Abstract

Driven by various health concerns, there is growing demand for plant-derived ingredients, used as pharmaceutical alternatives that claim certain physiological benefits for the human body. As such, nutraceuticals are defined as bioactive natural substances in the tissue of many plant species and mainly used to prevent human diseases, due to their anti-inflammatory and antioxidant properties. The emerging trend for manufacturing nutraceuticals in the form of dietary supplements or functional foods in a natural and sustainable manner has opened new avenues of plant cell culture technology over the past years. The advantages of this technology opposed to the wild harvesting or field cultivation are the controlled production according to the demand, preservation of the global biodiversity, as well as avoidance of associated ecological restrictions. Moreover, genetic engineering is a tool that provides a great opportunity for metabolic manipulation through overexpression, silencing, or disruption of one or more genes of the biosynthetic pathway of interest. In this chapter, we attempt to provide a framework of the cellular and molecular tools and their application regarding the enhanced production of nutraceuticals from plant cell cultures with special focus on flavonoids as ubiquitous metabolites in plant foods, including vegetables, fruits, nuts, and beverages possessing many beneficial effects over the human body.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

In the last decades, there has been an increased interest from both, scientific community and food industry, towards the identification of active molecules from natural sources that have beneficial health effects beyond their nutritional value (Carrizo et al. 2020). In 1989, Dr. Stephan DeFelice has introduced a joint term “nutraceutical” aiming to fill the gap between nutrition and pharmacological therapy. According to this definition, nutraceuticals are foods or part of foods with positive well-being and health promoting effects, including the prevention and/or treatment of a disease (Kalra 2003). However, compared to therapeutic drugs, nutraceuticals are not subject of patent protection or governmental regulations and could be used as preventive agents or adjuvants in medicinal therapy (Carrizo et al. 2020). Due to the lack of clear definition, nutraceuticals are frequently accepted as functional foods (since they are consumed as a part of the diet and improve the health status), but unlike them nutraceuticals are consumed under dosage forms like conventional drugs in the form of tablets, capsules, or solutions (Coppens et al. 2006). In this regard, nutraceuticals also differ from dietary supplements, whose main role is to supplement the diet by increasing the total dietary uptake of vitamins, amino acids, minerals, or botanicals without aiming the prevention or treatment of diseases (Ross 2000). From a nutritional perspective, the array of nutraceuticals has been extended to a source of both nutrients (carbohydrates, proteins, and fats) and non-nutrients (pro- and prebiotics, as well, as phytochemicals) and comprises food constituents, plant extracts, and food derivatives, including vitamins, amino acids, and minerals (Bergamin et al. 2019). Nutraceuticals may considerably vary in their chemical properties (molar mass, structure, polarity, functional groups, and charge) and biological activities. They could be classified as antioxidants (vitamins, enzymes, and minerals), dairy-based ingredients, plant extracts and phytochemicals, nutritional lipids and oils, fibers and carbohydrates, probiotics, prebiotics, amino acids, and proteins (Jain and Pundir 2013).

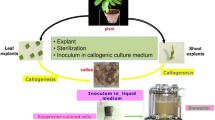

Phytochemicals comprise a great variety of chemicals structures and have dual purpose, such as defensive role in plants and specific pharmacological effect in humans. Many of these bioactive phytochemicals, such as alkaloids, triterpenes, and polyphenols (flavonoids, phenolic acids, anthocyanins, etc.), are essential source of nutraceuticals (Ho et al. 2021). However, when these nutraceuticals are derived from wild- or field-grown plants, their yield and consistence in quality are dependent on plant physiology state, harvest and storage processing, as well as, numerous environmental and geographical factors. Along with that, their specific application requires high purity, but when using whole plants there is risk from herbicides or pesticides contamination (Açıkgöz 2020). Therefore, plant-field harvesting might be environmentally destructive for native plants population, especially for rare and endangered plant species, and on the other hand, economically impractical due to the high operational costs, frequently accompanied with very low and inconsistent yields of the final product (Marchev et al. 2020). Alternatively, plant biotechnology based on plant in vitro systems cultivation offers a reliable and sustainable opportunity for the biotechnological production of plant-derived secondary metabolites (SMs) in strictly controlled aseptic conditions, avoiding the influence of climate and geographical conditions and the possibility to obtain products with consistent yield and quality. Major advances, here, are that plant in vitro systems have the potential to biosynthesize the full spectrum of metabolites typical for the mother plant and have the ability to adapt their metabolism according to the environment (Szopa et al. 2019). Therefore, plant in vitro systems are susceptible to genetic manipulations of the biosynthetic pathways or changes in cultural environment (additions of precursors, elicitors, and nutrient medium optimization) and allow commercialization through transfer of the biotechnological process from flask to large-scale production (Cui et al. 2014).

Here, we attempt to summarize recent examples for the biosynthesis of nutraceutical ingredients, with focus on flavonoid molecules derived from plant in vitro cultures. Their significance in cancer prevention and treatment has been described. Recent advances for manipulation of their biosynthetic pathway aiming their enhanced production are highlighted. Opportunities for lab- and large-scale production through bioreactor cultivation are discussed.

2 Role of Nutraceuticals in Prevention and Therapy of Human Malignancies

Many plants and herbs consumed by humans are known to contain relevant amounts of polyphenols which have been demonstrated to have many beneficial effects, such as antitumor, anti-inflammatory, antiallergic, antidiabetic, cardioprotective activity, and many others. They are ubiquitous in plant foods, including vegetables, fruits, nuts, and beverages, such as wine, tea, or cocoa. Specifically, the most abundant sources of flavonoids are apples, citrus fruits, berries, etc. In USA and Netherlands, the human flavonoid uptake is approximately 170 and 23 mg/day, expressed as aglycones, based on the content of five flavonoids, such as quercetin, kaempferol, myricetin, luteolin, and apigenin. The dietary consumption of polyphenols consists mainly of 80% flavanols, 8% flavonols, 6% flavanones, 5% anthocyanins, and less than 1% isoflavones and flavones. Therefore, it is not surprising that research has progressively shifted from cure to prevention, from drugs to lifestyle concept, including diet and food (Cas and Ghidoni 2018).

Cancer, the second leading cause of death globally, has accounted for nearly 9.6 million mortalities in 2018. According to World Health Organization (WHO) reports, one in six deaths globally is due to cancer. The major risk factors of cancer are low fruit and vegetable consumption, sedentary lifestyle, obesity, increased exposure to cancer-causing agents, including tobacco and alcohol consumption, just to name a few (Nalini et al. 2019). Numerous in vitro, in vivo, and epidemiological studies have shown the benefits of flavonoids and flavonoid-rich extracts in preventing or curing cancer, including lung (Amararathna et al. 2020), liver and breast (Ajji et al. 2020), ovarian (Carmi et al. 2020), colorectal (Dong et al. 2020), etc. and the main mechanisms of the anticancer activity were cell cycle arrest and inhibition of several signaling pathways, including extracellular signal-regulated kinase 1/2 (ERK1/2), phosphoinositide-3-kinase/protein kinase B (PI3K/AKT), nuclear factor-kappa B (NF-κB), mitogen-activated protein kinase (MAPK), and Wnt/β-catenin (Amararathna et al. 2020). An illustration of the main signaling pathways affected by flavonoids is presented on Fig. 16.1.

Signalling pathways in cancer. Active phytochemicals in extract from medicinal plants are the main source in prevention and therapy of cancer. Bioactivity of flavonoids influences the cascade mechanism of NF-κB, Wnt/β-catenin, and PI3K/AKT signaling pathways, leads to activation of apoptosis of the malignant cells, or reduces the cell cycle in current phase G2/M

Cell migration of cancer cells increases their motility and invasion and very often metastasis accounts as cause for over 90% of cancer-related mortality. The binding of nutraceuticals, such as flavonoids to actin (the main protein responsible for shape, adhesion, and motility of the cells), is one of the potential mechanisms that can limit actin polymerization and prevent cancer cell movement and invasion (Budryn et al. 2018). Quercetin-induced cytotoxicity in a dose-dependent manner in leukemic (CEM and K562) and breast cancer (T47D and EAC) cells is mediated through DNA fragmentation, cell cycle arrest and activated intrinsic pathway of apoptosis (Srivastava et al. 2016), as well as, suppressed expression of survivin and induced G0/G1 phase cell cycle arrest in breast cancer (MCF-7) cells (Deng et al. 2013). Among all the tested flavonoids (naringenin, quercetin, and naringin), quercetin had the lowest IC50 value of 32 μg/mL and reduced HepG2 and MCF-7 cell viability, increased the activation of caspase-3 and -8, and induced apoptosis through upregulation of proapoptotic genes Bax and Bid and downregulation of antiapoptotic genes BCL-2 and BCL-XL (Ajji et al. 2020). Quercetin and kaempferol blocked the growth of human colorectal cancer cell lines HCT116 and SW480 at G0/G1 phase. The key targets were cyclin-D1, MAPK8, and epidermal growth factor receptor (EGFR). These compounds induced cell apoptosis through modulation of PI3K signaling pathway and BCL-2 family proteins (Dong et al. 2020). As a flavonoid able to cross the blood brain barrier, quercetin was used to obtain synthetic quercetin derivatives that were able to induce cell cycle arrest and apoptosis in C6 glioma cells through inhibition of NF-κB and capsase-3 activation. The obtained derivatives appeared not cytotoxic to hippocampal organotypic cultures, used as a model of healthy neural cells (Kiekow et al. 2016). The Wnt/β-catenin signaling pathway has a key role in cell proliferation, cell motility, and stem cell differentiation and its aberrant activation can lead to tumorigenesis, cancer progression, and tumor cell metastasis. A quercetin-rich extract of Telectadium dongnaiense Pierre ex Cost (IC50 2 μg/mL) inhibited cell proliferation of HCT116 colon cancer cells, which correlated with its inhibitory effect on the expression of Wnt target genes, such as cyclin-D1, survivin, and c-myc (Kim et al. 2017). Quercetin could be used in combination with other plant-derived molecules, such as paclitaxel or resveratrol for the successful treatment of multidrug-resistant breast (Liu et al. 2020a) or prostate cancer (Singh et al. 2020). The hybrid combination (paclitaxel and quercetin) nanoparticles significantly decreased the IC50 values from 108.85 μg/mL (when paclitaxel was used as a single drug) to 11.76 μg/mL, which further resulted in higher apoptosis rate, G2M phase arrest, and stronger microtubule destruction in MCF7/ADR. This evidence revealed that quercetin increased the sensitivity of the cell line to paclitaxel and/or other therapeutic approaches, including chemotherapy (Liu et al. 2020a). The combination quercetin-resveratrol modulates the genes involved in cell cycle, apoptosis, fatty acid metabolism, transcription factors, androgen response, PI3K/AKT, and PTEN signaling. The decreased levels of EGFR, early growth response 3 (EGR3) and interleukin 6 (IL6), and increased levels of insulin growth factor binding protein 7 (IGFBP7) and NK3 homeobox-1 (NKX3.1) overall supported the antiprostate cancer effect of quercetin-resveratrol (Singh et al. 2020). The combinatorial application of quercetin and curcumin inhibited the cell proliferation of human melanoma cells (A375) through downregulation of Wnt/β-catenin signaling pathway proteins, cyclooxygenase 2 (COX-2), cyclin-D1, and Axin2. The IC50 value of this combination was significantly lower (1.5 μM) in comparison when both substances were used alone (50.0 and 8.5 μM; Srivastava and Srivastava 2019). Quercetin might be used as an adjuvant drug for treatment of cancer cells resistant to ionization irradiation therapy. The pretreatment of quercetin (20 μM) significantly reduced the ionization radiation to 5 Gy in colon cancer treatment by targeting Notch-1 signaling pathway (Li et al. 2020a, b). Gemcitabine resistance is a major issue for clinicians and patients with advanced cancers, making it crucial to determine ways to bolster its effects. Quercetin had a cytotoxic effect on gemcitabine-resistant pancreatic (PANC-1) and hepatocellular (HepG2) cancer. Quercetin lead to S phase arrest, tumor protein p53 upregulation, and cyclin-D1 downregulation (Liu et al. 2020b).

As a glucosylquercetin, rutin is more effective in skin carcinogenesis prevention. Rutin is able to prevent the UVB-induced inflammation in mice through inhibition of the induced COX-2 and inducible nitric oxide synthase (iNOS). Rutin inhibited the DNA binding of activator protein-1 (AP-1) and phosphorylation of signal transducer and activator of transcription-3 (STAT3) in mouse skin exposed to UVB (Choi et al. 2019). In addition, rutin significantly increased collagen type I and III and decreased metalloproteinase 1- and − 3 (MMP-1 and 3) in UVB-exposed mice (Her et al. 2020).

Most of the promising nutraceuticals, including flavonoids, have compromised bioavailability, due to their hydrophobic nature and very often remain unabsorbed without providing any therapeutic effect. Therefore, the bioavailability of nutraceuticals needs to be improved by enhancing the physicochemical properties like stability, solubility, and permeability. Hence, nanocarrier-based delivery systems of such supplementary products play an important role in the management and treatment of diseases (Shende and Mallick 2020). Quercetin gold nanoparticles in poly(D,L-lactide-co-glycolide) inhibited the liver cancer cell migration and colony formation. Quercetin also upregulated apoptosis markedly through the cleavage of caspase-9 and caspase-3 and induced the up-releasing cytochrome C (Ren et al. 2017). Quercetin-loaded nanoparticles exhibited improved inhibition on the growth and metastasis of triple negative breast cancer through inhibition of urokinase-type plasminogen activator, which mediates tumor growth and metastasis (Zhou et al. 2020). Nanoencapsulated quercetin was every efficient to combat with the hepatocarcinogenesis induced by diethylnitrosamine in rats (Ghosh et al. 2012).

3 Plant Cell Cultures as Potential Sources of Nutraceuticals

Plant SMs are of immense use as potential drugs, nutraceuticals, and food additives. Among the different classes of molecules, plant polyphenols constitute the largest group, of which flavonoids are the most abundant metabolites (Ali and Abbasi 2014) for the human health due to their role in treatment or prevention of cancer, cardiovascular diseases, gastrointestinal disorders, immune/autoimmune diseases, brain dysfunctions, diabetes, and obesity (Taghizadeh et al. 2019). Harvesting wild- or field-grown plant is not able to meet the growing demand for flavonoids for nutraceuticals and commercial use, which raises the awareness for serious ecological concerns (Thiruvengadam et al. 2016). In this regard, the use of plant in vitro system could be a viable alternative for reliable and continuous production of flavonoids, which allows the application of different strategies for manipulation of the growth variables, precursors, and elicitors that might modulate the biosynthetic pathway of the compounds, optimizing their production (Mendoza et al. 2018). Flavonoids, and especially kaempferol, quercetin, and rutin, comprise the main group of biologically active metabolites in many plants and are important biochemical markers authenticating the herbal plant materials and final products (Wang et al. 2015). They are found in many vegetables, fruits, and medicinal plants and represent a major part of the diet in many societies (Thwe et al. 2013).

Many plant in vitro systems have been established with the aim to produce flavonoids, but they rarely produce sufficient amounts of these SMs. For that reason, different plant in vitro systems, such as cell suspensions (Kubica et al. 2020; Vazquez-Marquez et al. 2016), hairy roots (HRs;), adventitious roots (ARs; Ho et al. 2021; Jiang et al. 2020), and shot type cultures (Szopa et al. 2019; Weremczuk-Jeżyna et al. 2020), have been investigated as potential source of flavonoids. Along with that, different approaches such as nutrient medium optimization (Cui et al. 2011), precursor feeding (Skrzypczak-Pietraszek et al. 2019), and application of biotic/abiotic elicitors have been frequently applied to enhance their biosynthesis (Huang et al. 2016; Li et al. 2020a, b). Elicitors are natural or synthetic molecules that initiate or improve the biosynthesis of SMs when introduced in small amounts into the living cell. Elicitors, such as jasmonic acid (JA), methyl jasmonate (MeJa), or salicylic acid (SA), are signaling molecules that respond to biotic or abiotic stress and induce catalytic reactions leading to enhanced SMs accumulation through activation of specific enzymes involved in their biosynthesis. The elicitor efficiency depends on its type, concentration, and time for treatment (Amani et al. 2021). Due to the smaller cell size (compared to tissue and organ cultures) and close characteristics to bacterial cell, suspension cultures offer a simplified system to study growth and production kinetics and potentially evaluate and implement optimal conditions for the production of SMs (Ali and Abbasi 2014). Flavonoid biosynthesis from cell suspension of Buddleja cordata Kunth (Vazquez-Marquez et al. 2016), Scrophularia striata Boiss (Ahmadi-Sakha et al. 2018), and Orostachys cartilaginous A. Bor has been reported (Wen et al. 2019). The most suitable for their cultivation were the stirred tank bioreactors (STB) operating at low (under 50 rpm) or high agitation speed (400 rpm) depending on the culture type and aeration rate between 0.05 and 0.1 vvm (Kubica et al. 2020; Vazquez-Marquez et al. 2016). However, due to the dedifferentiated nature of cell suspensions, they might lose their stable growth and biosynthetic characteristics (Marchev and Georgiev 2020). Therefore, in such cases plant tissue and organ cultures are the preferred system for production of SMs. Hairy roots obtained via Agrobacterium rhizogenes-mediated genetic transformation are genetically and biochemically stable, show rapid growth rate, and have the ability to biosynthesize SMs at levels comparable to that found in the mother plant (Thwe et al. 2013). For that reason, they have been frequently used to investigate the possibilities to manipulate the biosynthetic pathway of flavonoids (Huang et al. 2016). The capacity of the HRs to produce flavonoids might vary due to the random integration of the root-inducing plasmid in the plant genome, as well as, on the strain used for the genetic transformation (Thwe et al. 2016). The biosynthetic potential of HRs might be enhanced through application of elicitors (MeJa, UV-light) or overexpression of transcriptional factors (TFs) and genes encoding enzymes from the biosynthetic pathway discussed in more details further in the chapter (Huang et al. 2016; Li et al. 2020a, b; Yao et al. 2020).

4 Genetic Engineering of Plant Cell Cultures for Enhanced Production of Flavonoids

Flavonoids are a family of approximately 6000 nutraceuticals widely distributed in plants with great variety of significant biological functions, biosynthesized through shikimic acid, phenylpropanoid, and flavonoid pathways (Chung et al. 2018). All flavonoids possess a generic C6-C3-C6 structure comprising of 15 C-atoms, thus forming two aromatic A and B rings connected to one heterocyclic benzopyran C ring, which contains one oxygen. Depending on the modifications, especially hydroxylation and methylation reactions in the C ring are leading to the formation of more than 9000 derivatives (Marín et al. 2018). In this chapter, we have focused on a specific subtype of flavonoids classified as flavonols, whose main representatives, such as quercetin, kaempferol, myricetin, and rutin, present the major intake of the dietary flavonoids in most societies.

Among all the biosynthetic genes, the key ones are the phenylalanine ammonia lyase (PAL; EC 4.3.1.24), chalcone synthase (CHS; EC 2.3.1.74), chalcone isomerase (CHI; EC 5.5.1.6), and flavanone 3-hydroxylase (F3H; Bai et al. 2019). The biosynthetic pathway of flavonoids is illustrated in Fig. 16.2.

Illustration, presenting the biosynthetic pathway of flavonoids. PAL phenylalanine ammonia lyase (EC 4.3.1.24), TAL tyrosine ammonia lyase (EC 4.3.1.23), C4H cinnamate 4-hydroxylase (EC 1.14.14.91), ACC acetyl-CoA carboxylase (EC 6.4.1.2), 4CL 4-coumarate-CoA ligase (EC 6.2.1.12), CHS chalcone synthase (EC 2.3.1.74), STS stilbene synthase (EC 2.3.1.95), CHI chalcone isomerase (EC 5.5.1.6), F3′H flavonoid 3′-hydroxylase (EC 1.14.13.21), F3′5′H flavonoid 3′5´-hydroxylase (EC 1.14.13.88), FNS flavones synthase (EC 1.14.11.22), F3H flavanone 3-hydroxylase (EC 1.14.11.9), DFR dihydroflavonol 4-reductase (EC 1.1.1.219), ANS anthocyanidin synthase (EC 1.14.20.4), FLS flavone synthase (EC 1.14.11.22), 3GT flavonol 3-O-glucosyltransferase (EC 2.4.1.91), RhaT flavonol-3-O-glucoside L-rhamnosyltransferase (EC 2.4.1.159)

The entry metabolite and predecessor for the flavonoid biosynthesis in the phenylpropanoid pathway is the amino acid phenylalanine, which is deaminated by PAL to form trans-cinnamic acid that is further hydroxylated into para-coumaric acid by cinnamate 4-hydroxylase (C4H; EC 1.14.14.91). In plants, this enzyme catalyzes the initial steps in the production of diverse polyphenyl compounds and is mainly involved in defense mechanisms (Pervaiz et al. 2017). As an alternative in some plant species, para-coumaric acid can be produced by tyrosine from tyrosine ammonia lyase (TAL; EC 4.3.1.23). Further, the para-coumaric acid, which appeared to be the most limiting substrate in this pathway, is conjugated with coenzyme A by the enzyme 4-coumarate-CoA ligase (4CL; EC 6.2.1.12) to obtain para-coumaroyl-CoA. This is actually a branching point to other biosynthetic pathways, including coumarins, monolignols, or polyketides, such as flavonoids, isoflavonoids, and stilbenes (Chaves-Silva et al. 2018; Zhang et al. 2019). Para-coumaroyl-CoA is the initial substrate of the flavonoid pathway from which is generated naringenin chalcone through condensation of three molecules of malonyl-CoA by the first specific enzyme in the flavonoid biosynthetic pathway, named chalcone synthase (CHS; EC 2.3.1.74). At the same time, catalyzed by acetyl CoA carboxylase, acetyl CoA is converted to malonyl-CoA. Therefore, the A and C rings are formed by the acetate pathway, whereas B ring is derived from the shikimate pathway (Pervaiz et al. 2017). Subsequently, chalcone isomerase (CHI; EC 5.5.1.6) converts stereospecifically the chalcone to its isomer naringenin in a ring-closing step that forms the heterocyclic C ring. Naringenin appears to be a central intermediate, since it gives the start of different side branches for the synthesis of diverse classes of flavonoid molecules derived by the activity of functionalizing enzymes that might hydroxylate, reduce, alkylate, oxidize, and glycosylate the phenylpropanoid core structure (Huang et al. 2016). Further, the B ring of naringenin is hydroxylated by flavonoid 3′-hydroxylase (F3’H; EC 1.14.13.21) or flavonoid 3′5´-hydroxylase (F3´5’H; EC 1.14.13.88) to produce eriodyctiol or pentahydroxy-flavanone. All these (2S)-flavanones are further modified by the catalysis of flavanone 3β-hydroxylase (F3H; EC 1.14.11.9) in dihydroflavonols, such as dihydroquercetin, dihydrokaempferol, and dihydromyricetin. Dihydrokaempferol could be potentially directly oxidized by F3’H and F3´5’H to dihydroquercetin and dihydromyricetin (Zhang et al. 2019). Further, the enzyme flavone synthase (FLS; EC 1.14.11.22) catalyzes the hydroxylation of dihydroflavonols to their respective flavonols quercetin, kaempferol, and myricetin (Irmish et al. 2019). This enzyme is a member of the large enzyme family of 2-oxoglutarate-dependent dioxygenases (2OGDs) and is a key enzyme of the flavonoid biosynthetic pathway, acting at the diverging point into the flavonol subclass branch (Li et al. 2013). The other branching pathway is the biosynthesis of anthocyanins, according to which the obtained dihydroflavonols are reduced to colorless leucoanthocyanidins by dihydroflavonol 4-reductase (DFR; EC 1.1.1.219), which are then oxidized to colored anthocyanidins by the activity of anthocyanidin synthase (ANS; EC 1.14.20.4, synonyms leucocyanidin oxygenase: LDOX), which requires NADP as a cofactor and is oxoglutarate-dependent Fe2+/Fe3+ dioxygenase. These reactions are also high stereospecific with 2S, 3S, 4S configuration (Liu et al. 2014). After the biosynthesis of the flavonols, they might be subjected to glycosylation. For example, under the activity of flavonol 3-O¬-glucosyltransferase (3GT; EC 2.4.1.91) and flavonol-3-O-glucoside L-rhamnosyltransferase (RhaT; EC 2.4.1.159), quercetin is subsequently converted to isoquercetin and rutin (Abdel-Salam et al. 2021).

The main strategies adopted to alter metabolic pathways and improve phytochemical production might be summarized as: (1) gain-of-function of a gene of the pathway; (2) loss-of-function of a gene of the pathway; (3) ectopic expression of transcription factors (TFs) responsible for expressing all or most pathway genes, and (4) overexpression of a single gene encoding a rate-limiting enzyme (Nielsen et al. 2019). The SMs biosynthetic pathway is generally governed by its structural genes, which control the activity of enzymes involved in the pathway, as well as, regulatory genes that encode the TFs. On the other hand, the TFs regulate the structural genes activity through direct activation or repression through binding to the promoter region of the structural genes (Hidalgo et al. 2017). Flavonoid biosynthesis is regulated at transcriptional level by different families of TFs, in particular the multimeric unit formed by the members of the major TFs, such as myeloblastosis (MYB), Myc (encoding basic helix-loop-helix), and WDR (WD-repeat proteins), which are essential regulators in cell development and expression of genes involved in the flavonoid biosynthesis (Amani et al. 2021). Although the biosynthetic activity is dependent on the formation of an active WBM complex, the MYB TFs are sufficient to regulate the structural genes of the flavonoid branches, whereas the cofactors encoding the MYC and WDR have been exclusively associated with the anthocyanin accumulation (Czemmel et al. 2017). The activity of the TFs is regulated by a variety of abiotic/biotic elicitors or light exposure, which means that they are regulatory hubs between the elicitors or light-induced pathways and the SMs regulation (Huang et al. 2016; Li et al. 2020a, b).

The most exploited plant in vitro system to study the flavonoid biosynthesis are the HRs and in particular from the plant Fagopyrum tataricum Gaerth. and F. esculentum Moenh., since these plants have been recognized as a rich source of quercetin, kaempferol, myricetin, and especially rutin (Huang et al. 2016; Park et al. 2012). The UV-B stress treatment (used as abiotic elicitor) of F. tataricum HRs resulted in 5.18-fold increased content of rutin (from 0.93 to 4.82 mg/g DW). The observed effect was due to the enhanced expression of the structural genes FtPAL, FtCHI, FtCHS, FtF3H, and especially FtFLS-1, which was upregulated approximately 40-fold (Huang et al. 2016). The contents of rutin and quercetin in HR line Hokkai T8 were 0.25 and 0.03 mg/g DW, while their respective amounts in HR line T10 were 59.02 and 0.43 mg/g DW. This difference was due to the particular higher expression of FtPAL, FtCHI, FtCHS, FtF3H, FtF3’H, and FtFLS observed in HR line T10 (Thwe et al. 2013). Further, it was established that the A. rhizogenes strain is influencing the gene expression of the structural genes. The strain R100 showed higher expression levels of FtFLS-1, FtFLS-2, and F3’H2, while A4 strain showed significant expression of the key enzymes related to the anthocyanin biosynthetic pathway, such as ANS. This fact resulted in rutin accumulation of 22.31 μg/mg DW in the HR lines obtained with strain R100, while its content in the A4 HR lines was 13.04 μg/mg DW (Thwe et al. 2016). The potential of several flavonoid-specific TFs, such as FtMYB6 and AtMYB12, has been investigated in the management of the flavonoid pathway (Park et al. 2012; Yao et al. 2020). The overexpression of FtMYB6 in the HRs of tartary buckwheat promoted the activity of Ft4CL, F4C4H, FtCHI, FtF3H, and FtFLS-1 and doubled content of rutin and quercetin, while the amounts of kaempferol and myricetin increased six- and threefold, respectively. At the same time, the expression of FtDFR leading to anthocyanin synthesis remained unchanged (Yao et al. 2020). In a similar way, the overexpression of AtMYB12 elevated the expression levels of the same structural genes in F. esculentum leading to enhanced flavonoid production, without affecting the AtDFR and AtANS (Park et al. 2012). The exposure of F. tataricum HRs with blue light overexpressed the FtMYB116 TF and its targeted genes from the flavonoid pathway, especially FtCHI, FtF3H, FtFLS, FtF3’H, and FtRhaT, leading to five- and fourfold increased production of quercetin and rutin. The same TF was able to suppress the FtDFR and FtLAR (leucoanthocyanidin reductase; EC 1.17.1.3) and the production of anthocyanins, respectively (Zhang et al. 2019). The ectopic expression of VviMYBF1 promoted the flavonols and glycosylated flavonol biosynthesis, such as quercetin and quercetin derivatives. A positive correlation between VviMYBF1 and the expression of the structural genes VviFLS, Vvi3GT, and VviRhaT in “Chardonnay” HRs has been observed. Additionally, the expression of VviMYBF1 also altered the expression of the UV-B light-responsive HY5 homolog (VviHY5). Collectively, these results support the theory that the UV-B response machinery exists in grapes to propel flavonol accumulation through the activation of the regulatory network consisting of both MYB and bZIP TFs, such as VviMYBF1 and VviHY5 (Czemmel et al. 2017). Accordingly, the catechin and epicatechin biosynthesis has been boosted in cacao cell suspension after the formation of active complex between MYB12 and HY5, which overexpression was induced by blue light (Gallego et al. 2018). The effect of different abiotic and biotic elicitors over the flavonoid biosynthesis has been investigated as well. The total flavonoid content has been increased 1.57 and 1.80-fold when GlMYB4 and GlMYB88 have been overexpressed in Glycyrrhiza glabra Fisch cell suspension 9 h after the addition of 100 μM MeJa (Li et al. 2020a, b). Elicitation with 100 mg/L Ag nanoparticles in Brassica rapa ssp. rapa HRs resulted in the overexpression of BrMYB34 TF, which enhanced the expression levels of PAL, CHI, and FLS and increased the content of myricetin, quercetin, kaempferol, and rutin with 1.1 to 1.4-fold (Chung et al. 2018). As a low-cost alternative, chitosan has been used as an elicitor to enhance the biosynthesis of several flavonoids in Isatis tinctoria L. HRs. After treatment with chitosan at 150 mg/L for 36 h, the total flavonoid content has been increased 7.08-fold. In particular, the content of multiple hydroxyl substitute flavonoids rutin, quercetin, and kaempferol has been increased 8.27, 13.05, and 2.12-fold compared to the control. The most sensitive to chitosan were CHS and F3’H, the transcriptional abundance of which increased 45.13 and 41.04-fold after 12 h of treatment. The increased expression of CHS is important since this a gatekeeper enzyme in flavonoid biosynthesis, leading to the accumulation of naringenin chalcone as a basic C6-C3-C6 skeleton used in the flavonoid biosynthesis (Jiao et al. 2018). The cell wall elicitor (1% final concentration) from Piriformospora indica increased the content of catechin, kaempferol, luteolin, and myricetin up to twofold after 72 or 120 h treatment of Linum albul Kotschy ex Boiss. HRs. From the genes participating in the phenylpropanoid pathway, the highest expression level was observed for PAL (Tashackori et al. 2018). The same fungal elicitor was able to enhance the accumulation of rutin and apigenin and quercetin 5.7, 27.6, and 8.8-fold when used to treat the HRs of Ficus carica L. The highest expression level was observed for the PAL and CHS and 3GT genes, which activity was induced by MYB3 TF (Amani et al. 2021).

Along with the overexpression of single or multiple genes from the flavonoid biosynthetic pathway or the selective stimulation of flavonoid-specific TFs, another strategy could be the inhibition of the competitive pathways leading to the biosynthesis of other SMs. The suppression of NtDFR1 and 2 by RNA interference (Ri)-mediated posttranscriptional gene silencing in pink-flowered tobacco resulted in 72–97% reduction of the anthocyanin content. On the other hand, suppression of DFR increased the total levels of flavonoids due to (dihydro) flavonol biosynthesis, revealing the possibility to fine-tune the precursors flux to flavonoid biosynthesis (Lim et al. 2016).

5 Scale-up Strategies for Nutraceuticals Production

The cell transfer from flasks to bioreactor is an important step and main concern toward the large-scale production and hence commercialization of valuable SMs (Ahmadi-Sakha et al. 2018; Cui et al. 2011). Several biological (e.g., cell size, cell heterogeneity, and genetic instability) and technological barriers (sensitivity to shear stress, intensive mixing or aeration, foaming, cell adhesion, and aggregation) might result in relatively low amounts of the target metabolites, which is a bottleneck for their large-scale production (Marchev et al. 2020). Therefore, a suitable bioreactor design must solve these challenges and assure homogenous cell suspending and mixing that guarantee optimal mass and energy transfer, as well as, lower shear stress environment, despite the cell tendency to grow as aggregates and sediment during cultivation (Marchev et al. 2020).

Different approaches have been used to increase the biosynthetic capacity of flavonoids during bioreactor cultivation, such as selection of an appropriate bioreactor design (Cui et al. 2020; Kubica et al. 2020), type of impellers (Vazquez-Marquez et al. 2016), nutrient medium optimization (Jiang et al. 2020; Ho et al. 2021), agitation and aeration rate (Vazquez-Marquez et al. 2016), inoculum size (Cui et al. 2011), and cell culture elicitation (Wen et al. 2019). Examples for bioreactor production of flavonoids are presented in Table 16.1. Most of the bioreactor cultivations aiming the biosynthesis of flavonoids are based on ARs (Ho et al. 2021) or shoot type cultures in pneumatically driven bioreactors (Weremczuk-Jeżyna et al. 2020). The effect of nutritional factors (inorganic, organic compounds, and plant growth regulators) and initial inoculum concentration over the SMs production in ARs of Eurycoma longifolia Jack during cultivation in a 3-L balloon-type bubble bioreactor (BTBB) has been investigated. Nutrient medium constituents’ optimization is essential for maximizing the biomass growth and SMs biosynthesis. Among all the used media, only Murashige and Skoog (MS) and Gamborg’s B5 medium (B5) lead to increased lateral root branching and increased biomass accumulation. After optimization of all the nutrient components (3/4 MS medium, 30 g/L sucrose, and 3.0 mg/L indole-3-butyric acid) and inoculum amount (6 g/L), after 7 weeks of cultivation the final biomass increased double (3.22 g/L) and the total phenolics and total flavonoid amounts reached up to 8.04 and 2.95 mg/g DW, respectively. The BTBB are one of the most suitable constructions for cultivation of tissue and organ cultures, since the lower shear stress due to the lack of impellers (Cui et al. 2020). Optimum auxin concentration is critical for ARs growth and flavonoid accumulation. Indole-3-butyric acid (IBA) was more effective for lateral root branching and growth than 1-naphthaleneacetic acid (NAA) during the cultivation of Polygonum multiflorum Thunb. ARs in a 3-L BTBB. After selectin, the optimum nutrient medium components (2 mg/L IBA and 5% sucrose and 1X MS) achieved the highest root biomass (13.46 g/L DW), total phenolic (53.08 mg/g DW), and flavonoid compounds (25.10 mg/g DW). Salt strength higher than 1X may decrease the water potential and inhibit the absorption of water and mineral nutrients leading to inhibited root growth. Higher sucrose concentrations may cause loss of cell viability, reduced growth, and modified root morphology, due to the increased osmolarity of the culture medium, which is promoting the diffusion of metabolites from tissue to media (Ho et al. 2021). For the fed-batch cultivation of Oplopanax elatus (Nakai) Nakai ARs in a 5-L balloon-type airlift bioreactor, the optimum medium feeding factors were 60 g/L sucrose, 1X MS medium, 0.94 mM phosphorus, 30 mM nitrogen, and 3.0 mg/L IBA. Although phosphorus and nitrogen did not affect the root growth, they greatly influenced the flavonoid accumulation.

This medium was used as a feeding medium after 20 days of cultivation, after which the process continued for 20 days more. The fed-batch process has some advantages compared to the standard batch cultivation. Several restrictions, such as prolonged lag phase in the early culture stage, nutrient exhaustion, and product inhibition in the late stage, could be overcome. Thus, at the end of the cultivation, the total flavonoid content was 265.71 mg/g DW, of which 0.27 and 0.12 mg/g DW were quercetin and kaempferol (Jiang et al. 2020). After optimizing the inoculum density and aeration volume (3 g/L and 0.1 vvm), the biomass of Hypericum perforatum L. ARs contained 0.80 mg/g DW total flavonois, of which 1.33 and 14.01 μg/g DW were quercetin and hyperoside. It was established that higher inoculum densities (6.0–12.0 g/L) were not beneficial and resulted in decreased biomass content at the end of the cultivation. Higher aeration rates created turbulent flow leading to lower biomass accumulation, increased shear stress, and key volatiles, such as ethylene (Cui et al. 2011). The most suitable cultivation system among the temporary immersion systems (TIS), such as RITA® and Plantfrom™, as well as, nutrient sprinkle bioreactor (NSB) has been chosen for the shoots cultivation of Dracocephalum forrestii W.W. The highest biomass growth index (55.67 g/DW) was observed for the shoots in the RITA® bioreactor, while the NSB achieved the highest phenol content (24.15 mg/g DW). Both bioreactor systems are beneficial for cultivation of plant in vitro systems because they are not exposed to continuous immersion with medium or share forces, as frequently observed in mechanically agitated bioreactors. In both cases, the cultures are supported on a porous base, and in TIS, the plant cultures are immersed with medium at specific period of time at specific intervals, while in NSB the cultures are periodically sprayed with medium from the top of the vessel. The main advantage of these bioreactors are the increased culture multiplication and high biomass accumulation due to high nutrient availability, as well as, reduced hyperhydricity and physiological stress (Weremczuk-Jeżyna et al. 2020). The highest flavonoid content of 29.02 mg/100 g DW, 21.00 mg/100 g DW of which was rutin, was achieved during the cultivation of Schisandra chinensis Turcz shoot cultures in NSB. These amounts were 1.40, 1.32, 1.36, and 1.42-fold higher when compared with the flavonoid content accumulated in two continuous immersion systems (a cone type bioreactor and cylindrical type bioreactor) and two TIS (RITA® and Plantform™; Szopa et al. 2019). The Plantfrom™ bioreactor system working at 6 min immersion/24 h ensured 1.4-fold higher relative growth and enhanced biosynthesis of total phenolic (23.6 mg GAE/g DW) and flavonoid content (10.9 mg RE/g DW) compared to the semisolid cultivation of Lycium barbarum L. (Goji) shoot cultures (Ruta et al. 2020).

A frequently applied strategy to boost the flavonoid production during bioreactor cultivation is the elicitation of the plant in vitro systems. The elicitation of Panax ginseng C. A. Mey ARs with 200 μM SA had a superior effect in total flavonoid accumulation (88% compared to the non-treated control) than MeJa, during their cultivation in a 5-L STB. The effect of the elicitor was due to the caused abiotic stress through the generation of H2O2. The observed changes in the secondary metabolism were as consequences of the changes observed in the primary metabolism. The activities of the enzymes, glucose 6-phosphate dehydrogenase, PAL, substrate specific peroxidases, shikimate dehydrogenase, and β-glucosidase that generate precursors in the phenylpropanoid pathway, were highly expressed (Ali et al. 2007). The highest flavonoid content (up to 22.4-fold increase) was observed when shoot cultures of Centella asiatica (L.) Urban were treated with 50 μM MeJa during their cultivation in RITA®. The elicitor increased the content of the main flavonoid rutin 4.3-fold, while the highest kaempferol levels (22.4-fold increase) were observed by combined elicitor treatment of 50 μM MeJa and 50 μM ethephon. The amino acid L-phenyl alanine had a superior effect on the apigenin biosynthesis, the concentration of which was increased ninefold compared to the control (Skrzypczak-Pietraszek et al. 2019).

Several investigations report the biosynthesis of flavonoids from plant cell suspensions as well. After optimizing the inoculum size (0.9 g/L), the growth characteristics and biosynthetic potential of Verbena officinalis L. cell suspension in STB and BTBB were compared. At the end of the cultivation, the biomass in the STS and BTBB was 5.09 and 4.55-fold higher than the initial value. Along with that, the total phenolics in STB were 36.78 mg/100 g DW, while in the BTBB were 19.99 mg/100 g DW. This difference is due to the fact that STB assures more homogenous stirring and agitation of the cell suspension, which reflect in facilitated mass transfer, oxygen, and nutrient to the cells. The shear stress sensitivity was decreased by choosing low values of agitation and aeration, such as 33 rpm and 0.5 vvm (Kubica et al. 2020). The flavonoid production from Buddleja cordata Kunth was influenced from the agitation speed. The stirrer speed of 400 rpm resulted in production of 5.02 mg QE/ g DW total phenolics, while at 120 rpm the total phenolics were 4.43 mg QE/ g DW. The authors conclude that even at this stirring speed, the cells do not experience shear stress and there is sufficient medium and oxygen transfer that favors the SMs production (Vazquez-Marquez et al. 2016). To overcome problems with cell sedimentation with increasing cell density, the flow rate and agitation speed were increased from 0.5 to 1.5 L/min and from 110 to 170 rpm during the cultivation of Scrophularia striata Boiss cell suspension in a 10-L STB. The total flavonoid content was tenfold higher than that in the shake flask experiment, and in addition, rutin was biosynthesized only in the bioreactor (Ahmadi-Sakha et al. 2018). The elicitation with 100 μM SA doubled the content of total flavonoids compared to the control sample during the cultivation of Orostachys cartilaginous A. Bor cell suspension in 5-L balloon-type airlift bioreactor (Wen et al. 2019).

At a pilot-scale, flavonoid biosynthesis has been performed by cultivation of H. perforatum ARs in a 500-L horizontal drum type and 500-L airlift BTBB. At optimal cultivation parameters (1/2 MS medium with ammonium and nitrate ratio 5:25, 0.1 mg/L IBA, 0.1 mg/L kinetin, 30% sucrose, and 3 g/L inoculum), the airlift construction offered better growth and biosynthetic characteristics than the drum type bioreactor. The biomass yield was 1.4-fold higher, while the flavonoid content was 1.5-fold higher in the airlift BTBB (Cui et al. 2014).

6 Conclusions

Plant in vitro systems represent a superior source of bioactive SMs, especially flavonoids, which have been demonstrated to possess many beneficial effects, such as antineoplastic, anti-inflammatory, antiallergic, antidiabetic, cardioprotective activity, and many others. Although the examples given for the biological activities are based on cell lines or animals, it is of a critical importance to perform clinical investigations to elucidate the daily doses and toxicity effect for humans. Flavonoids are ubiquitous in plant foods, including vegetables, fruits, nuts, and beverages, such as wine, tea, or cocoa, and comprise main part of the human diet. Harvesting wild- or field-grown plant is not able to meet the growing demand for flavonoids for nutraceuticals and commercial use, which raises the awareness for serious ecological concerns. In this regard, the cultivation of plant in vitro systems could be a viable alternative for reliable and continuous production of flavonoids, which allows the application of different strategies for manipulation of the growth variables, precursors, and elicitors that might modulate the biosynthetic pathway of the compounds, optimizing their production. However, supreme results are achieved through selective overexpression or suppression of structural genes or TFs that can trigger to substrate pool to the desired metabolites or suppress competitive biosynthetic branches.

Essential for obtaining high yields of the desired SMs in bioreactors is the application of different optimization on process and cultivation parameters. The selection of an appropriate bioreactor configuration is a complex task in which the cultivation parameters (especially mixing and aeration) must be precisely equilibrated to achieve optimal growth and product synthesis.

References

Abdel-Salam E, Faisal M, Alatar A et al (2021) Genome-wide transcriptome variation landscape in Ruta chalepensis organs revealed potential genes responsible for rutin biosynthesis. J Biotechnol 325:43–56

Açıkgöz M (2020) Establishment of cell suspension cultures of Ocimum basilicum L. and enhanced production of pharmaceutical active ingredients. Ind Crop Prod 148:e112278

Ahmadi-Sakha S, Sharifi M, Niknam V et al (2018) Phenolic compounds profiling in shake flask and bioreactor system cell cultures of Scrophularia striata Boiss. In Vitro Cell Dev Biol Plant 54:444–453

Ajji PK, Walder K, Puri M (2020) Combination of balsamin and flavonoids induce apoptotic effects in liver and breast cancer cells. Front Pharmacol 11:574496

Ali M, Abbasi B (2014) Light-induced fluctuations in biomass accumulation, secondary metabolites production and antioxidant activity in cell suspension cultures of Artemisia absinthium L. J Photochem Photobiol B Biol 140:223–227

Ali M, Hahn E-J, Paek K-Y (2007) Methyl jasmonate and salicylic scid induced oxidative stress and accumulation of phenolics in Panax ginseng bioreactor root suspension cultures. Molecules 12:607–621

Amani S, Mohebodini M, Khademvatan S, Jafari M, Kumar V (2021) Piriformospora indica based elicitation for overproduction of phenolic compounds by hairy root cultures of Ficus carica. J Biotechnol 327:43–53

Amararathna M, Hoskin D, Rupasinge V (2020) Cyanidin-3-O-Glucoside-Rich haskap berry administration suppresses carcinogen-induced lung tumorigenesis in A/JCr mice. Molecules 25:3823

Bai S, Tao R, Tang Y et al (2019) BBX16, a B-box protein, positively regulates light-induced anthocyanin accumulation by activating MYB10 in red pear. Plant Biotechnol J 17:1985–1997

Bergamin A, Mantzioris E, Cross G et al (2019) Nutraceuticals: reviewing their role in chronic disease prevention and management. Pharmaceut Med 33:291–309

Budryn G, Grzelczyk J, Pérez-Sánchez H (2018) Binding of red clover isoflavones to actin as a potential mechanism of anti-metastatic activity restricting the migration of cancer cells. Molecules 23:2471

Carmi Y, Mahmoud H, Khamaisi H et al (2020) Flavonoids restore platinum drug sensitivity to ovarian carcinoma cells in a phospho-ERK1/2-dependent fashion. Int J Mol Sci 21:6533

Carrizo A, Izzo C, Forte M et al (2020) A novel promising frontier for human health: the beneficial effects of nutraceuticals in cardiovascular diseases. Int J Mol Sci 21:8706

Cas M, Ghidoni R (2018) Cancer prevention and therapy with polyphenols: sphingolipid-mediated mechanisms. Nutrients 10:940

Chaves-Silva S, dos Santos A, Júnior C et al (2018) Understanding the genetic regulation of anthocyanin biosynthesis in plants-tools for breeding purple varieties of fruits and vegetables. Phytochemistry 153:11–27

Choi K-S, Kundu J, Chun K-S et al (2019) Rutin inhibits UVB radiation-induced expression of COX-2 and iNOS in hairless mouse skin: p38 MAP kinase and JNK as potential targets. Arch Biochem Biophys 559:38–45

Chung IM, Rekha K, Rajakumar G, Thiruvengadam M (2018) Influence of silver nanoparticles on the enhancement and transcriptional changes of glucosinolates and phenolic compounds in genetically transformed root cultures of Brassica rapa ssp. rapa. Bioprocess Biosyst Eng 41:1665–1677

Coppens P, Silva M, Pettman S (2006) European regulations on nutraceuticals, dietary supplements and functional foods: a framework based on safety. Toxicology 221:5974

Cui X-H, Murthy H, Jin Y-X et al (2011) Production of adventitious root biomass and secondary metabolites of Hypericum perforatum L. in a balloon type airlift reactor. Bioresour Technol 102:10072–10079

Cui X-H, Murthy H, Paek K-Y (2014) Pilot-scale culture of Hypericum Perforatum L. adventitious roots in airlift bioreactors for the production of bioactive compounds. Appl Biochem Biotechnol 174:784–792

Cui XH, Murthy HN, Zhang JD et al (2020) Effect of nutritional factors on the accretion of secondary metabolites in Malaysian ginseng adventitious root cultures. Plant Biotechnol Rep 14:381–386

Czemmel S, Höll J, Loyola R et al (2017) Transcriptome-wide identification of novel UV-B- and light modulated flavonol pathway genes controlled by VviMYBF1. Front Plant Sci 8:1084

Deng X, Song H, Zhou Y et al (2013) Effects of quercetin on the proliferation of breast cancer cells and expression of survivin in vitro. Exp Ther Med 6(5):1155–1158

Dong B, Yang Z, Ju Q et al (2020) Anticancer effects of fufang yiliu yin formula on colorectal cancer through modulation of the PI3K/Akt pathway and BCL-2 family proteins. Front Cell Dev Biol 8:704

Gallego A, Tojas L, Parra O et al (2018) Transcriptomic analyses of cacao cell suspensions in light and dark provide target genes for controlled flavonoid production. Sci Rep 8:13575

Ghosh A, Ghosh D, Sarkar S et al (2012) Anticarcinogenic activity of nanoencapsulated quercetin in combating diethylnitrosamine-induced hepatocarcinoma in rats. Eur J Cancer Prev 21:32–41

Her Y, Lee T-K, Kim J et al (2020) Topical application of Aronia melanocarpa extract rich in chlorogenic acid and rutin reduces UVB-induced skin damage via attenuating collagen disruption in mice. Molecules 25:4577

Hidalgo D, Georgiev M, Marchev A et al (2017) Tailoring tobacco hairy root metabolism for the production of stilbenes. Sci Rep 7:17976

Ho TT, Le KC, Kim SW et al (2021) Culture condition optimization and FT-IR analysis of Polygonum multiflorum Thunb. Adventitious root cultures grown in an air-lift bioreactor system. Plant Cell Tiss Org Cult 144:371–381

Huang X, Yao J, Zhao Y et al (2016) Efficient rutin and quercetin biosynthesis through flavonoids-related gene expression in Fagopyrum tataricum Gaertn. Hairy root cultures with UV-B irradiation. Front Plant Sci 7:63

Irmish S, Ruebsam H, Jancsik A et al (2019) Flavonol biosynthesis genes and their use in engineering the plant antidiabetic metabolite montbretin A. Plant Physiol 180:1277–1290

Jain P, Pundir R (2013) Nutraceuticals: recent developments and future prospectives. In: Shahid M et al (eds) Recent trends in biotechnology and therapeutic applications of medicinal plants. Springer, Dordrecht, pp 213–223

Jiang X, Jin M, Piao X et al (2020) Fed-batch culture of Oplopanax elatus adventitious roots: feeding medium selection through comprehensive evaluation using an analytic hierarchy process. Biochem Eng J 167:107927

Jiao J, Gai Q-Y, Wang X et al (2018) Chitosan elicitation of Isatis tinctoria L. hairy root cultures for enhancing flavonoid productivity and gene expression and related antioxidant activity. Ind Crop Prod 124:28–35

Kalra E (2003) Nutraceutical—definition and introduction. AAPS PharmSci 5(3):25

Kiekow C, Figueiró F, Dietrich F et al (2016) Quercetin derivative induces cell death in glioma cells by modulating NF-κB nuclear translocation and caspase-3 activation. Eur J Pharm Sci 84:116–122

Kim W, Bach D-H, Ryu H et al (2017) Cytotoxic activities of Telectadium dongnaiense and its constituents by inhibition of the Wnt/β-catenin signaling pathway. Phytomedicine 34:136–142

Kubica P, Szopa A, Kokotkiewicz A et al (2020) Production of verbascoside, isoverbascoside and phenolic acids in callus, suspension, and bioreactor cultures of Verbena officinalis and biological properties of biomass extracts. Molecules 25(23):5609

Li X, Kim Y-B, Kim Y et al (2013) Differential stress-response expression of two flavonol synthase genes and accumulation of flavonols in tartary buckwheat. J Plant Physiol 170:1630–1636

Li Y, Chen X, Wang J et al (2020a) Two responses to MeJA induction of R2R3-MYB transcription actors regulate flavonoid accumulation in Glycyrrhiza uralensis Fisch. PLoS One 15(7):e0236565

Li Y, Wang Z, Jin J et al (2020b) Quercetin pretreatment enhances the radiosensitivity of colon cancer cells by targeting Notch-1 pathway. Biochem Biophys Res Commun 523:947–953

Lim S-H, You M-K, Kim D-H et al (2016) RNAi-mediated suppression of dihydroflavonol 4-reductase in tobacco allows fine-tuning of flower color and flux through the flavonoid biosynthetic pathway. Plant Physiol Biochem 109:482–490

Liu Z, Shi M, Xie D-Y (2014) Regulation of anthocyanin biosynthesis in Arabidopsis thaliana red pap1-D cells metabolically programmed by auxins. Planta 239(4):765–781

Liu M, Fu M, Yang X et al (2020a) Paclitaxel and quercetin co-loaded functional mesoporous silica nanoparticles overcoming multidrug resistance in breast cancer. Colloids Surf B Biointerfaces 196:11284

Liu Z-J, Xu W, Han J et al (2020b) Quercetin induces apoptosis and enhances gemcitabine therapeutic efficacy against gemcitabine-resistant cancer cells. Anticancer Drugs 31(7):684–692

Marchev A, Georgiev M (2020) Plant in vitro systems as a sustainable source of active ingredients for cosmeceutical application. Molecules 25(9):2006

Marchev A, Yordanova Z, Georgiev M (2020) Green (cell) factories for advanced production of plant secondary metabolites. Crit Rev Biotechnol 40(4):443–458

Marín L, Gutiérrez-del-Río I, Entrialgo-Cadierno R et al (2018) De novo biosynthesis of myricetin, kaempferol and quercetin in Streptomyces albus and Streptomyces coelicolor. PLoS One 13(11):e0207278

Mendoza D, Cuaspud O, Arias J et al (2018) Effect of salicylic acid and methyl jasmonate in the production of phenolic compounds in plant cell suspension cultures of Thevetia peruviana. Biotechnol Rep 19:e00273

Nalini D, Selvaraj J, Kumar G (2019) Herbal nutraceuticals: safe and potent therapeutics to battle tumor hypoxia. J Cancer Res Clin Oncol 146(1):1–18

Nielsen E, Temporiti M, Cella R (2019) Improvement of phytochemical production by plant cells and organ culture and by genetic engineering. Plant Cell Rep 38(10):1199–1215

Park N, Li X, Thwe A et al (2012) Enhancement of rutin in Fagopyrum esculentum hairy root cultures by the Arabidopsis transcription factor AtMYB12. Biotechnol Lett 34:577–583

Pervaiz T, Songtao J, Faghihi F et al (2017) Naturally occurring anthocyanin, structure, functions and biosynthetic pathway in fruit plants. J Plant Biochem Physiol 5:2

Ren K-W, Li Y-H, Wu G et al (2017) Quercetin nanoparticles display antitumor activity via proliferation inhibition and apoptosis induction in liver cancer cells. Int J Oncol 50:1299–1111

Ross S (2000) Functional foods: the food and drug administration perspective. Am J Clin Nutr 71:1735–1738

Ruta C, De Mastro G, Ancona S et al (2020) Large-scale plant production of Lycium barbarum L. by liquid culture in temporary immersion system and possible application to the synthesis of bioactive substance. Plan Theory 9(7):844

Shende P, Mallick C (2020) Nanonutraceuticals: a way towards modern therapeutics in healthcare. J Drug Delivery Sci Technol 58:101838

Singh C, Chhabra G, Ndiaye M et al (2020) Quercetin-resveratrol combination for prostate cancer management in TRAMP mice. Cancer 12:2141

Skrzypczak-Pietraszek E, Urbanska A, Zmudzki P (2019) Elicitation with methyl jasmonate combined with cultivation in the Plantform™ temporary immersion bioreactor highly increases the accumulation of selected centellosides and phenolics in Centella asiatica (L.) Urban shoot culture. Eng Life Sci 19:931–943

Srivastava S, Srivastava R (2019) Curcumin and quercetin synergistically inhibit cancer cell proliferation in multiple cancer cells and modulate Wnt/β-catenin signaling and apoptotic pathways in A375 cells. Phytomedicine 52:117–128

Srivastava S, Somasagara R, Hegde M et al (2016) Quercetin, a natural flavonoid interacts with DNA, arrests cell cycle and causes tumor regression by activating mitochondrial pathway of apoptosis. Sci Rep 6:240–249

Szopa A, Kokotkiewicz A, Bednarz M et al (2019) Bioreactor type affects the accumulation of phenolic acids and flavonoids in microshoot cultures of Schisandra chinensis (Turcz.) Baill. Plant Cell Tiss Org Cult 139:199–206

Taghizadeh M, Nasibi F, Kalantari K et al (2019) Evaluation of secondary metabolites and antioxidant activity in Dracocephalum polychaetum Bornm. Cell suspension culture under magnetite nanoparticles and static magnetic field elicitation. Plant Cell Tiss Org Cult 136:489–498

Tashackori H, Sharifi M, Chashmi N et al (2018) Piriformospora indica cell wall modulates gene expression and metabolite profile in Linum album hairy roots. Planta 248:1289–1306

Thiruvengadam M, Pekha K, Rajakumar J et al (2016) Enhanced production of anthraquinones and phenolic compounds and biological activities in the cell suspension cultures of Polygonum multiflorum. Int J Mol Sci 17:1912

Thwe AA, Kim JK, Li X et al (2013) Metabolomic analysis and phenylpropanoid biosynthesis in hairy root culture of tartary buckwheat cultivars. PLoS One 8(6):e65349

Thwe A, Valan Arasu M, Li X et al (2016) Effect of different agrobacterium rhizogenes strains on hairy root induction and phenylpropanoid biosynthesis in tartary buckwheat (Fagopyrum tataricum Gaertn). Front Microbiol 7:318

Vazquez-Marquez AM, Zepeda-Gómez C, Burrola-Aguilar C et al (2016) Effect of stirring speed on the production of phenolic secondary metabolites and growth of Buddleja cordata cells cultured in mechanically agitated bioreactor. Plant Cell Tiss Org Cult 139:155–166

Wang J, Quian J, Yao L et al (2015) Enhanced production of flavonoids by methyl jasmonate elicitation in cell suspension culture of Hypericum perforatum. Bioresour Bioprocess 2:5

Wen T, Hao Y-J, An X-L et al (2019) Improvement of bioactive compound accumulation in cell cultures of Orostachys cartilaginous A. Bor. through elicitation with salicylic acid and effect of cell extract on bioactive activity. Ind Crop Prod 139:111570

Weremczuk-Jeżyna I, Lisiecki P, Gonciarz W et al (2020) Transformed shoots of Dracocephalum forrestii W.W. Smith from different bioreactor systems as a rich source of natural phenolic compounds. Molecules 25(19):4533

Yao P, Huang Y, Dong Q et al (2020) FtMYB6, a light-induced SG7 R2R3-MYB transcription factor, promotes flavonol biosynthesis in tartary buckwheat (Fagopyrum tataricum). J Agric Food Chem 68(47):13685–13696

Zhang D, Jiang C, Huang C (2019) The light-induced transcription factor FtMYB116 promotes accumulation of rutin in Fagopyrum tataricum. Plant Cell Environ 42(4):1340–1351

Zhou Y, Chen D, Xue G et al (2020) Improved therapeutic efficacy of quercetin-loaded polymeric nanoparticles on triple-negative breast cancer by inhibiting uPA. RSC Adv 10:34517

Acknowledgments

This research received funding from the European Union’s Horizon 2020 research and innovation programme project PlantaSYST (SGA no. 739582 FPA no. 664620), and the BG05M2OP001-1.003-001-C01 project, financed by the European Regional Development Fund through the “Science and Education for Smart Growth” Operational Programme.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Marchev, A., Amirova, K., Georgiev, M. (2022). Genetic Engineering of Cell Cultures for Enhanced Production of Nutraceuticals. In: Belwal, T., Georgiev, M.I., Al-Khayri, J.M. (eds) Nutraceuticals Production from Plant Cell Factory. Springer, Singapore. https://doi.org/10.1007/978-981-16-8858-4_16

Download citation

DOI: https://doi.org/10.1007/978-981-16-8858-4_16

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-8857-7

Online ISBN: 978-981-16-8858-4

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)