Abstract

The catalytic hydrogenolysis of cellulose to polyols represents an attractive process for biomass conversion to value-added products with a high atom economy. In the past decade, extensive studies have been conducted and promptly accumulated a rich knowledge in this field. In this chapter, we focus on the review of reaction mechanisms and kinetics after a brief description of the catalyst development for this process. In view of the different polyol products, the present review is mainly composed of two parts: cellulose conversion to sugar alcohols and cellulose hydrogenolysis to ethylene glycol and 1,2-propylene glycol. The reaction mechanisms are discussed and summarized to obtain general rules in terms of the specific performance of various catalysts. The reaction kinetics of cellulose hydrogenolysis are analyzed on the basis of the kinetics of the individual reaction steps and their correlations in the whole route covering in detail the reactions of cellulose hydrolysis, sugar hydrogenation, retro-aldol condensation, and sugar condensations. Finally, the prospective for the reaction mechanism and kinetics study of cellulose hydrogenolysis is presented.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Cellulose

- Hydrogenolysis

- Polyols

- Hexitol

- Sugar alcohol

- Ethylene glycol

- Propylene glycol

- Kinetics

- Reaction mechanism

9.1 Introduction

Cellulosic biomass has been used as a fuel for millions of years. Also, as a fiber-rich material, it is widely applied to the production of cloth, paper, ropes, vessels, and buildings, thanks to its high tension strength and hardness. Most of these applications are of still in use today. Beyond these traditional uses, daily life demands ever more high-quality building blocks for material synthesis and convenient fuels for use [1–3]. In the past century, petroleum, coal, and natural gas supplied the world with tremendous amounts of energy and materials to achieve the current prosperity. However, this situation is facing increasing challenges due to the depletion of fossil energy resources and pressing environmental issues. To meet the long-term demand of sustainable development, it is necessary to explore cellulose transformation into a large variety of platform chemicals and fuels by chemical and biological techniques [1–6].

Differing from the fossil energy resources of petroleum and coal, cellulose contains rather high content of oxygen up to ca. 50 wt.% besides carbon and hydrogen elements. The abundant oxygen in cellulose is of some disadvantage for the transformation to fuels. However, if considered for the synthesis of chemicals, particularly oxygen-containing compounds such as polyols, prominent advantages can be shown over fossil resources. First, the transformation theoretically possesses a high atom economy since most hydroxyl groups of cellulose can be preserved in the target polyol products. Second, the value of polyol products is generally high, offering conversions with a good economic viability. Third, the market capacity of polyols is significant (30–40 million ton/a) but not too large, well fitting the moderate availability of biomass in view of the scales of collection, transportation, and storage.

The conversion of cellulosic biomass to polyols can be traced back to the 1930s [7, 8]. Because cellulose has a crystalline structure which strongly inhibits its degradation, conventional methods for polyol production from cellulose generally comprise two separated steps, i.e., hydrolysis of cellulose to soluble sugars with concentrated mineral acids and followed by hydrogenation or hydrogenolysis of polyols with transition metal catalysts. It is therefore highly desirable to develop novel green techniques for the direct hydrolytic hydrogenolysis of cellulose.

Recently, a one-pot catalytic hydrolytic hydrogenolysis of cellulose to polyols has been developed and was the target of intensive investigations [6, 9–33]. Heterogeneous catalysts are employed to take advantage of the convenience in recycling after reaction. Water is used as a green reaction medium, which not only participates in the hydrolysis reaction but also generates protons in situ at high temperatures to promote the cellulose hydrolysis. Reactions are conducted at temperatures of 423–523 K, at which cellulose is activated by subcritical water. Multiple reactions are coupled in one pot, involving polysaccharides hydrolysis, sugar isomerization, hydrogenation, retro-aldol condensation, decarbonylation, polymerization, and some other side reactions. The polyol products vary from C6 to C2 polyols, including sorbitol, mannitol, erythritol, glycerol, 1,2-propylene glycol, and ethylene glycol. The polyol distributions are highly dependent on the type of catalysts, reaction conditions, and reaction kinetics of the major reactions involved.

Significant progress has been made in cellulose hydrogenolysis to polyols in many aspects, including polyol production with high yields, reaction efficiency promotion, product selectivity control, development of less expensive catalysts, reaction-environment endurable catalysts, and raw biomass conversion. Nevertheless, a complete and insightful understanding of the reaction mechanism and kinetics is not yet available, and it is not an easy task to clearly identify the reaction mechanism and kinetics in the hydrogenolysis of cellulose although they are of paramount importance for the design of more efficient catalysts and processes. The obstacles are mainly set by the harsh reaction environment where most characterization techniques are not feasible for an in situ detection of reaction intermediates and active sites on catalysts. In addition, the multiple active components of catalysts strongly interact with each other, further increasing the complexity of studying the reaction kinetics. Considering that the reaction mechanisms are closely dependent on the catalyst, reaction conditions, and target products, in this chapter, we discuss and summarize the reaction mechanisms and kinetics following a brief description of catalysts for cellulose hydrogenolysis.

9.2 Cellulose Hydrogenolysis to Sugar Alcohols

9.2.1 Catalysts and Reaction Mechanisms

Sugar alcohols, mainly referring to sorbitol and mannitol, are high-value commodity chemicals widely used in drugs, food, and cosmetics [30]. Cellulose is composed of C6 glucan units and it should certainly be possible to use it for the production of sugar alcohols through a direct hydrolytic hydrogenation process. Glucan units in cellulose are linked via 1,4-glycosidic bonds and protected by the crystalline structure of cellulose. Accordingly, the catalysts must fulfill two functions for the cellulose hydrolytic hydrogenation: (1) the catalytic hydrolysis of cellulose to release glucose and soluble oligosaccharides and (2) the catalytic hydrogenation of sugars to form polyols [34]. The sugars formed during the reaction are metastable, i.e., they readily to undergo condensation to form humins under harsh reaction conditions. Therefore, for the production of hexitols from cellulose in high yields, the essential questions are how to realize cellulose hydrolysis without using a conventional mineral acid and how to keep the rates of tandem reactions in a suitable balance.

In 2006, Fukuoka and coworkers reported one-pot catalytic transformation of cellulose to sugar alcohols in hot water with heterogeneous catalysts, involving noble metal catalysts consisting of Pt/Al2O3, Pt/SiO2–Al2O3, Pt/HUSY, and Ru/HUSY [9]. After reaction at 463 K and 5 MPa H2 for 24 h, hexitols were obtained at a yield of 31 %. The researchers proposed that the Pt catalysts participate in the hydrogenation and also play a solid acid role in promoting cellulose hydrolysis. The acidic sites of catalysts on one hand originate from the acidic supports. On the other hand, they were generated by hydrogen atoms spilling over from metallic Pt sites to the support surface [9, 19]. The remarkable activity of noble metal sites for cellulose hydrolysis was further identified in later studies [35, 36]. For instance, over a mesoporous carbon-supported Ru catalyst, glucose was obtained at a yield of 34.2 %. The Ru sites were also found to be very active for the hydrolysis of oligosaccharides, which result from the preliminary degradation of cellulose [35]. The reaction mechanism of cellulose transformation over Pt/Al2O3 is presented in Fig. 9.1, wherein cellulose hydrolysis and sugar hydrogenation reactions are coupled in one pot.

Catalytic conversion of cellulose into sugar alcohols (Reprinted with permission from Ref. [9] Copyright 2006 by John Wiley & Sons Ltd)

Compared to the conventional transformation of cellulose to polyols using mineral acids and by multiple steps, the one-pot hydrolytic hydrogenation process with solid catalysts has several attractive features: (1) heterogeneous catalysts are less corrosive to the reaction equipment and can readily be recycled after the reaction, (2) the reaction process is simplified by coupling multiple reactions in one pot, and (3) the aqueous reaction medium is nontoxic to the environment. However, problems are also evident from the early work, e.g., a low efficiency of reaction, low selectivity to hexitols, and high cost of noble metal catalysts. Bearing in mind the potential advantages of this process and the known challenges for cellulose conversion, great endeavors were further made in the following years to obtain a more encouraging catalytic performance.

The active components of catalysts and reaction conditions for cellulose transformation to hexitols described in the literature vary over a wide range. The approaches to promote the catalytic performance can be largely ascribed to the following aspects: (1) reaction condition optimization, (2) novel acidic supports, (3) different hydrogenation components, (4) combining homogeneous and heterogeneous catalysis, (5) pretreatment of cellulose, and (6) hydrogen source alternatives to H2. In the following context, detailed discussions on the catalysts and reaction mechanisms will be presented along this classification.

As shown by Liu and coworkers, the reaction temperature has remarkable effects on the reaction efficiency [12]. When the reaction was performed at 518 K, its efficiency was significantly improved with 100 % cellulose conversion in 30 min, in contrast to a 24 h reaction at 463 K [9]. They proposed that protons are generated from subcritical water and act as acid to promote cellulose hydrolysis. The resulting sugars then undergo hydrogenation over transition metal catalysts to form hexitols. The reaction mechanism is shown in Fig. 9.2.

Catalytic conversion of cellulose into hexitols with the aid of in situ formed proton acid (Reprinted with permission from Ref. [12] Copyright 2007 by John Wiley & Sons Ltd)

For a good heterogeneous catalyst for cellulose hydrolytic hydrogenation, its support should not only fulfill the function of dispersing metallic active components but also afford acidic sites to compose a bifunctional catalyst. Various acidic supports were employed, including Al2O3 [9, 19, 37], SiO2-Al2O3 [9], ZSM-5 [25], MCM-41 [38], MCM-48 [38], H-USY [9], Cs3PW12O40 [21], AC-SO3H [39], MCM-41-n-SO3H [40], SiO2–SO3H [41], Zr-SBA-15 [42], zirconium phosphate (ZrP) [31, 43], PTA/MIL-100(Cr) [44], and NbOPO4 [45]. These supports possess Brønsted acid sites for cellulose hydrolysis and sometimes also afford Lewis acid sites for cellulose activation and sugar isomerization [31, 46]. After loading with transition metals Ru, Pt, Ni, Rh, or Ir, bifunctional catalysts were obtained and exhibited enhanced performance with hexitols yields reaching 60–90 %. Following this strategy, modification of a neutral support with acidic groups is feasible to improve the reaction rate of cellulose hydrolysis [41]. Also, the product selectivity can be modified to some extent with suitable interactions between the modifier and metal sites on the support. In one instance, Hou et al. showed that the sulfonic groups on SiO2–SO3H changed the electronic property of Ru nanoparticles, consequently improving the selectivity to sorbitol by inhibiting its further degradation (as shown in Fig. 9.3) [41].

Cellulose conversion over Ru/SiO2–SO3H catalyst (Reprinted with permission from Ref. [41] Copyright 2014 by the Royal Society of Chemistry)

The oxide-based bifunctional catalysts have reasonably good stability and can be reused for several times in the one-pot process. However, in a long-term operation, they still suffer from activity decay. The Brønsted acid sites on the oxide support surface gradually leach into the hot aqueous solution. Otherwise, the oxide support itself is transformed into hydroxide by the hot water, leading to the collapse of the pristine structure and the loss of acidic sites. Using carbon materials as catalyst carriers is a promising alternative approach to resolve this problem. Carbons are hydrothermally stable under the reaction conditions typically at temperatures of 423–573 K. Moreover, the surface of carbon materials can be furnished with plenty of OH and carboxyl groups. Such weak acidic sites have been found to contribute to the activation of the glycosidic bonds in cellulose and consequently promote the hydrolysis of cellulose [27, 35, 47–51]. Conversely, strong acid sites on carbon materials are unequivocally effective for cellulose hydrolysis [52–54]. In one instance, a 65 % hexitols yield was obtained over a 10 % Ru/AC-SO3H catalyst [39]. But unfortunately, SO3H groups on the activated carbon are not stable enough under the harsh reaction conditions required for crystalline cellulose conversion; they still suffered from gradual leaching during the reaction.

Besides the support, the hydrogenating metal is another important factor determining the hexitols yields in cellulose hydrolytic hydrogenation. Zhao and coworkers investigated nickel catalysts supported on a series of carriers, including Al2O3, SiO2, ZSM-5, bentonite, kieselguhr, and TiO2 [55]. They found that high activity for hydrogenation and inferior activity for dehydrogenation of Ni catalysts were essential for obtaining high yields of hexitols. The synergistic effect between Ni and acid–base sites of the support could accelerate the dehydrogenation of sorbitol to form glucose, which further undergoes retro-aldol condensation, hydrogenation, and dehydration to form small polyols at the expense of the hexitols yield. The proposed reaction pathway is depicted in Fig. 9.4.

The proposed reaction pathways for the cellulose hydrogenolysis over Ni catalysts (Reprinted from Ref. [55], Copyright 2014, with permission from Elsevier)

The ratio of hydrogenation sites and hydrolysis active sites affects the hexitols yield [44, 48]. Huang et al. found that to obtain a high yield of hexitols over a Ru-PTA/MIL-100(Cr) catalyst, the optimal quantity ratio of two catalytic functions should be kept in a range of 8.84 < nAcid/nRu < 12.90 [44].

Hydrolytic transformation of cellulose is normally conducted in compressed hot water, in which metallic particles of catalysts are liable to sinter during the reaction as a result of the so-called Ostwald ripening. The particles of transition metal, in particular non-precious metal such as Ni and Cu, slowly release metal ions into the hot aqueous solution, and the metal ions are then reduced to the metallic state over the hydrogenation sites and deposited there. The overall effect is that the small metal particles minimize and eventually disappear, while the large metal particles grow to larger ones parallel to the reaction running. The essential reason is associated with the difference in the relative surface free energy between metal particles of different sizes. Increasing metal loadings can increase the particle size and accordingly improve the catalyst stability. Fukuoka et al. showed that larger crystalline Ni particles were more resistant to sintering and to oxidation on the surface [56]. Another way to improve the stability of a metallic catalyst is modifying it with a second metal to form a bimetallic catalyst [27, 57]. Zhang and coworkers synthesized bimetallic catalysts, e.g., 1 %Rh-5 %Ni/MC and 4 %Ir-4 %Ni/MC, with a mesoporous carbon support and obtained 58 % hexitols yield [27]. The catalysts endured reactions at 518 K for at least four recycles without decay in the catalytic activity. Similarly, Zhao et al. synthesized a PtNi/ZSM-5 catalyst for cellulose hydrogenolysis [57]. Compared to the monometallic catalyst Ni/ZSM-5 [25], the bimetallic catalyst showed much better reuse stability, which was attributed to the formation of Pt-enriched alloy surface [57].

Besides noble metal catalysts, transition metal phosphide catalysts, e.g., Ni2P, are also suitable candidates to be used as bifunctional catalysts for cellulose hydrolytic hydrogenation [14, 58]. The nickel phosphide catalysts are prepared by impregnation of Ni phosphates on the supports followed by reduction in hydrogen. However, a small portion of Ni phosphate species cannot be completely reduced to nickel phosphides due to the strong interaction between Ni phosphate and the support. Thus, the reserved Ni phosphate provides acidic sites for the cellulose hydrolysis, cooperating with the reduced Ni phosphides for the hydrogenation of sugars to form hexitols in cellulose hydrogenolysis.

In summary, although a solid catalyst possesses advantages in separation and recycling after reaction, it must be pointed out that its effectiveness is much lower than that of a homogeneous catalyst. The reason lies in the interaction opportunities between the solid catalyst and water-insoluble cellulosic reactant, which is several orders of magnitude lower than that of a homogeneous catalyst [59]. Only the surface acid sites of the catalyst can be accessed at the beginning of the reaction because the dimensional size of cellulose fibers is some hundreds times larger than the pore size in the solid acid catalyst [59]. This greatly hinders cellulose depolymerization with high efficiency. In some cases, H3O+ species can be released from the solid acid into the reaction medium, such as an ionic liquid, leading to high reaction rates essentially due to the homogeneous catalysis [60, 61].

To achieve high reaction efficiency, many studies attempted to use water-soluble acids in combination with hydrogenation catalysts [18, 62–64]. Sels and coworkers combined a soluble heteropoly acid, i.e., H4SiW12O40, with a heterogeneous Ru/C catalyst for cellulose hydrolytic hydrogenation [63]. After 0.33 h reaction at 363 K, the ball-milled cellulose at 10 % concentration was almost completely converted with a 65 % hexitols yield. The reaction efficiency was increased by several orders of magnitude in comparison with that over typical solid catalysts [9, 12], even at the much milder reaction temperature. Besides the contribution of soluble heteropoly acid, the ball-milling pretreatment on cellulose also greatly enhanced reaction efficiency. In a control experiment, the cellulose conversion was lower than 80 % even after 4 h reaction if carried out without ball-milling pretreatment [63]. Another alternative way to improve the reaction efficiency is pre-depolymerizing cellulose with an acid [65]. Schüth, Rinaldi, and coworkers pretreated cellulosic feedstock by impregnating catalytic quantities of H2SO4 and subsequent ball milling for 2 h. In this way, cellulose was totally converted to water-soluble oligosaccharides and gave a 94.3 % hexitols yield through reaction at 423 K over a Ru/C catalyst. The reaction rate was 18–27 times faster than the best examples reported in literatures [65].

For the cellulose hydrolytic hydrogenation reaction, hydrogen is evidently required for sugar hydrogenation to form polyols. Fukuoka and coworkers studied the possibility to utilize in situ generated hydrogen for this process. They used 2-propanol as hydrogen resource instead of H2 gas in cellulose transformation [20, 66]. Over Ru/C catalysts, a higher hexitols yield was obtained in the presence of 2-propanol than that under 0.8 MPa H2 (46.9 % vs. 37.8 %). The reaction route is presented in Fig. 9.5.

Cellulose transformation over Ru/AC to hexitols with 2-propanol as a hydrogen donor (Reprinted with permission from Ref. [20] Copyright 2011 by the Royal Society of Chemistry)

Ma and coworkers tested cellulose hydrolytic hydrogenation using CO as a substitute for H2. The reaction was conducted under 4.5 MPa CO at 523 K for 30 min and produced hexitols at a yield of 25 % over a 7 %Pt–40 %Mo2C/C catalyst [67]. The Pt–Mo2C/C was deemed to act as a tandem catalyst, where the Pt–Mo2C domains were responsible for hydrogen generation via water-gas shift reaction and the Pt–C domains were responsible for the subsequent hydrogenation reaction.

9.2.2 Reaction Kinetics

As discussed above, different catalysts have been developed for cellulose hydrogenolysis to sugar alcohols. The detailed mechanisms to achieve high catalytic performance are not all the same and need to be discussed case by case. However, there are still some common rules followed in these reactions. It has been popularly accepted that the cellulose hydrolytic hydrogenation process is mainly composed of two consecutive reactions: cellulose hydrolysis to sugars and the sugars hydrogenation to hexitols, accompanied by some side reactions. This suggests that the study on the reaction kinetics of cellulose hydrogenolysis can be largely divided into two parts, i.e., hydrolysis reaction and hydrogenation reaction. A whole expression for the reaction kinetics of cellulose hydrogenolysis can be obtained according to the kinetics of individual reactions and their correlation in a model.

For the first reaction step, i.e., cellulose hydrolysis, there have been a plenty of studies conducted because this is a really important topic for biomass utilizations [35, 51, 59, 68–95]. Several recent reviews presented very comprehensive summary on the reaction kinetics for cellulose hydrolysis [59, 75, 76, 82, 85, 94]. As shown therein and the literatures cited, Saeman described the kinetics of cellulose hydrolysis with a model involving two consecutive pseudo-first-order reactions with respect to H+ concentration (Eq. 9.1) [68, 88]:

The reaction rate k can be represented by an Arrhenius equation modified with acid concentration (Eq. 9.2) [88]:

wherein k i0 is the pre-exponential factor, A is the concentration of acid, m i is the power of acid concentration, E i is the activation energy, T is the temperature, R is the universal gas constant, and m 1 and m 2 are the slopes of cellulose and glucose hydrolysis profiles, respectively [88]. Table 9.1 lists a series of parameter values obtained from acid hydrolysis of cellulose according to Saeman’s model. One notices that the apparent activation energies for cellulose hydrolysis to glucose are ca. 120–180 kJ/mol, but pre-exponential factors and acid exponents vary over a very wide range, i.e., 1010–1019 min−1 and 1.0 − 6.0, respectively [88].

The big discrepancy in the parameter values is caused by the different reaction conditions under which the Saeman’s model is invalid to describe the kinetics. Equation 9.1 was obtained at 443–463 K and acid concentrations in 0.2–2 %. However, if the reaction is conducted under conditions significantly different from those in Saeman’s study, the cellulose morphology, crystallinity, structure, and solubility would be remarkably changed and accordingly affect the validity of the reaction model [96]. For instance, the crystallinity of cellulose can be disrupted to amorphism by subcritical or supercritical water [91, 94], and the resulting amorphous cellulose is much easier to be hydrolyzed [59]. Cellulose has different types of crystallinity including celluloses I, II, IIII, IIIII, IVI, and IVII. It was found that the rate of cellulose decomposition depended on the types of crystalline cellulose and reaction temperatures when the hydrolytic reaction was conducted in at 503–543 K and 10 MPa [95]. Celluloses I, IIII, and IVI were easier than celluloses II, IIIII, and IVII to be degraded, and the E a for cellulose degradation were in a range of 50–70 kJ/mol. The difference of the E a values from those reported in other literatures were ascribed to definitions of decomposition processes and treatment conditions used [95].

In general, cellulose hydrolysis is unlikely to directly generate monosaccharides. Rather, as shown in Eq. 9.3, it typically comprises consecutive steps of cellulose hydrolysis to oligosaccharides and the further hydrolysis to glucose [82]:

The values of the kinetic constants (k 1, k 2) are correlated to the acid sites available and accessible in aqueous medium [97], the diffusion limitations of poly/oligosaccharides [98], and polymerization degrees of oligosaccharides [99]. The second step of oligosaccharides hydrolysis takes place more rapidly than the first one. Overend et al. observed the formation of sugar oligomers in the hydrolysis of α-cellulose, and the rate of glucose formation from oligomers was three times faster than the glucose formation from cellulose [100]. Therefore, the first step is the rate-determining step, and the overall reaction kinetics still follows Seaman’s equation in most cases.

The cellulose hydrolysis is possibly following two routes, i.e., one dominant route involving cleavage at the glycosidic bond and the other minor route involving cleavage at the ring oxygen [88]. As shown in Fig. 9.6 using a cellobiose molecule to represent cellulose, the attack of an acid proton happens at either glycosidic oxygen or ring oxygen, resulting in a cyclic or a noncyclic carbonium ion, respectively. The protonation of the glycosidic oxygen atom forms a cyclic carbonium cation and glucose, followed with further addition of water to form a saccharide and a proton. In the minor pathway, a proton attacks the ring oxygen to form a noncyclic carbonium cation. After the addition of water to the carbonium intermediate, two glucose molecules are produced [59, 88]. Regarding the protonation of the glycosidic oxygen, strong Brønsted acid sites are required (pK= <4). Vanoye et al. disclosed that the hydrolysis rate of cellobiose in ionic liquid shows an evident dependence on the pKa of the acid used in the reaction, as shown in Fig. 9.7 [101].

Mechanism of acid hydrolysis of cellobiose (Reprinted with permission from Ref. [88] Copyright 2014 by the American Chemical Society)

The initial rates of cellobiose hydrolysis in ionic liquid as a function of pKa of the acid for glucose formation (■) and glucose degradation (□) (Reprinted with permission from Ref. [101] Copyright 2009 by the Royal Society of Chemistry)

As for the cellulose hydrolysis over solid acid catalysts, numerous studies have been performed. As reviewed in a literature and papers cited therein [85], the solid acids involved metal oxides, polymer-based acids, sulfonated carbon-based acids, heteropoly acids, H-form zeolites, and supported metal catalysts. The reaction efficiency of cellulose hydrolysis over solid acid catalyst is determined by acid strength, acid density, surface polarity, functional groups on the surface, pore size of solids, and solvents. However, few of these studies provided the reaction kinetic data. Rinaldi and coworkers investigated the cellulose hydrolysis in ionic liquid [BMIM]Cl with the acid catalyst Amberlyst 15DRY [102]. They found that cellulose hydrolysis still follows a first-order reaction with respect to the amount of solid acid. The activation energy for cellulose hydrolysis was 108 kJ mol−1, which is lower than that with liquid acids (e.g., 170–180 kJ mol−1 in H2SO4).

Synergistic effects between the functional groups on the surface of solid acids could substantially decrease the activation energy of cellulose hydrolysis [103]. Pan et al. introduced –SO3H to partially replace –Cl groups in chloromethyl polystyrene (CP) resin and used it for the catalytic hydrolysis of crystalline cellulose. The best yield of glucose reached 93 % over CP–SO3H, in contrast to no hydrolysis of cellulose occurred when using sulfuric acid. The activation energy of cellulose hydrolysis was merely 83 kJ mol−1 at 373–413 K, which is much lower than that for sulfuric acid (170 kJ mol−1). The authors proposed that the chlorine (–Cl) groups play roles in binding cellulose via hydrogen bonds and the sulfonic acid groups (–SO3H) function as the hydrolytic sites. A similar synergistic effect was also observed on sulfonated carbon materials. Hara et al. studied cellulose hydrolysis over a sulfonated carbon catalyst and obtained 110 kJ mol−1 activation energy, which is again notably lower than that for sulfuric acid [53]. The decrease in E a was ascribed to phenolic groups (pKa of ca. 10) and carboxylic acid groups (pKa of ca. 4.7) coexisting with strong acid sites –SO3H (pKa ca. −2.8) on the sulfonated carbon surface. The weak acid sites adsorbed soluble oligosaccharides onto the surface of carbon material and promoted the overall reaction rate [104]. Katz et al. further manifested the promoting function of weak acidic OH-defect sites on the surface of supports for cellulose hydrolysis by comparatively studying the performance of modified silica and alumina in β-glucan hydrolysis [51]. The authors concluded that (1) OH-defect sites on the surface favored adsorption of the β-glu strand in highly constrained environment and (2) OH-defect sites activated glycosidic bonding for hydrolysis via hydrogen bonding.

As for the side reactions, typically sugar decomposition, its apparent activation energy is similar to that of cellulose hydrolysis, and the rates of sugar degradation and cellulose hydrolysis are also in the same order of magnitude under the harsh reaction conditions [59]. This is one reason why it is favorable to hydrogenate sugars in situ into stable sugar alcohols with high yields in the cellulose conversion.

The hydrogenation of glucose to sorbitol follows a Langmuir–Hinshelwood mechanism where the surface reaction is the rate-determining step (as shown in Table 9.2) [105–111]. Kapteijn et al. carried out a detailed study on the reaction kinetics of d-glucose hydrogenation over a 5 % Ru/C catalyst at 373–403 K, 4.0–7.5 MPa H2, and glucose concentration of 0.56–1.39 mol/L [108]. Three plausible models were used based on Langmuir–Hinshelwood–Hougen–Watson (LHHW) kinetics, i.e., Model (1) noncompetitive adsorption of hydrogen and glucose, Model (2) competitive adsorption of molecular hydrogen and glucose, and Model (3) competitive adsorption of dissociatively chemisorbed hydrogen and glucose. They found that hydrogenation rate was first order with respect to H2 pressure. But the reaction order with respect to glucose shifted from first order to zero order when the sugar concentrations increased from 0.3 mol/L to higher concentrations. The three models described the data satisfactorily. No inhibition by sorbitol or mannitol was observed. The activation energy of glucose hydrogenation over the Ru catalyst was 55 kJ/mol, which is well consistent with the values of ~60 kJ/mol in other studies [106, 108, 112]. Besides Ru catalysts, Ni catalysts are also extensively considered for glucose hydrogenation. The E a values of glucose hydrogenation over Ni are determined to be in a range of 63–82 kJ/mol [106, 107, 111].

For the hydrolytic hydrogenation of saccharide oligomers, two competing pathways were found to occur concurrently. Negahdar et al. conducted a kinetic study of the catalytic conversion of cellobiose to sorbitol by using a binary catalyst of silicotungstic acid and Ru/AC [112]. As shown in Fig. 9.8, they found that the cellobiose hydrogenolysis either follows a first step of hydrolytic reaction (route I) to form glucose or a first step of hydrogenation (route II) to form 3-d-glucopyranosyl-d-glucitol (cellobitol), which is subsequently hydrolyzed to sorbitol and glucose. Which route is to be followed is determined by the reaction temperature. At a moderate temperature, e.g., 393 K, cellobitol is the main product with a maximum selectivity of 81 %. Conversely, at notably higher temperatures, the cellobitol selectivity decreased to 1 % but with sorbitol selectivity rising up to 75 %. The results were ascribed to the different activation energies of the two reactions. Kinetic modeling showed that the E a for cellobiose hydrolysis was 115 kJ mol−1, in contrast to 76 kJ mol−1 for cellobiose hydrogenation to cellobitol. The subsequent hydrolysis of cellobitol and hydrogenation of glucose had E a values of 103 kJ mol−1 and 69 kJ mol−1, respectively. Therefore, route II, i.e., direct hydrogenation, is more preferable at lower temperatures. In addition, the hydrolysis of cellobitol is slightly easier than the hydrolysis of cellobiose (E a = 103 vs. 115 kJ mol−1). If one extends this conclusion to the hydrolytic hydrogenation of cellulose, the direct hydrogenation of terminal sugars of cellulose macromolecules could promote cellulose degradation to some extent.

Proposed reaction pathways for the conversion of cellobiose with silicotungstic acid and Ru/C (Reprinted with permission from Ref. [112]. Copyright 2014 by Elsevier Inc)

Taken all together, it is evident that the E a of sugar hydrogenation is much lower than that of cellulose hydrolysis, and the reaction rate of the former is rather faster than that of cellulose hydrolysis. In particular over a solid catalyst, the rate of cellulose hydrolysis is further decreased by orders of magnitude. In addition, as mentioned above, the side reaction of sugar degradation has activation energy and reaction rate comparable to that of cellulose hydrolysis. Therefore, the rate of hexitols production in cellulose hydrogenolysis is dominantly determined by the low rate of cellulose hydrolysis. This makes it relatively easier to model the reaction kinetics and control the reaction selectivity as compared with the production of smaller C2–C3 polyols, which will be discussed in the following section.

9.3 Cellulose Hydrogenolysis to Ethylene Glycol and 1,2-Propylene Glycol

9.3.1 Catalysts and Reaction Mechanism

Ethylene glycol (EG) and 1,2-propylene glycol (1,2-PG) are the two most produced man-made polyols, with global production reaching more than 30 million tons per year. They are widely used for the synthesis of fibers, package articles, antifreeze agent, unsaturated resins, and other commodity chemicals. Currently, EG and 1,2-PG are dominantly synthesized from ethylene and propylene via an epoxidation and hydration process. Using biomass, in particular the nonedible, cellulosic materials are of great attractiveness to prepare EG and 1,2-PG because of many merits inherent in this process, such as the high value of products, large market demand, and the renewability of feedstock.

In the last decade, catalytic hydrogenolysis of cellulose to EG and 1,2-PG has made significant progresses. One of the representative works is the direct catalytic conversion of lignocellulose to ethylene glycol (DLEG), which was first disclosed by Zhang, Chen, and coworkers in 2008 [13]. The tungsten carbide catalysts were initially used to substitute noble metal catalysts for cellulose hydrogenolysis to hexitols. However, the dominant product over the carbide catalyst was unexpectedly EG, not the conventional hexitols. The EG yield was 27 % over a W2C/AC catalyst and further improved to 61 % by introducing small amount of nickel to the tungsten carbide catalyst [13]. In the following years, higher EG yields up to 72–76 % were achieved by optimizing the preparation method of catalyst or using novel catalyst supports [15, 17, 23]. Besides tungsten carbides, the active components of catalysts were extended to tungsten phosphide [16], metallic tungsten-based binary catalysts [17, 113, 114], and tungsten oxide-based binary catalysts [26, 28, 115–118]. The cost of catalysts was greatly reduced due to the convenience in the preparation and the better reusability of catalysts without decay in the performance [28, 115]. The feedstock involved microcrystalline cellulose and raw biomass, in detail including corn stover [22], birch wood [24], miscanthus [119], concentrated glucose [116, 120], and Jerusalem artichoke [121]. The product distributions were tuned between EG, erythritol, and hexitols by varying the ratio of tungsten and hydrogenation metals [88]. Alternatively, the dominant product was altered from EG to 1,2-PG by changing the feedstock from glucose-based biomass to fructose-rich biomass such as Jerusalem artichoke [121]. On the basis of extensive studies, the reaction route and mechanism of this process were identified [17, 28, 29, 115, 122], and reaction kinetics are preliminarily modeled for the essential reactions [123–125]. All these progresses not only accumulate much valuable knowledge for academic interest but also provide a good foundation for the potential application of DLEG process in the future.

The reaction pathway and mechanism of DLEG are depicted in Fig. 9.9. Cellulose is first hydrolyzed into oligosaccharides and glucose by catalysis by Brønsted acids generated in subcritical hot water and by acid sites provided by the catalyst. The resulting glucose undergoes retro-aldol condensation (RAC) catalyzed by the tungsten species to form glycol aldehyde and eventually produce EG via hydrogenation over the metal sites of catalyst. The homogenous tungsten species (such as tungsten bronze HxWO3) are found to be uniquely active for the RAC reaction. Besides the major route for EG production, glucose isomerization happens in a minor route to form fructose, which produces 1,2-PG after a series of reactions involving RAC reaction, dehydration, rearrangement, and hydrogenation. For instance, Liu et al. employed basic active carbon as a secondary catalyst to enhance the isomerization of glucose to fructose. As a result, the product distribution was dramatically changed with 1,2-PG selectivity overwhelming that of EG (30.7 % vs. 16.6 %) in the presence of an optimal catalyst (50 %WO3/Al2O3 + Cact) [26].

The reaction network of cellulose hydrogenolysis in the presence of tungstenic binary catalysts (Reprinted with permission from Ref. [125] Copyright 2014 by the American Chemical Society)

In addition, and quite different from many previous studies in which hexitols were used as feedstock or reaction intermediates for the hydrogenolysis to form 1,2-PG and EG [55, 126–133], hexitols formation is competing with the glucose degradation in the DLEG process. The hexitols formed are found to be stable under the reaction conditions and cannot be further converted into EG and 1,2-PG [17, 115]. Accordingly, the balance between the rates of hydrogenation and RAC reaction of glucose largely determines the ratio of EG and hexitols yields [17, 29]. Apart from the activity for RAC reactions, the tungsten species can also play a role of heterogeneous acid sites for cellulose hydrolysis when they are highly dispersed on the alumina support and strongly interacting with it [26].

Besides tungstenic catalysts, some other effective binary catalysts have been developed for cellulose hydrogenolysis to EG and 1,2-PG. These catalysts include Ni/ZnO [134], Cu/CrOx-Ca(OH)2 [135], Pt–Sn/Al2O3 [136], Ni–La2O3 [32], Ru/C-NaOH [137], CuO/ZnO/Al2O3 [138], and Ru/NbOPO4 [139]. With respect to the catalytic performance, they are generally less selective to the EG formation but give remarkably higher yields of 1,2-PG in contrast to the tungstenic catalysts.

Some of amphoteric oxide-supported transition metal catalysts were also effective for the cellulose hydrogenolysis to glycols. Liu et al. investigated the catalytic performance of Ni–Sn/Al2O3 in the conversion of cellulose and obtained 53.9 % selectivity to acetol (the precursor of 1,2-PG) over a catalyst with Sn/Ni ratio of 0.5 [140]. The authors proposed that the SnOx domains catalyzed the isomerization of glucose to fructose and the C–C bond cleavage by retro-aldol condensation. In comparison with other basic sites of CeOx, ZnOx, and AlOx supported on Al2O3, the SnOx presented a larger concentration of stronger basic sites which facilitated the isomerization of glucose to fructose and its subsequent C–C bond cleavage. In a later study, the authors obtained hexitols and 1,2-PG from cellulose conversion by using a bimetallic catalyst of Pt–SnOx/Al2O3 which had enhanced hydrogenation activity as compared to the previously employed Ni–Sn/Al2O3 [136].

In another instance, amphoteric ZnO was used as a support for Ni and Ni–Cu catalysts. The overall yield of glycols (including EG, 1,2-PG, and butanediols) reached ca. 70 % [134, 141]. The authors proposed that it is the basic sites but not the acidic sites on the support surface play a critical role for the activity and selectivity of the catalysts.

Cu–Cr catalysts in the presence of Ca(OH)2 were studied for the production glycols, and 42.6 % yield of 1,2-PG and 31.6 % yield of EG were obtained with 10 % concentration of cellulose [135]. The reaction mechanism mainly involves hydrolytic hydrogenation of cellulose to hexitols and the subsequent hydrogenolysis of hexitols to 1,2-PG and EG. As shown in many other extensive studies, the basic sites and metallic dehydrogenation and hydrogenation sites play synergistic roles in polyol conversion to 1,2-PG and EG [55, 126–133].

As shown in Fig. 9.10, the first step of the reaction is sugar alcohol dehydrogenation over metallic sites to form glucose, fructose, and some other sugar isomers, followed by base-catalyzed retro-aldol condensation (RAC) to form glycolaldehyde and glyceraldehyde. After hydrogenation of the intermediates, EG, 1,2-PG, and glycerol are produced. The primary dehydrogenation step limits the rate of sugar alcohol hydrogenolysis, and the product distributions are determined by the competition between the hydrogenation steps and the RAC reaction [126]. Besides the RAC reaction accounting for the C–C bond breakage, Shanks et al. found that a decarbonylation reaction takes place and leads to the scission of the terminal C–C bond in polyol hydrogenolysis [143]. The reaction rates depended on the configuration of the polyol stereoisomers but not the carbon chain length. In addition, the primary hydroxyl groups of a polyol were more readily dehydrogenated than internal hydroxyl groups.

Reaction pathways for sorbitol conversion to EG and 1,2-PG, RAC represents retro-aldol condensation (Reprinted with permission from Ref. [142] Copyright 2010 by the Elsevier)

Different from the catalysts mentioned above, a La-based binary catalyst Ni–La2O3 presented versatile behaviors following a dual-route mechanism for EG production [32]. The main route is similar to that of tungsten-based catalysts, where cellulose is first hydrolyzed to glucose, followed by degradation to glycol aldehyde by the catalysis of La ions and hydrogenation over metallic Ni sites into EG. The other minor route is similar to that of the basic binary catalysts, such as Cu/CrOx-Ca(OH)2, where glucose is first hydrogenated to hexitols and then hydrogenolyzed to 1,2-PG and EG. The theoretical calculation showed glucose was activated by La–OH species to form a mannose complex via an epimerization reaction. The C2–C3 bond in the sugar complex was then broken through a 2,3-hydride shift reaction to form glycol aldehyde, the precursor of EG. Comparative studies showed that the E a for glucose degradation was lower than that for fructose, which could account for the higher yield of EG than 1,2-PG in the reaction. The catalyst was very efficient for cellulose hydrogenolysis even at a very low concentration of 0.2 mmol/L La (III). The highest combined yield of EG and 1,2-PG reached 63.7 %. The reaction mechanism is presented in Fig. 9.11.

Proposed reaction pathways for the conversion of cellulose to ethylene glycol and propylene glycol with the Ni-La(III) catalyst (Reprinted with permission from Ref. [32] Copyright 2014 by the American Chemical Society)

Besides cellulose hydrogenolysis in aqueous solution, Wang et al. reported their work using methanol as a solvent for cellulose hydrogenolysis [139]. The cellulose was converted to EG and ethylene glycol monoether (EGME) with an overall yield of 64 % over a Ru/NbOPO4 catalyst. The methanol was found to not only serve as a solvent for the reaction but also participated in glucose acetalization so that the C=O bond was protected for the next step reaction. The NbOPO4 promoted the cleavage of C–C bond in glucose, followed by hydrogenation by supported Ru particles to form the final EG-based products. In comparison with different dopants (W, Sn, Ni, Cu) in the catalyst, only the Ru−Ni/NbOPO4 catalyst was effective due to the suppression of further hydrogenolysis of products (EG and EGME) to CO and alkanes.

Palkovits and coworkers investigated hydrolytic hydrogenation of cellulose over a CuO/ZnO/Al2O3 catalyst at 518 K and 50 bar H2 and proposed a unified reaction mechanism according to the observed product distribution [144]. As shown in Fig. 9.12, there are many elementary transformations, including dehydration, dehydrogenation/hydrogenation, Lobry de Bruyn–van Ekenstein isomerization, and retro-aldol condensation, which play important roles in controlling the selectivity to simple polyols and carbohydrates. Besides the hydrolysis of glycosidic bond usually mentioned as the first step in the cellulose hydrogenolysis, an additional depolymerization mechanism involving only the reducing ends of cellulose and oligomers was proposed in this work. In this pathway, cellulose could directly release C2 and C4 molecules from the end of polysaccharides in the catalytic reaction. This is consistent with the results recently reported by Zhang and Wang [123]. They studied the cellobiose hydrogenolysis to EG with a tungstenic catalyst and found that cellobiose can be directly degraded to glycol aldehyde and glucosyl-erythrose via the RAC reaction prior to the hydrolysis to form glucose. But the activity of cellobiose in the RAC reaction is lower than that of glucose. In addition, the RAC reaction of cellobiose could promote the hydrolysis of cellobiose.

Depolymerization and degradation pathways of terminal glucose units in cellulose, ROH = cellulose, LBE represents Lobry de Bruyn–van Ekenstein isomerization, and RAC represents retro-aldol condensation (Reprinted with permission from Ref. [144] Copyright 2014 by John Wiley & Sons Ltd)

In summary, regardless of whether the reactants of hydrogenolysis are sugar oligomers, polysaccharides, or sugar alcohols, the sugar formation is the critical step in most of the reaction mechanisms. The C–C bond breakage takes place mainly via retro-aldol condensation through catalysis by transition metal species or bases. In addition, the degradation to monosaccharides, i.e., the direct degradation of cellulose and oligosaccharides from the reducing end sugar, also contributes to the EG and 1,2-PG formation as well as cellulose degradation. However, the relative contributions from different routes are still uncertain due to the lack of reaction kinetic data for each route.

9.3.2 Reaction Kinetics

Extensive studies have been performed in developing novel catalysts and processes for cellulose hydrolytic hydrogenolysis to polyols. However, few of them focused on the essential reaction kinetics, in particular for the formation of C2 and C3 glycols. This might be related to higher difficulty of studying reaction kinetics of cellulose hydrogenolysis to EG and 1,2-PG as compared to that of cellulose degradation to glucose and hexitols. Not only are the reaction conditions for the former usually harsher than the latter, but also more reactions are involved in this process, including retro-aldol condensation, isomerization, epimerization, hydrogenation, and condensation catalyzed by multifunctional active components in the catalysts (Fig. 9.9). One feasible strategy to obtain in-depth knowledge of the reaction kinetics is studying each elementary transformation individually and then integrating them into complete reaction kinetics on the basis of their relationship. To this end, using model reactants to replace recalcitrant solid cellulose and conducting the reactions at moderate conditions are necessary to obtain useful information. Moreover, because of the complexity of the reaction system, establishing reasonable kinetic models and making suitable presumptions and omission are required for overcoming obstacles in arriving at meaningful results.

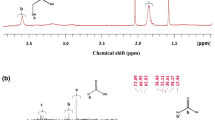

Zhang, Wang, and coworkers conducted detailed investigations on the reaction kinetics of cellulose hydrolytic hydrogenation to EG in the presence of tungsten-based binary catalysts. According to the reaction mechanism discussed above, they resolved the process of cellulose hydrogenolysis to EG into three consecutive reactions: (1) hydrolysis of cellulose to glucose, (2) retro-aldol condensation (RAC) of glucose to glycolaldehyde (GA), and (3) hydrogenation of GA to EG. As shown in Fig. 9.13, to simplify the reaction network, glucose was used as a substituted reactant for cellulose based on the consideration that glucose is the critical intermediate for the RAC reaction to form GA. Soluble ammonia metatungstate (AMT) was used as a homogeneous catalyst for the RAC reaction. Glucose isomerization reaction to fructose (accounting for 1,2-PG formation) was omitted according to the experimental results that the ratio of EG to 1,2-PG yields is very high (10:1–20:1) in the reaction. The reactions were conducted at milder temperatures of 423–503 K so that the reactant and products could be quantified more accurately.

The simplified kinetic model for glucose conversion to glycolaldehyde by catalysis of ammonium metatungstate. RAC refers to retro-aldol condensation (Reprinted with permission from Ref. [125]. Copyright 2014 by the American Chemical Society)

The Arrhenius equation obtained for the RAC reaction shows that it is a first-order reaction with respect to glucose. The activation energy E a for the RAC reaction is in the range of 141.3–148.8 kJ/mol, which is much higher than that of the sugar hydrogenation [116, 125]. This indicates that RAC is much more sensitive to the reaction temperature as compared to the sugar hydrogenation [115]. A high temperature would favor GA and EG formation. The pre-exponential coefficient was found to be as high as 5.39 × 1013, which is in good agreement with the features of a homogeneous catalytic reaction. Interestingly, the reaction order with respect to the concentration of AMT is 0.257 for the RAC reaction. This indicates that one AMT molecule might complex four molecules of glucose. At present, no characterization technique is available to identify the coordination numbers of tungsten in the sugar complex in the hot and compressed aqueous environment. Thus, the result of this kinetic study provides a valuable clue for the deeper investigations on the tungsten–sugar interactions with development of in situ measurement techniques in the future.

As the precursor of EG, GA readily undergoes side reactions, typically condensations, with a low E a of 52.7 kJ/mol and at reaction orders of 2–2.5 [116, 124]. This suggests that it is important to keep the GA concentration at a low level during the reaction so that EG can be obtained with high selectivity. Employing a semicontinuous reaction system has been proven to be a feasible way in practice, as shown in the studies of high concentration glucose conversion to EG [116, 120].

The catalytic behavior of metastable reaction intermediates was also tentatively analyzed in the kinetic study. In detail, the RAC reaction of glucose forms an equimolar amount of GA and erythrose, and the latter can be further degraded into two molecules of GA. Zhang and coworkers deduced the E a value of the erythrose RAC reaction by decoupling the dual reactions in the kinetic model equations. The obtained E a was 79.9 kJ/mol, notably lower than that of glucose RAC reaction (141.3 kJ/mol). This indicates that the C4 sugar is more reactive than glucose in the RAC reaction, which accounts for the experimental result that only a small amount of C4 polyols was formed in the reaction.

As for the kinetics study of GA hydrogenation to EG, Zhang and coworkers employed a Langmuir–Hinshelwood–Hougen–Watson (LHHW) model, which has been popularly accepted in the kinetic study of sugar hydrogenation over heterogeneous catalysts [106–108]. As elucidated in the reaction network (Fig. 9.9), the GA formation from glucose confronts a competitive reaction of glucose hydrogenation, which generates chemically stable hexitols at the expense of GA and EG production. Tables 9.3, 9.4, and 9.5 list the results of the kinetic studies. It was found that the E a values for GA and glucose hydrogenation are very similar (42.6 kJ/mol vs. 49.6 kJ/mol) over the Ru/AC catalyst. However, a detailed study disclosed that GA hydrogenation is still much favored over glucose hydrogenation due to several aspects. First, the adsorption equilibrium constant of GA (K GA) is twice as large as that of glucose (K G), suggesting that GA molecules are preferentially adsorbed on the Ru surface than glucose. Second, the rate constant of GA hydrogenation (k GA) is also twice as that of glucose (k G). Taken together, the rate of GA hydrogenation is therefore ca. four times faster than that of the glucose hydrogenation. Moreover, experimental results for the competitive hydrogenation of GA and glucose showed that the presence of GA significantly inhibited glucose hydrogenation. Glucose hydrogenation only starts to occur when GA has been almost consumed in the reaction.

Another important finding in the kinetics study is that tungsten species not only take charge of the catalysis of the RAC reaction to form GA but also impose a remarkable inhibitive effect on hydrogenation reactions over metallic Ru sites. Tungsten species strongly adsorbed on the Ru surface and poisoned the catalyst for hydrogenation, but the effect varies with reactants. The reaction order of AMT was −0.238 for GA hydrogenation and −0.691 for glucose hydrogenation, respectively. This indicates that the inhibitive effect of AMT is much more pronounced for glucose hydrogenation than GA hydrogenation. In other words, the presence of AMT further improves the priority of GA hydrogenation over glucose hydrogenation and ensures the high selectivity to EG in the reaction.

In conclusion, the reaction kinetics of the one-pot hydrogenolysis of cellulose to EG have been primarily identified by studying the kinetics of glucose conversion. Except for the first step of cellulose hydrolysis, the reaction kinetics were systematically investigated for the essentially important elemental reactions, including the RAC reaction, hydrogenation, and the side reaction of GA condensation. A series of reaction kinetics data have been obtained on the basis of the deep understanding of the reaction mechanism, rational models, and kinetics. The reaction behaviors of cellulose and sugars can be qualitatively explained or partially quantitatively predicted in terms of the kinetic results. These studies will provide valuable guidance for the design of more effective catalysts and catalytic processes with better controlled reaction selectivity.

9.4 Outlook

Catalytic hydrogenolysis of cellulose to polyols represents a green and promising process for the production of high-value commodity chemicals. In comparison with the traditional synthesis processes in petroleum industry, the biomass conversion possesses notable advantages, thanks to the renewability of feedstock, the high atom economy of the process, and the increasing economic viability conditioned by the rapid development of low-cost catalysts. After extensive investigations in the past decade, various effective catalysts have been developed and several different polyols have been obtained with high selectivity. The rules of “green chemistry” have been followed in designing the catalysts and exploring reaction processes for biomass conversion, as embodied by the convenience of reaction operation and smaller footprints of chemical processes in the environment. The reaction mechanisms for polyols formation are becoming deeply understood and some of reaction kinetics has been largely determined. However, because the cellulose hydrogenolysis is usually conducted in compressed hot water and high pressure H2, the reaction conditions are still harsh and many reactions are coupled in one pot. This greatly increases the difficulty in in situ monitoring the reaction intermediates, probing the catalytic active sites, and disclosing the reaction mechanisms at molecular levels. Future development of characterization techniques such as NMR, FTIR, Raman spectra, and HPLC would provide powerful support for such studies. In addition, more attention should be paid to the kinetic study of raw biomass conversion, by which the influence of impurities in biomass can be concurrently considered for the purpose of practical applications. With more progress in the understanding of reaction mechanism and kinetics, the process of cellulose hydrogenolysis could be better utilized for polyol production and eventually contribute to a sustainable bio-economy.

References

Delidovich I, Leonhardb K, Palkovits R (2014) Cellulose and hemicellulose valorisation: an integrated challenge of catalysis and reaction engineering. Energy Environ Sci 7:2803–2830

Chatterjee C, Pong F, Sen A (2014) Chemical conversion pathways for carbohydrates. Green Chem 17(1):40–71

Liu X, Wang X, Yao S, Jiang Y, Guan J, Mu X (2014) Recent advances in the production of polyols from lignocellulosic biomass and biomass-derived compounds. RSC Adv 4:49501–49520

Ruppert AM, Weinberg K, Palkovits R (2012) Hydrogenolysis goes bio: from carbohydrates and sugar alcohols to platform chemicals. Angew Chem Int Ed 51(11):2564–2601

Gallezot P (2012) Conversion of biomass to selected chemical products. Chem Soc Rev 41(4):1538–1558

Climent MJ, Corma A, Iborra S (2011) Converting carbohydrates to bulk chemicals and fine chemicals over heterogeneous catalysts. Green Chem 13(3):520–540

Improvements in or relating to the manufacture of glycerol and glycols (1933). Du Pont Patent GB19330035971

Method of converting aliphatic polyhydric alcohols to alcohols of lower molecular weight (1937). Ass of American Soap And Glyce Patent GB19370003458

Fukuoka A, Dhepe PL (2006) Catalytic conversion of cellulose into sugar alcohols. Angew Chem Int Ed 45(31):5161–5163

Rinaldi R, Schüth F (2009) Design of solid catalysts for the conversion of biomass. Energy Environ Sci 2(6):610–626

Dhepe PL, Fukuoka A (2008) Cellulose conversion under heterogeneous catalysis. ChemSusChem 1(12):969–975

Luo C, Wang S, Liu H (2007) Cellulose conversion into polyols catalyzed by reversibly formed acids and supported ruthenium clusters in hot water. Angew Chem Int Ed 46(40):7636–7639

Ji N, Zhang T, Zheng M, Wang A, Wang H, Wang X, Chen JG (2008) Direct catalytic conversion of cellulose into ethylene glycol using nickel-promoted tungsten carbide catalysts. Angew Chem Int Ed 47(44):8510–8513

Ding L, Wang A, Zheng M, Zhang T (2010) Selective transformation of cellulose into sorbitol by using a bifunctional nickel phosphide catalyst. ChemSusChem 3(7):818–821

Zhang Y, Wang A, Zhang T (2010) A new 3D mesoporous carbon replicated from commercial silica as a catalyst support for direct conversion of cellulose into ethylene glycol. Chem Commun 46(6):862–864

Zhao G, Zheng M, Wang A, Zhang T (2010) Catalytic conversion of cellulose to ethylene glycol over tungsten phosphide catalysts. Chin J Catal 31(8):928–932

Zheng M, Wang A, Ji N, Pang J, Wang X, Zhang T (2010) Transition metal-tungsten bimetallic catalysts for the conversion of cellulose into ethylene glycol. ChemSusChem 3(1):63–66

Geboers J, Van de Vyver S, Carpentier K, Jacobs P, Sels B (2011) Hydrolytic hydrogenation of cellulose with hydrotreated caesium salts of heteropoly acids and Ru/C. Green Chem 13(8):2167–2174

Kobayashi H, Ito Y, Komanoya T, Hosaka Y, Dhepe PL, Kasai K, Hara K, Fukuoka A (2011) Synthesis of sugar alcohols by hydrolytic hydrogenation of cellulose over supported metal catalysts. Green Chem 13(2):326–333

Kobayashi H, Matsuhashi H, Komanoya T, Hara K, Fukuoka A (2011) Transfer hydrogenation of cellulose to sugar alcohols over supported ruthenium catalysts. Chem Commun 47(8):2366–2368

Liu M, Deng W, Zhang Q, Wang Y (2011) Polyoxometalate-supported ruthenium nanoparticles as bifunctional heterogeneous catalysts for the conversions of cellobiose and cellulose into sorbitol under mild conditions. Chem Commun 47(34):9717–9719

Pang J, Zheng M, Wang A, Zhang T (2011) Catalytic hydrogenation of corn stalk to ethylene glycol and 1,2-propylene glycol. Ind Eng Chem Res 50(11):6601–6608

Ji N, Zheng M, Wang A, Zhang T, Chen JG (2012) Nickel-promoted tungsten carbide catalysts for cellulose conversion: effect of preparation methods. ChemSusChem 5(5):939–944

Li C, Zheng M, Wang A, Zhang T (2012) One-pot catalytic hydrocracking of raw woody biomass into chemicals over supported carbide catalysts: simultaneous conversion of cellulose, hemicellulose and lignin. Energy Environ Sci 5(4):6383–6390

Liang G, Cheng H, Li W, He L, Yu Y, Zhao F (2012) Selective conversion of microcrystalline cellulose into hexitols on nickel particles encapsulated within ZSM-5 zeolite. Green Chem 14(8):2146–2149

Liu Y, Luo C, Liu H (2012) Tungsten trioxide promoted selective conversion of cellulose into propylene glycol and ethylene glycol on a ruthenium catalyst. Angew Chem Int Ed 51(13):3249–3253

Pang J, Wang A, Zheng M, Zhang Y, Huang Y, Chen X, Zhang T (2012) Catalytic conversion of cellulose to hexitols with mesoporous carbon supported Ni-based bimetallic catalysts. Green Chem 14(3):614–617

Tai Z, Zhang J, Wang A, Zheng M, Zhang T (2012) Temperature-controlled phase-transfer catalysis for ethylene glycol production from cellulose. Chem Commun 48(56):7052–7054

Wang A, Zhang T (2013) One-pot conversion of cellulose to ethylene glycol with multifunctional tungsten-based catalysts. Acc Chem Res 46(7):1377–1386

Zhang J, Li J, Wu S, Liu Y (2013) Advances in the catalytic production and utilization of sorbitol. Ind Eng Chem Res 52(34):11799–11815

Liu Q, Liao Y, Wang T, Cai C, Zhang Q, Tsubaki N, Ma L (2014) One-pot transformation of cellulose to sugar alcohols over acidic metal phosphates combined with Ru/C. Ind Eng Chem Res 53(32):12655–12664

Sun R, Wang T, Zheng M, Deng W, Pang J, Wang A, Wang X, Zhang T (2014) Versatile Nickel–Lanthanum(III) catalyst for direct conversion of cellulose to glycols. ACS Catal 5(2):874–883

Pang J, Zheng M, Sun R, Song L, Wang A, Wang X, Zhang T (2015) Catalytic conversion of cellulosic biomass to ethylene glycol: effects of inorganic impurities in biomass. Bioresour Technol 175:424–429

Deng W, Wang Y, Zhang Q, Wang Y (2012) Development of bifunctional catalysts for the conversions of cellulose or cellobiose into polyols and organic acids in water. Catal Surv Asia 16(2):91–105

Kobayashi H, Komanoya T, Hara K, Fukuoka A (2010) Water-tolerant mesoporous-carbon-supported ruthenium catalysts for the hydrolysis of cellulose to glucose. ChemSusChem 3(4):440–443

Komanoya T, Kobayashi H, Hara K, Chun WJ, Fukuoka A (2014) Kinetic study of catalytic conversion of cellulose to sugar alcohols under low-pressure hydrogen. ChemCatChem 6(1):230–236

Shrotri A, Tanksale A, Beltramini JN, Gurav H, Chilukuri SV (2012) Conversion of cellulose to polyols over promoted nickel catalysts. Catal Sci Technol 2(9):1852

Käldström M, Kumar N, Tenho M, Mokeev MV, Moskalenko YE, Murzin DY (2012) Catalytic transformations of birch kraft pulp. ACS Catal 2(7):1381–1393

Han JW, Lee H (2012) Direct conversion of cellulose into sorbitol using dual-functionalized catalysts in neutral aqueous solution. Catal Commun 19:115–118

Wu Z, Ge S, Ren C, Zhang M, Yip A, Xu C (2012) Selective conversion of cellulose into bulk chemicals over Brønsted acid-promoted ruthenium catalyst: one-pot vs. sequential process. Green Chem 14(12):3336–3343

Zhu W, Yang H, Chen J, Chen C, Guo L, Gan H, Zhao X, Hou Z (2014) Efficient hydrogenolysis of cellulose into sorbitol catalyzed by a bifunctional catalyst. Green Chem 16(3):1534–1542

Niu Y, Wang H, Zhu X, Song Z, Xie X, Liu X, Han J, Ge Q (2014) Ru supported on zirconia-modified SBA-15 for selective conversion of cellobiose to hexitols. Microporous Mesoporous Mater 198:215–222

Liao Y, Liu Q, Wang T, Long J, Ma L, Zhang Q (2014) Zirconium phosphate combined with Ru/C as a highly efficient catalyst for the direct transformation of cellulose to C6 alditols. Green Chem 16(6):3305–3312

Chen J, Wang S, Huang J, Chen L, Ma L, Huang X (2013) Conversion of cellulose and cellobiose into sorbitol catalyzed by ruthenium supported on a polyoxometalate/metal-organic framework hybrid. ChemSusChem 6(8):1545–1555

Xi J, Zhang Y, Xia Q, Liu X, Ren J, Lu G, Wang Y (2013) Direct conversion of cellulose into sorbitol with high yield by a novel mesoporous niobium phosphate supported Ruthenium bifunctional catalyst. Appl Catal A Gen 459:52–58

Roman-Leshkov Y, Moliner M, Labinger JA, Davis ME (2010) Mechanism of glucose isomerization using a solid Lewis acid catalyst in water. Angew Chem Int Ed 49(47):8954–8957

Van de Vyver S, Geboers J, Dusselier M, Schepers H, Vosch T, Zhang L, Van Tendeloo G, Jacobs PA, Sels BF (2010) Selective bifunctional catalytic conversion of cellulose over reshaped Ni particles at the tip of carbon nanofibers. ChemSusChem 3(6):698–701

Van de Vyver S, Geboers J, Schutyser W, Dusselier M, Eloy P, Dornez E, Seo JW, Courtin CM, Gaigneaux EM, Jacobs PA, Sels BF (2012) Tuning the acid/metal balance of carbon nanofiber-supported nickel catalysts for hydrolytic hydrogenation of cellulose. ChemSusChem 5(8):1549–1558

Park DS, Yun D, Kim TY, Baek J, Yun YS, Yi J (2013) A mesoporous carbon-supported Pt nanocatalyst for the conversion of lignocellulose to sugar alcohols. ChemSusChem 6(12):2281–2289

Wang H, Zhu L, Peng S, Peng F, Yu H, Yang J (2012) High efficient conversion of cellulose to polyols with Ru/CNTs as catalyst. Renew Energy 37(1):192–196

Gazit OM, Katz A (2013) Understanding the role of defect sites in glucan hydrolysis on surfaces. J Am Chem Soc 135(11):4398–4402

Onda A, Ochi T, Yanagisawa K (2008) Selective hydrolysis of cellulose into glucose over solid acid catalysts. Green Chem 10(10):1033–1037

Suganuma S, Nakajima K, Kitano M, Yamaguchi D, Kato H, Hayashi S, Hara M (2008) Hydrolysis of cellulose by amorphous carbon bearing SO3H, COOH, and OH groups. J Am Chem Soc 130(38):12787–12793

Pang J, Wang A, Zheng M, Zhang T (2010) Hydrolysis of cellulose into glucose over carbons sulfonated at elevated temperatures. Chem Commun 46(37):6935–6937

Liang G, He L, Cheng H, Li W, Li X, Zhang C, Yu Y, Zhao F (2014) The hydrogenation/dehydrogenation activity of supported Ni catalysts and their effect on hexitols selectivity in hydrolytic hydrogenation of cellulose. J Catal 309:468–476

Kobayashi H, Hosaka Y, Hara K, Feng B, Hirosaki Y, Fukuoka A (2014) Control of selectivity, activity and durability of simple supported nickel catalysts for hydrolytic hydrogenation of cellulose. Green Chem 16(2):637

Liang G, He L, Arai M, Zhao F (2014) The Pt-enriched PtNi alloy surface and its excellent catalytic performance in hydrolytic hydrogenation of cellulose. ChemSusChem 7(5):1415–1421

Yang P, Kobayashi H, Hara K, Fukuoka A (2012) Phase change of nickel phosphide catalysts in the conversion of cellulose into sorbitol. ChemSusChem 5(5):920–926

Rinaldi R, Schuth F (2009) Acid hydrolysis of cellulose as the entry point into biorefinery schemes. ChemSusChem 2(12):1096–1107

Rinaldi R, Palkovits R, Schüth F (2008) Depolymerization of cellulose using solid catalysts in Ionic Liquids. Angew Chem Int Ed 47(42):8047–8050

Cai H, Li C, Wang A, Xu G, Zhang T (2012) Zeolite-promoted hydrolysis of cellulose in ionic liquid, insight into the mutual behavior of zeolite, cellulose and ionic liquid. Appl Catal B Environ 123:333–338

Palkovits R, Tajvidi K, Ruppert AM, Procelewska J (2011) Heteropoly acids as efficient acid catalysts in the one-step conversion of cellulose to sugar alcohols. Chem Commun 47(1):576–578

Geboers J, Van de Vyver S, Carpentier K, de Blochouse K, Jacobs P, Sels B (2010) Efficient catalytic conversion of concentrated cellulose feeds to hexitols with heteropoly acids and Ru on carbon. Chem Commun 46(20):3577–3579

Palkovits R, Tajvidi K, Procelewska J, Rinaldi R, Ruppert A (2010) Hydrogenolysis of cellulose combining mineral acids and hydrogenation catalysts. Green Chem 12(6):972–978

Hilgert J, Meine N, Rinaldi R, Schüth F (2013) Mechanocatalytic depolymerization of cellulose combined with hydrogenolysis as a highly efficient pathway to sugar alcohols. Energy Environ Sci 6(1):92–96

Shrotri A, Kobayashi H, Tanksale A, Fukuoka A, Beltramini J (2014) Transfer hydrogenation of cellulose-based oligomers over carbon-supported Ruthenium catalyst in a fixed-bed reactor. ChemCatChem 6:1349–1356

Li J, Liu L, Liu Y, Li M, Zhu Y, Liu H, Kou Y, Zhang J, Han Y, Ma D (2014) Direct conversion of cellulose using carbon monoxide and water on a Pt–Mo2C–C catalyst. Energy Environ Sci 7(1):393–398

Saeman JF (1945) Kinetics of wood saccharification hydrolysis of cellulose and decomposition of sugars in dilute acid at high temperature. Ind Eng Chem Res 37(1):43–52

Amarasekara AS, Wiredu B (2012) Aryl sulfonic acid catalyzed hydrolysis of cellulose in water. Appl Catal A Gen 417–418:259–262

Stephens CH, Whitmore PM, Morris HR, Bier ME (2008) Hydrolysis of the amorphous cellulose in cotton-based paper. Biomacromolecules 9:1093–1099

Tolonen LK, Zuckerstatter G, Penttila PA, Milacher W, Habicht W, Serimaa R, Kruse A, Sixta H (2011) Structural changes in microcrystalline cellulose in subcritical water treatment. Biomacromolecules 12(7):2544–2551

Adel AM, Abd El-Wahab ZH, Ibrahim AA, Al-Shemy MT (2010) Characterization of microcrystalline cellulose prepared from lignocellulosic materials. Part I. Acid catalyzed hydrolysis. Bioresour Technol 101(12):4446–4455

Al-Zuhair S (2008) The effect of crystallinity of cellulose on the rate of reducing sugars production by heterogeneous enzymatic hydrolysis. Bioresour Technol 99(10):4078–4085

Ni J, Wang H, Chen Y, She Z, Na H, Zhu J (2013) A novel facile two-step method for producing glucose from cellulose. Bioresour Technol 137:106–110

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83:1–11

Abdul KHP, Davoudpour Y, Islam MN, Mustapha A, Sudesh K, Dungani R, Jawaid M (2014) Production and modification of nanofibrillated cellulose using various mechanical processes: a review. Carbohydr Polym 99:649–665

Adel AM, Abd El-Wahab ZH, Ibrahim AA, Al-Shemy MT (2011) Characterization of microcrystalline cellulose prepared from lignocellulosic materials. Part II: Physicochemical properties. Carbohydr Polym 83(2):676–687

Guo J, Catchmark JM (2012) Surface area and porosity of acid hydrolyzed cellulose nanowhiskers and cellulose produced by Gluconacetobacter xylinus. Carbohydr Polym 87(2):1026–1037

Testova L, Nieminen K, Penttila PA, Serimaa R, Potthast A, Sixta H (2014) Cellulose degradation in alkaline media upon acidic pretreatment and stabilisation. Carbohydr Polym 100:185–194

Zhang J, Wu S, Li B, Zhang H (2012) Direct conversion of cellobiose into sorbitol and catalyst deactivation mechanism. Catal Commun 29:180–184

Gazit OM, Charmot A, Katz A (2011) Grafted cellulose strands on the surface of silica: effect of environment on reactivity. Chem Commun 47(1):376–378

Vilcocq L, Castilho PC, Carvalheiro F, Duarte LC (2014) Hydrolysis of oligosaccharides over solid acid catalysts: a review. ChemSusChem 7(4):1010–1019

Wuttke S, Negoi A, Gheorghe N, Kuncser V, Kemnitz E, Parvulescu V, Coman SM (2012) Sn-doped hydroxylated MgF(2) catalysts for the fast and selective saccharification of cellulose to glucose. ChemSusChem 5(9):1708–1711

Zakzeski J, Grisel RJ, Smit AT, Weckhuysen BM (2012) Solid acid-catalyzed cellulose hydrolysis monitored by in situ ATR-IR spectroscopy. ChemSusChem 5(2):430–437

Huang Y, Fu Y (2013) Hydrolysis of cellulose to glucose by solid acid catalysts. Green Chem 15(5):1095–1111

Kunov-Kruse AJ, Riisager A, Saravanamurugan S, Berg RW, Kristensen SB, Fehrmann R (2013) Revisiting the Brønsted acid catalysed hydrolysis kinetics of polymeric carbohydrates in ionic liquids by in situ ATR-FTIR spectroscopy. Green Chem 15(10):2843–2848

Mohd SZ, Yu Y, Wu H (2014) Insights into the primary decomposition mechanism of cellobiose under hydrothermal conditions. Ind Eng Chem Res 53(38):14607–14616

SriBala G, Vinu R (2014) Unified kinetic model for cellulose deconstruction via acid hydrolysis. Ind Eng Chem Res 53(21):8714–8725

Yu Y, Shafie ZM, Wu H (2013) Cellobiose decomposition in hot-compressed water: importance of isomerization reactions. Ind Eng Chem Res 52(47):17006–17014

Chundawat SP, Bellesia G, Uppugundla N, da Costa Sousa L, Gao D, Cheh AM, Agarwal UP, Bianchetti CM, Phillips GN Jr, Langan P, Balan V, Gnanakaran S, Dale BE (2011) Restructuring the crystalline cellulose hydrogen bond network enhances its depolymerization rate. J Am Chem Soc 133(29):11163–11174

Cantero DA, Bermejo MD, Cocero MJ (2013) Kinetic analysis of cellulose depolymerization reactions in near critical water. J Supercrit Fluids 75:48–57

Rogalinski T, Ingram T, Brunner G (2008) Hydrolysis of lignocellulosic biomass in water under elevated temperatures and pressures. J Supercrit Fluids 47(1):54–63

Rogalinski T, Liu K, Albrecht T, Brunner G (2008) Hydrolysis kinetics of biopolymers in subcritical water. J Supercrit Fluids 46(3):335–341

Schacht C, Zetzl C, Brunner G (2008) From plant materials to ethanol by means of supercritical fluid technology. J Supercrit Fluids 46(3):299–321

Abdullah R, Ueda K, Saka S (2014) Hydrothermal decomposition of various crystalline celluloses as treated by semi-flow hot-compressed water. J Wood Sci 60(4):278–286

Higgins HG, Goldsmith V, McKenzie AW (1958) The reactivity of cellulose. IV. The activation energy for heterogeneous acid hydrolysis. J Polym Sci 32(124):247–252

Xu C, Pranovich A, Vahasalo L, Hemming J, Holmbom B, Schols HA, Willfor S (2008) Kinetics of acid hydrolysis of water-soluble spruce o-acetyl galactoglucomannans. J Agric Food Chem 56(7):2429–2435

Carniti P, Gervasini A, Marzo M (2010) Silica-niobia oxides as viable acid catalysts in water: effective vs. intrinsic acidity. Catal Today 152(1–4):42–47

Lee YY, Iyer P, Torget RW (1999) Dilute-acid hydrolysis of lignocellulosic biomass. Adv Biochem Eng Biotechnol 65:93–115

Abatzoglou N, Bouchard J, Chornet E, Overend RP (1986) Dilute acid depolymerization of cellulose in aqueous phase: experimental. Can J Chem Eng 64(5):781–786

Vanoye L, Fanselow M, Holbrey JD, Atkins MP, Seddon KR (2009) Kinetic model for the hydrolysis of lignocellulosic biomass in the ionic liquid, 1-ethyl-3-methyl-imidazolium chloride. Green Chem 11(3):390–396

Rinaldi R, Meine N, vom Stein J, Palkovits R, Schüth F (2010) Which controls the depolymerization of cellulose in ionic liquids: the solid acid catalyst or cellulose? ChemSusChem 3(2):266–276

Shuai L, Pan X (2012) Hydrolysis of cellulose by cellulase-mimetic solid catalyst. Energy Environ Sci 5(5):6889–6894

Kitano M, Yamaguchi D, Suganuma S, Nakajima K, Kato H, Hayashi S, Hara M (2009) Adsorption-enhanced hydrolysis of beta-1,4-Glucan on graphene-based amorphous carbon bearing SO3H, COOH, and OH groups. Langmuir 25(9):5068–5075

Gallezot P, Nicolaus N, Fleche G, Fuertes P, Perrard A (1998) Glucose hydrogenation on ruthenium catalysts in a trickle-bed reactor. J Catal 180:51–55

Wisniak J, Simon R (1979) Hydrogenation of glucose, fructose, and their mixtures. Ind Eng Chem Prod Res Dev 18(1):50–57

Brahme PH, Doralswamy LK (1976) Modelling of a slurry reaction. Hydrogenation of glucose on Raney nickel. Ind Eng Chem Process Des Dev 15(1):130–137

Crezee E, Hoffer BW, Berger RJ, Makkee M, Kapteijn F, Moulijn JA (2003) Three-phase hydrogenation of D-glucose over a carbon supported ruthenium catalyst—mass transfer and kinetics. Appl Catal A Gen 251(1):1–17

Hoffer B (2003) The role of the active phase of Raney-type Ni catalysts in the selective hydrogenation of D-glucose to D-sorbitol. Appl Catal A Gen 253(2):437–452

McManus JR, Salciccioli M, Yu W, Vlachos DG, Chen JG, Vohs JM (2012) Correlating the surface chemistry of C2 and C3 aldoses with a C6 sugar: reaction of glucose, glyceraldehyde, and glycolaldehyde on Pd(111). J Phys Chem C 116(35):18891–18898

Dechamp N, Gamez A, Perrard A, Gallezot P (1995) Kinetics of glucose hydrogenation in a trickle-bed reactor. Catal Today 24:29–34

Negahdar L, Oltmanns JU, Palkovits S, Palkovits R (2014) Kinetic investigation of the catalytic conversion of cellobiose to sorbitol. Appl Catal B Environ 147:677–683

You SJ, Baek IG, Park ED (2013) Hydrogenolysis of cellulose into polyols over Ni/W/SiO2 catalysts. Appl Catal A Gen 466:161–168

Fabičovicová K, Malter O, Lucas M, Claus P (2014) Hydrogenolysis of cellulose to valuable chemicals over activated carbon supported mono- and bimetallic nickel/tungsten catalysts. Green Chem 16(7):3580–3588

Tai Z, Zhang J, Wang A, Pang J, Zheng M, Zhang T (2013) Catalytic conversion of cellulose to ethylene glycol over a low-cost binary catalyst of Raney Ni and tungstic acid. ChemSusChem 6(4):652–658

Zhao G, Zheng M, Zhang J, Wang A, Zhang T (2013) Catalytic conversion of concentrated glucose to ethylene glycol with semicontinuous reaction system. Ind Eng Chem Res 52(28):9566–9572

Cao Y, Wang J, Kang M, Zhu Y (2014) Efficient synthesis of ethylene glycol from cellulose over Ni–WO3/SBA-15 catalysts. J Mol Catal A Chem 381:46–53

Chambon F, Rataboul F, Pinel C, Cabiac A, Guillon E, Essayem N (2013) Cellulose conversion with tungstated-alumina-based catalysts: influence of the presence of platinum and mechanistic studies. ChemSusChem 6(3):500–507

Pang J, Zheng M, Wang A, Sun R, Wang H, Jiang Y, Zhang T (2014) Catalytic conversion of concentrated miscanthus in water for ethylene glycol production. AlChE J 60(6):2254–2262

Ooms R, Dusselier M, Geboers JA, Beeck BO, Verhaeven R, Gobechiya E, Martens JA, Redl A, Sels BF (2014) Conversion of sugars to ethylene glycol with nickel tungsten carbide in a fed-batch reactor: high productivity and reaction network elucidation. Green Chem 16(2):695–707