Abstract

Saccharina latissima is a carbohydrate-rich fast-growing seaweed (SW) which may be utilized as a marine energy crop. In this study, S. latissima was anaerobically digested for biogas production, and the effects of thermal pretreatment and codigestion with wheat straw (WS) were investigated. Batch experiments showed that pretreatment of SW increased the methane yield from 223 to 268 mL g-1 VS. Codigestion of SW and steam-exploded WS had a clear positive effect on biogas production, giving yields that were considerably higher than what would be expected on the basis of the yields obtained with either of the individual feedstocks. Thus, anaerobic digestion of blends of SW and lignocellulosic substrates provides a promising strategy for biogas production. Although thermal pretreatment increased the yield of biogas from SW such a harsh pretreatment is probably more relevant for the more recalcitrant lignocellulosic substrates.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Our dependency on fossil energy resources is problematic both because of climate change and resource depletion. In particular, it is a concern that global oil production will reach its maximum production in the near future (Aleklett et al. 2010). Thus there is an urgent need to develop alternative liquid fuels. Currently, biofuels such as biodiesel and bioethanol are mainly produced from crops that potentially also can be used as food. It is generally agreed that this should be avoided, and there is a great effort going on to develop second generation biofuels based on lignocellulosic biomass. Alternatively, biofuels could be based on marine biomass such as microalgae and macroalgae [seaweed (SW)]; such biofuels are often called “third generation biofuels.” Obvious advantages of SW biofuels include the nonuse of arable land and limited or no needs for the use of freshwater and external fertilizers.

Marine environments generate approximately 50% of global biomass (Carlsson et al. 2007) and have great potential to be exploited for the production of feedstock for biofuels. The total estimated annual value of the SW industry is US$ 5.5–6.8 billion and about 15 million tons of naturally growing and cultivated SW are harvested annually worldwide (Bartsch et al. 2008). Most of this SW cultivation consists of small scale farms in Asia, meaning that the potential production from industrial farms is much larger than the current production. SW is currently mainly utilized as food products for human consumption (McHugh 2003). SW production in terms of dry weight is reported to range from 3.3 to 11.1 kg m-2 year-1 for naturally occurring SW, while higher yields have been reported for cultivated species (Gao and McKinley 1993).

One possible biofuel is biomethane purified from biogas produced during anaerobic digestion of biomass. Biomethane is an excellent vehicle fuel, and its production is in fact regarded as one of the most energy efficient and environmentally benign ways to produce biofuels (Borjesson and Mattiasson 2008). Biogas may also be used to produce heat and electricity (Frigon and Guiot 2010).

Brown SW typically contain around 60% carbohydrates, the most important being alginate, laminaran, and mannitol, negligible amounts of lignin, and low concentration of cellulose. Consequently, conversion of algal biomass to methane by anaerobic digestion is relatively easy compared to lignocellulosic substrates (Horn 2009).

Laminaria spp. and other related brown SW exhibit large seasonal variations in their composition (Haug and Jensen 1954; Adams et al. 2011a), and it has recently been shown how seasonal changes of Laminaria digitata affect methane and ethanol production (Adams et al. 2011b). In Norwegian waters, the storage carbohydrates laminarin and mannitol are found in highest concentrations during the period October–November (Haug and Jensen 1954). From previous studies, it is known that these storage carbohydrates are good substrates for fermentation to ethanol (Horn et al. 2000a, b; Adams et al. 2009) or anaerobic digestion to biogas (Østgaard et al. 1993). Alginate and other organic compounds in the SW are also digested to biogas (Østgaard et al. 1993; Moen et al. 1997; Horn and Østgaard 2001). All in all, available studies indicate that biogas production from brown SWs may be a favorable strategy for the production of marine biofuels. However, much more work needs to be done to develop this area to its full potential, both in terms of biomass cultivation systems (Kraan 2011; not discussed here) and in further development of biogas production processes.

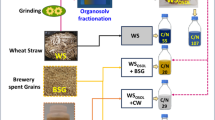

In the present study, we have analyzed the effect of two process parameters on biogas production from the brown SW, Saccharina latissima. Firstly, we have studied how steam explosion, a known thermal pretreatment method for biomass deconstruction (Ramos 2003), affects biogas yields. Secondly, we have evaluated the codigestion of untreated SW and steam-exploded wheat straw (WS) for biogas production, since lignocellulosic substrates alone are not efficiently digested to biogas due to a high C/N ratio. Thus blending WS with N-rich SW would potentially be beneficial for the biogas process.

Materials and methods

Saccharina latissima was grown for one season in the Trondheimsfjord (63°N, 10°E) and harvested and collected on August 24, 2010 by Seaweed Energy Solutions (Trondheim, Norway). It was packed and shipped frozen to the Norwegian University of Life Sciences (UMB) in Ås, Norway on the same day. The delivered material was stored in aliquots at -20°C prior to further use. The dry matter content (DM) of the fresh SW was 12.4%. WS (Triticum aestivum L.) was kindly provided by Sala-Heby Energi (Sala, Sweden).

Substrate processing

Stored SW was defrosted and cut into ~5 cm2 pieces, then ground to a finely shredded slurry using a 5.0 L grinder (Grindomix GM 300, Retsch, Germany). Zipped plastic pouches were used to store the aliquots of the slurry (~500 g) which were frozen at -20°C prior to further use. The WS was milled to pass a sieve of 10 mm (SM2000, Retsch) and stored at room temperature.

Steam explosion pretreatment

Pretreatment was performed at the steam explosion facility designed by Cambi AS (Asker, Norway) and located at the UMB in Ås, Norway (Horn et al. 2011b). Thawed SW (900 g) was steam exploded at 130 and 160°C for 10 min. The pressure vessel was preheated for 10 min at the desired temperature before each run. Similarly, milled WS was subjected to steam explosion at 210°C for 10 min. The pretreated samples were packed and stored at -20°C until the biogas experiments were started.

Inoculum

The inoculum for biogas production was obtained from a local sewage treatment plant, Nordre Follo Wastewater Treatment Plant (Vinterbro, Norway), which runs large-scale continuous anaerobic digestion of municipal waste at mesophilic temperatures. The inoculum was diluted with water (1:1), and aliquots were added to the experimental bottles. The initial pH of the diluted inoculum was 8.0. Prior to adding substrate, the bottles were incubated anaerobically at 37°C for 1 week to remove most of the endogenous methane potential of the inoculum.

Batch test

Biogas production was carried out in two sets of experiments. In the first experiment, untreated SW and two steam-exploded SW samples (SW130°C,10 min and SW160°C, 10 min; steam exploded for 10 min at 130 and 160°C, respectively) were digested anaerobically in batch flasks to investigate the effect of the pretreatment on biogas production. In the second experiment, steam exploded WS, untreated SW, and five different blends of SW and WS (85:15, 50:50, 15:85, 25:75, and 75:25) were digested.

For both experiments, the batch fermentations (including inoculum alone as control) for biogas production were performed in triplicates. In the first phase, substrates corresponding to a final concentration of 1.5 g L-l VS were added and mixed with 600 mL preincubated inoculum having 10.5 g L-l VS into 1,125 mL bottles followed by addition of distilled water to make the final mass of the mixture 700 g. The bottles were flushed with nitrogen and closed with rubber stoppers and aluminum screw caps before transferring to the shaker (Multitron Standard, Infors HT, Switzerland) for incubation (37°C, 90 rpm, 66 days). On the 67th day, at the start of the second phase, bottles were fed with the same amount of substrate as in the first phase and incubated as before (37°C, 90 rpm). This addition of new substrate led to a small reduction in the head space volume of the bottles which was corrected for in the calculations of biogas production. On the 119th day, the experiment was terminated.

Calculation and analysis

Pressures generated in the bottle digesters were measured digitally (GMH 3161 Greisinger Electronic, Germany) at fixed time intervals and released. Biogas composition was analyzed by gas chromatography (3000 Micro GC, Agilent Technologies, USA) equipped with a thermal conductivity detector (TCD) using helium as a carrier gas (Westerholm et al. 2010). A standard mixture of methane, carbon dioxide, and nitrogen was used for calibration. Based on the head space volume of the bottles and measurements of methane concentrations, the ideal gas law was used for calculating the biogas production during the experiments.

Total nitrogen and carbon content was determined by Dumas combustion (AOAC 990.03). Ammonium concentration was measured using HACH-LANGE spectrophotometric kit. DM and ash contents were determined by drying the samples at 105 and 550°C overnight, respectively.

Statistical analysis

The data sets for the two experiments were analyzed by one-way analysis of variance (ANOVA) (α = 0.05) using Microsoft Excel (see Tables 1 and 2). ANOVA was also used when comparing methane production data for selected samples.

Results

Steam explosion pretreatment

WS was pretreated by steam explosion using a temperature of 210°C and 10 min residence time. The pH of the pretreated straw was 4.4. SW was steam exploded at 130 and 160°C using 10 min residence time. Steam explosion of the ground SW resulted in a brownish slurry, where much of the structure in the biomass was destroyed. The pH of the SW was 8.7 and was not affected by steam explosion. The pretreatment led to a small reduction of the C/N ratio of SW probably due to loss of volatile organic compounds (Table 1).

Biogas production from SW

Untreated and pretreated SW were anaerobically degraded in batch flasks at 37°C. Figure 1 shows the specific methane production (endogenous methane production from the inoculum has been subtracted) from SW and pretreated SW for the 119 days digestion period. On the 67th day, a second batch of substrate was added in all the flasks, explaining the drop in the specific methane production at that point.

Accumulated methane production for seaweed and pretreated seaweed. On day 67, a second batch of substrate was added, explaining why at that point the methane yields per gram of VS dropped. The yields reported in Table 1 are those obtained after 119 days

The methane yield from untreated SW was 223 mL g-1 VS, whereas both pretreated fractions showed a marginal improvement (P < 0.1) of the yield to values ranging from 260 to 268 mL g-1 VS (Table 1). Steam explosion thus had a positive effect on digestion of SW, increasing the methane yield up to 20%. The final methane contents in the biogas produced were in the range 57–59% for all three digestions (Table 1).

Ammonium ion concentration was in the 1,105–1,120 ppm range for the pretreated SW, while it was 1,003 ppm for the untreated SW. The pH was stable during the incubation period and the final pH was similar for all digested samples (Table 1).

Biogas production from blends of SW and WS

The codigestion of untreated SW and pretreated WS was investigated by using 5 different blends of SW and WS (Fig. 2). The experiment was run the same way as the experiment described above, i.e., at 37°C and with addition of more substrate on the 67th day. In addition to the experimental methane yields (Table 2, column 2), the methane yields for the blends were also estimated based on the yields from SW and WS alone (Table 2, column 3). Higher actual yields for the blends compared to the estimated yields indicate a synergistic effect for the codigestions. Thus Table 2 shows that all blends produced more methane than would be expected based on the methane production from each substrate alone, i.e., they showed synergy.

Accumulated methane production for blends of WS and SW. The raw materials used for the fermentations are indicated to the left, using the same coding as in Table 2, except for WS210°C, 10 min, which in this figure is indicated by WS. On day 67, a second batch of substrate was added, explaining why at that point the methane yields per gram of VS dropped. The yields reported in Table 2 are those obtained after 119 days

All the codigestions had a significantly (P < 0.05) higher methane production than WS alone (Table 2). Compared to methane production from SW alone, only the SW:WS blend of 75:25 was significantly (P < 0.05) higher. All other blends had methane yields similar to SW alone. The final methane contents in the biogas produced were in the range 53–58% for all digestions (Table 2), where the lowest content was found in the digestions with highest WS content.

Ammonium ion concentration was in the 800–1,200 ppm range for all bottles, the lowest value being found for the WS digestion. The pH was stable during the incubation period and the final pH was similar for all digested fractions (Table 2).

Figure 3 summarizes the methane production for both experiments giving values for first phase, second phase, and total. For most of the digestions more biogas was produced in the second phase than the first phase. The WS digestion was very slow in the initial phase, but nearly doubled in the second phase. The steam exploded SW samples showed lower methane production in the second phase.

Cumulative methane yields in the two phases. The graphs show accumulated methane for the various fermentations in phase 1 (white), phase 2 (grey), and in total (black). The raw materials used for the fermentations are coded as in Tables 1 and 2, except for WS210°C, 10 min which in this figure is indicated by WS. Methane production in Phase 2 was estimated on the assumption that all original substrate was consumed in Phase 1

Discussion

Steam pretreatment is a well-known pretreatment technology for lignocellulosic materials (Ramos 2003) drastically increasing both saccharification yields and biogas yields (Horn et al. 2011a). The temperatures (130 and 160°C) used for pretreatment of SW were chosen lower than what is typically used for lignocellulosic biomass due to SW being a less recalcitrant biomass (Horn 2009). The results show that steam explosion can increase the methane yield from SW up to 20% (Table 1). The SW storage carbohydrates mannitol and laminarin are easily digested (Horn and Østgaard 2001), and the main effect of SE is probably to increase the digestibility of alginate which is degraded relatively slowly under anaerobic conditions (Moen et al. 1997). The specific methane yield obtained for unpretreated SW (223 mL g-1 VS) is similar to yields obtained by others in similar batch experiments (e.g., Østgaard et al. 1993). To our knowledge, this is the first time thermal pretreatment has been tested as a pretreatment method for biogas production from SW. Very recently, it has been shown that thermal pretreatment of Saccharina (Laminaria) japonica increases fermentative hydrogen production (Jung et al. 2011). Biogas production from microalgae has also been reported (Sialve et al. 2009; Mussgnug et al. 2010). In some cases, pretreatment of microalgae has been used to increase fermentative hydrogen production (Nguyen et al. 2010).

The results of the codigestion experiments (Fig. 2 and Table 2) show clear synergistic effects of blending WS and SW. This may be due to a dilution effect on inhibitors in the straw fraction, but also to possible adsorption of inhibitors to the SW biomass. SW is known to adsorb phenolic compounds (Aravindhan et al. 2009; Chung et al. 2007; Navarro et al. 2008). Also, blends of SW and straw will have C/N ratios that are more conducive for biogas production than straw alone (Table 2). C/N ratios around 30 are considered optimal for methane production during anaerobic digestion, whereas these ratios are close to 100 (much too high) and close to 10 (too low) for WS and SW, respectively. The results do not indicate an optimum SW to straw blending ratio, although a dominance of SW in the mix seems positive. Codigestion of SW and lignocellulosic materials is interesting since continuous digestion of lignocellulosic substrates alone tends to be difficult due to the low nitrogen content of this biomass. Mixing SW with WS is clearly conducive for increasing the methane production from straw since all blends produced significantly more methane than the straw alone. The mixing of SW with straw does only increase the methane yield significantly in one blend ratio compared to SW alone. Thus the main effect of codigestion is to increase the digestibility of straw. However, adding straw to SW did not significantly reduce the methane production compared to digestion of only SW. It is important to note that the overall methane production from blends is much greater than the sum of separate digestions of SW and straw.

Digestion of WS produced 98 mL g-1 VS methane, which is only 44% of the yield obtained with untreated SW. This may be due to inhibition of the microbial community by inhibitors, such as phenolic compounds, furfural, and HMF, produced during SE of straw (Horn et al. 2011b; Laser et al. 2002; Hwang and Cheng 1991). Figure 3 shows that the biogas production from WS was twice as high in the second phase compared to the first phase of digestion, indicating that the microbial community is able to adapt to the substrate. The high C/N ratio of WS (Table 2) may also contribute to the low yield.

Most of the digestions produced more methane in the second phase of the incubation period. This is probably due to adaption of the microbial community to the substrate. The WS digestion was particularly slow in the initial phase, indicating that adaptation of the inoculum to the SW biomass was easier than adaptation the lignocellulosic biomass. For the steam-exploded SW samples, the methane production was lower in the second phase of degradation. This may be explained by production of inhibitors during the pretreatment of SW which the microbial community not easily adapts to. The highest total methane yields were found for the two pretreated SW fractions and the SW:WS blend of 75:25.

The present study shows that SW is a good feedstock for production of methane by anaerobic digestion and that thermal pretreatments may help in maximizing methane yields. Steam explosion of the SW led to increased methane yields, but the effects were not very large and one might thus wonder whether such a harsh pretreatment is as relevant for SW as it is for lignocellulosic substrates (Horn et al. 2011a, b). We also show that mixing of SW and WS leads to synergistic effects on methane production. Thus, in principle, SW is an interesting feedstock to go into the biomass mixture used for production of biofuels.

With a productivity of 40 dry t ha-1 year-1, a SW farming area of 2,500 km2 (the size of Luxembourg) could annually produce 10 million t of dry SW (Kraan 2011). Using an average VS content of 70%, this equals 7 million t VS, which corresponds to 1.6 billion m3 methane (Table 1, untreated SW). This equals about 15.6 TW h of energy (10 kW h m-3) or a specific energy production of 6.2 GW h km-2 (225 GJ ha-1) sea area. For comparison, gross biogas output from agricultural crops in Sweden has been estimated to range from 80 to 140 GJ ha-1 year-1. However, in these calculation by-products, such as straw were not included (Borjesson and Mattiasson 2008). Clearly, SW has considerable potential as a feedstock for biofuels. It may also be beneficial to integrate production of biofuels with other products developing a SW biorefinery concept (Kraan 2011).

References

Adams J, Gallagher J, Donnison I (2009) Fermentation study on Saccharina latissima for bioethanol production considering variable pre-treatments. J Appl Phycol 21:569–574

Adams JMM, Ross AB, Anastasakis K, Hodgson EM, Gallagher JA, Jones JM, Donnison IS (2011a) Seasonal variation in the chemical composition of the bioenergy feedstock Laminaria digitata for thermochemical conversion. Bioresour Technol 102:226–234

Adams J, Toop TA, Donnison I, Gallagher J (2011b) Seasonal variation in Laminaria digitata and its impact on biochemical conversion routes to biofuels. Bioresour Technol 102:9976–9984

Aleklett K, Höök M, JakobssonK LM, Snowden S, Söderbergh B (2010) The peak of the oil age — analyzing the world oil production reference scenario in world energy outlook 2008. Energy Policy 38:1398–1414

Aravindhan R, Rao JR, Nair BU (2009) Application of a chemically modified green macro alga as a biosorbent for phenol removal. J Environ Manag 90:1877–1883

Bartsch I, Wiencke C, Bischof K, Buchholz C, Buck B, Eggert A, Feuerpfeil P, Hanelt D, Jacobsen S, Karez R, Karsten U, Molis M, Roleda M, Schubert H, Schumann R, Valentin K, Weinberger F, Wiese J (2008) The genus Laminaria sensu lato: recent insights and developments. Eur J Phycol 43:1–86

Borjesson P, Mattiasson B (2008) Biogas as a resource-efficient vehicle fuel. Trends Biotechnol 26:7–13

Carlsson A, van Beilen J, Moller R, Clayton D (2007) Micro- and macro-algae: utility for industrial applications. In: Bowles D (ed) Outputs from the EPOBIO project. CPL Press, Newbry, p 82

Chung MK, Tsui MTK, Cheung KC, Tam NFY, Wong MH (2007) Removal of aqueous phenanthrene by brown seaweed Sargassum hemiphyllum: sorption-kinetic and equilibrium studies. Sep Purif Technol 54:355–362

Frigon JC, Guiot SR (2010) Biomethane production from starch and lignocellulosic crops: a comparative review. Biofuels Bioprod Bioref 4:447–458

Gao K, McKinley K (1993) Use of macrolgae for marine biomass production and CO2 remediation: a review. J Appl Phycol 6:45–60

Haug A, Jensen A (1954) Seasonal variations in the chemical composition of Alaria esculenta, Laminaria saccharina, Laminaria hyperborea, and Laminaria digitata from Northern Norway Rep Norw Inst Seaweed Res No 4

Horn SJ (2009) Seaweed biofuels: production of biogas and bioethanol from brown macroalgae. Vdm Verlag Dr Mueller E K, Germany

Horn SJ, Østgaard K (2001) Alginate lyase activity and acidogenesis during fermentation of Laminaria hyperborea. J Appl Phycol 13:143–152

Horn SJ, Aasen IM, Østgaard K (2000a) Production of ethanol from mannitol by Zymobacter palmae. J Ind Microbiol Biotechnol 24:51–57

Horn SJ, Aasen IM, Østgaard K (2000b) Ethanol production from seaweed extract. J Ind Microbiol Biotechnol 25:249–254

Horn SJ, Estevez MM, Nielsen HK, Linjordet R, Eijsink VGH (2011a) Biogas production and saccharification of Salix pretreated at different steam explosion conditions. Bioresour Technol 102:7932–7936

Horn SJ, Nguyen QD, Westereng B, Nilsen PJ, Eijsink VGH (2011b) Screening of steam explosion conditions for glucose production from non-impregnated wheat straw. Biomass Bioenergy 35:4879–4886

Hwang PC, Cheng SS (1991) Treatment of p-cresol with a recirculating UASB reactor using the concept of kinetic control. Water Sci Technol 24:133–140

Jung KW, Kim DH, Shin HS (2011) Fermentative hydrogen production from Laminaria japonica and optimization of thermal pretreatment conditions. Bioresour Technol 102:2745–2750

Kraan S (2011) Mass-cultivation of carbohydrate rich macroalgae, a possible solution for sustainable biofuel production. Mitig Adapt Strateg Glob Chang. doi:10.1007/s11027-010-9275-5

Laser M, Schulman D, Allen SG, Lichwa J, Antal MJ Jr, Lynd LR (2002) A comparison of liquid hot water and steam pretreatments of sugar cane bagasse for bioconversion to ethanol. Bioresour Technol 81:33–44

McHugh D (2003) A guide to the seaweed industry. Fisheries Technical Paper. FAO, Rome

Moen E, Horn S, Østgaard K (1997) Alginate degradation during anaerobic digestion of Laminaria hyperborea stipes. J Appl Phycol 9:157–166

Mussgnug JH, Klassen V, Schluter A, Kruse O (2010) Microalgae as substrates for fermentative biogas production in a combined biorefinery concept. J Biotechnol 150:51–56

Navarro AE, Portales RF, Sun-Kou MR, Llanos BP (2008) Effect of pH on phenol biosorption by marine seaweeds. J Hazard Mater 156:405–441

Nguyen TAD, Kim KR, Nguyen MT, Kim MS, Kim D, Sim SJ (2010) Enhancement of fermentative hydrogen production from green algal biomass of Thermotoga neapolitana by various pretreatment methods. Int J Hydrogen Energy 35:13035–13040

Østgaard K, Indergaard M, Markussen S, Knutsen SH, Jensen A (1993) Carbohydrate degradation and methane production during fermentation of Laminaria saccharina (Laminariales, Phaeophyceae). J Appl Phycol 5:333–342

Ramos LP (2003) The chemistry involved in the steam treatment of lignocellulosic materials. Quim Nova 26:863–871

Sialve B, Bernet N, Bernard O (2009) Anaerobic digestion of microalgae as a necessary step to make microalgal biodiesel sustainable. Biotechnol Adv 27:409–416

Westerholm M, Roos S, Schnürer A (2010) Syntrophaceticus schinkii gen. nov., sp. nov., an anaerobic, syntrophic acetate-oxidizing bacterium isolated from a mesophilic anaerobic filter. FEMS Microbiol Lett 309:100–104

Acknowledgments

This project was financially supported by the Norwegian Research Council projects 190877, 192874 and 193817. Seaweed Energy Solutions is thanked for providing the seaweed biomass.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vivekanand, V., Eijsink, V.G.H. & Horn, S.J. Biogas production from the brown seaweed Saccharina latissima: thermal pretreatment and codigestion with wheat straw. J Appl Phycol 24, 1295–1301 (2012). https://doi.org/10.1007/s10811-011-9779-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-011-9779-8