Abstract

Nearly 20% of all animal protein comes from seafood, which is often a good source of vitamins, minerals, and omega-3 fatty acids. Since the beginning of the 1990s, the production of marine fisheries has stayed the same. This is because of the massive fishing pressure on wild fish stocks and human activities. The increasing scarcity of fish meal (FM), the most expensive feed ingredient in aqua feed, may pose a future threat to aquaculture expansion. This chapter examines the role of single-cell ingredients (SCI) and microbes (microbial-based systems, MBS) in circular economy-based sustainable aquaculture production of farmed fish and shellfish. Single-cell organisms (e.g. bacteria, yeasts, and microalgae) and microbial-based systems (MBS) such as biofloc and periphyton play critical roles in reducing nitrogen (N) and phosphorus (P) loss from fish diets to the environment by volarising aquaculture wastes. Single-cell protein (SCP) and single-cell oil (SCO) are derived from microbial biomass that contains a high concentration of antioxidants and other bio-active components such as amino acids, long-chain polyunsaturated fatty acids (LC-PUFA), carotenoids, glucan, mannan, pullulan, xylitol, polyhydroxy butyrate (PHB), and polyhydroxyalkanoate (PHA). These dietary compounds stimulate the immune system, improve reproductive performance, and increase disease resistance in farmed fish species. With zero-water exchange and a low ecological footprint, biofloc technology can support intensive fish or shrimp production at a lower cost. To ensure that the aquaculture industry takes advantage of SCP and MBS, advanced but affordable technology to produce these agents must be developed to improve production, reduce feed costs, and minimise the harmful effects of SCP anti-nutritional factors.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Fish contributes essentially to human nutrition, providing various health benefits in terms of protein, essential fatty acids (EFA), long-chain polyunsaturated fatty acids (LC-PUFA), and eicosapentaenoic acid (EPA) and minerals (Gephart et al. 2020; Kok et al. 2020). Fish and other aquatic foods from marine environments are central to meeting food and nutrition security goals, providing more than 3.3 billion people with 20% of their animal protein intake (FAO 2020; Gephart et al. 2020). However, fish production from the marine environment has been static since the late 1980s (Tacon and Metian 2018; FAO 2020). In contrast, aquaculture production has increased, with inland and fin fish aquaculture accounting for 51.3 Mt and 54.3 Mt, respectively, of the total fish production from all sectors (FAO 2020). In 2018, fed aquaculture represented more than 70% of global aquaculture production (Hua et al. 2019; Naylor et al. 2021), with carp, shrimp, tilapia, catfish, and salmon accounting for about 75–80% of farmed fish and shellfish combined (FAO 2020; Naylor et al. 2021). Freshwater fish species represented about 75–83.6% of total global edible farmed fish production, mainly under intensive net cage systems, including lakes, reservoirs, and rivers (FAO 2020; Naylor et al. 2021). The rapid growth of aquaculture makes it one of the fastest food-producing sectors globally (FAO 2020). According to Waite et al. (2014), fish production from the sector will increase to 140 Mt in 2050 and provide a source of high-quality protein in the future. Engle et al. (2017) estimated that aquaculture could close roughly 14% of the “gap” between global animal protein consumption today and the animal protein requirement in 2050.

However, aquaculture is heavily reliant on fish meal (FM) to fuel growth, particularly for major farmed species such as catfish, shrimp, and salmon (Cottrell et al. 2020), which accounted for 18% (15 Mt) of total aquaculture production in 2018 (FAO 2020). According to Boyd et al. (2022), formulated feed containing FM and fish oil (FO) accounts for roughly two thirds of fin fish and crustacean production. Concerns about the sustainability of aquaculture have recently arisen because of a decline in FM and FO production from capture fisheries (Costello et al. 2020). This decline may impact global aquaculture production of carnivorous fish such as salmon, trout, sea bream, sea bass, and shrimp, which rely on FM and FO to meet stringent requirements (Chatvijitkul et al. 2016; Kok et al. 2020). The shift from reliance on marine products to crop-based aquaculture increases competition for land and water (Fry et al. 2016; Chatvijitkul et al. 2016; Hua et al. 2019) via crop production (maize, rapeseed, wheat, soya bean) (Fry et al. 2016). Despite the declining use of FM and FO in aqua feed, feed accounts for 50–70% of the production cost of fish farming operations (Waite et al. 2014); it is also responsible for approximately 90% of the cumulative environmental impact of aquaculture supply chains (Kok et al. 2020; Naylor et al. 2021). The rapid growth rate of human populations (Engle et al. 2017; Hua et al. 2019) will increase aquaculture competition for natural resources and their ecological limits (Engle et al. 2017; Costello et al. 2020; Naylor et al. 2021) through habitat loss or degradation, mainly for shrimp farming (Carvalho Pereira et al. 2021), and through discharge of waste and nutrient-rich sludge (Carvalho Pereira et al. 2021).

The rapid expansion of the aquaculture sector is also associated with environmental issues such as greenhouse gas (GHG), carbon dioxide (CO2), methane (CH4), and nitrous oxide (NO2) emissions, which contribute to climate change (Boyd and McNevin 2015; Boyd et al. 2022; Fang et al. 2022; Luo et al. 2018). Other aspects of aquaculture production’s environmental impacts include toxic and ecotoxic effects (Camargo and Alonso 2006); toxic residue in fish and antimicrobial resistance due to chemical use (antibiotics, hormones, pesticides, fertilisers Kawsar et al. 2022); increasing land, water, and energy requirements for feed production (Chatvijitkul et al. 2016; Fry et al. 2016); and global incidences of disease outbreaks in aquaculture systems (FAO 2020; Gephart et al. 2020; Kok et al. 2020). The impressive growth rate of aquaculture (11%, 2000–2019) in Sub-Saharan Africa is hampered by fish disease (e.g. Ghana), high production costs, and prohibitive feed prices, combined with the impact of the COVID-19 pandemic (Ragasa et al. 2022a, b), and the unavoidable threat to food security posed by Ukraine’s ongoing war.

Chemical treatment and recirculating aquaculture systems (RAS) are two methods for reducing the environmental impact of aquaculture (Badiola et al. 2018). However, the risks of chemical contamination of water and fish, the high cost of RAS operation, and the discharge of nutrient-rich sludge have significant environmental consequences (Badiola et al. 2018; Carvalho Pereira et al. 2021). Practices that improve environmental performance include reducing feed conversion ratio (FCR) and increasing productivity with fewer inputs (water, land, and energy) required per tonne of production to reduce aquaculture’s impact on resource use and the environment (Chatvijitkul et al. 2016; Costello et al. 2020). To achieve the goal of sustainable aquaculture, researchers tested several novel protein sources: Food and feed-processing wastes (Boyd et al. 2019; Jones et al. 2020); microbial-based food systems (Martínez-Córdova et al. 2017; Viau et al. 2020; Muthoka et al. 2021); and single-cell organisms (Martínez-Córdova et al. 2017; Viau et al. 2020; Muthoka et al. 2021). (Maizatul et al. 2017; Shah et al. 2018; Boyd et al. 2019; Costello et al. 2020; Carter and Codabaccus 2022). Single-cell organisms (e.g. bacteria, yeasts, and microalgae) and microbial-based systems (MBS) such as biofloc and periphyton play critical roles in reducing nutrient loss to the environment by recycling nutrients and volatilising waste from aquaculture (Chavan and Mutnuri 2019). The process can produce protein-rich biomass (SCP) and microalgae biomass (MAB) with an excellent nutritional profile (Azim and Little 2008; Goncalves et al. 2017; Gullian-Klanian et al. 2020; Pacheco et al. 2020; Adeoye et al. 2021; Ahmad et al. 2022; Maizatul et al. 2017; Han et al. 2019; Ansari et al. 2021; Muthoka et al. 2021; Tinh et al. 2021, Liao et al. 2022). This chapter reviewed the contributions of single-cell ingredients (SCI) to circular economy-based sustainable aquaculture production of farmed fish and shellfish. The current literature on the nutritive and feeding value of microbial-based systems and single-cell ingredients in aquaculture was reviewed.

2 Overview of Sustainable Alternative Protein Sources

Several researchers have reviewed some nutritional approaches in the literature to improve the sustainability of aquaculture and reduce its associated environmental impact (reduced P and N) (Gasco et al. 2019; Costello et al. 2020; Naylor et al. 2021; Albrektsen et al. 2022); namely, plant protein (PP), and plant by-product derived from the fermentation industry (e.g. distillers dried grains and solubles—DDGS) (El-Husseiny et al. 2018; Amer et al. 2019). These innovative approaches can help create a circular economy by making better use of food waste and natural resources (Ragasa et al. 2022a, b). Nonetheless, several factors limit their use in aquaculture: high anti-nutritional factors (for example, phytic acid in PP, Krogdahl et al. 2010), low essential amino acids (EAA) (Makkar et al. 2014), deficiencies of EFA and LC-PUFAs (Fry et al. 2016; Malcorps et al. 2019), low nutritional quality (Hua et al. 2019), and sustainability issues related to aquaculture.

3 Microbial-Based Food Systems and Single-Cell Proteins as Novel Ingredients in Aquaculture

For sustainable aquaculture production, MBS and single-cell organisms (e.g. bacteria, yeasts, and microalgae) represent a valuable feed protein (SCP) and lipid or single-cell oil (SCO) (Crab et al. 2007; Azim and Little 2008; Tibbetts et al. 2017; Sillman et al. 2019). They can also reduce the environmental impact of intensive aquaculture production through nutrient cycling (Martiınez-Cordova et al. 2014; Martínez-Córdova et al. 2017; Huang 2020; Campanati et al. 2022) and waste removal (e.g. bacteria and microalgae Goncalves et al. 2017; Jung et al. 2017; Spalvins et al. 2019; Huang 2020). SCP and MBS (for example, biofloc) may also offer an alternative to antibiotics in aquaculture production by reducing the negative impact of disease on fish health and increasing fish immunity (Durigon et al. 2019; Wang et al. 2019; Agboola et al. 2020; Wang et al. 2022a, b). Dietary SCP can also reduce global feed demand, closing the gap between fish production and demand in aquaculture (Shah et al. 2018; Ahmad et al. 2022; Campanati et al. 2022).

3.1 Microbial-Based Food Systems in Aquaculture: Nutritional Composition and Feeding Value

Microbial-based food systems are a collection of microscopic organisms that live in a matrix (bacteria, fungi, rotifer, zooplankton, and microalgae). A biofloc is an aggregation of microorganisms such as algae, fungi, ciliates, flagellates, rotifers, and detritus that contain essential amino acid (EAA) comparable to commercial shrimp feed (Najdegerami et al. 2015; Ju et al. 2008). Reportedly, biofloc enhances growth in fish species (Ekasari et al. 2015; Dauda et al. 2017, 2018a, b; Aboseif et al. 2022). Microbial floc and MBSs provide essential nutrients and increase digestive enzymes in fish (Najdegerami et al. 2015; Viau et al. 2016); however, the nutritional composition of these food sources is dependent on several factors, including the type of microbial system (Table 9.1, periphyton, biofilms, and bioflocs), their association with organic and inorganic materials (detritus, sludge) and the carbon (C) source ((Nevejan et al. 2016). Protein concentration in bioflocs, for example, can range from 140 to 500 g/kg of dry matter (DM), with greater levels observed for bioflocs created in shrimp tanks utilising aquaculture wastewater (Martiınez-Cordova et al. 2014). Ekasari et al. (2014a, b) found that the >100 m biofloc group had more protein and fat content than the other size categories. In contrast, the 0.48 m biofloc group had the most excellent amino acid (AA) content. According to Dauda et al. (2017), the crude protein (CP) of biofloc generated from various C sources ranged from 113.9 g/kg DM (rice bran) to 312.7 g/kg DM (sucrose).

3.2 Biofloc Systems

Increasing the abundance of heterotrophic bacteria in the biofloc system reduces the toxic inorganic N species and P in the system (Tinh et al. 2021; Aboseif et al. 2022). It also increases biomass yield compared to that of C added by algae (Avnimelech et al. 2014) and in tanks without C (Tinh et al. 2021). The addition of a carbon source lowers the concentrations of potentially toxic total ammonia nitrogen (TAN) and nitrate–nitrogen (NO2–N) in biofloc systems (Debbarma et al. 2022), allowing for greater reuse of biofloc-derived aquaculture wastewater (up to 100%) (Figueroa-Espinoza et al. 2022). Crab et al. (2007) reported that the inclusion of carbohydrate (CHO) reduced CP from 400 to 250 g/kg of dry matter (DM) without compromising shrimp production. Biofloc replaced 500–1000 g/kg of DM of the FM in fish and crustacean diets, according to Martínez-Córdova et al. (2017). According to Kumar et al. (2015), rice flour added to a culture tank of black tiger shrimp Penaeus monodon (Fabricius, 1978) in a biofloc technology (BFT) system resulted in better growth in shrimp fed a 32% CP diet than in shrimp fed a 40% CP diet. Debbarma et al. (2022) found that adding C at 0 mL/L, 1.7 mL/L (C/N 10), 6 mL/L (C/N 15), 13 mL/L (C/N 20), and 14.6 mL/L (C/N 25) increased floc volume and improved fish growth performance when comparing the potential of biofloc in the production of panda (Ompok bimaculatus, 0.082 g). The authors also observed increases in digestive enzymes (lipase, amylase, and protease) in the gut, liver, and muscle in the biofloc group, with a C/N of 20, showing overall improvement in production performance and water quality compared to other groups.

These observations show that applying a C source in an aquaculture system stimulates microbial growth and improves access to nutrient-rich microbial floc, effectively enhancing growth performance (Wang et al. 2015). The magnitude of growth response depends on the type of C source with biofloc produced from glycerol (Dauda et al. 2017) and tapioca resulting in better growth and feed utilisation (Ekasari et al. 2014a, b). The daily feeding rate (e.g. common carp fed up with 75% biofloc (Najdegerami et al. 2015), fish stocking density (Table 9.2, Fauji et al. 2018), and the amount of biofloc used (Wang et al. 2015) are all factors that influence fish growth. Biofloc technology (BFT) enables a decrease in the amount of feed applied for fish feeding (Kaya et al. 2019). A study carried out by Aboseif et al. (2022) showed that in addition to increased growth and feed utilisation, biofloc enhanced carcass protein content and increased the population of lactic acid bacteria (LABs) in the gut, demonstrating the probiotic effect of biofloc; the authors concluded that increasing the C/N facilitated higher assimilation of nutrients (EAA, LC-PUFA, and protein) and decreased total N discharge in the water.

3.3 Periphyton Systems

Periphyton is a type of MBS that serves as an important natural food source for aquatic animals due to its high concentration of essential dietary nutrients (Martiınez-Cordova et al. 2014). Bacteria, fungi, protozoa, snails, chironomids, oligochaetes, and crustaceans comprise periphyton which is attached to submerged substrates (Azim et al. 2002). These organisms provide live food for cultured fish (Azim et al. 2002; Miao et al. 2021;Muthoka et al. 2021; Saikia and Das 2014), reduce feed input in the system (Garcia et al. 2016), and improve water quality (Garcia et al. 2016). (Li et al. 2019; Muthoka et al. 2021; Saikia and Das 2014). When compared to a control without periphyton, a source of C is added to the system to maintain an optimum C/N of 10–20, which increases the growth of the microbial community and improves fish growth performance and yield (Guo et al. 2020; Tinh et al. 2021). (Asaduzzaman et al. 2008; Garcia et al. 2017). Muthoka et al. (2021) reported that Nile tilapia (12 g) raised in the periphyton technology (PPT) system in a fertilised pond (1 m deep) and fed at 3% body weight for 3 months exhibited higher WG, SGR, and lower FCR than non-PPT systems; the abundance of diatom and zooplankton communities was higher with reduced cyanobacteria and decreased ammonia (NH3), Fish raised in PPT-based systems in cages grew faster than fish raised in periphyton-based systems (Garcia et al. 2016; Tammam et al. 2020). However, David et al. (2021) reported that PPT in a cage system did not benefit from feed restriction when compared to a system with full feeding but no periphyton; this was due to the study’s low N/P ratio when compared to previous research with PPT (27:1, Garcia et al. 2017).

3.4 Biofilm Systems

A biofilm is a microbial consortium consisting of microalgae, bacteria, protozoans, fungi, and metazoans that are attached to a submerged substrate. It is critical for fish species whose diet does not consist of plant matter (Martiınez-Cordova et al. 2014). Dar and Bhat 2020; Dar et al. 2020). Biofilms are made up of microorganisms from various domains held together by EPS on surfaces (Dar et al. 2020), whereas biofloc is made up of heterotrophic bacteria (HB), phytoplankton, zooplankton, and protozoa attached to a floating surface (Porchas-Cornejo et al. 2017). Biofilms are high in protein, lipids, and LC-PUFA, which are beneficial to fish, particularly tilapia (Martínez-Córdova et al. 2017). Biofilms are critical to the live food sources of many farmed fish species (Garibay-Valdez et al. 2019; Ortiz-Estrada et al. 2019).

Viau et al. (2016, 2020) reported improved growth and reproductive success of pink shrimp in a zero-water system with biofilm as a single feed source, as well as reduced N loss. According to Lara et al. (2017), biofilm reduced feed input by 35% compared to the group reared in biofloc without artificial feed or biofilm. Wang et al. (2022a, b) found that augmentation of microalgae–bacteria with biofilm carriers increased fish production in recirculating ponds; bacteria–microalgae–biofilm decreased total ammonia-N (TAN) and nitrite–N by 51.28% and 33.48%, respectively. FM can be replaced in a fish diet by a biofilm-based single-cell protein (SCP) derived from purple phototrophic bacteria (PPB) (Delamare-Deboutteville et al. 2019). MBS is a powerful bioremediation tool for heavy metals and other contaminants in aquatic environments (Dar et al. 2020; Dar and Bhat 2020).

3.5 Microbial-Based Systems as Immunostimulants in Aquaculture

In addition to enhancing growth, the incorporation of MBS, such as biofloc, in aquaculture production systems improves water quality (Crab et al. 2007; Ekasari et al. 2014a, 2015; Dauda et al. 2018b); controls harmful pathogens (Crab et al. 2007; Martínez-Córdova et al. 2017); and increases beneficial gut microbiota (Crab et al. 2007). (Clenfuegos-Martinez et al. 2022). Biofloc minimises the environmental effect of aquaculture when compared to other aquaculture production technologies (Dauda et al. 2018a, b). Biofloc includes beneficial components such as EFA, carotenoids, chlorophylls (Ju et al. 2008), poly-hydroxybutyrate (PHB), Gulian-Klanian et al. 2020), and polyhydroxyalkanoate (PHA). These chemicals have been shown to promote immunological response and reproductive performance in farmed fish species (Ekasari et al. 2014a, b, 2015; Bossier and Ekasari 2017), as well as suppress pathogenic microorganisms (Supono et al. 2014; Matassa et al. 2015). Biofloc has several value-added components, such as antioxidants that boost aquatic animal immunity (Ekasari et al. 2014a, b; Yu et al. 2020). (Liu et al. 2018). Simultaneously, biofloc stimulates fish immune systems (Ekasari et al. 2014a, b; Liu et al. 2018; Karimi et al. 2019; Yu et al. 2020), effectively overcoming the problem of antibiotic abuse in aquaculture (Martínez-Córdova et al. 2017; Durigon et al. 2019; Wang et al. 2019) by enhancing disease resistance (Dauda et al. (Bentzon-Tilia et al. 2016). Biofloc promoted innate immunity (phenoloxidase and respiratory burst activity) and improved resistance to infectious myonecrosis virus (IMNV) in Pacific white shrimp (L. vannamei) juveniles, according to Ekasari et al. (2014a, b).

4 Single-Cell Protein and Their Application in Aquaculture

4.1 Production of Single-Cell Protein (SCP)

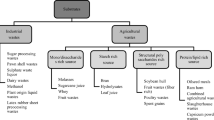

Several researches have shown that SCP and microbial consortia might be used in biomass and feed production (Overland et al. 2013; Bakhshi et al. 2018; Vidakovic et al. 2019). Protein obtained from yeast, fungus, microalgae, and bacteria may be used to make SCP or microbial protein (MP) (Nasseri et al. 2011; Bharti et al. 2014; Glencross et al. 2020). These microbes are grown on agricultural and industrial wastes (cassava waste, bran, bagasse, paper pulp, sucrose, ethanol, polysaccharides, industrial by-products, dairy waste, Jach et al. 2022) via solid/semi-solid state fermentation (SSF, Sharif et al. 2021) or submerged fermentation (SMF) using free-flowing liquid substrates (molasses, broth) (Bharti et al. 2014; Upadhyaya et al. 2016; Kuzniar et al. 2019). The following steps are involved in SCP production, depending on the culture technique and microorganism used (Ritala et al. 2017): preparation of nutrient media, possibly from waste; enzymatic hydrolysis (for yeast production, Overland and Skrede 2016); cultivation, including SSF; separation and concentration of SCP, in some cases drying; and final processing of SCP into ingredients and products (Ritala et al. 2017; Jach et al. 2022). In contrast to yeast SCP, bacterial SCP (Spirulina, Methylococcus, or Methylophilus) undergoes a secondary drying process (Overland et al. 2010). The drying phase in SCP processing allows for incorporation in extruded/pelleted feeds (Glencross et al. 2020). Microalgae, a high-protein source (510–740 g/kg), may be cultivated in various conditions and organic substrates (Han et al. 2019; Acquah et al. 2021). Microalgae farming yields more biomass (4–15 tonnes per acre per year) than traditional protein sources (0.6–2 hectare per year, Acquah et al. 2021). Microalgal extraction produces biopeptides, animal feed, and feed additives (Ahmad et al. 2022; Campanati et al. 2022). However, depending on the species, microalgae’s solid cell wall composition limits its usage as feed (Raji et al. 2020). As a result, multiple techniques (for example, mechanical disruption) that assist in protein extraction, concentration, isolation, or purification of various products, including feed, are used to improve protein extraction efficiency (Amorim et al. 2021). SCP-manufacturing techniques for many microorganisms have been examined by Anupama and Ravindra (2000), Nasseri et al. (2011), Upadhyaya et al. (2016), Sharif et al. (2021), Albrektsen et al. (2022), and Jach et al. (2022) (yeast, bacteria, and fungi).

A recent trend in SCP production has seen an increase in the usage of different by-products (off-gas biogas and syngas) (Teixeira et al. 2018) derived from a variety of sources such as dairy wastes (whey, biogas, biohydrogen, bioethanol, protease, and bio-active substances, Sar et al. 2022); fruit and potato-processing wastewater (Sharif et al. 2021); and alkane wastewater (Sharif et al. 2021), agro-industrial waste, and industrial residue (Jones et al. 2020; Overland and Skrede 2016; Ritala et al. 2017; Jach et al. 2022; Leeper et al. 2022). Recent improvements in microbial technology have resulted in better and enhanced MB production using gas bioreactor fermentation technology (Matassa et al. 2016; Sillman et al. 2019; Albrektsen et al. 2022). Many new businesses are manufacturing MP from natural gas, primarily CH4)-using methanotrophic bacteria (Ritala et al. 2017; Teixeira et al. 2018; Kuzniar et al. 2019; Jones et al. 2020). Banks et al. (2022) predicted a $24 billion growth in alternative proteins by 2024, thus, lowering operational costs in the future owing to economies of scale. Compared to FM, SCP has a higher production volume and market value (Table 9.3). Industries that use current microbial biotechnology and better downstream processes have a bright future (Matassa et al. 2016; Ritala et al. 2017).

4.2 Nutritional Composition of SCP

SCP derived from bacteria has a high-protein content that ranges from 500 to 800 g protein kg−1 dry weight (DW) (Table 9.4). In comparison to yeast and microalgae SCP, bacterial meals (BM) have the most methionine (Overland et al. 2010).Protein levels in dietary microalgae range from 500 g/kg (Nannochloropsis oculata, Sarker et al. 2020) to 600 g/kg (Pavlova sp., Wei et al. 2022) and 700–710 g/kg (Spirulina maxima), depending on the species (Maizatul et al. 2017; Shah et al. 2018; Hua et al. 2019). The nutritional profile of microalgae meal (MAM) was superior to that of fish meal (FM) (Bharti et al. 2014; Shah et al. 2018). Microalgae are rich sources of docosahexanoic acid DHA (300 g/kg, Schizochytrium sp., Sarker et al. 2020), with high ADC of protein (83%), lipids (91%), omega-6 6-PUFA (94%), omega-3 PUFA (99%), and (EPA + DHA, 99%) recorded for marine microalgae (Pavlova sp. 459, Tibbetts and Patelakis 2022).

The nutritional content of yeast SCP is affected by the fermentation technique, species, and downstreaming procedure (Hansen et al. 2021). Yeast SCP protein content varied between 380 and 600 g/kg (Albrektsen et al. 2022). C. utilis and Kluyveromyces marxianus have lately sparked attention as possible protein sources in aqua feed (Overland and Skrede 2016; Jones et al. 2020). These yeasts have been granted “generally recognized as safe” (GRAS) classification by the US Food and Drug Administration (FDA), which is given to drugs that are not detrimental to health (Overland and Skrede 2016). Despite higher contents of non-protein N in the form of nucleic acids in yeast (10–15%, Overland and Skrede 2016; Ritala et al. 2017; Albrektsen et al. 2022), the analysis of nutrients in yeast protein and FM reveals similar contents of most indispensable AA on a CP basis (Glencross et al. 2020; Albrektsen et al. 2022). Yeast protein has more lysine, leucine, and isoleucine than FM, but less methionine, tryptophan, arginine, and lysine (Glencross et al. 2020). Yeast, on the other hand, has a better FAO protein scoring pattern than FM (Anupama 2000; Glencross et al. 2020), based on human EAA needs to quantitatively assess protein quality (Matassa et al. 2016). The CP and lipid of five yeast S. cerevisiae, Cyberlindnera jadinii, Kluyveromyces marxianus, Blastobotrys adeninivorans, and Wickerhamomyces anomalous are 380–520 g/kg and 7–89 g/kg, respectively (Agboola et al. 2020), with a comparable chemical score (a ratio of the individual digestible AA in each yeast product and the (Agboola et al. 2020). S. cerevisiae, on the other hand, contains more methionine and cysteine but less lysine than other yeast species (Agboola et al. 2020).

4.3 Nutritional Feeding Value of SCP in Aquaculture

The potential of SCP as a future feed ingredient in aqua feed production for larval and adult fish/shellfish with opportunities for future expansion and commercialisation has recently been realised (Carter and Codabaccus 2022). Beal et al. (2018) reported that it is possible to substitute 30% of world FM and FO with microalgae MP, which can improve the sustainability of fisheries and aquaculture. On the other hand, while performing a 10-year FM and FO replacement meta-analysis, Cottrell et al. (2020) reported that dietary SCP can reduce forage fish demand to 8–10 Mt based on projected aquaculture growth scenarios of faster growth rate and global shifts in consumer preferences in 2030, which is below the ecosystem-based fisheries management limit of fish supply (8.65–10.27Mt). Studies with marine and freshwater fish species show that dietary MP is essential for the growth and physiology of aquatic species (Crab et al. 2007; Azim and Little 2008; Vidakovic et al. 2019; Gullian-Klanian et al. 2020; Mahmoud et al. 2020).

4.4 Yeast SCP

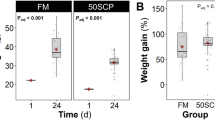

Yeasts and many co-products of ethanol-fermented yeast, such as dry distiller grains with solubles, DDGS (Overland et al. 2013; Overland and Skrede 2016; Shurson 2018; Glencross et al. 2020; Rimoldi et al. 2020) improve fish growth (Overland et al. 2013; Goda et al. 2019) and protein availability (88–98%, Overland et al. 2013; Langeland et al. 2016). Fayeofori and Bob-Manuel (2014) reported good growth and FCR for Nile tilapia fed up to 500 g/kg YM compared to the FM diet. In contrast, including 328 g/kg YM in the diet was ideal for African catfish (Clarias gariepinus). The replacement of FM with YM (200–300 g/kg) improved protein digestibility (80%) in O. niloticus fry (Olvera-Novoa et al. 2002), and rainbow trout fed a practical diet (Martin et al. 1993). According to Olvera-Novoa et al. (2002), it is possible to replace up to 650 g/kg of animal protein with a mixture of SBM (200 g/kg), alfalfa leaf protein concentrate (150 g/kg), and torula yeast C. jadinii (300 g/kg) in tilapia fry diets without adverse effects on fish performance. Gumus et al. (2016) reported good growth and improved feed utilisation in the goldfish-fed diet supplemented with brewer’s YM (350 g/kg diet) than in other yeast diets (0, 150, 250, and 450 g/kg). Compared to FM, dietary supplementation of non-saccharomyces enhanced growth in Nile tilapia (Rhodotorula mucilaginosa, Chen et al. 2019), rainbow trout (Wickerhamomyces anomalous, Vidakovic et al. 2019), shrimp (C. aquaetextoris, Babu et al. 2013), and Atlantic salmon (Kluyveromyces marxianus, Overland et al. 2013; C. utilise, Overland et al. 2013; Sahlmann et al. 2019).

A recent study by Leeper et al. (2022) showed that torula yeast (C. jadinii) cultivated on wood hydrolysates can replace 200 g/kg FM without affecting the growth performance of Atlantic salmon. However, the authors reported that while dietary yeast (100 g/kg) supplementation promoted growth by enhancing LAB associated with host fish, the population of Staphylococcus increased in the gut as the dietary yeasts increased in the diet to 200 g/kg, suggesting that a plant-based diet could alter the gut microbiome and reduce intestinal function. Differences between the single and combined yeast substitution levels in the mix might be due to dietary composition and CP level, which for Atlantic salmon, is met mainly by FM supply (Costello et al. 2020; Naylor et al. 2021). Current research has shown that a protein-rich solid fermentation culture method is suitable for yeast production, which can be a source of feed in aquaculture. After 8 weeks of culture, Wang et al. (2022a, b) discovered that supplementing the hybrid grouper (Epinephelus fuscoguttatus × Ephelus lanceolatus) diet with dietary yeast culture (YC, ESTAQUA®) (20 and 40 g/kg) stimulated growth and improved antioxidant and immune (immunoglobulin) response parameters. The post-challenge test against Vibrio harveyi infection revealed that YC enhanced disease resistance and improved fish survival. The authors found higher intestinal microflora (Blautia and Lactobacillus) than in the control group without YC. After 12 weeks, Hao et al. (2022) discovered that replacing dietary FM with S. cerevisiae-derived YC (200 g/kg diet) increased WG and decreased FCR in channel catfish (Ictalurus punctatus). The expression of the intestinal HIF1 gene increased while intestinal Nf-kB gene expression was down-regulated in the group that fed on YC. The authors reported a higher relative abundance of Firmicutes and Turicibacter in fish with YC than in control fish. Fish survival improved in fish challenged with Aeromonas veronii Hm091 and A. hydrophila NJ2.

The high nucleic acid and indigestible cell wall contents (Rimoldi et al. 2020) in yeast protein products constrain their use as a dietary protein source in aqua feed because they limit digestive enzymes and nutrient digestibility in fish (Nasseri et al. 2011; Glencross et al. 2020). Homogenisation (centrifugation), cell wall crushing and spray drying (Hansen et al. 2021), enzymatic treatment (Rimoldi et al. 2020), and extrusion (Overland et al. 2013) are applied to reduce the high cell wall content (Glencross et al. 2020) and enhance protein solubility and digestibility in fish (Atlantic salmon, Hansen et al. 2021). Fish can tolerate nucleic acid due to their efficient hepatic uricase activity that degrades plasma uric acid (Karimi et al. 2019).

4.5 Bacterial SCP

Protein derived from BM in aquaculture is gaining popularity due to its high nutritive value and palatability in aqua feed with the potential to improve the growth and welfare of several fish species (Biswas et al. 2020; Adeoye et al. 2021), and reduce plant-induced enteritis in the intestine (Romarheim et al. 2013). Table 9.5 presents the results from various studies that evaluated the use of BM in fish production. The response varied with the type of bacteria and fish species used. For example, FM substitution (100–200 g/kg diet) by the bacteria Corynebacterium ammoniagenes SCP in the diet of white leg shrimp resulted in good growth, nutrient utilisation and whole-body protein compared to FM control (Hamidoghli et al. 2018). The use of C. autoethanogenum in the diet of largemouth bass (Micropterus salmoides) indicated that dietary levels up to 156–204 g/kg could replace FM without affecting fish growth, haemato-biochemistry, digestive capacity, as well as protein digestibility and intestinal morphology (Zhu et al. 2022). A similar response in black sea bream (Acanthopagrus schlegelii) fed a diet with C. autoethanogenum has been reported previously (Chen et al. 2019a, b).

A study with an Atlantic salmon-fed diet supplemented with Methylococcus BM improved growth performance and reduced soybean-induced distal enteritis and intestinal inflammation (Romarheim et al. 2013; Vasanth et al. 2015), suggesting the potential of Methylococcus bacteria in enhancing gut health and immune protection as well as replacing SBM in the fish diet. Chen et al. (2022), while evaluating the performance of Pacific white shrimp (L. vannamei) fed a diet supplemented with methanotroph (M. capsulatus, Bath), observed no significant impact on growth performance and feed utilisation. Similarly, a recent study with Pacific white shrimp (L. vannamei) showed that dietary substitution of FM (25%) with M. capsulatus Bath (15, 30, and 45%) did not affect the growth performance and feed utilisation of shrimp compared to the FM reference control group, which indicated the possibility of incorporating BM as an alternative protein source in fish diets (Chen et al. 2022). Recent studies have revealed that PPB, a novel protein-rich MP source (670–737 g/kg CP), grows exclusively on wastewater under anaerobic conditions in light (Alloul et al. 2021). Delamare-Deboutteville et al. (2019) reported that PPB replaced 660 g FM/kg in the diet of Asian sea bass (Lates calcarifer), a high-value carnivorous fish, without affecting growth and feed utilisation. A recent study by Alloul et al. (2021) reported that white leg shrimp (P. vannamei) fed a diet supplemented with purple non-sulphur bacteria (a PPB): The shrimp fed with Rhodobacter capsulatus (110 g/kg feed protein) and Rhodopseudomonas palustris (50 g/kg feed protein) displayed higher WG (5–25% and 26%), respectively, compared to commercial feed. The authors also found that dietary inclusion of PPB enhanced resistance against Vibrio infection and reduced NH3 stress compared to the control diet, indicating the suitability of PPB in sustainable fish production.

4.6 Microalgae SCP

4.6.1 Effect on Fish Growth

Several kinds of literature have reported the aquaculture potential of microalgae meal (MAM) as a replacement for FM in the fish diet with a positive impact on growth and feed utilisation in fish (Mahmoud et al. 2020; Raji et al. 2020). In several pieces of literature on aqua feed formulations, the most commonly used microalgae are Chlorella spp. (Tibbetts et al. 2017; Raji et al. 2020), Scenedesmus sp. (Skalli et al. 2020), and Spirulina (Olvera-Novoa et al. 1998). It is possible to incorporate 300 or 600 g/kg of MAM into the diet without affecting growth performance (Sørensen et al. 2016). However, the effect of dietary supplementation of MAM varies with the source of microalgae species used, the composition of the diet, as well as fish species and fish size. While Hajiahmadian et al. (2012) reported significantly higher growth in Golden Barb (Puntius gelius) fed a diet with Spirulina meal (200 g/kg diet) as a replacement for FM, the dietary inclusion of 500 g/kg Spirulina meal produced comparable FCR and WG in silver seabream (Rhabdosargus sarba) fed an FM-based diet. Cardinaletti et al. (2018) evaluated the performance of European sea bass, Dicentrarchus labrax, fed a diet with a blend of 18% of freeze-dried microalgae (Tisochysis lutea and Tetraselmis suecica) meal and 15% FM and found no difference in growth performance with fish fed the control diet (27.5% FM). Radhakrishna et al. (2015) showed that C. vulgaris meal substituted about 500 g FM/kg in the diet of postlarvae freshwater prawns. Macrobrachium rosenbergii without affecting growth and survival.

Olvera-Novoa et al. (1998) reported improved growth and feed utilisation of 20–40% Spirulina meal (104.7–314.1 g/kg) substituted FM in the diet of O. mossambicus (Peters) fry, whereas the supplementation of the diet with de-fatted biomass of N. oculata (80 g/kg) or whole cells of Schizochytrium sp. (32 g/kg) enhanced WG and SGR of Nile tilapia (34.5 g). The economic conversion ratio ($0.95/kg of fish) of Nile tilapia was reduced relative to fish that fed on the reference diet with FM and FO ($1.03/kg) (Sarker et al. 2020). However, Tibberts et al. (2017) found that feeding Atlantic salmon with whole-cell C. vulgaris-enriched diets reduced WG and increased FCR compared to a reference diet with FM. However, MAB combined with PP (e.g. rapeseed and Chlorella) replaced FM in the diet without affecting growth and feed utilisation (Shi et al. 2017).

4.6.2 Effect on Nutrient Digestibility in Fish

Dietary microalgae supplementation improves growth by enhancing nutrient availability in fish (Gamble et al. 2021). Gamble et al. (2021) reported that dietary Schizochytrium sp, Chlorella and Spirulina had a significantly higher apparent digestibility coefficient (ADC, 74.02–81.53%) of phosphorus (P) in Nile tilapia than FM control group (71.7%). Shah et al. (2018) reported that the high ADC of nutrients in Sprirulina (Arthrospira, 86.1% of CP) and Chlorella (80.0% of EAA) compared well with conventional feed stuff. Feeding European sea bass (D. labrax) and rainbow trout (Oncorhynchus mykiss) with freeze-dried Isochrysis sp. (14%, Tibaldi et al. 2015) and whole cells of Schizochytrium sp. (30%, Bélanger et al. 2021) improved the ADC of CP (92.6% and 90.8%), lipid (87.6% and 85.9%), and energy (85% and 84.3%). Similarly, Nile tilapia and African catfish-fed dietary Schizochytrium sp meal (Sarker et al. 2016; Teuling et al. 2017) and C. vulgaris and S. maxima meal (Teuling et al. 2017), respectively, showed high lipid ADC of 80–98% and >80%, respectively. Raji et al. (2020) evaluated the performance of C. gariepinus fed diet supplemented with Chlorella and Spirulina for 42 days. The study showed that higher ADC of protein (98.64–98.66% vs 97.71%), lipid (96.51–96.67% vs 92.77%), energy (93.2–94.66% vs 86.04%, lysine (99.05–99.34% vs 98.59%), and PUFA (98.92–99.01% vs 97.51%) were higher than the fish that fed on FM diet.

Some studies showed that dietary microalgae supplementation did not improve ADC of essential nutrients in some species (Shi et al. 2017; Roy et al. 2011). For example, while dietary Nannochloropsis, Phaeodactylum, and Isochrysis up to 240 g/kg in the diet did not affect feed intake, nutrient digestibility of Nannochloropsis and Isochrysis was reduced compared to control (Skrede et al. 2011). These findings are consistent with a study which showed that the combination of dried Nannochloropsis sp. and Isochrysis sp. reduced feed intake, nutrient utilisation, and somatic indices in algae-fed (15–30%) Atlantic cod as compared to the control group. The reduced feed utilisation could be attributed to palatability issues related to the rigid cell wall content of microalgae.(Shah et al. 2018; Acquah et al. 2021). A recent study with Atlantic salmon-fed whole-cell Pavlova 459 meal (20 g/kg) showed that ADC of protein (90.1% vs 92.3%) and lipid (91% vs 94.4%) were lower than that of the FM-based reference diet (Tibbetts and Patelakis 2022). The reduced ADC of nutrients observed in these findings might be related to microalgae cell composition, microalgae source, diet composition, processing techniques used, and fish species and experimental conditions.

Homogenisation (Tibbetts et al. 2017), acid hydrolysis (Patnaik et al. 2019), pasteurisation (Agboola et al. 2019), bead milling (Agboola et al. 2019), and spray drying (Raji et al. 2020) can reduce the cell wall content and improve the feeding value of MAM. Tibbetts et al. (2017) found that dietary inclusion of cell-ruptured C. vulgaris biomass did not affect protein ADC at 60, 120, 240, and 300 g/kg diet (Table 9.5). However, dietary whole-cell MAB significantly reduced protein ADC at >60 g/kg diet. Similarly, ADC of all AA was unaffected by cell-ruptured MAB compared to reduced ADC of whole-cell biomass. Teuling et al. (2019) observed that cell wall ruptured N. gaditana meal improved the availability of nutrients in the diet of juvenile Nile tilapia, O. niloticus. Agboola et al. (2019) reported higher ADC of protein (83.8% vs 77.4%) and lipid (81.8% vs 65.4%) of C. gariepinus fed the diet supplemented with bead-milled N. gaditana meal (300 g/kg) compared to untreated microalgae. A blend of MAB with PP can enhance microalgae utilisation. In this instance, Shi et al. (2017) fed crucian carp (C. auratus gibelio) a diet based on a mixture of rapeseed meal and Chlorella meal (0, 25%, 50%, 75%, and 100%) as a replacement for FM for 6 weeks. In contrast, dietary de-fatted N. oculata and DHA-rich Schizochytrium sp improved the ADC of protein, lipid, and AA in Nile tilapia (34.5 g). The enhanced digestive enzyme activities in the fish-fed Schizochytrium sp meal diet may have improved nutrient availability in the fish (Sarker et al. 2020).

4.6.3 Effect on Fish Carcass Quality and Reproductive Performance

Studies show that dietary microalgae improve the carcass quality of aquatic animals (Roy and Pal 2014; Chang et al. 2017) through enrichment with LC-PUFAs (Stoneham et al. 2019). Dietary MAM in fish diets can replace or supplement FO (Haas et al. 2015; Allen et al. 2019; Guimaraes et al. 2019; Stoneham et al. 2019) and FM in aqua feed (Adel et al. 2017; Shi et al. 2017; Abugrara et al. 2019; Patnaik et al. 2019) without affecting growth performance, suggesting that microalgae contribute to nutrient-sensitive fish production in aquaculture. Stoneham et al. (2019) evaluated the effect of FO (10, 30, 50 g/kg diet) replacement with Schizochytrium sp meal (17.5, 52.6, 87.7 g/kg diet). They observed no significant difference in WG and carcass FA amongst the diets after 8 weeks of feeding juvenile Nile tilapia (160 g). However, compared to the group fed the 50 g/kg FO diet (165% and 232%), the diet supplemented with 87.7 g/kg Schizochytrium sp showed higher fillet n-3 (189%) and LC-PUFA (298%) (Stoneham et al. 2019). Dietary supplementation with 10–20% Pav 459 meal (2.86% EPA and 1.45% DHA) exhibited no significant differences in carcass DHA, EPA, and most FAs compared to Atlantic salmon fed the control diet based on FM after 12 weeks of culture, which indicates that MAM from Pav 459 is a good source of protein and n-3 LC-PUFA in farmed fish species (Wei et al. 2022). For 21 days, Carvalho et al. (2022) studied the performance of gilthead sea bream (Sparus aurata, 0.48 mg) fed dietary marine heterotroph Schizochytrium limacinum (19% DHA), alga fermentation-derived Crypthecodinium cohnii (39.5% DHA), and S. limacinum (49% DHA). The authors found that it is possible to replace FO with microalgae oil in the diet with increased DHA in the fillet of gilthead sea bream (S. aurata, 0.48 mg).

Cardona et al. (2022) showed that the carcass quality of female rainbow trout (O. mykiss) fed a plant-based diet containing Schizochytrium sp. meal (69 g/kg diet) or Schizochytrium sp. oil (26 g/kg) as a replacement for FM or FO in commercial feed, respectively, for 8 weeks, showed high PUFA n-6 and n-3 levels compared to the control group that had no MAM in the diet. The authors, however, reported that the reproductive success of females, as measured by egg weight, absolute fecundity, and relative fecundity, was similar to that of brood stock females fed a commercial diet. Kohal et al. (2018) and Zhang et al. (2020) also reported improved reproductive performance and survival of red cherry shrimp (Neocaridina davidi) and yellow tail cichlids (Pseudotropheus acei) fed a diet containing Spirulina meal when compared with a control diet without microalgae.

4.6.4 Effect on Immunomodulation in Fish

Studies reveal that dietary microalgae plays a positive role in fish immunomodulation. For example, Zhang et al. (2014) reported improved physiology and enhanced innate immunity of gibel carp (C. auratus gibelio) fed a diet containing Chlorella meal. Similarly dietary supplementation of C. Vulgaris (60–80 g/kg diet) enhanced immune response and improved resistance of M. rosenbergii postlarvae against A. hydrophila infection (Maliwat et al. 2017). A recent study with pacu (Piaractus mesopotamicus) exposed to 2.5 mg/L NH3 for one hour after a 45-day feeding with dietary Spirulina (A. platensis, 40–60 g/kg diet) in place of FM indicated that microalgae stimulated the immune system and enhanced antioxidant enzymes as compared to control fish that did not feed on Spirulina (Carneiro et al. 2022). According to the authors, these effects seem to be attributable to antioxidant compounds present in Arthrospira, which mitigated NH3 toxicity. Ma et al. (2022) found that dietary supplementation with microalgae (Schizochytrium sp., A. platensis, C. sorokiniana, Chromochloris zofingiensis, Dunaliella salina) enhanced the immune status and intestinal health of zebrafish (Danio rerio), comparing groups fed non-microalgae supplemented diets.

5 Application of Single-Cell Oil (SCO) in Aqua Feed: Effect on Fish Growth and Nutrient Digestibility

Single-cell oils (lipids derived from microorganisms) are a potential nutrient source in aqua feed, providing fish with a cheap source of lipid and EFA (Glencross et al. 2020; Lee et al. 2022). Oleaginous microbes can be grown on organic wastes with high lipid biomass recovery, ranging from 560 g/kg DW (Fusarium exquisite, Yang and Hu 2019) to 750 g/kg DW of lipid (Schizochytrium sp, Spalvins et al. 2019). Compared to dietary FM, SCO is more efficient at reducing FO inclusion in the diet, which reduces aquaculture demand for forage fish (Cottrell et al. 2020). According to Cottrell et al. (2020), dietary microalgae oil can replace 100% FO without affecting carcass quality (DHA + EPA) compared to 20%, 10%, and 25% soy oil or soy oil blend replacement for salmonids, shrimps, and marine fishes, respectively.

The majority of research has focused on Schizochytrium SCO products, which have a high protein (91.4%) and lipid digestibility (94.2%) for rainbow trout (Lee et al. 2022). A study conducted by Sarker et al. (2020) revealed that whole-cell Schizochytrium (6.2%) and de-fatted N. oculata (8% without FM) completely replaced FO in Nile tilapia after 184 days of feeding. The study concluded that the microalgae blend enhanced fillet macro-minerals and DHA deposition in the fillet of the group that fed on FM- and FO-free feed (5.15 mg/g) compared to the reference diet (2.47 mg/g). In contrast, Carvalho et al. (2020) reported that a dietary blend of microalgae oil, poultry oil, and rapeseed oil enhanced the EPA/DHA profile and fillet quality of gilthead seabream (S. aurata) when compared with fish fed with poultry oil or rapeseed oil. The authors concluded that microalgae oil replaced 52.8 g/kg of FO and 150 g/kg of FM in a PP-based diet of gilthead seabream. Sarker et al. (2016) reported that dietary Schizochytrium enhanced growth performance, fillet DHA and LC-PUFA of Nile tilapia, compared to fish fed with an FO diet. Lee et al. (2022) found that Schizochytrium (80%) replaced FO in rainbow trout without affecting growth, fillet quality, or lysozyme activity. In a post-challenge test against bacteria (Lactococcus garvieae 1 × 108 CFU/mL), microalgae outperformed FM in terms of fish survival. Katerina et al. (2020) evaluated the lifelong performance and fillet quality of Atlantic salmon reared from tank phase (18 g in freshwater to 800 g in salt water) on FO, or S. limacinum biomass (SLB) or a mix (FO + SLB) to slaughter stage (3 kg) in sea cages on FO or SCL for 11 months. At the end of the trial, the fish fed on SCB had higher body weight (3.3 kg vs 2.8 kg), fillet DHA + EPA, and higher ADC of LC-PUFA and DHA when compared to the FO and FO + SLB groups. There was no difference in fillet colour or odour between the FO and SCB groups, even though the SCB group had more astaxanthin than the FO group. Hossain et al. (2022) reported that the feeding of sobaity sea bream (Sparidentex hasta) with a high DHA algae meal diet containing 9.34% DHA improved fish growth, fillet DHA, serum lysozyme activities, and superoxide dismutase when compared with commercial finisher feed and basal diet (no added DHA). However, the fish fed the high DHA algae diet were similar to FO with similar DHA as the algal meal, suggesting the possibility of replacing FO in the diet.

6 Sustainability and Environmental Performance of SCP and Microbial-Based Systems

Dietary SCP can enhance aquaculture sustainability (Overland et al. 2010; Hua et al. 2019; Sillman et al. 2019). Compared to conventional agriculture, Pikaar et al. (2017) claim that MP or SCP can increase overall nutrient efficiency by 2.5 times, with 3 to 10 times lower nitrogen loss (43% improved protein efficiency). This significant ecological function makes MB, a sustainable third-generation protein source after FM and soy protein (Matassa et al. 2015, 2016; De Vrieze et al. 2019; Sillman et al. 2019). A recent study that linked the absolute planetary boundary to the sustainable environmental performance of MP showed that aerobic HB grown on potato-processing waste in a bioreactor emitted lesser N and P and caused reduced land-use change than FM and SBM, which suggests the sustainability of MP as an alternative to conventional protein sources (Owsianiak et al. 2022). Linder (2019) estimates that by 2050, replacing 10–19% of conventional crop-based protein feed with MP can reduce global cropland area, N loss, and greenhouse gas emissions.

Unlike terrestrial crops (Schlechtriem et al. 2016), microorganisms do not require pesticides or insecticides (Sillman et al. 2019) for cultivation. They demand less space, water, and land than conventional agriculture (Swain et al. 2018) and terrestrial PP production (Matassa et al. 2015; Sillman et al. 2019). In comparison to conventional proteins such as SBM, MP requires 128 times less land and five times less water to produce 1 kg of protein (Matassa et al. 2016; Sillman et al. 2019). Sakarika et al. (2022) reported that MP requires 40,000 less land (0.05 m2/kg protein vs 2279 m2/kg protein) and 20 times less water (282 L/kg protein vs 5516 L/kg protein), and higher N efficiency (430 g N consumed/kg N supplied vs 40 g N consumed/kg N supplied) than meat.

Several studies have reported significantly reduced GHG, water, and land requirements with MP from renewable energy sources like the wind (Sillman et al. 2019), electricity (Jourdin et al. 2018), and solar (Matassa et al. 2016; De Vrieze et al. 2019).The production of MP through innovative continuous fermentation culture processes allows high volumetric productivities (3–4 kg MP/m3 per hour, Matassa et al. 2016), with a physical footprint that is a factor of 1000 smaller than any conventional vegetable protein production system (Matassa et al. 2015). Despite the small amount of land required for FM processing (Matassa et al. 2016), the C footprint analysis shows that MP emits less CO2 (1.7-tonne CO2eq/tonne MP) than FM (CO2 eq/tonne protein). Besides achieving feasible industrial-scale production and cost competitiveness with FM, the final MP product is comparable to FM in terms of EAA profile and overall nutritive value (Overland et al. 2010; Kuzniar et al. 2019). Durigon et al. (2019) found that MBSs require little or no water exchange and have a low environmental impact (Dauda et al. 2018a, b; Liu et al. 2018). While conventional aquaculture ponds require approximately 20,000 L of water per kg of fish or shrimp produced, Martínez-Córdova et al. (2017) reported that the water demand in biofloc systems could be as low as 200 L per kg and that the cost of raising fish in biofloc systems is lower than in conventional RAS systems (Crab et al. 2007).

7 Conclusion, Future Perspectives, and Opportunities

Given that future farming systems will have to be increasingly more self-contained, not only in terms of farm biosecurity and potential disease exclusion/impacts but also in terms of water reuse and minimising nutrient discharge, improving the functionality of aqua feeds will be of paramount importance in guiding the long-term sustainable development of the fed fin fish and crustacean aquaculture sector toward the development of a more environmentally friendly and nutrient-sensitive production system. Novel techniques (for example, aerobic/anaerobic fermentation technology, gas bioreactor fermentation, and microbial electrosynthesis, Jourdin et al. 2018; Jones et al. 2020) will be required to up-scale production and improve the nutritional value of SCP feed ingredients. Using anaerobic digestion to exploit the C content of microalgae from high organic load wastewater for MP without dewatering (drying) can reduce the high cost and environmental footprint of microalgae production. Harvesting, dewatering, and lipid extraction from MAB pose challenges due to the high energy requirements. Batch, fed-batch, continuous bioreactors, and semi-continuous cultivation are all examples of anaerobic fermentation (AnF) that can improve the production performance of microalgae, particularly in relation to high-rate sludge systems. Co-cultivation of bacteria and microalgae in bioreactors can reduce energy demand associated with the production process, which could reduce the climate change and ozone depletion impact potential of MP and support the United Nations’ sustainable development goals (Owsianiak et al. 2022). Novel approaches like heat shock treatment and alkaline hydrolysis (Sakarika et al. 2022) can mitigate ANF (trypsin inhibitors, heavy metals, nucleic acid, and cell wall contents) associated with low nutritional value and acceptance of SCP (Ahmad et al. 2022). Bioreactors can also remove suspended solids (95–99.5%) and nutrients (>90% for NO3-, NO2-, and NH3) from aquaculture wastewater (Avnimelech et al. 2014). Large-scale biofloc production in external bioreactors (ex situ biofloc) can ensure MP availability and reduce aquaculture’s environmental impact.

A good selection of microbes with improved nutritional quality or growth characteristics could improve their efficiencies and reduce the cost of production through metagenomics (Diwan et al. 2021). Metagenomics can be applied to evaluate the potential for isolation and culture of aquaculture-relevant microbial species. Post-genomic and cutting-edge technologies like transcriptomics and shotgun proteomics can provide insights into microbial cellular processes and function (Kumar et al. 2016; Diwan et al. 2021). The application of proteomic techniques, including the gel-based techniques like two-dimensional gel electrophoresis (2-DE or 2D PAGE, Schrama et al. 2018), sequential window acquisition of all theoretical spectra (SWATH) technology (for quantifying and distinguishing strains of MP, Kumar et al. 2016), electrospray ionisation mass spectrophotometry (ESI-MS, Graham et al. 2007), gel-free nano liquid chromatography electrospray ionisation (LC-ESI, Kumar et al. 2016), liquid chromatography coupled to tandem mass spectrophotometry (LC-MS/MS, Timmins-Schifman et al. 2018), label-based isobaric tag for relative and absolute quantitation (iTRAQ, Rodrigues et al. 2017), stable isotope labelling by/with amino acids in cell culture (SILAC, Rodrigues et al. 2017), quantitative real-time polymerase chain reaction (qRT-PCR, for detecting, identifying, and quantifying pathogens, (Kumar et al. 2016), and matrix-assisted laser desorption ionisation time of flight mass spectrophotometry (MALDI-TOF MS, Singhal et al. 2015), will advance knowledge about the physiology and metabolism of microorganisms in aquaculture through changes in proteome (complete set of protein expressed by a genome, tissue, or organism. These methods will also facilitate the rapid identification of mass microbial samples consisting of diverse microorganisms of different strains, species, and genera.

References

Aboseif AM, Flefil NS, Taha MKS, Tahoun UM, Abdel Mola HR, El Haroun E, Van Doan H, Goda AMS-A (2022) Influence of dietary C: N: P ratios on Nile tilapia Oreochromis niloticus growth performance and formation of water biotic communities within a biofloc system containment. Aquac Rep 24(4):101136. https://doi.org/10.1016/j.aqrep.2022.101136

Abugrara AM, El-Sayed HS, Zaki MAA, Nour AE-AM (2019) Utilization of Nannochloropsis oceanica alga for biodiesel production and the de-lipidated biomass for improving Red tilapia aquaculture. Egypt J Aquatic Biol Fish 23(4):421–436

Acquah C, Ekezie, FG, Udenigwe CC (2021) Potential applications of microalgae-derived proteins and peptides in the food industry. In: Cultured microalgae for the food industry. https://doi.org/10.1016/B978-0-12-821080-2.00011-3

Adel M, Lazado CC, Safari R, Yeganeh S, Zorriehzahra MJ (2017) Aqualase®, a yeast-based in-feed probiotic, modulates intestinal microbiota, immunity and growth of rainbow trout Oncorhynchus mykiss. Aquac Res 48:1815–1826

Adeoye AA, Akegbejo-samsons Y, Fawole FJ, Olatunji PO, Muller N, Wan AH, Davies SJ (2021) From waste to feed, dietary utilisation of bacterial protein from fermentation of agricultural wastes in African catfish (Clarias gariepinus) production and health. Aquaculture 531:735850. https://doi.org/10.1016/j.aquaculture.2020.35850

Agboola JO, Teuling E, Wierenga PA, Grupen H, Schrama JW (2019) Cell wall disruption: an effective strategy to improve the nutritive quality of microalgae in African catfish (Clarias gariepinus). Aquac Nutr 25(4):783–797. https://doi.org/10.1111/anu.12896

Agboola JO, Overland M, Skrede A, Hansen JO (2020) Yeast as major protein-rich ingredient in aquafeeds: a review of the implications for aquaculture production. Rev Aquac 13(2):949–970. https://doi.org/10.1111/raq.12507

Ahmad A, Hassan SW, Banat F (2022) An overview of microalgae biomass as a sustainable aquaculture feed ingredient: food security and circular economy. Bioengineered 13(4):9521–9547. https://doi.org/10.1080/21655979.2022.2061148

Albrektsen S, Kortet R, Skov PV, Ytteborg E, Gitlesen S, Kleinegris D, Mydland L-T, Hansen JO, Lock E-J, Mørkøre T, James P, Wang X, Whitaker RD, Vang B, Hatlen B, Daneshvar E, Bhatnagar A, Jensen LB, Øverland M (2022) Future feed resources in sustainable salmonid production: a review. Rev Aquac 14:1790–1812. https://doi.org/10.1111/raq.12673

Allen KM, Habte-Tsion HM, Thompson KR, Filer K, Tidwell JH, Kumar V (2019) Freshwater microalgae (Schizochytrium sp.) as a substitute to fish oil for shrimp feed. Sci Rep 9:6178. https://doi.org/10.1038/s41598-019-41020-8

Alloul A, Wille M, Lucenti P, Bossier P, Van Stappen G, Vlaeminck SE (2021) Purple bacteria as added-value protein ingredient in shrimp feed: Litopenaeus vannamei growth performance, and tolerance against Vibrio and ammonia stress. Aquaculture 530:735788. https://doi.org/10.1016/j.aquaculture.2020.735788

Amer SA, Osman A, Al-Gabri NA, Elsayed SAM, El-Rahman GIA, Elabbasy MT, Ahmed SAA, Ibrahim RE (2019) The effect of dietary replacement of fish meal with whey protein concentrates on the growth performance, fish health, and immune status of Nile tilapia Fingerlings, Oreochromis niloticus. Animals 9:1003. https://doi.org/10.3390/ani9121003

Amorim ML, Soares J, Coimbra JSD, Leite MD, Albino LFT, Martins MA (2021) Microalgae proteins: production, separation, isolation, quantification, and application in food and feed. Crit Rev Food Sci Nutr 61(12):1976–2002. https://doi.org/10.1080/10408398.2020.1768046

Ansari FA, Guldhe A, Gupta SK, Rawat I, Bux F (2021) Improving the feasibility of aquaculture feed by using microalgae. Environ Sci Pollut Res 28:43234–43257

Anupama RP (2000) Value-added food: single cell protein. Biotechnol Adv 18:459–479

Asaduzzaman M, Wahab MA, Verdegem MCJ, Huque S, Salam MA, Azim ME (2008) C/N ratio control and substrate addition for periphyton development jointly enhance freshwater prawn Macrobrachium rosenbergii production in ponds. Aquaculture 280:117–123

Avnimelech Y, De Scryver P, Emerenciano M, Kuhn D, Ray A, Taw N (2014) A practical guide book, 3rd edn. Avnimelech Y (ed) The World Aquaculture Society, Baton Rouge, LA

Azim ME, Little DC (2008) The bioflocs technology (BFT) in indoor tanks: water quality, bioflocs composition, and growth and welfare of Nile tilapia (Oreochromis niloticus). Aquaculture 283:29–35

Azim ME, Verdegem MCJ, Khatoon H, Wahab MA, van Dam AA, Beveridge MCM (2002) A comparison of fertilization, feeding and three periphyton substrates for increasing fish production in freshwater pond aquaculture in Bangladesh. Aquaculture 212:227–243

Babu DT, Antony SP, Joseph SP, Bright AR, Philip R (2013) Marine yeast Candida aquaetextoris S527 as a potential immunostimulant in black tiger shrimp Penaeus monodon. J Invertebr Pathol 112:243–252

Badiola M, Basurko OC, Piedrahita R, Hundley P, Mendiola D (2018) Energy use in recirculating aquaculture systems (RAS): a review. Aquac Eng 81:57–70

Bakhshi F, Najdegeramib EH, Manaffarc R, Tukmechid A, Farah KR (2018) Use of different carbon sources for the biofloc system during the grow-out culture of common carp (Cyprinus carpio L.) fingerlings. Aquaculture 484:259–267

Banks M, Johnson R, Giver L, Bryant G, Guo M (2022) Industrial production of microbial protein products. Curr Opin Biotechnol 75:102707. https://doi.org/10.1016/j.copbio.2022.102707

Beal CM, Gerber LM, Thongrod S, Phromkunthong W, Kiron V, Granados J, Archibald I, Greene CH, Huntley ME (2018) Marine microalgae commercial production improves sustainability of global fisheries and aquaculture. Sci Rep 8:15064. https://doi.org/10.1038/s41598-018-33504-10

Bélanger A, Sarker PK, Bureau DP, Chouinard Y, Vandenberg GW (2021) Apparent digestibility of macronutrients and fatty acids from microalgae (Schizochytrium sp.) fed to rainbow trout (Oncorhynchus mykiss): a potential candidate for fish oil substitution. Animals 11(2):456. https://doi.org/10.3390/ani11020456

Bentzon-Tilia M, Sonnenschein EC, Gram L (2016) Monitoring and managing microbes in aquaculture—towards a sustainable industry. Microb Biotechnol 9:576–584

Bharti V, Pandey PK, Koushlesh SK (2014) Single cell proteins: a novel approach in aquaculture systems. World Aquac: 62–63. www.was.org

Biswas A, Takakuwa F, Yamada S, Matsuda A, Saville RM, Leblanc A, Silverman JA, Sato N, Tanaka H (2020) Methanotroph (Methylococcus capsulatus, Bath) bacteria meal as an alternative protein source for Japanese yellowtail, Seriola quinqueradiata. Aquaculture 529:735700. https://doi.org/10.1016/j.aquaculture.2020.735700

Bossier P, Ekasari J (2017) Biofloc technology application in aquaculture to support sustainable development goals. Microb Biotechnol 10(5):1012–1016

Boyd CE, McNevin AA (2015) Aquaculture, resource use, and the environment. Wiley. 368pp

Boyd CE, D’Abramo LR, Glencross BD, Huyben DC, Juarez LM, Lockwood GS, McNevin AA, Tacon AGJ, Teletchea F, Tomasso JR Jr, Tucker CS, Valenti C (2019) Achieving sustainable aquaculture: historical and current perspectives and future needs and challenges. J World Aquac Soc 51:578–633

Boyd CE, McNevin AA, Davis RP (2022) The contribution of fisheries and aquaculture to the global protein supply. Food Secur 14(3):805–827. https://doi.org/10.1007/s12571-021-01246-9

Camargo JA, Alonso A (2006) Ecological and toxicological effects of inorganic nitrogen pollution in aquatic ecosystems: a global assessment. Environ Int 32:831–849

Campanati C, Willer D, Schubert J, Aldridge DC (2022) Sustainable intensification of aquaculture through nutrient recycling and circular economies: more fish, less waste, blue growth. Rev Fish Sci Aquac 30(2):143–169

Cardinaletti G, Messina M, Bruno M, Tulli F, Poli BM, Giorgi G, Chini-Zittelli G, Tredici M, Tibaldi E (2018) Effects of graded levels of a blend of Tisochrysis lutea and Tetraselmis suecica dried biomass on growth and muscle tissue composition of European sea bass (Dicentrarchus labrax) fed diets low in fish meal and oil. Aquaculture 485:173–182

Cardona E, Segret E, Cachelou Y, Vanderesse T, Larroquet L, Hermann A, Surget A, Corraze G, Cachelou F, Bobe J, Skiba-Cassy S (2022) Effect of microalgae Schizochytrium sp. supplementation in plant diet on reproduction of female rainbow trout (Oncorhynchus mykiss): maternal programming impact of progeny. J Anim Sci Biotechnol 13:33. https://doi.org/10.1186/s40104-022-00680-9

Carneiro WF, Castro TFD, Reichel T, Uzeda PL, Palacios CAM, Murgus LDS (2022) Diets containing Arthrospira platensis increase growth, modulate lipid metabolism, and reduce oxidative stress in pacu (Piaractus mesopotamicus) exposed to ammonia. Aquaculture 547:737402. https://doi.org/10.1016/jj.aquaculture.2021.737402

Carter CG, Codabaccus MB (2022) Assessing the value of single cell ingredients in aqua feeds. Curr Opin Biotechnol 76:102734. https://doi.org/10.1016/j/copbio.2022.102734

Carvalho Pereira J, Lemoine A, Neubauer P, Junne S (2021) Perspectives for improving circular economy in brackish shrimp aquaculture. Aquac Res 53:1169–1180

Carvalho M, Montero D, Rosenlund G, Fontanillas R, Ginés R, Izquierdo M (2020) Effective complete replacement of fish oil by combining poultry and microalgae oils in practical diets for gilthead sea bream (Sparus aurata) fingerlings. Aquaculture 529:735696. https://doi.org/10.1016/j/aquaculture.2020.735696

Carvalho M, Marotta M, Xu H, Geraert P-A, Kaushik S, Montero D, Izquierdo M (2022) Complete replacement of fish oil by three microalgal products rich in n-3 long-chain polyunsaturated fatty acids in early weaning micro diets for gilthead sea bream (Sparus aurata). Aquaculture 558:738354. https://doi.org/10.1016/j.aquaculture.2022.738354

Chang JS, Show PL, Ling TC, Chen CY, Ho SH, Tan CH, Nagarajan D, Phong WN (2017) Photobioreactors. In: Current developments in biotechnology and bioengineering: bioprocesses, bioreactors and controls, pp 313–352. https://doi.org/10.1016/B978-0-444-63663-8.00011-2

Chatvijitkul S, Boyd CE, Davis DA, McNevin AA (2016) Embodied resources in fish and shrimp feeds. J World Aquac Soc 48:7–19

Chavan R, Mutnuri S (2019) Tertiary treatment of domestic wastewater by Spirulina platensis integrated with microalgal biorefinery. Biofuels 10:33–44

Chen XQ, Zhao W, Xie SW, Xie JJ, Zhang ZH, Tian LX et al (2019a) Effects of dietary hydrolyzed yeast (Rhodotorula mucilaginosa) on growth performance, immune response, antioxidant capacity and histomorphology of juvenile Nile tilapia (Oreochromis niloticus). Fish Shellfish Immunol 90:30–39

Chen Y, Sagada G, Xu B, Chao W, Zou F, Ng W, Sun Y, Wang L, Zhong Z, Shao Q (2019b) Partial replacement of fish meal with Clostridium autoethanogenum single-cell protein in the diet for juvenile black sea bream (Acanthopagrus schlegelii). Aquac Res 51(3):1000–1011

Chen Y, Chi S, Zhang S, Dong X, Yang Q, Liu H, Tan B, Xie S (2022) Evaluation of Methanotroph (Methylococcus capsulatus, Bath) bacterial meal on body composition, lipid metabolism, protein synthesis and muscle metabolites of Pacific white shrimp (Litopenaeus vannamei). Aquaculture 547:737517. https://doi.org/10.1016/j.aquaculture.2021.737517

Chowdhury AJK, Zakaria NH, Abidin ZAZ, Rahman MM (2016) Phototrophic purple bacteria as feed supplement on the growth, feed utilization and body compositions of Malaysian mahseer Tor tambroides Juveniles. Sains Malays 45(1):135–140

Clenfuegos-Martinez K, Monroy-Dosta MDC, Hamdan-Partida A, Hernandez-Vergara MP, Aguirre-Garrido JF, Bustos-Martinez J (2022) Effect of the probiotic Lactococcus lactis on the microbial composition in the water and in the gut of freshwater prawn (Macrobrachium rosenbergii) cultivate in biofloc. Aquac Res 53:3877–3889. https://doi.org/10.1111/are.15889

Costello C, Cao L, Gelcich S, Cisneros-Mata MA, Free CM, Froehlich HE, Golden CD, Ishimura G, Maier G, Macadam-Somer I, Mangin T, Melnychuk MC, Miyahara M, Moor CLD, Naylor R, Nøstbakken N, Ojea E, O’Reilly E, Parma AM, Plantinga AJ, Thilsted SH, Lubchenco J (2020) The future of food from the sea. Nature 588:95–100. https://doi.org/10.1038/s41586-020-2616-y

Cottrell RS, Blanchard JL, Halpern BS, Metian M, Froehlich HE (2020) Global adoption of novel aquaculture feeds could substantially reduce forage fish demand by 2030. Nat Food 1:301–308

Crab R, Avnimelech Y, Defoirdt T, Bossier P, Verstraete W (2007) Nitrogen removal techniques in aquaculture for a sustainable production. Aquaculture 270:1–14

Dar SA, Bhat RA (2020) Aquatic pollution stress and role of biofilms as environment clean-up technology. In: Qadri H, Bhat RA, Dar GH, Mehmood MA (eds) Freshwater pollution dynamics and remediation. Springer Nature, Singapore, pp 293–318

Dar SA, Lone FA, Dar SA, Bhat RA, Bashir I, Mir SA, Dar ZA (2020) Biofilm: an innovative modern technology for aquatic pollution remediation. In: Bhat RA et al (eds) Bioremediation and biotechnology, vol. 2, pp 207–219. https://doi.org/10.1007/978-3-030-40333-1_12

Dauda AB, Romano N, Ebrahimi M, Karim M, Natrah I, Kamarudin MS, Ekasari J (2017) Different carbon sources affects biofloc volume, water quality and the survival and physiology of African catfish Clarias gariepinus fngerlings reared in an intensive biofoc technology system. Fish Sci. https://doi.org/10.1007/s12562-017-1144-7

Dauda AB, Romano N, Chen WW, Natraha I, Kamarudin MS (2018a) Differences in feeding habits influence the growth performance and feeding efficiencies of African catfish (Clarias gariepinus) and lemon fin barb hybrid (Hypsibarbus wetmorei ♂ × Barboides go nionotus ♀) in a glycerol-based biofloc technology system versus a recirculating system. Aquac Eng 82:31–37

Dauda AB, Romano N, Ebrahimi M, Teh JC, Ajadi A, Chong CM, Karim M, Natrah I, Kamarudin MS (2018b) Influence of carbon/nitrogen ratios on biofloc production and biochemical composition and subsequent effects on the growth, physiological status and disease resistance of African catfish (Clarias gariepinus) cultured in glycerol-based biofloc systems. Aquaculture 483:120–130

David LH, Campos DWJ, Pinho SM, Romera DM, Garcia F (2021) Growth performance of Nile tilapia reared in cages in a farm dam submitted to a feed reduction strategy in a periphyton-based system. Aquac Res 53(3):1147–1150

De Vrieze J, Verbeecka K, Pikaar I, Boered J, Wijk AV, Rabaey K, Verstraete W (2019) The hydrogen gas bio-based economy and the production of renewable building block 3 chemicals, food and energy. N Biotechnol 55:12–18. https://doi.org/10.1016/j.nbt.2019.09.004

Debbarma R, Meena DK, Biswas P, Meitei MM, Singh SS (2022) Portioning of microbial waste into fish nutrition via frugal biofloc production: a sustainable paradigm for greening of environment. J Clean Prod 334:130246. https://doi.org/10.1016/jclepro.2021.130246

Delamare-Deboutteville J, Batstone DJ, Kawasaki M, Stegman S, Salini M, Tabrett S, Smullen R, Barnes AC, Hülsen T (2019) Mixed culture purple phototrophic bacteria is an effective fishmeal replacement in aquaculture. Water Res X 4:100031. https://doi.org/10.1016/j.wroa.2019.100031

Diwan AD, Harke SN, Krishna G, Panche AN (2021) Aquaculture industry prospective from gut microbiome of fish and shellfish: an overview. J Anim Physiol Anim Nutr 106(2):441–469

Durigon EG, Almeida APG, Jerônimo GT, Baldisserotto B, Emerenciano MGC (2019) Digestive enzymes and parasitology of Nile tilapia juveniles raised in brackish biofloc water and fed with different digestible protein and digestible energy levels. Aquaculture 506:35–41

Ekasari J, Azhar MH, Surawidjaja EH, Nuryati S, De Schryver P, Bossier P (2014a) Immune response and disease resistance of shrimp fed biofloc grown on different carbon sources. Fish Shellfish Immunol 41:332–339

Ekasari J, Angela D, Waluyo SH, Bachtiar T, Surawidjaja EH, Bossier P, De Schryver P (2014b) The size of biofloc determines the nutritional composition and the nitrogen recovery by aquaculture animals. Aquaculture 426:105–111

Ekasari J, Rivandi DR, Firdausi AP, Surawidjaja EH, Zairin M, Bossier P, De Schryver P (2015) Biofloc technology positively affects Nile tilapia (Oreochromis niloticus) larvae performance. Aquaculture 441:72–77

Ekpeni LEN, Benyounis KY, Aboderheeba AKM, Nkem-Ekpeni FF, Stokes J, Olabi AG (2015) Yeast: a potential biomass substrate for the production of cleaner energy (biogas). The 6th International Conference on Applied Energy – ICAE2014. Energy Procedia 61:1718–1731

El-Husseiny OM, Hassan MI, El-Haroun ER, Suloma A (2018) Utilization of poultry by-product meal supplemented with L-lysine as fish meal replacer in the diet of African catfish Clarias gariepinus (Burchell, 1822). J Appl Aquac 30(1):63–75. https://doi.org/10.1080/10454438.2017.1412844

Engle C, Abramo LR, Slater MJ (2017) Global aquaculture 2025: editorial. J World Aquac Soc 48(1):1–4

Fang X, Zhao J, Wu S, Yu K, Huang J, Ding Y, Hu T, Xiao S, Liu S, Zou J (2022) A two-year measurement of methane and nitrous oxide emissions from freshwater aquaculture ponds: affected by aquaculture species, stocking and waste management. Sci Total Environ 813:151863. https://doi.org/10.1016/j.scitotenv.2021.151863

FAO (2018) The state of world fisheries and aquaculture 2018-meeting the sustainable development goals. Rome, 227 pp.

FAO (2020) The state of world fisheries and aquaculture 2020: sustainability in action. Rome, 227pp. https://doi.org/10.4060/ca9229en

Fauji H, Budiardi T, Ekasari J (2018) Growth performance and robustness of African catfish Clarias gariepinus (Burchell) in biofloc-based nursery production with different stocking densities. Aquac Res 49:1339–1346

Fayeofori GB-M, Bob-Manuel FG (2014) A comparative study of the effect of yeast single cell protein on growth, feed utilization and condition factor of the African catfish Clarias gariepinus (Burchell) and tilapia, Oreochromis niloticus (Linnaeus) fingerlings. Afr J Agric Res 9:2005–2011

Figueroa-Espinoza J, Rivas-Vega ME, Mariscal-Lopez MDLA, Emerenciano MGC, Martinez-Porchas M, Miranda-Baeza A (2022) Reusing water in a biofloc culture system favours the productive performance of the Nil tilapia (Oreochromis niloticus) without affecting the health status. Aquaculture 558:738363. https://doi.org/10.1016/j.aquaculture.2022.738363

Frost and Sullivan (2018) Emerging protein sources for fish feed. Frost and Sullivan

Fry JP, Love DC, MacDonald GK, West PC, Engstrom PM, Nachman KE, Lawrence RS (2016) Environmental health impacts of feeding crops to farmed fish. Environ Int 91:201–214

Gamble MM, Sarker PK, Kapuscinski AR, Kelson S, Fitzgerald DS, Schelling B, De Souza AVB, Tsukui T (2021) Toward environmentally sustainable aquafeeds: managing phosphorus discharge from Nile tilapia (Oreochromis niloticus) aquaculture with microalgae-supplemented diets. Elem Sci Anth 9:1. https://doi.org/10.1525/elementa.2020.00170

Garcia F, Romera DM, Sousa NS, Paiva-Ramos I, Onaka EM (2016) The potential of periphyton-based cage culture of Nile tilapia in a Brazilian reservoir. Aquaculture 464:229–235

Garcia F, Sabbag OJ, Kimpara JM, Romera DM, Sousa NS, Onaka EM, Ramos IP (2017) Periphyton-based cage culture of Nile tilapia: an interesting model for small-scale farming. Aquaculture 479:838–844

Garibay-Valdez E, Martínez-Córdova LR, Vargas-Albores F, GollasGalván T, Lago-Leston A, Calderón K, Martínez-Porchas M (2019) Biofilm consumption shapes the intestinal microbiota of shrimp (Penaeus vannamei). Aquac Nutr 25:427–435

Gasco L, Biasato I, Dabbou S, Schiavone A, Gai F (2019) Animals fed insect-based diets: state-of-the-art on digestibility, performance and product quality. Animals 9(4):170. https://doi.org/10.3390/ani9040170

Gephart JA, Golden CD, Asche F, Belton B, Brugere C, Froehlich HE, Fry JP, Halpern BS, Hicks CC, Jones RC, Klinger DH, Little DC, McCauley DJ, Thilsted SH, Troell M, Allison EH (2020) Scenarios for global aquaculture and its role in human nutrition. Rev Fish Sci Aquac 29:122–138. https://doi.org/10.1080/23308249.2020.1782342

Glencross BD, Huyben D, Schrama JW (2020) The application of single-cell ingredients in aquaculture feeds—a review. Fishes 5:22. https://doi.org/10.3390/fishes5030022

Goda AA-S, Srour TM, Omar E, Mansour AT, Baromh MZ, Mohamed SA, El-Haroun E, Davies SJ (2019) Appraisal of a high-protein distiller’s dried grain (DDG) in diets for European sea bass, Dicentrarchus labrax fingerlings on growth performance, haematological status and related gut histology. Aquac Nutr 25(4):808–816. https://doi.org/10.1111/anu.12898

Goncalves AL, Pires JCM, Simoes M (2017) A review on the use of microalgal consortia for waste water treatment. Algal Res 24(Part B):403–415. https://doi.org/10.1016/j.algal.2016.11.008

Guimaraes AM, Schleder DD, Nagata M, Nóbrega RO, Fracalossi DM, Seiffert WQ, Vieira FDN (2019) Aurantiochytrium sp. meal can replace fish oil in practical diets for the juvenile Pacific white shrimp. Aquac Nutr 25:798–807

Gullian-Klanian M, Díaz MD, Solís MJS, Aranda J, Moral PM (2020) Effect of the content of microbial proteins and the poly-β-hydroxybutyric acid in biofloc on the performance and health of Nile tilapia (Oreochromis niloticus) fingerlings fed on a protein-restricted diet. Aquaculture 519:734872. https://doi.org/10.1016/j.aquaculture.2019.734872

Gumus E, Aydin B, Kanyilmaz M (2016) Growth and feed utilization of goldfish (Carassius auratus) fed graded levels of brewers yeast (Saccharomyces cerevisiae). Iran J Fish Sci 15(3):1124–1133