Abstract

Non-traditional soil stabilizers are widely used for treating weak materials. These additives are cost- and time-effective alternatives to more traditional materials such as lime and cement. It has been well established that the treatment of natural soil with chemical additives will gradually affect the size, shape, and arrangement of soil particles. Furthermore, the degree of improvement is dependent on the quantity and the pattern of new products formed on and around the soil particles. In this paper, unconfined compressive strength (UCS) test was performed as an index of soil improvement on mix designs treated with calcium-based powder stabilizer (SH-85). The time-dependent changes in shear strength parameter and compressibility behavior of treated soil were also studied using standard direct shear and one-dimensional consolidation tests. In order to better understand the shape and surface area of treated particles, FESEM, N2-BET, and particle size distribution analysis were performed on soil-stabilizer matrix. From engineering standpoint, the UCS results showed that the degree of improvement for SH-85-stabilized laterite soil was roughly five times stronger than the untreated soil at the early stages of curing (7-day period). Also, a significant increase in the compressibility resistance of treated samples with curing time was observed. Based on the results, less porous and denser soil fabric was seen on the surface of clay particles. FESEM images of the treated mix designs showed the formation of white lumps in the soil fabric with the cementitious gel filling the pores in the soil structure.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The chemical stabilization technology is a chemically modified method that can stabilize or reinforce soils with weak engineering properties. Some of the more common chemical compounds used in various geotechnical applications are enzymes, liquid polymers, resins, acids, silicates, and lignin derivatives. However, due to the commercial nature of these brands, their exact chemical composition has not been disclosed [3, 9, 19, 20, 22, 29, 32]. Reviews of past studies show that the type of soil and stabilizer play an important role in the stabilization process [15, 24, 31]. Furthermore, there have been noticeable important dissimilarities in the stabilization mechanism of tropical soils from the moderate climates [13].

Residual soils are products of chemical weathering and thus their characteristics are dependent upon environmental factors of climate, parent material, topography and drainage, and age. Optimization of these factors occurs in tropical regions where heavy rainfall and warm temperatures are most conducive to chemical weathering and deep residual soil profiles develop that led to the production of laterite soil deposits. Laterite soils are highly weathered reddish tropical soils that have concentrated oxides of iron and aluminum with kaolinite, the predominant clay mineral [33]. There are six areas of the globe that this group of soil is found and they are; Africa, India, Southeast Asia, Australia, Central, and South America [34].

Laterite soils are widely used as fill materials for various construction works in most tropical countries. In recent years, the laboratory tests carried out on chemically stabilized soils have paid much attention to analyzing the impacts of additives on the engineering properties of treated soil with little focus on the stabilization process. Also, in contrast to traditional stabilizers such as lime [27], study on the morphological changes associated with the use of non-traditional stabilizers has been rather limited. Furthermore, it was important to carry out a complete assessment to fully understand the microstructure of soil treated with commercially available agents. In this paper, the development of the microstructure of laterite soil treated with new type of calcium-based powder stabilizer (SH-85) and its relation to the engineering behavior were investigated. First of all, unconfined compressive strength (UCS), standard direct shear, and one-dimensional consolidation tests of untreated and treated soil were examined to find the shear and compressibility properties of samples. Finally, the microstructure and morphology of SH-85 stabilized laterite soil were examined using field emission scanning electron microscopy (FESEM), Brunauer, Emmett and Teller (BET) surface area and particle size distribution analysis, respectively.

2 Research methodology

2.1 Materials

This study was conducted on the residual laterite soil that is usually found in tropical areas. Residual soil was obtained from a depth of 2–3 m below the ground surface. The soil was air-dried under laboratory conditions, after which pebbles and plant roots were removed. Soil passing the 2-mm sieve was only used in the experiments. The particle size distribution, engineering properties, and chemical characteristics obtained from energy-dispersive X-ray spectrometry (EDAX) spectra of the natural soil are illustrated in Fig. 1, Tables 1 and 2, respectively. In Fig. 2, the X-ray diffraction (XRD) result indicates that the main minerals present in the laterite soil were kaolinite (2θ = 12.5°, 20°, 35°, 38°, 46°, 55°), quartz (2θ = 27°, 36.5°, 42.5°, 50°), geothite (2θ = 21.5°, 36.5°, 41°, 53°), and gibbsite (2θ = 18.5°, 20°, 27°, 38°) [17].

A new calcium-based powder stabilizer, commercially labeled as SH-85, was used in this study. The exact chemical composition of this stabilizer has not been released, since it is a commercially registered brand. Table 3 shows the general chemical properties of this stabilizer based on EDAX result.

2.2 Sample preparation

The results of laboratory studies on the laterite soils have revealed significant changes in their compaction properties due to oven-drying [33]. In order to avoid the mentioned changes, air-drying method was used for all soil specimens. The specimens were sieved by a 2-mm mesh to confirm the uniformity of the soil. In order to prepare various mix designs, a standard protocol was used. The first step was conducted based on clause 3.3.4.2 of BS 1377: Part 4: [5]. This step included the determination of the optimum moisture content (OMC) for natural soil and soils mixed with different amount of stabilizer. In the second step, 3, 6, 9, 12, and 15 % of stabilizer (SH-85) were added to the soil and mixed with the optimum water. In order to prepare a homogeneous mix, irregular hand mixing with palette knives was done. Then after, the target dry density and moisture content were reached by compressing the samples in a steel cylindrical mold fitted with a collar that accommodated all the mixtures. The required compaction was done by a hydraulic jack using persistent compaction based on clause 4.1.5 of BS 1924: Part 2: [6]. Finally, the cylindrical samples were extruded using a steel plunger, trimmed and placed in a plastic bottle, and wrapped in several runs of cling film. These samples were cured for 3, 7, 14, 28, and 90 days in a 27 ± 2 °C temperature-controlled room [35]. The shear strength tests were carried out by standard direct shear test. Two-layered compaction was performed on the soil specimens that were 60 mm in diameter and 20 mm in height. The untreated soil samples were sheared immediately as control specimen, but treated samples were only sheared after being cured with a controlled temperature. One-dimensional consolidation tests were performed on the untreated and treated soil. Samples were prepared in three layers in an oedometer ring (50 mm diameter and 20 mm height) to the required density using static compaction. This technique was adapted to avoid possible soil disturbance in the subsequent sample cutting and fitting into the oedometer ring [11, 22]. Samples were then placed in a plastic bag and cured inside a humid room at 27 ± 2 °C. It should be noted that all samples were made by optimum moisture content and 90 % of maximum dry density [1]. A characterized specimen designation scheme was used to ease the presentation of results. The first and second characters in the mentioned scheme indicated the soil name and type of treatment, respectively. The mentioned characters included LC for laterite clay, UNT for untreated, PST for powder stabilizer treated, and D for days.

2.3 Testing program

The general characterization studies of the present investigation were categorized into macro- and micro-characterization analyses. The soil improvement index was determined by conducting serious of UCS test (BS 1924: Part 2: [6] on multiple specimens at different time intervals. A rate of axial strength equal to 1 % per minute was applied to the samples. The acquisition data unit (ADU) was used to record the applied load and axial deformation, automatically. The failure of each specimen was defined by its peak axial stress. The failed specimens were dried and weighted in the end of each test to calculate their moisture content.

The shear strength tests were carried out by applying a constant strain rate of 0.6 mm/min on the soil samples placed inside standard shear boxes until the soil had failed or reached a maximum horizontal displacement of 10 mm. This displacement was chosen based on the capability of the machine used. The standard procedures used here are BS 1377: part 7: 1990 and ASTM 3080 (as mentioned in Head [6]. In addition, three different normal stresses exerted on those samples were 28, 56, and 112 kPa. Lastly, based on the several tests on natural soil and treated samples with the application of different normal stress, relationship between the applied normal stress and shear stresses were plotted.

One-dimensional consolidation test was performed in accordance with BS 1377: Part 5 (BSI, 1990e) using a 50 mm diameter and 20-mm high-consolidation ring. After curing, each specimen was removed from the plastic bag and placed into the consolidometer cell with filter paper and porous stones at both ends of the specimen. The loading range was from 12.5 to 800 kPa and was applied in double increments in each stage and unloaded to 100 kPa. It should be stressed that each loading and unloading stage was left for 24 h [2, 4, 10, 25].The displacements and loads were recorded automatically by acquisition data unit (ADU).

For identifying the mineralogical composition of the laterite soil, powder XRD (Bruker D8 advance diffractometer) using Cu-Kα radiation (1.540 Å) at 40 kV and 100 mA was employed. The scanning range of (2θ) was from 10° to 90° with a 0.02° step size and one second dwelling time for every single step. Finally, mineralogy analysis was carried out based on the Bragg data in the standard powder diffraction file as in JCPDS [17]. To prepare the test samples, they were grinded using a pestle and mortar to a fine yet homogenous powder form, placed in an aluminum holder with elliptical opening, and evenly spread with the help of a microscope slide to achieve a smooth surface. A minimum number of three specimens were tested by the XRD test to provide mineralogy of the soil.

Field emission scanning electron microscopy (FESEM) is a common technique used to determine the microstructural properties of soil fabric, providing information on the size, shape, and the state of orientation and aggregation of soil particles. This method could be implemented in soil stabilization studies, in order to visualize the topographical features and, moreover, to observe the formation of new cementitious materials that are hard to detect using other analyzing instruments. In this study, the morphological and elemental composition of the samples and their crystal phase are analyzed through FESEM (JSM-6701F JEOL) with an attached EDAX. The test samples for FESEM and EDAX analyses were prepared by drying the soil, placing them onto an aluminum stub covered with double-sided carbon tape, and using a vacuum sputter coater to coat the samples with platinum for 120 s at 30 mA under high vacuum until they were completely covered and ready to be used for the microscopic analysis.

The particle surface area is an essential feature to understand both the physical and chemical properties of the treated soil. This is because many chemical reactions in soils occur at the surface [23]. Among the most frequent approach for evaluating the surface area of solid materials is that of Brunauer et al. [7], regarded as the BET technique. The approach depends on gathering isotherm report for the physical adsorption of an inert gas and modeling the adsorption figures with the use of BET isotherm equation [30]. In this study, the surface area was derived through physical adsorption of nitrogen gas by means of micromeritics surface area analyzer (Pules ChemiSorb 2705). It is also microprocessor controlled and interacts with a XP-based PC which allows for physisorption investigation. In this method, small amount of cured sample was placed in the sample container. Nitrogen gas was pumped in after degassing for 1 h at 130 °C, and the outer area value was estimated adopting the single-point BET technique.

The particle size distribution of a soil can be important in understanding its physical and chemical properties. It affects the strength and load-bearing properties. The particle size analyses were carried out using CILAS Particle Size Analyzer. The CILAS 1180 Particle Size Analyzer utilizing laser diffraction technique with laser light wavelength, λ, 635 nm is able to measure particles ranging from 0.04 to 2,500 μm. The size distributions of the tested specimens were determined based on Fraunhofer diffraction theory by using the software Particle Expert version 5.12. The entire tests were carried out with approximately 0.2 g sample and other test procedures were in accordance with BS ISO 13320:2009 (particle size analysis–laser diffraction methods). It should be noted that all the experiments in this study were performed in the geotechnic and chemical laboratory of the faculty of civil engineering and faculty of science, in Universiti Teknologi Malaysia (UTM).

3 Results and discussion

Figure 3 shows the results of UCS tests of stabilized mixture of laterite soil and SH-85 at different time intervals. Apparently, the SH-85 treatment significantly enhanced the strength characteristics of the natural soil. The 9 % SH-85-treated samples with a 7-day curing time achieved a compressive strength of 1,087 kPa. This was approximately five times greater than the untreated soil strength and was gained much faster in comparison with other calcium-based type stabilizers such as lime which required a 8-month curing period to achieve a 633 kPa compressive strength [13]. It should be stressed that the rate of strength development was rather limited to the first 7 days of curing (1,087 kPa) and reached a value of 1,364 kPa for 90-day-cured samples. This indicated that most part of the soil-stabilizer reactions happened at the early stages of curing. Furthermore, based on the obtained results, 9 % of SH-85 was chosen as the optimum value that was added to the laterite soil for consolidation and microstructural studies.

Shear strength is another important feature in geotechnical engineering or more specifically, the stability of slopes, shallow foundations, cuts, fills, dams, pavements design, and the stresses on retaining walls. Generally speaking, it governs the stability and robustness of a particular structure under expected maximum loading. Achieved parameters of shear strength [cohesion (c) and internal friction angle (ϕ)] of untreated and treated laterite soil with 9 % of SH-85 at different curing time are presented in Figs. 4 and 5. It should be stressed that the untreated sample cohesion and internal friction angle gained 38.6 kPa and 22.3°, respectively. From figures, it is observed that both cohesion and internal friction angle of specimens increased greatly after curing. It can be seen that the cohesion of treated samples increased about three times than that of uncured samples after 7-day curing period when added 9 % of SH-85 to the soil. In addition, the cohesion of 90-day-cured sample gained 131 kPa. Also, it is observed that the internal friction angle of specimens had a marginal changed with the increase in SH-85 concentration. However, it is clear that by an increase in the curing time, both cohesion and internal friction angle of treated specimens increased, but for both shear parameters, the most part of changes in shear parameters happened after first 7 days of curing period which shows the fast reaction times between soil and SH-85. For example, about 80 % of increment in cohesion happened after 7-day curing time. The rise in the shear strength parameter of treated samples was believed to be due to the activities of cationic exchange as well as the presence of cementitious component which can decrease soil porosity while increasing its shear strength. Based on the results it seems that the formation of the new cementation compounds in soil-stabilizer reactions leads to the increases in bonding and interlocking forces between soil particles due to the high rigidity and rough surfaces of the compounds formed and as a result, the strength, cohesion, and the angle of internal friction of the soil improved after treatment [8, 16, 18].

The changes in the geotechnical parameters of chemically treated soils are due to complex short- and long-term reactions between additive and soil. Figures 6 and 7 show the results of one-dimensional consolidation test on untreated and 9 % SH-85-treated samples at different time intervals. As can be seen from the curves, the compression index (C c), swelling index (C s), coefficient of consolidation (c v), and coefficient of volume compressibility (m v) for untreated soil were 0.35, 0.042, 8.73–35.9 m2/year, and 0.113 m2/MN, respectively. It should be noted that a wide stress range from 100 to 400 kPa was arbitrarily selected to observe different consolidation parameters variations. The results of treated laterite soil showed that the c v and m v values were gradually decreased with curing time [11, 12, 26]. The data presented further indicated a drastic reduction in C c and C s with time. Hence in general, the SH-85 treatment reduced the compressibility properties of the treated soil. The reduction in the compressibility behavior of the treated samples were believed to be due to the formation of new cementing products which resulted in greater resistance to compression at same stress degrees [25, 28].

In order to study the morphology of the stabilized soil, FESEM was used in the present study. Figure 8a–d shows the results of FESEM for pure SH-85, untreated soil, and treated soil, respectively. As can be seen, the SH-85 had a continuous and flake-shaped structure. The presence of big packets of porous soil particles was evident in untreated sample. Images of the treated mix designs with the SH-85 stabilizer showed the formation of white lumps and web-shaped cementitious compounds in the soil fabric (90 days curing) [8, 14, 27]. Figure 9a–c shows the spectrums of EDAX for the untreated soil, SH-85 additive, and treated laterite soil with SH-85 after 7-day curing period, respectively. As can be seen from the Fig. 9c, the peak intensities of the calcium have significant reduction after mixing and curing. The latter was due to the consumption of calcium in the newly formed cementing product in SH-85-treated samples. It should be noted that by means of energy-dispersive X-ray spectrometer (EDAX) technique, these compounds were roughly identified as calcium aluminate hydrate (CAH) [14, 17].

The specific surface area is an important property in assessing the physical interaction of clayey soils with chemical stabilizers. The N2-BET results of untreated and SH-85-treated laterite soil at 7-, 28-, and 90-day curing period are presented in Fig. 10. As shown, a considerable reduction in the surface area of treated samples was evident at the early stages of curing. With further curing, a rise in the BET surface area of treated samples was evident. This was probably due to the action of stabilizer in increasing the number of accessible pores among the clay particles. However, after 90-day curing, a reduction in the surface area of treated sample was observed. The recrystallization of the cementitious component was believed to be the main mechanism responsible for this decrease.

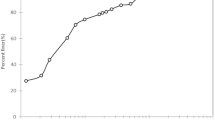

Figure 11 indicates the particle size distribution graphs of untreated laterite soil and treated samples with SH-85 non-traditional additive at different curing periods. It should be noted that during sample preparation for this test, some degree of bond breaking will occur. This will cause a large flocculated cluster to break down into smaller clusters. Hence, this method is also likely to underestimate the equivalent particle cluster size of treated soil. However, Chew et al. [10] mentioned that the underestimation of the particle size in MIP studies is probably much more serious than this method. As can be seen, for treated soils, there was a shift to the right of particle size and their postulated subsequent cementation by deposition of CAH, which is consistent with aggregation and cementation that indicated with FESEM micrographs. Based on the results, the reaction products during the pozzolanic activity were formed like a cover around the soil particles and led to increase in its size. Also, it was clear that the development of the particle size increased with an increase in curing time; however, this increment was rather small after 7 days. The later was consistent with the others macro- and microstructural tests and could be the reason of increase in the shear parameter and compressibility resistance of treated samples at the early stage of curing time. As well as, the result of the particle size distribution for untreated and treated sample with SH-85 non-traditional additive at different curing period is listed in Table 4. As can be seen from the tables, 28 % of untreated laterite soil was in clay size and after treated with SH-85, the percentage of clay reduced to 26 % after 7-day curing time. On the other hand, the silt and sand size of the treated samples increased by increasing curing period. Also, from the table, it is clear that the increment in particle size was rather small for the curing period after 7 days. The latter can confirm the fast reaction between selected additives and laterite soil.

4 Conclusions

This study was carried out in an attempt to further explain the effects of SH-85 non-traditional additive on laterite soil structure. The UCS data for laterite clay mix designs showed that the stabilization process was rapid for the selected stabilizer. For instance, 80 % of the strength improvement happened within the first 7 days. These improvements in terms of strength were faster and higher and in terms of execution were more cost- and time-efficient in comparison with the traditional stabilizers such as lime and cement. Also, the result of direct shear test indicated that the shear parameter of treated laterite soil increased with curing time because of formation of new cementitious products that filled the porous structure of natural soil. In addition, the result of consolidation tests showed that the SH-85 was effective in improving the compressibility characteristics of laterite soil and that the treated samples showed higher resistance to compressibility compared with the natural soil. This was because of the new cementitious compounds which coated the soil particles and led to denser soil fabric with curing time. The latter was in good agreement with the FESEM results. Moreover, the result of BET analysis indicated that the stabilization process reduces the external surface area by filling the soil pores. Lastly, the data of particle size distribution presented that the treated soil particles covered by CAH have bigger size in comparison with the untreated soil particles.

References

Ahmad K (2004) Improvement of a tropical residual soil by electrokinetic process. Doctoral dissertation, UniversitiTeknologi Malaysia, Faculty of Civil Engineering

Ahmad K, Taha MR, Kassim KA (2011) Electrokinetic treatment on a tropical residual soil. Proc ICE-Ground Improv 164(1):3–13

Ahmed FB, Atemimi YK, Ismail MAM (2013) Evaluation the effects of styrene butadiene rubber addition as a new soil stabilizer on geotechnical properties. EJGE 18:735–748

Bobet A, Hwang J, Johnston CT, Santagata M (2011) One-dimensional consolidation behavior of cement-treated organic soil. Can Geotech J 48(7):1100–1115

British Standards Institution (1990) British Standard methods of test for soils for civil engineering purposes: Part 4, compaction-related tests. London, BS 1377

British Standards Institution (1990) British Standard methods of test for soils for civil engineering purposes: Part 2, classification tests. London, BS 1377

Brunauer S, Emmett PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60:309–319

Cai Y, Shi B, Tang CS (2006) Effect of polypropylene fibre and lime admixture on engineering properties of clayey soil. Eng Geol 87(3):230–240

Ceylan H, Gopalakrishnan K, Kim S (2010) Soil stabilization with bioenergy coproduct. Transp Res Rec J Transp Res Board 2186(1):130–137

Chew SH, Kamruzzaman AHM, Lee FH (2004) Physicochemical and engineering behavior of cement treated clays. J Geotech Geoenviron Eng 130(7):696–706

de Brito Galvão TC, Elsharief A, Simões GF (2004) Effects of lime on permeability and compressibility of two tropical residual soils. J Environ Eng 130(8):881–885

Eberemu AO (2011) Consolidation properties of compacted lateritic soil treated with rice husk ash. Geomat (GM) 1(3):70–78

Eisazadeh A (2010) Physicochemical behavior of lime and phosphoric acid stabilized clayey soil. Doctoral dissertation, UniversitiTeknologi Malaysia, Faculty of Civil Engineering

Eisazadeh A, Kassim KA, Nur H (2011) Characterization of phosphoric acid-and lime-stabilized tropical lateritic clay. Environ Earth Sci 63(5):1057–1066

Eisazadeh A, Kassim KA, Nur H (2013) Morphology and BET surface area of phosphoric acid stabilized tropical soils. Eng Geol 154:36–41

Ho MH, Chan CM (2011) Some mechanical properties of cement stabilized Malaysian soft clay. World Acad Sci Eng Technol 74:24–31

JCPDS (1995) Index to the powder diffraction file. International Center for Diffraction Data, Swarthmore, PA

Jie YX, Li GX, Tang F, Jin Y, Hua JX (2012) Soil stabilization in the fill project of the olympic rowing-canoeing park in Beijing. J Mater Civ Eng 25(4):462–471

Katz LE, Rauch AF, Liljestrand HM, Harmon JS, Shaw KS, Albers H (2011) Mechanisms of soil stabilization with liquid ionic stabilizer. Transp Res Rec J Transp Res Board 1757(1):50–57

Liu J, Shi B, Jiang H, Huang H, Wang G, Kamai T (2011) Research on the stabilization treatment of clay slope topsoil by organic polymer soil stabilizer. Eng Geol 117(1):114–120

Lorenzo GA, Bergado DT (2004) Fundamental parameters of cement-admixed clay-new approach. J Geotech Geoenviron Eng 130(10):1042–1050

Marto A, Latifi N, Sohaei H (2013) Stabilization of laterite soil using GKS soil stabilizer. Electr J Geotech Eng (EJGE) 18:521–532

Mitchell JK, Soga K (2005) Fundamentals of soil behavior, 3rd edn. Wiley, New York

Morin WJ, Todor PC (1979) Laterite and lateritic soils and other problem soils of the tropics. IPR, 1979. cap. 7 e 8

Nalbantoglu Z, Tuncer ER (2001) Compressibility and hydraulic conductivity of a chemically treated expansive clay. Can Geotech J 38(1):154–160

Rajasekaran G, Narasimha Rao S (2002) Compressibility behaviour of lime-treated marine clay. Ocean Eng 29(5):545–559

Rajasekaran G, NarasimhaRao S (1997) Lime stabilization technique for the improvement of marine clay. Soils Found 37(2):97–104

Rao SM, Shivananda P (2005) Compressibility behaviour of lime-stabilized clay. Geotech Geol Eng 23(3):309–319

Rauch AF, Harmon JS, Kat LE, Liljestrand HM (2002) Measured effects of liquid soil stabilizers on engineering properties of clay. Transp Res Rec J Transp Res Board 1787(1):33–41

Rauch AF, Katz LE, Liljestrand HM (2003) An analysis of the mechanisms and efficacy of three liquid chemical soil stabilizers. Volume 1. Texas Department of Transportation

Tingle JS, Santoni RL (2003) Stabilization of clay soils with nontraditional additives. Transp Res Rec J Transp Res Board 1819(1):72–84

Tingle JS, Newman JK, Larson S, Weiss CA, Rushing JF (2007) Stabilization mechanisms of nontraditional additives. Transp Res Rec J Transp Res Board 1989(1):59–67

Townsend FC (1985) Geotechnical characteristics of residual soils. J Geotech Eng 111(1):77–94

Zelalem A (2005) Basic engineering properties of lateritic soils found in Nejo–Mendi road construction area, Welega

Zhang T, Xu YY, Wang H (2012) Application and curing mechanism of soil stabilizer. Adv Mater Res 557:809–812

Acknowledgments

The author wish to acknowledge the financial supports given by the Ministry of Science, Technology and Innovation (MOSTI) and Universiti Teknologi Malaysia (UTM), and the supports from the Construction Research Alliance and Construction Research Centre UTM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Latifi, N., Marto, A. & Eisazadeh, A. Physicochemical behavior of tropical laterite soil stabilized with non-traditional additive. Acta Geotech. 11, 433–443 (2016). https://doi.org/10.1007/s11440-015-0370-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-015-0370-3