Abstract

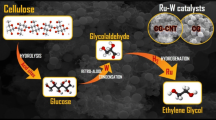

The efficient utilization of renewable lignocellulosic biomass has attracted much attention in recent years. One of the most desirable routes for the transformation of cellulose, the main component of lignocellulosic biomass, is to convert cellulose under mild conditions selectively into a value-added chemical or into a platform compound, which can be easily converted to versatile chemicals or fuels in the subsequent step. The activation of cellulose, typically starting by the cleavage of its glycosidic bonds, under mild conditions and the selective formation of a particular molecule are critical challenges. Bifunctional catalysts coupling the acid sites for the activation of the glycosidic bonds via hydrolysis and the metal nanoparticles for the hydrogenation or oxidation of glucose intermediate have shown promising performances for the conversion of cellulose or cellobiose into hexitols or gluconic acid in water under mild conditions. This short review has summarized some recent studies on the development of such bifunctional catalysts or catalytic systems. The following two kinds of bifunctional catalysts or catalytic systems have mainly been discussed: (1) a liquid acid in combination with a supported metal catalyst, (2) solid acid-supported metal nanoparticles. Emphases have been laid on the conversions of cellulose or cellobiose into sorbitol and gluconic acid catalyzed respectively by ruthenium and gold nanoparticles loaded on carbon nanotubes bearing acid sites.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The depletion of fossil resources (particularly petroleum), which are mainly supporting the current energy and chemical industries, has greatly stimulated the research into developing efficient routes for the utilization of renewable biomass resources [1–9]. Moreover, the use of biomass may have the possibility of reducing the emission of CO2, and thus contributes to establishing the “lower carbon society”, because the CO2 released from the chemical processes will be captured in the growth of biomass through photosynthesis [3]. The Roadmap for Biomass Technologies in the US predicted that about 25 % of chemicals and about 20 % of transportation fuel will be produced from biomass by 2030 [3]. Similarly, the European Technology Platform for Sustainable Chemistry estimated that up to 30 % raw materials for chemical industry will be produced from biomass by 2025 [7]. Although it is still in dispute whether the production of biofuel from plants is worthwhile, there is no discrepancy for the use of biomass for the production of chemicals [10].

Among various biomass resources, lignocellulosic biomass is the most abundant and is non-edible, and thus is expected to be a promising alternative for sustainable production of chemicals [11, 12]. Typically, lignocellulosic biomass is composed of 40–50 % cellulose, 20–40 % hemicellulose and 20–30 % lignin. It is clear that the transformation of cellulose, the major component of lignocellulosic biomass, to chemicals is essential for establishing the sustainable production of chemicals. Although the processes for the high-temperature gasification and pyrolysis of cellulose producing synthesis gas (H2 + CO), which can be used for methanol synthesis or Fischer–Tropsch synthesis, are relatively mature, these processes surfer from the problems of high energy input and low selectivity [6]. Undoubtedly, a mild-temperature and highly selective catalytic route is more desirable. The catalytic transformations of cellulose under mild conditions have become a hot research area in recent years, and there exist some excellent review papers in this area [13–25].

Structurally, cellulose is a crystalline polymer of d-glucose linked by β-1,4-glycosidic bonds (Fig. 1). The repeated glucose units define the degree of polymerization (DP) of cellulose. Depending on the origin and the pretreatment of the raw lignocellulosic biomass, the DP of cellulose may vary from 100 to 15,000. The oligosaccharides with DP from 2 to 6 are soluble in water, and those from 7 to 13 or larger are soluble in hot water at least to some extent. The structure and property of the polysaccharides with DP larger than 30 become similar to cellulose [26]. Meanwhile, because of the huge amounts of hydroxyl groups in cellulose, there exist extensive intra- and inter-molecular hydrogen bonding networks, which make the crystalline structure of cellulose robust [26]. The attack of the β-1,4-glycosic bonds in cellulose by catalytic sites is much more difficult than the α-1,4-glycosidic bonds in starch, which adopts a helical structure [13–15]. Microcrystalline cellulose is insoluble in water and in most organic solvents at mild temperatures. All these facts have caused difficulties in efficient activation of cellulose under mild conditions. Moreover, there are various kinds of C–C and C–O bonds in cellulose macromolecules. The selective cleavage of particular C–C or C–O bonds to produce a particular compound is also a difficult challenge.

It is known that cellulase enzymes function for the hydrolysis of cellulose to glucose in aqueous medium under mild conditions [26]. However, the enzymatic hydrolysis is a high-cost process and is impractical for large-scale production of glucose. Mineral acids, particularly H2SO4, are also known to catalyze the hydrolysis of cellulose to glucose. In this reaction, the β-1,4-glycosidic bonds in cellulose are selectively activated by the Brønsted acids in aqueous medium. Although relatively high yields (30–70 %) of glucose can be achieved using concentrated H2SO4, the handling of concentrated H2SO4 and the corrosion problem significantly increase the cost of the process. The hydrolysis of cellulose with dilute mineral acids (<1 %) is more feasible at a commercial scale. However, high temperatures (typically >473 K) are required for efficient conversions of cellulose when dilute acids are used [27, 28]. Further degradations of glucose occur facilely under such circumstances, leading to lower selectivity and yield of glucose.

Keggin-type heteropolyacids have also been studied for the hydrolysis of cellulose. Shimizu et al. [29] found that for the conversion of cellulose or cellobiose, the yield of glucose in aqueous medium at 423 K increased in the order of H3PW12O40 > H4SiW12O40 > HClO4 > H2SO4 > H3PO4, which could be correlated with the deprotonation enthalpy of these acids. Highly negatively charged heteropolyacids, H5BW12O40 and H5AlW12O40 with stronger Brønsted acidity exhibited better activity for the hydrolysis of cellulose [30]. Our studies revealed that heteropolyacids could also catalyze the conversion of cellulose in methanol or ethanol to methyl or ethyl glucosides [31, 32].

Many studies have been devoted to developing solid acid catalysts for the hydrolysis of cellulose to glucose [22–24]. Among these catalysts, carbon materials bearing SO3H groups [33–38], sulfonated resins [39] and layered metal oxides [40] have attracted particular attention. Excellent performances for the formation of glucose have been observed by using solid materials possessing SO3H groups. However, the stability of these materials may be problematic because of the leaching of SO3H groups in water medium at high temperatures (≥423 K) used for the conversion of cellulose. On the other hand, the layered metal oxides only exhibited very low yield of glucose [40].

Besides glucose, polyols and organic acids are also versatile building block chemicals for the production of various chemicals [7]. For the direct conversion of cellulose into polyols or organic acids, a bifunctional or multifunctional catalyst or catalytic system is required. The bifunctional catalyst can not only perform cascade reactions or multi-step conversions in one pot but may also increase the overall efficiency or the product selectivity. The concepts of coupling different active sites have recently attracted much attention because of their potentials in many difficult and complicated transformations. Several kinds of synergistic effects can be expected by coupling two different kinds of active sites or two reactions (Fig. 2) [41]. For example, the coupling at the level of active sites may decrease the energy of the transition state, and thus increase the reaction rate (Fig. 2a). The coupling of a thermodynamically favorable reaction (the second-step reaction) with a reaction forming a reactive product (the first-step reaction) can increase the yield of the overall reaction (Fig. 2b). Even if the first-step reaction is thermodynamically favorable, the selectivity can be improved if the second-step reaction leads to a thermodynamically or kinetically more stable product (Fig. 2c, d).

This article will describe some recent research results for the development of bifunctional catalysts or catalytic systems efficient for hydrolysis–hydrogenation and hydrolysis–oxidation of cellulose or cellobiose into hexitols and gluconic acid. Key factors influencing the catalytic behaviors will be analyzed to provide insights for rational design of more active and selective catalysts for cellulose transformations. Possible reaction mechanisms will also be discussed with an aim to understand deeply the conversion process of cellulose.

2 Hydrolysis–Hydrogenation of Cellulose or Cellobiose into Hexitols

2.1 Efficient Catalysts or Catalytic Systems for the Conversion of Cellulose or Cellobiose into Hexitols

Figure 3 shows the reaction scheme for the conversions of cellulose and cellobiose into sorbitol in water medium in the presence of H2 via the hydrolysis–hydrogenation process. Sorbitol is an important chemical widely used in food and pharmaceutical industries as a sweetener. It can be used as a platform chemical for the synthesis of various value-added chemicals such as isosorbide, 1,4-sorbitan, glycerol, glycols, lactic acid and l-sorbose, which is a precursor of vitamin C [7, 13]. Sorbitol may also be exploited for the production of H2 and liquid alkane fuels [42–44].

The groups of Kou [45], Fukuoka [46] and Liu [47] performed pioneering work on the conversion of cellobiose or cellulose into sorbitol 5–6 years ago. Kou and co-workers [45] demonstrated that poly(N-vinyl-2-pyrrolidone) (PVP) stabilized Ru nanoclusters with sizes of 2.4 ± 0.4 nm could efficiently catalyze the conversion of cellobiose into sorbitol in H2 in aqueous solution with pH controlled. Selective conversion of cellobiose into sorbitol was observed only under acidic conditions (pH 2), whereas under neutral or basic conditions (pH 7 or 10), the selectivity of sorbitol became significantly lower. This clearly points out the importance of the combination of acidity of the catalytic system and Ru nanoclusters, which function for hydrogenation.

Fukuoka and Dhepe [46] reported that sorbitol with a yield of 25 % could be obtained from the direct transformation of cellulose over a Pt/γ-Al2O3 catalyst in water medium in the presence of H2 (5 MPa) at 463 K for 24 h. Mannitol, another hexitol, was also formed with a yield of 6 %. They compared the catalytic performances of Pt catalysts supported on different supports including metal oxides such as SiO2, γ-Al2O3, TiO2 and ZrO2, zeolites and mesoporous materials. γ-Al2O3, H-USY zeolite and SiO2–Al2O3 were found to provide higher yields of hexitols (25–30 %). It was speculated that the acidity of the support might play a role in the formation of sorbitol, but the activity seemed not correspond well to the apparent strength of acidity.

It is known that the ionization constant of water changes with temperature and becomes three times higher at 523 K than that at room temperature [48]. The enhanced ability of hot water to produce more H3O+ and OH− may allow hot water to function as acid or base catalysts [48, 49]. Actually, Eckert and co-workers [49] showed that the hot water at 473 K displayed in situ acid effect, accelerating the hydrolysis of β-pinene. Using this unique feature of hot water, Liu and co-workers [47] designed an intriguing bifunctional system by combining the reversibly generated H3O+ with an activated carbon-supported ruthenium (Ru/C) catalyst. They found that the conversion of cellulose increased sharply from 5.6 to 83 % with an increase in reaction temperature from 478 to 533 K, in consistent with the higher concentration of H3O+ at higher temperature. The main products were hexitols, the selectivity of which showed a maximum at around 513 K. A yield of hexitols of 39.3 % (sorbitol: 34.6 %) could be achieved for the conversion of microcrystalline cellulose at 518 K under H2 pressure of 6 MPa. It was demonstrated that the use of other solvents such as ethanol and dioxane instead of water caused no conversion of cellulose under the same reaction conditions, confirming the importance of in situ generated H3O+ in hot water. The supercritical or near-supercritical water was also effective for the conversion of cellulose in the absence of any added catalyst [50, 51], but the reaction conditions were much more strict (pressure > 23 MPa, temperature > 573 K) and the selectivity to a particular product was lower.

The work by Liu and co-workers [47] is quite interesting because of the use of hot water as acid catalyst. However, reaction temperatures higher than 500 K are required for obtaining a reasonable yield of hexitols due to the limit of acidity of water at lower temperatures. Some subsequent studies demonstrated that the combination of dilute liquid mineral acids such as H2SO4 and HCl with a solid hydrogenation catalyst, typically supported noble metal, can efficiently catalyze the conversion of cellulose to hexitols at mild temperatures (<473 K). For example, Palkovits et al. [52] found that the combination of 0.5 or 2.5 % H3PO4 or H2SO4 with Pt, Pd and Ru catalysts loaded on carbon catalyzed the conversion of cellulose to hexitols at 433 K. Up to 60 % yield of sugars and sugar alcohols could be achieved in the presence of 2.5 % H2SO4 and 5 wt% Ru/C at 433 K under H2 pressure of 50 bar. Sels and co-workers [53] reported that, in the presence of trace amount of HCl (35–177 ppm), a Ru/H-USY (USY: ultra-stable Y zeolite) catalyst provided 60 % sugar alcohols and 33 % sorbitans, which were cyclodehydration products of sorbitol, for the transformation of ball-milled cellulose at 463 K under H2 atmosphere (5 MPa). For the conversion of microcrystalline cellulose, a (0.1 M HCl + 5 wt% Ru/C) catalytic system produced sorbitol and sorbitans with yields of 36.9 and 21.9 %, respectively at 468 K for 0.5 h [54]. Further increases in reaction temperature or reaction time led to the formation of isosorbide with high yields. For example, an isosorbide yield of about 50 % was obtained at 488 K for 6 h by using this catalytic system. Isosorbide was a further cyclodehydration product of sorbitans, and the reaction pathways for the conversion of sorbitol to sorbitans and further to isosorbide are displayed in Fig. 4 [54].

Reaction pathways for the formation of isosorbide from cellulose via sorbitol and sorbitans [54]

Besides mineral acids, a heteropolyacid, H4SiW12O40, was also demonstrated to be useful for the conversion of cellulose in combination with supported noble metal catalyst [55]. A hexitol yield of 85 % was obtained for the conversion of ball-milled cellulose catalyzed by the H4SiW12O40 (0.055 M)–Ru/C combination in water under H2 (5 MPa) at 463 K [55]. In combination with H4SiW12O40 with a higher concentration (0.7 M), a Pt catalyst could catalyze the conversion of cellulose to sorbitol with a yield of 54 % under mild conditions of 333 K and H2 pressure of 0.7 MPa [56].

Although excellent performances have been achieved by using these systems containing a liquid acid, the recovery of the liquid acid is problematic for these systems. Moreover, the corrosion of the reactor and the leaching of noble metals from the solid hydrogenation catalyst may become serious in acidic reaction media.

In this context, it would be more desirable to develop a bifunctional solid catalyst capable of working at lower temperatures. We found that, as compared with typical metal oxides such as SiO2, γ-Al2O3, MgO and CeO2, a carbon nanotube (CNT) pretreated by concentrated HNO3 was a better support of Ru nanoparticles for the conversion of cellulose at 458 K (Fig. 5a) [57]. Over a 1.0 wt% Ru/CNT catalyst, a sorbitol yield of 69 % could be obtained at 458 K under H2 pressure of 5 MPa for the conversion of cellulose pretreated by 85 % H3PO4. Besides sorbitol, mannitol, erythritol and glycerol were also formed with yields of 4.0, 5.0 and 5.0 %, respectively. As compared with other metals such as Fe, Co, Ni, Ir, Pt, Rh and Pd, Ru was found to be the most efficient active metal for the formation of sorbitol (Fig. 5b). The Ru/CNT was also stable during the repeated uses, and a sorbitol yield of 61 % was obtained after the repeated uses for four recycles.

Table 1 summarizes some typical results reported for the catalytic conversion of cellulose into hexitols. Among the catalysts without added liquid acid, the Ru/CNT catalyst exhibited relatively better catalytic performances for the conversion of cellulose to sorbitol. Besides noble metal-based catalysts described above, nickel, a non-noble transition metal, has also been exploited for the conversion of cellulose to hexitols. An activated carbon-supported Ni2P catalyst provided sorbitol with a yield of 48 % at 498 K under H2 atmosphere [59]. The acidity formed due to excess phosphorus on surfaces and the metal-like feature of Ni2P were proposed to be responsible for the hydrolysis and the hydrogenation reactions. However, the catalyst could not be used repeatedly. The leaching of phosphorus was mainly responsible for the deactivation in the recycling uses. Sels and co-workers [60] designed and prepared a carbon nanofiber (CNF)-supported Ni catalyst with Ni nanoparticles on the tips of CNTs for the conversion of cellulose in water in the presence of H2. A hexitol yield of ~27.6 % (sorbitol: ~22.7 %; mannitol: ~4.9 %) was obtained over this Ni/CNF catalyst for the conversion of microcrystalline cellulose at 503 K for 4 h. The yield of hexitols increased to 56.5 % for the conversion of ball-milled cellulose at 463 K for 24 h. The H3O+ reversibly formed in hot water was proposed for the hydrolysis reaction. This catalyst exhibited significantly higher performances than Ni/Al2O3 or Ni/AC prepared by the impregnation method. The location of Ni particles was claimed to be a key factor. The Ni particles attached at the tips of CNFs might be more easily accessed by cellulose, leading to better catalytic performances. Moreover, the reshaped crystal structure of Ni particles during the catalyst preparation stage might suppress the undesired C–C and C–O bond breaking, resulting higher selectivities to hexitols.

2.2 Key Factors Determining the Ru/CNT-Catalyzed Conversion of Cellulose or Cellobiose into Sorbitol

As described above, the Ru/CNT catalyst exhibited relatively better catalytic performances for the conversion of cellulose to sorbitol in water. In this section, we will discuss the key factors determining the catalytic behaviors for the conversion of cellulose using the Ru/CNT catalyst as an example.

First, the crystallinity of cellulose is a crucial factor in affecting its conversion. Ball milling is known to be a simple means to decrease the crystallinity of cellulose, and the conversion of the ball-milled cellulose usually affords higher product yield (Table 1). The pretreatment of cellulose by H3PO4 aqueous solution could also alter the crystallinity of cellulose [61]. We uncovered that the crystallinity and the DP of cellulose could be changed systematically by varying the concentration of H3PO4 and the time used for pretreatment. Based on this, we investigated the effect of the crystallinity of cellulose on the formation of sorbitol. The result revealed that the decrease in the crystallinity or the DP significantly increased the sorbitol yield. As displayed in Fig. 6, the yield of sorbitol increased from 11 to 69 % by decreasing the crystallinity and DP from 85 % and 221 to 33 % and 106, respectively. By increasing the amount of catalyst from 0.05 to 0.14 g, the yield of sorbitol could be increased from 11 to 36 % for the conversion of cellulose with a crystallinity of 85 %.

It is demonstrated that the amorphous region of cellulose is more susceptible to acid hydrolysis than the crystalline region [62]. This may be one of the reasons for the higher reactivity of cellulose with a lower crystallinity [58]. However, our recent experimental result suggests that the difference in the solubility of celluloses with different crystallinities in hot water may also be responsible for their different reactivities. In our experiment, we first treated the celluloses (1.0 mmol) with different crystallinities in hot water (458 K) in the presence of H2 for 10 h, and then analyzed the oligosaccharides dissolved in aqueous solution. The amount of oligosaccharides dissolved in aqueous solution (in mmol of glucose unit) was found to increase from 0.06 to 0.13, 0.22 and 0.35 mmol upon decreasing the crystallinity from 85 to 56, 39 and 33 %. The oligosaccharides dissolved in aqueous phase should be attacked by the solid catalyst (Ru/CNT) much more easily than the solid cellulose, leading to higher reactivity of cellulose with lower crystallinity. Based on these results, we propose that the conversion of cellulose may not undergo the true solid (cellulose)–solid (catalyst) phase reaction but may undergo a liquid (dissolved oligosaccharides)–solid (catalyst) phase reaction. As shown in Fig. 7, the oligosaccharides dissolved in aqueous medium were first converted to polyols (mainly sorbitol) in the presence of Ru/CNT catalyst under H2. The conversion of the dissolved oligosaccharides would cause further dissolution of cellulose to oligosaccharides into hot water, and more products can be obtained.

Second, the functionalization of CNT significantly affects the catalytic performance of Ru/CNT catalyst. Prior to the loading of Ru nanoparticles, CNTs were pretreated by HNO3 or HCl to remove the remaining Ni catalysts used for CNT preparation. Figure 8 displays the catalytic performances of Ru catalysts loaded CNTs pretreated by concentrated (37 %) HCl and by HNO3 with different concentrations. Ru loaded the CNT pretreated by 37 % HCl provided a sorbitol yield of 30 % for the conversion of cellulose (crystallinity: 33 %) in water at 458 K for 24 h under H2. The yield of sorbitol became higher when HNO3 was used for CNT pretreatment, and it increased steadily upon increasing the concentration of HNO3. Similar results were obtained for the conversion of cellobiose to sorbitol at 458 K for a shorter time (3 h) (Fig. 8b) [63]. XPS studies revealed that the binding energies of Ru 3d 5/2 over these catalysts were around 280.3 eV, indicating that the Ru species were all in metallic state. TEM measurements uncovered that the mean size of Ru nanoparticles were 8.6–8.9 nm in all these catalysts. NH3–TPD studies (Fig. 9) suggested the generation of acidity on CNTs after the pretreatment by HNO3, whereas the pretreatment by concentrated HCl did not generate acidity on CNTs. Moreover, the amount of acid sites increased with the concentration of HNO3. It is known that the pretreatment of CNTs by concentrated HNO3 can generate oxygen-containing functional groups such as hydroxyl, carbonyl and carboxylic groups on CNT surfaces [64]. NH3–TPD results allow us to propose that the oxygen-containing functional groups act as acid sites on CNTs. The role of such acid sites has also been recognized in Fischer–Tropsch synthesis for catalyzing the mild hydrocracking of C≥21 to C10–C20 hydrocarbons in the presence of Ru nanoparticles [65]. The correlation of characterization results with catalytic performances suggests that the acid sites on CNT play key roles in enhancing the conversions of cellulose and cellobiose by facilitating the cleavage of the glycosidic bonds.

Effect of the pretreatment of CNTs on catalytic performances of Ru/CNT catalysts for the conversions of cellulose (a) and cellobiose (b) to sorbitol. Reaction conditions: a for cellulose conversion: cellulose, 0.16 g; catalyst, 0.050 g; H2O, 20 cm3; H2, 5 MPa; temperature, 458 K; time, 24 h and b for cellobiose conversion: cellobiose, 0.50 mmol; catalyst, 0.050 g; H2O, 20 cm3; H2, 5 MPa; temperature, 458 K; time, 3 h

Third, the chemical state of Ru species and the mean size of Ru particles exert influences on the conversion of cellulose to sorbitol. Generally, Ru0 nanoparticles were believed to be active phase for hydrogenation reactions. However, Fukuoka and co-workers [66] recently suggested that cationic Ru species were the active phase over a Ru/C catalyst, which could catalyze the transfer hydrogenation of cellulose using 2-propanol as a source of hydrogen. We have investigated the chemical state of the active Ru species for the conversion of cellulose to sorbitol over the Ru/CNT catalyst. We prepared 1 wt% RuO2/CNT catalyst by impregnating CNT with RuCl3, followed by calcination at 623 K. XPS studies confirmed that Ru species were in Ru4+ state. This RuO2/CNT catalyst showed quite lower product yields (sorbitol: 9 %, mannitol: 4 %) in the conversion of cellulose (crystallinity: 33 %) at 458 K. After the reduction of RuO2/CNT by H2 at 623 K to Ru/CNT, in which Ru was confirmed to be in metallic state by XPS, the yield of sorbitol increased significantly to 69 % under the same reaction conditions. The Ru/CNT catalyst prepared by an ethylene glycol reduction method, which contained Ru0 nanoparticles, also provided excellent sorbitol yield (64 %). These observations reveal that Ru0 particles are the active phase for the hydrogenation during the conversion of cellulose in water in the presence of H2.

To gain information on size effect in the Ru/CNT-catalyzed cellulose or cellobiose conversion, a series of Ru/CNT catalysts with mean sizes of Ru nanoparticles ranging from 2.4 to 12 nm were prepared by the impregnation method followed by different post-treatments and by the ethylene glycol reduction method [63]. It was clarified that the direct reduction of the impregnated RuCl3/CNT by H2 at 773 K led to the formation of smaller Ru particles (mean size: 2.4 nm) homogeneously distributed on CNTs, while the reduction of the RuO2/CNT obtained by calcining the RuCl3/CNT at 623 K by H2 resulted in bigger Ru particles (8.7 and 12 nm depending on the H2 reduction temperature). The heating of the mixture of RuCl3 and CNTs in ethylene glycol solution caused the deposition of Ru particles with medium mean sizes (5.1 and 6.8 nm) on CNTs. XPS measurements confirmed that Ru species in these catalysts were in metallic state. Figure 10 displays catalytic performances of these Ru/CNT catalysts for the conversion of cellulose with a crystallinity of 33 % in water at 458 K under 5 MPa H2. There exists an optimum mean size of Ru nanoparticles at 8.7 nm for the formation of sorbitol. The catalyst with a larger mean size (12 nm) of Ru particles showed a lower conversion of cellulose, and thus the lower yield of sorbitol. On the other hand, considerable amounts of degradation products have been observed for the catalysts containing smaller Ru particles. Thus, the lower yields of sorbitol for the catalysts with smaller Ru particles are due to the lower selectivity. In other words, the smaller Ru nanoparticles accelerate further degradations of sorbitol.

2.3 Reaction Mechanism for Ru/CNT-Catalyzed Conversion of Cellobiose into Sorbitol

It is generally believed that the conversion of cellulose starts from the cleavage of glycosidic (C–O–C) bonds linking the glucose rings via acid-catalyzed hydrolysis even though bifunctional or multifunctional catalysts are concerned [17–20, 46, 47]. However, there only exist very limited studies devoting to mechanistic studies on the conversion of cellulose catalyzed by bifunctional catalysts.

Through kinetic studies on the conversion of a ball-milled cellulose (crystallinity: 22 %) over a Pt/BP2000 (BP2000: Black Pearls 2000, a carbon black) catalyst in water under H2 (5 MPa) at 463 K, Fukuoka and co-workers [58] proposed that the reaction consisted of the hydrolysis of cellulose to glucose via water-soluble oligosaccharides, which underwent quick hydrolysis to glucose, and the hydrogenation of glucose to sorbitol (Fig. 11). Mannitol was proposed to be formed from the hydrogenation of fructose, an intermediate of glucose isomerization. It is proposed that H3O+ generated in hot water may catalyze the hydrolysis of cellulose in this system. The comparison of kinetic parameters with and without the supported Pt catalyst indicates that the Pt/BP2000 without any acidity may participate in the cleavage of glycosidic bonds, which is usually performed by acid sites. Fukuoka and co-workers [37] once reported that a Ru/CMK-3 (CMK-3: a mesoporous carbon) could catalyze the hydrolysis of cellulose to glucose. Characterizations indicated that Ru species existed in RuO2∙2H2O clusters with a size of about 1.1 nm [67]. It was proposed that the RuO2·2H2O might function as a Brønsted acid for the conversion of cellulose [67], but further clarifications are still needed. The nature of the acid sites over the Pt/BP-2000 is unclear. Synergistic effects may also have to be considered.

Proposed reaction mechanism for the conversion of cellulose to sorbitol and mannitol over Pt/BP2000 catalyst [58]

Cellulose is a very complex macromolecule. It is quite difficult to precisely analyze either qualitatively or quantitatively the very initial products from cellulose, which should be some kinds of polymers. Thus, a rigorous kinetic analysis for cellulose conversions is not easy. In this context, the knowledge on the reaction mechanism for the conversion of cellobiose, which is the simplest model molecule of cellulose, is helpful. Figure 12 displays time courses for the conversion of cellobiose in water in the presence of H2 over the Ru/CNT catalysts with four different mean sizes of Ru nanoparticles [63]. At the very initial stage, it was not glucose but 3-β-d-glucopyranosyl-d-glucitol that was formed as the main product. Only the catalyst with a larger mean Ru size produced glucose with a considerable yield at the initial reaction stage (Fig. 12d). This indicates that the predominant reaction in the first step for the conversion of cellobiose over the Ru/CNT catalyst is the hydrogenolysis of the C–O bond in one glucose ring in cellobiose molecule (Step I in Fig. 13). The hydrolysis of the glycosidic bond linking the two glucose ring to glucose is only a minor route (Step I′ in Fig. 13). The prolonging of the reaction time decreased the yield to 3-β-d-glucopyranosyl-d-glucitol and increased that to sorbitol. This suggests the hydrolysis of 3-β-d-glucopyranosyl-d-glucitol to produce sorbitol and glucose in the subsequent step. However, the yield of glucose was always quite low at any times of reaction. We have confirmed that the hydrogenation of glucose (Step III in Fig. 13) proceeded very quickly over the Ru/CNT catalysts under our reaction conditions [63]. Degradation products were formed at longer reaction times particularly in larger amounts over the catalysts with smaller mean sizes of Ru nanoparticles (2.4 and 5.1 nm). Mannitol was also formed at longer reaction time, and the yield of mannitol was higher over the catalyst with a smaller size of Ru particles. Mannitol may be formed by the isomerization of sorbitol or by the hydrogenation of fructose, which is an isomer of glucose (Fig. 11). Since we did not observe the formation of fructose and the concentration of glucose was quite low in our system, the direct isomerization of sorbitol to mannitol may be the main route.

Time courses for the conversion of cellobiose over Ru/CNT catalysts with different mean sizes of Ru nanoparticles (Reproduced with permission from Elsevier) [63]. Mean size of Ru particles: a 2.4 nm, b 5.1 nm, c 8.7 nm, and d 12 nm. Reaction conditions: cellobiose, 0.50 mmol; catalyst, 0.050 g; H2O, 20 cm3; H2, 5 MPa; temperature, 458 K; time, 24 h

Proposed reaction mechanism for the conversion of cellobiose over Ru/CNT catalyst (Reproduced with permission from Elsevier) [63]

The reaction mechanism in Fig. 13 is quite different from the general consensus that the cleavage of glycosidic bonds via acid-catalyzed hydrolysis is the first step for the conversion of cellulose or oligosaccharides. We speculate that this may be due to the higher hydrogenation ability and the weaker acidity of the Ru/CNT catalyst. Actually, Kou and co-workers [45] also observed the formation of 3-β-d-glucopyranosyl-d-glucitol during the conversion of cellobiose catalyzed by PVP-stabilized Ru nanoclusters dispersed in neutral water medium (pH 7). However, they did not consider the route of sorbitol formation via 3-β-d-glucopyranosyl-d-glucitol possibly because of the relatively milder conditions they used (393 K) and the lack of acidity at pH of 7. To confirm the mechanism in Fig. 13, we performed further studies for the Ru/CNT catalysts by using cellobiose, 3-β-d-glucopyranosyl-d-glucitol and sorbitol as substrates.

For the conversion of cellobiose, it was found that the reaction could proceed at a milder temperature (423 K) and the selectivity to 3-β-d-glucopyranosyl-d-glucitol could reach >95 % at 423 K over the Ru/CNT catalysts [63]. We measured the initial rates over the Ru/CNT catalysts with different mean sizes of Ru particles. Figure 14 shows that the rate of cellobiose conversion increased sharply upon decreasing the mean size of Ru particles; the rate over the catalyst possessing a mean Ru size of 2.4 nm is about 15 times higher than that over the one with a mean Ru size of 12 nm. We further calculated the TOF, i.e., the amount (mol) of cellobiose converted per amount (mol) of surface Ru atom per time, for the conversion of cellobiose at 423 K (Fig. 14). It becomes clear that the hydrogenolysis of cellobiose to 3-β-d-glucopyranosyl-d-glucitol is a structure-sensitive reaction, and smaller Ru nanoparticles favor this reaction.

When 3-β-d-glucopyranosyl-d-glucitol was used as the reactant, the reaction could not occur at 423 K and higher temperatures were required. This indicates that, over the Ru/CNT catalyst, the conversion of 3-β-d-glucopyranosyl-d-glucitol (Step II in Fig. 13) is a relatively slower step as compared to the conversion of cellobiose to 3-β-d-glucopyranosyl-d-glucitol (Step I in Fig. 13). The rates of 3-β-d-glucopyranosyl-d-glucitol conversion over the Ru/CNT catalysts with different mean sizes of Ru particles were measured to be 71–139 mmol g −1cat h−1, which were slightly dependent on the mean sizes of Ru. We speculate that this arises from the difference in catalyst acidity because different post-treatments have been employed for the preparation of the Ru/CNT catalysts with different mean sizes of Ru particles [63].

For the conversion of sorbitol, mannitol and degradation compounds were observed. An early patent also disclosed the isomerization of sorbitol to mannitol over a Ni-based catalyst at 443 K under H2 atmosphere [68]. We have proposed a tentative mechanism for the formation of mannitol from sorbitol (Fig. 15). We speculate that the H and OH linked with the C2 atom in sorbitol might be activated by Ru nanoparticles, forming a transition state. The H atom generated from gaseous H2 on Ru nanoparticle may subsequently attack the C2–O bond from the opposite side, producing mannitol. We found that the Ru/CNT catalysts containing Ru nanoparticles with smaller mean sizes (2.4 and 5.0 nm) were more active for the isomerization and degradation of sorbitol. Mannitol selectivities of 40–50 % could be obtained in the conversion of sorbitol over these catalysts at 458 K and under a H2 pressure of 5 MPa. The conversion of sorbitol increased significantly upon decreasing the mean size of Ru particles. This can explain the results obtained in Figs. 10 and 12 that the catalyst with a smaller mean Ru size affords lower sorbitol yields for both cellulose and cellobiose conversions. It is noteworthy that the design of a tri-functional catalyst, which is capable of catalyzing the selective cleavage of the C–C bond in sorbitol in addition to the hydrolysis and the hydrogenation, may result in the selective formation of lighter polyols. For examples, Ni–W2C/AC and WO3–Ru/C catalysts could catalyze the formation of ethylene glycol and propylene glycol possibly because of the ability of WO3 to cleave the C–C bonds in sugar intermediates [69, 70].

3 Hydrolysis–Oxidation of Cellobiose or Cellulose into Gluconic Acid

Although some efficient catalysts or catalytic systems have been developed for catalytic transformations of cellulose or cellobiose into polyols, the consumption of H2 is required. The search for other more economical route for the production of value-added chemicals from cellulose is also of high significance. The oxidative transformation of cellulose into organic acids, which can also act as key platform molecules [7], in the presence of cheaper oxygen or air would be a promising route. Moreover, some organic acids themselves are important chemicals or chemical intermediates. For example, gluconic acid is widely used in the pharmaceutical and food industries.

Actually, the oxidation of cellulose was investigated many years ago by using NO2 as an oxidant without catalyst [71, 72]. The products were polyuronic acids, i.e., the oxidized polymers with primary hydroxyl groups in cellulose being converted to carboxyl groups. Similar oxidation of cellulose also occurred when NaOCl was used as an oxidant in the presence of 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO) and NaBr in water [73]. However, during these oxidation processes, the DP of cellulose also underwent changes [73], and the separation of various carboxyl group-containing polymers seemed very difficult. Moreover, O2 cannot be used for the oxidation of cellulose to polyuronic acids. Therefore, the catalytic transformation of cellulose, selectively forming a particular product, e.g., gluconic acid, by O2 or air is more attractive.

Currently, gluconic acid is mainly produced by the enzymatic oxidation of glucose. Many studies have been devoted to the selective oxidation of glucose to gluconic acid by O2, and Au nanoparticles are demonstrated to be particularly promising catalysts for this reaction [74–81]. It can be expected that the direct conversion of cellulose to gluconic acid requires a bifunctional catalyst or catalytic system possessing hydrolysis and oxidation abilities (Fig. 16). We first examined the possibility of Au nanoparticles loaded on various supports including SiO2, Al2O3, TiO2, H-ZSM-5, HY, MgO, AC, graphite, XC-72 and CNT for the conversion of cellobiose to gluconic acid in the presence of O2 in water medium [82]. Higher conversions of cellobiose (>80 %) were obtained over Au/Al2O3, Au/MCM-41, Au/TiO2, Au/MgO and Au/CNT at 418 K, but the selectivity to gluconic acid over Au/Al2O3, Au/MCM-41, Au/TiO2 and Au/MgO were lower than 50 %. The Au/CNT exhibited significantly higher selectivity to gluconic acid than the other catalysts examined in our work.

Key factors determining the activity and selectivity for the conversion of cellobiose to gluconic acid have been investigated. The studies using various supports for the conversion of gluconic acid under similar reaction conditions clarified that Al2O3 and MgO were too active for the conversion of gluconic acid, whereas CNT was inert toward the conversion of gluconic acid. Thus, one reason for the higher selectivity of the Au/CNT catalyst is the higher stability of gluconic acid over it under reaction conditions.

The acidic groups on CNT surfaces generated by pretreatment with concentrated HNO3 have been demonstrated to play crucial roles in the selective conversion of cellobiose to gluconic acid. It is known that the acidity of CNTs depends on the concentration of HNO3 [57, 63, 65] (Fig. 9). Figure 17 displays the effect of the pretreatment of CNTs before loading Au nanoparticles on the catalytic behaviors of the Au/CNT. It is noteworthy that the mean sizes of Au nanoparticles in these samples are quite similar and are located in the range of 5.6–6.7 nm [82]. Thus, the differences in catalytic behaviors displayed in Fig. 17 can mainly be ascribed to the difference in acidity of CNTs. The Au/CNT catalysts with CNT pretreated by concentrated HNO3 showed higher conversions of cellobiose than that with CNT pretreated by concentrated HCl, indicating the role of acidity in enhancing the activation of β-1,4-glycosidic bond. More interestingly, the selectivity of gluconic acid depended more strongly on the acidity. The higher concentration of HNO3 used for CNT pretreatment, in other words, the stronger acidity, led to higher selectivity and higher yield to gluconic acid. The conversions of gluconic acid over the Au/CNT catalysts with CNT pretreated by HCl and by different concentrations of HNO3 suggest that the catalyst with a stronger acidity can suppress the conversion of gluconic acid (Fig. 18). These observations allow us to conclude that the acidic groups on catalyst surfaces contribute both to the conversion of cellobiose and to the inhibition of consecutive oxidation of gluconic acid.

The role of Au in the conversion of cellobiose has been investigated by examining the effect of Au loadings. Without Au loading, the CNT alone exhibited a lower conversion of cellobiose (27 %) at 418 K. The main product was glucose (selectivity 80 %) without any formation of gluconic acid [82]. This was due to the acid catalysis function of CNTs. The loading of Au onto CNTs not only changed the main product from glucose to gluconic acid but also significantly accelerated the conversion of cellobiose. For example, by loading 0.5 wt% Au onto CNTs, the conversion of cellobiose increased from 27 to 80 % and the selectivity of gluconic acid increased from 0 to 85 %, respectively. The significant increase in the conversion of cellobiose should arise from the synergistic effect of the dual active sites over the Au/CNT catalyst. Although the mechanism is still ambiguous, such synergistic effects have been observed for many bifunctional catalysts for the cascade conversions of cellulose or cellobiose [46, 52–57].

Kinetic measurements for the conversion of cellobiose over the 0.5 wt% Au/CNT catalyst suggested that glucose was the reaction intermediate, and gluconic acid was formed via the oxidation of glucose. Further conversion of gluconic acid led to degradation products such as acetic acid, glycolic acid, oxalic acid and succinic acid. Air could also be employed as an oxidant for the conversion of cellobiose into gluconic acid.

Table 2 summarizes several bifunctional catalysts reported to date for the conversion of cellobiose by O2 to gluconic acid [82–85]. A sulfonated-activated carbon (AC-SO3H)-supported Pt catalyst catalyzed the formation of gluconic acid from cellobiose and starch in water at 393 K under ambient air [83]. A gluconic acid yield of 46 % was obtained from cellobiose after 24 h reaction. Gluconic acid yield of 96 % was achieved over an Au catalyst loaded Keggin-type polyoxometalate (Cs2HPW12O40) in water at 418 K under 0.5 MPa of O2 [84]. This catalyst was prepared by an impregnation method and contained Au nanoparticles with sizes in 1–3 nm. Similar to CNTs, the acidic Cs2HPW12O40 also was inert toward the further conversion of gluconic acid [84]. An Au/Cs1.2H1.8PW12O40 prepared by deposition–precipitation method exhibited similar catalytic performance for the oxidative conversion of cellobiose to gluconic acid [85]. Moreover, this catalyst could also catalyze the formation of gluconic acid from cellulose, and a gluconic acid yield of 60 % was gained at 418 K under 1 MPa of O2. The acidity and the size of Au nanoparticles were demonstrated to be key factors [85]. Although the proton-bearing polyoxometalate-supported Au catalysts could be used repeatedly to some extent for the conversion of cellobiose [84, 85], this kind of catalyst underwent significant deactivation during the recycling uses for the conversion of cellulose due to the leaching of H+-rich hydrophilic moiety over long-term hydrothermal reactions [85]. Future studies are needed for developing more stable catalysts for the oxidative transformation of cellulose to gluconic acid.

4 Concluding Remarks

Catalytic transformations of cellulose into valuable chemicals or platform compounds such as polyols and organic acids under mild conditions have become a hot research area in recent years. This article has briefly summarized some recent advances in the development of bifunctional catalysts or catalytic systems for the hydrolysis–hydrogenation and hydrolysis–oxidation of cellulose or cellobiose into hexitols and gluconic acid.

The combination of a liquid acid and a supported noble metal catalyst, for example diluted H2SO4, diluted HCl or H4SiW12O40 in combination with Ru/C, represents one kind of bifunctional catalytic systems. Liquid acid alone is known to catalyze the hydrolysis of cellulose to glucose, but the efficiency is not high enough under mild conditions. The addition of a hydrogenation catalyst (typically a supported metal nanoparticle catalyst) can significantly enhance the conversion of cellulose and obtain polyols as the main products in the presence of H2. Although high efficiency could be obtained by using liquid acid-based bifunctional catalytic systems, the problems of separation of catalyst and products and/or corrosion remain to solve. Moreover, the leaching of metal component from the hydrogenation catalyst may become serious in the presence of a mineral acid. It is of interest that hot water at temperatures >473 K can also function as “liquid acid”, converting cellulose into polyols in combination with supported metal nanoparticles.

Solid acid (e.g., Al2O3 and HNO3-pretreated CNT)-supported metal (e.g., Ru and Pt) nanoparticles represent another kind of bifunctional catalysts for the conversion of cellulose in water under H2 atmosphere. Significant synergistic effects also exist over these catalysts. This article has especially focused on a CNT-supported Ru catalyst, which produces hexitols with yields of 73 and 40 % for the conversions of celluloses with crystallinities of 33 and 85 %, respectively at 458 K. The effects of key factors including the acidity generated on CNT surfaces by HNO3 pretreatment, the chemical state of Ru, the mean size of Ru nanoparticles and the crystallinity of cellulose have been discussed in detail. A stronger acidity generated by using concentrated HNO3 for CNT pretreatment and a medium mean size of Ru (7–8 nm) result in a higher sorbitol yield. Smaller Ru particles are detrimental to the selectivity because they also catalyze the degradation of sorbitol. Mechanistic studies for the Ru/CNT catalyst using cellobiose as a model molecule suggest that the first step is the hydrogenolysis of C–O bond in one cellulose ring to 3-β-d-glucopyranosyl-d-glucitol but not the cleavage of β-1,4-glycosidic bond. This step is a structure-sensitive reaction and smaller Ru nanoparticles favor the formation of 3-β-d-glucopyranosyl-d-glucitol. The hydrolysis to cleave the β-1,4-glycosidic bond catalyzed by the acid sites occurs in the subsequent step to produce sorbitol and glucose, which is converted to sorbitol very quickly. The first step is more facile than the second step because of the higher hydrogenation ability of the Ru/CNT catalyst.

The CNT bearing acidic sites is also an efficient support for the oxidative conversion of cellobiose to gluconic acid in water medium under O2 atmosphere when Au nanoparticles are loaded. Gluconic acid yield of 80 % could be obtained at 418 K. As compared with other metal oxide supports, the selectivity of gluconic acid is significantly higher because CNTs are quite inert toward the conversion of gluconic acid. It has been demonstrated that the acidity of CNTs plays key roles in the selective formation of gluconic acid by not only accelerating the conversion of cellobiose but also inhibiting the consecutive conversion of gluconic acid. On the other hand, Au nanoparticles account for the selective oxidation of glucose, the reaction intermediate, to gluconic acid by O2. The presence of Au nanoparticles on CNTs also markedly accelerates the conversion of cellobiose due to the synergistic effects.

The cascade hydrolysis–hydrogenation or hydrolysis–oxidation of cellulose has been demonstrated to be a useful strategy to convert cellulose into hexitols or gluconic acid with high yields under mild conditions. Synergistic effects clearly exist between acid sites and metal nanoparticles in the bifunctional catalytic systems. For improving the performances of these bifunctional catalysts, to further develop more efficient and stable solid acid materials and to keep the high reactivity of the active metal nanoparticles (for example, to avoid sintering of metal nanoparticle) under hydrothermal reaction conditions used for cellulose transformations are particularly important.

References

Ragauskas AJ, Williams CK, Davison BH, Britovsek G, Cairney J, Eckert CA, Frederick WJ, Hallett JP, Leak DJ, Liotta CL, Mielenz JR, Murphy R, Templer R, Tschaplinski T (2006) Science 311:484

Himmel ME, Ding SY, Johnson DK, Adney WS, Nimlos MR, Braday JW, Foust TD (2007) Science 315:804

Chheda JN, Huber GW, Dumesic JA (2007) Angew Chem Int Ed 46:7164

Alonso DM, Bond JQ, Dumesic JA (2010) Green Chem 12:1493

Huber GW, Iborra S, Corma A (2006) Chem Rev 106:4044

Corma A, Iborra S, Velty A (2007) Chem Rev 107:2411

Kamm B (2007) Angew Chem Int Ed 46:5056

Gallezot P (2008) ChemSusChem 1:734

Ruppert AM, Weinberg K, Palkovits R (2012) Angew Chem Int Ed 51:2564

Michel H (2012) Angew Chem Int Ed 51:2516

Klemm D, Heublein B, Fink HP, Bohn A (2005) Angew Chem Int Ed 44:3358

Zhou CH, Xia X, Lin CX, Tong DS, Beltramini J (2011) Chem Soc Rev 40:5588

Dhepe PL, Fukuoka A (2007) Catal Surv Asia 11:186

Dhepe PL, Fukuoka A (2008) ChemSusChem 1:969

Fukuoka A, Dhepe PL (2009) Chem Rec 9:224

Yang P, Kobayashi H, Fukuoka A (2011) Chin J Catal 32:716

Kobayashi H, Komanoya T, Guha SK, Hara K, Fukuoka A (2011) Appl Catal A 409–410:13

Kobayashi H, Ohta H, Fukuoka A (2012) Catal Sci Technol 2. doi:10.1039/C2CY00500J

Van de Vyver S, Geboer J, Jacobs PA, Sels BF (2011) ChemCatChem 3:82

Geboers JA, Van de Vyver S, Ooms R, Op de Beeck B, Jacobs PA, Sels BF (2011) Catal. Sci. Technol. 1:714

Hara M (2010) Energy Environ Sci 3:601

Shimizu K, Satsuma A (2011) Energy Environ Sci 4:3140

Rinaldi R, Schüth F (2009) Energy Environ Sci 2:610

Rinaldi R, Schüth F (2009) ChemSusChem 2:1096

Cabiac A, Guillon E, Chambon F, Pinel C, Rataboul F, Essayem N (2011) Appl Catal A 402:1

Zhang Y-HP, Lynd LR (2004) Biotechnol Bioeng 88:797

Zhao H, Kwak JH, Wang Y, Franz JA, White JM, Holladay JE (2006) Energy Fuels 20:807

Zhao H, Holladay JE, Wang Y, White JM, Zhang ZC (2007) J Biobased Mater Bioenergy 1:210

Shimizu K, Furukawa H, Kobayashi N, Itaya Y, Satsuma A (2009) Green Chem 11:1627

Ogasawara Y, Itagaki S, Yamaguchi K, Mizuno N (2011) ChemSusChem 4:519

Deng WP, Liu M, Zhang QH, Tan XS, Wang Y (2010) Chem Commun 46:2268

Deng WP, Liu M, Zhang QH, Wang Y (2011) Catal Today 164:461

Onda A, Ochi T, Yanagisawa K (2008) Green Chem 10:1033

Van de Vyver S, Peng L, Geboers J, Schepers H, de Clippel F, Gommes CJ, Goderis B, Jacobs PA, Sels BF (2010) Green Chem 12:1560

Suganuma S, Nakajima K, Kitano M, Yamaguchi D, Kato H, Hayashi S, Hara M (2008) J Am Chem Soc 130:1278

Pang J, Wang A, Zheng M, Zhang T (2010) Chem Commun 46:6935

Kobayashi H, Komanoya T, Hara K, Fukuoka A (2010) ChemSusChem 3:440

Lai D, Deng L, Li J, Liao B, Guo Q, Fu Y (2011) ChemSusChem 4:55

Rinaldi R, Palkovits R, Schüth F (2008) Angew Chem Int Ed 47:8047

Takagaki A, Tagusagawa C, Domen K (2008) Chem Commun 5363

Simonetti DA, Dumesic JA (2009) Catal Rev 51:441

Huber GW, Shabaker JW, Dumesic JA (2003) Science 300:2075

Huber GW, Cortright RD, Dumesic JA (2004) Angew Chem Int Ed Engl 43:1549

Metzger JO (2006) Angew Chem Int Ed 45:696

Yan N, Zhao C, Luo C, Dyson PJ, Liu H, Kou Y (2006) J Am Chem Soc 128:8714

Fukuoka A, Dhepe PL (2006) Angew Chem Int Ed 45:5161

Luo C, Wang S, Liu H (2007) Angew Chem Int Ed 46:7636

Nolen SA, Liotta CL, Eckert CA, Gläser R (2003) Green Chem 5:663

Chamblee TS, Weikel RR, Nolen SA, Liotta CL, Eckert CA (2004) Green Chem 6:382

Saka S, Ueno T (1999) Cellulose 6:177

Sasaki M, Fang Z, Fukushima Y, Adschiri T, Arai K (2000) Ind Eng Chem Res 39:2883

Palkovits R, Tajvidi K, Procelewska J, Rinaldi R, Ruppert A (2010) Green Chem 12:972

Geboers J, Van de Vyver S, Carpentier K, Jacobs P, Sels B (2011) Chem Commun 47:5590

Liang G, Wu C, He L, Ming J, Cheng H, Zhuo L, Zhao F (2011) Green Chem 13:839

Geboers J, Van de Vyver S, Carpentier K, de Blochouse K, Jacobs P, Sels B (2010) Chem Commun 46:3577

Geboers J, Van de Vyver S, Carpentier K, Jacobs P, Sels B (2011) Green Chem 13:2167

Deng W, Tan X, Fang W, Zhang Q, Wang Y (2009) Catal Lett 133:167

Kobayashi H, Ito Y, Komanoya T, Hoska Y, Dhepe PL, Kasai K, Hara K, Fukuoka A (2011) Green Chem 13:326

Ding L, Wang A, Zheng M, Zhang T (2010) ChemSusChem 3:818

Van de Vyver S, Geboers J, Dusselier M, Schepers H, Vosch T, Zhang L, Van Tendeloo G, Jacobs P, Sels B (2010) ChemSusChem 3:698

Zhang YHP, Cui J, Lynd LR, Kuang LR (2006) Biomacromolecules 7:644

Kontturi E, Vuorinen T (2009) Cellulose 16:65

Deng W, Liu M, Tan X, Zhang Q, Wang Y (2010) J Catal 271:22

Serp P, Corras M, Kalck P (2003) Appl Catal A 253:337

Kang J, Zhang S, Zhang Q, Wang Y (2009) Angew Chem Int Ed 48:2565

Kobayashi H, Matsuhashi H, Komanoya T, Hara K, Fukuoka A (2011) Chem Commun 47(8):2366

Komanoya T, Kobayashi H, Hara K, Chun W, Fukuoka A (2011) Appl Catal A 407:188

Kasehagen L, Chester W (1962) US Patent 3047635

Ji N, Zhang T, Zheng M, Wang A, Wang H, Wang X, Chen JG (2008) Angew Chem Int Ed 47:8510

Liu Y, Luo C, Liu H (2012) Angew Chem Int Ed 51:3249

Yackel EC, Kenyon WO (1942) J Am Chem Soc 64:121

Kenyon RL, Hasek RH, Davy LG, Broadbooks KJ (1949) Ind Eng Chem 41:2

Perez DS, Montanari S, Vignon MR (2003) Biomacromolecules 4:1417

Besson M, Gallezot P (2000) Catal Today 57:127

Biella S, Prati L, Rossi M (2002) J Catal 206:242

Comotti M, Pina CD, Matarrese R, Rossi M (2004) Angew Chem Int Ed 43:5812

Önal Y, Schimpf S, Claus P (2004) J Catal 223:122

Basheer C, Swaminathan S, Lee HK, Valiyaveettil S (2005) Chem Commun 409

Baatz C, Prüße U (2007) J Catal 249:34

Onda A, Ochi T, Kajiyoshi K, Yanagisawa K (2008) Appl Catal A 343:49

Ishida T, Kinoshita N, Okatsu H, Akita T, Takei T, Haruta M (2008) Angew Chem Int Ed 47:9265

Tan XS, Deng WP, Liu MQ, Zhang H, Wang Y (2009) Chem Commun 7179

Onda A, Ochi T, Yanagisawa K (2011) Catal Commun 12:421

Zhang J, Liu X, Hedhili MN, Zhu Y, Han Y (2011) ChemCatChem 3:1294

An D, Ye A, Deng W, Zhang Q, Wang Y (2012) Chem Eur J 18:2938

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Nos. 21173172, 21103143 and 21033006), the Research Fund for the Doctoral Program of High Education (No. 20090121110007), the National Basic Research Program of China (No. 2010CB732303), the Key Scientific Project of Fujian Province (2009HZ0002-1), and the Program for Changjiang Scholars and Innovative Research Team in University (No. IRT1036).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, W., Wang, Y., Zhang, Q. et al. Development of Bifunctional Catalysts for the Conversions of Cellulose or Cellobiose into Polyols and Organic Acids in Water. Catal Surv Asia 16, 91–105 (2012). https://doi.org/10.1007/s10563-012-9136-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10563-012-9136-1