Abstract

This review discusses topical chemical routes and their catalysis for the conversion of cellulose, hexoses, and smaller carbohydrates to lactic acid and other useful α-hydroxy acids. Lactic acid is a top chemical opportunity from carbohydrate biomass as it not only features tremendous potential as a chemical platform molecule; it is also a common building block for commercially employed green solvents and near-commodity bio-plastics. Its current scale fermentative synthesis is sufficient, but it could be considered a bottleneck for a million ton scale breakthrough. Alternative chemical routes are therefore investigated using multifunctional, often heterogeneous, catalysis. Rather than summarizing yields and conditions, this review attempts to guide the reader through the complex reaction networks encountered when synthetic lactates from carbohydrate biomass are targeted. Detailed inspection of the cascade of reactions emphasizes the need for a selective retro-aldol activity in the catalyst. Recently unveiled catalytic routes towards other promising α-hydroxy acids such as glycolic acid, and vinyl and furyl glycolic acids are highlighted as well.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Biomass-to-chemicals

- Catalysis

- Cellulose

- Renewables

- Lactic acid

- Vinyl glycolic acid

- Biodegradable polymers

1 Introduction

The search for oil-independent and renewable alternatives for the production of chemicals, fuels, and materials has led to an increased interest in the use of biomass as a feedstock [1, 2]. The catalytic conversion of biomass, and in particular that of the most abundant and non-edible lignocellulosic feedstock, has led to new pathways for the synthesis of chemicals, biofuels, and polymer building blocks [3–17]. Cellulose is the single most abundant organic compound on Earth [8, 18]. As this biopolymer exclusively consists of glucose, a 6-carbon aldose, as seen in Fig. 1, its selective conversion to desired chemical compounds is feasible [8, 9, 19].

Chemical catalysis, either in homogeneous or heterogeneous mode, is a formidable strategy to convert cellulose and sugar feedstock selectively into chemicals, and, since the turn of the century, publication numbers on catalytic carbohydrate conversion have been rising progressively. In a way, they all contribute to the concept of installing biorefineries in analogy with the existing petrochemical refineries [18]. The ideal biorefinery is thought to supply a select portfolio of both low value biofuels and high value bio-based chemicals and monomers [18, 20–22]. The choice of the desired chemicals from carbohydrate biomass is crucial and, therefore, we have recently developed a chemical selection tool from a chemist’s point of view, based on a newly defined functionality index (F:C) of a potential target molecule and the atom economy of its formation. This analysis is found in the first chapter of this volume [23]. When applied to lactic acid, a commercial bio-derived chemical of great interest, a high functionality index of 1.33 is calculated due to its carboxyl and α-hydroxyl group on its 3-carbon backbone. Moreover, as it is a structural isomer of triose sugars, its formation from cellulose, hexoses, or trioses implies a transformation with an atom economy of 100%.

Lactic acid is thus a perfectly suited chemical target to produce from biomass carbohydrates and no petrochemical routes for its formation are likely to take over. Once a proper chemical target molecule is selected, a fundamental understanding of the reaction network is crucial in order to tackle its selective formation from cellulosic biomass and to design the process steps and the catalytic activity required. The transformation of cellulose into lactic acid or other α-hydroxy acids (AHA), as seen in Fig. 1, is a key illustration of the proposed assessment [23] and its novel catalytic formation routes will be discussed in depth in this review chapter.

The next two sections of this review chapter will introduce the reader to the world of lactic acid. The acid is both a key platform chemical of the biorefinery concept, from which other interesting molecules may be formed (Sect. 2), and a monomer for commercial bioplastic polylactic acid (PLA) (Sect. 3). In the platform approach, the assessment from Chap. 1 in this volume [23] proves its value, as it is an equally useful tool to seek out the most desired routes for transforming a biomass-derived platform molecule as it is to select the most relevant carbohydrate-based chemicals from a chemist's point of view. In what follows, the desired catalytic cascade from cellulose to lactic acid will be described (Sect. 4) as well as the specific catalytic data reported for different feedstock (Sects. 5 and 6). Section 7 will introduce the reader to recent synthesis routes for other useful AHA compounds such as furyl and vinyl glycolic acid, as well as others shown in Fig. 1. Before concluding this chapter, Sect. 8 will provide a note on the stereochemistry of the chemically produced AHAs.

2 Lactic Acid as a Platform Molecule

Lactic acid (LA) is one of the top carbohydrate-derived chemicals and it was recently included in Bozell and Petersen’s revised selection of the top ten sugar-based chemicals [10, 24]. The conversion of carbohydrates into LA via anaerobic fermentation has been known for ages [25]. The first industrial fermentation was developed by A. Boehringer in 1895 and at the present time the global installed production capacity is estimated at 0.5 Mton year−1 [10, 26, 27]. The current fermentation process and its issues will be critically discussed in Sect. 3 in light of the major application of LA today, i.e., as monomer for commercial bioplastic PLA [28]. Besides being used for polyester synthesis, LA is seriously considered as a platform chemical for the synthesis of a diverse range of chemicals such as pyruvic acid, 2,3-pentanedione, and acrylic acid [10, 29].

In the light of preserving functional reactivity and pursuing high atom economy, the synthesis of LA is an excellent example (F:C = 1.33; atom economy AE = 100% [23]) and the original configuration of functional groups in LA provides a high chemical reactivity, allowing for a multitude of different conversion routes. Most of these conversions have been reported feasible in high product selectivity, given the presence of a suitable chemocatalyst (mostly heterogeneous) and the appropriate process conditions. A lactic acid-product family tree was developed in our recent review with detailed emphasis on the role of chemocatalysis in using LA as a platform molecule for different chemicals. As the catalytic conversion of LA is not within the scope of this review we refer the reader to this work for catalytic details [10]. Here, we will discuss the position of frequently reported chemicals produced from LA in the modified van Krevelen diagram, as introduced in the first chapter of this volume [23], and, together with the atom economy, this allows us to select the most feasible chemicals from LA. Figure 2 shows that lactic acid transformation in nearly every direction on the modified van Krevelen plot is feasible.

Modified van Krevelen plot demonstrating the conversion of LA into various chemicals. PLA = polylactic acid. F:C = functionality index as defined in Chap. 1 [23]

To start with, a single dehydration of LA – typically a shift to the left on the plot – leads to acrylic acid as the major product. Such dehydration is interesting as it preserves the functionality per carbon in the molecule (2). The atom economy (AE) of this dehydration is as high as 80% with water as the only by-product. The reaction is usually catalyzed in the gas phase by phosphates, sulfates, clays, modified zeolites, or oxides with dual mild acid–base character, yielding acrylic acid at around 65% [30–34]. The current synthesis of acrylic acid is performed via the partial oxidation of petrochemical propene (1) in the presence of steam with equal atom economy [35].

Even though the functional nature of LA is perfectly suited to synthesize acrylic acid in one step, the main driver for replacing the acrylic petrochemical route is an economic one and this demands a lower production price of lactic acid. At the moment, prices of both acids are similar, in the range of 1.2–2.0 USD kg−1.

Other chemicals, like 2,3-pentanedione [36] and acetaldehyde [37], are synthesized from LA via loss of water combined with decarbox(n)ylation. A side product of these reactions is CO2 or CO, which presents a loss in one carbon atom and thus a drop in atom economy. 2,3-Pentanedione is a valuable fine chemical, used as an aroma and flavor, but other properties, like its condensation with two phenols, might lead to interesting plasticizers (as an alternative to bisphenol A) and polycarbonate building blocks [168]. Although its functionality index of 0.8 is seriously lowered with respect to LA, as seen in Fig. 2, its structure contains very useful vicinal keto groups. In our analysis found in Chap. 1 of this volume [23], 2,3-pentanedione was found in the second circle of the F:C plot ranked per carbon number, indicating that the synthesis routes from carbohydrate and petrochemistry likely compete with each other. Its current small scale production is via extraction from dairy waste. The carbohydrate-based route via LA follows a reaction mechanism entailing a sequence of Claisen-condensation, decarboxylation, and dehydration. The reaction runs in the gas phase over supported phosphates [36] or alkali hydroxides [38], typically yielding 50% of 2,3-pentanedione. This reaction has a low atom economy of 55% calculated from LA (or from glucose), as seen in (3). A petrochemical route has been patented, via reacting hydroxyacetone with acetaldehyde (4), which is more atom efficient [39]. In the light of choosing between the carbohydrate path via LA or the fossil path, a detailed cost analysis should shed light on the economics. Given the availability of cheap LA, the renewable option could be a feasible route, but only after carefully comparing feedstock (acetaldehyde + hydroxyacetone vs LA) and process costs. The lower AE of the LA route is a big disadvantage. Note, however, that hydroxyacetone and acetaldehyde can also be made from renewable glycerol [40].

LA-based acetaldehyde is formed by a dehydration and decarbonylation sequence according to (5) and is shown in Fig. 2. The functionality index F:C of acetaldehyde is 1 and thus predicts a decent reaction, but the atom economy of 49% is very low. To keep the H-index constant for only a slightly lower functionality, the reaction indeed requires the elution of CO as side-product. Decomposition of LA to acetaldehyde, H2, and CO2 is also known. Katryniok et al. showed that the reaction can be catalyzed via decarbonylation in the gas phase with supported heteropolyacids at 275°C in excellent yield (90%) at high conversion (92%) [37]. Although acetaldehyde is fairly functional, it is only a 2-carbon unit, and petrochemical routes via selective oxidation (of natural gas derived ethene) will likely always dominate.

Another common reaction with α-hydroxy acids such as LA is the self-condensation under water-removal circumstances, forming lactoyl lactate, oligomers, or lactide – the cyclic di-ester of LA (6) [10, 41]. These condensation reactions are dehydrations and thus retain the full functionality in the molecule, while lowering the H index; see Fig. 2. Moreover, the atom economy of 80% is high with only water as side-product. Lactide is the true industrial precursor of PLA and the atom economy of 80% is equally valid for PLA [42].

Besides self-esterification, alkyl lactates can easily be made under acid or base catalysis in excess of alcohol or via water removal according to (7) [43]. The atom economy is high and the conversion only slightly reduces the F:C index with respect to LA. This reduction is larger with increasing length of alkyl chain in the alcohol part, but in absolute functionality (F, definition see Chap. 1 [23]), no loss is at hand. These alkyl esters harness realistic potential as green solvents. Ethyl lactate in particular, with its high boiling point, low vapor pressure, and low surface tension, receives increasing attention for solvent application and is currently commercially available at a medium scale. The molecule is moreover composed of two bio-derived platform chemicals and fully biodegradable [43, 44].

Another intensively studied reaction is the conversion of LA into 1,2-propanediol (propylene glycol) with hydrogen according to (8) [45]. This reaction proceeds with a significant loss of functionality, viz. from 1.33 to 0.67, while the atom economy of 81% is medium high. It can be written as a hydrogenation and subsequent hydrogenolysis, as seen in Fig. 2. Propylene glycol is mainly used as an antifreeze, solvent, and polyester precursor. Its commercial production involves the epoxidation of propylene with peroxides in the presence of Lewis acid catalysts like Mo or Ti, followed by hydration of the oxirane function [46]. If H2O2 is used as oxidant, a 100% atom economy is achieved with the petrochemical oxidation route according to (9). It will be difficult for the carbohydrate-based route to propanediol via LA (or glucose) to compete with this established route, due to the higher feedstock cost and lower atom economy. Our analysis in Chap. 1 of this volume predicted this competition, as propylene glycol is found on the edge of the third circle in the F:C vs carbon number plot, found in Fig. 9 of [23].

Finally, the oxidation of LA to pyruvic acid has been described with both heterogeneous and bio-catalysts. Pyruvic acid is the simplest α-keto acid and may be considered as an added-value fine chemical for the synthesis of drugs and agrochemicals, as well as being an antioxidant [29, 47]. The oxidation of the α-hydroxyl of LA corresponds to an upward shift in the modified van Krevelen plot along a +1/2 slope (Fig. 2), yielding a high F:C of 1.67 with a high atom economy (10). The commercial production at the moment is already carbohydrate-based, as predicted again by Chap. 1 of this volume [23], via the fermentation of glucose with free or immobilized enzyme catalysis [48]. Pyruvic acid is the end product of the energy providing glycolysis pathway in living cells.

To conclude, LA has tremendous potential as a high volume platform chemical to produce a range of different products. Our assessment along the guidelines of Chap. 1 of this volume [23] is summarized in Fig. 3, presenting the atom economy as a function of the functionality index. The dashed box indicates the zone with higher or equal F:C as LA and at least 80% of AE. This plot thus predicts the following order of importance/viability of lactic acid-derived chemicals: pyruvic acid > lactide = PLA = acrylic acid > methyl and ethyl lactate >> propylene glycol > 2,3-pentanedione > acetaldehyde. The drop in atom economy for the last two chemicals is too severe, and more AE efficient petrochemical precursors can be found. In the case of pyruvic acid, LA has to compete with a direct carbohydrate-based bio-catalytic process [48]. In fact, Fig. 3 would be identical if the reactions were considered to start from glucose or cellulose itself, because the atom economy for making LA from this feedstock is 100%.

The versatile nature of the multifunctional LA is thus ideal to offer the chemical side of the biorefinery the necessary adaptability to product demand and market prices, and it is encouraging to see the high selectivity of the conversions with heterogeneous catalysis [10]. Today, only the synthesis of esters and polymers (via lactide) among the described reactions is processed on a commercial scale. Lactide is, for instance, produced commercially by Purac (Corbion) and Galactic (Futerro, with Total), the largest producers of lactic acid in the world, as well as by Natureworks, the largest PLA producer. Commercialization of other chemicals from LA is currently hampered by the cost of its fermentative production from glucose, as explained in the next section. The interest in bio-derived chemicals and PLA bioplastics, and the rising demand for green solvent ethyl lactate, should be a stimulus for researchers to develop novel chemocatalytic pathways to LA or to improve current fermentation processes, preferably direct from cellulosic biomass. After a short discussion on the current fermentation to LA and its use as a monomer for PLA, a comprehensive summary of the newly-developed chemocatalytic routes will be given.

3 Lactic Acid as Key Monomer for Biodegradable Polyesters

Lactic acid is the key building block of the second largest volume commercial bio-plastic, namely PLA. This renewable polymer is a biodegradable and biocompatible (in vivo) thermoplastic polyester [28, 49–51]. These unique features render the PLA polymer suitable for many custom applications, for instance in medicine, such as prostheses and in drug delivery, while PLA is also a suitable replacement for certain forms of polystyrene, polypropylene, and polyethylene-terephthalate, e.g., in packaging, fibers, and textiles. On the downside, two major bottlenecks hamper the worldwide megaton-scale breakthrough of PLA: (1) its production cost and (2) some of its properties such as its brittleness, certain barrier properties, too pronounced hydrophobicity, and lack of reactive side groups [52]. Nonetheless, up to 187,000 metric tons of LA were produced in 2011, with a tentative estimated forecast of up to 600,000 tons in 2020 [10, 53, 54].

The synthesis of PLA and its cost-driving bottlenecks are presented in Fig. 4. The first step is the fermentative synthesis of (usually l-) LA with bacteria or yeast. Elegant reviews on this anaerobic fermentation are available elsewhere [55–58]. LA is further converted to its cyclic dimeric ester lactide via a two-stage process consisting of a pre-polymerization and a backbiting reaction (second frame in Fig. 4). This l,l-lactide is the actual monomer for high molecular weight PLA. PLA synthesis proceeds via ring-opening polymerization, usually carried out in molten lactide in the presence of minute amounts of metal catalyst (e.g., Sn, Al) [59]. The lactide route is industrially preferred over the direct synthesis of PLA via polycondensation, especially for the production of high molecular weight PLA. Such high molecular weight is important to ensure high performance in physical properties such as melt points and strengths. Polycondensation is a less controlled process and leads to shorter, more polydisperse chains and thus PLA of inferior quality [60]. In addition, such condensation is a tedious process because of the removal of water from a molten, highly viscous polycondensate [61]. The lower-right corner of Fig. 4 shows a pie chart with a rough estimate of the total PLA production cost, from the carbohydrate feedstock to the PLA plastic pellet. It is estimated that about 50% of the total cost is governed by the fermentative LA synthesis from glucose or sucrose. Another 30% is spent on the transformation of LA to the lactide, while the remaining cost is dedicated to the polymerization of lactide and the pelleting [169].

Current industrial synthesis of (L-)PLA from carbohydrate feedstock: the fermentative synthesis of L-LA; the chemical two-step synthesis of the cyclic intermediate (l,l-) lactide and the polymerization to PLA. A pie chart shows a rough estimate of each of the frames’ contribution to the total production cost of PLA, from sugar to pellet

In order to facilitate the production of PLA on a megaton scale, as suited for a commodity plastic, it is imperative to focus on alternative production routes to LA, as this is clearly the largest cost factor for producing PLA. The main reason for this cost is displayed in Fig. 4 as well: the fermentation is a slow and laborious process, which requires continuous pH buffering with alkali, ending up with dilute Ca-lactate salt in water. To release LA from this salt, acid work-up with H2SO4, viz. the acidification step in Fig. 4, is needed but leads to the production of CaSO4 in quantities up to 1 ton per ton of LA. Moreover, the batch process is slow, corresponding to a low volumetric productivity ranging between 0.3 and 5 g L−1 h−1 [62, 63]. Aside from the gypsum issue, numerous downstream purifying steps are in place (Fig. 4) due to the complex nature of the fermentation’s living broth. To obtain pure LA via fermentation, final steps include a laborious esterification, distillation, and hydrolysis. Recently, some progress has been made in gypsum-free and other improved fermentation technologies [57], as well as in simultaneous saccharification and fermentation of cellulose feedstock [64], but the steep rise in PLA and ethyl lactate demand will further stress the fermentative process.

The global drive to degradable and recyclable polymers and the success of PLA herein thus demands a cheaper, more efficient, and waste-free LA production process. Therefore, researchers are looking for novel selective chemocatalytic routes from cellulose and carbohydrates to produce LA and its esters [10, 65, 66]. Cheaper and greater availability of LA will unlock its potential as platform chemical in a dedicated biorefinery approach. Indeed, the molecule is multifunctional and thus versatile to convert into various high value chemicals, as discussed before [29, 30, 67–69]. Before describing the state-of-the-art of the catalytic results in more detail (Sects. 5 and 6), the next section will be devoted to clarifying the mechanism and the catalytic requirements to convert cellulose into lactates.

4 Reaction Pathways and Catalytic Requirements

The price of refined sugar syrups of, e.g., glucose and sucrose, viz. around 250–500 USD ton−1, is much higher than that of raw cellulose. Direct conversion of low-value cellulose into highly priced LA or lactates, the precursors of a booming bioplastics market, is thus desired but challenging since as many as six reactions need to be controlled in a cascade reaction fashion, as seen in Fig. 5.

Step 1 is the acid- (or base-) catalyzed hydrolysis of cellulose into d-glucose. This reaction is hampered by the recalcitrant nature of the cellulose structure due to the presence of semi-crystalline and apolar domains [8]. The cellulose structure comprises chains organized into planes as a result of many inter- and intra-chain hydrogen-bonds. These planes stack on top of each other, rendering cellulose quite crystalline and hydrophobic [8, 70]. Besides several one-pot approaches combining, for instance, hydrolysis of cellulose with other reactions, such as the hydrogenation of cellulose to sorbitol [5, 71–77] or the cascade to LA in Fig. 5, the production of glucose from cellulose itself is a field of great interest on its own, as it provides an entry of cheap glucose in the biorefinery. Several groups have obtained intriguing results for this reaction in different ways [9, 78–85]. With respect to cascade transformations directly from cellulose in water, Brønsted acid-catalyzed hydrolysis is most frequently used; it is performed by taking advantage of the increased proton concentration in hot water [86] or by mineral acids such as HCl [71], heteropoly acids [87], or solid acid catalysts [71, 73, 84, 88]. The glucose yields range from 50% to 80%, depending on the catalyst nature, cellulose type and loading (usually as low as 1–5 wt% in water) and the reaction temperature (in the range of 120–180°C). The main difficulty in keeping the glucose yield high is the reactive nature of glucose, ultimately forming furans by acid catalysis and humins at higher temperatures and concentrations. Therefore, others have foreseen direct cellulose conversion to more stable molecules such as sorbitol, isosorbide [89–91], and levulinic acid [92, 93]. While (hydrolysis) reactions with cellulose in hot water have been investigated deeply, reactions in alcoholic solvents are underexplored. In addition to some heteropoly acids [94], organic acids can be used such as the combined In(OTf)3 and p-toluenesulfonic acid system, reported in a cascade towards methyl levulinate with 74% yield at 180°C [95]. While alcoholysis of cellulose to more stable products like α-methyl-glycoside is obvious [94], it is usually the major side reaction towards methyl levulinate.

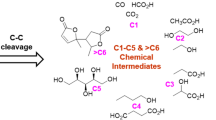

Step 2 is the isomerization of glucose to fructose. This reaction involves the conversion of the aldohexose into the 2-ketohexose. Retro-aldol reaction of the aldohexose leads to a C4 and C2 sugar, whereas the ketohexose leads to the two trioses, dihydroxyacetone (DHA) and glyceraldehyde (GLY). As the pathway to LA involves the trioses, selective glucose isomerization is essential, its conversion being limited by equilibrium in the operational temperature window. The isomerization of aldo- to ketoses can proceed via an acid-catalyzed hydride shift, a base-catalyzed mechanism with a proton shift (and intermediate enol), or via a concerted 1,2-hydride shift in neutral media [96, 97]. The latter isomerization mechanism occurs at mild temperatures (100°C) in the presence of Lewis acid catalysts, first reported by Davis and co-workers for hexoses with the use of Sn-containing Beta zeolites (BEA topology). The 1,2-hydride shift was proven with labeling experiments [96, 98, 99]. Our group recently noticed an increased isomerization activity per tin site for a Sn-Beta zeolite, which was synthesized via a dealumination-grafting sequence instead of via the common hydrothermal synthesis in the presence of HF [100]. A recent experimental comparison of reported homogeneous and heterogeneous catalysts for the glucose-to-fructose conversion has been reported [101]. Triose aldo-keto isomerization has also been assessed [97], but, in general, this reaction proceeds at lower temperatures than hexose isomerization, likely due the solely linear nature and higher reactivity of trioses. Since glucose-to-fructose isomerization is essential in the route to LA, the reaction should be fast, as otherwise glucose undergoes side reactions such as dehydrations or retro-aldol, leading to 2- and 4-carbon sugars. While being considered by-products in the pathway of cellulose to LA, these small sugars are valuable building blocks for the synthesis of other interesting α-hydroxy acids, as highlighted in Sect. 7.

Step 3 is the retro-aldol reaction of fructose into the trioses DHA and GLY. We have already described its atom economy and impact on functionality in Chap. 1 of this volume [23]. Retro-aldol is the reverse reaction of the better known aldol addition. The reaction is rare, but most famous in metabolic pathways like the third stage of glycolysis: the splitting of fructose-1,6-bisphosphate into DHA- and GLY-3-phosphate, catalyzed by aldolase A enzymes [102]. The reaction is catalyzed by a reactive lysine in the active pocket of the retro-aldolases [103, 104]. It also depends on equilibrium thermodynamics (with the inverse aldol) and reactions pulling trioses away from this. Currently, there is no chemocatalyst known that is able to perform the reaction at temperatures below 140°C. W, Pb, and Sn-based catalysts show retro-aldol activity above 150°C in water. Thermally uncatalyzed retro-aldol is demonstrated in (near) supercritical water [105, 106]. However, low selectivity is observed due to a plethora of other reactions with lower energy barriers, occurring in the high temperature conditions. One should keep in mind that C–C splitting in retro-aldol is indeed more demanding than, for instance, dehydration or hydrogenation of sugars. Development of active catalysts that selectively promote the retro-aldol reaction channel is therefore imperative.

A milestone publication in this respect came in 2010 from Holm et al., with a paper on the selective conversion of sucrose, fructose, and glucose to lactates with Sn-Beta zeolites [107]. Apparently, isolated Sn4+, coordinated in the silica framework, is able to catalyze retro-aldol chemistry at temperatures around 160°C, besides being an efficient aldo-keto isomerization catalyst, as described above. The mechanistic details are, however, not fully elucidated. A tentative mechanism was given by Taarning et al., shown in Fig. 6 [108].

Fructose undergoing retro-aldol reaction to glyceraldehyde and dihydroxyacetone, catalyzed by an isolated Sn4+ site in Sn-beta zeolite. Adapted from [108]

Step 4 in the route to LA from cellulose deals with the dehydration of the triose sugars, according to a retro-Michael mechanism, forming the unstable intermediate pyruvic aldehyde (or methyl glyoxal). This reaction is typically performed by Brønsted acid catalysis, although Lewis acids are also capable of this water elimination [109]. More mechanistic details on retro-Michael mechanisms are found in the first chapter of this volume [23].

Step 5 converts the multifunctional and thus reactive pyruvic aldehyde into its hemiacetal or hydrate, when performed in water or alcohol. Brønsted acidity typically catalyzes these reactions. Strong acidity even leads to di-acetalization, e.g., pyruvic aldehyde diethyl acetal in ethanol [65, 110].

Step 6 is the final step in the cellulose-to-lactic acid cascade, involving the isomerization of the 2-keto-hemi-acetal (here: pyruvic aldehyde hydrate) into a 2-hydroxy-carboxylic acid. This reaction is known to proceed in basic media following a Cannizzaro reaction with 1,2-hydride shift [111]. Under mild conditions, Lewis acids are able to catalyze this vital step, which can also be seen as an Meerwein-Ponndorf-Verley reduction reaction mechanism. The 1,2-hydride shift has been demonstrated with deuterium labeled solvents [110, 112]. Attack of the solvent molecule (water or alcohol) on pyruvic aldehyde (step 5) and the hydride shift (step 6) might occur in a concerted mechanism, but the presence of the hemi-acetal in ethanol has been demonstrated for pyruvic aldehyde with chromatography by Li et al. [113] and for 4-methoxy ethylglyoxal with in situ 13C NMR by Dusselier et al. (see Sect. 7) [114].

To conclude, the one-pot conversion of cellulose-to-lactic acid (or lactate ester in alcoholic media) thus follows a complex cascade reaction network involving at least six reactions. These reactions have different catalytic needs, but, in general, the presence of both Lewis and Brønsted acidity are paramount for catalytic success. Brønsted acidity is key to the hydrolysis of cellulose (step 1) at mild temperatures (<200°C), and to some extent to the dehydration of triose (step 4), whereas Lewis acid sites play a vital role in the isomerization reaction of glucose-to-fructose (step 2), the retro-aldol (step 3), and the 1,2-hydride shift (step 6). Steps 4 and 5 are relatively less demanding; they are catalyzed by both acid types.

Rather than performing the whole cascade in one pot, many reports are available which describe the catalytic needs of some individual steps. For instance, the conversion of trioses to LA (and its esters) has been studied over various catalysts by several authors. Since the number of steps is reduced from six to three (only steps 4–6 in Fig. 5), an understanding of the mechanism and description of the catalytic criteria are more evident.

5 Catalytic Conversion of Mono- and Disaccharides into Lactates

5.1 Trioses to Lactic Acid and Its Esters

As triose sugars are not abundant in nature, they are not the preferred feedstock for LA production. Oxidation of glycerol might result in a mixture of trioses, but the selectivity at full conversion is currently not high enough [40, 115]. Yet reactions with trioses are crucial for mechanistic purposes.

Conversion of trioses to lactates has been achieved in near quantitative yields in both water and alcohols in the presence of a suitable catalyst. In water, the reaction is more tedious and slower, and catalyst deactivation owing to the produced LA is more pronounced. In alcohol, the formation of the di-acetal side-product is an issue. Figure 7 summarizes the triose-to-lactate pathways. Step 4, the initial dehydration of the triose, is thought to be rate-determining in this cascade when conducted in the presence of a Lewis acid [66], but generally, it strongly depends on the catalyst and temperature.

A first eye-opening report on the conversion of trioses to alkyl lactates in alcoholic media was produced by Hayashi and Sasaki in 2005 [112], after earlier attempts by Eriksen [116] and Kelly [117]. With a simple catalytic procedure using Lewis acidic SnCl2 and SnCl4 salts (10 mol% on 0.625 M of triose) in different alcohols they achieved yields above 80% of methyl, ethyl and butyl lactate, in a 1 h reaction at 90°C. Later, Rasrendra et al. explored this reaction in water, and, there, different catalytic trends were found [118]. Whereas Sn2+ and Sn4+ were clearly superior to Cr3+ and Al3+ chlorides in Hayashi’s work in alcohol, in water Cr3+ and Al3+ were better catalysts for LA synthesis. They showed a 90% yield in 1.5 h at 140°C using 5 mol% of Al3+ on 0.1 M of triose. In our experience, working with Sn salts in water entails the formation of polymeric Sn-(hydr)oxide precipitate. With AlCl3, the authors have assessed the activation energies for step 4, viz. the triose dehydration to pyruvic aldehyde, and the concerted steps 5 and 6, viz. LA from pyruvic aldehyde. Values of 93 and 58 kJ mol−1 were respectively calculated, proving dehydration (step 4) to be the rate-limiting step under mild conditions. In the presence of Al and Cr halides, the pH of the reaction medium was lowered to about 3, and it was shown that the released protons assisted in the rate-determining dehydration step [118]. Finally, alkaline earth metal hydroxides and especially Ca(OH2) at 2:1 OH−:DHA ratio in water, were found to be very active for the conversion of DHA to LA via the keto-enol route, with yields up to 59% at only 25°C for 1 h. However, such alkali approaches are corrosive and end up with lactate salts instead of the free acid, and the advantage of Lewis acid catalysis over fermentation in these basic conditions is thus lost [119]. Although these homogeneous studies are very informative, the search for heterogeneous catalysts has received increasing attention since Sels and co-workers reported the first heterogeneous catalyzed triose conversion based on H-USY zeolites [120].

The use of heterogeneous catalysts has many advantages, such as their easy separation and reuse. Sels et al. have further unraveled the active sites of the USY zeolite and they have noticed a clear connection between the ethyl lactate selectivity and the amount of extra-framework aluminum [110]. While most framework Al in common zeolites delivers Brønsted acidity when counterbalanced with H+, steam and acid treated zeolites like USYs also contain several types of extra-framework Al such as AlO(OH) and Al(OH)2+ and they offer the required Lewis acidity. Thus, Brønsted acidity is required to dehydrate the trioses, while Lewis acidity favors the 1,2-hydride shift. Too strong Brønsted acidity should be avoided since it favors the formation of the di-alkyl acetals instead of lactates (see Fig. 7). High selectivity is thus obtained in the presence of a medium density of (weak) Brønsted sites, together with a high density of Lewis acidic sites. Such a balance was found by investigating the commercial CBV USY-zeolite series. Figure 8a shows that the optimal Lewis (extra-framework) vs Brønsted (framework) balance was present in CBV 600 – with 27% of framework Al – leading to the highest lactate selectivity of 77% at 90°C. Independently, West et al. have confirmed the use of USY for lactate synthesis from trioses, and also studied a continuous flow setup. Furthermore, they unraveled the reasons for catalyst deactivation [121]. In alcoholic media, the deactivation is nearly zero, but in water, the presence of LA (pKa 3.72) destroys the zeolite structure. Another reason for deactivation is the deposition of carbonaceous cokes, which is said to derive from side reactions with methylglyoxal or LA.

Catalytic trends for the conversion of dihydroxyacetone at 90°C in ethanol. (a) Selectivities of different USY zeolites with varying amount of framework aluminum. (b) Sn-containing carbon-silica catalysts: correlation between n° of weak Brønsted acid sites (measured by CO x release in TPD-experiments) and initial conversion rate. Based on data from [110] and [66]

Alongside the classic Si- and Al-containing zeolites, the design and catalytic use of zeolites and other microporous materials with Lewis acidic heteroatoms has been reported, with a focus on substituted heteroatoms in zeolite frameworks. In 2009, Taarning et al. used Sn-Beta zeolites and reported LA and lactate yields of 90% and 99%, respectively, for the complete conversion of DHA in water and methanol, respectively, at either 100°C or 80°C with an Si:Sn ratio of 125 [65]. The reaction was near to completion after 6 h. The initial turnover frequency was calculated to be 45 mol molSn h−1. In comparison, Hayashi’s soluble SnIVCl4.5H2O salt only reached about 4.2 mol molSn h−1. Since then, numerous reports have surfaced in the literature studying (among other catalysts) the use of Sn-MCM-41 [113], Sn-SBA-15 [122], Sn-MFI [123], Sn-montmorillonite [124], Sn-MWW [125], gallium oxides [113], desilicated MFI zeolites [126], GaUSY as well as other post-synthetic galliated-zeolites [127, 128], and novel Sn-Beta zeolites made via dealumination and post-synthetic Sn incorporation [129]. A comparison of some of the reported (metal-substituted) zeolites for the conversion of DHA in water or alcoholic media is given in Table 1. Entries 1–4, reported by Taarning et al., compare different Lewis acid-containing Beta zeolites (BEA) and a classic Al-Beta for their activity in the conversion of DHA to methyl lactate in methanol. Clearly, Sn is the most active Lewis acid for this conversion in comparison to Zr and Ti. The Brønsted acidic Al-Beta mostly catalyzed the formation of the di-acetal side product in line with the high framework Al in the USY series of Sels et al. (see Fig. 8a) [110]. Not only is the conversion with Sn-Beta complete and the selectivity near 99%, the zeolite with Sn is also able to perform this reaction at a lower reaction temperature of 80°C, whereas the other metals required 115°C. A higher reaction temperature is needed in water to compensate for the slower reaction, but the yield remained high (entry 5, Table 1). Tsapatsis and co-workers compared hydrothermal Sn-MFI (small pore zeolite) and Sn-Beta (large pore zeolite) for the title conversion and noticed a higher yield for the MFI topology in their conditions (entry 7).

As hydrothermally synthesized Sn-BEA and Sn-MFI zeolites are difficult to synthesize, other synthesis methods following post-synthetic metal incorporation or modification were attempted. For a start, Hermans and co-workers have devised a new synthesis route to Sn-Beta via complete dealumination in strong acid, followed by solid state Sn exchange using SnIIacetate. They noticed a high productivity of their catalyst due to the high Sn content (10 wt%, entry 6). Secondly, inspired by Hermans et al., Hensen and co-workers have reported the full deboronation of B-MWW and subsequent grafting with SnCl4.5H2O in the presence of hexamethyleneimine [125]. The choice for MWW was for reasons of accessibility in anticipation of converting more bulky substrates such as glucose and fructose (see later) along with trioses. The MWW topology comprises a 10-membered ring interlayer pore opening connected to a 12-membered ring supercage and an independent intralayer sinusoidal 10-membered ring channel [130]. Sn-MWW exhibited comparable activities to Sn-Beta (entry 8). In light of avoiding Sn and inspired by the extra-framework Al Lewis acidic results of USY, Dapsens et al. have investigated the creation of Lewis acid sites from Al containing ZSM-5 (MFI) zeolites via alkaline desilication [126]. They have demonstrated a highly selective Lewis acidic site for making LA from trioses in water, but they also noted that the catalyst was in need of a high reaction temperature (entry 9, Table 1) and that the catalyst stability was limited. Their research showed leaching of Al species from the zeolite caused by the low pH of the LA product solution. Dapsens et al. continued their effort by working in ethanol and by creating gallium Lewis acid sites by metalation during desilication in alkaline conditions in USY zeolites [127, 128]. These zeolites are the most selective non-tin materials reported at temperatures below 100°C in alcoholic media; one catalytic experiment is illustrated in entry 10. Entries 11 and 12 display two entries of the CBV series of Sels and coworkers and the effect of temperature.

The importance of a balanced catalyst with appropriate number and strength of Lewis and Brønsted acid sites has been demonstrated by de Clippel et al. They have designed a porous carbon–silica composite with independently tunable mild Brønsted acidic sites and Lewis acid Sn [66]. The catalyst was composed of an Si-MCM-41, grafted with Lewis Sn sites (e.g., 0.5 wt%), and filled with intraporous carbon by furfural impregnation and pyrolysis under helium. A schematic representation of the catalyst structure is displayed in Fig. 9. The intraporous carbon compound has weak surface acidic groups such as –COOH and phenols, which could easily be tuned by changing the temperature in the pyrolysis or by a post-synthetic oxidization treatment in air, while the Sn content is easily changed in the grafting step. In this way, for a given content of Sn, it was unambiguously shown that the rate could be enhanced sevenfold simply by increasing the mild Brønsted sites per Sn, in line with the acceleration of the rate-limiting triose dehydration step (4 in Fig. 7). The figure of merit is shown in Fig. 8b. The rise in initial reaction rate in function of the amount of Brønsted acidity, measured as the release of CO x species in separate TPD analysis, is apparent. Comparing the initial turnover per Sn for the parent Sn-MCM, viz. 41 mol molSn h−1, in close agreement with that of Sn-Beta, with the record of 289 mol molSn h−1 for the optimal hybrid catalyst, validates the mechanistic proposal [66]. More information on the design and synthesis of nanohybrid and nanocomposite catalysts for use in multi-functional cascades – as often needed in selective catalytic approaches for biomass conversion – is found in our recent review [131].

Carbon silica composite catalyst design, based on Sn-grafted Si-MCM-41 and intraporous carbon with mild Brønsted acid sites. Adapted from [66]

5.2 Hexose-Based Sugars: Sucrose, Glucose, Fructose

The conversion of hexoses to LA is one of the most atom efficient cascade transformations out there, fully preserving (and even enhancing) chemical functionality (F:C of 1.17 for hexoses, vs 1.33 for LA, see [23]). However, the reshuffle of O atoms in the molecule and the selective C–C breakage requires multiple steps, and a selective catalyst. There is currently good insight into the reaction network with the details presented in Figs. 5 and 11.

5.2.1 Reactions in Alcoholic Solvents

Realization of high alkyl lactate yields from trioses in various alcohols is thus possible. For hexoses this implies that steps 2 and 3 of the reaction cascade in Fig. 5 require extra attention, before the known triose chemistry can ensue. The isomerization in step 2 is not difficult, but one encounters the equilibrium situation between glucose and fructose. As a consequence, the substrate selectivity in step 3 is probably most challenging since fructose, and not glucose, should be converted via retro-aldol. Besides, other side reactions like sugar dehydration and sugar alkylation (when performed in alcohol) are competitive as well. Lobo has pointed out the resemblances of the glucose-to-lactate route with the natural glycolysis pathway in living cells [132]. The conversion of trioses into LA via pyruvic aldehyde in turn presents a biomimetic of the enzymatic glyoxalase system, as suggested by Sels et al. [120].

The major breakthrough in lactate synthesis from hexoses was made in 2010 by Holm et al., who applied Sn-Beta to convert sucrose at 160°C in methanol, yielding 64% methyl lactate. Figure 10 summarizes the key catalytic results in black. As mechanistically proposed in Fig. 6, Sn4+ is capable of coordinating both a hydroxy and the keto group of fructose, thereby facilitating retro-aldol cleavage in the β position (between C3 and C4) to the carbonyl. This reaction is attributed to the known tendency of Lewis acid SnIV to coordinate −OH bonds rather than to form Sn–O–C bonds [133, 134]. Besides being active for this particular C–C scission, equally important, Sn-Beta Lewis acid sites do not easily dehydrate hexoses or form stable methyl glucosides, two competitive side reactions [135].

Comparison of catalytic yields of methyl lactate for the conversion of hexose-based sugars in methanol with different heterogeneous catalysts. CSM = carbon silica composite. Conditions: 160°C, 20 h, 22.5 mgsugar mL−1, 16 mgcatalyst mL−1 (slightly different for CSM: respectively 155°C, 30 and 21 mg mL−1). All conversions >95%. Data from [66, 107, 125]

de Clippel et al. also tested their bifunctional carbon–silica composite material (Sn-CSM) for this reaction with slightly lower methyl lactate yield (up to 45% from sucrose), as seen in Fig. 10 in grey. They figured out that the Brønsted acidity, which was beneficial to accelerate the triose reactions, caused multiple side reactions such as methyl glucoside formation and dehydration towards levulinate esters. The use of composites with less Brønsted acidity was necessary to obtain a high methyl lactate yield. The presence of low amounts of these sites was, however, still beneficial, as parent siliceous Sn-MCM only yielded 18% [66].

Hensen and co-workers have used the Sn-MWW zeolite (see above) to convert hexoses to methyl lactate and they achieved identical results for glucose and fructose as with Sn-Beta, but somewhat lower yields (50%) were analyzed for reactions with sucrose (blue bars in Fig. 10) [125].

In Fig. 10, two trends emerge: (1) the catalysts achieve higher yields for the disaccharide sucrose when compared to that of the monosaccharides, fructose and glucose; furthermore, (2) no difference is found in methyl lactate yields for the Sn-zeolites, when the reaction is carried out with glucose or fructose, except in the case of the composite Sn-CSM, which shows remarkable higher yields with fructose when compared to glucose (32% vs 17%), respectively. The latter effect is due to the lower tendency of grafted Sn in mesoporous silica to isomerize glucose into fructose. Indeed, in contrast to the Sn zeolites [99], low isomerization capacity of the Sn-CSM was demonstrated for glucose in water at 100°C [66].

The notable difference in methyl lactate yield from sucrose or hexoses is likely attributed to the higher thermostability and hydrolytic resistance of the disaccharide. Sucrose is a non-reducing sugar with both carbonyl groups protected in the α,β-(1 → 2) glycosidic bond [136]. Consequently, the slow release of hexoses from sucrose in solution prevents unwanted side reactions with the more labile glucose and fructose. Such effects have also been witnessed in the conversion of cellulose to sorbitol and ethylene glycol, for which the highest selectivity is obtained when cellulose hydrolysis is rate-determining [72, 137]. An elegant solution to this phenomenon is the use of a fed-batch reactor system with glucose feedstock, mimicking the slow release of glucose from cellulose hydrolysis and thus minimizing side reactions [138, 139]. Such endeavors remain unexplored for lactate synthesis, and one could envision the use of more recalcitrant inulin polymers (containing anhydrofructose units) or a fed-batch reactor feeding hexoses.

Aside from the superior catalysts mentioned above, Osmundsen et al. have reported the use of hydrothermally synthesized Sn-SBA-15, Sn-MCM-41, and Sn-MFI for sucrose to methyl lactate in methanol, but their yields ranged between 20% and 30% [122]. A similar 18% yield was reported for the parent material of the Sn-CSM catalysts. This mesoporous stannosilicate was made via Sn grafting procedure [66]. Murillo et al. reported a yield of 43% of methyl lactate from glucose, with a different hydrothermal Sn-MCM-41 [140]. Apart from tin-catalysts, Liu et al. reported on the use of basic MgO in MeOH, but only 30% of methyl lactate was formed for glucose and other hexoses at a high 200°C [141].

To conclude, 4 years of research since the original report still demonstrate the superior activity of the original Sn-Beta to convert sucrose directly to methyl lactate in methanol [107]. The catalyst is recyclable at least up to six times by intermittent calcination, and the methyl lactate yield remains 60% at full conversion after 20 h, even when more concentrated sucrose (10 wt%) was used, corresponding to a volumetric productivity of 3.3 glactate Lreactor −1 h−1. Since both this heterogeneous and the fermentative approach mainly run the process on sucrose or hexoses, a comparison is made in Table 2 for a set of parameters. It may be clear that the heterogeneous route is clearly a less complex process with many advantages, but mainly the lower selectivity and volume productivity need to be improved in order to overtake the fermentation. Moreover, racemic lactates are produced which can be seen as a disadvantage for direct L-PLA synthesis, but interestingly also provide an equal source of d-isomer, given a successful enantioseparation, as explained in Sect. 8.

Despite the unique ability of Sn-zeolites, their performance in terms of activity and selectivity is the main issue to improve before competing with the fermentation route. In our belief, the race to search for better heterogeneous catalysts has just started. A profound study of the formation of the side-products is the first step towards the design of outstanding catalysts. All identified side products seen when using Sn-CSM and Sn-Beta in methanol are incorporated in Fig. 11, with their respective origins indicated in specific colors: red (methylation of sugars), blue (retro-aldol derivatives of glucose), and black (dehydration products, usually via fructose).

Side products in the sucrose-to-lactate (green) conversion in MeOH and their origin: blue: retro-aldol of glucose (see Sect. 7); red: methanolysis of sucrose or acetalization of glucose; black: dehydration of sugars to HMF, furan ethers and humins. MMHB: methyl-4-methoxy-2-hydroxybutanoate, MVG: methyl vinyl glycolate, MHB: methyl-2-hydroxybutanoate, GADMA: glycolaldehyde dimethyl acetal. HG = hydrogenation

To start with, in methanol – which always contains some water unless extreme solvent drying is pursued – sucrose either undergoes hydrolysis or solvolysis. The latter is indicated in red in Fig. 11 and usually yields methyl-d-glucopyranoside and fructose from sucrose instead of methyl-fructoside and glucose. These methylated sugars are non-reducing and chemically more stable; they are considered unreactive to retro-aldol chemistry, since their ether bond should be hydrolyzed prior to be of use in the lactate synthesis.

Second, the retro-aldol reaction applied to glucose (indicated in blue) is the major side reaction, yielding C2 and C4 sugars, which in turn undergo multiple chemical transformations. The most common products are 4-carbon backbone α-hydroxy acid esters: methyl-4-methoxy-2-hydroxybutanoate (MMHB), methyl vinyl glycolate (MVG), and methyl-2-hydroxybutanoate (MHB). The formation of these intriguing and useful esters from tetroses was recently unraveled by Dusselier et al., and the reaction networks are discussed in more detail in Sect. 7. Their formation bears a close resemblance to that of the lactate system, but important differences exist. Besides the four carbon products, the diose glycolaldehyde is converted to methyl glycolate or its di-acetal GADMA. For instance, in the conversion of sucrose with the optimal Sn-containing CSM composite, in total 10% of the input sugar was converted according to the blue pathway [66].

Lastly, dehydration of hexoses produces side products (indicated in black). Both di- and tri-methoxylated acetals of HMF, as well as methyl levulinate, were analyzed and their formation is usually enhanced by the presence of Brønsted acidity. de Clippel et al., for instance, noticed an increase in these products from <1% with the optimal Sn-CSM composite to about 18% with an oxidized CSM, bearing a high density of Brønsted acid sites. Excess of these sites was less problematic in the case of triose conversion (see Fig. 8b), due to the lower process temperature and the less complicated cascade. For Sn-Beta, alongside 8% of MVG, no major side product was identified. The deficiency in carbon is probably due to some humin formation, which can proceed from glucose as well as from HMF, as recently demonstrated [142, 143]. Their presence indicates that the retro-aldol reaction is not fast enough, thereby allowing the free aldehyde groups of the sugars to undergo unwanted side reactions.

5.2.2 Reactions in Water

The conversion of sucrose to LA in water was assessed with Sn-Beta zeolite, but only low yields of LA of less than 30% were encountered [107]. Besides LA, HMF and levulinic acid were analyzed in the product mixture. One reason of the significant change in product spectrum was related to the auto-catalytic effect of LA. Its acidity lowers the pH of the medium, thereby enhancing the dehydration rate with an increase of HMF and the likes in the product spectrum as a result [107]. Pronounced carbonaceous deposits on the catalysts confirmed its deactivation by LA, similar to the triose reaction in water.

Besides the above-mentioned heterogeneous catalytic approaches in alcoholic or aqueous media, the use of soluble Lewis acidic salts in water has recently been investigated under catalytic conditions for glucose and fructose. Heeres and co-workers explored the use of Al3+ and Cr3+ salts at 140°C in 2010, but they have found only about 20% of LA with AlCl3 [144]. Lanthanide triflates such as Er(OTf)3 have been reported to yield around 50% of LA from the common hexose sugars. This reaction was, however, carried out at a high 240°C [145]. A breakthrough for this reaction in water was made very recently by Wang et al., who discovered the remarkable catalytic nature of Pb2+ for the reaction of hexoses (and even cellulose; see below) to LA. In the presence of 7 mM of PbNO3, for instance, a 25.5 mM solution of glucose or fructose was transformed, respectively, into 65% and 74% of LA at 170°C, with unparalleled selectivity [146]. Fructose was noticed as the intermediate when reacting glucose, and the reaction mechanism was explained in agreement with steps 2–6 in Fig. 5. Computational results indicated that the presence of the lead ions significantly lowered the activation barrier for the retro-aldol reaction of fructose. This research is considered an important result, as the group of very active (at mild temperature) retro-aldol elements now contains an additional member, albeit a very toxic one. Besides these mild hydrothermal catalytic approaches, near critical water has been investigated as reactive medium for LA production as well, both from sugars and cellulose, with several homogeneous and heterogeneous catalysts. These often alkaline approaches, are not the scope of this review, but noteworthy studies in high temperature flow setups have been reported by Bicker et al., using ZnSO4, [170] and Esposito et al [171]. The latter reported LA yields up to 57 % on a 0.025 M glucose solution with 0.1 M of Ba(OH)2 at 250°C for 3 minutes.

5.3 Other Carbohydrates, Pseudo-hemicellulose, and Glycolaldehyde

Holm et al. further exploited Sn-Beta for the conversion of hemicellulosic sugars such as pentoses in near identical conditions as in Fig. 10. For one, they obtained a yield of 42% of methyl lactate for xylose [147]. Retro-aldol here evidently delivers glycolaldehyde along with a triose and, therefore, 5% of GADMA (structure in Fig. 11) was found, alongside 7% of MVG. Furthermore, a pseudo-hemicellulosic model mixture was assessed, composed of 1/6 of each of following sugars: xylose, arabinose, ribose, glucose, mannose, and galactose. Their conversion with Sn-Beta yielded 43% of methyl lactate in methanol, in line with the linear combinations of the yields attained for each sugar individually. Interestingly, the conversion of glycolaldehyde resulted in 16% methyl lactate, 27% MVG, 7% GADMA, and 6% MMHB. This is an intriguing result, as (1) the formation of 4-carbon backbone esters MMHB and MVG from the C2 sugar implies Sn-Beta catalyzes aldol reactions and (2) the formation of lactate implies that retro-aldol reaction occurs simultaneously under these conditions (160°C, methanol). Both observations indicate that hexoses were formed from subsequent aldol reactions with glycolaldehyde. A detailed reaction pathway to convert glycolaldehyde to methyl lactate is presented in Fig. 12. The presence of the intermediately formed hexose sugars was supported by the presence of trace amounts of HMF. Later, the selective conversion of glycolaldehyde to the useful 4-carbon backbone α-hydroxy esters MVG and MMHB instead of lactates was targeted by Dusselier et al. as discussed in Sect. 7 [148].

6 Direct Catalytic Conversion of Cellulose into Lactic Acid

Despite promising results with sugars, the direct use of cheaper cellulose is of course more appealing. A first attempt towards converting cellulose was made by feeding cellobiose in presence of Sn-Beta [147]. Cellobiose is a disaccharide of glucose with a β-(1-4) glycosidic linkage similar to that of cellulose. The authors have reported that only 13% of methyl lactate yield was obtained after 44 h of reaction at 160°C. Furthermore, in contrast to the near complete conversion for sucrose after only 20 h, 39% of unconverted sugars were recovered for cellobiose, resulting in a lactate selectivity of only 21%. This points to a low hydrolysis activity of the Sn Lewis acid sites (step 1 in the cascade in Fig. 5) or a limited accessibility to the glycosidic bond. The direct use of cellulose in catalytic conditions has been reported as well, but yields of LA (or esters) never exceeded 30% [149]. A first heterogeneous example of this was given by Chambon et al., using AlW (tungstated alumina) with a yield up to 28% of LA with 60% selectivity at 190°C for 24 h [150].

In 2013, remarkable progress was made when two research groups independently published on cellulose conversion, either in the presence of lanthanide triflates [145] or Pb2+ ions [146], showing LA yields of 89% and 68%, respectively. Soluble lanthanide triflates are famous Lewis acid catalysts because they retain their pure Lewis acid property in H2O, in contrast to soluble Al and Sn salts (which provide Brønsted acidity as well or decompose). Moreover, for homogeneous catalyst standards, they are easy to recover. Wang et al. have screened a range of triflates for the conversion of untreated cellulose at 240°C under an inert 2 MPa N2 atmosphere [145]. Despite the severe temperature, all triflates produced LA yields above 50%. Lanthanides with the smallest ionic radius such as erbium, ytterbium, and lutetium provide the best results (see Fig. 13). The authors stated that the smaller cation radius of a metal explains its stronger ability to coordinate wih the hydroxyl groups and that this lead to the higher catalytic activity.

Different lanthanide triflates for the conversion of cellulose to LA. 240°C, 2 MPa N2, 30 min, 0.3 g cellulose, 0.05 g triflate, 30 mL H2O. Adapted from [145]

The hydrolysis of cellulose was ascribed in this report to be promoted by hydroxonium ions from water auto-protolysis. Since Wang et al. worked at 240°C, this is in agreement with other reports showing Brønsted acid catalysis in water above 200°C [86]. Moreover, the yield and conversion dropped to only 14% and 25%, respectively, at 200°C, confirming the need for Brønsted acidity from the hot water and thus the lack of hydrolysis capacity of the La triflates. In a search for industrial relevance, the authors tested higher cellulose loadings. For 0.5 g cellulose in 30 mL water, under the conditions of Fig. 13, they achieved a LA yield of 50%. A quick calculation reveals a corresponding volumetric productivity of 17.7 gLA Lreactor −1 h−1. At 0.1 g cellulose, their yield mounted to 89% of LA, but at a lower productivity of 6.3 gLA Lreactor −1 h−1. These volumetric productivities are considerably high when compared to those of the fermentation and heterogeneous approach on hexoses in Table 2. Reactions with soluble catalysts are often more laborious though: the lanthanide catalysts were recovered via vacuum distillation, diethyl ether dissolution, and solvent evaporation, but could be reused several times. The ether dissolution was needed to separate the catalyst from the humins formed. This report is very interesting because it demonstrates high yields at short reaction times, with the need for hot water to promote cellulose hydrolysis [145].

Direct conversion of cellulose to LA was also achieved under milder conditions in the presence of Pb(II) ions [146]. As hydrolysis was too slow at 190°C for crystalline cellulose, ball-milling was used to enhance its reactivity. Such mechanical treatment is an effective way to decrease the biopolymer’s crystallinity and to enhance the accessibility for chemicals (and catalysts) by increasing the surface area [8, 9, 78, 151–153]. Here, ball-milling reduced the crystallinity from 85% to 33%, as ascertained by XRD analysis. Among a series of other ions (7 mM) assessed at this temperature, Pb was highly selective to LA, yielding 68% after 4 h for 0.5 wt% cellulose solutions in water. Second best was Al3+, in line with the catalytic results of Heeres et al. [144], showing 35% LA yield. Untreated cellulose required 15 h at 190°C to reach complete conversion with a LA yield of 62%. This reaction rate is quite fast, indicating that Pb2+ salt itself, in contrast to the previous lanthanides, also assists the hydrolysis step (step 1 in Scheme 5). A more concentrated 2.5 wt% cellulose slurry of milled cellulose was converted in 10 h in the presence of 6 mM of Pb2+ at 190°C, yielding 55% LA, corresponding to a volumetric productivity of 1.5 gLA Lreactor −1 h−1. Besides purified cellulose, several raw biomass feedstocks were converted and LA yields were always around 40%. Interestingly, the authors demonstrated an autocatalytic assistance of LA to fasten the hydrolysis of cellulose, as shown in Fig. 14. The intentional addition of LA significantly shortened the reaction time (by a factor of 3) to achieve 60% yield of LA in the conversion of microcrystalline cellulose.

Enhancement of the rate of LA formation from microcrystalline cellulose in the presence of Pb2+ with addition of LA. 190°C, 3 MPa N2, 30 min, 0.5 g cellulose, 7 mM PbIINO3, 100 mL H2O. Adapted from [146]

Besides these experimental achievements, the authors have discussed the reaction pathway thoroughly; their reaction network is in line with the reaction scheme in Fig. 5. Thermodynamics were calculated and DFT calculations suggested that the coordination of PbII with three oxygen atoms of fructose increases the positive charge of the C4-OH, facilitating its proton transfer to C2 = O, and thus the retro-aldol of fructose. Apart from this, Pb(II)-OH was postulated to be the active species in solution. Although Pb2+ could be completely recovered from the reaction, it is a very toxic cation. Nevertheless, this research demonstrates the potential of chemocatalysis to convert cellulose to LA and should therefore motivate the search for more environmentally friendly catalysts [146].

7 Catalytic Synthesis of Other Biomass Derived α-Hydroxy Acids

7.1 C2: Glycolic Acid

Besides LA, other α-hydroxy acids (AHA) are very intriguing molecules as well, because of their multifunctionality and their relevance for polyesters. For instance, the biodegradable polymer polyglycolic acid is of commercial interest. Its monomer, glycolic acid (or 2-hydroxy acetic acid, GA) is, however, not derived from renewable resources at the moment, but via the carbonylation of formaldehyde with H2SO4 [154]. A route via the hydrolysis of molten monochloroacetic acid with NaOH is also known [155]. It is used in dyeing and printing and it acts as a Ca2+ ion chelator and antibacterial agent. In 2011, about 40 ktons were produced worldwide [154]. The synthesis of polyglycolic acid from glycolic acid is analogous to PLA from LA (Fig. 4) and thus proceeds via ring-opening polymerization of glycolide, its cyclic dimer [59].

As the current synthesis of GA is non-renewable, the development of biomass derived and more efficient routes is an interesting topic. Two catalytic carbohydrate-based approaches deserve some attention. In light of the valorization of cellulose to LA discussed above, the approach by Zhang et al. is of interest as they have reported the conversion of α-cellulose into GA in one pot over a phosphomolybdic acid catalyst (H3PMo12O40). This reaction proceeded in water at 180°C under light oxygen pressure (0.6 MPa) and is shown in Fig. 15 [156]. At best, 0.2 g of cellulose was converted in 20 mL of water containing 15 mM of heteropoly acid over the course of 1 h, yielding 49% of glycolic acid and 10% of formic acid [156]. This is impressive, considering the conditions and the fact that the cascade seen in Fig. 15 is as complicated as that in the formation of LA; it involves not only hydrolysis of cellulose and multiple retro-aldols of many sugars, but also the oxidation of glycolaldehyde and formaldehyde. The F:C index of glycolic acid is 2, and this route from carbohydrates has a theoretical atom economy of 100%, indicating a realistic alternative to the petrochemical route for GA [23].

Proposed pathway for converting cellulose to glycolic acid. Adapted from [156]

Beside the direct approach from cellulose presented above, Dapsens et al. recently proposed a route to convert glyoxal to GA under mild conditions with heterogeneous catalysis in both batch and flow conditions [154]. Glyoxal is currently obtained through oxidation of acetaldehyde or ethylene glycol [157], but it is also present in pyrolysis bio-oil, albeit in low quantities ranging from 1 to 3 wt%. Some catalysts known for their LA synthesis from trioses were tested, such as extra-framework aluminum containing USY zeolites and Sn-MFI. The latter, for instance, produced about 91% yield of GA at 90°C after 6 h, using 0.2 g of glyoxal in 3.8 mL H2O. The reaction mechanism was studied via deuterium labeling and was found to proceed exclusively via a 1,2-hydride shift mechanism of the mono-hydrate form of glyoxal as seen in Fig. 16. This is in complete analogy with the conversion of trioses to lactates [110]. The conversion of GA into alkyl glycolates was demonstrated in alcoholic media as well [154].

7.2 C4: 4-Alkoxy-2-Hydroxybutanoates and Vinyl Glycolic Acid

Inspired by the easy conversion of trioses to lactates, and determined to unravel the faith of the retro-aldol products of glucose, viz. erythrose and glycolaldehyde (the blue pathway in Fig. 11), Dusselier et al. set out to convert tetrose sugars with a focus on 4-carbon AHA esters in order to present a mechanistic proposal [114]. They have discovered the unique catalytic property of Sn halides to form methyl vinylglycolate (MVG) and methyl-4-methoxy-2-hydroxybutanoate (MMHB) from tetroses. For instance, in 1 h at 80°C, with 10 mol% of SnCl4.5H2O, 83% of MMHB and 2% of MVG were analyzed in a reaction using 0.63 M erythrulose in methanol. In situ NMR spectroscopy, deuterium labeling, and control experiments with intermediates revealed the individual pathways to both 4-carbon AHA esters. The cascade, shown in Fig. 17, starts with two consecutive retro-Michael dehydrations, of which the mechanistic details are visualized in the first chapter of this volume [23]. They lead to the highly reactive proposed intermediate vinyl glyoxal. Its reactive aldehyde group quickly transforms into a hemi-acetal, as seen in Fig. 17, identical to the case of pyruvic aldehyde in lactate synthesis. The reactivity of this molecule is decisive for the reaction selectivity: either a 1,4-addition of MeOH or a Lewis acid catalyzed 1,2-hydride shift ensues. The former leads to the in situ observed 4-methoxy-ethylglyoxal-hemi-acetal (MEGHA in Fig. 17) intermediate, which then undergoes a 1,2-hydride shift into MMHB. However, occurrence of the 1,2-hydride shift of the hemi-acetal of vinyl glyoxal prohibits the 1,4-addition and MVG is formed instead. The kinetic competition between the hydride shift and the 1,4-addition is thus key to the product outcome. In methanol, the addition is fast and thus MMHB is found as the major product. In isopropanol, the 1,4-addition is more hindered, whereas the intramolecular hydride shift is not affected by the alkyl chain of the hemi-acetal and thus isopropyl vinyl glycolate was found as the major product [114]. Hydrolysis of these ester mixtures renders access to different 4-alkoxy-2-hydroxy-butanoic acids and/or vinyl glycolic acid (VGA).

The fate of glycolaldehyde under similar conditions was the subject of another study [148]. This 2-carbon sugar feedstock is of more relevance due to its pronounced presence, up to 10 wt%, in cellulose pyrolysis oils [158–160]. The authors proved that, under the same catalytic conditions, tin salts catalyzed the aldol reaction of two glycolaldehyde units into tetrose sugars, as seen in grey in Fig. 17, as well as the ensuing reactions. The rate-determining step of the entire glycolaldehyde to MMHB and MVG cascade was, however, not found in the aldol addition. Due to the alcoholic solvent, glycolaldehyde dimethylacetal (GADMA, seen in Fig. 11) was formed immediately after dissolving the 2-carbon sugar. In order to allow aldol, hydrolysis of GADMA to unprotect the active carbonyl group is necessary and rate-determining. By adding small amounts of water to methanol (1:7), the reaction rate was enhanced almost fivefold. Finally, Dusselier et al. also presented the first proof of the usefulness of these monomers by incorporating vinyl glycolic acid (VGA, via hydrolysis of MVG) together with LA into a co-polymer by polycondensation, as seen in Fig. 18. The resulting polymer had an enhanced thermal stability, a function of the amount of VGA incorporated (denoted as x). The vinyl side group was preserved during the polymerization. This PLA polymer with vinyl side groups has tremendous potential, as it makes it easy for one to modify or create more complex PLA-based polyesters. The vinyl group proved, for instance, accessible to thiol-ene functionalization chemistry, which rendered a PLA with enhanced hydrophilic properties with respect to identically made pure L-PLA [148]. Moreover, VGA, with its F:C value of 1.25 and a theoretical atom economy of 85% (via glucose, considering retro-aldol and C2-aldol coupling [23]) is an excellent and viable biomass target chemical, which is difficult to prepare from fossil resources.

7.3 C6: Furyl Glycolic Acid

The group of Dumesic recently reported on a novel and inventive route for the renewable production of furyl glycolic acid (FA) [161]. This is a pseudo-aromatic AHA, likely suitable for co-polymerization with LA. An inspiring combination of both enzymatic and heterogeneous catalysis proved key in the new route (Fig. 19). In short, glucose is converted into cortalcerone via glucosone using recombinant Escherichia coli strains expressing pyranose-2-oxidase and aldos-2-ulose dehydratase in whole cell catalysis. Cortalcerone is then dehydrated towards furyl glyoxal hydrate over a Brønsted acidic Al-Beta zeolite. The final step in the hybrid cascade is the 1,2-hydride shift turning the hydrate into FA with the Lewis acidic Sn-Beta zeolite. The last two steps of this cascade were also attempted in one pot using a methanol/water mixture in presence of an Al-containing Sn-Beta zeolite. This material, possessing both Brønsted and Lewis acid sites, achieved 42% selectivity to FA at 53% cortalcerone conversion at 85°C in 0.5 h [161].

Pathway for the conversion of glucose to furyl glycolic acid (FA), via enzymatic cortalcerone synthesis, Brønsted acid, and Lewis acid catalysis. Based on [161]

This example nicely illustrates the integration of bio- and chemocatalysis in creating novel added-value chemicals such as FA from biomass [162, 163]. FA has a very high functionality index of 1.33 and the reaction runs at moderate atom economy of 67% (see Chap. 1 of this volume [23]). Moreover, petrochemical-based routes to this compound seem highly unlikely. The co-polymerization of FA with LA or GA should be looked into, as interesting polymer properties are bound to surface due to the unique position of the furan ring as side group in the PLA based co-polyester. Next to the aforementioned vinyl glycolic acid – with proven polymer potential – this monomer could present new opportunities for functional PLA or bio-derived polyesters.

8 Note on the Stereochemistry of Chemically Produced Lactates

The above-mentioned chemical catalytic routes lead to racemic AHA mixtures. For the direct use of LA (or its esters) as a solvent or platform molecule for achiral molecules like acrylic acid and pyruvic acid, stereochemistry does not matter. The properties of the polyester PLA, the major application of LA, however, suffer tremendously if d and l isomers are built in irregularly [28]. This is exemplified by atactic PLA, made from racemic LA, which is an amorphous polymer with low performance and limited application. However, when l- and d-lactic acid are processed separately into their respective isotactic l- and d-PLA, as discovered by Tsuji et al., a stereocomplex is formed upon blending these polymers. This polymer exhibits enhanced mechanical and thermal properties [28, 164]. A productive route to d-lactic acid is, however, missing today. If the chemocatalytic routes to LA are to become viable, enantiomer resolution of the racemate needs to be performed. Given separation success, a cheap source of d-lactic acid will be unlocked immediately, providing an additional advantage over the fermentation route (cfr. Table 2).

The separation has proved to be difficult, although methods based on supported liquid membranes with chiral selectors [165] and selective enzymatic oxidation to pyruvic acid have been reported [166]. Either the enantiomer selectivity is too low or the loss of one of the lactate isomers is limiting. To overcome this, our group recently reported a very productive approach for enantioseparation, based on the hydrolysis of racemic lactates with Candida rugosa lipase, as seen in Fig. 20. Van Wouwe et al. reported volumetric productivities of about 18 g L−1 h−1 for ethyl lactate hydrolysis at 45°C after only 2 h, with the molar enantiomeric purity of the product at 95% (l-lactic acid divided by total LA). The separation of the d-ester from l-lactic acid in water is straightforward. The hydrolysis of a series of alkyl lactates and other AHA esters (based on GA or 4-carbon AHAs) was demonstrated [167].

9 Summary, Conclusions, Outlook

α-Hydroxy acids (AHA) are very useful molecules with a wide applicability, especially in the production of renewable and degradable polyesters, but also as a platform chemical in the biorefinery approach and in the portfolio of green solvents (e.g., ethyl lactate) and plasticizers (e.g., butyl glycolate). The F:C analysis in Sect. 2 showed that these molecules retain the high functionality present in the carbohydrate feedstock, and their synthesis proceeds according to a very high atom economy (100 % for lactic acid). The great potential of AHAs is exemplified by lactic acid, the most studied molecule of its kind. The rising demand for lactic acid is driven by the need for the above-mentioned green applications and, in particular, the ever-growing popularity of the commercial bioplastic PLA. This success, however, stresses the current fermentative production route for its synthesis, which requires long reaction times and costly purification steps, besides producing gypsum waste. Novel routes for the chemical synthesis of lactic acid or alkyl lactates starting from trioses, hexose sugars, and even cellulose are therefore progressively under development, and this progress is usually based on the use, design, and fine-tuning of Lewis and Brønsted acidic heterogeneous and homogeneous catalytic sites. The ultimate goal, the conversion of cellulose to lactic acid, requires many individual reaction steps in a one-pot cascade fashion and these steps face different catalytic needs. In this chapter we have reviewed and highlighted some of the most promising chemocatalytic approaches and pointed out the greatest bottleneck, namely combining a selective Lewis acid catalyzed retro-aldol of hexose sugars with the Brønsted acidic hydrolysis of cellulose. Care has to be taken with the latter acidic sites, as they usually also promote the dehydration of hexoses to HMF and humin formation. Besides LA, other AHA of interest include glycolic acid, vinyl glycolic acid, methoxy-2-hydroxy-butanoic acid, and furyl glycolic acid. These mostly novel molecules with high functionality are only just beginning to receive attention. Their bio-based production with inventive catalytic approaches, perhaps incorporating enzymatic catalysis, for instance, for enantioseparation, harnesses great potential. Besides, their synthesis from carbohydrates usually entails a high atom economy. The co-polymerization of vinyl glycolic acid with lactic acid showed that the search for new AHA monomers is worthwhile, as they are easily incorporated in PLA-based polymers, hereby leading to novel functional polyesters. The great advantage of having an additional functional group in the side chain of a PLA-type polyester was immediately proven, by its easy post-synthetic functionalization, which allowed subtle tuning of the hydrophilic properties of the polyester. A multitude of variations are yet about to be discovered.

References

Ragauskas AJ, Williams CK, Davison BH, Britovsek G, Cairney J, Eckert CA, Frederick WJ, Hallett JP, Leak DJ, Liotta CL, Mielenz JR, Murphy R, Templer R, Tschaplinski T (2006) The path forward for biofuels and biomaterials. Science 311:484–489

Vennestrøm PNR, Osmundsen CM, Christensen CH, Taarning E (2011) Beyond petrochemicals: the renewable chemicals industry. Angew Chem Int Ed 50(45):10502–10509

Climent MJ, Corma A, Iborra S (2014) Conversion of biomass platform molecules into fuel additives and liquid hydrocarbon fuels. Green Chem 16:516–547

Corma A, Iborra S, Velty A (2007) Chemical routes for the transformation of biomass into chemicals. Chem Rev 107:2411–2502