Abstract

The increasing demand for environmental protection and renewable energy has made bioenergy technologies such as anaerobic digestion substantially attractive. The main objective of this study is to determine the biogas yield from the raw seaweed Eucheuma cottonii and waste products using anaerobic digestion, operated under different physical conditions. Seaweeds comprise of a thallus (leaf like) and sometimes a stem and a foot (holdfast). Seaweed has the potential to be developed into the raw and waste material for biogas due to higher growth rates, greater production yields, and higher carbon fixation rates than land crops. Seaweed has 4–39% carbohydrate content and a high moisture content with low lignin compared to other terrestrial plants, thus it is simpler to be degraded. The integration of the findings may be the key to make seaweed waste product that is more efficient and affordable to serve as a sustainable and renewable energy source. The study used 1.5 L anaerobic digesters for fresh and 3-month-old Eucheuma sp. evaluated at different stages by monitoring the pH, chemical oxygen demand, and biogas production. The study found that within 18 days, the anaerobic digestion of E. cottonii seaweed yielded 0.4–1 ml biogas/g seaweed with up to 56% methane content.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Biogas is a renewable source of energy that can be harvested to reduce the impact on environment and health of the rural and urban population. The idea of producing gas from extracted waste material could be seen as early as the seventeenth century. It was first discovered by Jon Baptita Van Helmont, who said that organic waste that is in the process of decaying could generate flammable gas; then Count Alessandro Volta continued the study by concluding that the amount of decaying organic matter is directly proportional to the amount of gas produced [1].

The biogas produced usually contains 50–65% methane, 35–50% carbon dioxide [2]. However, the proportions of methane and carbon dioxide vary with the duration and extent of biomethanation over the retention time [3]. Even though all the organic materials degrade and produces biogas in anaerobic digesters, it is still an interesting subject of study due to the complexity of the bioconversion process. The main three parameters that affect anaerobic digester performance are the: (i) feedstock characteristics, (ii) reactor design, and (iii) operational conditions of which temperature and pH are the most important parameters [4].

Even though methane has a commercial value, its emission to the environment causes the greenhouse effect and when compared to natural gas, it has half the calorific values. One of the primary causes of the greenhouse gas emissions of CO2 and CH4 release is due to landfilling [5]. Hence, appropriate collection and tapping of the biogas produced are vital to reduce its impact on the environment. Besides, biogas technology also transforms organic waste to high-quality fertilizers [6].

The extensive coastline in Malaysia is surrounded by numerous islands and thus provides habitats for seaweed proliferation. Sabah is one state in Malaysia which is commercially producing seaweeds and this is increasing and highlighted as one of the most important aquaculture commodities. Seaweed has the potential to be developed into the raw and waste material for biogas production. It is a multicellular plant with no roots, with stems, and leaves that grow in salt or fresh water. Seaweed has 4–39% carbohydrate content and a high moisture content with low lignin compared to other terrestrial plants, thus it is easier to degrade [7, 8]. Seaweed does not require land freshwater for cultivation thus does not compete with the growing of food crops or with the residential land, hence the choice of utilizing seaweed algae as a biomass material for biogas is high. Furthermore, new harvesting techniques and valuable co-products produced by some algal strains have been discovered. These improvements have led to a rise in interest for using these organisms for bioenergy generation [9]. The biomethane potential of seaweed is greatly dependent on its chemical composition, which is highly variable due to its type, habitat, cultivation method and time of harvest [10]. It also has a low C/N ratio that might cause problems in the anaerobic digester [11]. Seaweeds have methane yields ranging from 0.14 to 0.40 m3/kg volatile solids (VS), which is similar to methane production from primary sewage sludge and therefore suitable as a raw material for anaerobic fermentation [12]. Biogas production from seaweed process has been demonstrated to be technically viable, however, the cost of this process is still high and there is a need to reduce the cost of the raw material by at least 75% over current levels before it is competitive in the current market [13]. A recent study by Seghetta et al. [14] reveals that whether it is used for energy via anaerobic digestion or protein production, seaweed provides environmental benefits in terms of mitigation of climate change, with biogas production from dried Laminaria digitata being the most favorable scenario.

The edible seaweed Eucheuma cottonii is also known as Kappaphycus alvarezii. Seaweeds are usually classified into three broad groups which are brown seaweed (Phaeophyceae), red seaweed (Rhodophyceae), and green seaweed (Chlorophyceae) [15]. With over 6000 species, red algae top the algae phylum, followed by brown algae with 2000 species, and green algae with 1200 species [16]. Sabah Malaysia is the main center of seaweed production, with Semporna the most active district [17]. Therefore, the possibility to utilize rich seaweed biomass in Sabah for biogas production is high. This could help curb the main pollution issues while also helping to reduce the usage of commercial fossil fuel by exploring the biogas production from seaweed. But there are challenges in using seaweed for biogas production, such as high water content, variations in nutrient content because of season changes, low C/N ratio [18] and the algal cell walls that can be hard to break down [19]. To tackle these issues, wet anaerobic digestion or other pretreatments were introduced into parts of the systems with modification of carbon-rich materials such as biosludge to reduce the toxicity of ammonia [20].

Consequently, the main objective of this study was to determine and assess the biogas production possibility of E. cottonii seaweed using two types of fresh and waste and comparing different physical sizes range of seaweed in an anaerobic digester. Seaweed was chosen due to the huge local availability and feasibility of biogas production feasibility with low carbohydrate and high moisture content, which helps in degrading the biomass into biogas.

2 Materials and Methods

2.1 Substrates and Inoculums

Seaweed biomass or Eucheuma sp. were bought from Kota Kinabalu market in Sabah Malaysia. Two types substrates material shown in Fig. 1a and b, which are fresh (green colored) and waste (white pale) seaweeds were stored at room temperature of 23 °C for 3 days and 3 months, respectively, before feeding to the anaerobic digesters.

Horse manure was used as inoculum to digest the energy crops and biomass. Horse manure has a higher carbon and nitrogen content than carbon and nitrogen content in cow manure, which is a source of energy for microorganisms [21]. The feeding took place to catalyze the process of extracting biogas. The manure was locally available and collected from Sabandar Leisure Rides in Tuaran, Sabah, and each 1 kg manure is dissolved in 6 L distilled water to maintain consistency in the digesters.

2.2 Reactors and Operations

Six identical reactors with a liquid volume of 1.5 L, labeled as R1, R2, R3 for raw type and W1, W2, and W3 for waste type were equipped with a magnetic stirrer to provide sufficient mixing for substrates. Table 1 summarizes the substrate ID and its main physical characteristic.

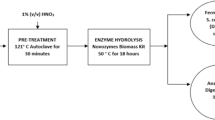

The respective digesters were filled with 500 g seaweed substrate and 1 L horse inoculum. The rotation speed was set at a rate of 70 RPM and ran continuously for 18 days. Figure 2 shows the schematic drawing of the anaerobic digester setup used for the experiment. The prototype used was 1.5 L in volume, which was made from the plastic airtight container, connected with a flow meter and balloon for gas collection. The reactor was wrapped with black-painted aluminum foil to trap and maintain heat inside the digester at 29–31 °C (mesophilic condition) using a hot plate magnetic stirrer continuously monitored using a thermometer. The collected biogas was determined by using gas analyzer (GasAlertMax XT II) for the methane gas, whereas digesters pH was measured by using pH meter (Hanna HO9811-5), and chemical oxygen demand (COD) was determined by using Azide Modification Method (DR890 Colorimeter).

3 Results and Discussions

3.1 Effect of Temperature and on pH Seaweed

The seaweed family of Solieriaceae; E. cottonii, was studied to generate biogas in an anaerobic digester. The variation of temperature during anaerobic digester was recorded over the range 29–31 °C, ensuring a suitable temperature of mesophilic condition as recorded in Fig. 3. The highest temperature value recorded was on the third (3rd) day of the experiment at 31.2 °C, while the lowest reading was 29.6 °C, obtained on the sixth (6th) day of the experiment. Methane production has been documented over a various range of temperature, but the most productive is either mesophilic conditions, at 30–35 °C or the thermophilic range at 50–55 °C [22]. Furthermore, limitations in a thermophilic digester caused a much longer startup period than a mesophilic digester to allow mesophilic sludge to acclimatize with the substrate as well as the temperature shift [23]. Hence, the seaweed anaerobic digesters were under mesophilic temperature condition as expected. The monitored temperature in this study falls in the mesophilic range of mesophilic with uniform temperature changes less than 2 °C. This is acceptable because the anaerobic process is very sensitive to abrupt temperature changes that may cause unbalance between microbial population and thus the normal limit is about 2 °C per day [24].

The influence of the physical condition of the seaweed substrate in relation to its pH and COD was shown in the Figs. 4 and 5. It was observed that over the initial 4–5 days, the pH was alkaline for all substrates and then dropped to become acidic. Based on the recorded pH, raw seaweed fermented after 5th day whereas waste seaweed earlier on its 2nd day. The pH value varied because of the volatile fatty acids concentration, alkalinity, and buffering capacity of the system [25]. It was observed that the pH would drop gradually to a value of around 6.0. This was due to the early phases of anaerobic digestion, acidogenesis, and acetogenesis. The phases increased the amount of H+ ions in the digester and prevailed over the methanogenesis phase thus giving a reduction of pH value.

During the second phase of acidogenesis (fermentation) stage, the hydrolysed products are altered to volatile unsaturated fats, alcohols, aldehydes, ketones, ammonia, carbon dioxide, water, and hydrogen by the acid-forming bacteria. The organic acids formed are acetic acid, propionic acid, butyric acid, and valeric acid. Volatile fatty acids with more than four-carbon chain cannot be utilized directly by methanogens [26] as observed in the case of raw seaweed type.

The accompanying stage is acetogenesis, where organic acids are further oxidized to acetic acid, hydrogen, and carbon dioxide which are utilized as a part of the following procedure. Acetogenesis likewise incorporates acetic acid generation from hydrogen and carbon dioxide by acetogens and homoacetogens. The transition of the substrate causes the pH of the system to drop which is beneficial to acidogenic and acetogenic organisms as confirmed by Ostrem [27].

The final processes of digestion are methanogenesis. The optimum pH for the methanogenesis stage is a pH between 7.2 and 8.2, if the pH falls below 6, the anaerobic degradation rate will decrease, and this depends on the balanced activity of microorganisms [10]. However, the process can tolerate a pH range of 6.5 up to 8.0 [4]. In this study, the pH after 18 days in the digester showed that waste seaweed (W1, W2, and W3) has undergone methanogenesis beginning on the 6th day and stabilizing near pH 7.7 for the rest of study. Comparatively, raw seaweed (R1, R2, and R3) were still below pH 7 and might continue into the methanogenesis stage after the 15th day. Based on the recorded pH, similar trends were found regardless of the physical condition of seaweed, either in its original size or cut and shredded.

The COD-recorded initially was high in the range of 38,000–42,000 mg/L which may be attributed to the inoculum of horse dung. But the measured COD between raw and waste seaweed reactors was almost identical and gave a consistent outcome. Nevertheless, it was observed that the COD decreased over the 18-day process with an average of 30–40%. For both raw and waste seaweed, the 5 cm size gave a higher COD value and this could be due to the optimum size that consumes oxygen during decomposition as observed from other work [28]. The results were shown in Fig. 5.

3.2 Effect of Biogas Production Between Raw and Waste Seaweed

The biogas production is shown in Fig. 6. The volumes are quoted at normal pressure and the temperature found inside the anaerobic tanks. The biogas generation was relatively low at the start, then increased and gradually leveled off for all the samples. In the anaerobic setup, the biogas production started to increase significantly indicating that a high proportion of waste was being broken down into simpler molecules. Biogas production of seaweed within the 18-day testing period was recorded between 200 and 500 mL per 500 g of seaweed samples which is equivalent to 0.4–1 mL/g of seaweed. In spite of variations of species and geographical influences, different pretreatment and longer duration (more than 2 weeks of digestion process) the biogas produced was less than the result of Kawaroe et al. [29] that produced up to 2 mL/g.

Among the three sizes of seaweeds, the smallest of 1 cm shows the highest biogas volume produced. This is because the smaller size of seaweed has a higher surface area that exposes seaweed and allows a faster reaction. In this study, the biogas volume produced was greatly influenced by the physical condition where 1 cm seaweed > 5 cm > original size. Furthermore, the raw type shows a higher biogas volume and it is expected to produce more biogas after 18th day; however, a duration of more than 18 days was not further explored in this work as the biogas produced was targeted to be purified using a membrane process in our future study.

The analysis of biogas composition is illustrated in Fig. 7 and shows the range of 55–57% methane gas for waste-type seaweed. Raw-type biogas products were not measured and reported here due to the longer reaction time needed for the methanogenesis stage as explained previously, based on pH evolution measurements. It should be noted that the biogas produced will also contain mixtures of other gases such as carbon dioxide, hydrogen sulfide, and carbon monoxide [4] which could not be measured due to the restrictions of the gas analyzer used in this work. However, the study found that the physical condition of seaweed whether shredded or the original size did not produce significant differences in methane production. The 500 g waste seaweed which had been kept for 3 months before undergoing anaerobic digestion had produced up to 56% of methane as shown in Fig. 7. The results of biogas produced by seaweed show a positive outcome and consistent with the common composition of 55–60% methane content reported by other works [4, 30] and could become a useful supplement for efficient anaerobic digestion operation [31].

4 Conclusion

A study into the effect of seaweed size of raw and waste biomass of E. cottonii was conducted for biogas production. In light of the results obtained, it was concluded that raw and waste (3 months) seaweed produced biogas and the duration or rate of the digestion process was affected by the pH. The seaweed size has only a minor influence in biogas production and chemical oxygen demand during decomposition. This attempt for E. cottonii yielded 0.4–1 ml/g biogas with up to 56% methane within 18 days in a 1.5 L anaerobic digester laboratory setup.

References

Abbasi T, Tauseef SM, Abbasi SA (2012) A brief history of anaerobic digestion and biogas. Biogas Energy: 11–23

World Energy Council (1994) New renewable energy resources: a guide to the future. London Kogan page limited

Kavuma C (2013) Variation of methane and carbon dioxide yield in a biogas plant MSc. Thesis report, Royal Institute of Technology, Stockholm, Sweden

Ciobla AE, Lonel L, Dumitrel G-A, Popescu F (2012) Comparative study on factors affecting anaerobic digestion of agricultural vegetal residues. Biotechnol Biofuels 5:39

Lungkhimba HM, Karki AB, Shrestha JN (2010) Biogas production from anaerobic digestion of biodegradable household wastes. Sci Technol 11(1):167–172

Mshandete A, Kivaisi A, Rubindamayugi M, Mattiasson B (2004) Anaerobic batch co-digestion of sisal pulp and fish wastes. Bayero J Bioresour Technol 95:19–24

Sitompul JP, Bayu A, Soerawidjaja TH, Lee HW (2012) Studies of biogas production from green seaweeds. Int J Environ Bioenergy 3(3):132–144

Vivekanand V, Eijsink VGH, Horn SJ (2012) Biogas production from the brown seaweed Saccharina latissima: thermal pretreatment and codigestion with wheat straw. J Appl Phycol 24:1295–1301

Mussgnug JH, Klassen V, Schluter A, Kruse O (2010) Microalgae as substrates for fermentative biogas production in a combined biorefinery concept. J Biotechnol 150(1):51–56

Tabassum MR, Xia A, Murphy JD (2017) Potential of seaweed as a feedstock for renewable gaseous fuel production in Ireland. Renew Sustain Energy Rev 68(Part 1):136–146

Yen HW, Brune DE (2007) Anaerobic co-digestion of algal sludge and waste paper to produce methane. Bioresour Technol 98(1):130–134

Reith JH, Huijgen W, Van Hal J, Lenstra J (2009) Seaweed potential in the Netherlands. Macroalgae - Bioenergy Research Forum, Plymouth, UK

Bruton T, Lyons H, Lerat Y, Stanley M, Rasmussen MB (2009) A review of the potential of marine algae as a source of biofuel in Ireland. Sustainable Energy Ireland, Dublin, Ireland

Seghetta M, Romeo D, D’Este M, Alvarado-Morales M, Angelidaki I, Bastianoni S, Thomsen M (2017) Seaweed as innovative feedstock for energy and feed—evaluating the impacts through a Life Cycle Assessment. J Clean Prod 150:1–15

Mohamed S, Hashim SN, Abdul Rahman H (2012) Seaweeds: a sustainable functional food for complementary and alternative therapy. Trends Food Sci Technol 2(2):83–96

Venugopal V (2011) Polysaccharides from seaweed and microalgae marine polysaccharides food applications. CRC Press, Boca Raton, USA, pp 89–129

Sade A, Ali I, Ariff MRM (2006) The seaweed industry in Sabah, East Malaysia. Jati-J SE Asian Stud 11:97–107

Montingelli ME, Tedesco S, Olabi AG (2015) Biogas production from algal biomass: a review. Renew Sustain Energy Rev 43:961–972

Ramos-Suárez JL, Carreras N (2014) Use of microalgae residues for biogas production. Chem Eng J 242:86–95

Wang M, Sahu AK, Rusten B, Park C (2013) Anaerobic co-digestion of microalgae Chlorella sp. and waste activated sludge. Bioresour Technol 142:585–590

Kusch S, Oechsner H, Jungbluth T (2008) Biogas production with horse dung in solid-phase digestion systems. Bioresour Technol 99(2008):1280–1292

Choorit W, Wisarnwan P (2007) Effect of temperature on the anaerobic digestion of palm oil mill effluent. Electron J Biotechnol 10(No. 3, Issue of July 15):376

Poh EP, Chong MF (2010) Thermophilic palm oil mill effluent (POME) treatment using a mixed culture cultivated from POME. Chem Eng Trans 21:811–816

Marcos VS (2005) Biological wastewater treatment in warm climate regions. IWA Publishing, London

Abdulkarim BI (2017) Anaerobic digestion: an increasingly acceptable treatment option for organic fraction of municipal solid waste. Int J Sci Res Publ 7(1):79–82

Wang Y, Kuninobu M, Ogawa HI, Kato Y (1999) Degradation of volatile fatty acids in highly efficient anaerobic digestion. Biomass Bioenergy 16:407–416

Ostrem K (2004) Greening waste: anaerobic digestion for treating the organic fraction of municipal solid wastes. Master thesis, Columbia University

Hajji A, Rhachi M (2013) The influence of particle size on the performance of anaerobic digestion of municipal solid waste. Energy Proc 36(2013):515–520

Kawaroe M, Slundik, Wahyudi R, Lestari DF (2017) Comparison of biogas production from macroalgae Eucheuma cottonii in anaerobic degradation under different salinity conditions. World Appl Sci J 35(3):344–351

Deublein D, Steinhauser A (2008) Biogas from waste and renewable resources. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Kuroda K, Akiyama Y, Keno Y, Nakatani N, Otsuka K (2014) Anaerobic digestion of marine biomass for practical operation. J Marine Sci Technol 19:280–291

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Bolong, N., Asri, H.A., Ismail, N.M., Saad, I. (2018). Effect of Seaweed Physical Condition for Biogas Production in an Anaerobic Digester. In: Horan, N., Yaser, A., Wid, N. (eds) Anaerobic Digestion Processes. Green Energy and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-10-8129-3_10

Download citation

DOI: https://doi.org/10.1007/978-981-10-8129-3_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-8128-6

Online ISBN: 978-981-10-8129-3

eBook Packages: EnergyEnergy (R0)