Abstract

For the past few decades, Earth’s terrestrial and aquatic ecosystems have been altered dramatically by human actions. Many industrial activities have significant adverse effects on the environment; a lot of mass-produced chemicals that play a critical role in our everyday lives present risks to living things during their manufacture, use and disposal. The pollutants often persist in the environment for a long time; therefore, there is a call for research and development of remediation procedures that lead to successful removal of emerging contaminants from water, air, sediments and soils. One of the leading sample preparation techniques in trace element analysis is the extraction. The technique is available in different modifications and it is applicable for both organic and inorganic pollutants. This chapter presents an overview of different extraction techniques which represent an important step in preparing samples for analysis of metals, organic compounds and other substances that can act as environmental pollutants. The reliability of solid-liquid extraction for separation of Cu2+, Ni2+, Cd2+ and Pb2+ ions from contaminated soils and river sediments prior to their determination by flame atomic absorption spectrometry is illustrated by the original experiment. The efficacy of different types of extraction agents was evaluated: Triton X-100 and Triton X-114 as synthetic non-ionic surfactants’ representatives, secondary metabolites of Aspergillus niger and quillaja saponin as a natural surfactant that meets the green chemistry concept. Environmental samples known to contain considerable amounts of heavy metals were collected from four areas of historical mining activity in Slovakia – Šobov, Pezinok, Richňava and Jaklovce.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Analytical

- Heavy metals

- Liquid-liquid extraction

- Quillaja saponin

- Sediment

- Soil

- Solid-liquid extraction

- Solvent

- Surfactant

- Water analysis

5.1 Introduction

The use of materials, many of which are now recognized as hazardous, has been increasing continuously in different fields of applications throughout the last decades. Although production and an intentional use of certain substances has already been restricted, banned or is about to be banned and thus their release into the environment has been considerably reduced or eliminated, the issue sustains as these substances tend to persist in the environment and accumulate in animal and human tissues. Since the harmful effects and potential toxicity on living organisms of many of these compounds have long been confirmed, the concerns about their presence in the environment are rising.

The selection of suitable remediation procedure that leads to successful removal of emerging contaminants from the media stands on their precise identification and quantification. The proper chemical characterization of the industrial and municipal waters, sediments and soils is closely related to the selection of appropriate analytical techniques. Liquid- and solid-phase (micro)extraction in combination with gas chromatography, liquid chromatography and spectrometric methods, such as flame atomic absorption spectrometry, electrothermal atomic absorption spectrometry, inductively coupled plasma optical emission spectrometry and inductively coupled plasma mass spectrometry, are techniques considered as most responsible for the progress in the detection of wide range of contaminants.

Based on literature research, this chapter gives an overview of different methods currently used for sample preparation in the analysis of substances that have been accidentally or deliberately introduced into our environment and have a harming potential. For the scope of this work, the discussion will be limited to the brief description of the techniques with an emphasis on their suitability for preconcentration and determination of particular categories of environmental contaminants. In this chapter, the effectiveness of solid-liquid extraction as one of the commonly used techniques for the removal of heavy metal cations from contaminated soils and sediments is illustrated by the original experiment; for separation of Cu2+, Ni2+, Cd2+ and Pb2+ prior to their determination by flame atomic absorption spectrometry (FAAS), following types of extraction agents were compared: (1) two types of octyl-phenoxy-poly-ethoxy-ethanol (Triton X-100 and Triton X-114) representing the group of popular synthetic non-ionic surfactants, and (2) secondary metabolites of microscopic filamentous fungus Aspergillus niger and (3) saponin isolated from the bark of Quillaja saponaria tree as the examples of agents derived from biological material, meeting the requirements for green surfactants.

5.2 The Role of Extraction in Environmental Analysis

The effects of human activity on the environment have raised an increasing concern since the 1970s, and international policy frameworks have been developed and implemented over the past decades to control and mitigate this impact (ISDR 2007). Nowadays, our environment is constantly being sampled and analysed for a variety of purposes, including for the assessment of the quality of drinking water, groundwater, river and seawater, wastewaters, effluents and sewage sludge, sediments, soil and biota. In order to be able to detect even very low concentrations of pollutants in the ecosystems, it is necessary to follow a series of steps.

The overall process of data gathering, analysis and interpretation starts with sampling. This step involves collecting samples that faithfully represent a waste or element of the environment from which they are taken. Samples must not be contaminated during collection and handling, and analyte concentrations must not change between the time of collection and analysis (EPA Victoria 2009). If an unrepresentative sample is obtained due to choosing an inappropriate technique or cross-contamination, even the careful laboratory analysis that follows cannot ensure delivery of accurate and reliable data.

Prior to analysis performed by instrumental methods that dominate modern analytical chemistry, most samples require preparation. This may involve mechanical operations such as crushing, sieving and blending, air−/freeze−/oven−/microwave-drying and different operations that fall under three main categories of chemical and physico-chemical sample pretreatment: (1) isolation and clean-up, (2) sample preconcentration and (3) sample derivatization. The isolation of the chemical specie(s) of interest (i.e. analyte) from sample matrix (air, water, sediment, soil, biota, etc.) is achieved by various separation methods, such as (co)precipitation, filtration, adsorption on a sorbent, decantation, centrifugation, magnetic separation, evaporation, distillation, dissolution, digestion and, by one of the leading sample preparation techniques in trace element analysis, extraction. Some analytes also need to be cleaned up from co-extracted, non-target substances and/or increased in concentration prior to analysis or detection. Besides being thought of as a separation technique, extraction is also being frequently used for both of these purposes, i.e. sample purification and preconcentration.

Occasionally, it is also necessary to transform a chemical compound (educt) into another similar compound (derivative) by altering one or more of its functional groups (definition given by the Royal Society of Chemistry). This can be done for various reasons: (1) to enhance extraction efficiency, (2) to boost detection sensitivity or (3) to make compounds more amenable to a particular analysis mode (Kudlejova et al. 2012). For instance, if the analyte is not volatile enough to be conveniently determined via headspace extraction (Jeannot 2007), it can be derivatized to improve its volatility. The derivatizing agent can be added to the sample before, during or after sample extraction. The first two options may lead to enhanced sensitivity and selectivity of both extraction and detection and, in case of solid-phase microextraction, to determination of analytes that are normally not amenable by this method. Regarding post-extraction derivatization, it can only improve the chromatographic behaviour and detection properties, not the extraction efficiency (Pawliszyn 2002; Kudlejova et al. 2012). The fact that extraction and derivatization can be performed simultaneously is illustrated for example in the study on in-matrix derivatization of amphetamine-like molecules, where Mohamed (2017) presents a simple method in which both procedures can be carried out in one step.

Sample preparation is a critical step and the main source of uncertainties in the analysis of environmental samples (Ribeiro et al. 2014); it adds complexity to the analytical process, but on the other hand it is a potential source of bias, variance, contamination and mechanical loss. Therefore, sample preparation should be planned carefully and adequately documented to provide a complete record of the sample history (Keith et al. 1983). Especially derivatization should be performed only when necessary, since the derivatizing agents can interfere and introduce errors in the system (Kudlejova et al. 2012).

After pretreatment, samples are finally prepared to be measured by highly selective and sensitive instrumental analytical methods, such as molecular spectroscopic methods (UV-vis, fluorescence, infrared (IR) and Raman spectroscopy), atomic spectroscopic methods (atomic absorption flame and non-flame spectrometry, atomic fluorescence flame and non-flame spectrometry and atomic emission spectrometry (including inductively coupled plasma (ICP) and microwave plasma (MP)), chromatographic methods (gas chromatography (GC), liquid chromatography (LC), high-performance liquid chromatography (HPLC) and thin-layer chromatography (TLC)), mass spectrometric methods, electrochemical methods, thermal methods and radiological methods.

5.3 The Types of Extraction Techniques

Extraction is considered a crucial step in most chemical analyses; it entails removing the target analyte from the sample matrix and passing it into the phase required for identification and quantification performed mostly by spectroscopic and chromatographic techniques. The analyte might be one specific compound or a group of compounds of similar nature. Solubilization and separation of the analyte of interest from other material is done with an appropriate solvent, chosen with regard to the solubility of the target analyte and on the balance of cost, safety and environmental concerns. In order to perform an extraction, the analyte must have a higher solubility in the latter phase than in the starting phase (JoVE 2019). The starting phase might be the original sample matrix or a solution in which the sample has been dissolved or digested (Tissue 2013). Two most common types of laboratory extraction are liquid-liquid and solid-liquid extraction; their principles, the types and amounts of solvents used and some current trends that favour effective analyte extractions from environmental matrices are discussed in the next section. The most widely used liquid-liquid and solid-liquid extraction procedures with their advantages, drawbacks and suitability for the extraction of different compounds are presented in Table 5.1.

5.3.1 Liquid-Liquid Extraction

Liquid-liquid extraction (LLE) also known as ‘solvent extraction’ or ‘partitioning’ is a method to separate compounds or metal complexes based on their relative solubilities in two different liquids that differ in their density, polar (usually water) and non-polar (organic solvent) (Berk 2013). Most organic compounds will partition into the organic phase and salts and ionic forms of solutes will remain in water (Tissue 2013). In the simplest case, the system consists of three components: solute(s), carrier liquid and solvent. The initial mixture, containing one or more solutes dissolved in the carrier liquid, is mixed with the solvent. Upon mixing, the solute is transferred from the carrier liquid to the solvent. The denser solution settles to the bottom. The location of the solute will depend on the properties of both liquids and the solute (JoVE 2019). Hexane and cyclohexane are solvents from the alkane family widely used for extracting non-polar compounds (e.g. organochlorine and some organophosphorus pesticides), whereas dichloromethane and chloroform are typical solvents used for the extraction of non-polar to medium polarity organic pollutants (Kassim et al. 2005; Chirila and Drăghici 2013).

Although LLE is probably the oldest separation technique in analytical chemistry, it still remains one of the most powerful and versatile sample clean-up and preconcentration methods (Jeannot 2007; Saha et al. 2017). It is frequently used in the chemical and petrochemical (for the separation of aromatic components and the extraction of metals from aqueous solution), mining (as a second step out of three in oxide ore processing) and pharmaceutical industry to separate products from each other (Kiezyk and Mackay 1971; Berk 2013; Stanley et al. 2015). In wastewater treatment, it is primarily used for the removal of phenols, creosols and other phenolic acids. These wastewater streams arise principally in petroleum refineries, coke-oven plants in steel industry and plastics industry (Kiezyk and Mackay 1971).

Even if LLE offers many advantages, it is gradually being set aside due to an extensive use of SPE (Saha et al. 2017). Many recent developments in LLE have focused on the reduction of the amounts of solvent used, on environmental factors as well as on the automation of the process in conjunction with chromatographic analysis. To minimize the disadvantages of LLE while preserving the advantages it offers, various modifications of the technique have been introduced recently, such as direct extraction from aqueous solution into a small volume of organic solvent, headspace techniques and microextraction followed by back-extraction into a small volume of aqueous solution. These methods are referred to as liquid-phase microextraction (LPME) or solvent microextraction techniques (Jeannot 2007; Saha et al. 2017).

There are three main variants of LPME, single-drop liquid-phase microextraction (SD-LPME or SDME), hollow fibre liquid-phase microextraction (HF-LPME) and dispersive liquid-liquid microextraction (DLLME); the latter represents the latest development in LPME. All of them are simple, rapid, cost-effective and environmentally friendly since the volume of organic solvent used is typically in the microliter range. These methods also do not have sample carryover problems associated with SPME (Quigley et al. 2016).

The DLLME technique uses somewhat bigger volumes of organic solvents than SDME, but it still only involves microliters. DLLME, much like SDME, is also often being combined with GC, HPLC, ET-AAS and FAAS methods. DLLME can also be coupled to other extraction techniques, such as SPE, SFE, SBSE and nano techniques. The use of ultrasonic waves with DLLME has gained increasing popularity in recent years because UA-DLLME provides an increased rate of mass transfer of the analyte from aqueous phase into the fine extracting droplets (Albero et al. 2015). For instance, UA-DLLME was successfully applied for the simultaneous determination of alkylphenols, parabens and bisphenols (Jain et al. 2014), polybrominated diphenyl ethers (Zhang et al. 2013) or dechlorane along with other chlorinated flame retardants (Hsieh et al. 2013) in water samples. A sample preparation technique related to DLLME (Przyjazny 2019) which uses the property of non-ionic surfactants to form micelles in aqueous solutions and to become turbid when heated to particular temperature (so-called cloud point temperature) is termed cloud point extraction (CPE). Above this temperature, the micellar solution separates into two phases: a surfactant-rich phase of a small volume and a diluted aqueous phase (Hagarová and Urík 2016). CPE is a simple, rapid, versatile, inexpensive and environmentally friendly method utilized for separation and preconcentration of trace metals from aqueous solutions which has recently become an attractive area of research and an alternative to LLE (Saha et al. 2017). Regarding HF-LPME, the extraction yields obtained by this method are higher than those gained by direct SDME, since hydrophobic hollow fibres permit the use of vigorous stirring rates to increase the speed of the extraction kinetics (Saha et al. 2017).

Supported liquid membrane extraction (SLME) and microporous membrane liquid-liquid extraction (MMLLE) are techniques that use hydrophobic porous membranes impregnated by organic solvent, which separates two immiscible phases. Liquid membranes have been successfully used in an extraction of metals and organic pollutants, mainly pesticides, such as phenoxy acid, dinitrophenol, sulfonylurea and triazine herbicides from waters and wastewaters (Bartolome et al. 2007; Msagati et al. 2008; Chirila and Drăghici 2013). A competitive advantage of membrane-based techniques is that they can be coupled to a variety of other analytical methods such as ion chromatography (IC), LC, GC, capillary electrophoresis and atomic absorption spectrometry.

5.3.2 Solid-Liquid Extraction

When the sample matrix is solid and the phase required to be analysed is of liquid nature, the process is called solid-liquid extraction. It begins with wetting of the matrix surface with a solvent or immersing the whole matrix in a solvent and letting the solvent penetrate into the pores of the sample particulates. This is followed by the dissolution of extractable material, transport of the solute(s) from inside to the surface of the solid particles and the dispersion of the solute within the bulk of the solvent surrounding solid particles by diffusion and agitation (Berk 2013). The solid phase is then removed by filtration. The key factor in a procedure is the proper selection of the solvent; however, extraction efficacy is significantly influenced also by other parameters, such as pressure, temperature, particle size, agitation, etc. Working under conditions of elevated pressure facilitates the solvent to penetrate sample pores. An increase in temperature usually increases solubility of the extractables in the solvent, diffusion coefficients and solvent’s capacity to disrupt matrix-solute interactions (Barahona et al. 2019). However, in certain cases the solvent selectivity towards desired extractable is higher at lower temperatures. The extraction rate is enhanced with solid particle size reduction. In this context, samples are crushed, ground, milled, flaked or sliced into thin strips prior to extraction (Berk 2013). This gives an increased surface area per unit volume of solids to be leached and reduced distance to be traversed within the solid by the solvent and the extract (Tiwari 1995). The higher extraction yields can be often obtained by agitation which increases the contact surface between the sorbent and the analyte (Tashakkori et al. 2017). It does not affect extraction rate in case that any variations in extraction yields can be attributed to the other factors (e.g. heat treatment history) rather than to kinetic ones (Cogan et al. 1967).

The general solid-liquid extraction procedure is applicable in a range of fields including environmental monitoring. It can be used to extract a broad range of semi-volatile environmental pollutants that partition primarily on soils and sludges, such as polycyclic aromatic hydrocarbons (PAHs), and polychlorinated biphenyls (PCBs) and pesticides; it is probably the most widely used procedure in the analysis of pesticides in solid samples (Barahona et al. 2019). Because of the potential health effects, identification and quantification of these species is of academic interest and also widely practiced in the environmental consulting industry and in government agencies (JoVE 2019).

Solid-liquid extraction includes various techniques based on the contact of a certain amount of sample with an appropriate solvent (Barahona et al. 2019). Shaking is a very simple way to extract pollutants bound weakly to the sample; for strongly bound analytes it might not be effective enough. The method is applicable to a wide range of soil types and petroleum contaminants (Schwab et al. 1999). The principle of this method is based on the manual or automatic shaking of the sample in the presence of solvent for a certain period of time. The preferable organic water-miscible solvents are acetone, acetonitrile and methanol. Water-immiscible solvents (e.g. dichloromethane, hexane) can also be used, depending on the properties of the analyte. In order to make this process more efficient, shaking can be coupled to UAE. The acoustic cavitation and some mechanical effects induced by ultrasound enhance the agitation of the solvent and solute, thus increasing the contact area between solid and liquid phase, resulting in a better penetration of solvent into sample matrix. Owing to this, extraction times and the amount of solvents used in the shaking process are considerably reduced (Gutte et al. 2015; Barahona et al. 2019).

Although first described in 1879, Soxhlet extraction is still one of the most relevant and frequently used solid-liquid extraction techniques in environmental analysis. It has been used for an isolation of non-polar and semi-polar trace organic contaminants from a wide variety of solid materials, such as sediments, soils, sludges, wastes and biological structures (Wells 1978; Domini et al. 2005; Kassim et al. 2005). It is very useful when it comes to separation of poorly soluble compounds. Soxhlet extraction normally uses polar organic solvents or mixtures; non-polar solvents such as n-hexane are used to extract non-polar contaminants, such as OCPs and PCBs (Wells 1978). The long Soxhlet extraction times have prompted the development of modified extractors, such as revolutionary RaFaTec solvent extraction unit (Foss Tecator AB, Höganäs, Sweden). The apparatus offered considerable advantages in terms of time and solvent use, it also allowed the evaporation and collection of solvent further improving efficiency and the results were comparable to the traditional method (Bicking 2000). First introduced in 1975, it had quickly gained widespread acceptance and become an inspiration for an improved system Soxtec™ launched by FOSS 6 years later.

The more recent improvement of the method allows the application of microwaves to Soxhlet apparatus. This significantly accelerates the process of extraction of PCBs from contaminated soils (from 24 h to 70 min) and reduces the organic solvent disposal since 75–80% of the extractant can be recycled. The extractor also enables a fully automated extraction of two samples simultaneously (Luque-Garcia and Luque de Castro 2003). Other innovative methods include ultrasound-assisted Soxhlet (UASE) developed in 2004 (Luque-Garcia and Luque de Castro 2004) with an ultrasonic probe immersed in a water bath that circulates around the Soxhlet chamber or Sono-Soxhlet system with an ultrasonic probe inserted directly into the extraction chamber so an ultrasound can be applied within an extraction reactor (Djenni et al. 2013). Nevertheless, Soxhlet extraction is frequently referred to as the benchmark technique so the results obtained with newer extraction techniques are compared to those obtained by Soxhlet extraction (Dean 2000).

Traditional extraction techniques, such as liquid-liquid extraction and Soxhlet extraction, require large volumes of toxic organic solvents, thus creating new environmental hazards, increasing the risk of cancer and contributing to the ozone layer depletion. The newer extraction techniques such as SFE, MAE, ASE, SPE, SPME and hot water extraction are very attractive because they use much smaller or no amounts of solvents (O’Reilly et al. 2005; Risticevic et al. 2010), they are rapid and environmentally friendly.

Unlike Soxhlet, supercritical fluid extraction (SFE) represents a green technology that offers several advantages over conventional extraction methods. It is a process of separating the extractant from the matrix using supercritical fluids as an extracting solvent. A solute is usually separated from a solid matrix, but liquid matrices can be used as well. Supercritical fluid is any substance at a temperature and pressure above its critical point, where distinct liquid and gas phases do not exist. It can diffuse through solids like a gas, which facilitates the extraction of analytes located in not easily accessible pores, and dissolve materials into their component parts like a liquid (Sapkale et al. 2010; Chirila and Drăghici 2013). The power of supercritical fluid as a solvent depends largely on its density. Near the critical point of a fluid, even modest change in pressure or temperature may result in significant changes in the physico-chemical properties of the solvent, such as its density, diffusivity, or solubility characteristics (Padrela et al. 2009; Naresh et al. 2013).

Nowadays, more than 90% of all analytic SFE are carried out with supercritical carbon dioxide (Saha et al. 2017; Pannu et al. 2018) which has been available since the 1980s (Buckle 2015). It is an attractive alternative to organic solvents such as halogenated hydrocarbons (e.g. chloroform, dichloromethane) since it has a relatively low critical temperature (31 °C) and pressure (74 bar), it is non-flammable, accessible in high purity and very low cost (it can be captured for use with no need for synthesis and processing), it can be readily isolated from the extract and it leaves no toxic residues behind, thus posing no threat to the environment or human health (Rozzi et al. 2002; Naresh et al. 2013). In the supercritical state, CO2 has a polarity comparable to liquid pentane what makes it suitable for the solubilization of lipophilic compounds (Saha et al. 2017). The major drawback of CO2 as a non-polar solvent medium and a linear molecule with no net dipole moment is a significant difficulty in dissolving polar and ionic species (Peach and Eastoe 2014). The addition of a small amount of polar co-solvent (modifier) enhances the solubilizing capacity of the supercritical CO2, making it possible to extract more polar molecules (Wrona et al. 2017). Most popular co-solvents are ethanol, water and methanol. Other fluids used in SFE include methane, ethane, ethylene, propane, propylene, ammonia, pentane, n-butane, n-hexane, acetone, nitrous oxide (N2O), dichlorodifluoromethane, trifluoromethane, argon, xenon, etc. Other supercritical fluids that have been getting more attention in environmental SFE are freons and sulfur hexafluoride (SF6). The latter is a non-polar but easily polarizable molecule and as a supercritical fluid it has been reported to selectively extract aliphatic hydrocarbons with a chain length of up to C-24 from mixtures containing both aliphatic and aromatic hydrocarbons (Saha et al. 2017). Due to the legal limitations of solvents and solvent residues (Vági et al. 2005) the interest in supercritical fluid technology has grown in the past two decades, being increasingly proposed as an alternative to many conventional solvent-based processes (Padrela et al. 2009). It is widely used in petroleum industry for the determination of aromatics as well as for other hydrocarbon separations.

Ultrasound-assisted extraction (UAE), also known as ultrasonic solvent extraction, is also considered a good option for the extraction of organic compounds from different matrices. The use of ultrasound enhances contact between solvent and solid due to an increase of pressure which aids penetration of the solvent into material and mass transfer, and increase of temperature which improves solubility and diffusivity (Saha et al. 2017). Even if originally developed for solid samples, the ultrasound radiation has recently been coupled to microextraction techniques to enable the analysis of liquid samples (Albero et al. 2015). Sonication can be used with other extraction techniques to enhance their efficiency. For instance, it can be combined with a stir bar sorptive extraction technique (SBSE) for an extraction and preconcentration of halogenated phenols from sediments (Tölgyessy et al. 2009).

Besides ultrasonic waves, microwaves are another form of radiation that is recognized as a simple and valuable tool in applied chemistry. Microwave-assisted extraction (MAE) is a procedure that uses microwaves that easily penetrate into the sample pores making the solvent trapped in pores to heat evenly and rapidly. In contrast to conventional heating where a certain period of time is needed to heat the vessel before heat is transferred to the solution, the extraction time is significantly reduced with MAE because with microwaves the heat is transferred directly to the solvent (Lopez-Avila 2000; Llompart et al. 2019). In their work, Hailemariam et al. (2016) compared the efficiency of MAE, Soxhlet extraction and sonication for the recovery of several classes of pollutants in soils and sediments. The average recovery value for phenolic compounds obtained by MAE was 71% vs. 52% and 57% for Soxhlet and sonication, respectively. This technique also generated higher recoveries for most of the organochlorine pesticides investigated, except for 4,4′-DDT and dieldrin which were more efficiently recovered by Soxhlet extraction. Similarly, using MAE resulted in higher recoveries of phthalate esters in comparison with traditional techniques.

The change in temperature and pressure is another way of increasing speed and efficiency of conventional extraction methods. Accelerated solvent extraction (ASE), also referred in the literature as pressurized solvent extraction (PSE), pressurized liquid extraction (PLE), pressurized fluid extraction (PFE), high-pressure solvent extraction (HPSE), high-pressure high-temperature solvent extraction (HPHTSE), pressurized hot solvent extraction (PHWE), subcritical solvent extraction (SSE) and enhanced solvent extraction (Duarte et al. 2014; Sánchez-Camargo et al. 2017), has been developed as another alternative to Soxhlet extraction, maceration, percolation or reflux, offering advantages with respect to solvent consumption, extraction yields, extraction time and automation. First ASE has been applied for the extraction of environmental hazards from solid matrices. Within a very short time it was approved by the US Environmental Protection Agency (EPA) for the extraction of semi-volatiles or base neutral acids (BNAs), PAHs, polychlorinated biphenyls (PC13s), organochlorine and organophosphorous pesticides, total petroleum hydrocarbons (TPH) and dioxins from solid samples. Especially when extracting dioxins, the time with ASE is reduced to 20 min in comparison to 18 h using Soxhlet (Höfler 2002; Stojić et al. 2018).

ASE combines elevated pressure and temperature with liquid solvents to accelerate the process of extraction which is done in a closed vessel at 50–200 °C and pressure of 1500–2000 psi. Higher temperature increases the extraction kinetics, while elevated pressure keeps the solvent in liquid phase above its boiling point (Björklund et al. 2000). The series of different sample size can be processed and the instrumentation allows extraction in unattended operation (Lopez-Avila 2000). The extraction can be performed in static and dynamic mode or as a combination of these two modes, which is often viewed as the best option. The reason is the dynamic ASE requires a larger volume of solvent than the static one which makes it less suitable for trace analysis. Static ASE, on the other hand, may lead to incomplete extraction because of the limited volume of solvent used (Mandal et al. 2015).

When it comes to solid-liquid extraction techniques performed mostly on fluids and aqueous samples, the most widely accepted one is probably a solid-phase extraction (SPE) in which a target compound is retained by a chromatographic stationary phase material packed in disposable cartridges or enmeshed in inert matrix of an extraction disk and subsequently eluted in a selective solvent. It can be used either as a sample clean-up method or as a preconcentration method. Nowadays, the large variety of commercially available sorbents makes this technique suitable for the determination of analytes of divergent chemical structures and polarities (Escarpa et al. 2012; Chirila and Drăghici 2013). The novel adsorbent materials being used for solid-phase extraction of pollutants in environmental samples include carbon nanotubes, TiO2 nanotubes, graphene, ion imprinting polymers, magnetic materials (or combination of ion imprinting and magnetic materials), core-shell materials, mesoporous materials, metal organic frameworks and sorbents of biological origin derived from bacteria, yeast, algae and fungi (Xiao et al. 2016).

Along with LLE, SPE is a main method for the extraction of organic pollutants and heavy metals (Fig. 5.1). However, SPE is becoming more popular for analyte preconcentration and matrix removal than LLE, due to its simplicity and economic advantage in terms of time and solvent used (Picó et al. 2007). In recent decades, the use of SPE has increased due to development of new materials that may find application as solid sorbents (Płotka-Wasylka et al. 2015)

Publications on different types of extraction procedures identified using a systematic search of scientific papers published between 1998 and 2018. (Source: ISI Web of Knowledge (Web of Science); publications tagged with the keywords “solid-phase” (SP), “liquid-liquid” (LL), “ultrasound-assisted” (UA), “microwave-assisted” (MA), “cloud point” (CP), “Soxhlet”)

The high capital cost of SFE, MAE and ASE and in some cases the level of expertise required to operate the instruments effectively still represent a barrier to their wide acceptance. In this context, the use of SPME, introduced in 1989, has been proposed (Belardi and Pawliszyn 1989; Dean 2000). It has been used routinely in combination with GC and GC/MS and successfully applied to a wide variety of compounds, especially for the extraction of volatile and semi-volatile organic contaminants from water samples. It was also introduced for direct coupling with HPLC and LC/MS in order to analyse weakly volatile or thermally labile compounds not amenable to GC or GC/MS (Kataoka et al. 2000). In order for this simple, efficient and solvent-free method to be used also on solid samples, the analyte must be released from solid matrix and enter either liquid or a gaseous phase. There are several approaches that can be adopted for the extraction of analytes from solid matrices. These include direct extraction of the analytes from a soil-water suspension or slurry, extraction of the analyte from the sample matrix using hot water or headspace extraction. The first two approaches assume that the analyte is highly soluble in water and that water is a suitable solvent to liberate the analyte from the matrix. The latter scenario assumes that the analytes of interest are volatile or semi-volatile so that they are available in the headspace above the sample (Dean 2000).

In 2015, Ghiasvand and Pirdadeh-Beiranvand introduced an effective and inexpensive device for cooling/heating assisted solid-phase microextraction (CHA-SPME) for an analysis of volatile and semi-volatile species in complex solid samples, with no need of sample pretreatment and with minimal manipulation compared to conventional SPME. The proposed device coupled to GC-FID was successfully used for the extraction and determination of PAHs in contaminated soils. Besides SPME, it can be utilized for simultaneous cooling of the extraction phase and heating of the sample matrix in LPME, NTD (needle trap devices) and INCAT (inside needle capillary adsorption trap) methods, all used for environmental sample preparation.

Another promising trend in the search for faster, simpler, cheaper and more environmentally friendly sample preparation and separation techniques has been the utilization of electrical driving force. In recent years, a noticeable progress has been made in this field and some new electrically assisted microextraction techniques have been introduced, such as electrically assisted SPME coupled to liquid chromatography-mass spectrometry that was applied for determination of trace levels of organophosphate insecticide in water (Yang and Lee 2010) or electrically assisted LPME used for determination of β2-receptor agonist drugs in wastewater (Rezazadeh et al. 2012). One of the very attractive areas of use, rarely pointed out in literature, is synthesizing and preparing the membranes and solid-phase sorbents for SPE or SPME (Yamini et al. 2014). Membrane-protected SPME can be used for the analysis of a wide range of environmental materials, including air, water, sediment and soil.

Stir bar sorptive extraction (SBSE) operates on a similar principle as SPME which involves partitioning of the target analyte between (usually an aqueous-based liquid) sample and a stationary phase-coated stir bar (Chirila and Drăghici 2013). In SBSE, stir bars are coated with polydimethylsiloxane (PDMS). When compared to SPME, it is characterized by a higher sorption capacity due to the presence of large volumes of coating material (Nießner and Schäffer 2017). SBSE is rapid and simple, which makes it ideal for automation and in situ measurements (Nilsson 2000) and it can be effectively applied to different kinds of environmental matrices, such as water, wastewater, soils, biological fluids and gases (Saha et al. 2017).

5.4 Surfactants of Biological Origin as Eco-friendly Extractants for Environmental Pollutants Removal

The extraction using surfactants is one of the several applicable methods for the remediation of petroleum hydrocarbons (Goswami et al. 2018) and heavy metals in soils. After their utilization, water-soluble surfactants are very difficult to recover or reuse. Generally, if not biodegradable, they are discharged as part of wastewater to the environment. In order to conserve energy resources and to reduce their environmental impact, surfactants should be recycled, particularly after industrial use. Therefore, the development of surfactants with enhanced biodegradability and recyclability using renewable resources under environmentally benign conditions has been desired (Banno et al. 2013). With respect to green chemistry principles, there is a tendency to substitute synthetic surfactants with naturally derived alternatives. Microbial surfactants offer numerous benefits over synthetic ones. Due to their versatility, biodegradability, low toxicity, high activity even under extreme conditions (such as extreme pH and salinity), high effectivity in biodegradation and solubilization of low solubility compounds and mild production conditions (Mulligan 2005; Morita et al. 2016; Costa et al. 2018; Inamuddin et al. 2021), they have been identified as promising agents in remediation technologies. Unfortunately, a substantial portion of biodegradable materials are at a production cost disadvantage against synthetic substances which limits their manufacture and large-scale application.

Biosurfactants are surface-active compounds that are produced extracellularly or as part of the cell membrane by bacteria, yeasts and fungi (Mulligan 2005) and due to their remarkable properties they are considered multifunctional biomolecules of the twenty-first century (Santos et al. 2016). All biosurfactants are amphiphilic molecules with a polar (hydrophilic) moiety consisting of mono-, oligo- or polysaccharides, peptides or proteins, and a non-polar (hydrophobic) group usually containing saturated, unsaturated and hydroxylated fatty acids or fatty alcohols (Lang 2002) that partition at liquid-liquid, liquid-gas or liquid-solid interfaces. Such structure predestines them for the use in a range of industrial applications where emulsification/de-emulsification, foaming, wetting, coating, detergency and dispersion take place (Farn 2006; Santos et al. 2016). In recent years, emulsifying, solubilizing and mobilizing (Usman et al. 2016) potential of biosurfactants has been intensely explored for the remediation of different organic and inorganic environmental contaminants.

Biosurfactant ability of changing the surface and interfacial tensions and stabilizing emulsions is a measure of its effectiveness, while critical micelle concentration (CMC) is commonly used to measure surfactant efficacy (Pacwa-Płociniczak et al. 2011). CMC is a physical characteristic that indicates the concentration of surfactant above which micelles start to form (IUPAC 1997). The lower the CMC, the less surfactant is required to decrease the surface tension (Desai and Banat 1997), i.e. to effectively emulsify, solubilize and disperse waste materials at the surface (Abhijit 2017). The CMC of biosurfactants ranges from 1 to 2000 mg L−1 (Santos et al. 2016) and among surfactant types classified according to the composition of their head (as non-ionic, anionic, cationic and amphoteric), the lowest CMCs are generally found in the non-ionic category (Abhijit 2017). For instance, CMCs of Triton X-100 and Triton X-114 – two high purity, inexpensive, commercially available non-ionic detergents suitable for most biological applications used in our experiment aimed at heavy metal removal from contaminated soils, are 0.24 and 0.2 mM, respectively.

To determine its appropriate application, the surfactant is being ranked by its hydrophilic-lipophilic balance (HLB) value which is a common term used in industry and reflects the degree to which a surfactant is hydrophilic or lipophilic. Surfactants with low HLB (< 10) are more lipophilic, thus more oil (fat) soluble, and create water-in-oil emulsions, whereas HLB values over 10 indicate predominantly hydrophilic molecules with better water solubility that stabilize oil-in-water emulsions. A value of 10 corresponds to a compound with equal affinity for water and oil; complete water solubility of a surfactant occurs at HLB of ~7.3 (Burch et al. 2010; Rami et al. 2017). In cleaning applications, high HLB scale valued surfactants are often used to emulsify oily soils (Király 2013).

Based on their molecular weight, biosurfactants can be classified as (1) low molecular weight (low-mass) molecules including glycolipids, phospholipids and lipopeptides efficient in lowering surface and interfacial tension and (2) high molecular weight (high-mass) polymers such as amphipathic polysaccharides, proteins, lipopolysaccharides, lipoproteins or their complex mixtures that are more effective at stabilizing oil-in-water emulsions (Rosenberg and Ron 1999; Pacwa-Płociniczak et al. 2011).

5.4.1 Rhamnolipids

Rhamnose lipids, or rhamnolipids, are glycolipids often described as ‘the best-studied’ representatives of bacterial surfactants (e.g. Müller et al. 2012; Thiengmag et al. 2016; Liu et al. 2018). The evolution of sensitive analytical techniques has enabled great progress to be made in the identification of a wide diversity of rhamnolipid congeners and homologues (about 60) that are produced at different concentrations by bacterial species mainly from strains of Pseudomonas and Burkholderia (Abdel-Mawgoud et al. 2010). Because of their anionic structure, rhamnolipids have been proposed as a suitable material for the removal of some heavy metals present in their cationic form, such as Cd2+, Pb2+, Zn2+, Ni2+, Ba2+ and Sr2+ from soil and water (Miller 1995; Elouzi et al. 2012). Due to their excellent emulsification properties, rhamnolipids also boost remediation of crude oil-contaminated sites. Their addition in the soil enhances bacterial colonization, growth, survival and metabolic activity (Rahman et al. 2003; Costa et al. 2010; Tahseen et al. 2016) and helps microorganisms with uptake and assimilation of many aliphatic hydrocarbons such as linear alkanes, which are poorly soluble in water but provide a good nutrient source for P. aeruginosa (Hommel 1994). Promising results have also been reported for the removal of PAHs, which are recognized as being carcinogenic and hard to degrade environmental pollutants (Makkar and Rockne 2003; Yu et al. 2011). PAHs make up about 85% of the composition of creosote, which is besides copper chromium arsenate and pentachlorophenol a major chemical used in the wood-preserving industry worldwide. Bruguera et al. (2017) focused their research on areas around wood preservation facilities that are often highly contaminated due to practices such as the use of unlined wood treatment cells and the disposal of wastes in unlined lagoons, and long-term leaching of preservatives from treated wood onto site soils. Their study concludes the high potential of rhamnolipids (JBR 425) to extract PAHs from such contaminated soils. However, the ionic strength and the cations present in the soil solution of creosote-polluted soils should be considered when rhamnolipids are used as extractants for remediation purposes (Madrid et al. 2019).

5.4.2 Sophorolipids

Of all currently known biological surface-active agents, rhamnolipids are believed to have the highest potential for becoming the next generation of biosurfactants. However, the first microbiological surfactants introduced on the market were another member of glycolipid group – sophorolipids (Müller et al. 2012). Sophorolipids are synthesized through the fermentation by a number of non-pathogenic yeasts such as Candida bombicola (Le et al. 2016) which produces high yields of sophorolipids from vegetable oils and sugars (Mulligan 2005), C. apicola, Rhodotorula bogoriensis, etc. Like rhamnolipids, they solubilize hydrophobic compounds and hence increase their bioavailability for subsequent remediation. Sophorolipids lower the surface tension of water from 73 to about 30–40 mN m−1 and have a CMC of 40–100 mg L−1 (Hubert et al. 2012).

There is a growing number of studies that found these biosurfactants to be very efficient for the remediation of petroleum hydrocarbon-polluted soils, even outperforming the conventional detergents of chemical origin (such as Triton X-100), which are in fact considered a new class of chemical pollutants in aquatic environments. Goswami et al. (2018) compared the performance of environmentally friendly sophorolipids derived from two yeast, C. bombicola and Yarrowia lipolytica, with synthetic Triton X-100 on such contaminated soils. The best results were obtained with the biosurfactants produced by C. bombicola, where 40–68% reduction of contaminant concentration was achieved using the biosurfactant compared to 37–38% reduction when using Triton X-100.

5.4.3 Lipopeptides

Among other categories of biosurfactants, lipopeptides are particularly interesting because of their potent surface activity (Meena and Kanwar 2015). They can act as antibiotics, antiviral and antitumor agents, immunomodulators and specific toxins and enzyme inhibitors (Rodrigues et al. 2006). Besides their application in medicine, lipopeptides can be counted among promising dispersants in oil spill remediation. The one with the greatest potential in the group is probably surfactin, a cyclic lipopeptide produced by various strains of Bacillus subtilis. It was identified in 1968 and named after its exceptional surfactant activity (Arima et al. 1968). It has been reported as the strongest lipopeptide surfactant so far (Liu et al. 2015) with the ability to decrease the surface tension of water from 72 to 27 mN m−1 at a concentration as low as 20 μM and the interfacial tension of the water/n-hexadecane system from 43 to values <1 mN m−1 (Lang 2002; Yeh et al. 2005). There has been a broad spectrum of applications proposed for this compound including its utilization in petroleum recovery and spill mitigation (Liu et al. 2015), since surfactin enhances bioavailability of water-insoluble substrates and regulates the attachment/detachment of microorganisms to and from surfaces (Rosenberg and Ron 1999). Possessing exceedingly favourable features, including low toxicity, high biodegradability and no or minimal loss of activity under harsh conditions such as extreme temperatures, pH and salinity, as well as a high surface activity and low CMC values, surfactin is decidedly a candidate for either ex situ biosurfactant injection or in situ biosurfactant production that lead to an enhancement in oil recovery from subsurface reservoirs (Banat et al. 2010; Liu et al. 2015).

Schaller et al. (2004) yielded favourable results when examining the effect of altering salt concentration (0–10% NaCl), pH (3–10) and temperature (21–70 °C) on the performance of surfactin produced by B. subtilis ATCC 21332 cultures; high salt concentration, high temperature and high pH describe the conditions of many oil reservoirs and can affect compound’s activity. Al-Wahaibi et al. (2014) reported that biosurfactants produced by B. subtilis B30 identified as a mixture of lipopeptides similar to surfactin gave stable emulsions with a wide range of hydrocarbons including light and heavy crude oil, and remained stable over a broad range of pH, salinity and temperature. The crude biosurfactant preparation enhanced light oil recovery by 17–26% and heavy oil recovery by 31%.

Similarly, lipopeptides secreted by B. subtilis HSO121 showed good dispersion effectiveness on crude oil at low surfactant-to-oil ratios and remained active over changes in temperature (15–25 °C), pH values (5–11) and salinity (0–4% NaCl). Lipopeptides showed excellent activity in accelerating degradation of long-chain hydrocarbons after 2 days. The degradation rates of alkanes treated by lipopeptides after 1 day and 2 days were 38.78% and 71.45%, respectively, which were much higher than those of commercial dispersant-treated group (9.16% and 34.16% after 1 day and 2 days treatment) (Feng et al. 2019).

5.4.4 Saponins

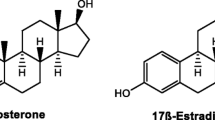

Many surface-active compounds can be derived from renewable plant resources (Xu et al. 2011). Although microbial surfactants are generally considered to have more advantages than plant-based surfactants in terms of scale-up capacity, versatile properties and rapid production (Randhawa and Rahman 2014), there are several plant-based biosurfactants exhibiting excellent functional properties, among which the best known are those belonging to the structurally diverse class of compounds that derived their name from their ability to form soap-like foams in aqueous solutions – saponins (Hill 2003). Saponins can be isolated from more than a hundred plant families (Samal et al. 2017) as well as from several marine invertebrates including Antarctic starfish of the family Asteriidae and sea cucumbers; they are also present in some marine sponges, soft coral and small fish (De Marino et al. 1998; Xiao et al. 2019). Among the most studied plant materials that were found to be rich in saponins are ginseng, licorice root, asparagus, soybeans, sugar beet, chickpea, green pea, horse chestnut, quinoa, etc. (Price et al. 1987; Fenwick et al. 1991; Shidhaye et al. 2008; Cheok et al. 2014; Shin et al. 2015). Saponins are amphipathic glycosides containing one or more hydrophilic glycoside (sugar) chain(s) on a triterpene or steroid aglycone backbone also known as sapogenin (Fig. 5.2). Due to the presence of a lipid-soluble aglycone and water-soluble sugar chain(s) in their structure, saponins are regarded as surface-active compounds with detergent, wetting, emulsifying and foaming properties (Üstündağ and Mazza 2007).

Schematic illustration of saponin composition. These heterosides are composed of a water-soluble glucidic chain and a triterpenic or steroidic liposoluble structure; however, variation in saponin composition is high. Possible structures of triterpenic and steroidic aglycones (Chaieb 2010) are shown on the right side of the figure

The recent advances in extraction techniques for bioactive compounds present in plant material have been thoroughly reviewed (e.g. by Sasidharan et al. 2010; Azmir et al. 2013); there are several methods to obtain saponin from a plant. Traditional extraction techniques include maceration, which is a very slow process of solid-liquid extraction, and Soxhlet and reflux extraction where a distillation process is involved (Cheok et al. 2014). In conventional extraction, the extractability of the desired compound from plant material depends mainly on the solubility of this compound (the solute) in the solvent, mass transfer kinetics of the product and matrix interactions (Spigno and De Faveri 2009). It is often necessary to use high volumes of the solvent to extract the target solute, even if the process is being aided by heating, and mechanical stirring or shaking to elevate the temperature (Cheok et al. 2014). Furthermore, the ability of the solvent to extract various substances from natural material leads to the use of excess solvent volumes in order to ensure efficient extraction of the desired bioactive compound. The green technologies employed in saponin extraction are UAE, MAE and ASE (Heng et al. 2013). Compared to conventional extraction, these techniques meet the green chemistry concept, i.e. they are environmentally friendly, offer safer chemical synthesis, allow the use of alternative and less hazardous substances, use only small amounts of catalyst, reduce energy consumption, maximize atom economy, prevent waste, avoid chemical derivatization and minimize potential for accidents (Anastas and Warner 1998; Azmir et al. 2013).

5.4.4.1 Quillaja Saponins

The soap bark tree or soapbark (Quillaja saponaria) is one of the major commercial sources of saponins (Cheeke 2000); saponin extracted from the bark of this tree can be used as a natural low molecular weight biosurfactant (Bai and McClements 2016), its chemical structure is outlined in Fig. 5.3. The micelle-forming properties of quillaja saponins may be affected by temperature, salt concentration and pH of the aqueous phase (CMC increases with temperature and pH and decreases with raising salt concentration; the size of micelles has been found to increase strongly with temperature but to have little dependence on salt concentration or pH) (Mitra and Dungan 1997). Nonetheless, a growing number of studies have reported that saponins could effectively remove heavy metals and complex organic chemicals such as PAHs and PCBs from various polluted environmental substrates. Gao et al. (2012) compared the efficacy of quillaja saponin and sophorolipid produced from the yeast strain Wickerhamiella domercqiae for the Pb2+, Ni2+ and Cr3+ removal from the sludge collected from an industrial water treatment system. From the two non-ionic biosurfactants used in batch and column experiments, saponin was found to be more efficient at the removal of selected heavy metals from polluted sludge. Saponin molecule contains the carboxyl group (–COOH) on its hydrophilic head (Fig. 5.3) by which saponin forms complexes with metal ions in aqueous solutions (Hong et al. 2002). Saponin showed selectivity for target metals and mainly reacted with heavy metals in fraction bound to carbonates and in fraction bound to Fe-Mn oxides. The subsequent metal recovery was achieved by precipitation in alkaline solution and reached 89.7%, 91.1% and 99.1% for Pb2+, Ni2+ and Cr3+, respectively.

The structure of quillaja saponin (Chen et al. 2008) according to Higuchi formula (1986). Unlike the hydrophobic tail of conventional surfactants that typically has only one long straight hydrocarbon chain, saponin molecule consists of a hydrophobic fused ring of triterpenes with two hydrophilic sugar chains attached to positions C-3 and C-28. These oligosaccharide chains carry various moieties, such as β-D-glucuronic acid, anionic carboxyl group and non-ionic glycoside groups. The ability of carboxyl groups to form complexes with metal ions in aqueous solutions appears to play an important role in their removal from contaminated materials

Batch extraction is a simple separation technique used in environmental analysis. In its simplest form, a batch extraction system consists of an agitated mixing vessel where the solids are being mixed with the solvent and a solid-liquid separation device. Decanter centrifuges are advantageously used as separators (Berk 2013). Song et al. (2008) conducted the batch experiments with soils spiked with phenanthrene and cadmium to evaluate pollutant removal efficacy of saponin. Phenanthrene partitioned into a surfactant micelle, thus becoming directly bioavailable to organisms capable of degrading PAHs, whereas Cd2+ was effectively removed from soil via its complexation with the external carboxyl groups of saponin micelle. At saponin concentration of 3.75 g L−1, a removal yield of 87.7% for Cd2+ and 76.2% for phenanthrene was obtained. The removal efficacy of saponin was greater than that of Triton X-100 and citric acid. EDTA removed Cd2+ effectively at low concentration; however, this substance is quite persistent in the environment due to its low biodegradability and may have a toxicity effect on soil microorganisms and plants (Hauser et al. 2005). The removal of Cd2+ was not constraining the removal of phenanthrene which demonstrates a substantial potential of saponins for the removal of heavy metals and PAHs from soils.

Cao et al. (2013) investigated the simultaneous desorption of metal elements (Pb2+, Cu2+) and polychlorinated biphenyl (PCB) from the combined contaminated soil with a novel combination of saponin and S,S-ethylenediamine disuccinic acid (EDDS) – an aminopolycarboxylic acid that can be used as a chelating agent, thus offering a biodegradable alternative to synthetic EDTA (Kaushik 2015). The maximal desorption of contaminants was achieved by addition of 10 mmol L−1 EDDS and 3 g L−1 saponin, and was 99.8%, 85.7% and 45.7% for Pb2+, Cu2+ and PCB, respectively. In the presence of the mixed solution of 5 mmol L−1 EDTA and 20 mmol L−1 Triton X-100, the maximal desorption was only 88%, 74.4% and 53.3% for Pb2+, Cu2+ and PCB, respectively. These results suggest the combination of saponin and EDDS may have practical application in remediation of soils co-contaminated by hydrophobic organic compounds and metals.

5.5 Experimental: A Solid-Liquid Extraction with Synthetic and Biological Surfactants for the Removal of Cu, Pb, Ni and Zn from Contaminated Soils and Sediments

As an example of solid-liquid extraction with the use of synthetic and biological surface-active agents for the removal of heavy metals from contaminated soils and river sediments, the extraction of Cu, Pb, Ni and Zn with two synthetic non-ionic surfactants Triton X-100 and Triton X-114 (octyl-phenoxy-poly-ethoxy-ethanol with polyoxyethylene chain length of 9.5 and 7.5, respectively), biosurfactant saponin (isolated from the bark of Quillaja saponaria tree) and secondary metabolites of microscopic filamentous fungus Aspergillus niger was evaluated in laboratory-scale batch experiments.

Soil and sediment samples with elevated concentrations of heavy metals were collected from four different industrially stressed areas of Slovakia (Fig. 5.4); for characteristics, see Table 5.2.

Topographical position of the sampling sites in Slovakia. For details on soils and sediments sampled, see Table 5.2

The town of Banská Štiavnica is the oldest mining town in Slovakia, the history of mining in this district dates back to the late Bronze Age. The prosperity of the town reached its peak in the eighteenth and nineteenth centuries, by the end of the nineteenth century mining fell into decline and the last mine was closed in 2001. However, the effects of former mining activities are numerous in their impact on the environment of the region. At this place it should also be noted that ‘closed’ or ‘abandoned’ mine status does not necessarily imply that the problems are less than those experienced in active mining areas, since the environmental standards were considerably lower in the past and the competence of the authorities could have been rather limited (Puura and D’Alessandro 2005). One of the most critical areas is Šobov, situated 3 km northeast of Banská Štiavnica city. It is an open mine where hydrothermal quartzite was extracted and then transported, crushed and grinded at a nearby plant in Banská Belá for refractory bricks. The mined ore often contained pyrite and clay minerals, mainly illite and pyrophyllite (Uhlík and Šucha 1997) which were left on site as waste and had been accumulated along over 30 years (Šottník et al. 2002). In the course of time, pyrite deposited on the pile in large amounts has been under the slow attack of weathering processes and oxidized, forming sulfuric acid. The acid attacks other minerals and accelerates migration of different toxic elements (Kubová et al. 2004, 2005; Bujdoš et al. 2005). The water that flows out from the mine site represents typical acid mine drainage with high metal concentrations and pH as low as 1.2–2.5. The major dissolved components are Al, Fe and SO42−, followed by Zn, Mn, Cu, Pb and As (Matúš 2007; Matúš and Kubová 2005, 2006, 2008; Matúš et al. 2003, 2004, 2005, 2006). The dissolved salt concentrations remain between 15 and 50 g L−1 (Šucha et al. 1997; Šottník et al. 2002). The acid mine drainage is associated with enormous damage to the entire surrounding habitat, it causes significant changes in soil properties and plant species richness. In the last decades, different remediation strategies have been implemented to reduce negative influence of these waters, but with little success. In 1999, a passive treatment system was designed to treat acid mine drainage, with aerobic terrace with wetland vegetation arranged in the last stage (Šottník and Šucha 2001). In order to at least partially prevent the negative effect of acid mine drainage, a simple construction – the surface channel system – has been built to collect acid water that flows out of the dumps into an open pool from which it is subsequently delivered by an underground tube into the deep abandoned mine (Lintnerová 2002). The polluted area covers an estimated 145,000 m2, badlands with no vegetation or humus cover spread for 35,000 m2 (Dlapa et al. 2002; Šottník et al. 2002; Medveď et al. 2004, 2006, 2008).

The second sampling site was situated in Pezinok region (Little Carpathian Mts.), in so-called Pezinok-Pernek crystalline complex, known for its ore deposits. The sample was taken from the soil at a Sb ore dump site situated on the south-eastern side of the mountain above the town. This area has several thousand years of history in ore mining. With a series of little breaks, it was mined for antimony until the early 1990s, when an interest in antimony had dropped off due to the end of the Cold War; besides that, only residual deposits of Sb remained on the site. The ore mining and dressing have significantly contributed to Sb and As contamination of soils, sediments and waters (Čerňanský et al. 2007, 2009; Urík et al. 2007; Kubová et al. 2008a, b; Kališ and Matúš 2011; Littera 2011). Nowadays, a surface water leaking out of the mining dump has a pH of 4–6.5, and although it is partially purified by a natural process of mechanical sedimentation and sorption in the sludge pond, the water mineralization is about 1.25 g L−1 and water is high in content of sulphates (680 mg L−1), Fe (31.2 mg L−1) and heavy metals (Andráš et al. 2004a; Šlesárová 2006). Due to the polymetallic nature of the deposit, it can be assumed that the oxidation of the sulphidic material continues (pyrite is commonly found in polymetallic ore) and therefore the deposit can be classified as a potential source of acid mine drainage. The presence of carbonates in the surrounding rocks contributes to the neutralisation of the acid with calcium carbonate, thereby preventing more intense acid mine drainage formation. However, the conditions at the sludge lagoons should be monitored, as the neutralizing potential of the carbonates can be exhausted, and the character of the acid mine drainage pH may change towards markedly acid values (Luptáková and Andráš 2018). Such a change could trigger calamitous degradation process and cause the substantial contamination of the surrounding landscape (Andráš et al. 2004b).

The area in Spiš-Gemer Ore Mt. (Spišsko-Gemerské Rudohorie) chosen for stream sediment sampling was industrially stressed during the long period of time, pollution problems caused by mining operations date back to the thirteenth century (Špaldoň et al. 2006). Large deposits of precious and industrial metals and their processing characterized this region for centuries, many of these deposits are now considered as sources of acid mine drainage. Ore deposits in Jaklovce and in the surrounding area were mainly mined for iron, mercury (cinnabar), copper and silver; processing of iron ore was conducted in a nearby town of Richňava as well. A dramatic change in ore processing came with the introduction of the waterwheel, by which the industry solved the problem of power. This meant that ironworks now had to be sited next to streams and rivers where there was an adequate supply of water (Hayman 2016). The ore had to be freighted to the river. Until the second half of the fourteenth century, furnaces were built on the site of local ore mines. Relocating works contributed to the further contamination of the river systems in the area. The valley is polluted with Hg, Cu, As, S and nitrates. Hornád river suffers from a poor water quality in a long-term sense, heavy copper contamination was detected near the confluence of the Hornád and Hnilec rivers, and both rivers show high levels of As, Hg and Zn (Klinda et al. 1994). Apart from geological and industrial points of view, another reason of reduced environmental quality of the Hornád river valley is poor environmental awareness of the local community. Inadequate and uncontrolled disposal of communal and other waste (such as scrap metals, plastics, building material, chemicals, etc.), particularly discarding of waste on illegal dumps with a close distance to the river, continues to pose a significant problem (Jablonská et al. 2009).

The collection of sediment samples was carried out in accordance with the Methodical Instruction of the Slovak Ministry of Environment (1998). Chemical analyses were performed on fine-grained fluvial sediment, since a number of pollutants carried by a river tend to bind to a very fine fraction which is being delivered to the riverbanks and adjacent river channels where it settles as the water flow velocity decreases, thus allowing pollution to accumulate. The processes by which benthic organisms stir sediment within the riverbed (i.e. bioturbation) destroying physical sedimentary structures and creating biological structures occur within a 5–20 cm thick region known as the surface mixing layer (Nittrouer et al. 2007); therefore, the upper 20 cm of sediment was taken with a grab corer. Before chemical analysis, samples from stream sediments were dried at 40 °C and passed through a 0.125 mm mesh. A fraction with the particle size <0.125 mm was then ground in an agate mortar to fine powder <0.09 mm. Soil samples were collected at a depth of 0–20 cm. Under laboratory conditions, soil was air-dried, homogenized by quartering, sieved through a 2-mm mesh and subsequently processed as given above.

The batch extraction experiments were conducted at a sample to extracting solution ratio of 1:5 (5 g of soil, 25 ml of extracting solution). Five g of the sample was weighed and placed in a 100 ml high-density polyethylene (HDPE) bottle, 25 ml of the extracting solution were then added and the bottle was sealed with a HDPE top. Each bottle was hand-shaken for about 1 min to ensure the sample was fully saturated with solution, and the bottles were subsequently shaken in a mechanical shaker (Unimax 2010, Heidolph, Germany) at 250 rpm for 24 h. After shaking, the soil-solution mixture was centrifuged (MPW-360 centrifuge, Mechanika Precyzyjna, Warsaw, Poland) at 4000 rpm for 30 min. The supernatant was then poured through a glass funnel holding a Whatman 42 filter to remove any floating particles or debris, and the concentration of heavy metals (Cu, Pb, Ni, and Zn) was determined by flame atomic absorption spectrometry (FAAS) carried out on a Perkin-Elmer 1100B spectrometer (USA) with air-acetylene flame (air 8 L min−1, acetylene 3.5 L min−1). The batch extractions were performed in triplicates to ensure reproducibility of the results.

Total concentrations of Cu, Pb, Ni and Zn in samples were determined after decomposition as follows. 0.5 g of sample in a polytetrafluoroethylene (PTFE) vessel with a mixture of mineral acids (15 ml of 48% HF, 1 ml of 65% HNO3 and 1 ml of 70% HClO4) was heated in a water bath at 80 °C for 2 h. The mixture was then allowed to settle down overnight. Next day, the samples were evaporated to wet salts, 5 ml of HF were added and heated until the fumes of HClO4 were formed. Then, 1 ml of HNO3, 1 ml of HClO4 and 10 ml of H3BO3 (saturated solution) were added and samples were heated to dryness. The dried mass was heated again with an addition of 10 ml of deionized water in a water bath for 1–2 h. To purify the solution, 3 ml of HNO3 and 3–5 drops of 30% H2O2 were added and the solution was allowed to digest in a water bath until dissolving the residues. Then, the sample solution was transferred into a 25 ml volumetric flask and filled up to the mark with deionized water (Medveď et al. 1998, 2003). Total contents of heavy metals in contaminated soils and sediments were determined by FAAS and are presented in Table 5.3.

In soil samples, the total contents of Cu and Zn exceed limit values. Furthermore, the Šobov soil is contaminated also by Pb and soil around the Pezinok deposit shows an inadmissible degree of Zn pollution. The analysis of river sediments for Cu, Pb, Ni and Zn indicates high levels of contamination, except for Pb in Jaklovce sediment which does not exceed permitted limit value. It should be pointed out that Slovak threshold values for contaminants in sediments are unbelievably lenient, therefore, the limit concentrations established in European Union directive (EU WFD 2000) that are far more strict and closer to common standards than limits set by Slovak legislation are listed as well (see Table 5.3). Based on these limits and on the data reported by other authors who conducted their research in the area, the results indicate a long-term Cu, Ni, Zn and to some extent also Pb contamination in Hornád and Hnilec river sediments which should be of concern from the standpoint of health of aquatic ecosystem. Regarding future directions for research, particular attention should be given to the issue of resuspension and remobilisation of hazardous elements from sediments during dry seasons when low flows are experienced because the adverse effects may become significant (Ilie et al. 2014).

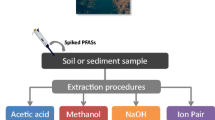

The removal of heavy metals cations, such as Cu2+, Ni2+, Cd2+ and Pb2+, has been receiving extensive attention; in some cases, removal yields close to 100% have been reported. During the last decade, the non-ionic surfactants and Aspergillus niger strain’s metabolites have been successfully applied in the extraction of Zn, As, Cd, Pb, Cu, Al, Fe, Sn, Co, Au, Mn, Se, Sb and Si from various solid substrates in a series of experiments undertaken by our research team (Kolenčík et al. 2011, 2013a, b; Urík et al. 2014, 2015, 2018, 2019; Boriová et al. 2016; Milová-Žiaková et al. 2016; Polák et al. 2018, 2019). In this study, the agents mentioned above showed only a weak capability to remove accumulated metals from collected samples (removal efficacy <6%; see Table 5.4). In contrast, a natural plant-based biosurfactant saponin with the removal percentage range of 14–46% proved itself as a promising biodegradable agent for Cu, Ni and Zn remediation from contaminated soils and sediments (Fig. 5.5). Maximal removal yields were achieved at saponin concentration of 2% (m/v) and removal incubation time of 24 h. Higher concentrations and longer incubation time have brought no improvement in removal efficacy. A higher removal efficacy can though be achieved by multiple washing. This parameter is always affected by environmental variables such as soil and sediment composition, soil pH, cation exchange capacity, particle size, permeability and the presence of other contaminants.

The removal of Zn, Ni, Cu and Pb from contaminated soils and sediments by non-ionic surfactants Triton X-100 (TX-100), Triton X-114 (TX-114), metabolites of Aspergillus niger (MTBs) and quillaja saponin (QuSa); none of the agents were effective enough to release Pb from the structures to which it was adhered. SoS soil Šobov, SoP soil Pezinok, SeR sediment Richňava, SeJ sediment Jaklovce

A modified sequential extraction procedure (SEP), originally proposed by the Commission of the European Communities Bureau of Reference (BCR) (Rauret et al. 1999), applied to the same sediment samples (Vojteková et al. 2008; Blašková et al. 2013) allowed to distinguish different fractions (water-soluble and extractable fraction, metals bound to carbonates easily extractable by a weak acid and metals bound to Mn and Fe oxides) of the heavy metals studied. If we compare recovery values for Cu, Ni and Zn given by the two extraction techniques, a percentage computed as a sum of the amounts determined in steps one and two of SEP was similar to the value obtained by the extraction with saponin. It indicates that the most mobile fractions (water soluble and acid extractable) were easily released in the presence of selected biosurfactant. Regarding Pb, no presence of this element was detected in the first two steps of SEP. The maximum recovery yields were attained in step three of SEP (0.1 mol L−1 NH2OH.HCl), reaching about 50–80% of total Pb content in sediment samples; such a finding is consistent with the ability of Pb to co-precipitate with Mn and Fe oxides (reducible sediment fraction) (Vojteková et al. 2008) and thereby remain stable for a relatively long period of time. Saponin was not able to release Pb from such structures.

The hazard level associated with a heavy metal-contaminated site depends significantly on the chemical form and speciation of the metal. It can be concluded that if the most mobile fractions pose an increased risk of contamination and re-entering biogeochemical cycles, the current risk of Pb contamination in Richňava and Jaklovce is low. It can be also mentioned that the sites in which metal ions exist mainly in residual forms, such as Pb in phosphates (e.g. Pb3(PO4)2, PbHPO4, Pb5(PO4)3Cl), PbS and PbSO4, present little or no hazard to the environment and living organisms (Ogundiran and Osibanjo 2009).

5.6 Conclusions

The residues of organic and inorganic substances found in soils, sediments, waters and aquatic biota have been of environmental concern since the 1960–1970s. Although production of many hazardous chemicals has been gradually banned across the world since the 1970s, the amounts released in the environment can be counted in millions of tons. Moreover, new substances that are harmful to living organisms are being produced by polluting industries every day; they are commonly used in agriculture; worldwide, companies routinely pollute our natural resources with their waste. Many of these compounds are resistant to biological and chemical degradation, thus persisting in the environment for a long period of time. For their determination in different environmental matrices, sample preparation can be time-consuming and challenging but still an essential part of the whole contaminant analysis process. Due to a low concentration of pollutants and often a complex nature of collected samples, separation and pre-concentration prior to analysis become even more important. Among sample preparation methods, liquid-liquid extraction and solid-phase extraction are reported to be the most frequently used for isolation and clean-up, sample preconcentration and derivatization. Both techniques are available in different modifications and both are applicable for an extraction of organic and inorganic pollutants. It is evident that much effort has been devoted to improving extraction procedures in order to make the process more effective, faster, simpler, less expensive and eco-friendly. In this context, conventional surfactants are gradually being replaced with substances of biological origin that are equally or even more efficient and are not harmful to the environment and human health. In our study on extraction of metal ions from solid materials using liquid solvent, we tested plant-derived surfactant saponin for the recovery of selected heavy metals from soils and river sediments collected in environmentally stressed areas. The experiment conducted indicates that this approach can be successfully applied to recover Cu, Ni and Zn from contaminated soils and sediments. Good removal rates were achieved after single washing; to increase the yields, multiple washing might be needed. Although scientific studies that have been published on this topic point to a high efficiency of biosurfactants in removing metals from contaminated sites, more information is required with regard to the interactions between these compounds and contaminants in order to utilize their full potential in remediation technologies.

References

Abdel-Mawgoud AM, Lépine F, Déziel E (2010) Rhamnolipids: diversity of structures microbial origins and roles. Appl Microbiol Biotechnol 86:1323–1336. https://doi.org/10.1007/s00253-010-2498-2

Abhijit SP (2017) Efficiency of surfactants in pigment dispersion. Paintindia 67:55–70

Albero B, Sánchez-Brunete C, García-Valcárcel AI et al (2015) Ultrasound-assisted extraction of emerging contaminants from environmental samples. TrAC Trends Anal Chem 71:110–118. https://doi.org/10.1016/j.trac.2015.03.015

Al-Wahaibi Y, Joshi S, Al-Bahry S et al (2014) Biosurfactant production by Bacillus subtilis B30 and its application in enhancing oil recovery. Colloid Surf B 114:324–333. https://doi.org/10.1016/j.colsurfb.2013.09.022

Anastas PT, Warner JC (1998) Green chemistry: theory and practice. Oxford University Press, New York, 135 p. ISBN: 9780198502340

Andráš P, Kušnierová M, Adam M et al (2004a) Biooxidácia rudných minerálov na ložisku Pezinok. Acta Montan Slovaca 9:442–453. (in Slovak)

Andráš P, Kušnierová M, Adam M et al (2004b) Bacterial leaching of ore minerals from waste at the Pezinok deposit (Western Slovakia). Slovak Geol Mag 12:79–90

Arima K, Kakinuma A, Tamura G (1968) Surfactin, a crystalline peptidelipid surfactant produced by Bacillus subtilis: isolation, characterization and its inhibition of fibrin clot formation. Biochem Biophys Res Commun 31:488–494. https://doi.org/10.1016/0006-291X(68)90503-2

Azmir J, Zaidul ISM, Rahman MM et al (2013) Techniques for extraction of bioactive compounds from plant materials: a review. J Food Eng 117:426–436. https://doi.org/10.1016/j.jfoodeng.2013.01.014

Bai L, McClements DJ (2016) Formation and stabilization of nanoemulsions using biosurfactants: Rhamnolipids. J Colloid Interface Sci 479:71–79. https://doi.org/10.1016/j.jcis.2016.06.047