Abstract

Valorization of the agro-industrial wastes and development of energy saving sustainable wastewater treatment systems has gained importance by the increasing demand on energy and water worldwide. Microbial fuel cell is an emerging technology with the ability of simultaneous wastewater treatment and electricity generation by harvesting the chemical energy in organic wastes and wastewaters. Agro-industry wastewaters mainly composed of carbohydrates, proteins, lipids, and various nutrients have been effectively used as a substrate for the microorganisms in bioenergy producing treatment systems. Agricultural wastes including the residues of various crops, pomace and peelings of fruits and vegetables, dairy wastes, and livestock wastes are the renewable feedstock for the microbial fuel cell systems. In addition to being used as a substrate, the agricultural wastes are used for electrode and proton exchange membrane fabrication in microbial fuel cell applications. In this chapter, a brief information and examples from the recent literature on vegetable oil processing, brewery and wine, dairy and livestock wastewater treatment, and utilization of agricultural residues in microbial fuel cells are presented. The power density, coulombic efficiency, and chemical oxygen demand removal efficiencies reported for different agricultural wastes are summarized. Finally, the challenges and future perspectives of microbial fuel cell technology are discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Wastewaters generated from domestic, industrial, agricultural, and municipal activities contain a wide variety of pollutants including toxic organic and inorganic compounds and biological components which may cause many adverse effects on environmental and human health [65]. Since many of the water resources are polluted there is a need for effective water treatment technologies [39]. In order to reach high pollution removal efficiencies an increasing capacity of equipment leading to an increase in energy consumption has been used in the wastewater treatment facilities. The electric energy consumed in the wastewater treatment processes accounts for 25–40% of the total operating costs. A significant portion of the required energy is provided from non-renewable sources. Since the use of these energy sources resulted in emission of air pollutants and environmental depletion, development of energy efficient wastewater treatment methods plays a highly important role in environmental protection [108]. Depending on the composition of the wastewater and the treatment method applied, approximately 0.5–2 kWh/m3 of treated water energy is required for wastewater treatment. Wastewater contains nearly 3–10 times the energy (in the form of organic substance, nutritional elements, and thermal energy) required to treat it. By harvesting the chemical energy hidden in wastewater, the treatment technologies can become energy-producing processes instead of being energy-consuming applications [28]. Agricultural and food industries are one of the important contributors to worldwide environmental pollution. Effluents of agro-food industries threaten the environmental health since they contain high organic matter and traces of organic pollutants. Therefore the treatment of agro-food industry wastewaters requires appropriate and comprehensive management methods [42, 79].

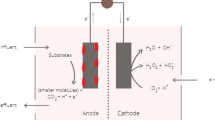

2 Working Principle

Microbial fuel cell is an emerging technology producing clean and sustainable energy during the degradation of pollutants. It is a low-cost and environmentally friendly method for the treatment of biowastes, which reduces the biomass energy loss and greenhouse gas emissions. The energy in the biomass is extracted and the chemical energy in organic compounds is converted into electricity in microbial fuel cells [86, 94]. A typical microbial fuel cell (shown in Fig. 1) consists of anode and cathode chambers separated by a proton exchange membrane. Exoelectrogens, which have the ability to transfer electrons extracellularly, oxidize the organic substances into electrons and protons in the anode chamber into electrons, protons, and carbon dioxide. The diffusion of the protons through the ion exchange membrane produces a potential difference between anode and cathode. The electrons flow through the external circuit to the cathode chamber where the electrons and protons react with oxygen to form water and electrical energy is generated [84, 99].

Many types of electrochemically active microorganisms including bacteria, archaea, and fungi have proven to be useful in microbial fuel cells. Pure or mixed culture microorganisms can be used in microbial fuel cells. The mixed cultures are synergistic communities playing different roles in the nutrient cycle. Some of the microorganisms digest nutrients while some others protect the biofilm against hazardous factors such as heavy metals. Generally, soil, marine sediments, domestic wastewater, and activated sludge including mixed cultures have been used to inoculate the microbial fuel cells. Though the growth of the pure cultures is slow, mixed cultures take longer time to reach a steady current generation in microbial fuel cells [13, 52]. The performance of microbial fuel cells depends on various factors such as reactor configuration, electrode materials, external resistance, selection of proton exchange membrane, operating pH and temperature, bacterial community, substrate, and ionic strength of electrolyte [47, 57]. Microbial fuel cells provide renewable energy to meet the global electricity requirement. This method has many advantages over other wastewater treatment methods such as [4]:

-

obtaining high efficiencies due to direct conversion of organic substances into electricity,

-

the ability of operation at ambient conditions,

-

potential use in remote areas where the electrical infrastructure is insufficient, and,

-

involving an anaerobic process reducing the bacterial biomass in comparison to the aerobic systems.

2.1 Configurations

Microbial fuel cell systems have been basically designed with dual and single chamber configurations. The primitive design for the microbial fuel cells is dual chamber or H-type configuration. Though the performance of double chambered microbial fuel cells is higher in terms of current generation and pollutant removal efficiency, the single chamber air cathode configuration is developed to reduce the cost of the process by minimizing the complexity. In the single chamber configuration there is only an anode chamber attached to the membrane cathode assembly. While one side of the cathode is bonded to the membrane, the other side is in contact with air. In addition to the basic configurations, U-tube and stack microbial fuel cell systems are available for different applications. For the large-scale operations stack microbial fuel cell configuration is used to obtain high voltage and current outputs [99, 100].

2.2 Performance Evaluation

The performance of microbial fuel cells is assessed by several measurements and calculations including the current density, power density, and coulombic efficiency. During the microbial fuel cell operations, the voltage is measured and recorded. The current, I [A], is calculated from Ohm’s law:

where R is the external resistance [Ohm, Ω] and V is the voltage [V].

The power, P [W] is calculated by multiplying the voltage and current. The current and power are normalized to the projected surface area of the anode to determine the current and power densities [96].

where a [m2] is the surface area of the anode.

Alternatively, power can be normalized with respect to liquid volume in the anode chamber to evaluate the volumetric power density.

The coulombic efficiency is defined as the ratio of the total Coulombs calculated by integrating the current over time to the theoretical amount of Coulombs available based on the decrease in pollutant concentration. If the treatment efficiency is evaluated considering the chemical oxygen demand removal [18, 34, 95]:

where t is reaction time (s), F is Faraday’s constant, b is the number of moles of electrons exchanged per mole of O2, ΔCOD is the change in chemical oxygen demand (g/L), and MW is the molecular weight of the O2, and v [L] is the volume of wastewater.

3 Treatment of Agro-Industrial Wastes and Wastewaters in Microbial Fuel Cells

The agro-food industries generate a huge amount of organic matter that can be used for energy recovery [12]. In addition to the agricultural residues in solid form, edible oil wastewaters, fruit and vegetable processing wastewaters, winery and brewery wastewaters, and the animal husbandry wastewaters including the effluents of dairy and livestock industries are categorized under the agro-food processing wastes.

3.1 Pretreatment of the Agricultural Residues

Agro-industrial wastes derived from various sources including animal husbandry, crop harvesting, edible oil production, and food and beverage processing have been found in the environment. The agricultural wastes that are used as feedstock in bioenergy production processes can be categorized into four main generations depending on their usage areas.

First generation feedstocks consist of easily available and edible food crops such as wheat, corn, rice, and sorghum. Though the food crops can be effectively used as fuel in energy production processes, the main challenge for their utilization is the food versus fuel dilemma. Second generation feedstocks include non-food crops like woody and grassy crops, residues of edible food crops (e.g., straw, husk, and bran of various crops) and bagasse, pomace, and peelings of fruits and vegetables. Third generation feedstocks comprise non-food marine biomass which is mainly algae. The fourth generation feedstocks are the engineered microorganisms which are genetically modified bacteria and algae. From first to fourth generation feedstocks are illustrated in Fig. 2 [30, 63, 74].

Agricultural residues are a promising feedstock for low-cost energy production in bioelectrochemical systems due to their renewability. However, the microorganisms in microbial fuel systems are usually unable to use lignocellulosic biomass directly for bioenergy generation. Therefore, physical, chemical, and biological pretreatment methods have been applied to make complex carbohydrate structures available for bioconversion processes [24]. In the physical pretreatment processes chipping, milling, and grinding are applied to increase the biodegradability of agricultural biomass by reducing the size of the particles. Acidic or alkali chemicals are used in chemical pretreatment processes. Acidic pretreatment operated by using mineral or dicarboxylic acids facilitates enzymatic hydrolysis of lignocellulosic material and enhances the energy efficiency in microbial fuel cells. NaOH, KOH, hydrazine, ammonia, or lime are used as alkali pretreatment agents in case low lignin content biomass is used in microbial fuel cells. Biological pretreatment enhances the sugar yield via hydrolyzation and disruption of the crystal structure of lignocellulosic materials in the presence of bacteria and fungi [62].

3.2 Utilization of Agricultural Residues in Electrode and Proton Exchange Membrane Fabrication

A remarkable amount of agricultural residues are produced globally and it has an enormous potential to utilize biowastes [87] such as crop residues (e.g. wheat straw, corn stem, rice husk, etc.), vegetable and fruit peelings (particularly citrus peelings), fruit pomace, and sugarcane bagasse. Generally, the agro-industrial wastes have been utilized as a substrate in microbial fuel cells. Alternatively, these wastes can be used in ion exchange membrane or electrode fabrication. For instance [80], deal with the preparation of ceramic membrane by blending rice husk ash with soil. They reported that ceramic membranes having 10% rice husk ash provided higher proton mass transfer [80].

Jiao et al. [41] used rice husk-derived activated carbon in cathode fabrication and the experimental results showed that a satisfactory power density output (293.4–317.7 mW/m2) was gained in the presence of rice husk-based electrodes [41]. Karthikeyan et al. [43] investigated the potential of king mushroom, wild mushroom, and corn stem to be used for the fabrication of electrode materials by carbonization procedures. The maximum bio electrocatalytic current obtained by using carbon electrode derived from corn stem (3.12 mA/cm2) was 8 times higher than the plain graphite electrode [43]. Bose et al. [11] prepared activated carbon from sugarcane waste to fabricate cathode. A power density of 0.40 mA/m2 was obtained while 64% of chemical oxygen demand (COD) removal was achieved in the microbial fuel cell system [11]. Pepè Sciarria et al. [76] carbonized olive mill waste and salted pistachio nut shells to prepare biochar which was used as catalysts in air cathode microbial fuel cells. The maximum power density obtained by using olive mill waste-derived biochar was approximately 15 times higher than that obtained by a commercial carbon black [76].

3.3 Utilization of Agricultural Residues and Wastewaters as Substrate

Crop residues

Crop residues are one of the most suitable substrates for microbial fuel cells since they are abundantly available and can be converted into sugar monomers and protein easily in the presence of most of the microorganisms. In literature, the performance of microbial fuel cells fed by straw, stalk, and husk of various crops has been widely investigated in recent studies. Wheat straw, which contains up to 40% cellulose, 26% hemi-celluloses, and 23% lignin, is a plentifully available biomass. [72] performed the degradation of wheat straw in a dual chamber microbial fuel cell by using white rot fungi and a maximum power density of 33.19 mW was achieved [72]. Song et al. [91] utilized wheat straw in solid phase microbial fuel cell system for the removal of Pb and Zn in contaminated soil. The metal removal efficiencies of the solid phase microbial fuel cells increased with the straw ratio. By the addition of 3% wheat straw, Pb removal efficiency enhanced from 15 to 37.2%, and Zn removal efficiency increased from 7.3 to 15.1% whereas the power density increased from 10.5 to 25.7 mW m−2 [91]. Rice is served as the staple food for about half the world’s population and its production rate reaches 731 million tons/year. Therefore, rice straw is one of the most common lignocellulosic residues that can be used in biomass-derived energy production [31]. Daud et al. [20] utilized rotten rice as an organic source for bacterial species to produce electricity and remove the metals (Cd, Pb, Cr, Ni, Co, Ag, and Cu) in wastewater. The maximum power and current densities were calculated as 2.9 mW/m2 and 168.42 mA/m2, respectively. The metal removal efficiencies varied between 82.2 and 99.88% [20]. Raychaudhuri and Behera [81] synthesized ceramic membranes by using soil with clay and rice husk ash. A dual chamber microbial fuel cell unit was used to treat rice husk mill wastewater. 72.4 ± 0.9 COD removal and 4.08 ± 0.08 W/m3 of power density were obtained [81]. Cornstalk, as an abundant renewable biomass resource, can be used as a substrate in microbial fuel cells effectively. Li et al. [50] developed a corn straw hydrolyzates-fed microbial fuel system and obtained a power density of 23.5 ± 6.0 mW/m2 [50]. Nwaokocha et al. [67] treated Nigerian corn starch wastewater in a dual chamber microbial fuel cell. The maximum current density and power density were found to be 7.7 mW/cm2 and 8.10 mA/cm2, respectively [67].

Molasses residues

Molasses wastewater generated in sugar refineries contains high concentrations of organic substances including sugar, pectin, and protein. Since molasses wastewater contains large amounts of nutrient for the microorganisms, biochemical treatment methods can be applied [103]. Naina Mohamed et al. [64] treated sugar industry wastewater by using FeMoO4 doped graphite plate electrode in microbial fuel cell. The power density was found to be 106 ± 3 mW/m2. COD removal efficiency and coulombic efficiency were calculated as 79.8 ± 1.5% and 21.3 ± 0.5%, respectively [64]. Hassan et al. [32] utilized sugarcane molasses in a dual chamber microbial fuel cell and 188.5 mW/m2 of power density was obtained. The coulombic efficiencies were in the range of 59.8–28.03% whereas the COD removal efficiency reached to 81.7% [30]. [98] realized benzene removal and power generation in a double chamber benthic microbial fuel cell fed with sugarcane waste. 82.3% of benzene removal efficiency and 24.2 mW/m2 of power density were achieved [98].

Fruit wastes

Kondaveeti et al. [46] treated citrus waste in a single chamber air cathode microbial fuel cell for simultaneous bioelectricity generation and organic reduction. Microbial fuel cell was operated at four organic loading conditions. When the organic load increased from 3 to 12 kg/m3, the COD removal efficiencies decreased from 45.8 to 63.8 mW/m2, and the coulombic efficiencies decreased from 21.3 to 33.2% [46]. Moharir and Tembhurkar [61] investigated the influence of recirculation of anolyte on electricity generation using food waste substrate in a two chamber microbial fuel cell. The microbial fuel cell operation was carried out in fed-batch mode at various COD contents of 500–1250 mg/L. The recirculation improved the bioelectricity production in microbial fuel cells. The maximum current density, power density, and coulombic efficiencies were determined to be 150.30 mA/m2, 29.23 mW/m2, and 14.22% respectively, in recirculated microbial fuel cell systems [61]. Divya Priya and Pydi Setty [21] treated cashew apple juice in microbial fuel cell for bioelectricity production. The maximum power density was calculated as 31.57 mW/m2 at a current density of 350 mA/m2 [21]. He et al. [33] used an air cathode single chamber microbial fuel cell to treat fruit waste extracts and sludge fermentation liquid. Four microbial fuel systems which were fed by glucose, fruit waste extracts (FWEs), sludge fermentation liquid (SFL), and mixture of SFL and FWEs were operated. The electricity generation was improved significantly by adding fruit waste extracts. The soluble organic matter removal was above 90% in all of the microbial fuel cell (MFC) systems. The bioelectricity conversion efficiencies for SFL-MFC, FWEs-MFC, and the mixture-MFC were evaluated as 1.061, 0.718, and 1.391 kWh/kg COD, respectively [33]. Kebaili et al. [44] utilized the fruit wastes to prepare fermented fruit juice inoculum. They used a two chambered microbial fuel cell consisting of platinum grid cathode and graphite rod anode inoculated with fruit leachate. Sucrose and fructose were used as fuel and the performances of graphite carbon and graphite felt bio-anodes were compared. The power dentistry reached up to 20 mW/m2 in the presence of graphite carbon whereas graphite felt provided a power density of 25 mW/m2 [44].

Solid phase applications

In addition to the liquid phase applications, fruit wastes can be utilized in solid phase microbial fuel cells. Hariti et al. [29] studied on the reduction of agro-industrial waste pollutants and energy production in a solid phase microbial fuel cell by utilization of the citrus industry wastes as substrate. The marine sediments were mixed with orange peel waste and treated in microbial fuel cells. The effect of the orange peel amount and external resistance on bioelectricity generation and organic matter reduction were investigated. The maximum power density and total organic carbon were recorded as 0.28 W/m2 and 55%, respectively [29]. The recent studies on microbial fuel cell performances using agricultural wastes and wastewater as a substrate is reported in Table 1.

Edible oil wastewaters

Olive, palm, coconut, cottonseed, peanut, rapeseed, soybean, and sunflower seed are the major sources used for vegetable oil production in the world. The edible oil industries generate large amounts of wastewater and the organic and nutrient constituents of the untreated wastewaters damage the aquatic life. Recently, instead of applying ordinary treatment methods, conversion of the agricultural wastes into useful products or energy has gained attraction due to the fast growth of vegetable oil industries [49]. For instance, [26] investigated the performance of the mirobial fuel cell by using vegetable oil industry wastewaters as a substate. The power densities at 25 and 35 °C were found to be 2166–6119 mW/m2, respectively. The coulombic efficiencies and the COD removal efficiencies varied between 33.0–36.5% and 80%–90%, respectively [26]. Liu and Vipulanandan [53] used metallic nanoparticles of Fe, Ni, and Fe/Ni were used as cathode catalysts to improve power production in a dual chamber microbial fuel cell fed with used vegetable oil. Fe nanoparticles promoted bacterial growth and biosurfactant formation and showed the greatest catalytic effect on the microbial fuel cell performance by incresing the power density up to 66.4 mW/m3 [53].

Olive oil and palm oil processing effluents discharged from the vegetable oil industries are the most commonly treated wastewaters in microbial fuel cells.

Olive oil wastewaters

Olive oil production process is one of the most significant commercial agro-food industries in Mediterranean countries due to the growing interest in olive oil consumption [58]. In literature it reported that approximately 8 × 106 tons of olive mill wastewater is generated worldwide annually and nearly half of the total volume of the olive oil mill output is released as wastewater [7]. The olive oil wastewater generated per unit mass of olive processed values is reported as 40–55 L/100 kg of olives for traditional batch press and 80–120 L/100 kg of olives for continuous solid–liquid centrifuge systems. The chemical and biochemical oxygen demand of the olive oil wastewaters generally varied between 80–200 g/L and 50–100 g/L, respectively [25]. One m3 of olive oil mill wastewater is equivalent to 100–200 m3 of domestic sewage in terms of pollution influence. Olive oil mill wastewaters contain high amounts of sugars, proteins, phenols, lipids, and phosphorus that microorganisms can metabolize [1, 97]. The release of improperly treated olive oil wastewaters may result in contamination of soil and water resources, phytotoxic impacts on aquatic fauna, and ecological equilibria. The conventional wastewater treatment methods usually do not provide a high effectiveness for the elimination of the hazardous pollutants in the olive oil mill wastewaters [69]. Microbial fuel cell treatment is a promising solution for the removal of pollutants in olive oil wastewaters. [8] investigated the treatment of phenol containing synthetic wastewater and olive oil wastewater in dual chamber microbial fuel cells in the presence of phenol-adapted activated sludge and Ralstonia eutropha. In case the olive oil wastewater was fed to the microbial fuel cell the highest power density was found to be a value of 7.8 mW/m2 whereas the COD removal efficiency was 48% [8]. Pepè Sciarria et al. [78] treated the mixtures of olive oil wastewater and domestic wastewater in a single chamber microbial fuel cell. A power density of 124.6 mW/m2 was achieved. The total chemical oxygen demand (TCOD) and BOD5 removal efficiencies were calculated as 60% and 69%, respectively, yielding 29% of coulombic efficiency [78].

Palm oil wastewaters

Palm oil is an inexpensive product which has many application areas in food, cosmetic, pharmaceutical, and biofuel industries [14]. Palm oil wastewaters contain high organic content mainly composed of oil and fatty acids, carbohydrates, proteins, and a remarkable amount of cellulose, which make the palm oil wastewaters suitable for biological treatment processes. Usually, generation of one ton of crude palm oil requires approximately 5–7.5 tons of water, and nearly half of the used water produces palm oil mill effluent [2]. High chemical and biochemical oxygen demand content and organic nitrogen and phosphorus concentration level of the palm oil wastewaters can cause significant environmental problems if discharged without an efficient treatment [15]. Sarmin et al. [82] used palm oil mill effluent as a substrate in a two chambered microbial fuel cell. The power density was improved up to 500 mW/m2 in the presence of yeast-bacteria inoculum whereas the chemical oxygen demand removal efficiency was enhanced up to 90% [82]. Islam et al. [37] investigated the performance of a dual chamber microbial fuel cell inoculated with Klebsiella variicola for the treatment of palm oil mill effluent. 4.5 W/m3 power density and 63% coulombic efficiency were evaluated while the chemical oxygen demand removal efficiency was 58% [37]. Sedighi et al. [83] treated palm oil wastewater in a two chambered microbial fuel cell. The highest power density at the optimum conditions was 58.19 mW/m2 and the maximum COD removal was calculated as 94.8% [83]. Baranitharan et al. [9] operated a double chamber microbial fuel cell using diluted palm oil mill effluent. The maximum power density, COD removal efficiency, and coulombic efficiency were evaluated as 22 mW/m2, 70%, and 24%, respectively [9]. A list of microbial fuel cell performances using vegetable oil wastes as a substrate is reported in Table 2.

3.4 Winery and Brewery Wastewaters

Winery wastewaters

Winery wastewater is mainly generated from the washing steps operated to clean tanks, floors, equipment, and barrels in the wine production processes. Additionally, product losses, bottling facilities, and filtration units contribute the winery wastewater generation. Winery effluents contain many pollutants including ethanol, sugars, organic acids, and phenolic compounds. The estimated winery residues are between 1.3 and 1.5 kg per liter of wine produced, 75% of which is winery wastewater. It is reported that the chemical oxygen demand concentration of winery wastewaters are in the range of 500–45,000 mg/L and total suspended solids varied between 12 and 7300 mg/L whereas the biological oxygen demand concentration is approximately 0.4–0.9 of the chemical oxygen demand value [36, 85]. The excessive use of water, pesticide use, and presence of semi-solid organic wastes including grape marc, vinasses, lees, and sludge, and the seasonal changes in the wastewater parameters make the winery wastes difficult to be treated [10].

Therefore, conventional treatment methods are generally not sufficient for the removal of the wastes generated by wineries. Microbial fuel cell is a promising solution for the treatment of winery wastewaters. Liu et al. [54] operated an air cathode microbial fuel cell inoculated with anaerobic winery sludge to treat synthetic winery wastewater The maximum power density and the COD removal efficiency were found to be 54 mW/m2 and 77 ± 7%, respectively [54]. Penteado et al. [75] investigated the winery wastewater treatment in the presence of various carbon electrodes in a dual chamber microbial fuel cell. The highest power density was found at 420 mW/m2 by using carbon felt and the maximum COD removal was around 11% [75]. Pepe Sciarria et al. [77] studied on the treatment of white and red wine lees in a single chamber air cathode microbial fuel cell. They reported that the power densities were calculated as 111 and 262 mW/m2 by using red and white wine lees, respectively. The reduction of chemical and biochemical oxygen demand was 27% and 83%, respectively for red wine lees while the removal efficiencies were evaluated as 90% and 95% for white wine lees [77].

Brewery wastewaters

Brewery is one of the sectors that consumes a large amount of water and energy. During the beer production extracts of hops, malt, sugar, and water are mixed and fermented by using yeast. Beer is reported as the fifth most consumed beverage in the world. The discharged by-products such as spent grains, and yeast surplus are responsible for environmental pollution. Additionally, cleaning of tanks, bottles, equipment, and floors generates large amounts of wastewater. In order to produce 1 L of beer, 3–10 L of wastewater is generated depending on the production process [6, 89]. Brewery wastewaters are generally more concentrated in comparison to domestic wastewater by tenfold varying from 3000 to 5000 mg COD/L. Brewery wastewater can be utilized as substrate effectively in microbial fuel cells due to the low strength and low inhibitory compound concentration and high carbohydrate content of the food-based wastewater [24, 28]. Negassa et al. [66] studied on brewery industry wastewater treatment in a double chambered microbial fuel cell inoculated with locally isolated microorganisms. The chemical oxygen demand, biochemical oxygen demand, and total suspended solid removal efficiencies were found to be in the range of 79 − 83%, 55–67%, and 76–78%, respectively, while 0.8 W/m3 of power density was achieved [66]. Lu et al. [55] investigated the brewery wastewater treatment performance of a twenty-liter continuous flow microbial fuel cell. It is depicted that the maximum power density, coulombic efficiency, and chemical oxygen demand removal efficiencies were 1.61 mW/m2, 13.9%, and 94.6%, respectively [55].

Stackable configurations

Yuvraj and Aranganathan [106] analyzed the stacked microbial fuel cell performances. Series–parallel setup conjugation yielded a maximum power density of 1345 mW/m2 and 81% of chemical oxygen demand removal by using brewery effluent [106]. Dong et al. [22] designed a ninety liter stackable microbial fuel cell system and used for brewery wastewater treatment. Diluted wastewater and raw wastewater were used at the first and second stages, respectively. The chemical oxygen demand and suspended solid removal efficiencies were 84.7% and 81.7% at the first stage and 87.6% and 86.3% at the second stage, respectively. The power densities changed from 138 ± 4 to 181 ± 21 mW/m2 [22]. The performances of microbial fuel cells fed with winery and brewery wastewaters are shown in Table 3.

3.5 Dairy Industry Wastewaters

The dairy industries manufacture various products including pasteurized milk, skim milk, cream, butter, cheese, yoghurt, ice cream, and milk dessert via transformation of raw milk. The dairy wastewaters containing carbohydrates, lipids, proteins, phosphorous, and nitrates are characterized by high concentrations of chemical and biochemical oxygen demand, oil and grease, total suspended solids, total nitrogen, and total phosphorus [45, 88, 102]. Dairy industry is one of the noticeable sectors, which generates waste thrice the volume of milk produced, and also it discharges a large amount of processed water varying between 3.739 and 11.217 mm3 of waste annually. The manufacturing steps of dairy products involve water consuming units such as tanks, cleaning stores, exchangers, channels, and homogenizers generating effluents with a high organic waste content [40]. The composition of dairy wastewater varies depending on the product type, milk constituents including lactose, casein, and inorganic salts, unit operations in the process, and the detergents and disinfectants used for washing. The chemical oxygen demand and biochemical oxygen demand changed between 80–95,000 mg L−1 and 40–48,000 mg L−1, respectively [3].

Treatment in dual chamber MFC

Sivakumar [90] treated dairy industry wastewater in a double chambered salt bridge microbial fuel cell. The maximum chemical oxygen demand removal efficiency reached to 89.7%. The current and power densities obtained from dairy industry wastewater treatment were 1309.09 mA/m2 and 1067.33 mW/m2, respectively [90].

Cecconet et al. [12] operated two parallel microbial fuel cell reactors continuously for the treatment of real dairy industry wastewater. The results showed that high organic matter removal can be accomplished by recovering a maximum power density of 27 W/m3. The average COD removal efficiencies were 80 ± 10% for the first microbial fuel cell reactor and 83 ± 11% for the second reactor. On average, the first microbial fuel cell reactor exhibited a coulombic efficiency of 20 ± 16%, while the second reactor provided a lower efficiency of 14 ± 11% [12].

Treatment in single chamber MFC

Choudhury et al. [16] treated real dairy wastewater in a single chamber microbial fuel cell inoculated with Shewanella algae. The maximum power and current densities reached to 50 mW/m2 and 141 mA/m2, respectively. The coulombic efficiency was calculated as 27.45% whereas 92.21% of COD removal efficiency was obtained [16]. Marassi et al. [59] investigated the dairy wastewater treatment and energy generation performance of an air cathode microbial fuel cell. The scaled-up approach revealed that a maximum power density of 0.48 W/m3 was accomplished. Total chemical oxygen demand and total biochemical oxygen demand removal efficiencies were determined as 93% and 95%, respectively [59]. Choudhury et al. [17] investigated the power generation from simulated and real dairy wastewater treatment in a single chamber microbial fuel cell by using Escherichia coli −K-12. After the two consecutive synthetic dairy wastewater feedings, real dairy wastewater feedings at various chemical oxygen demand values were carried out. The power density and the current density were found to be 1.05 W/m2 and 8.01 A/m2 respectively. 67.53% of coulombic efficiency and 95.45% of COD removal efficiency were achieved [17]. Vilas Boas et al. [101] operated microbial fuel cell inoculated with Lactobacillus pentosus to treat dairy industry effluents. A maximum power density of 5.04 ± 0.39 mW/m2 was accomplished whereas the COD removal efficiencies were in the range of 42–58% [101].

Treatment of cheese whey

Antonopoulou et al. [5] studied on valorization of cheese whey in a single chamber air cathode microbial fuel cell. Microbial fuel cell was fed with two different substrates which are filter-sterilized raw cheese whey and pretreated-acidified diluted cheese whey to investigate the influence of the organic load. According to the experimental results, filter-sterilized cheese whey was a promising substrate for electricity production. When filter-sterilized wastewater was replaced by acidified-pretreated wastewater, the performance of the microbial fuel cell was not affected significantly [5]. Ghasemi et al. [27] applied two different biological methods for the treatment of cheese whey and concentrated cheese whey. In the first method, fermentation of cheese whey were performed in an immobilized cell reactor to produce lactic acid. In the second method whey and concentrated cheese whey were utilized as carbon sources in a microbial fuel cell. The power densities were found to be 188.8 and 288.12 mW/m2 for whey and concentrated whey-fed microbial fuel cells while the COD removal efficiencies were evaluated as 95% and 86% respectively [27].

Treatment of mixtures

The performance of the microbial fuel cell systems was tested for the treatment of dairy wastewater containing various types of mixtures. For instance [60], studied on biofuel and bioenergy production from the mixture of cheese whey and livestock waste. Biogas production and electricity generation were achieved in an anaerobic co-digestion reactor and a dual chambered microbial fuel cell, respectively [60]. Tajdid Khajeh et al. [93] realized the treatment of mixed dairy and dye wastewaters. Various dairy products comprising milk, cheese water, and yogurt water were mixed with Acid Orange 7 dye in different combinations and fed to the microbial fuel cell as substrate. The maximum power density, coulombic efficiency, and decolorization were obtained as 44.05 mW/m2, 1.76%, and 92.18% respectively, for the mixture of cheese water and Acid Orange 7 [93]. Colombo et al. [19] used four sets of membraneless single chamber microbial fuel cells fed with different agricultural organic substrates in the form of dried powder. Cheese whey, kitchen waste (a mixture of animal and vegetal food), fish waste, and citrus pulp were utilized as substrate in microbial fuel cells. The maximum COD removal was evaluated as 98.77% in the presence of obtained cheese whey substrate and the maximum coulombic efficiency was calculated as 9.91% in the presence of kitchen waste [19]. A list of microbial fuel cell performances using dairy wastewater as substrate is presented in Table 4.

3.6 Livestock Wastewaters

A remarkable increase in demand for animal products has been observed worldwide and the livestock industry has been developed fast in the last decades to produce the required amount of meat, eggs, and milk. More concentrated and large-scale livestock farms have been established to enhance the production capacity, which increased the livestock wastewater generation in turn. Livestock wastewaters are composed of manure, urine, and flushing water and contain nutrients, heavy metals, antibiotics, and pathogens [35, 107].

Livestock wastewaters are generally characterized by high chemical oxygen demand, biological oxygen demand, nitrogen, and phosphorus content. High concentrations of phosphorus and nitrogen in livestock effluents contribute to results in eutrophication of receiving water bodies [71]. Therefore, the application of efficient treatment methods is needed for the removal of contaminants in livestock wastewaters.

Cow manure and urine

Syed et al. [92] operated a single chamber microbial fuel cell that was fed with pretreated cow dung (PCD) and pretreated buffalo dung (PBD). The highest chemical and biochemical oxygen demand removal efficiencies and the power density were evaluated as 80%, 87%, and 12.75 mW/m2, respectively, with PBD. The coulombic efficiencies obtained with PBD and PCD were calculated as 0.53% and 0.48%, respectively [92]. Xin et al. [105] used Cu2O decorated reduced graphene oxide composite as cathode catalyst for the treatment of cattle wastewater. The maximum power density and coulombic efficiency of 3D air cathode microbial fuel system reached to 1362 mW/m2 and 54.9%, respectively, and the average COD removal rate was found to be 71.5% [105]. Xie et al. [104] treated cow manure slurry by using a single chamber air-cathode microbial fuel cell. The performances of microbial fuel cells inoculated with activated sludge or domestic sewage were compared to the performance obtained with raw cow manure slurry. The maximum power density and chemical oxygen demand removal were found to be 1.259 ± 0.015 W/m2 and 84.72 ± 0.48%, respectively, by using activated sludge and cow manure sludge [104].

Jadhav et al. [38] treated cow’s urine in a dual cell microbial fuel cell. The power density varied between 3.08 and 5.23 W/m3 and the highest chemical oxygen demand, nitrate, and carbohydrate removal efficiencies were 79%, 77 ± 4.1%, and 80 ± 3.9%, respectively [38].

Swine wastewater

Li et al. [51] used an airlift-type photosynthetic microbial fuel cell for the treatment of swine wastewater. Swine wastewater was used as inoculum in anodic chamber whereas algae was used in cathodic chamber. The maximum value of power density was 3.66 W/m3 and the removal efficiencies of chemical oxygen demand, total organic carbon, NH4+–N, and total phosphorous were calculated as 96.3%, 95.1%, 99.1%, and 98.9%, respectively [51]. Lai et al. [48] treated swine wastewater collected from animal husbandry. Various 3D laminated composite electrodes were prepared by using zinc-coated metallic wires or stainless steel wires as sheath and carbon fibers as core. The maximum power density, coulombic efficiency, and the chemical oxygen demand removal efficiencies were between 0.6–121.9 mW/m2, 0.6–45.8% and 30.4–81.5%, respectively, depending on the electrode type [48]. Ma et al. [56] investigated the effect of hydraulic retention time on microbial fuel cell performance in treatment of pig manure and a swine wastewater mixture. The power densities, chemical oxygen demand, and coulomb efficiency were in the range of 0.5–13 mW/m2, 59–83%, and 0.2–7.1%, respectively, depending on the hydraulic retention time varying between 13 and 20 days [56]. The recent studies on treatment of livestock wastes in microbial fuel cell are summarized in Table 5.

4 Conclusion and Future Perspective

Microbial fuel cell technology as an alternative sustainable wastewater treatment method has a great potential for energy generation and utilization of agro-industrial wastes and wastewaters. The chemical energy in the agricultural wastes is converted into electricity in microbial fuel cells. However, there are still some bottlenecks associated to the application of microbial fuel cells. The main challenges are the insufficient power output and the difficulty in scale up limiting the industrial applications. The direct movement of electrons from the microorganism to the electrode is limited by the transfer resistances which are denoted as overpotentials. The overpotentials reduce the potential obtained from the microbial fuel cell and decline the energy efficiency. The losses can be categorized as (i) the activation overpotentials occurring due to the activation energy that has to be overcome by the reacting species, (ii) concentration polarization expressed as the inability to maintain the initial substrate concentration in the bulk medium at high power densities, and (iii) ohmic losses arising from the electrode, membrane and electrolyte resistances [23, 70]. Considering the energy losses in microbial fuel cell systems, development of innovative low-cost electrodes providing high electrical conductivity, favoring biofilm formation, and improving the stability is one of the significant issues this technology should focus on in the future. Additionally, fabricating ecofriendly membrane materials with enhanced proton conductivity, less crossover of substrate and O2, and anti-fouling features is needed for efficient microbial fuel cell operations [68, 73]. Various approaches have been used in recent researches to fabricate environmentally friendly and efficient electrode and proton exchange membranes. Utilization of agricultural wastes particularly in the form of carbonized materials contributes not only the valorization of wastes but also the development of sustainable electrode and membrane materials with high surface areas. Using biocathodes consisting of microorganisms is an alternative solution to improving the power output of the microbial fuel systems. Even though very high pollutant removal efficiencies exceeding 90% can be achieved in agro-industrial wastewater treatment, reaching high coulombic efficiencies affected by the energy losses is a challenge for microbial fuel cell systems. Consumption of substrate in undesired reactions such as the direct oxidation of substrate by diffused oxygen and the metabolic reactions of non-exoelectrogens species are the important factors causing energy losses. Selection of appropriate microorganisms, electrodes, and membranes and operation at optimum reaction conditions minimize the energy losses. In addition to decreasing the energy losses, increasing the volume of treated wastewater is another crucial requirement of industrial applications. In this frame, the use of stacking the microbial fuel cells is a common solution while tubular and other stacked designs are being developed for practical applications. Up to date immense advances in microbial fuel cells have been recorded and the developments will continue to be able to operate at large scales with high-energy recovery. Microbial fuel cell is a unique method for the conversion of organic wastes into electricity without giving any external energy. Microbial fuel cells are capable of being modified easily for performance improvement. It is anticipated that microbial fuel cell technology, which is in the field of interest of many disciplines such as materials science and biotechnology, will enable simultaneous wastewater treatment and sustainable energy production in the future.

References

Abbattista R, Ventura G, Calvano CD, Cataldi TRI, Losito I (2021) Bioactive compounds in waste by-products from olive oil production: applications and structural characterization by mass spectrometry techniques. Foods 10:1–28. https://doi.org/10.3390/foods10061236

Ahmad A, Buang A, Bhat AH (2016) Renewable and sustainable bioenergy production from microalgal co-cultivation with palm oil mill effluent (POME): a review. Renew Sustain Energy Rev 65:214–234. https://doi.org/10.1016/j.rser.2016.06.084

Ahmad T, Aadil RM, Ahmed H, Rahman U ur, Soares BCV, Souza SLQ, Pimentel TC, Scudino H, Guimarães JT, Esmerino EA, Freitas MQ, Almada RB, Vendramel SMR, Silva MC, Cruz AG (2019) Treatment and utilization of dairy industrial waste: a review. Trends Food Sci Technol 88:361–372. https://doi.org/10.1016/j.tifs.2019.04.003

Alzate-Gaviria L (2011) Microbial fuel cells for wastewater treatment. In: Einschlag FSG (ed) Waste water—Treatment and reutilization. InTech, pp 151–170

Antonopoulou G, Ntaikou I, Bebelis S, Lyberatos G (2021) On the evaluation of filtered and pretreated cheese whey as an electron donor in a single chamber microbial fuel cell. Biomass Convers Biorefinery 11:633–643. https://doi.org/10.1007/s13399-020-00653-w

Ashraf A, Ramamurthy R, Rene ER (2021) Wastewater treatment and resource recovery technologies in the brewery industry: current trends and emerging practices. Sustain Energy Technol Assess 47:101432. https://doi.org/10.1016/j.seta.2021.101432

Atallah E, Kwapinski W, Ahmad MN, Leahy JJ, Zeaiter J (2019) Effect of water-sludge ratio and reaction time on the hydrothermal carbonization of olive oil mill wastewater treatment: hydrochar characterization. J Water Process Eng 31:100813. https://doi.org/10.1016/j.jwpe.2019.100813

Bagheri M, Daneshvar R, Mogharei A, Vahabzadeh F (2020) Phenol-acclimated activated sludge and Ralstonia eutropha in a microbial fuel Cell for removal of olive oil from mill wastewater. Korean J Chem Eng 37:1233–1240. https://doi.org/10.1007/s11814-020-0538-x

Baranitharan E, Khan MR, Prasad DMR, Teo WFA, Tan GYA, Jose R (2015) Effect of biofilm formation on the performance of microbial fuel cell for the treatment of palm oil mill effluent. Bioprocess Biosyst Eng 38:15–24. https://doi.org/10.1007/s00449-014-1239-9

Bolzonella D, Papa M, Da Ros C, Anga Muthukumar L, Rosso D (2019) Winery wastewater treatment: a critical overview of advanced biological processes. Crit Rev Biotechnol 39:489–507. https://doi.org/10.1080/07388551.2019.1573799

Bose D, Sridharan S, Dhawan H, Vijay P, Gopinath M (2019) Biomass derived activated carbon cathode performance for sustainable power generation from microbial fuel cells. Fuel 236:325–337. https://doi.org/10.1016/j.fuel.2018.09.002

Cecconet D, Molognoni D, Callegari A, Capodaglio AG (2018) Agro-food industry wastewater treatment with microbial fuel cells: energetic recovery issues. Int J Hydrogen Energy 43:500–511. https://doi.org/10.1016/j.ijhydene.2017.07.231

Chandrasekhar K, Kadier A, Kumar G, Nastro RA, Jeevitha V (2018) Challenges in microbial fuel cell and future scope. In: Das D (ed). Springer International Publishing, Cham

Cheng YW, Chong CC, Lam MK, Leong WH, Chuah LF, Yusup S, Setiabudi HD, Tang Y, Lim JW (2021) Identification of microbial inhibitions and mitigation strategies towards cleaner bioconversions of palm oil mill effluent (POME): a review. J Clean Prod 280:124346 . https://doi.org/10.1016/j.jclepro.2020.124346

Chia WY, Chong YY, Chew KW, Vimali E, Jayaram M, Selvarajoo A, Muthuvelu KS, Varalakshmi P, Show PL, Arumugasamy SK (2020) Outlook on biorefinery potential of palm oil mill effluent for resource recovery. J Environ Chem Eng 8:104519. https://doi.org/10.1016/j.jece.2020.104519

Choudhury P, Ray RN, Bandyopadhyay TK, Basak B, Muthuraj M, Bhunia B (2021) Process engineering for stable power recovery from dairy wastewater using microbial fuel cell. Int J Hydrog Energy 46:3171–3182. https://doi.org/10.1016/j.ijhydene.2020.06.152

Choudhury P, Ray RN, Bandyopadhyay TK, Bhunia B (2020) Fed batch approach for stable generation of power from dairy wastewater using microbial fuel cell and its kinetic study. Fuel 266:117073. https://doi.org/10.1016/j.fuel.2020.117073

Civan G, Palas B, Ersöz G, Atalay S, Bavasso I, Di Palma L (2021) Experimental assessment of a hybrid process including adsorption/photo fenton oxidation and microbial fuel cell for the removal of dicarboxylic acids from aqueous solution. J Photochem Photobiol Chem 407:1–8. https://doi.org/10.1016/j.jphotochem.2020.113056

Colombo A, Schievano A, Trasatti SP, Morrone R, D’Antona N, Cristiani P (2017) Signal trends of microbial fuel cells fed with different food-industry residues. Int J Hydrogen Energy 42:1841–1852. https://doi.org/10.1016/j.ijhydene.2016.09.069

Daud NNM, Ahmad A, Yaqoob AA, Ibrahim MNM (2021) Application of rotten rice as a substrate for bacterial species to generate energy and the removal of toxic metals from wastewater through microbial fuel cells. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-021-15104-w

Divya Priya A, Pydi Setty Y (2019) Cashew apple juice as substrate for microbial fuel cell. Fuel 246:75–78 . https://doi.org/10.1016/j.fuel.2019.02.100

Dong Y, Qu Y, He W, Du Y, Liu J, Han X, Feng Y (2015) A 90-liter stackable baffled microbial fuel cell for brewery wastewater treatment based on energy self-sufficient mode. Bioresour Technol 195:66–72. https://doi.org/10.1016/j.biortech.2015.06.026

ElMekawy A, Hegab HM, Dominguez-Benetton X, Pant D (2013) Internal resistance of microfluidic microbial fuel cell: challenges and potential opportunities. Bioresour Technol 142:672–682. https://doi.org/10.1016/j.biortech.2013.05.061

Fadzli FS, Bhawani SA, Adam Mohammad RE (2021) Microbial fuel cell: recent developments in organic substrate use and bacterial electrode interaction. J Chem 2021. https://doi.org/10.1155/2021/4570388

Fiorentino A, Gentili A, Isidori M, Lavorgna M, Parrella A, Temussi F (2004) Olive oil mill wastewater treatment using a chemical and biological approach. J Agric Food Chem 52:5151–5154. https://doi.org/10.1021/jf049799e

Firdous S, Jin W, Shahid N, Bhatti ZA, Iqbal A, Abbasi U, Mahmood Q, Ali A (2018) The performance of microbial fuel cells treating vegetable oil industrial wastewater. Environ Technol Innov 10:143–151. https://doi.org/10.1016/j.eti.2018.02.006

Ghasemi M, Ahmad A, Jafary T, Azad AK, Kakooei S, Wan Daud WR, Sedighi M (2017) Assessment of immobilized cell reactor and microbial fuel cell for simultaneous cheese whey treatment and lactic acid/electricity production. Int J Hydrog Energy 42:9107–9115. https://doi.org/10.1016/j.ijhydene.2016.04.136

Gude VG (2016) Wastewater treatment in microbial fuel cells—An overview. J Clean Prod 122:287–307. https://doi.org/10.1016/j.jclepro.2016.02.022

Hariti M, Chemlal R, Drouiche M, Mameri N (2021) The influence of organic pollutant load and external resistance on the performance of a solid phase microbial fuel cell fed orange peel wastes. Environ Prog Sustain Energy 40:1–8. https://doi.org/10.1002/ep.13667

Hassan SHA, el Nasser A, Zohri A, Kassim RMF (2019) Electricity generation from sugarcane molasses using microbial fuel cell technologies. Energy 178:538–543. https://doi.org/10.1016/j.energy.2019.04.087

Hassan SHA, Gad El-Rab SMF, Rahimnejad M, Ghasemi M, Joo JH, Sik-Ok Y, Kim IS, Oh SE (2014) Electricity generation from rice straw using a microbial fuel cell. Int J Hydrog Energy 39:9490–9496. https://doi.org/10.1016/j.ijhydene.2014.03.259

Hassan SS, Williams GA, Jaiswal AK (2019) Moving towards the second generation of lignocellulosic biorefineries in the EU: drivers, challenges, and opportunities. Renew Sustain Energy Rev 101:590–599. https://doi.org/10.1016/j.rser.2018.11.041

He J, Xin X, Pei Z, Chen L, Chu Z, Zhao M, Wu X, Li B, Tang X, Xiao X (2021) Microbial profiles associated improving bioelectricity generation from sludge fermentation liquid via microbial fuel cells with adding fruit waste extracts. Bioresour Technol 337:125452. https://doi.org/10.1016/j.biortech.2021.125452

Heilmann J, Logan BE (2006) Production of electricity from proteins using a microbial fuel cell. Water Environ Res 78:531–537. https://doi.org/10.2175/106143005x73046

Hu H, Li X, Wu S, Yang C (2020) Sustainable livestock wastewater treatment via phytoremediation: current status and future perspectives. Bioresour Technol 315:123809 . https://doi.org/10.1016/j.biortech.2020.123809

Ioannou LA, Puma GL, Fatta-Kassinos D (2015) Treatment of winery wastewater by physicochemical, biological and advanced processes: a review. J Hazard Mater 286:343–368. https://doi.org/10.1016/j.jhazmat.2014.12.043

Islam MA, Woon CW, Ethiraj B, Cheng CK, Yousuf A, Khan MMR (2017) Correlation of power generation with time-course biofilm architecture using Klebsiella variicola in dual chamber microbial fuel cell. Int J Hydrog Energy 42:25933–25941. https://doi.org/10.1016/j.ijhydene.2017.08.193

Jadhav DA, Jain SC, Ghangrekar MM (2016) Cow’s urine as a yellow gold for bioelectricity generation in low cost clayware microbial fuel cell. Energy 113:76–84. https://doi.org/10.1016/j.energy.2016.07.025

Jalilnejad Falizi N, Güngören Madenoğlu T, Kukul Kurttaş Y, Meriç K, Gürgülü H, Özçakal E, Cengiz Üremek N, Ballice L, Yüksel M, Sağlam M, Kabay N (2020) Production of biodiesel from safflower plant cultivated using membrane bioreactor (MBR) effluent discharged from wastewater treatment plant. J Chem Technol Biotechnol 95:527–534. https://doi.org/10.1002/jctb.6237

Janet Joshiba G, Senthil Kumar P, Femina CC, Jayashree E, Racchana R, Sivanesan S (2019) Critical review on biological treatment strategies of dairy wastewater. Desalin Water Treat 160:94–109. https://doi.org/10.5004/dwt.2019.24194

Jiao Y, Hu Y, Han L, Zhou M (2020) Activated carbon derived from rice husk as efficient oxygen reduction catalyst in microbial fuel cell. Electroanalysis 32:2969–2975. https://doi.org/10.1002/elan.202060409

Jiménez-Tototzintle M, Oller I, Hernández-Ramírez A, Malato S, Maldonado MI (2015) Remediation of agro-food industry effluents by biotreatment combined with supported TiO2/H2O2 solar photocatalysis. Chem Eng J 273:205–213. https://doi.org/10.1016/j.cej.2015.03.060

Karthikeyan R, Wang B, Xuan J, Wong JWC, Lee PKH, Leung MKH (2015) Interfacial electron transfer and bioelectrocatalysis of carbonized plant material as effective anode of microbial fuel cell. Electrochim Acta 157:314–323. https://doi.org/10.1016/j.electacta.2015.01.029

Kebaili H, Kameche M, Innocent C, Ziane FZ, Sabeur SA, Sahraoui T, Ouis M, Zerrouki A, Charef MA (2021) Treatment of fruit waste leachate using microbial fuel cell: preservation of agricultural environment. Shengtai Xuebao/Acta Ecol Sin 41:97–105. https://doi.org/10.1016/J.CHNAES.2020.09.004

Kolev S (2017) General characteristics and treatment possibilities of dairy wastewater—A review. Food Technol Biotechnol 53:237–242

Kondaveeti S, Mohanakrishna G, Kumar A, Lai C, Lee JK, Kalia VC (2019) Exploitation of citrus peel extract as a feedstock for power generation in microbial fuel cell (MFC). Indian J Microbiol 59:476–481. https://doi.org/10.1007/s12088-019-00829-7

Kugarajah V, Dharmalingam S (2021) Effect of silver incorporated sulphonated poly ether ether ketone membranes on microbial fuel cell performance and microbial community analysis. Chem Eng J 415:128961. https://doi.org/10.1016/j.cej.2021.128961

Lai MF, Lou CW, Lin JH (2018) Improve 3D electrode materials performance on electricity generation from livestock wastewater in microbial fuel cell. Int J Hydrog Energy 43:11520–11529. https://doi.org/10.1016/j.ijhydene.2017.06.047

Lee ZS, Chin SY, Lim JW, Witoon T, Cheng CK (2019) Treatment technologies of palm oil mill effluent (POME)and olive mill wastewater (OMW): a brief review. Environ Technol Innov 15:100377. https://doi.org/10.1016/j.eti.2019.100377

Li F, An X, Wu D, Xu J, Chen Y, Li W, Cao Y, Guo X, Lin X, Li C, Liu S, Song H (2019) Engineering microbial consortia for high-performance cellulosic hydrolyzates-fed microbial fuel cells. Front Microbiol 10:1–10. https://doi.org/10.3389/fmicb.2019.00409

Li M, Zhou M, Tian X, Tan C, Gu T (2021) Enhanced bioenergy recovery and nutrient removal from swine wastewater using an airlift-type photosynthetic microbial fuel cell. Energy 226:120422. https://doi.org/10.1016/j.energy.2021.120422

Li M, Zhou M, Tian X, Tan C, McDaniel CT, Hassett DJ, Gu T (2018) Microbial fuel cell (MFC) power performance improvement through enhanced microbial electrogenicity. Biotechnol Adv 36:1316–1327. https://doi.org/10.1016/j.biotechadv.2018.04.010

Liu J, Vipulanandan C (2017) Effects of Fe, Ni, and Fe/Ni metallic nanoparticles on power production and biosurfactant production from used vegetable oil in the anode chamber of a microbial fuel cell. Waste Manag 66:169–177. https://doi.org/10.1016/j.wasman.2017.04.004

Liu T, Nadaraja AV, Friesen J, Gill K, Lam MI, Roberts DJ (2021) Narrow pH tolerance found for a microbial fuel cell treating winery wastewater. J Appl Microbiol 131:2280–2293. https://doi.org/10.1111/jam.15102

Lu M, Chen S, Babanova S, Phadke S, Salvacion M, Mirhosseini A, Chan S, Carpenter K, Cortese R, Bretschger O (2017) Long-term performance of a 20-L continuous flow microbial fuel cell for treatment of brewery wastewater. J Power Sour 356:274–287. https://doi.org/10.1016/j.jpowsour.2017.03.132

Ma D, Jiang ZH, Lay CH, Zhou D (2016) Electricity generation from swine wastewater in microbial fuel cell: hydraulic reaction time effect. Int J Hydrog Energy 41:21820–21826. https://doi.org/10.1016/j.ijhydene.2016.08.019

Malekmohammadi S, Mirbagheri SA (2021) A review of the operating parameters on the microbial fuel cell for wastewater treatment and electricity generation. Water Sci Technol 84:1309–1323. https://doi.org/10.2166/wst.2021.333

Malvis A, Hodaifa G, Halioui M, Seyedsalehi M, Sánchez S (2019) Integrated process for olive oil mill wastewater treatment and its revalorization through the generation of high added value algal biomass. Water Res 151:332–342. https://doi.org/10.1016/j.watres.2018.12.026

Marassi RJ, Queiroz LG, Silva DCVR, dos Santos FS, Silva GC, de Paiva TCB (2020) Long-term performance and acute toxicity assessment of scaled-up air-cathode microbial fuel cell fed by dairy wastewater. Bioprocess Biosyst Eng 43:1561–1571. https://doi.org/10.1007/s00449-020-02348-y

Michalopoulos I, Chatzikonstantinou D, Mathioudakis D, Vaiopoulos I, Tremouli A, Georgiopoulou M, Papadopoulou K, Lyberatos G (2017) Valorization of the liquid fraction of a mixture of livestock waste and cheese whey for biogas production through high-rate anaerobic Co-digestion and for electricity production in a microbial fuel cell (MFC). Waste Biomass Valoriz 8:1759–1769. https://doi.org/10.1007/s12649-017-9974-1

Moharir PV, Tembhurkar AR (2018) Effect of recirculation on bioelectricity generation using microbial fuel cell with food waste leachate as substrate. Int J Hydrog Energy 43:10061–10069. https://doi.org/10.1016/j.ijhydene.2018.04.072

Moradian JM, Fang Z, Yong YC (2021) Recent advances on biomass-fueled microbial fuel cell. Bioresour Bioprocess 8. https://doi.org/10.1186/s40643-021-00365-7

Moravvej Z, Makarem MA, Rahimpour MR (2019) The fourth generation of biofuel. Elsevier Inc.

Naina Mohamed S, Thomas N, Tamilmani J, Boobalan T, Matheswaran M, Kalaichelvi P, Alagarsamy A, Pugazhendhi A (2020) Bioelectricity generation using iron(II) molybdate nanocatalyst coated anode during treatment of sugar wastewater in microbial fuel cell. Fuel 277:118119. https://doi.org/10.1016/j.fuel.2020.118119

Nath A, Mishra A, Pande PP (2019) A review natural polymeric coagulants in wastewater treatment. Mater Today Proc 46:6113–6117. https://doi.org/10.1016/j.matpr.2020.03.551

Negassa LW, Mohiuddin M, Tiruye GA (2021) Treatment of brewery industrial wastewater and generation of sustainable bioelectricity by microbial fuel cell inoculated with locally isolated microorganisms. J Water Process Eng 41:102018. https://doi.org/10.1016/j.jwpe.2021.102018

Nwaokocha CN, Giwa SO, Layeni AT, Kuye SI, Samuel OD, Ogunbona CK, Adebayo JK, Sosanya A, Babalola A (2021) Microbial fuel cell: bio-energy production from Nigerian corn starch wastewater using iron electrodes. Mater Today Proc 46:5565–5569. https://doi.org/10.1016/j.matpr.2020.09.345

Obileke KC, Onyeaka H, Meyer EL, Nwokolo N (2021) Microbial fuel cells, a renewable energy technology for bio-electricity generation: a mini-review. Electrochem commun 125:107003. https://doi.org/10.1016/j.elecom.2021.107003

Ochando-Pulido JM, Pimentel-Moral S, Verardo V, Martinez-Ferez A (2017) A focus on advanced physico-chemical processes for olive mill wastewater treatment. Sep Purif Technol 179:161–174. https://doi.org/10.1016/j.seppur.2017.02.004

Oliveira VB, Simões M, Melo LF, Pinto AMFR (2013) A 1D mathematical model for a microbial fuel cell. Energy 61:463–471. https://doi.org/10.1016/j.energy.2013.08.055

Othman I, Anuar AN, Ujang Z, Rosman NH, Harun H, Chelliapan S (2013) Livestock wastewater treatment using aerobic granular sludge. Bioresour Technol 133:630–634. https://doi.org/10.1016/j.biortech.2013.01.149

Pal M, Sharma RK (2020) Development of wheat straw based catholyte for power generation in microbial fuel cell. Biomass Bioenergy 138:105591. https://doi.org/10.1016/j.biombioe.2020.105591

Palanisamy G, Jung HY, Sadhasivam T, Kurkuri MD, Kim SC, Roh SH (2019) A comprehensive review on microbial fuel cell technologies: processes, utilization, and advanced developments in electrodes and membranes. J Clean Prod 221:598–621. https://doi.org/10.1016/j.jclepro.2019.02.172

Pandit S, Savla N, Sonawane JM, Sani AM, Gupta PK, Mathuriya AS, Rai AK, Jadhav DA, Jung SP, Prasad R (2021) Agricultural waste and wastewater as feedstock for bioelectricity generation using microbial fuel cells: recent advances. Fermentation 7. https://doi.org/10.3390/fermentation7030169

Penteado ED, Fernandez-Marchante CM, Zaiat M, Gonzalez ER, Rodrigo MA (2017) Influence of carbon electrode material on energy recovery from winery wastewater using a dual-chamber microbial fuel cell. Environ Technol (United Kingdom) 38:1333–1341. https://doi.org/10.1080/09593330.2016.1226961

Pepè Sciarria T, de Oliveira MAC, Mecheri B, D’Epifanio A, Goldfarb JL, Adani F (2020) Metal-free activated biochar as an oxygen reduction reaction catalyst in single chamber microbial fuel cells. J Power Sour 462. https://doi.org/10.1016/j.jpowsour.2020.228183

Pepe Sciarria T, Merlino G, Scaglia B, D’Epifanio A, Mecheri B, Borin S, Licoccia S, Adani F (2015) Electricity generation using white and red wine lees in air cathode microbial fuel cells. J Power Sourc 274:393–399. https://doi.org/10.1016/j.jpowsour.2014.10.050

Pepé Sciarria T, Tenca A, D’Epifanio A, Mecheri B, Merlino G, Barbato M, Borin S, Licoccia S, Garavaglia V, Adani F (2013) Using olive mill wastewater to improve performance in producing electricity from domestic wastewater by using single-chamber microbial fuel cell. Bioresour Technol 147:246–253. https://doi.org/10.1016/j.biortech.2013.08.033

Rajagopal R, Saady NMC, Torrijos M, Thanikal JV, Hung YT (2013) Sustainable agro-food industrial wastewater treatment using high rate anaerobic process. Water (Switzerland) 5:292–311. https://doi.org/10.3390/w5010292

Raychaudhuri A, Behera M (2020) Ceramic membrane modified with rice husk ash for application in microbial fuel cells. Electrochim Acta 363:137261. https://doi.org/10.1016/j.electacta.2020.137261

Raychaudhuri A, Behera M (2021) Enhancement of bioelectricity generation by integrating acidogenic compartment into a dual-chambered microbial fuel cell during rice mill wastewater treatment. Process Biochem 105:19–26. https://doi.org/10.1016/j.procbio.2021.03.003

Sarmin S, Tarek M, Roopan SM, Cheng CK, Rahman Khan MM (2021) Significant improvement of power generation through effective substrate-inoculum interaction mechanism in microbial fuel cell. J Power Sour 484:229285. https://doi.org/10.1016/j.jpowsour.2020.229285

Sedighi M, Aljlil SA, Alsubei MD, Ghasemi M, Mohammadi M (2018) Performance optimisation of microbial fuel cell for wastewater treatment and sustainable clean energy generation using response surface methodology. Alex Eng J 57:4243–4253. https://doi.org/10.1016/j.aej.2018.02.012

Sekar AD, Jayabalan T, Muthukumar H, Chandrasekaran NI, Mohamed SN, Matheswaran M (2019) Enhancing power generation and treatment of dairy waste water in microbial fuel cell using Cu-doped iron oxide nanoparticles decorated anode. Energy 172:173–180. https://doi.org/10.1016/j.energy.2019.01.102

Serrano L, de la Varga D, Ruiz I, Soto M (2011) Winery wastewater treatment in a hybrid constructed wetland. Ecol Eng 37:744–753. https://doi.org/10.1016/j.ecoleng.2010.06.038

Shen J, Wang C, Liu Y, Hu C, Xin Y, Ding N, Su S (2018) Effect of ultrasonic pretreatment of the dairy manure on the electricity generation of microbial fuel cell. Biochem Eng J 129:44–49. https://doi.org/10.1016/j.bej.2017.10.013

Shen R, Liu Z, He Y, Zhang Y, Lu J, Zhu Z, Si B, Zhang C, Xing XH (2016) Microbial electrolysis cell to treat hydrothermal liquefied wastewater from cornstalk and recover hydrogen: degradation of organic compounds and characterization of microbial community. Int J Hydrog Energy 41:4132–4142. https://doi.org/10.1016/j.ijhydene.2016.01.032

Shi W, Healy MG, Ashekuzzaman SM, Daly K, Leahy JJ, Fenton O (2021) Dairy processing sludge and co-products: a review of present and future re-use pathways in agriculture. J Clean Prod 314:128035. https://doi.org/10.1016/j.jclepro.2021.128035

Simate GS, Cluett J, Iyuke SE, Musapatika ET, Ndlovu S, Walubita LF, Alvarez AE (2011) The treatment of brewery wastewater for reuse: state of the art. Desalination 273:235–247. https://doi.org/10.1016/j.desal.2011.02.035

Sivakumar D (2021) Wastewater treatment and bioelectricity production in microbial fuel cell: salt bridge configurations. Int J Environ Sci Technol 18:1379–1394. https://doi.org/10.1007/s13762-020-02864-0

Song TS, Zhang J, Hou S, Wang H, Zhang D, Li S, Xie J (2018) In situ electrokinetic remediation of toxic metal-contaminated soil driven by solid phase microbial fuel cells with a wheat straw addition. J Chem Technol Biotechnol 93:2860–2867. https://doi.org/10.1002/jctb.5638

Syed Z, Sonu K, Sogani M (2021) Cattle manure management using microbial fuel cells for green energy generation. Biofuels Bioprod Biorefining, 1–11. https://doi.org/10.1002/bbb.2293

Tajdid Khajeh R, Aber S, Nofouzi K, Ebrahimi S (2020) Treatment of mixed dairy and dye wastewater in anode of microbial fuel cell with simultaneous electricity generation. Environ Sci Pollut Res 27:43711–43723. https://doi.org/10.1007/s11356-020-10232-1

Tamboli E, Eswari JS (2018) Microbial fuel cell configurations: an overview. Elsevier, B.V

Tee PF, Abdullah MO, Tan IAW, Mohamed Amin MA, Nolasco-Hipolito C, Bujang K (2016) Performance evaluation of a hybrid system for efficient palm oil mill effluent treatment via an air-cathode, tubular upflow microbial fuel cell coupled with a granular activated carbon adsorption. Bioresour Technol 216:478–485. https://doi.org/10.1016/j.biortech.2016.05.112

Toczyłowska-Mamińska R, Szymona K, Król P, Gliniewicz K, Pielech-Przybylska K, Kloch M, Logan BE (2018) Evolving microbial communities in cellulose-fed microbial fuel cell. Energies 11:1–12. https://doi.org/10.3390/en11010124

Tsagaraki E, Lazarides HN, Petrotos KB, Olive Mill wastewater treatment. In: Oreopoulou V, Russ W (eds) Utilization of by-products and treatment of waste in the food industry. Springer, US, Boston, pp 133–157

Umar MF, Rafatullah M, Abbas SZ, Mohamad Ibrahim MN, Ismail N (2021) Enhanced benzene bioremediation and power generation by double chamber benthic microbial fuel cells fed with sugarcane waste as a substrate. J Clean Prod 310:127583. https://doi.org/10.1016/j.jclepro.2021.127583

Varanasi JL, Das D (2018) Bioremediation and power generation from organic wastes using microbial fuel cell. In: Das D (ed) Microbial fuel cell. Springer International Publishing, Cham, pp 285–306

Venkata Mohan S, Velvizhi G, Annie Modestra J, Srikanth S (2014) Microbial fuel cell: critical factors regulating bio-catalyzed electrochemical process and recent advancements. Renew Sustain Energy Rev 40:779–797. https://doi.org/10.1016/j.rser.2014.07.109

Vilas Boas J, Oliveira VB, Marcon LRC, Simões M, Pinto AMFR (2019) Optimization of a single chamber microbial fuel cell using Lactobacillus pentosus: influence of design and operating parameters. Sci Total Environ 648:263–270. https://doi.org/10.1016/j.scitotenv.2018.08.061

Wang Y, Serventi L (2019) Sustainability of dairy and soy processing: a review on wastewater recycling. J Clean Prod 237:117821. https://doi.org/10.1016/j.jclepro.2019.117821

Wu CH, Liu SH, Chu HL, Li YC, Lin CW (2017) Feasibility study of electricity generation and organics removal for a molasses wastewater by a waterfall-type microbial fuel cell. J Taiwan Inst Chem Eng 78:150–156. https://doi.org/10.1016/j.jtice.2017.05.019

Xie B, Gong W, Ding A, Yu H, Qu F, Tang X, Yan Z, Li G, Liang H (2017) Microbial community composition and electricity generation in cattle manure slurry treatment using microbial fuel cells: effects of inoculum addition. Environ Sci Pollut Res 24:23226–23235. https://doi.org/10.1007/s11356-017-9959-4

Xin S, Shen J, Liu G, Chen Q, Xiao Z, Zhang G, Xin Y (2020) High electricity generation and COD removal from cattle wastewater in microbial fuel cells with 3D air cathode employed non-precious Cu2O/reduced graphene oxide as cathode catalyst. Energy 196:117123. https://doi.org/10.1016/j.energy.2020.117123

Yuvraj C, Aranganathan V (2018) Configuration analysis of stacked microbial fuel cell in power enhancement and its application in wastewater treatment. Arab J Sci Eng 43:101–108. https://doi.org/10.1007/s13369-017-2720-y

Zhang N, Liu W, Peng Y, Song X (2021) Anaerobic membrane bioreactors for livestock wastewater treatment and resource recovery: opportunities and challenges. Curr Pollut Reports 7:277–285. https://doi.org/10.1007/s40726-021-00192-6

Żyłka R, Karolinczak B, Dąbrowski W (2021) Structure and indicators of electric energy consumption in dairy wastewater treatment plant. Sci Total Environ 782. https://doi.org/10.1016/j.scitotenv.2021.146599

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Palas, B., Ersöz, G., Atalay, S. (2022). Bioremediation of Agro-Industries Pollutants Through Microbial Fuel Cells. In: Ahmad, A., Mohamad Ibrahim, M.N., Yaqoob, A.A., Mohd Setapar, S.H. (eds) Microbial Fuel Cells for Environmental Remediation. Sustainable Materials and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-19-2681-5_13

Download citation

DOI: https://doi.org/10.1007/978-981-19-2681-5_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-2680-8

Online ISBN: 978-981-19-2681-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)