo-oxidative reactions.

2.8 Tensile Properties

Tensile strength and elongation at break were obtained according to ASTM D882. The tensile strength test was performed using the Universal Testing machine (Instron 3365, Buckinghamshire). The crosshead speed was fixed at 10 mm/min. The samples were prepared according to the dimensions provided by the standard. For each test, five samples were analyzed. The tensile properties were calculated as the average value from the obtained results.

2.9 Water Absorption

The water absorption test was carried according to the ASTM D570 standard. Prepared films were cut into 76.2 mm × 25.4 mm pieces, dried for 24 h in an oven at 50 °C, cooled in a desiccator, and weighed. The water absorption data of films was obtained by soaking them in water for 2 h. After that, films were dried with a cloth and immediately weighed. And after, those samples were soaked in water for another 24 h and weighed. The water absorption capacity of composites was calculated as follows.

2.9.1 Biodegradability

The biodegradability test was carried out according to the aerobic compost environment test [26]. Initially, the starch-based thin films were cut into pieces of 2.0 × 2.0 cm and weighed before being tested. Then, the samples were buried inside the soil at a depth of 3 cm at 25 °C and water was sprayed to maintain the moisture of the compost. The weights of the samples were measured after 15 days.

3 Results and Discussion

3.1 Physical Properties

According to visual examination, the obtained cassava starch-based thermoplastic films were transparent, odorless, and easy to handle. Film thickness varied from 0.32 to 0.37 mm. The prepared cassava starch-based thermoplastic films are shown in Fig. 1.

Thermoplastic starch films were visually transparent and when the oil content for both CO and VO was incresed, the transparency of the films reduced.

3.2 SEM Observation

Figure 2 shows the SEM micrographs at 1000 × magnification of surface of thermoplastic starch films with oil.

As shown in Fig. 2, the microstructures of cassava starch-based thermoplastic films with different concentrations of CO and VO were evaluated by SEM. It was observed that the surface of the control film (TPS without oil) was homogeneous and continuous without any granules or pores (Fig. 1a). The films containing CO and VO (Fig. 1b, c) showed a discontinuous and porous structure and some oil droplets could be seen. It can be suggested that CO and VO were not dispersed homogeneously within the thermoplastic films [11].

3.3 X-ray Diffraction (XRD)

Preparation of thermoplastic film by casting method generally leads to solubilization of amylose followed by the destruction of starch crystalline structure [27]. Diffraction patterns of the control cassava starch-based thermoplastic film and cassava starch-based thermoplastic films with CO and VO oil in different contents are given in Fig. 3.

Diffraction pattern of the control film (TPS) showed a broad diffraction peak in 15–20° 2θ region. It indicates the destruction of A-type crystal structure. According to the literature, characteristic peaks (2θ) for the structure of cassava starch are at 15°, 17°, 18°, 20°, 23°, and 26° [28]. When adding the CO and VO, the shape of the peak has changed: diffraction peaks became wider. The oil-added thermoplastic films showed broad diffraction peak in 15–25° 2θ region.

3.4 Fourier Transforms Infrared Spectroscopy (FTIR)

The FTIR spectra of control cassava starch-based thermoplastic film and cassava starch-based thermoplastic films with CO and VO oil in different contents are depicted in Fig. 4.

All FTIR showed a peak which was evident at wave number 3200–3300 cm−1 (Fig. 4), indicates a hydrogen-bonded O-H stretching. All thermoplastic films had peaks in the range 2850–2950 cm−1 corresponding to a C-H functional group [29,30,31]. The peaks at 2920 cm−1 and 2850 cm−1 indicate the presence of long-chain alkyl groups. The peaks around 2850 cm−1 intensified with CO and VO contents’ increasing, which confirmed the presence of oils [32]: [11]. The characteristic peak at 1750 cm−1 corresponds to stretching of C = O group of ester bonds. When increasing the oil contents, it displayed more intense bands at wavenumbers of 1750 cm−1 [11]. Another peak in the range 1620–1650 cm−1 corresponds to water absorption. A peak at 1320–1380 cm−1 in corresponding to bending vibration of a C-H group and C-O of an aromatic ring was also evident. Peaks corresponding to bending vibration of C-O, and O-H in the range of 1010–1070 cm−1 was also present in all samples. [29,30,31].

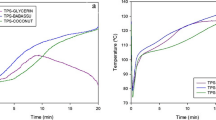

3.5 Thermogravimetric Analysis (TGA)

Thermogravimetric (TG) and its derivative thermogravimetric (DTG) curves were used to evaluate the thermal stability of the cassava starch-based thermoplastic films with oils (shown in Fig. 5).

When the temperature was below 100 °C, a lower thermal weightlessness was observed. It could be due to the evaporation of water or the small molecular impurities. Films containing oil started to show different degrees of weightlessness at 180 °C. This will happen due to the thermal degradation of fatty acids in films with CO and VO. After 300 °C, thermoplastic films showed insistent weightlessness. This could be attributed to the thermal degradation of the starch components in the films [33,34,35]

3.6 Tensile Properties

Tensile strength and elongation at break of the thermoplastic thin films with CO ad VO are shown in Figs. 6 and 7, respectively.

As the CO content and VO content increased, the tensile strength of the thermoplastic film showed an increasing trend, followed by a decrease. When the concentration of oil was 10 wt %, the tensile strength of the film with CO reached its highest value (3.56 MPa), and the tensile strength of the film with VO reached its highest value (4.18 MPa). Moreover, the tensile strength of film containing VO is higher than the tensile strength of film containing CO for the same oil concentration. However, the addition of CO and VO in high concentration (over 20 wt%), reduced the tensile strength of the thermoplastic films by weakening the interactions between the starch molecules. This could happen due to increased discontinuity of lipid molecules in the starch matrix [34]

The elongation at break decreased with the increase in coconut oil and vegetable oil. TPS without oil shows lower elongation at break value compared with TPS with 5, 10, and 20% CO and 5 and 10% VO.

3.7 Water Absorption

Figure 8 shows the water absorption properties of cassava starch-based thermoplastic with CO and VO in different oil concentrations.

After introducing CO and VO into the composites, only a slight decrease in water absorption of the films were observed until the oil content reached 20% w/w concentration. This can be attributed to the hydrophilic character of starch and glycerol [36]. The improved water resistance properties for TPS with oil content up to 20% w/w was due to the hydrophobic characteristic of coconut oil and vegetable oil. Fatty acids improve the hydrophobic properties of the TPS films, thus increase the water resistance properties [11, 34, 37]. This behaviour is consistent with the results of previous studies [38]. However, a significant enhancement in water resistance properties were expected due to hydrophobic nature of coconut oil and vegetable oil. The addition of VO reduced the water solubility better than CO at the same oil concentration for 5% w/w and 10% w/w. The oil with 40% w/w concentration TPS film showed slightly high-water absorption when compared to the reference TPS film. This can happen due to the differences in density between oils and cassava starch leading to the movement of lipid aggregates to the material surfaces by damaging cohesive structural integrity [11].

3.8 Biodegradability

In biodegradation test, all the thermoplastic thin films showed a significant degradation within 15 days. The percentage weight loss of all the thin films was 50–70%.

4 Conclusion

In this work, different percentages of refined coconut oil and vegetable oil (palm olein oil) were added into the cassava starch-based thermoplastic plasticized using glycerol. The prepared films were thermally and mechanically characterized. It was observed that the addition of coconut oil and vegetable oil contributes significantly to characteristics’ improvement for all tested standards. Vegetable oil was more effective than coconut oil for lower oil concentration. Overall, this study recommended that CO and VO have potential to be formulated in the cassava starch-based thermoplastic for packaging since the CO and VO are non-toxic plant-based material.

References

Liu H, Xie F, Yu L, Chen L, Li L (2009) Thermal processing of starch-based polymers. Prog Polym Sci 34(12):1348–1368

Zhang Y, Rempel C, McLaren D (2014) Thermoplastic starch. In: H JH (ed) Innovations in food packaging. Elsevier, Texas, pp 391–412

Jiang B, Li S, Wu Y, Song J, Chen S, Li X, Sun H (2018) Preparation and characterization of natural corn starch-based composite films reinforced by eggshell powder. CyTA J Food 16(1):1045–1054

Tapia-Blacido D, Mauri A, Menegalli F, Sobral P, Anon M (2007) Contribution of the starch, protein, and lipid fractions to the physical, thermal, and structural properties of amaranth (amaranthus caudatus) flour films. J Food Sci 72(5):E293–E300

Moshood T, Nawanir G, Mahmud F, Mohamad F, Ahmad M, AbdulGhani A (2022) Sustainability of biodegradable plastics: new problem or solution to solve the global plastic pollution? Curr Res Green Sustain Chem 5:100273

Mali S, Grossmann M, Garcia M, Martino M, Zaritzky N (2006) Effects of controlled storage on thermal, mechanical and barrier properties of plasticized films from different starch sources. J Food Eng 75(4):453–460

Morgan N, Choct M (2016) Cassava: Nutrient composition and nutritive value in poultry diets. Animal Nutr 2(4):253–261

Lopez O, Zaritzky N, Grossmann M, Garcia M (2013) Acetylated and native corn starch blend films produced by blown extrusion. J Food Eng 116(2):286–297

Liu P, Sun S, Hou H, Dong H (2016) Effects of fatty acids with different degree of unsaturation on properties of sweet potato starch-based films. Food Hydrocolloids 61:351–357

Brandelero R, Grossmann M, Yamashita F (2012) Films of starch and poly(butylene adipate co-terephthalate) added of soybean oil (SO) and Tween 80. Carbohyd Polym 90(4):1452–1460

Yang J, Ching Y, Julai JS, Chuah C, Nguyen D, Lin P (2022) Comparative study on the properties of starch-based bioplastics incorporated with palm oil and epoxidized palm oil. Polym Polym Compos 30. https://doi.org/10.1177/09673911221087595

Chieng B, Ibrahim N, Then Y, Loo Y (2014) Epoxidized vegetable oils plasticized poly(lactic acid) biocomposites: mechanical thermal and morphology properties. Molecules 19(10):16024–16038

Silverajah V, Ibrahim N, Yunus W, Hassan H, Woei C (2012) A comparative study on the mechanical, thermal and morphological characterization of poly(lactic acid)/epoxidized palm oil blend. Int J Mol Sci 13(5):5878–5898

Tee Y, Talib R, Abdan K, Chin N, Kadir Basha R, Md Yunos K (2015) Comparative study of chemical, mechanical, thermal, and barrier properties of poly(lactic acid) plasticized with epoxidized soybean oil and epoxidized palm oil. BioResources 11(1)

Ali F, Chang Y, Kang S, Yoon J (2008) Thermal, mechanical and rheological properties of poly (lactic acid)/epoxidized soybean oil blends. Polym Bull 62(1):91–98

Xu Y, Qu J (2009) Mechanical and rheological properties of epoxidized soybean oil plasticized poly(lactic acid). J Appl Polym Sci 112(6):3185–3191

Thuy N, Duc V, Liem N (2018) Properties of poly(lactic acid) plasticized by epoxidized rubber seed oil. Viet J Chem 56(2):181–186

Liu L, Kerry J, Kerry J (2006) Effect of food ingredients and selected lipids on the physical properties of extruded edible films/casings. Int J Food Sci Technol 41(3):295–302

Bhasney S, Patwa R, Kumar A, Katiyar V (2017) Plasticizing effect of coconut oil on morphological, mechanical, thermal, rheological, barrier, and optical properties of poly(lactic acid): a promising candidate for food packaging. J Appl Polym Sci 134(41):45390

Lopera-Valle A, Caputo J, Leão R, Sauvageau D, Luz S, Elias A (2019) Influence of epoxidized canola oil (eCO) and cellulose nanocrystals (CNCs) on the mechanical and thermal properties of polyhydroxybutyrate (PHB)—poly(lactic acid) (PLA) blends. Polymers 11(6):933

Volpe V, De Feo G, De Marco I, Pantani R (2018) Use of sunflower seed fried oil as an ecofriendly plasticizer for starch and application of this thermoplastic starch as a filler for PLA. Ind Crops Prod 122:545–552

Boateng L, Ansong R, Owusu W, Steiner-Asiedu M (2016) Coconut oil and palm oil’s role in nutrition, health and national development: a review. Ghana Med J 50(3):189–196

Fediol.eu (2022) EU vegetable oil and protein meal industry association. https://www.fediol.eu/data/fatty%20acids.pdf. Accessed 25 Aug 2022

Sampaio K, Ceriani R, Silva S, Taham T, Meirelles A (2011) Steam deacidification of palm oil. Food Bioprod Process 89(4):383–390

Belibi P, Daou J, Ndjaka J, Nsom B, Michelin L, Durand B (2014) A comparative study of some properties of cassava and tree cassava starch films. Phys Proc 55:220–226

Wahyuningtiyas N, Suryanto H (2017) Analysis of biodegradation of bioplastics made of cassava starch. J Mech Eng Sci Technol 1(1):24–31

Parker R, Ring S (2001) Aspects of the physical chemistry of starch. J Cereal Sci 34(1):1–17

Teixeira E, Róz A, Carvalho A, Curvelo A (2005) Preparation and characterisation of thermoplastic starches from cassava starch, cassava root and cassava bagasse. Macromol Symp 229(1):266–275

Almeida M, Alves R (2010) Determination of amylose content in starch using Raman spectroscopy and multivariate calibration analysis. Anal Bioanal Chem 2693–2701

Mendes J, Paschoalin R, Carmona V, Sena Neto A, Marques A, Marconcini J, Mattoso L, Medeiros E, Oliveira J (2016) Biodegradable polymer blends based on corn starch and thermoplastic chitosan processed by extrusion. Carbohyd Polym 137:452–458

Syafri E, Kasim A, Abral H, Asben A (2017) Effect of precipitated calcium carbonate on physical, mechanical and thermal properties of cassava starch bioplastic composites. Int J Adv Sci Eng Inf Technol 7(5):1950

Fang J, Fowler P, Tomkinson J, Hill C (2002) An investigation of the use of recovered vegetable oil for the preparation of starch thermoplastics. Carbohyd Polym 50(4):429–434

Edhirej A, Sapuan SM, Jawaid M, Zahari NI (2017) Preparation and characterization of cassava bagasse reinforced thermoplastic cassava starch. Fibers Polym 18:162–171

Fangfang Z, Xinpeng B, Wei G, Wang G, Shi Z, Jun C (2019) Effects of virgin coconut oil on the physicochemical, morphological and antibacterial properties of potato starch-based biodegradable films. Int J Food Sci Technol 55(1):192–200

Wang W, Wang K, Xiao J, Liu Y, Zhao Y, Liu A (2017) Performance of high amylose starch-composited gelatin films influenced by gelatinization and concentration. Int J Biol Macromol 94:258–265

Xiong Z, Yang Y, Feng J, Zhang X, Zhang C, Tang Z, Zhu J (2013) Preparation and characterization of poly(lactic acid)/starch composites toughened with epoxidized soybean oil. Carbohyd Polym 92(1):810–816

Ai Y, Hasjim J, Jane J (2013) Effects of lipids on enzymatic hydrolysis and physical properties of starch. Carbohyd Polym 92(1):120–127

Šuput D, Lazić V, Pezo L, Markov S, Vaštag Ž, Popović L, Radulović A, Ostojić S, Zlatanović S, Popović S (2016) Characterization of starch edible films with different essential oils addition. Polish J Food Nutr Sci 66(4):277–285

Acknowledgements

The authors wish to express their sincere appreciation to Accelerating Higher Education Expansion and Development (AHEAD) for the financial assistance (AHEAD/RA3/DOR/65).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Fernando, N.M.L. et al. (2023). Effects of Refined Coconut Oil and Vegetable Oil on the Mechanical, Thermal, Morphological, and Biodegradable Properties of Cassava Starch-Based Thermoplastic (TPS) Films. In: Dissanayake, R., et al. ICSBE 2022. ICSBE 2022. Lecture Notes in Civil Engineering, vol 362. Springer, Singapore. https://doi.org/10.1007/978-981-99-3471-3_5

Download citation

DOI: https://doi.org/10.1007/978-981-99-3471-3_5

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-3470-6

Online ISBN: 978-981-99-3471-3

eBook Packages: EngineeringEngineering (R0)